Page 1

!

If the information in these instructions is not followed exactly, a

fire or explosion may result, causing property damage, personal

injury or death.

INSTALLATION INSTRUCTIONS

FOR UPFLOW & DOWNFLOW/HORIZONTAL HIGH

EFFICIENCY CONDENSING GAS FURNA CES

RGRA/RGRJ AND RGTA/RGTJ SERIES

92-23531-16-09

SUPERSEDES 92-23531-16-08

THESE INSTRUCTIONS ARE

INTENDED AS AN AID TO

QUALIFIED SERVICE

PERSONNEL FOR PROPER

INSTALLATION, ADJUSTMENT

AND OPERATION OF THIS

UNIT. READ THESE

INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING

INSTALLATION OR

OPERATION. FAILURE TO

FOLLOW THESE

INSTRUCTIONS MAY RESULT

IN IMPROPER INSTALLATION,

ADJUSTMENT, SERVICE OR

MAINTENANCE, POSSIBLY

RESULTING IN FIRE,

ELECTRICAL SHOCK, CARBON

MONOXIDE POISONING,

EXPLOSION, PROPERTY

DAMAGE, PERSONAL INJURY

OR DEATH.

Do Not Destroy this Manual.

Please read carefully and keep

in a safe place for future

reference by a serviceman.

WARNING

Recognize this symbol as an indication of Important Safety Information!

!

— Do not store or use gasoline or other

flammable vapors and liquids, or other

combustible materials in the vicinity of this

or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

• Do not return to your home until

authorized by the gas supplier or fire

department.

— DO NOT RELY ON SMELL ALONE TO

DETECT LEAKS. DUE TO VARIOUS

FACTORS, YOU MAY NOT BE ABLE TO

SMELL FUEL GASES.

• U.L. recognized fuel gas and CO

detectors are recommended in all

applications, and their installation should

be in accordance with the manufacturer’s

recommendations and/or local laws,

rules, regulations, or customs

— Improper installation, adjustment, alteration,

service or maintenance can cause injury,

property damage or death. Refer to this

manual. Installation and service must be

performed by a qualified installer, service

agency or the gas supplier.

WARNING

!

PROPOSITION 65: THIS FURNACE CONTAINS FIBERGLASS

INSULATION. RESPIRABLE PARTICLES OF FIBERGLASS ARE

KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER.

EXHAUST GAS FROM THIS FURNACE CONTAINS CHEMICALS,

INCLUDING CARBON MONOXIDE, KNOWN TO THE STATE OF

CALIFORNIA TO CAUSE BIRTH DEFECTS OR OTHER

REPRODUCTIVE HARM.

WARNING

!

FOR YOUR SAFETY

!

Page 2

INSTALLATION CHECK LIST

REFER TO INSTALLATION INSTRUCTIONS

GAS SUPPLY

Adequate pipe size

Correct supply pressure (during furnace operation)

Manifold pressure

No gas leaks

ELECTRICAL

115 V.A.C. supply (Single Circuit)

Polarity observed

Furnace properly grounded

Adequate wire size

FURNACE INSTALLATION

Adequate clearance to combustibles

Adequate clearance for service (at front)

DUCT STATIC PRESSURE

in. w.c. on heating speed

in. w.c. on cooling speed

Air temperature rise

CONDENSATE LINE

Trap filled with water

Vented

Sloped toward drain

Condensate drain line hoses connected

and clamped

Freeze protection (if necessary)

VENTING – DIRECT VENT

in. diameter – intake pipe

in. diameter – exhaust pipe

ft. of pipe – intake air

no. of elbows – intake air

ft. of pipe – exhaust pipe

no. of elbows – exhaust pipe

TERMINATIONS – DIRECT VENT

VERTICAL

Intake – 12" min. above roof/snow level

Correct relationship – exhaust to intake

VERTICAL – CONCENTRIC (RXGY-E02)

Intake – 12" min. above roof/snow level

HORIZONTAL – STANDARD (RXGY-D02, -D03)

Correct relationship – exhaust to intake

12" min. above grade/snow level

HORIZONTAL – ALTERNATE (RXGY-D02, -D03 OR -D04)

Correct relationship – exhaust to intake

Above anticipated snow level

HORIZONTAL – CONCENTRIC (RXGY-C01)

12" min. above grade/snow level

Intake “Y” rotated above center

Exhaust sloped toward furnace

VENTING – NON-DIRECT VENT

in. diameter – exhaust pipe

ft. of pipe – exhaust

no. of elbows

TERMINATION – NON-DIRECT VENT

VERTICAL

12" min. above roof/snow level

HORIZONTAL – STANDARD

12" min. above grade/snow level

HORIZONTAL – ALTERNATE

Above anticipated snow level

2

Page 3

3

IMPORTANT: TO INSURE PROPER INSTALLATION AND OPERATION OF

THIS PRODUCT, COMPLETELY READ ALL INSTRUCTIONS PRIOR TO

ATTEMPTING TO ASSEMBLE, INSTALL, OPERATE, MAINTAIN OR REPAIR

THIS PRODUCT. UPON UNPACKING OF THE FURNACE, INSPECT ALL

PARTS FOR DAMAGE PRIOR TO INSTALLATION AND START-UP.

CONTENTS

Safety Precautions...................................................................................................1

Installation Check List ..............................................................................................2

Location Requirements and Considerations............................................................5

Venting and Combustion Air Piping .......................................................................12

Combustion and Ventilation Air..............................................................................14

Vent Pipe Installation..............................................................................................17

Condensate Drain/Neutralizer................................................................................27

Converting Downflow to Horizontal........................................................................29

Gas Supply and Piping...........................................................................................31

Electrical Wiring......................................................................................................35

Accessories............................................................................................................37

Start-Up Procedures...............................................................................................44

Air Flow...................................................................................................................46

Maintenance...........................................................................................................50

Troubleshooting......................................................................................................53

Wiring Diagrams.....................................................................................................59

➤ Installation Instructions are updated on a regular basis. This is done as

product changes occur or if new information becomes available. In this

publication, an arrow (➤) denotes changes from the previous edition or additional

new material.

Page 4

GENERAL INFORMATION

The RGRA/RGRJ and RGTA/RGTJ

series furnaces are design-certified

by AGA/CGA for use with natural and

propane gases as follows:

1. As non-direct vent central forced

air furnaces taking combustion

air from the installation area or

using air ducted from the outside.

2. As direct vent central forced air

furnaces with all combustion air

supplied directly to the furnace

burners through a special air

intake system outlined in these

instructions.

4

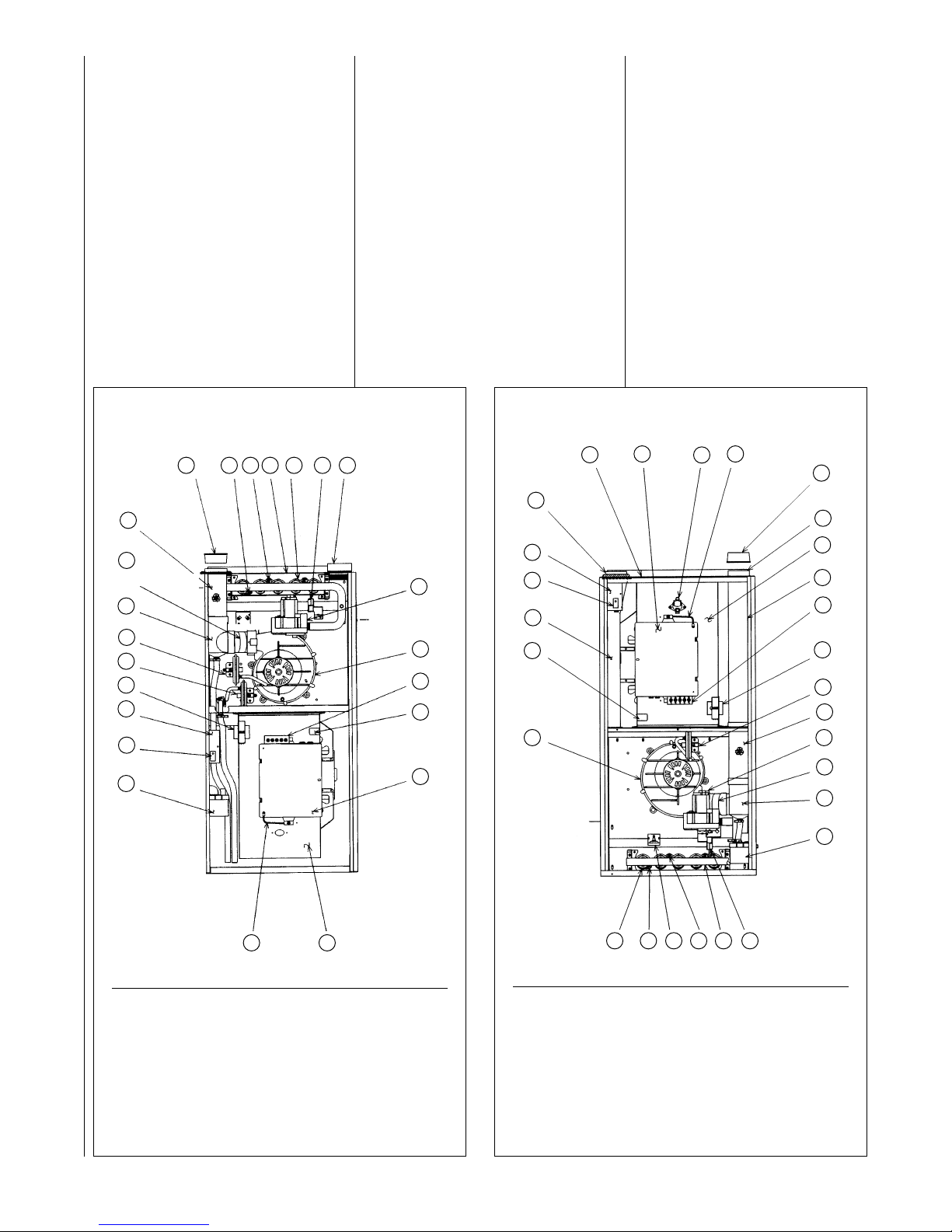

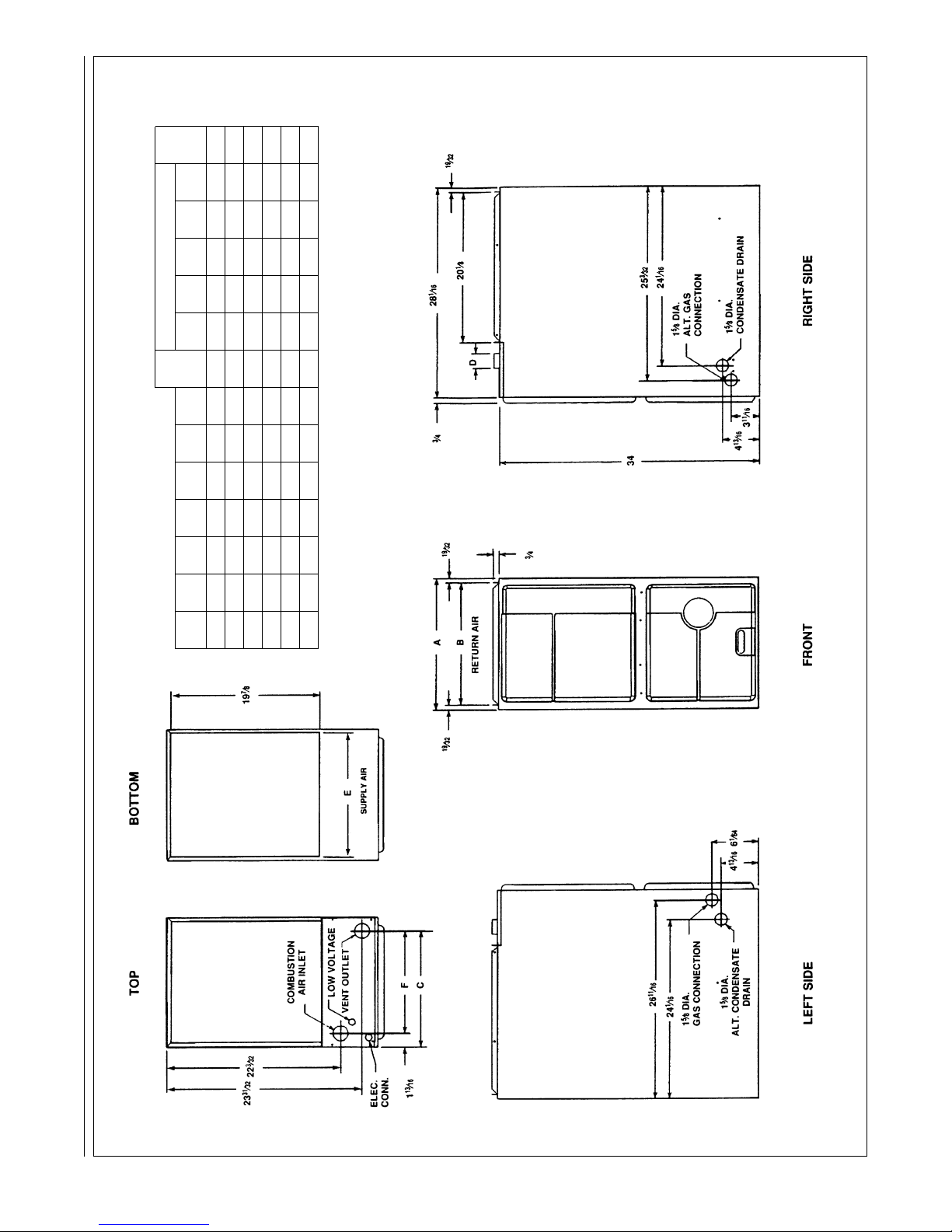

FIGURE 1

UPFLOW FURNACE

FIGURE 2

DOWNFLOW/HORIZONTAL FURNACE

Install this furnace in accordance with

the American National Standard

Z223.1 – latest edition entitled

“National Fuel Gas Code” (NFPA54)

and requirements or codes of the

local utilities or other authorities

having jurisdiction. This is available

from the following:

National Fire Protection

Association, Inc.

Batterymarch Park

Quincy, MA 02269

American Gas Association

1515 Wilson Blvd.

Arlington, VA 22209

Install units in Canada in accordance

with CAN/CGA-B149, local

installation codes and authorities

having jurisdiction. CAN/CGA-B149 is

available from:

Canadian Gas Association

55 Scarsdale Road

Don Mills, Ontario, Canada M3B, 2R3

2425262728

ITEM ITEM

NO. PART NAME NO. PART NAME

1 INDUCED DRAFT BLOWER 15 LOW VOLTAGE TERMINAL

2 CAPACITOR 16 TRANSFORMER

3 INLET AIR CHASE 17 PRESSURE SWITCH

4 DOOR SWITCH 18 OUTLET AIR PIPE

5 JUNCTION BOX 19 GAS VALVE

6 INLET PIPE CONNECTOR 20 CONNECTOR

7 TOP PLATE 21 EXHAUST TRANSITION

8 ELECTRICAL BOX 22 CONDENSATE TRAP

9 AUXILLIARY LIMIT 23 IGNITER

10 CONTROL BOX COVER GROUND 24 MANIFOLD

11 VENT CAP PLUG 25 OVERTEMPERATURE SWITCH

12 EXHAUST CONNECTION 26 ROLLOUT SWITCH

13 BLOWER 27 SENSOR

14 EXHAUST PIPE EXTENSION 28 BURNER

ITEM ITEM

NO. PART NAME NO. PART NAME

1 CONDENSATE TRAP 13 TOP PLATE

2 DOOR SWITCH 14 BURNER

3 JUNCTION BOX 15 IGNITER

4 TRANSFORMER 16 COMBUSTION AIR INLET

5 BLOCKED DRAIN PRESSURE SWITCH 17 GAS VALVE

6 MAIN PRESSURE SWITCH 18 INDUCED DRAFT BLOWER

7 EXHAUST TRANSITION 19 LOW VOLTAGE TERMINAL

8 CONNECTOR 20 CAPACITOR

9 OUTLET AIR PIPE 21 ELECTRICAL BOX

10 VENT CAP PLUG 22 BLOWER

11 SENSOR 23 CONTROL BOX

12 OVERTEMPERATURE SWITCH

COVER GROUND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

2

3

4

5

6

7

8

9

10 11 12 13 14 15 16

17

18

19

20

21

2223

GAS INLET

OPTIONAL

COMBUSTION

AIR INLET

I409 I409

GAS

INLET

PVC

PVC

Page 5

GENERAL INFORMATION

1.

IMPORTANT: If furnace

operation is required during

construction, and air ladened

with corrosive compounds such

as chlorine and fluorine are

present, provisions must be

taken to provide clean outdoor

combustion and ventilation air to

the furnace. Compounds of

chlorine and fluorine, when

burned with combustion air, form

acids which will cause corrosion

of a heat exchanger. Some of

these compounds are found in

paneling, dry wall, tile adhesives,

paints, stains and varnishes,

solvents and masonry curing and

cleaning materials.

DO NOT INSTALL THIS FURNACE

IN A MOBILE HOME!! This furnace

is not approved for installation in a

mobile home. Doing so could cause

FIRE, PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

WHEN THIS FURNACE IS

INSTALLED IN A RESIDENTIAL

GARAGE, IT MUST BE INSTALLED

SO THE BURNERS AND IGNITION

SOURCE ARE LOCATED NO LESS

THAN 18 INCHES ABOVE THE

FLOOR. THIS IS TO PREVENT

THE RISK OF IGNITING FLAMMABLE VAPORS WHICH MAY

BE PRESENT IN A GARAGE.

ALSO, THE FURNACE MUST BE

LOCATED OR PROTECTED TO

AVOID PHYSICAL DAMAGE BY

VEHICLES. FAILURE TO FOLLOW

THESE WARNINGS CAN CAUSE A

FIRE OR EXPLOSION, RESULTING

IN PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

5

2.

IMPORTANT: If installing the

unit over a finished ceiling or

living area, be certain to install

an auxiliary condensate drain

pan under the entire unit. This

auxiliary drain pan should extend

under any evaporator coil

installed with the furnace.

3.

IMPORTANT: If using a cooling

evaporator coil with this

furnace:

a. be sure the air passes over

the heat exchanger before

passing over the cooling

coil. The cooled air passing

over the warm ambient air

inside the heat exchanger

tubes can cause

condensation inside the tubes

resulting in corrosion and

eventual failure.

b. install a parallel duct system

to divert all the air from the

furnace allowing it to pass

over the cooling coil only. Use

dampers or other means to

prevent chilled air from

passing over the heat

exchanger.

If these are manual dampers, they

must be equipped to prevent heating

or cooling operation unless the

damper is in the full heat or cool

position.

!

WARNING

!

WARNING

4.

IMPORTANT: Install the

furnace level. If it is not level,

condensate cannot drain

properly, possibly causing

furnace shut down.

NOTE: These furnaces are approved

for installation in attics, as well as

alcoves, utility rooms, closets and

crawlspaces. Provisions must be

made to prevent freezing of

condensate.

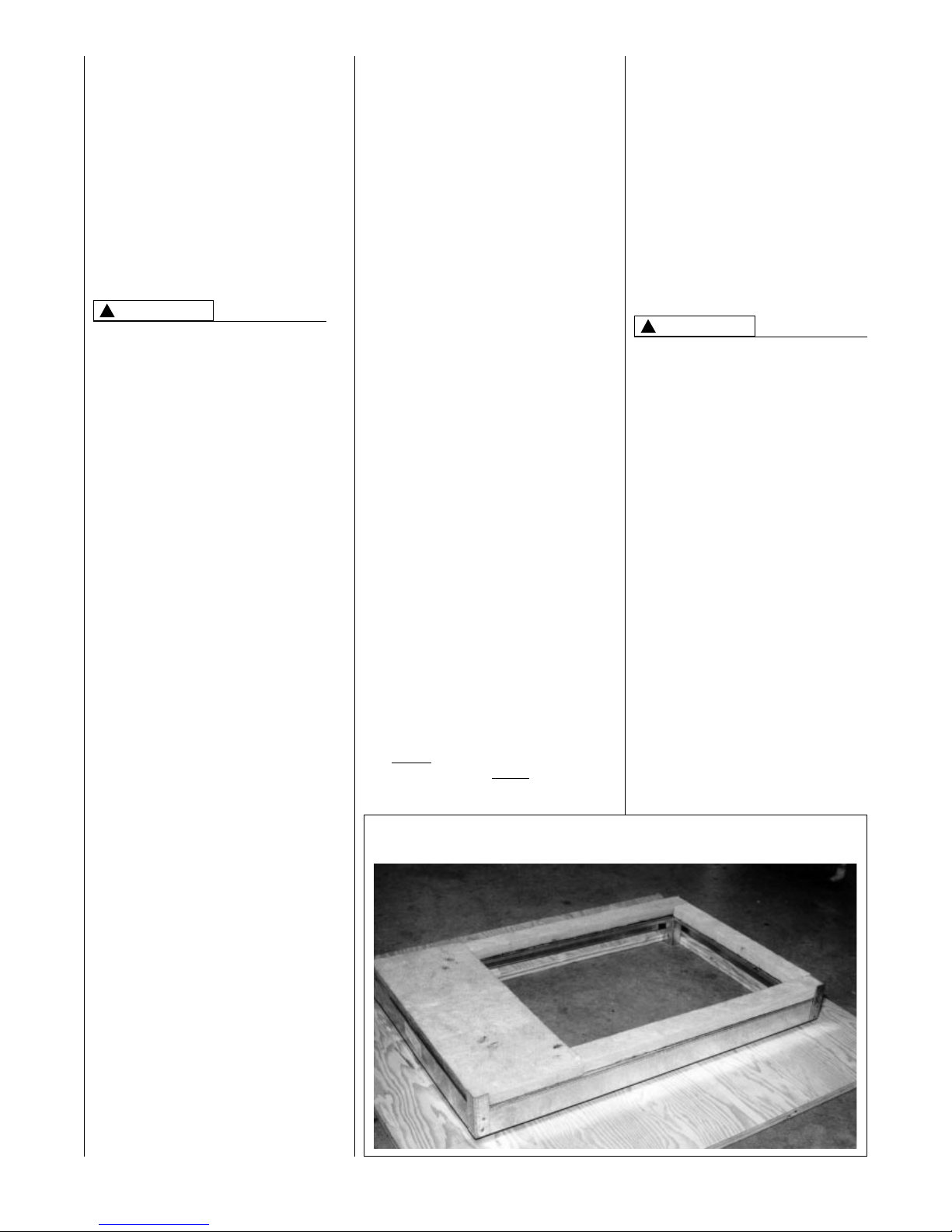

5.

IMPORTANT: If this furnace is

installed in a garage, attic

and/or any unconditioned

space, install a self-regulating

heat tape around the

condensate trap and along the

entire length of the condensate

drain in the unconditioned

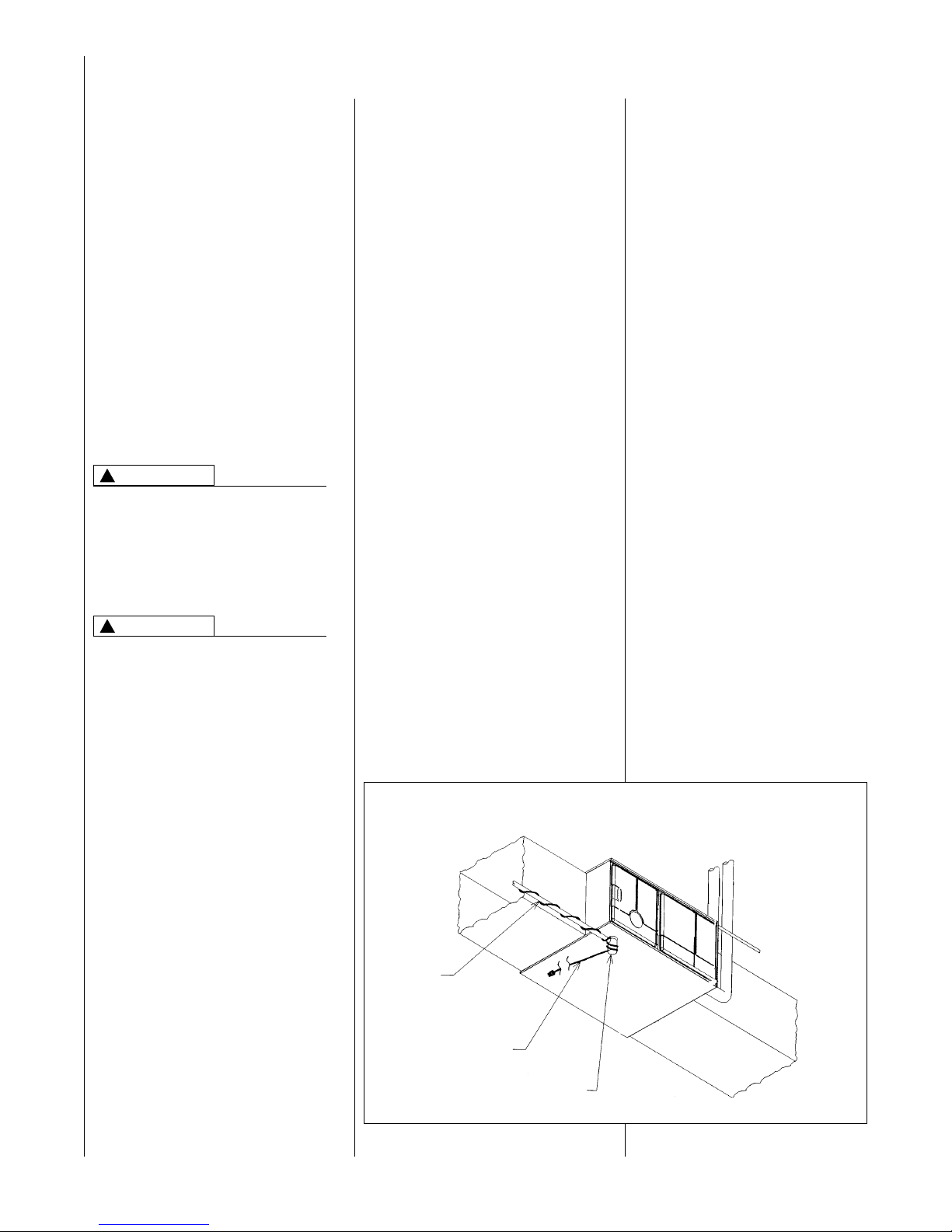

space. See Figure 3.

When the condensing horizontal

gas furnace is installed in an

unconditioned space where the

temperature would be capable of

reaching close to or below 32°F

(0°C). A SELF-REGULATING

HEAT TAPE IS REQUIRED ON

THE CONDENSATE DRAIN,

ALONG WITH AN INSULATION

WRAP. The heat tape should

meet the following requirements:

LOCATION REQUIREMENTS AND CONSIDERATIONS

FIGURE 3

HORIZONTAL FURNACE W/HEAT TAPE ON CONDENSATE TRAP

DRAIN

PIPE

HEAT

TAPE

TRAP

I526

Page 6

6

a. The heat tape must be UL

listed.

b. The heat tape must be

installed per the

manufacturer’s instructions for

the entire length of drain pipe

in the unconditioned space.

c. The heat tape should be rated

at 5 or 6 watts per foot at

120V.

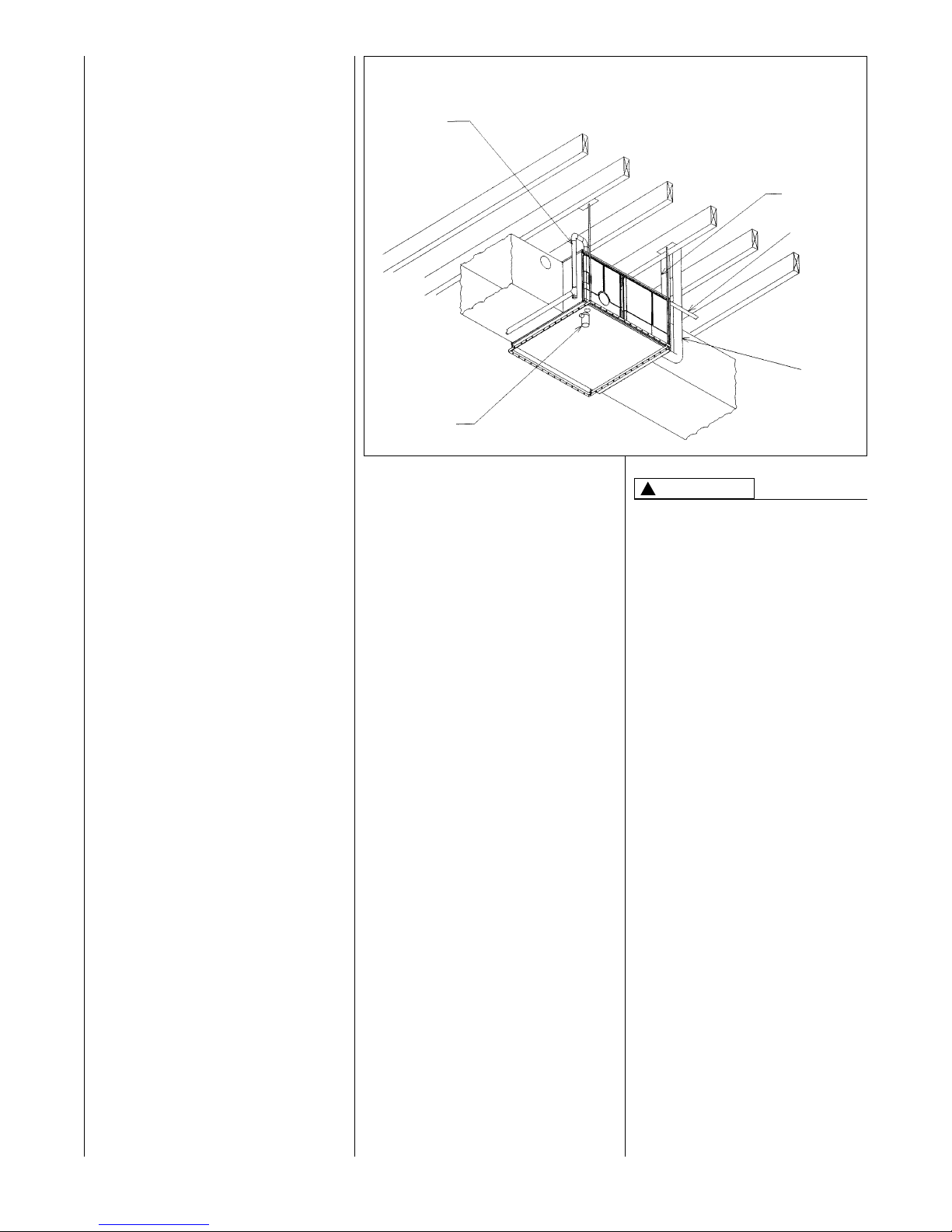

IMPORTANT: Support this unit

when installed. Since this

furnace is suitable for attic or

crawl space installation, it may

be installed on combustible wood

flooring or by using support

brackets. See Figure 4.

6.

IMPORTANT: If installing in a

utility room, be sure the door

is wide enough to:

a. allow the largest part of the

furnace to pass; or

b. allow any other appliance

(such as a water heater)

to pass.

7. IMPORTANT: This furnace is

not approved or recommended

for installation on its back,

with access doors facing

upwards.

CLEARANCE ACCESSIBILITY

The design of forced air furnaces with

input ratings as listed in the tables

under Figures 6, 7 and 8 are certified

by the AGA Laboratories and CGA

Laboratories for the clearances to

combustible materials shown in

inches.

FIGURE 4

HORIZONTAL FURNACE INSTALLED W/SUPPORT BRACKETS

GAS

PIPE

TRAP

EXHAUST

FAN

ELECTRICAL

CONDUIT

INTAKE

VENT

See name/rating plate and clearance

label for specific model number and

clearance information.

Service clearance of at least 24

inches is recommended in front of

all furnaces.

FOR PURPOSES OF SERVICING

THIS APPLIANCE, ACCESSIBILITY

CLEARANCES, WHERE GREATER,

MUST TAKE PRECEDENCE OVER

FIRE PROTECTION CLEARANCES.

UPFLOW AND HORIZONTAL

FURNACES ARE DESIGNCERTIFIED FOR INSTALLATION

ON COMBUSTIBLE FLOORS.

NOTE, HOWEVER, THAT FURNACES MUST NOT BE INSTALLED

DIRECTLY ON CARPETING, TILE

OR OTHER COMBUSTIBLE

MATERIAL OTHER THAN WOOD

FLOORING. INSTALLATION ON A

COMBUSTIBLE MATERIAL CAN

RESULT IN FIRE, CAUSING

PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

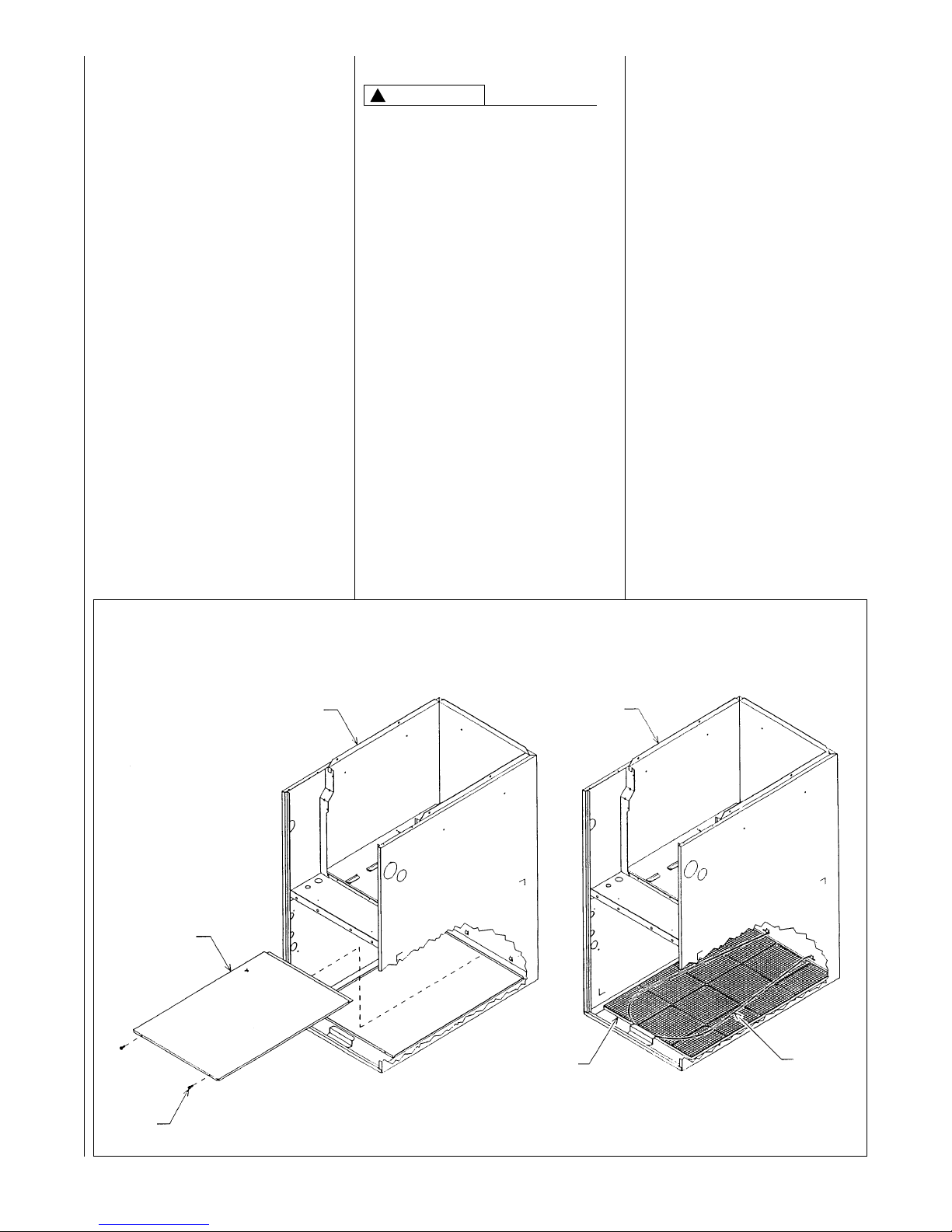

Upflow furnaces are shipped with a

bottom closure panel installed. When

bottom return air is used, remove the

panel by removing the two screws

attaching the panel to the front base

angle. See Figure 5.

!

WARNING

I522

Page 7

7

SITE SELECTION

1. Select a site in the building near

the center of the proposed, or

existing, duct system.

2. Give consideration to the vent

system piping when selecting the

furnace location. Be sure the

venting system can get from the

furnace to the termination with

minimal length and elbows.

3. Locate the furnace near the

existing gas piping. Or, if running

a new gas line, locate the

furnace to minimize the length

and elbows in the gas piping.

4. Locate the furnace to maintain

proper clearance to combustibles

as shown in the following tables.

!

WARNING

COMBUSTIBLE MATERIAL MUST

NOT BE PLACED ON OR AGAINST

THE FURNACE JACKET. THE

AREA AROUND THE FURNACE

MUST BE KEPT CLEAR AND FREE

OF ALL COMBUSTIBLE

MATERIALS INCLUDING GASOLINE AND OTHER FLAMMABLE

VAPORS AND LIQUIDS.

PLACEMENT OF COMBUSTIBLE

MATERIALS ON, AGAINST OR

AROUND THE FURNACE JACKET

CAN CAUSE AN EXPLOSION OR

FIRE RESULTING IN PROPERTY

DAMAGE, PERSONAL INJURY OR

DEATH. THE HOMEOWNER

SHOULD BE CAUTIONED THAT

THE FURNACE AREA MUST NOT

BE USED AS A BROOM CLOSET

OR FOR ANY OTHER STORAGE

PURPOSES.

FIGURE 5

BOTTOM PANEL REMOVAL

JACKET ASSEMBLY

SOLID BOTTOM

NOTE:

BACK FLANGE OF SOLID BOTTOM FITS

UNDERNEATH JACKET. SIDES AND FRONT

FLANGES FIT OVER FLANGES ON JACKET.

SCREW

(2) REQ’D.

JACKET ASSEMBLY

FILTER

FILTER

ROD

SOLID BOTTOM REMOVAL

FILTER & ROD LOCATION

ADS 5422-01

Page 8

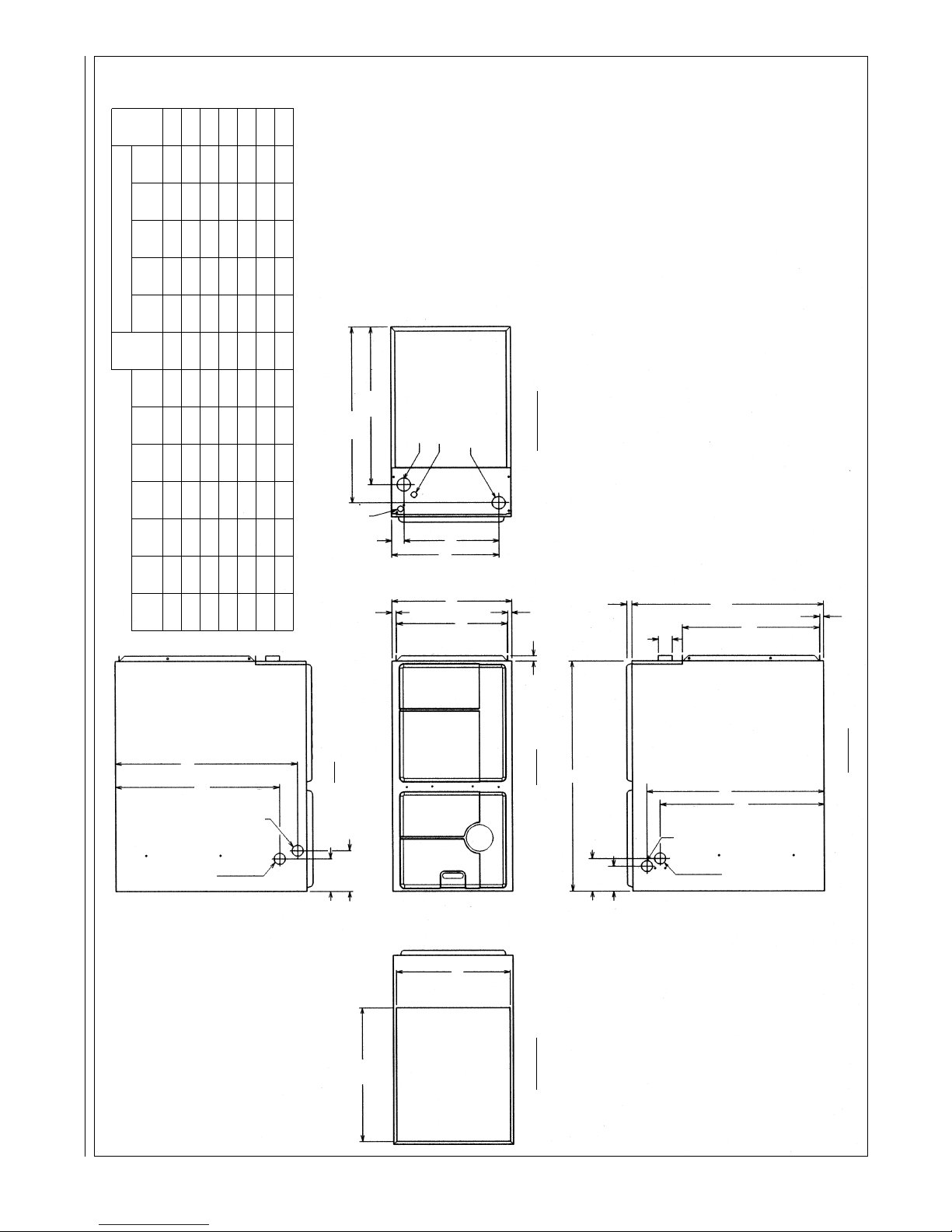

FIGURE 6

CLEARANCE TO COMBUSTIBLES, UPFLOW UNITS

8

UPFLOW MODELS MINIMUM CLEARANCE (IN.)

LEFT RIGHT SHIP

MODEL A B C D E F

SIDE SIDE

BACK TOP FRONT VENT

WGTS

04 17

1

/2 16

11

/32 15

5

/8 21513

25

/32 00012*0 111

06 17

1

/2 16

11

/32 15

5

/8 21513

25

/32 00012*0 117

07 17

1

/2 16

11

/32 15

5

/8 21513

25

/32 00012*0 123

09 21 19

27

/32 19

1

/8 218

1

/217

9

/32 00012*0 148

10 21 19

27

/32 19

1

/8 218

1

/217

9

/32 00012*0 152

12 24

1

/2 23

11

/32 22

5

/8 22220

25

/32 00012*0 160

I392

➤*A service clearance of at least 24 inches is recommended in front of all furnaces.

Page 9

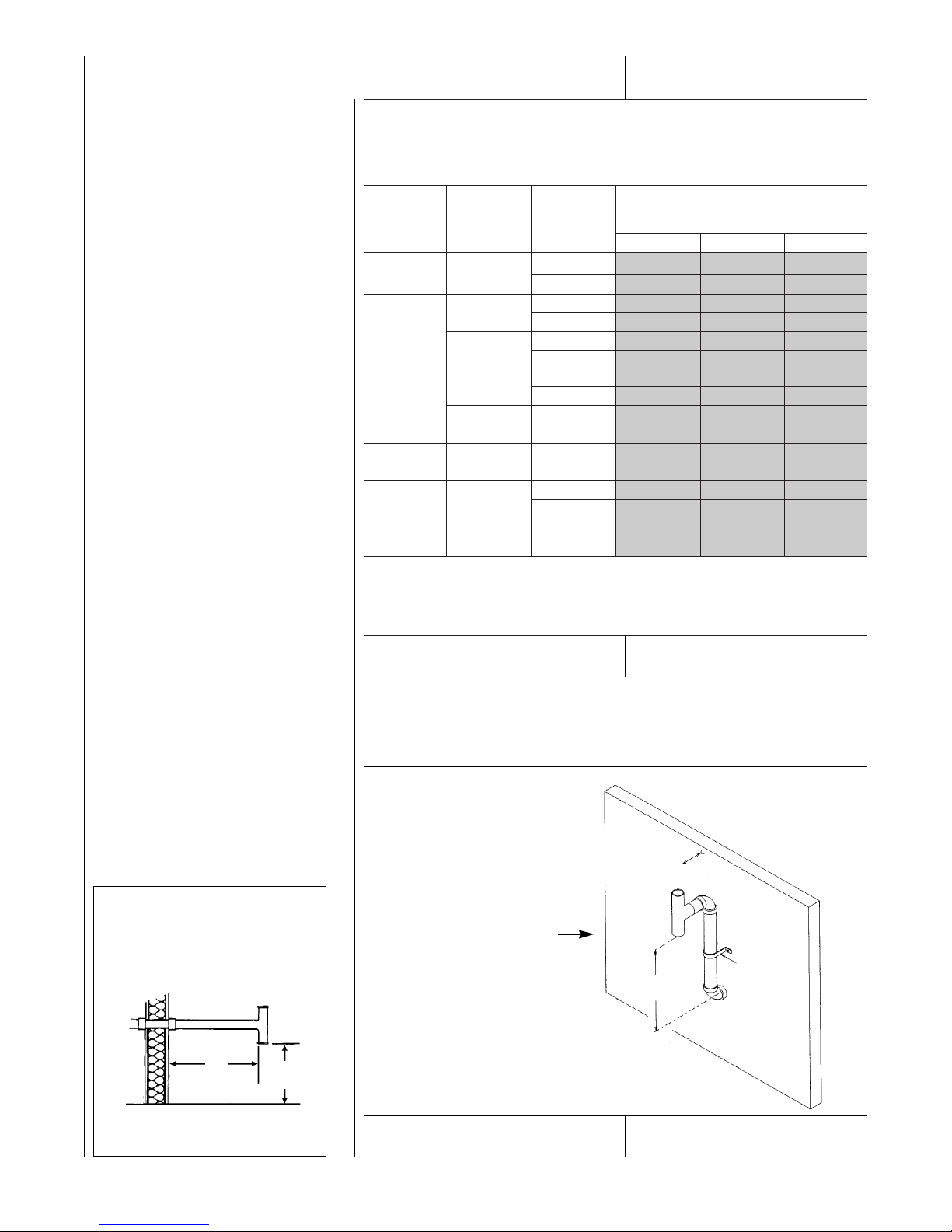

FIGURE 7

CLEARANCE TO COMBUSTIBLES, DOWNFLOW UNITS

9

DOWNFLOW MODELS MINIMUM CLEARANCE (IN.)

LEFT RIGHT SHIP

MODEL A B C D E F

SIDE SIDE

BACK TOP FRONT VENT

WGTS

04 17

1

/2

16

11

/32

15

5

/8

216

5

/8

13

7

/8

00012*0 111

06 17

1

/2 16

11

/32 15

5

/8 216

5

/813

7

/8 00012*0 117

07 17

1

/

2 16

11

/

32 15

5

/

8 216

5

/

813

7

/

8 00012*0 123

09 21 19

27

/

32 19

3

/

16 220

1

/

817

3

/

8 00012*0 148

10 21 19

27

/

32 19

3

/

16 220

1

/

817

3

/

8 00012*0 152

12 24

1

/

2 23

11

/

32 22

5

/

8 223

5

/

820

7

/

8 00012*0 160

I393

➤*A service clearance of at least 24 inches is recommended in front of all furnaces.

Page 10

➤ FIGURE 8

CLEARANCE TO COMBUSTIBLES, HORIZONTAL UNITS

DOWNFLOW MODELS MINIMUM CLEARANCE (IN.)

LEFT RIGHT SHIP

MODEL A B C D E F

SIDE SIDE

BACK TOP FRONT VENT

WGTS

04 17

1

/2 16

11

/32 15

5

/8 216

5

/813

7

/8 00012*0 111

06 17

1

/2 16

11

/32 15

5

/8 216

5

/813

7

/8 00012*0 117

07 17

1

/2 16

11

/32 15

5

/8 216

5

/813

7

/8 00012*0 123

07 21 19

27

/32 19

3

/16 220

1

/817

3

/8 00012*0 123

09 21 19

27

/32 19

3

/16 220

1

/817

3

/8 00012*0 148

10 21 19

27

/32 19

3

/16 220

1

/817

3

/8 00012*0 152

12 24

1

/2 23

11

/32 22

5

/8 223

5

/820

7

/8 00012*0 160

10

I520

*A service clearance of at least 24 inches is recommended in front of all furnaces.

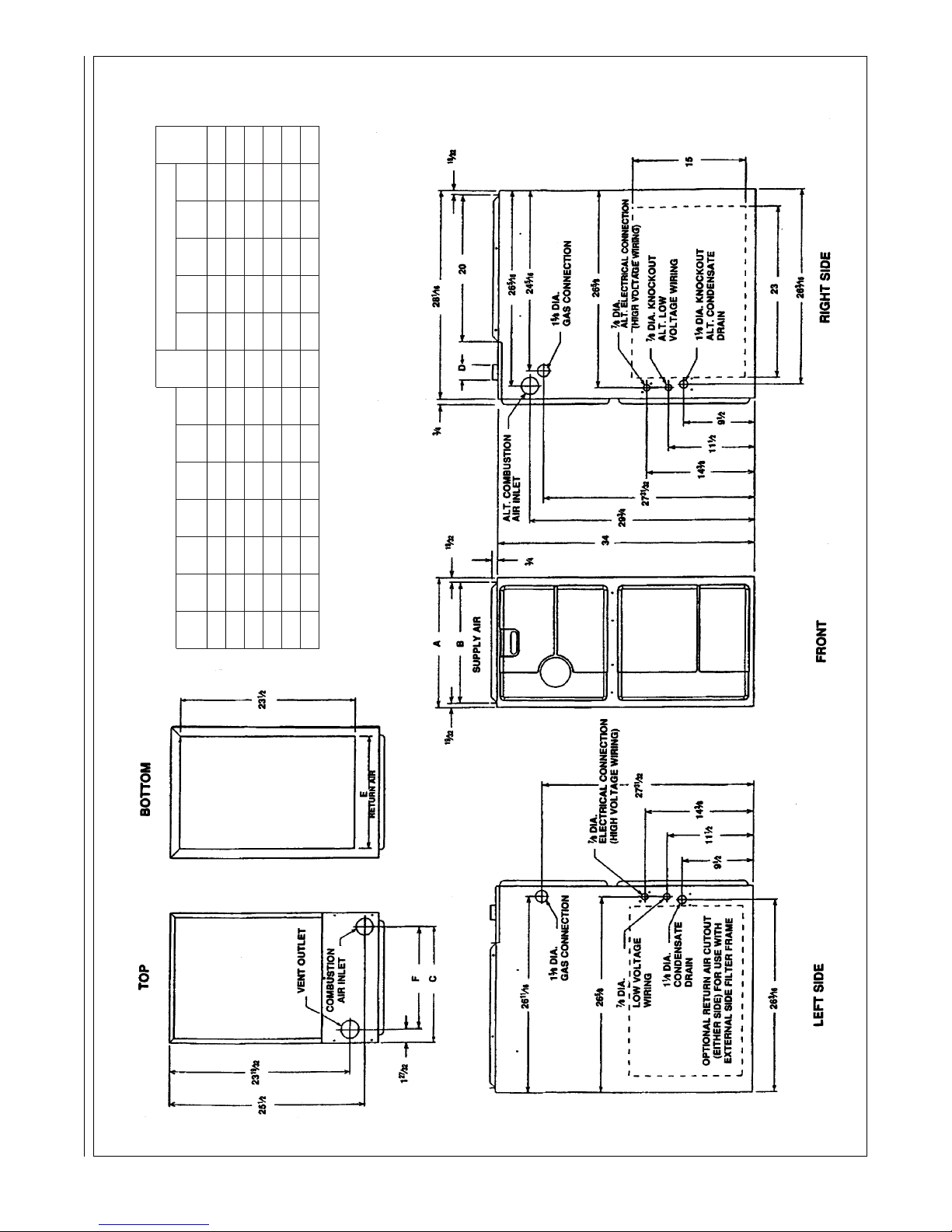

1

5

⁄8 DIA.

ALT. CONDENSATE

DRAIN

1

5

⁄8 DIA.

GAS

CONNECTION

TOP

LEFT SIDE FRONT

BOTTOM

RIGHT SIDE

4

13

⁄16

6

1

⁄64

24

1

⁄16

19

7

⁄8

23

31

⁄32

1

13

⁄16

34

4

13

⁄16

25

3

⁄32

D

28

1

⁄16

20

1

⁄18

19

⁄32

24

1

⁄16

3

⁄4

3

11

⁄16

1

5

⁄8 DIA.

ALT. GAS

CONNECTION

1

5

⁄8 DIA.

CONDENSATE

DRAIN

COMBUSTION

AIR INLET

LOW VOLTAGE

RETURN

AIR

VENT OUTLET

22

3

⁄32

ELECT.

CONN.

19

⁄32

19

⁄32

3

⁄4

E

B

A

C

F

SUPPL

Y

26

11

⁄16

Page 11

11

DUCTING

Proper air flow is required for the

correct operation of this furnace.

Too little air flow can cause erratic

operation and can damage the heat

exchanger. The duct system must

carry the correct amount of air for

heating and cooling if summer air

conditioning is used.

Size the ducts according to

acceptable industry standards and

methods. The total static pressure

drop of the air distribution system

should not exceed 0.5" w.c.

NEVER ALLOW THE PRODUCTS

OF COMBUSTION FROM THE

FLUE TO ENTER THE RETURN AIR

DUCTWORK OR THE

CIRCULATED AIR SUPPLY. ALL

RETURN DUCTWORK MUST BE

ADEQUATELY SEALED AND

SECURED TO THE FURNACE

WITH SHEET METAL SCREWS;

AND JOINTS, TAPED. ALL OTHER

DUCT JOINTS MUST BE SECURED

WITH APPROVED CONNECTIONS

AND SEALED AIRTIGHT. WHEN AN

UPFLOW FURNACE IS MOUNTED

ON A PLATFORM WITH RETURN

THROUGH THE BOTTOM, IT MUST

BE SEALED AIRTIGHT BETWEEN

THE FURNACE AND THE RETURN

AIR PLENUM. THE FLOOR OR

PLATFORM MUST PROVIDE

SOUND PHYSICAL SUPPORT OF

THE FURNACE WITHOUT

SAGGING, CRACKS, OR GAPS,

AROUND THE BASE, PROVIDING A

SEAL BETWEEN THE SUPPORT

AND THE BASE.

FAILURE TO PREVENT

PRODUCTS OF COMBUSTION

FROM BEING CIRCULATED INTO

THE LIVING SPACE CAN CREATE

POTENTIALLY HAZARDOUS

CONDITIONS, INCLUDING

CARBON MONOXIDE POISONING

THAT COULD RESULT IN

PERSONAL INJURY OR DEATH.

DO NOT, UNDER ANY

CIRCUMSTANCES, CONNECT

RETURN OR SUPPLY DUCTWORK

TO OR FROM ANY OTHER HEAT

PRODUCING DEVICE SUCH AS A

FIREPLACE INSERT, STOVE, ETC.

DOING SO MAY RESULT IN FIRE,

CARBON MONOXIDE POISONING,

EXPLOSION, PERSONAL INJURY

OR PROPERTY DAMAGE.

IMPORTANT: Some high efficiency

filters have a greater than normal

resistance to air flow. This can

adversely affect furnace operation.

BE SURE TO CHECK AIR FLOW if

using any filter other than the factoryprovided filter.

UPFLOW UNITS

1. Position the unit to minimize long

runs of duct or runs of duct with

many turns and elbows.

2. Open the return air compartment.

a. If using side or back return air,

do not remove the bottom

base.

b. Cut an opening in the side or

back. The opening should

be cut the full width of the

knockouts on the unit.

c. Remove the bottom base if

using bottom return air.

NOTE: Where the maximum air flow

is 1800 CFM or more, both sides or

the bottom must be used for return

air.

3. Connect the return duct or return

air cabinet to the unit. Make the

connection air tight to prevent

entraining combustion gases

from an adjacent fuel-burning

appliance.

4. Be sure to have adequate

space for the unit filter.

NOTE: DO NOT take return air

from bathrooms, kitchens,

furnace rooms, garages, utility or

laundry rooms, or cold areas.

5. If summer air conditioning is

desired, position the indoor coil

on the top of the unit. Insure that

no air can bypass this coil.

6. Connect the supply air plenum to

the furnace plenum opening.

IMPORTANT: If a flexible duct

connector must be used, it

MUST

be rated for a minimum

temperature of 250

°F.

continuous.

DOWNFLOW UNITS

1. Position the unit to minimize long

runs of duct or runs of duct with

many turns and elbows.

2. If summer air conditioning is

desired, position the indoor coil

on the bottom of the unit. Insure

that no air can bypass this coil.

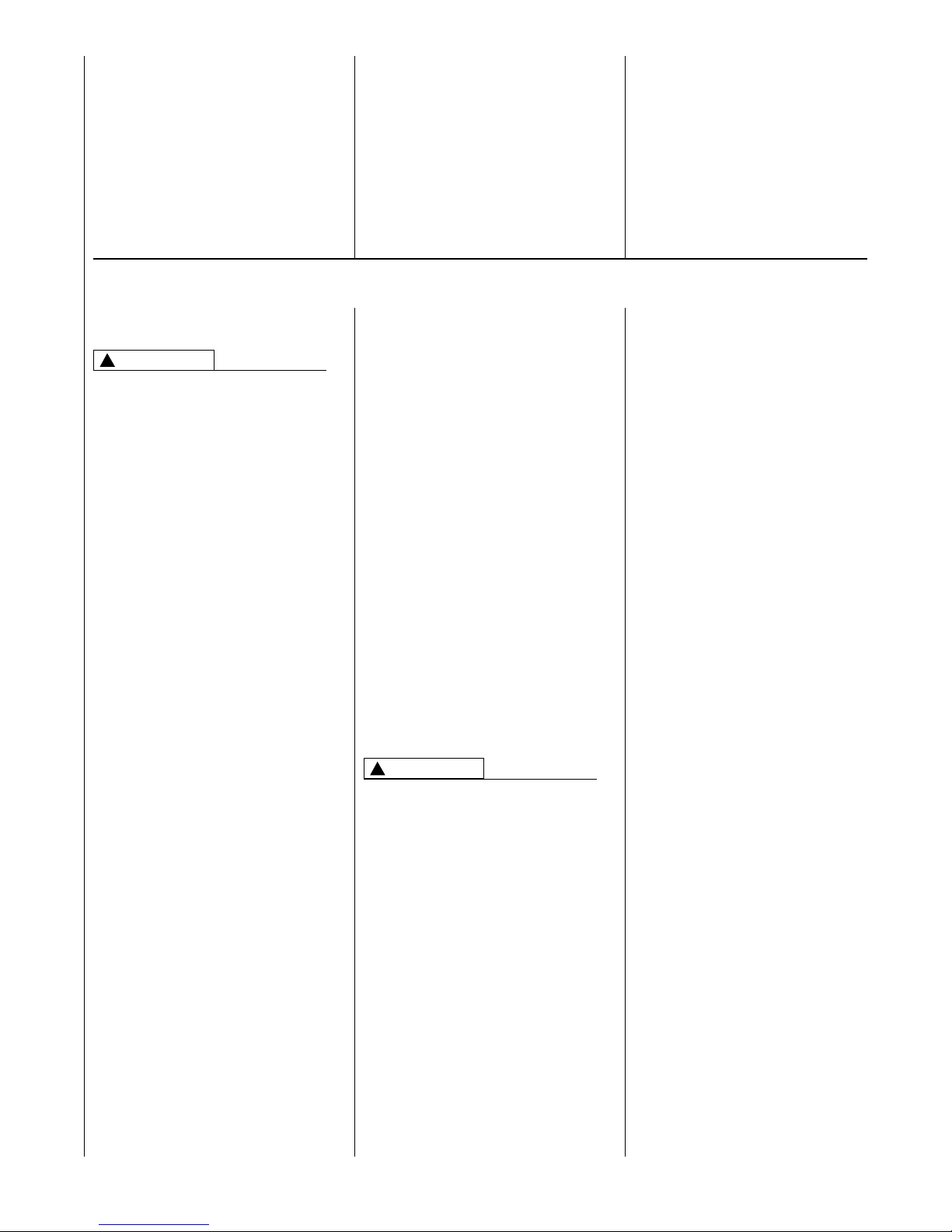

3. If installing on a combustible floor

and not using an air conditioning plenum, install the special

non-combustible floor base. See

Figure 9.

THE DOWNFLOW FURNACE

DESIGN IS CERTIFIED FOR

INSTALLATION ON A NONCOMBUSTIBLE FLOOR. USE THE

SPECIAL BASE SPECIFIED ON

THE FURNACE CLEARANCE

LABEL. FAILURE TO INSTALL THE

SPECIAL BASE MAY RESULT IN

FIRE, PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

THIS SPECIAL BASE IS SHIPPED

FROM THE FACTORY AS AN

ACCESSORY.

4. Connect the furnace to the

supply air plenum.

5. Connect the return air ducting to

the return air opening at the top

of the unit. Make the connection

air tight to prevent entraining

combustion gases from an

adjacent fuel-burning appliance.

6. Be sure to have adequate

space for the unit filter.

NOTE: DO NOT take return air

from bathrooms, kitchens,

furnace rooms, garages, utility or

laundry rooms, or cold areas.

!

WARNING

!

WARNING

FIGURE 9

COMBUSTIBLE FLOOR BASE

Page 12

12

GENERAL INFORMATION

READ AND FOLLOW ALL INSTRUCTIONS IN THIS SECTION.

FAILURE TO PROPERLY VENT

THIS FURNACE CAN CAUSE

CARBON MONOXIDE POISONING

OR AN EXPLOSION OR FIRE,

RESULTING IN PROPERTY

DAMAGE, PERSONAL INJURY

OR DEATH.

This furnace removes both sensible

and latent heat from the combustion

flue gases. Removal of latent heat

results in condensation of flue gas

water vapor. This condensed water

vapor drains from the secondary heat

exchanger and out of the unit into a

drain trap.

When installed as a non-direct vent

furnace, only exhaust piping is

required and inside combustion air

may be used. Refer to section on

“

COMBUSTION & VENTILATION AIR

FOR FURNACE INSTALLATIONS.”

Direct vent installations require a

dedicated combustion air and venting

system. All air for combustion is taken

from the outside atmosphere and all

combustion products are discharged

to the outdoors.

The combustion air and vent pipe

fittings must conform to American

National Standards Institute (ANSI)

and American Society for Testing

Materials (ASTM) standards

D1785 (Schedule 40 PVC), D2665

(PVC-DWV), D2241 (SDR-21 and

SDR26-26 PVC), D2661 (ABS-DWV)

or F628 (Schedule 40 ABS-DWV).

In Canada all combustion air and vent

pipe must be CSA- or ULC-certified

Schedule 40 PVC, PVC-DWV or

ABS-DWV.

IMPORTANT: The plastic combustion

air and venting components are of

Schedule 40 PVC. If using ABS

piping, ensure that the solvent

cement is compatible for joining

PVC to ABS components or use a

mechanical connection that can

withstand the vent temperatures and

are corrosion resistant.

NOTE: Schedule 40 ABS-DWV pipe

and fittings may be used as an

alternate to PVC pipe for the

combustion air inlet and vent pipes.

NOTE: Cellular core PVC is also

approved for use. It must be schedule

40PVC-DWV cellular pipe for nonpressure applications and

manufactured under ASTM F-891.

OVERTEMPERATURE

SAFETY SWITCHES

Furnaces are equipped with safety

switches in the control compartment

to protect against overtemperature

conditions caused by inadequate

combustion air supply. The switches

for the upflow and downflow models

are located in the burner

compartment. If a switch is tripped it

must be manually reset.

DO NOT JUMPER THESE

DEVICES! IF ONE OF THESE

SWITCHES SHOULD TRIP, A

QUALIFIED INSTALLER, SERVICE

AGENCY OR THE GAS SUPPLIER

MUST BE CALLED TO CHECK

AND/OR CORRECT FOR

ADEQUATE COMBUSTION AIR

SUPPLY. DO NOT RESET THE

SWITCHES WITHOUT TAKING

CORRECTIVE ACTION TO ASSURE

THAT AN ADEQUATE SUPPLY OF

COMBUSTION AIR IS MAINTAINED

UNDER ALL CONDITIONS OF

OPERATION. FAILURE TO DO SO

CAN RESULT IN CARBON

MONOXIDE POISONING OR

DEATH. IF THIS UNIT IS MOUNTED

IN A CLOSET, THE DOOR MUST

BE CLOSED WHEN MAKING THIS

CHECK.

REPLACE THESE SWITCHES

ONLY WITH THE IDENTICAL

REPLACEMENT PART.

EXISTING VENT SYSTEMS

When the installation of this furnace

replaces an existing furnace that is

removed from a vent system serving

other appliances, the vent system is

likely to be too large to properly vent

the remaining attached appliances.

The following steps should be

followed with each appliance

remaining connected to the original

common vent system. Place the

appliance to be tested in operation,

while the other appliances remaining

connected to the common vent

system are not in operation. Test the

operation of each appliance

individually by the following method.

1. Permanently seal any unused

openings in the common venting

system.

2. Visually inspect the venting

system for proper size and

horizontal pitch and determine

that there is no blockage,

restriction, leakage, corrosion or

other deficiencies which could

cause an unsafe condition.

3. If practical, close all building

doors, windows and all doors

between the space where the

appliances remaining connected

to the common venting system

are located.

Turn on clothes dryers and any

appliance not connected to the

common venting system. Turn on

any exhaust fans, such as range

hoods and bathroom exhausts,

so they will operate at maximum

speed. Do not operate a summer

exhaust fan. Close fireplace

dampers.

VENTING AND COMBUSTION AIR PIPING

!

WARNING

!

WARNING

HORIZONTAL UNIT

IMPORTANT: THIS FURNACE MAY

ONLY BE INSTALLED SO AS

WHEN FACING THE FRONT OF

THE FURNACE, SUPPLY AIR IS

DISCHARGED ON THE LEFT HAND

SIDE.

1. Position the unit to minimize long

runs or runs with many turns and

elbows.

2. If summer air conditioning is

desired, position the indoor coil

on the left end of the unit. Insure

that no air can bypass this coil.

3. Connect the furnace to the

supply air plenum.

4. Connect the return air ducting to

the return air opening at the right

end of the unit. Make the

connection air tight to prevent

entraining combustion gases

from an adjacent fuel-burning

appliance.

5. Be sure to have adequate

space for the unit filter.

NOTE: DO NOT take return air

from bathrooms, kitchens,

furnace rooms, garages, utility or

laundry rooms, or cold areas.

Page 13

CEMENTING JOINTS

Properly seal all joints in the PVC

vent using the following materials and

procedures.

PVC CLEANER-PRIMER AND

PVC MEDIUM-BODY SOLVENT

CEMENT

IMPORTANT:

After cutting pipe,

remove all ragged edges and burrs.

This is important to prevent reduction

in pressure drop throughout the

system.

1. Cut pipe end square. Chamfer

edge of pipe. Clean fitting socket

and pipe joint area of all dirt,

grease and moisture.

2. After checking pipe and socket

for proper fit, wipe socket and

pipe with cleaner-primer. Apply

a liberal coat of primer to inside

surface of socket and outside of

pipe. Read instructions included

with the primer for proper

application.

3. Apply a thin coat of cement

evenly in the socket. Quickly

apply a heavy coat of cement to

the pipe end and insert pipe into

fitting with a slight twisting

movement until it bottoms out.

NOTE: Cement must be fluid; if

not, recoat.

4. Hold the pipe in the fitting for 30

seconds to prevent the tapered

socket from pushing the pipe out

of the fitting.

5. Wipe all excess cement from the

joint with a rag. Allow 15 minutes

before handling. Cure time varies

according to fit, temperature and

humidity.

NOTE: Stir the solvent cement

frequently while using. Use a natural

bristle brush or the dauber supplied

with the can. The proper brush size is

one inch.

IMPORTANT: For Proper Installation

DO NOT use solvent cement that

has become curdled, lumpy or

thickened.

DO NOT thin. Observe shelf

precautions printed on containers.

For application below 32°F, use only

low-temperature-type solvent

cement.

13

4. Follow the lighting instructions.

Place the appliance being

inspected into operation. Adjust

the thermostat so the appliance

will operate continuously.

5. Test for spillage at the draft hood

relief opening after 5 minutes of

main burner operation. Use the

flame of a match or candle, or

smoke from a cigarette, cigar

or pipe.

6. After it has been determined that

each appliance that remains

connected to the common

venting system properly vents

(when tested as outlined above),

return doors, windows, exhaust

fans, fireplace dampers and any

other gas-burning appliance to

their previous conditions of use.

7. If improper venting is observed

during any of the above tests, the

common venting system must be

resized. Refer to latest edition of

the National Fuel Gas Code

ANSI Z223.1, 1992 or the AGAGAMA venting tables for

Category I furnaces.

When the furnace is installed in the

same space with other gas

appliances such as a water heater, be

sure there is an adequate supply of

combustion and ventilation air for the

other appliances. Do not delete or

reduce the combustion air supply

required by the other gas appliances

in this space. See Z223.1, National

Fuel Gas Code (NFPA54) or

CAN/CGA-B149.1 and .2 for determining the combustion air requirements for gas appliances. An

unconfined space must have at least

50 cubic feet (volume) for each

1,000 BTUH of the total input of all

appliances in the space. If the open

space containing the appliances is in

a building with tight construction

(contemporary construction), outside

air may still be required for the

appliances to burn and vent properly.

Outside air openings should be sized

the same as for a confined space.

JOINING PIPE AND

FITTINGS

PVC SOLVENT CEMENTS AND

PRIMERS ARE HIGHLY FLAMMABLE. PROVIDE ADEQUATE

VENTILATION AND DO NOT

ASSEMBLE NEAR HEAT SOURCE

OR AN OPEN FLAME. DO NOT

SMOKE. AVOID SKIN OR EYE

CONTACT. OBSERVE ALL

CAUTIONS AND WARNINGS

PRINTED ON MATERIAL CONTAINERS. FAILURE TO FOLLOW

THESE GUIDELINES MAY RESULT

IN FIRE, EXPLOSION OR

ASPHYXIATION CAUSING

PERSONAL INJURY OR DEATH.

All pipe, fittings, solvent cement,

primers and procedures must

conform to American National

Standard Institute and American

Society for Testing and Materials

(ANSI/ASTM) standards in the U.S.

Pipe and Fittings - ASTM-D1785,

D2466, D2665, D2231, D2661 and

F628.

PVC Primer and Solvent Cement ASTM-D2564

ABS Pipe and Fittings - Use ABS

Primer and Solvent Cement D2235

Procedure for Cementing Joints ASTM-D2855

IMPORTANT: The plastic combustion

air and venting components are of

PVC. If using ABS piping, ensure that

the solvent cement is compatible for

joining PVC to ABS components or

use a mechanical connection that can

withstand the vent temperatures and

are corrosion resistant.

!

WARNING

Page 14

14

NON-DIRECT

FURNACE INSTALLATIONS

THE FURNACE AND ANY OTHER

FUEL-BURNING APPLIANCE MUST

BE PROVIDED WITH ENOUGH

FRESH AIR FOR PROPER

COMBUSTION AND VENTILATION

OF THE FLUE GASES. MOST

HOMES WILL REQUIRE THAT

OUTSIDE AIR BE SUPPLIED INTO

THE FURNACE AREA. FAILURE

TO DO SO CAN CAUSE

PERSONAL INJURY OR DEATH

FROM CARBON MONOXIDE

POISONING.

Adequate facilities for providing air for

combustion and ventilation must be

provided in accordance with section

5.3, “Air for Combustion and

Ventilation” of the National Fuel Gas

Code, ANSI Z223.1-1992, CAN/CGA

B149.1 and 2, or applicable provisions for the local building codes,

and not obstructed so as to prevent

the flow of air to the furnace.

IMPORTANT: Air for combustion and

ventilation must not come from a

corrosive atmosphere. Any failure

due to corrosive elements in the

atmosphere is excluded from

warranty coverage.

The following types of installation

(but not limited to the following) will

require OUTDOOR AIR for combustion, due to chemical exposures:

• Commercial buildings

• Buildings with indoor pools

• Furnaces installed in laundry rooms

• Furnaces in hobby or craft rooms

• Furnaces installed near chemical

storage areas.

Exposure to the following substances

in the combustion air supply (but not

limited to the following) will also

require OUTDOOR AIR for

combustion:

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine-based swimming pool

chemicals

• Water softening chemicals

• De-icing salts or chemicals

• Carbon tetrachloride

• Halogen type refrigerants

• Cleaning solvents (such as

perchloroethylene)

• Printing inks, paint removers,

varnishes, etc.

• Hydrochloric acid

• Cements and glues

• Antistatic fabric softeners for

clothes dryers

• Masonry curing and acid washing

materials

Combustion air must be free of acidforming chemicals such as sulphur,

fluorine and chlorine. These elements

are found in aerosol sprays,

detergents, bleaches, cleaning

solvents, air fresheners, paint and

varnish removers, refrigerants and

many other commercial and

household products. When burned in

a gas flame, vapors from these

products form acid compounds. The

acid compounds increase the dew

point temperature of the flue products

and are highly corrosive after they

condense.

ALL FURNACE INSTALLATIONS

MUST COMPLY WITH THE

NATIONAL FUEL GAS CODE AND

LOCAL CODES TO PROVIDE

ADEQUATE COMBUSTION AND

VENTILATION AIR FOR THE

FURNACE. FAILURE TO DO SO

CAN RESULT IN EXPLOSION,

FIRE, PROPERTY DAMAGE,

CARBON MONOXIDE POISONING,

PERSONAL INJURY OR DEATH.

Combustion air requirements are

determined by whether the furnace is

in an open (unconfined) area or in a

confined space such as a closet or

small room.

EXAMPLE 1:

FURNACE LOCATED IN AN

UNCONFINED SPACE

Using indoor air for combustion.

An unconfined space must have at

least 50 cubic feet for each 1,000

BTUH of the total input for all

appliances in the space. Here are a

few examples of the room sizes

required for different inputs. The sizes

are based on 8-foot ceilings.

BTUH Minimum Sq. Feet Typical Room Size

Input With 8' Ceiling With 8' Ceiling

45,000 281 14' x 20' OR 16' x 18'

60,000 375 15' x 25' OR 19' x 20'

75,000 469 15' x 31' OR 20' x 24'

90,000 563 20' x 28' OR 24' x 24'

105,000 657 20' x 33' OR 26' x 25'

120,000 750 25' x 30' OR 24' x 32'

If the open space containing the

furnace is in a building with tight

construction, outside air may still be

required for the furnace to operate

and vent properly. Outside air

openings should be sized the same

as for a confined space.

EXAMPLE 2:

FURNACE LOCATED IN A

CONFINED SPACE

A confined space (any space smaller

than shown above as “unconfined”)

must have openings into the space

which are located in accordance with

the requirements set forth in the

following subsections A and B. Size

the openings by how they are

connected to the heated area or to

the outside,

and by the input of all appliances in

the space.

If confined space is within a building

with tight construction, combustion air

must be taken from outdoors or area

freely communicating with the

outdoors.

A. USING INDOOR AIR FOR

COMBUSTION

IMPORTANT: Air should not be

taken from a heated space with

a fireplace, exhaust fan or other

device that may produce a

negative pressure.

If combustion air is taken from the

heated area, the openings must

each have at least 100 square

inches of free area. Each opening

must have at least one square inch

of free area for each 1,000 BTUH

of total input in the space. Here

are some examples of typical

openings required.

COMBUSTION AND VENTILATION AIR

!

WARNING

!

WARNING

Page 15

15

BTUH Free Area

Input Each Opening

45,000 100 square inches

60,000 100 square inches

75,000 100 square inches

90,000 100 square inches

105,000 105 square inches

120,000 120 square inches

B. USING OUTDOOR AIR FOR

COMBUSTION

IMPORTANT: Do not take air

from an attic space that is

equipped with power ventilation.

The confined space must

communicate with the outdoors in

accordance with Methods 1 or 2.

The minimum dimension of air

openings shall not be less than 3

inches. Where ducts are used,

they shall be of the same crosssectional area as the free area of

the openings to which they

connect.

Method 1

Two permanent openings, one

located within 12 inches of the top

and one located within 12 inches

of the bottom of the enclosure,

shall be provided. The openings

shall communicate directly, or by

ducts, with the outdoors or spaces

(crawl or attic) that freely

communicate with the outdoors.

a. Where directly communicating

with the outdoors or where

communicating to the outdoors

through vertical ducts as shown in

Figure 11, each opening shall

have a minimum free area of 1

square inch for each 4,000 BTUH

of total appliance input rating in the

enclosure.

BTUH Free Area Round Pipe

Input Each Opening Size

45,000 11.25 square inches 4"

60,000 15.00 square inches 5"

75,000 18.75 square inches 5"

90,000 22.50 square inches 6"

105,000 26.25 square inches 6"

120,000 30.00 square inches 6"

b. Where communicating with

outdoors through horizontal ducts,

each opening shall have a

minimum free area of 1 square

inch for each 2,000 BTUH of total

input rating of all equipment in the

enclosure.

Here are some typical sizes.

BTUH Free Area Round Pipe

Input Each Opening Size

45,000 22.50 square inches 6"

60,000 30.00 square inches 6"

75,000 37.50 square inches 7"

90,000 45.00 square inches 8"

105,000 52.50 square inches 8"

120,000 60.00 square inches 9"

Method 2

One permanent opening, located

within 12 inches of the top of the

enclosure, shall be permitted

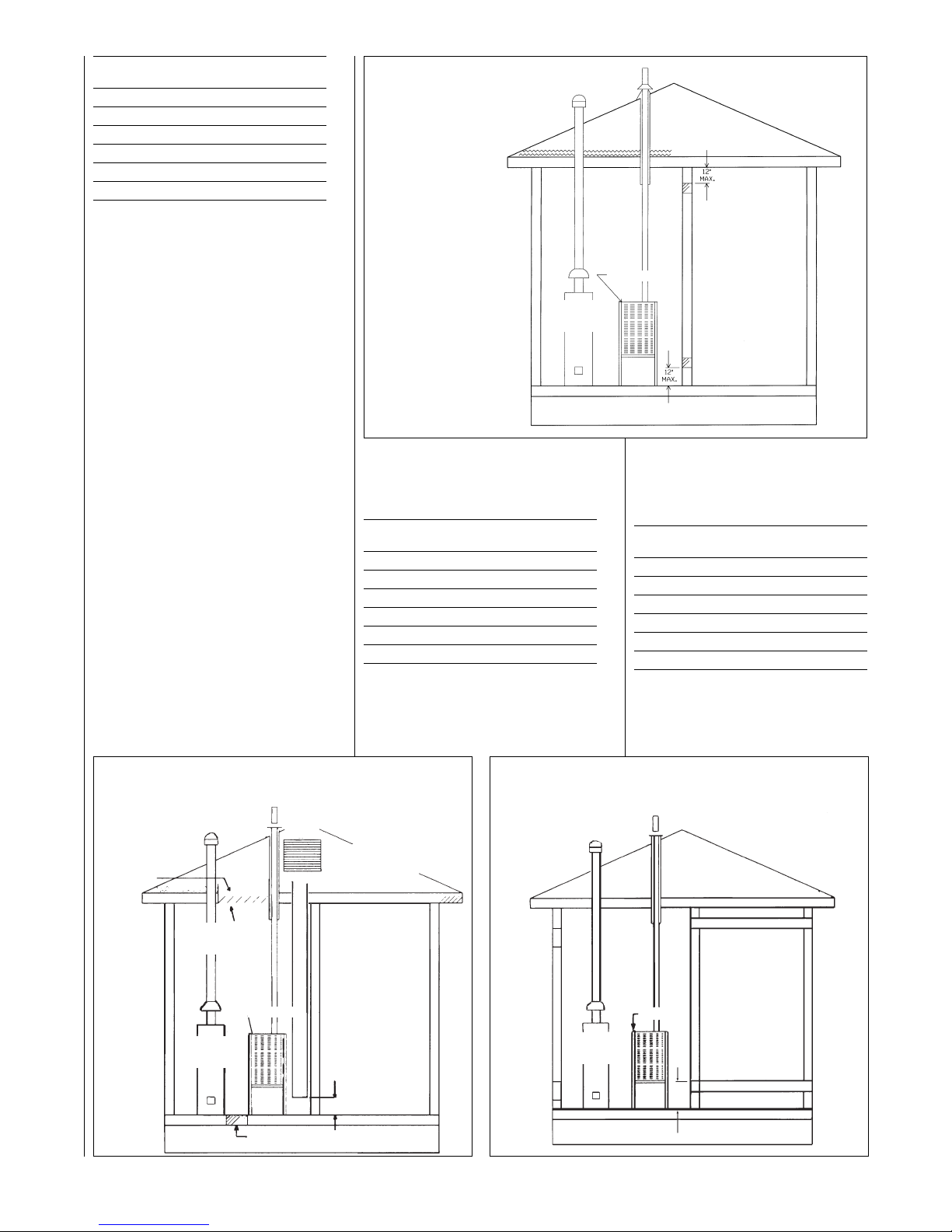

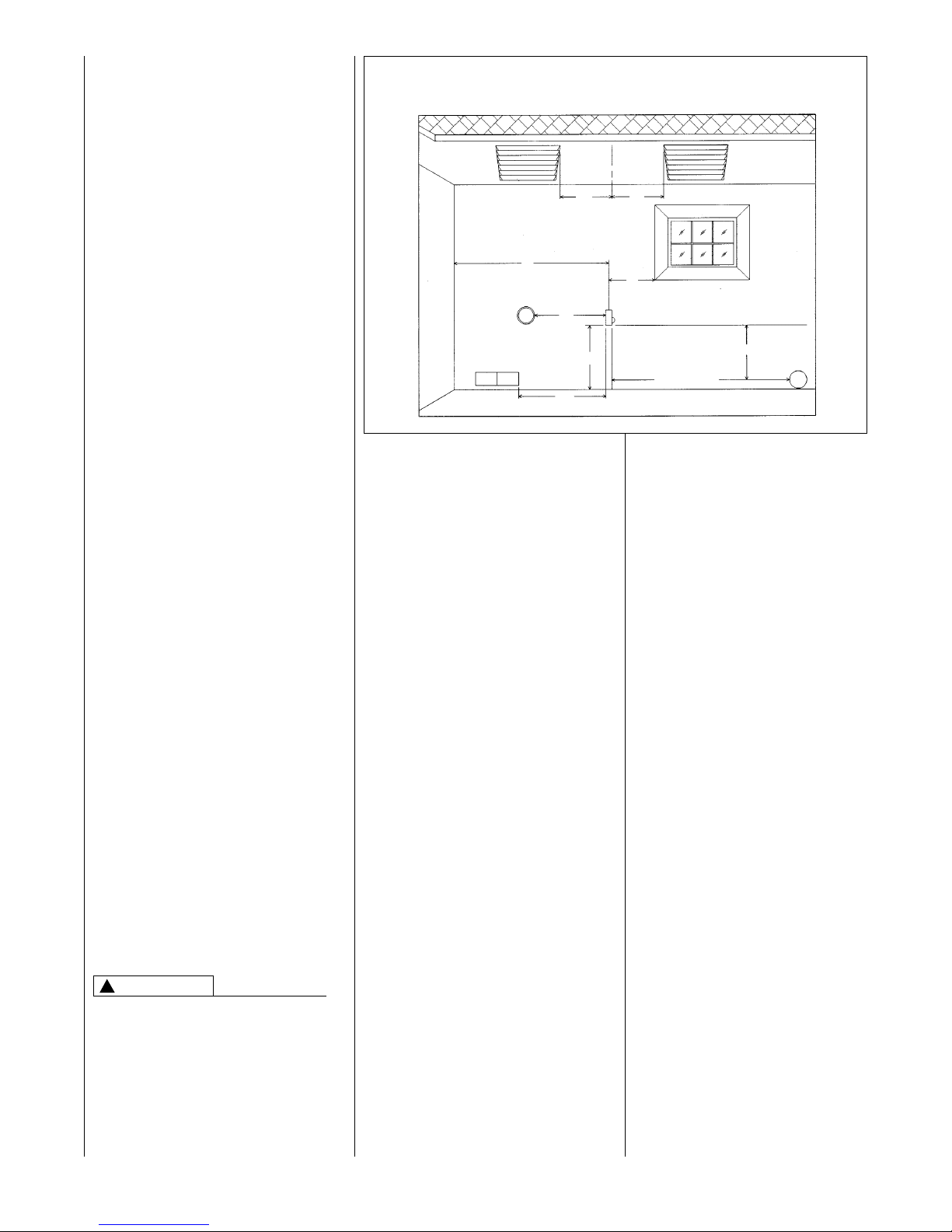

FIGURE 11

AIR FROM ATTIC/CRAWL SPACE

FIGURE 12

OUTSIDE AIR USING A HORIZONTAL DUCT

FIGURE 10

AIR FROM HEATED SPACE

NOTE:

EACH OPENING SHALL

HAVE A FREE AREA OF

NOT LESS THAN ONE

SQUARE INCH PER

1,000 BTU PER H0UR OF

THE

TOTAL

INPUT

RATING OF ALL

EQUIPMENT IN THE

ENCLOSURE, BUT NOT

LESS THAN 100

SQUARE INCHES.

GAS

WATER

HEATER

FURNACE

GAS

WATER

HEATER

GAS

WATER

HEATER

FURNACE

FURNACE

12" MAX.

12"

MAX.

1 SQ. INCH PER

4000 BTUH INLET AIR

OUTLET AIR 1 SQ. INCH

PER 2000 BTUH

INLET AIR 1 SQ. INCH

PER 2000 BTUH

1 SQ. INCH PER

4000 BTUH

OUTLET AIR

OUTLET AIR

IN ATTIC

MUST BE

ABOVE

INSULATION

OPTIONAL 1 SQ. INCH PER 4000 BTUH INLET AIR

VENTILATED

ATTIC GABLE OR

SOFFIT VENTS

GABLE

VENT

Page 16

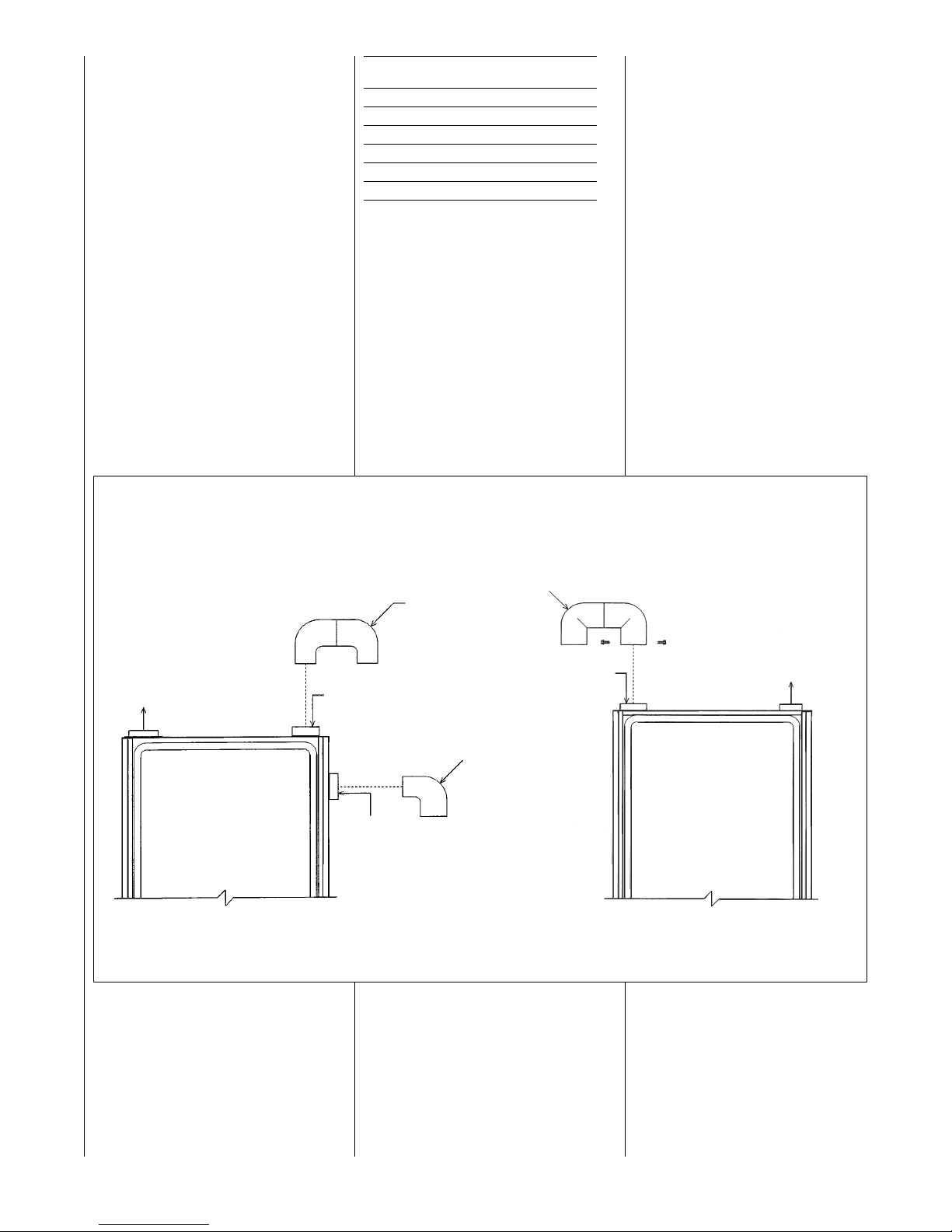

FIGURE 13

COMBUSTION AIR FITTING

UPFLOW DOWNFLOW/HORIZONTAL

2" PVC

DOUBLE

ELBOW

TOP

OPTION

EXHAUST

2" PVC ELBOW

SIDE

OPTION

2" PVC

DOUBLE

ELBOW*

COMBUSTION AIR

EXHAUST

ATTACH DOUBLE ELBOW TO INTAKE AIR

COLLAR AND SECURE WITH TWO SHEET

METAL SCREWS TO PREVENT ACCIDENTAL

BLOCKAGE OF INTAKE AIR OPENING.

➤ *NOTE: WHEN FURNACE IS INSTALLED IN

A HORIZONTAL POSITION ONLY ONE 90°

ELBOW IS REQUIRED. INSTALL THE ELBOW

SO THE OPEN END IS POINTED DOWNWARD.

ATTACH DOUBLE ELBOW TO TOP INLET

AIR OPENING OR 90° ELBOW TO SIDE

INLET AIR OPENING TO PREVENT

ACCIDENTAL BLOCKAGE OF INTAKE

OPENING. PLUG OPENING NOT USED.

16

I337 I336

where the equipment has

clearances of at least 1 inch from

the sides and back and 6 inches

from the front of the appliance.

The opening shall directly

communicate with the outdoors or

communicate through a vertical or

horizontal duct to the outdoors or

spaces (crawl or attic) that freely

communicate with the outdoors,

and shall have a minimum free

area of:

a. 1 square inch for each 3,000

BTUH of the total input rating of all

equipment located in the enclosure

and

BTUH Free Area Round Pipe

Input Each Opening Size

45,000 15.00 square inches 4"

60,000 16.67 square inches 5"

75,000 25.00 square inches 6"

90,000 30.00 square inches 6"

105,000 35.00 square inches 7"

120,000 40.00 square inches 7"

b. Not less than the sum of the

areas of all vent connectors in the

confined space.

If unit is installed where there is an

exhaust fan, sufficient ventilation

must be provided to prevent the

exhaust fan from creating a negative

pressure.

Combustion air openings must not be

restricted in any manner.

CONSULT LOCAL CODES FOR

SPECIAL REQUIREMENTS.

Return air grilles and warm air

registers must not be obstructed.

CONNECTION TO

FURNACE

IMPORTANT: When indoor

combustion air is used, the inlet air

opening at the furnace must be

protected from accidental blockage.

On upflow models, install a 90° elbow

pointing downward in the side inlet air

opening or a double elbow pointing

downward in the top inlet air opening.

On downflow/horizontal models,

install a double elbow in the top inlet

air opening. See Figure 13.

Page 17

ELEVATED SINGLE PIPE ALTERNATE TEE TERMINATION

See Figure 15. The tee termination may be elevated up to 24 inches above the

wall penetration if required for anticipated snow levels. Use 2 medium-radius, 2-in.

PVC elbows and 2-in. PVC pipe, attaching the tee so it is 12 inches from the wall.

17

NON-DIRECT VENT

INSTALLATION

GUIDELINES

IMPORTANT: FAILURE TO

CORRECTLY FOLLOW ALL

VENTING GUIDELINES MAY

RESULT IN ERRATIC FURNACE

OPERATION, FREEZE-UP OF

COMBUSTION AIR OR EXHAUST

AIR PIPING OR SOOTING OF THE

FURNACE.

All exhaust piping must be installed in

compliance with Part 7, “Venting of

Equipment,” of the latest edition of the

National Fuel Gas Code NPFA54/

ANSI Z223.1-, CAN/CGA-B149, local

codes or ordinances and these

instructions.

1. Vertical piping is preferred.

2. All horizontal piping must slope

upward a minimum of

1

/4 inch

per foot of run so that

condensate drains toward the

furnace.

3. All horizontal runs must be

supported at least every 4 feet.

No sags or dips are permitted.

4.

IMPORTANT: DO NOT

COMMON VENT WITH ANY

OTHER APPLIANCE. DO NOT

INSTALL IN THE SAME CHASE

OR CHIMNEY WITH A METAL

OR HIGH TEMPERATURE

PLASTIC PIPE FROM

ANOTHER GAS OR FUELBURNING APPLIANCE

UNLESS THE REQUIRED

MINIMUM CLEARANCES TO

COMBUSTIBLES ARE

MAINTAINED BETWEEN THE

PVC PIPE AND OTHER PIPES.

5. All vent runs through unconditioned spaces where belowfreezing temperatures are

expected should be insulated

with 1-in. thick, medium-density,

foil-faced fiberglass. An

equivalent “arm-a-flex” or

FIGURE 14

TEE TERMINAL – FOR

STANDARD HORIZONTAL

SINGLE PIPE INSTALLATION

FIGURE 15

ALTERNATE HORIZONTAL

TERMINATION FOR

NON-DIRECT VENT

INSTALLATIONS

12"

FROM

24"

MAX.

PIPE

SUPPORT

STRAP

OUTSIDE

WALL

VENT

12"

12" MIN. ABOVE

GRADE OR

SNOW LEVEL

I198

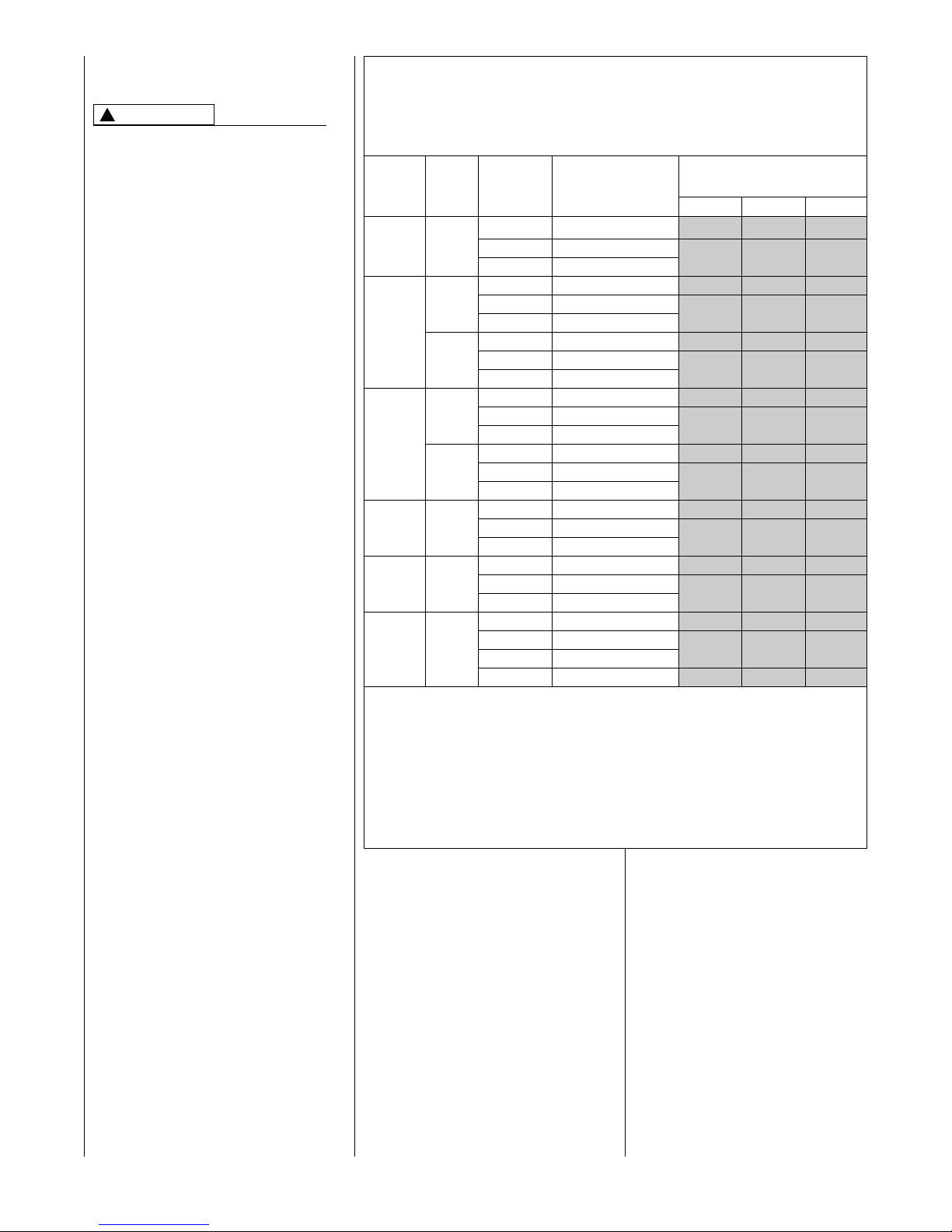

NUMBERS OF ELBOWS

45° OR 90°

Medium / Long Radius ONLY

1-2 3-4 5-6

45,000 2”

Standard 60 55 50

Alternate 55 50 45

2”

Standard 35 30 25

Alternate 30 25 20

60,000

3”

Standard 120 120 115

Alternate 120 120 110

2”

Standard 20 15 10

Alternate NR NR NR

75,000

3”

Standard 110 105 95

Alternate 80 70 65

90,000 3”

Standard 90 85 75

Alternate 60 50 45

105,000 3”

Standard 80 75 65

Alternate 50 40 35

120,000 3”

Standard 70 65 55

Alternate 40 30 25

NOTES:

1. *N.R. - NOT RECOMMENDED.

2. MAXIMUM OF 6 - 90 DEGREE ELBOWS MAY BE USED. DO NOT COUNT ELBOWS REQUIRED FOR

ALTERNATE TERMINATION. USE ONLY MEDIUM OR LONG SWEEP ELBOWS.

3.

➤ A 45° DEGREE ELBOW IS CONSIDERED ONE ELBOW.

FURNACE

INPUT

➤TABLE 1

FOR NON-DIRECT VENT APPLICATIONS - AIR FOR COMBUSTION

PROVIDED FROM INDOORS

MAXIMUM ALLOWABLE LENGTH IN FEET OF EACH EXHAUST PIPE AND INTAKE PIPE

VENT PIPE INSTALLATION

PIPE

SIZE

TERMINATION

Page 18

“rub-a-tex” insulation may also be

used as long as there is no heat

tape applied to the vent pipe. For

horizontal runs where water may

collect, wrap the vent pipe with

self-regulating 3 or 5 watt heat

tape. The heat tape must be

U.L. listed and installed per the

manufacturer’s instructions.

6. The minimum vent pipe length is

5 feet.

STANDARD INSTALLATIONS

The single-pipe system requires an

exhaust pipe only. Combustion air

may be taken from the furnace

installation area or ducted to the

furnace area from the outside.

Size the exhaust pipe as specified in

Table 1. This table lists the maximum

allowable length in feet of the exhaust

pipe that may be used for all furnace

inputs as related to the number of

elbows required and the termination.

(See shaded area.)

Vertical through-the-roof installations

do not require a vent termination. Use

2-in. PVC pipe extending a minimum

of 12 inches above the anticipated

level of snow accumulation. See

exhaust pipe requirements, Figure 20.

When 3-in. vent pipe is used from

furnace to the roof, reduce it to

2 inches before penetrating the roof.

A maximum of 18 inches of 2-in. pipe

may be used below the roof.

Horizontal vent terminations require a

2-in. PVC tee positioned 12 inches

from the outside wall. See exhaust

pipe requirements, Figure 21. When

3-in. pipe is used from the furnace to

the outside wall, reduce it to 2 inches

before penetrating the wall. A

maximum of 18 inches of 2-in. pipe

may be used inside the wall.

An alternate termination may be used

as shown in Figure 15 to clear

anticipated snow levels. The tee may

be raised up to 24 inches above the

wall penetration. Use two mediumradius bend, 2-in. PVC elbows and a

length of 2-in. PVC pipe so that the

elbows are on 24-in. centers.

NON-DIRECT VENT TERMINATION

LOCATION REQUIREMENTS

MOISTURE IN THE COMBUSTION

PRODUCTS CONDENSES AS IT

LEAVES THE TERMINATION. THIS

CONDENSATE CAN FREEZE ON

EXTERIOR WALLS, UNDER THE

EAVES, AND ON SURROUNDING

OBJECTS. SOME DISCOLORATION IS TO BE EXPECTED.

HOWEVER, IMPROPER LOCATION

18

OR INSTALLATION CAN CAUSE

STRUCTURAL OR EXTERIOR

FINISH DAMAGE TO THE

BUILDING.

Non-direct venting location

requirements are slightly different in

some cases than direct venting. Install

a non-direct vent with the following

minimum clearances.

See Figure 16.

1. Locate the bottom of the vent

terminal at least 12 inches above

grade. Increase the 12-in.

minimum to keep the terminal

openings above the level of snow

accumulation, where applicable.

2. The vent shall not terminate over

public walkways or over an area

where condensate or vapor could

create a nuisance or hazard.

3. 4 feet below, 4 feet horizontally

from, or 1 foot above any door,

window soffit, under eave vent or

gravity air inlet to the building.

4. The vent terminal shall have a

minimum horizontal clearance of

4 feet from electric meters, gas

meters, regulators and relief

equipment.

5. 6 feet from an inside corner

formed by two exterior walls –

10 feet is the recommended

distance.

6. Locate it 3 feet above any forced

air inlet located within 10 feet.

Any fresh air or make-up air inlet,

such as for a dryer or furnace

area, is considered a forced air

inlet.

!

CAUTION

FIGURE 16

NON-DIRECT VENT TERMINATION CLEARANCES

I133

SOFFIT

VENTS

FRESH

AIR

INTAKE

*NOTE: FOR DISTANCES OVER 10* NO

VERTICAL RESTRICTIONS APPLY.

INSIDE

CORNER

ELECTRIC

METER

10* RECOMMENDED

12( MIN.

UP TO10**

4*

4*

3*

4*

4*

4*

6*

7. Avoid areas where dripping

condensate may cause problems,

such as above planters, patios, or

adjacent to windows where

steam may cause fogging.

In addition to the minimum clearances

listed above, the vent location should

also be governed by the following

guidelines.

1. Do not terminate under any kind

of patio or deck. If running the

vent under a deck, insulate it to

insure no condensate freezes

and blocks the pipe.

2. Do not locate on the side of a

building with prevailing winter

winds. This will help prevent

moisture from freezing on walls

and overhangs (under eaves).

3. Do not extend vent directly

through brick or masonry

surfaces. Use a rust-resistant

sheet metal or plastic backing

plate behind vent.

4. Do not locate too close to shrubs

as condensate may stunt or kill

them.

5. Minimum vertical clearances of 1

foot are recommended for

overhangs up to 1 foot horizontal.

The vertical clearance should be

increased equally for each

additional increase in horizontal

overhang to a maximum vertical

clearance of 6 feet.

6. Caulk all cracks, seams and

joints within 6 feet horizontally

and above and below vent.

Page 19

19

DIRECT VENT

INSTALLATIONS

READ AND FOLLOW ALL

INSTRUCTIONS IN THIS SECTION.

FAILURE TO PROPERLY VENT

THIS FURNACE CAN CAUSE

CARBON MONOXIDE POISONING

OR AN EXPLOSION OR FIRE,

RESULTING IN PROPERTY

DAMAGE, PERSONAL INJURY

OR DEATH.

Direct vent installations require a

dedicated combustion air and venting

system. All air for combustion is taken

from the outside atmosphere and all

combustion products are discharged

to the outdoors. Therefore, no

ventilation or combustion air

openings are required.

IMPORTANT: The plastic combustion

air and venting components are of

Schedule 40 PVC. If using ABS

piping ensure that the solvent cement

is compatible for joining PVC to ABS

components or use a mechanical

connection that can withstand the

vent temperatures and are corrosion

resistant.

INSTALLATION GUIDELINES

All exhaust piping must be installed in

compliance with Part 7, “Venting of

Equipment,” of the latest edition of the

National Fuel Gas Code NPFA54/

ANSI Z223.1-, CAN/CGA-B149, local

codes or ordinances and these

instructions.

1. Vertical piping is preferred.

2. All horizontal piping must slope

upward a minimum of

1

/4 inch

per foot of run so that condensate

drains toward the furnace.

3. All horizontal runs must be

supported at least every 4 feet.

No sags or dips are permitted.

4.

IMPORTANT: DO NOT COMMON VENT WITH ANY OTHER

APPLIANCE. DO NOT INSTALL

IN THE SAME CHASE OR

CHIMNEY WITH A METAL OR

HIGH TEMPERATURE PLASTIC PIPE FROM ANOTHER

GAS OR FUEL-BURNING

APPLIANCE UNLESS THE

REQUIRED MINIMUM

CLEARANCES TO

COMBUSTIBLES ARE

MAINTAINED BETWEEN THE

PVC PIPE AND OTHER PIPES.

5. All vent runs through unconditioned spaces where belowfreezing temperatures are

expected should be insulated

with 1-in. thick, medium-density,

foil-faced fiberglass. An

equivalent “arm-a-flex” or “rub-atex” insulation may also be used

as long as there is no heat tape

applied to the vent pipe. For

horizontal runs where water may

collect, wrap the vent pipe with

self-regulating 3 or 5 watt heat

tape. The heat tape must be

!

WARNING

➤TABLE 2

FOR DIRECT VENT APPLICATIONS - AIR FOR COMBUSTION

PROVIDED FROM OUTDOORS

MAXIMUM ALLOWABLE LENGTH IN FEET OF EACH EXHAUST PIPE AND INTAKE AIR PIPE

U.L. listed and installed per the

manufacturer’s instructions.

6. The minimum vent pipe length is

5 feet.

Size the exhaust and combustion air

intake pipes as specified in Table 2.

This table lists the maximum allowable length in feet of the exhaust and

combustion air intake pipes that may

be used for all furnace inputs as

related to the number of elbows

required and the termination (see

shaded area).

FURNACE

INPUT

PIPE

SIZE

TERMINATION

VENT TERMINATION

KIT RECOMMENDED

(RXGY-D0* Kits for

Horizontal Venting Only)

1 - 2 3 - 4 5 - 6

NUMBER OF ELBOWS

45° or 90°

Medium / Long Radius ONLY

Standard RXGY-D02 65 60 55

45,000 2” Concentric RXGY-C01/RXGY-E02

55 50 45

Alternate RXGY-D02

Standard RXGY-D02 40 35 30

2” Concentric RXGY-C01/RXGY-E02

30 25 20

Alternate RXGY-D02

60,000

Standard RXGY-D03 120 120 120

3” Concentric RXGY-C01/RXGY-E02

110 105 100

Alternate RXGY-D03

Standard RXGY-D02 20 15 10

2” Concentric Not Recommended

NR NR NR

Alternate Not Recommended

75,000

Standard RXGY-D03 120 120 120

3” Concentric RXGY-C01/RXGY-E02

100 95 85

Alternate RXGY-D03

Standard RXGY-D03 110 105 95

90,000 3” Concentric RXGY-C01/RXGY-E02

50 40 35

Alternate RXGY-D03

Standard RXGY-D03 110 105 95

105,000 3” Concentric RXGY-C01/RXGY-E02

50 40 35

Alternate RXGY-D03

Standard RXGY-D03 105 100 90

120,000 3”

Concentric RXGY-C01/RXGY-E02

45 35 30

Alternate RXGY-D03

Alternate RXGY-D04 105 95 90

NOTES:

1. N.R. - NOT RECOMMENDED.

2. MAXIMUM OF 6 ELBOWS MAY BE USED. DO NOT COUNT ELBOWS IN ALTERNATE TERMINATION KIT.

MEDIUM OR LONG SWEEP ELBOWS MAY BE USED.

3. ➤ A 45 DEGREE ELBOW IS CONSIDERED ONE ELBOW.

4. CONCENTRIC TERMINATION NO. RXGY-C01 IS FOR THRU-THE-WALL VENTING.

5. CONCENTRIC TERMINATION NO. RXGY-E02 IS FOR THRU-THE-ROOF VENTING.

6. USE KITS RXGY-DO2 (2") OR RXGY-D03 (3") FOR STANDARD OR ALTERNATE THRU-THE-WALL VENTING.

7. USE KITS RXGY-D04 FOR ALTERNATE VENTING OF 120,000 BTUH UNITS WITH LONG RUNS.

Page 20

20

➤ALTERNATE

TERMINATIONS

ALTERNATE HORIZONTAL

DIRECT VENT TERMINATIONS

KIT NOS. RXGY-D02, -D03

AND -D04

The combustion air and exhaust

terminations may be raised a

maximum of 60 inches above the

wall penetration to maintain the

required 12 inch clearance above

grade or snow level. See Figure 17.

Size the pipe length according to

Table 2.

IMPORTANT: The following

guidelines must be met when

extending beyond 24 inches of pipe

on the exterior of the structure:

• Size the entire vent system

according to the concentric, not

standard, termination shown in

Table 2.

COMBUSTION AIR FOR

DIRECT VENT

INSTALLATIONS

THE COMBUSTION AIR SYSTEM

DESIGNED FOR THIS FURNACE

MUST BE USED.

When this furnace is installed as a

direct vent forced air furnace, all

combustion air is supplied directly to

the burner through a special air inlet

system outlined in these instructions.

This system consists of field-supplied

Schedule 40 or 26 SDR-PVC pipe

and one of the following horizontal

vent termination kits: RXGY-D02,

RXGY-D03, RXGY-D04, RXGY-C01

or RXGY-E02.

NOTE: Schedule 40 ABS-DWV pipe

and fittings may be used as an

alternate to PVC pipe for the

combustion air inlet and vent pipes.

The combustion air for this furnace is

supplied directly from the outdoors

through the combustion air inlet

system.

When the furnace is installed in the

same space with other gas

appliances, such as a water heater,

be sure there is an adequate supply

of combustion and ventilation air for

the other appliances. Do not delete or

reduce the combustion air supply

required by the other gas appliances

in this space. See Z223.1, National

Fuel Gas Code (NFPA54) or

CAN/CGA-B149.1 and .2 for determining the combustion air requirements for gas appliances. An

unconfined space must have at least

50 cubic feet (volume) for each

1,000 BTUH of the total input of all

appliances in the space. If the open

space containing the appliances is in

a building with tight construction

(contemporary construction), outside

air may still be required for the

appliances to burn and vent properly.

Outside air openings should be sized

the same as for a confined space.

STANDARD TERMINATIONS

STANDARD VERTICAL

TERMINATIONS

COMBUSTION AIR PIPING

Use two medium-radius sweep

elbows to keep the inlet downward to

prevent entry of rain. See Figure 20

for the proper relationship of

combustion air to exhaust

termination.

STANDARD HORIZONTAL

TERMINATIONS

COMBUSTION AIR PIPING

When 3-in. pipe is used between the

furnace and outside wall, reduce it

to 2 inches before penetrating the

wall. Up to 18 inches of 2-in. pipe

may be used inside the wall.

The standard horizontal intake air

termination for all models is a 2-in.

PVC coupling with a wind deflector

vane (provided) attached. Cut a

2

1

/4-in. length of 2-in. PVC pipe.

Connect this pipe and another 2-in.

PVC coupling to the coupling at the

wall. The outer coupling must

terminate 4 inches from the wall. See

Figure 21, Detail B, for vane location.

Attach vane in vertical position with

PVC solvent.

IMPORTANT: To ensure proper

furnace operation, the supplied

vane must be installed in the

vertical position as shown in Figure

21, Detail B.

The combustion air inlet terminal

must be located with respect to the

exhaust terminal as shown in Figure

21, Detail C.

➤ IMPORTANT: All furnaces with

horizontal air intakes, except those

using horizontal concentric vent kit

RXGY-C01, must have a drain tee

assembly and trap installed as

close to the furnace as possible.

This is to drain any water that may

be in the combustion air pipe to

prevent it from entering the

furnace combustion chamber.

These parts are included in kits

RXGY-D02 (for 2-in. pipe), RXGYD03 (for 3-in. pipe) and RXGY-D04

(special for the 120,000 BTU

furnace installed with the alternate

horizontal termination). Attach the

trap to the bottom of the tee with

PVC solvent. Connect the other

end to a suitable drain, as to the

downstream of a condensate trap

on the furnace.

STANDARD VERTICAL

TERMINATIONS

EXHAUST VENT PIPING

Vertical through-the-roof vent appli-

cations do not require an exhaust

terminal. The exhaust vent must

terminate at least 12 inches above

the combustion intake air termination.

The exhaust vent for models with

inputs of 90,000 through 120,000

BTUH is 2-in. PVC pipe 120,000

BTUH models with excessively long

runs require 2

1

⁄2(. Refer to Table 2 for

proper application. This must

be reduced to 1( or 1

1

⁄2( the last

12 inches for models with inputs of

45,000 through 75,000 BTUH.

See Figure 22.

STANDARD HORIZONTAL

TERMINATIONS

EXHAUST PIPING

For direct vent systems the standard

termination is 2-in. PVC pipe

extending 12 inches from the wall for

furnaces with inputs from 90,000 to

120,000 BTUH. Install a 2-in. coupling

at the outside wall to prevent the

termination from being pushed

inward. When 3-in. pipe is used

between the furnace and outside wall,

reduce to 2 inches before penetrating

the wall. The standard termination is

1

1

/2 -in. PVC pipe extending outward

12 inches from the wall for models

with inputs of 45,000 to 75,000

BTUH. Install a 2-in. to 1

1

/2-in.

coupling at the outside wall to prevent

pushing the termination back into the

wall. See Figure 21, Detail B.

The combustion air and exhaust

terminations must be at least 12

inches above grade and must be

oriented with respect to each other as

shown in Figure 21. Refer to section

on alternate venting options when

higher snow levels are anticipated.

Page 21

21

FIGURE 17

ALTERNATE HORIZONTAL DIRECT VENT TERMINATION

SEE DETAIL A

60( MAX.

PIPE

SUPPORT

STRAP

3( MAX.

NOTE: 3-1/2(

MAX. WHEN

D04 KIT IS

USED.

EXHAUST VENT FOR

MODELS WITH

INPUT OF 45,000 THRU

75,000 BTU

DETAIL A

EXHAUST VENT

21/2" PVC FOR MODELS WITH 120,000 BTU INPUT

(KIT NO. RXGY-D04)

2" PVC FOR MODELS WITH INPUTS OF 90,000 THRU 120,000

BTU. REDUCE TO 11/2" FOR MODELS WITH INPUTS OF 45,000

THRU 75,000 BTU. ELBOWS AND RISERS ARE 2" PVC.

INTAKE VENT

21/2" PVC FOR MODELS WITH

120,000 BTU INPUT.

2" PVC ELBOWS AND RISER

MODELS WITH INPUTS OF 45,000

THRU 105,000 BTU.

USE KIT NO. RXGY-D02 WHEN 2" PIPE

IS USED BETWEEN FURNACE AND

OUTSIDE WALL. USE KIT NO. RXGY-D03

WHEN 3" PIPE IS USED.

FIGURE 18

VERTICAL CONCENTRIC VENT KIT - RXGY - E02

12" FIXED

48" MAX.

INLET AIR

12" ABOVE

AVERAGE SNOW

ACCUMULATION

INSTALL ROOF

FLASHING

ROOF LINE

INLET AIR PIPE

2"

USE 2" x 3" INCREASER

IF VENT IS 3" PIPE

(FIELD SUPPLIED)

VENT FROM

FURNACE

INLET AIR FROM

FURNACE, USE

3" x 2" BUSHING

IF INLET IS 2" PIPE

(FIELD SUPPLIED)

➀

➁

➂

➄

➃

➅

➆

➀

➁

➂

➃

➄

➅

➆

2" SCH40 PVC PIPE

3" TYPE SDR 26 PVC PIPE

2" x 3" BUSHING (MODIFIED)

3" x 3" x 3" WYE

2" x 4" COUPLING (MODIFIED)

3" x 45° STREET ELBOW

2" COUPLING

(FIELD SUPPLIED)

• Insulate the entire length of vent

pipe, between the elbow where the

pipe exits the wall and the elbow

where the termination is made, with

a closed-cell insulation, such as

“Arm-a-Flex” or “Rub-a-Tex” with a

minimum of 1/2( thickness.

• All elbows installed on the exterior

of the building must be of the long

sweep nature.

• As required for the horizontal piping

ran within the structure, any pipe

ran horizontal outside the structure

must slope upward a minimum of

1/4( per foot run so that condensate

drains toward the furnace.

From the top elbow in the exhaust

pipe, extend a length of PVC pipe

outward so that it terminates exactly

12 inches from the wall. See Figure

17. Reduce the termination pipe

extension to is 1

1

/2 inch pipe for

45,000 BTUH through 75,000 BTUH

units.

The 45,000 BTUH unit only uses kit

RXGY-D02. The 60,000 BTUH and

75,000 BTUH units may use kits

RXGY-D02 or RXGY-D03 depending

on pipe lengths and number of

elbows. Use kit RXGY-D03 with

90,000 BTUH through 120,000 BTUH

units. The RXGY-D04 kit only

applies to the 120,000 BTUH unit

using an alternate termination and

excessively long runs. See Table 2.

The following are parts lists for the

RXGY-D02, RXGY-D03 and RXGYD04 alternate horizontal direct vent

termination kits:

RXGY-D02

1. 2-in. tee with reducer assembly

2.

1

/2-in. PVC 6-in. dia. trap

3. PVC vane

4. 2-in. PVC elbow

5. 1

1

/2-in. PVC nipple with coupling

6. PVC strap

7. vent template

RXGY-D03

1. 3-in. tee with reducer assembly

2.

1

/2-in. PVC 6-in. dia. trap

3. PVC vane

4. 2-in. PVC elbow

5. PVC strap

6. vent template

I339

I338

12( FROM WALL

Page 22

22

HORIZONTAL CONCENTRIC

TERMINATION

This kit is for horizontal intake air pipe

runs and may be installed through

walls up to 16 inches thick. See

Figure 19. Complete installation

instructions are supplied with the kits.

FIGURE 19

HORIZONTAL CONCENTRIC VENT KIT NO. RXGY-C01

(DIRECT VENT INSTALLATIONS)

RXGY-D04

1. 2

1

/2-in. PVC elbow

2. 3" x 2

1

/2" PVC bushing

3. 2

1

/2" x 61/2" long PVC pipe

4. 2

1

/2" x 16" long PVC pipe

5. 2

1

/2" x 21" long PVC pipe

6. PVC vane

7. ➤

3-in. tee with reducer assembly

8. 6-in. dia. 1/2-in. PVC trap

9. PVC strap

10. vent template

NOTE: The RXGY-D04 kit only

applies to the 120,000 BTUH unit

using an alternate termination and

excessively long runs.

CONCENTRIC

TERMINATIONS

ALTERNATE VERTICAL

CONCENTRIC VENT

KIT NO. RXGY-E02

This kit is for vertical intake air/vent

runs and may be installed through

roofs up to 9 inches thick. One

4

1

/8-in. diameter hole is required

through the roof for the installation.

See Figure 18 for the general layout.

Complete installation instructions are

included with the kit.

Page 23

23

FIGURE 20

STANDARD VERTICAL DIRECT VENTING

UPFLOW MODEL SHOWN (TYPICAL FOR DOWNFLOW MODELS)

FIGURE 21

STANDARD HORIZONTAL DIRECT VENTING

UPFLOW MODEL SHOWN (TYPICAL FOR DOWNFLOW MODELS)

I407

EXHAUST

TERMINATION

➀

➁

3" MAX.

SEPARATION

COMBUSTION AIR

PIPE

12" MIN.

SEPARATION

12" MIN. ABOVE

ROOF LEVEL

ROOF LINE

EXHAUST PIPE

COMBUSTION

AIR PIPE

SUPPLY AIR

RETURN AIR

EXHAUST VENT

➂

➃

3"

MAX.

EXHAUST

VENT

ROOF LINE

COMBUSTION

AIR PIPE

12"

MIN.

12" MIN.

ANTICIPATED

SNOW LEVEL

COMBUSTION

AIR PIPE

3"

MAX.

EXHAUST

VENT

12"

MIN.

12" MIN.

3"

MAX.

12" MIN.

12" MIN. ABOVE

ANTICIPATED SNOW LEVEL

➄

NOTES:

➀

THE COMBUSTION AIR PIPE

MUST TERMINATE IN THE

SAME PRESSURE ZONE AS

THE EXHAUST PIPE.

➁

INCREASE THE 12-IN. MINIMUM

TO KEEP TERMINAL OPENING ABOVE

ANTICIPATED LEVEL OF SNOW

ACCUMULATION WHERE

APPLICABLE.

➂

WHEN 3-IN. DIAM. PIPE IS USED,

REDUCE TO 2-IN. DIAMETER BEFORE

PENETRATING ROOF. A MAXIMUM OF

18 IN. OF 2-IN. PIPE MAY BE USED

BEFORE PASSING THROUGH ROOF.

➃

SUPPORT VERTICAL PIPE EVERY 6

FEET.

➄

EXHAUST TERMINATION - TERMINATE

THE LAST 12 INCHES WITH 2( PVC

PIPE ON 90,000 THROUGH 120,000

BTUH MODELS. REDUCE AND

TERMINATE THE LAST 12 INCHES

WITH 1

1

⁄2( PVC PIPE ON 45,000

THROUGH 75,000 BTUH MODELS.

PITCHED ROOF INSTALLATIONS

NOTES:

➀

SUPPORT HORIZONTAL PIPE

EVERY FOUR FEET.

➁

WHEN 3 IN. PIPE IS USED REDUCE TO 2 IN.

BEFORE PENETRATING OUTSIDE WALL.

➂

18 IN. MAXIMUM. 2 IN. DIAMETER PIPE MAY

BE USED INSIDE THE WALL.

➃

DETAIL “A” - EXHAUST TERMINATION

TERMINATE THE LAST 12 INCHES WITH 2(

PVC PIPE ON 90,000 THROUGH 120,000