Page 1

RGLR

Parts List

06-November-2012

This parts list is current as of the above revision date.

See http://www.rheempartslists.net/92-42800-RGLR.pdf for the current revision.

80% Gas Furnaces - 2 Stage

Page 2

Table of Contents

Model Explanation.... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . ... Page 3

Parts Numbers

Panels - Miscellaneous ... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... .... Page 4

Electrical Group . ..... ..... ..... ..... ..... .... . .... . .... ..... ..... ..... ..... ..... .... . .... . .... ..... ..... ..... ... Page 5

Blower Group... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... ..... .... . .... . .... ..... ..... ..... .... Page 5

Heat Exchanger-Burner Group.... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... ..... .... . .... . .... ..... . Page 6

Gas Controls ... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... .... Page 6

Orifice Selection Chart.... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... ..... .... . .... . .... ..... ..... .... Page 7

Drawings/Photographs

Exploded View .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... . Page 8

Blower Assembly ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... ..... .... . .... . .... ..... ..... ..... ... Page 9

Burner Assembly ... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... .... Page10

Notes/Disclaimer . ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... ..... .... . .... . . Page 11

Page 2 of 11

06-November-2012

92-42800-RGLR

Page 3

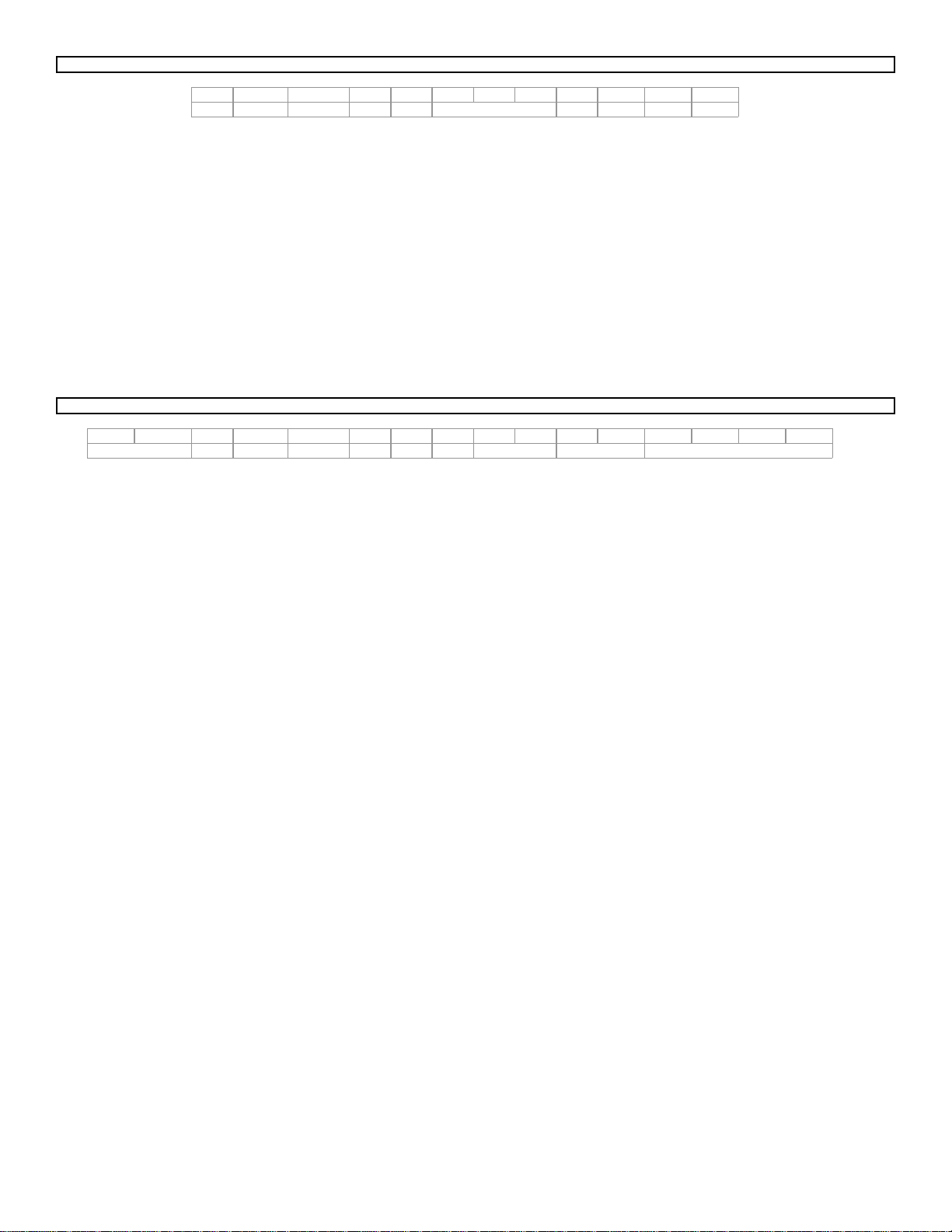

R G L R - 0 7 E A M K R

(1) (2) (3) (4) (5) (6) (7) (8) (9)

(1) TRADEBRAND IDENTIFICATION (6) VARIATION

A = Std. Cabinet

(2) MODEL B = Wide Cabinet

G = Gas Furnace

(7) BLOWER DESIGNATION

(3) TYPE M = 11 x 7

L = Downflow R = 11 x 10

(4) DESIGN SERIES /VARIATION (8) AIRFLOW

K = 800-1200 CFM

(5) HEATING INPUT DESIGNATION Q = 1000-1600 CFM

07 = 75,000 BTU/HR M = 1200-2000 CFM

10 = 100,000 BTU/HR

12 = 120,000 BTU/HR (9) FUEL DESIGNATION

R = Natural Gas - U.S. and Canada

E = Electric Ignition

N = Electric Ignition with NOX

G R 5 D 7 0 7 F 1 5 0 6 9 9 9 9

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

(1) GAS CODE (6) MOTOR HORSEPOWER

(2) LIMIT CONTROL (7) PLANT

F = Fort Smith, AR

(3) BLOWER

(8) WEEK

(4) HEATING ELEMENT

(9) YEAR

(5) SPECIAL AREA REQUIREMENT

(10) PRODUCTION NUMBER

MODEL NUMBER EXPLANATION

SERIAL NUMBER EXPLANATION

Page 3 of 11

06-November-2012

92-42800-RGLR

Page 4

MODEL

No. Notes

1 Jacket AS-66991-22 AS-66991-23 AS-66991-23 AS-66991-24

2 Top Plate AE-66981-02 AE-66981-03 AE-66981-03 AE-66981-04

3 Blower/Filter Door AS-67894-01 AS-67895-01 AS-67895-01 AS-67896-01

4 Burner Door AS-101734-01 AS-101735-01 AS-101735-01 AS-101736-01

Plug Button - 1-3/16 in. opening (2) 45-22980-01 45-22980-01 45-22980-01 45-22980-01

Door Angle AE-66980-02 AE-66980-02 AE-66980-03 AE-66980-04

5 Mounting Control Plate AE-67877-01 AE-67877-01 AE-67877-01 AE-67877-01

6 Junction Box AE-61475-02 AE-61475-02 AE-61475-02 AE-61475-02

7 Junction Box Cover AE-61476-02 AE-61476-02 AE-61476-02 AE-61476-02

9 Flue Pipe AE-66691-14 AE-66691-14 AE-66691-14 AE-66691-14

10 Flue Pipe Enclosure AE-66982-01 AE-66982-01 AE-66982-01 AE-66982-01

11 Flue Pipe Enclosure Door AE-66983-01 AE-66983-01 AE-66983-01 AE-66983-01

12 Rear Baffle AE-66994-02 AE-66994-06 AE-66994-06 AE-66994-04

14 Pressure Switch See Electrical Group

15 Door Switch - Push Button See Electrical Group

16 Limit - Main Limit (Heat Exchanger Panel) See Electrical Group

17 Limit - Manual Reset (Burner Compartment) See Electrical Group

18 Limit - Heat Assisted (BlowerHousing) See Electrical Group

19 Transformer See Electrical Group

20 Power Factor Choke See Electrical Group

21 Induced Draft Blower w/Gasket See Electrical Group

22 Blower Assembly See Blower Group

27 Heat Exchanger Assembly See Heat Exchanger Group

28 Heat Exchanger Bracket See Heat Exchanger Group

29 Filter (2) 54-22699-01 54-22699-01 54-22699-01 54-22699-02

30 Filter Rack AE-66681-01 AE-66681-01 AE-66681-01 AE-66681-01

37 NOX Burner Inserts See Heat Exchanger Group

38 NOX Insert Retainer See Heat Exchanger Group

39 Gas Valve See Gas Controls

40 Integrated Furnace Control Board (IFC) See Gas Controls

41 ECM Interface Control Board See Gas Controls

HEATING CAPACITY

VARIATION

BLOWER DESIGNATION

AIRFLOW

PANELS, SHEET METAL, MISCELLANEOUS

RGLR

07

A

M

K

RGLR

07

B

R

Q

RGLR

10

B

R

M

RGLR

12

A

R

M

Page 4 of 11

06-November-2012

92-42800-RGLR

Page 5

MODEL

No. Notes

14 Stk,2 Pressure Switch 42-102341-02 42-102341-02 42-102341-02 42-102341-02

15 Stk Door Switch - Push Button 42-22692-04 42-22692-04 42-22692-04 42-22692-04

16 Stk Limit - Main Limit (Heat Exchanger Panel) 47-25349-13 47-25349-16 47-25349-02 47-25349-12

17 Stk Limit - Manual Reset (Burner Compartment) 47-22861-03 47-22861-03 47-22861-03 47-22861-03

18 Stk Limit - Heat Assisted (Blower Housing) 47-22860-06 47-22860-06 47-22860-06 47-22860-06

19 Stk Transformer w/Fuse - Before F1106 46-22863-04 46-22863-04 46-22863-04 46-22863-04

19 Stk Transformer w/Fuse - After F1106 46-101496-01 46-101496-01 46-101496-01 46-101496-01

20 Power Factor Choke 46-24256-02 46-24256-02 46-24256-02 46-24256-02

21 Stk Induced Draft Blowerw/Gasket 70-101888-01 70-101888-01 70-101888-02 70-101888-02

Wiring Harness - 9 pin to (3 pin and 7 terminals) 45-24371-21 45-24371-21 45-24371-21 45-24371-21

Wiring Harness - 4 pin to (3 pin from IFC Board) 45-24371-26 45-24371-26 45-24371-26 45-24371-26

Wiring Harness - 2 pin to (1 terminal and 1 strip back from Junction Box) 45-24371-37 45-24371-37 45-24371-37 45-24371-37

Wiring Harness - 4 pin from blower shelf to (4 pin to Induced Draft Motor) 45-24371-48 45-24371-48 N/A N/A

Wiring Harness - 4 pin from blower shelf to (5 pin to Induced Draft Motor) N/A N/A 45-24371-49 45-24371-49

Wiring Harness - 16 pin to 16 pin from IFC Board (After F3407) 45-102641-01 45-102641-01 45-102641-01 45-102641-01

Wiring Harness - 9 pin to 12 pin from IFC Board (After F3407) 45-102668-01 45-102668-01 45-102668-01 45-102668-01

Wiring Harness - 9 pin to 12 pin from IFC Board (Before F3407) 45-24371-25 45-24371-25 45-24371-25 45-24371-25

No. Notes

22 Stk Blower Assembly (Includes items 23-26) AS-67876-29 AS-67876-30 AS-67876-31 AS-67876-32

23 Housing AS-61674-21 AS-61674-06 AS-61674-06 AS-61674-06

24 Stk Blower Motor (ECM) 51-24374-21 51-24375-17 51-24376-20 51-24376-21

25

Motor Mount 70-24104-02 70-24104-02 70-24104-02 70-24104-02

Motor Mount Bracket (4) AE-61956-01 AE-61956-01 AE-61956-01 AE-61956-01

26 Stk Blower Wheel 70-24254-02 70-23111-20 70-23111-20 70-23111-20

HEATING CAPACITY

VARIATION

BLOWER DESIGNATION

AIRFLOW

ELECTRICAL GROUP

Wiring Harness - 5 pin from Indoor Blower Motor to two 2 pin connectors

(After F3407)

Wiring Harness - 5 pin from Indoor Blower Motor to two 2 pin connectors

(Before F3407)

Wiring Harness - 16 pin to 15 pin from ECM Interface Control (Before

F3407)

MODEL

HEATING CAPACITY

VARIATION

BLOWER DESIGNATION

AIRFLOW

BLOWER GROUP

Motor Mount Kit: includes grommets, screws, nuts, motor mount and

motor mount brackets

RGLR

07

A

M

K

45-102643-01 45-102643-01 45-102643-01 45-102643-01

45-24371-31 45-24371-31 45-24371-31 45-24371-31

45-24258-08 45-24258-08 45-24258-08 45-24258-08

RGLR

07

A

M

K

70-24104-82 70-24104-82 70-24104-82 70-24104-82

RGLR

07

B

R

Q

RGLR

07

B

R

Q

RGLR

10

B

R

M

RGLR

10

B

R

M

RGLR

12

A

R

M

RGLR

12

A

R

M

Page 5 of 11

06-November-2012

92-42800-RGLR

Page 6

MODEL

No. Notes

27 Stk Heat Exchanger Assembly AS-100561-01 AS-66997-22 AS-66997-04 AS-66997-05

28 Heat Exchanger Bracket (2) AE-67846-02 AE-67846-02 AE-67846-02 AE-67846-02

32 Stk Burner Assembly AS-60993-03 AS-60993-03 AS-60993-04 AS-60993-05

33 Burner Support AE-60997-02 AE-60997-02 AE-60997-03 AE-60997-04

34 Burner Support Bracket (2) AE-61588-02 AE-61588-02 AE-61588-02 AE-61588-02

35 Stk Manifold (w/o Orifices) 81-101149-02 81-101149-02 81-101149-03 81-101149-04

36 Burner Orifice - Natural Gas See Orifice Selection Chart

36 Burner Orifice - LP See Orifice Selection Chart

36 Number of Orifices (3) (3) (4) (5)

37 NOX Burner Inserts

38 NOX Insert Retainer AE-67872-02 AE-67872-02 AE-67872-03 AE-67872-04

No. Notes

39 Stk Gas Valve - Natural Gas 60-23490-08 60-24394-01 60-23490-12 60-101921-01

39 Stk Gas Valve - LP See Note 1 See Note 1 See Note 1 See Note 4

40 3

40 Stk,3 Replacement Integrated Furnace Control Board (IFC) Kit - See Note 3 62-102637-81 62-102637-81 62-102637-81 62-102637-81

41 3 ECM Interface Control - See Note 3 62-24340-04 62-24340-04 62-24340-04 62-24340-04

42 Stk Flame Sensor 62-23543-01 62-23543-01 62-23543-01 62-23543-01

43 Stk Direct Spark Ignitor 62-24164-01 62-24164-01 62-24164-01 62-24164-01

Direct Spark Ignitor Bracket AE-61885-02 AE-61885-02 AE-61885-02 AE-61885-02

LP Conversion Kit:

Stk U.S. Models FP-09 FP-09 FP-09 FP-32

Stk Canadian Models FP-10 FP-10 FP-10 FP-32

No. Notes

39 Stk Gas Valve - Natural Gas 60-101921-01

39 Stk Gas Valve - LP See Note 4

40 Stk Integrated Furnace Control Board (IFC) 62-102637-01

41 ECM Interface Control N/A

42 Stk Flame Sensor 62-23543-01

43 Stk Direct Spark Ignitor 62-24164-01

Direct Spark Ignitor Bracket AE-61885-02

LP Conversion Kit:

Stk U.S. Models FP-32

Stk Canadian Models FP-32

HEATING CAPACITY

VARIATION

BLOWER DESIGNATION

AIRFLOW

HEAT EXCHANGER, BURNER / MANIFOLD

MODEL

GAS CODE

GAS CONTROLS

Original Integrated Furnace Control Board (IFC) See Note 3

MODEL

GAS CODE

GAS CONTROLS

RGLR

07

A

M

K

AS-67875-01

(2)

RGLR

FC

62-24320-02 62-24320-02 62-24320-02 62-24320-02

RGLR

GX

RGLR

07

B

R

Q

AS-67875-01

(2)

RGLR

FL

RGLR

10

B

R

M

AS-67875-01

(3)

RGLR

FR

RGLR

12

A

R

M

AS-67875-01

(4)

RGLR

GR

Page 6 of 11

06-November-2012

92-42800-RGLR

Page 7

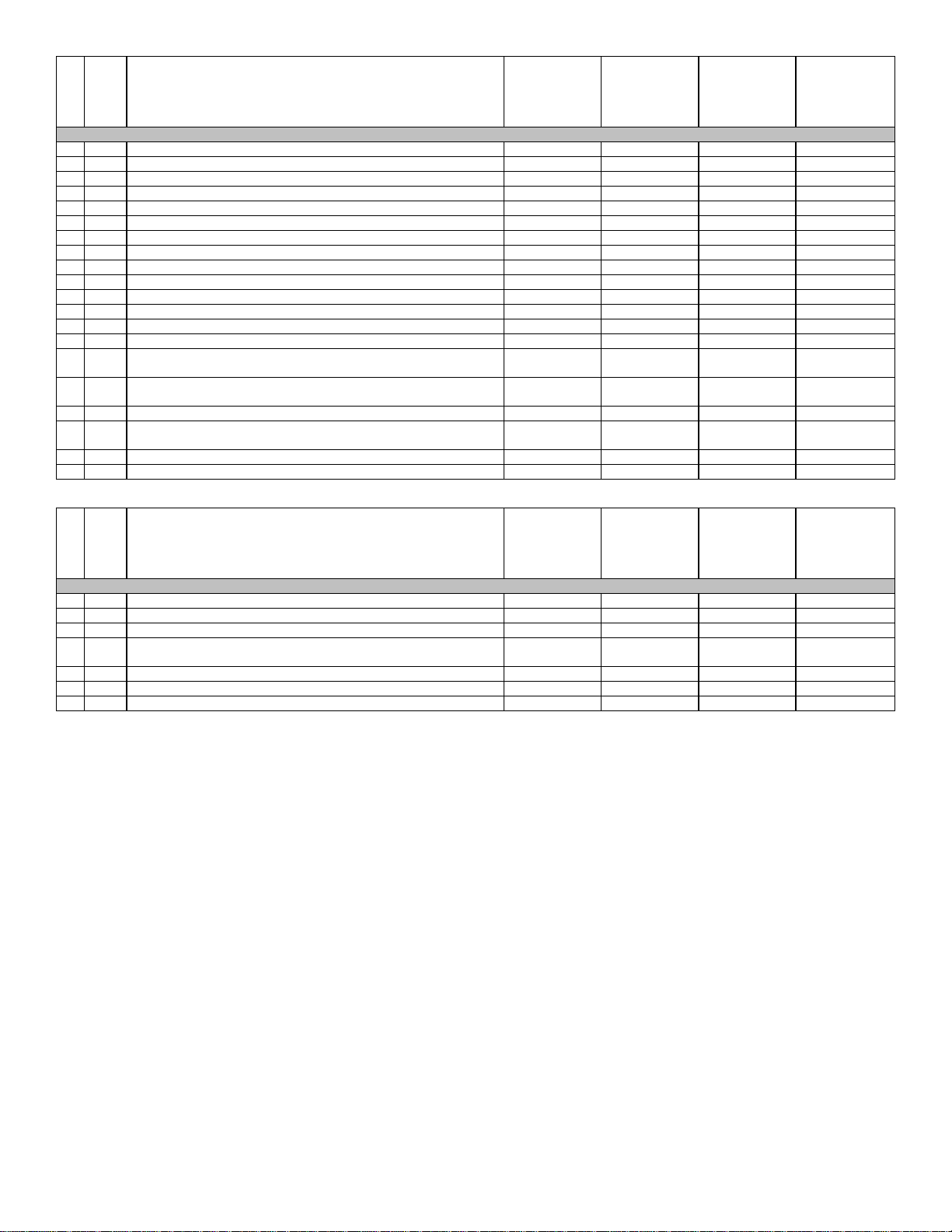

CAUTION: Selection of the correct Natural Gas Orifice requires the following information for the specific installation:

1) Altitude in of the installation (ft.).

2) Average energy content of the Natural Gas fuel from the local supplier (BTU/cu. ft.).

For detailed information and instructions for Orifice selection, see the Gas Furnace LP Conversion Kit Index 92-21519-59 and the latest edition of the

National Fuel Gas Code Handbook, or the National Standard of Canada, Natural Gas and Propane Installation Code, CAN B149.1.

CAUTION:This information is provided for replacement purposes only. Conversion for operation at High Altitude must be done using the kit specified

on the product specification sheet for the unit.

NOTE:This Orifice sizing chart is based on 25,000 BTU/HR per burner.

NOTE: Factory installed orifices are calculated and sized based on a Natural Gas heating value of 1075 BTU/cu. ft. and an elevation of 0 - 3000 ft.

Elevation (ft.)

EnergyValue

(BTU/cu. ft.)

850 62-22175-38 62-22175-39 62-22175-40 62-22175-41 62-22175-41 62-22175-42 62-22175-42 62-22175-43

900 62-22175-40 62-22175-41 62-22175-42 62-22175-42 62-22175-42 62-22175-43 62-22175-43 62-22175-44

975 62-22175-41 62-22175-42 62-22175-42 62-22175-42 62-22175-43 62-22175-43 62-22175-44 62-22175-44

1075 62-22175-42 62-22175-42 62-22175-43 62-22175-43 62-22175-43 62-22175-44 62-22175-44 62-22175-45

1170 62-22175-43 62-22175-44 62-22175-44 62-22175-44 62-22175-45 62-22175-45 62-22175-46 62-22175-47

CAUTION: Selection of the correct LP Orifice requires the altitude of the specific installation (ft.).

For detailed information and instructions for Orifice selection, see the Gas Furnace LP Conversion Kit Index 92-21519-59 and the latest edition of the

National Fuel Gas Code Handbook (NFG), or the National Standard of Canada, Natural Gas and Propane Installation Code, CAN B149.1.

CAUTION:This information is provided for replacement purposes only. Conversion to LP or for operation at High Altitude should be done using the

kit(s) specified on the product specification sheet for the unit.

NOTE:This Orifice sizing chart is based on 25,000 BTU/HR per burner. Also, the chart is developed using the specified pressure setting of 10 in. water column

instead of the 11.0 in water column used by the NFG and CANB149.1.

NOTE: Orifices supplied in the LP Conversion Kit are calculated and sized based on an altitude of 0 - 4000 ft.

Elevation (ft.) Orifice

0 - 2000 62-22175-54

2001 - 3000 62-22175-54

3001 - 4000 62-22175-54

4001 - 5000 62-22175-54

5001 - 6000 62-22175-54

6001 - 7000 62-22175-54

7001 - 8000 62-22175-55

8001 - 9000 62-22175-55

9001 - 10000 62-22175-55

0 - 1999 2000 - 2999 3000 - 3999 4000 - 4999 5000 - 5999 6000 - 6999 7000 - 7999 8000 - 8999

80% GAS FURNACE - ORIFICE SELECTION CHART - NATURAL GAS

80% GAS FURNACE - ORIFICE SELECTION CHART - LP

Page 7 of 11

06-November-2012

92-42800-RGLR

Page 8

Exploded View

Page 8 of 11

06-November-2012

92-42800-RGLR

Page 9

Blower Assembly

Page 9 of 11

06-November-2012

92-42800-RGLR

Page 10

Burner Assembly

Page 10 of 11

06-November-2012

92-42800-RGLR

Page 11

NOTES

Stk It is recommended that stock be maintained for this part.

N/A Not Applicable

1 Order the specified LP Conversion Kit.

2 The specified replacement pressure switch may have a different pressure setting than that originally supplied.

3 These models were originally supply with two control boards, a larger Integrated Furnace Control Board (IFC) and

a smaller ECM Interface Control. For replacement, the specified kit replaces both boards.

4 Order Gas Valve for Natural Gas along with LP Conversion Kit.

DISCLAIMER: This document is intended to provide general replacement parts information to aid qualified

service personnel in the repair of these models. The complete Model and Serial Number of the unit under repair

should be specified when selecting and ordering replacement parts. Specifications and illustrations are subject

to change without notice. Document 92-42800-RGLR supersedes all previous parts lists for these models. See

http://www.rheempartslists.net/92-42800-RGLR for the latest revision of this document. The manufacturer

assumes no obligation for errors or omissions. Service personnel must verify the proper and safe operation of

equipment after the replacement of any original components.

P.O. Box 17010

Fort Smith, AR 72917-7010

Loading...

Loading...