Page 1

INSTALLATION INSTRUCTIONS

FOR RGFE UPFLOW, RGGE DOWNFLOW & RGJF DEDICATED

HORIZONTAL HIGH EFFICIENCY MODULATING CONDENSING

GAS FURNACES

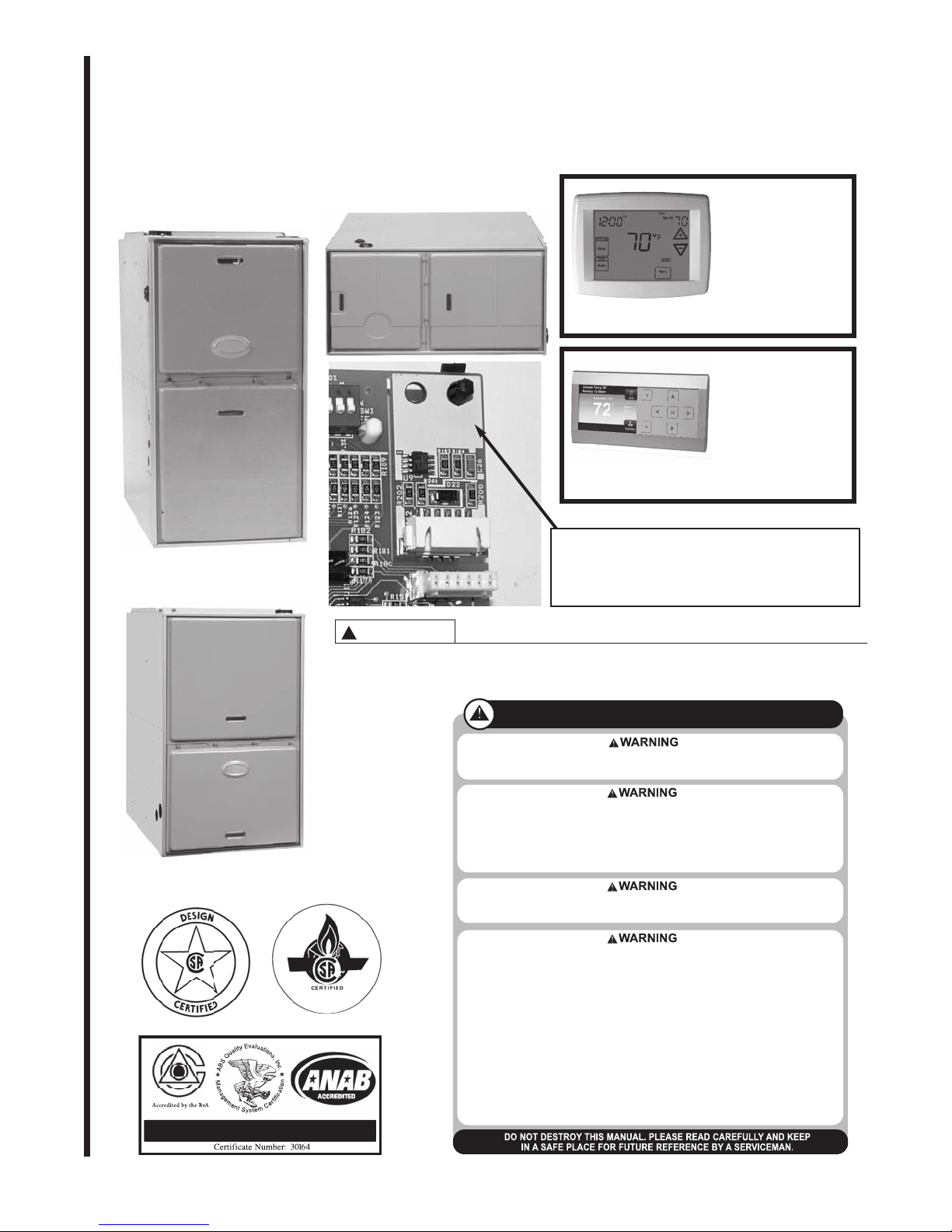

RGJF

RGFE

RGGE

SEE PAGE 112

SEE PAGE 122

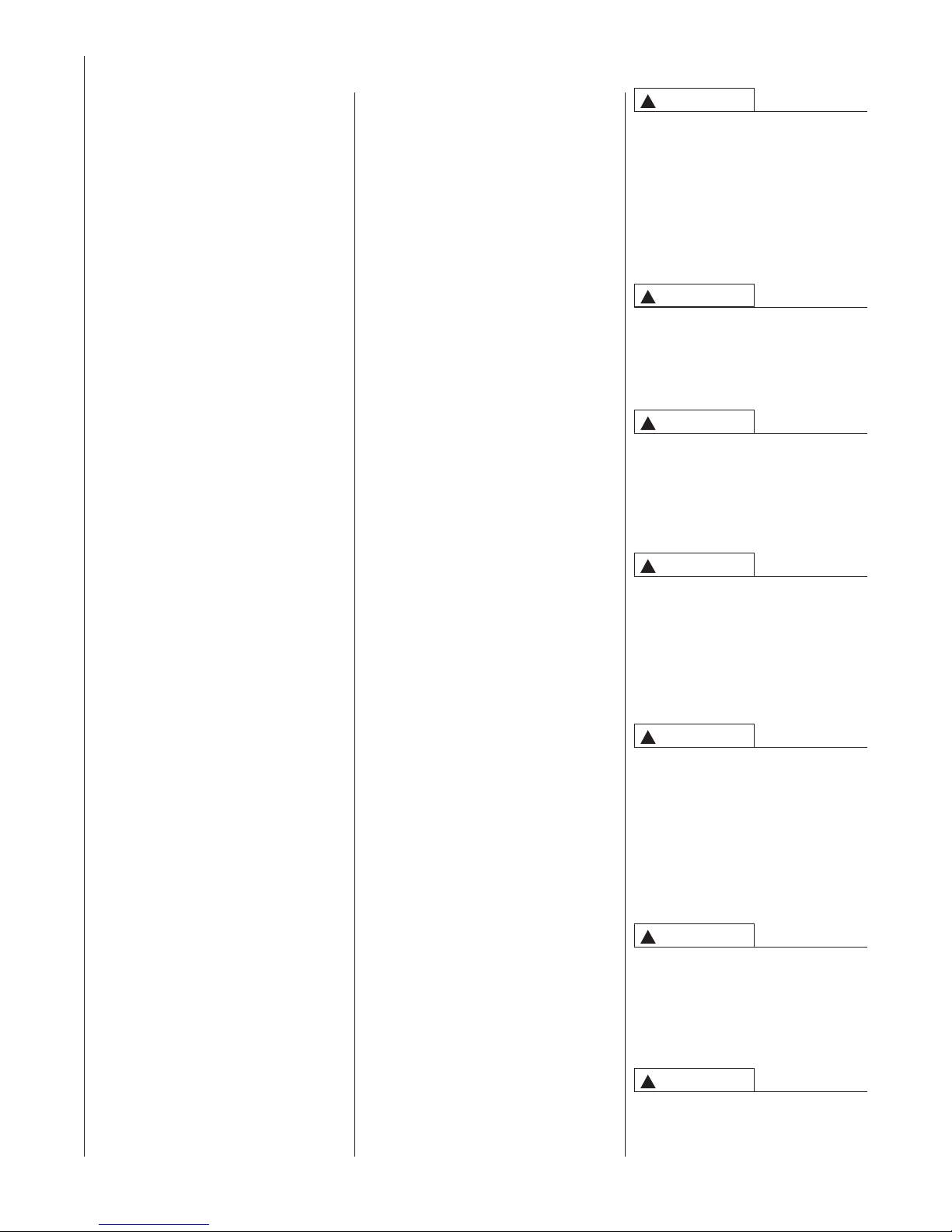

This Memory Card must be removed (broken away) from the

furnace control when the control is replaced. The card must

be inserted into the connector at J15 of the replacement control. Failure to retain this memory card with the furnace when

replacing the furnace control could result in no operation

when the furnace control is replaced.

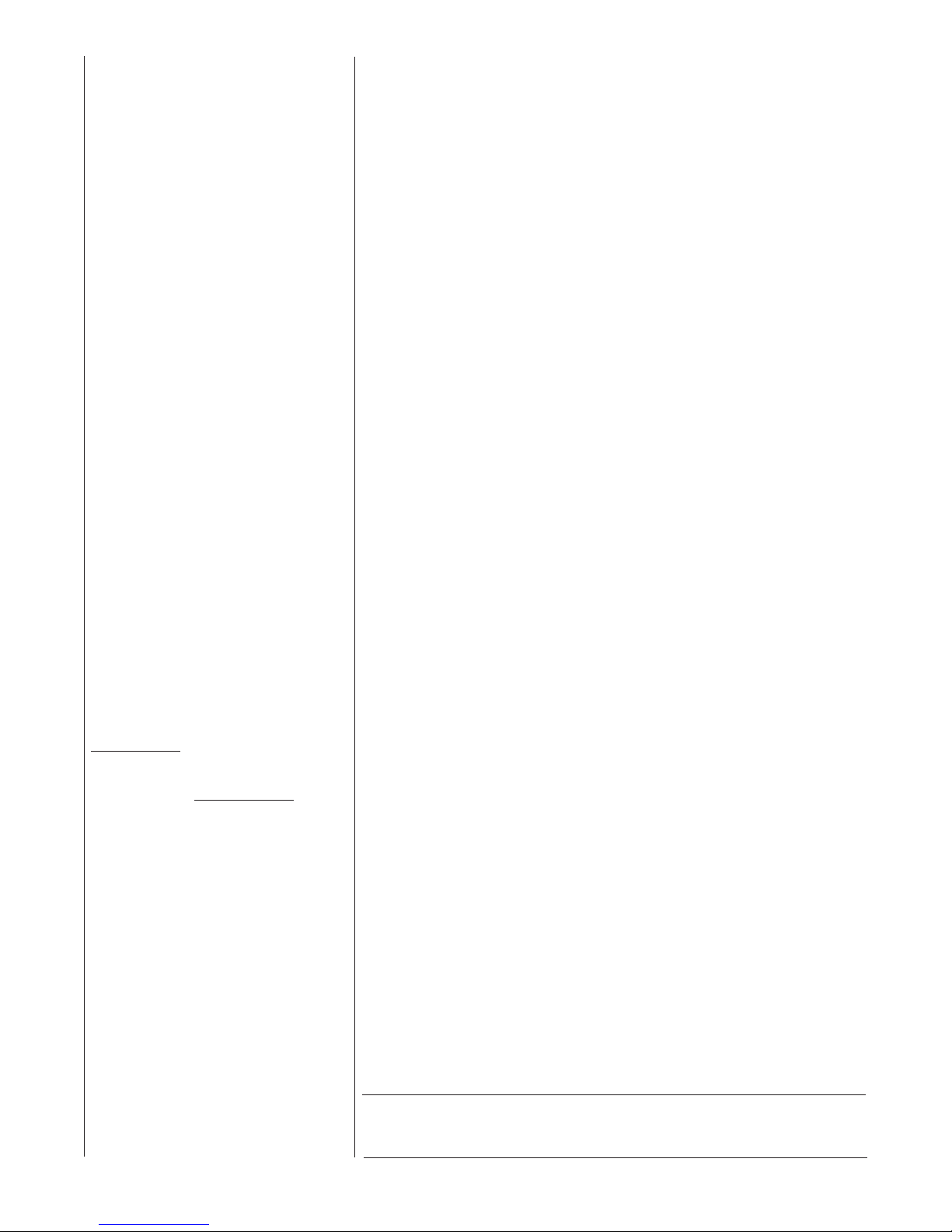

MODULATING

THERMOSTAT

INSTALLATION

MODULATING

COMMUNICATING

THERMOSTAT

INSTALLATION

ISO 9001:2008

WARNING

!

DO NOT EXCHANGE MEMORY CARDS BETWEEN 2 OR MORE DIFFERENT FURNACES. DOING

SO COULD RESULT IN UNEXPECTED OPERATION – INCLUDING INADEQUATE AIRFLOW DURING HEATING (AND OTHER MODES) OR A LOSS OF HEAT.

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORTANT SAFETY

INFORMATION!

IF THE INFORMATION IN THESE INSTRUCTIONS IS NOT FOLLOWED EXACTLY, A FIRE OR EXPLOSION

MAY RESULT, CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED SERVICE PERSONNEL FOR PROPER

INSTALLATION, ADJUSTMENT AND OPERATION OF THIS UNIT. READ THESE INSTRUCTIONS

THOROUGHLY BEFORE ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO FOLLOW THESE

INSTRUCTIONS MAY RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR

MAINTENANCE, POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK, CARBON MONOXIDE POISONING, EXPLOSION, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

PROPOSITION 65 WARNING: THIS PRODUCT CONTAINS CHEMICALS KNOWN TO THE STATE OF

CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

— Do not store or use gasoline or other flammable vapors and liquids, or other combustible materials

in the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions

• If you cannot reach your gas supplier, call the fire department.

• Do not return to your home u

— DO NOT RELY ON SMELL ALONE TO DETECT LEAKS. DUE TO VARIOUS FACTORS, YOU MAY NOT

BE ABLE TO SMELL FUEL GASES.

• U.L. recognized fuel gas and CO detectors are recommended in all applications, and their installation should be in accordance with the manufacturer’s recommendations and/or local laws, rules

regulations, or customs.

— Improper installation, adjustment, alteration, service or maintenance can cause injur

damage or death. Refer to this manual. Installation and service must be performed by a qualified

installer, service agency or the gas supplier. In the commonwealth of Massachusetts, installation

must be performed by a licensed plumber or gas fitter for appropriate fuel.

ntil authorized by the gas supplier or fire department.

y, property

92-24161-75-00

Page 2

IMPORTANT: All Rheem products

meet current Federal OSHA Guidelines

for safety. California Proposition 65

warnings are required for certain products, which are not covered by the

OSHA standards.

California's Proposition 65 requires

warnings for products sold in California

that contain, or produce, any of over

600 listed chemicals known to the

State of California to cause cancer or

birth defects such as fiberglass insulation, lead in brass, and combustion

products from natural ga

s.

All “new equipment” shipped for sale in

California will have labels stating that

the product contains and/or produces

Proposition 65 chemicals. Although we

have not changed our processes, having the same label on all our products

facilitates manufacturing and shipping.

We cannot always know “when, or if”

products will be sold in the California

market.

You may receive inquiries from customers about chemicals found in, or

produced by, some of our heating and

air-cond

itioning equipment, or found in

natural gas used with some of our

products. Listed below are those chemicals and substances commonly associated with similar equipment in our

industry and other manufacturers.

• Glass Wool (Fiberglass) Insulation

• Carbon Monoxide (CO)

• Formaldehyde

• Benzene

More details are available at the

Websites for OSHA (Occupational

Safety and Health Administration), at

www.osha.gov

and the State of

California's OEHHA (Office of

Environmental Health Hazard

Assessment), at www.oehha.org.

Consumer education is important since

the chemicals and substances on the

list are found in our daily lives. Most

consumers are aware that products

present safety and health risks, when

improperly used, handled and maintained.

Installation Instructions are updated on

a regular basis. This is done as product

changes occur or if new information

becomes available. In this publication,

an arrow ➤ denotes changes from the

previous edition or additional new

material.

TABLE OF CONTENTS

SAFETY INFORMATION ..........................................................................................................................................3

INSTALLATION CHECK LIST...................................................................................................................................5

GENERAL INFORMATION .......................................................................................................................................6

IMPORTANT INFORMATION ABOUT EFFICIENCY AND INDOOR AIR QUALITY..............................................8

LOCATION REQUIREMENTS AND CONSIDERATIONS.......................................................................................9

CLEARANCE-ACCESSIBILITY....................................................................................................................10

SITE SELECTION .........................................................................................................................................11

DIMENSIONS AND CLEARANCE TO COMBUSTIBLES...........................................................................12

UPFLOW MODELS.............................................................................................................................12

DOWNFLOW MODELS......................................................................................................................13

HORIZONTAL MODELS.....................................................................................................................14

DUCTING ......................................................................................................................................................15

SUPPLYAIR SENSOR .................................................................................................................................17

VENTING AND COMBUSTION AIR PIPING.........................................................................................................18

INSTALLATION WITH PRE-EXISTING VENT SYSTEMS..........................................................................18

JOINING PIPE AND FITTINGS....................................................................................................................19

CEMENTING JOINTS...................................................................................................................................19

NON-DIRECT VENT PIPE INSTALLATION ...........................................................................................................20

DIRECT VENT PIPE INSTALLATION ....................................................................................................................24

CONCENTRIC TERMINATIONS..................................................................................................................26

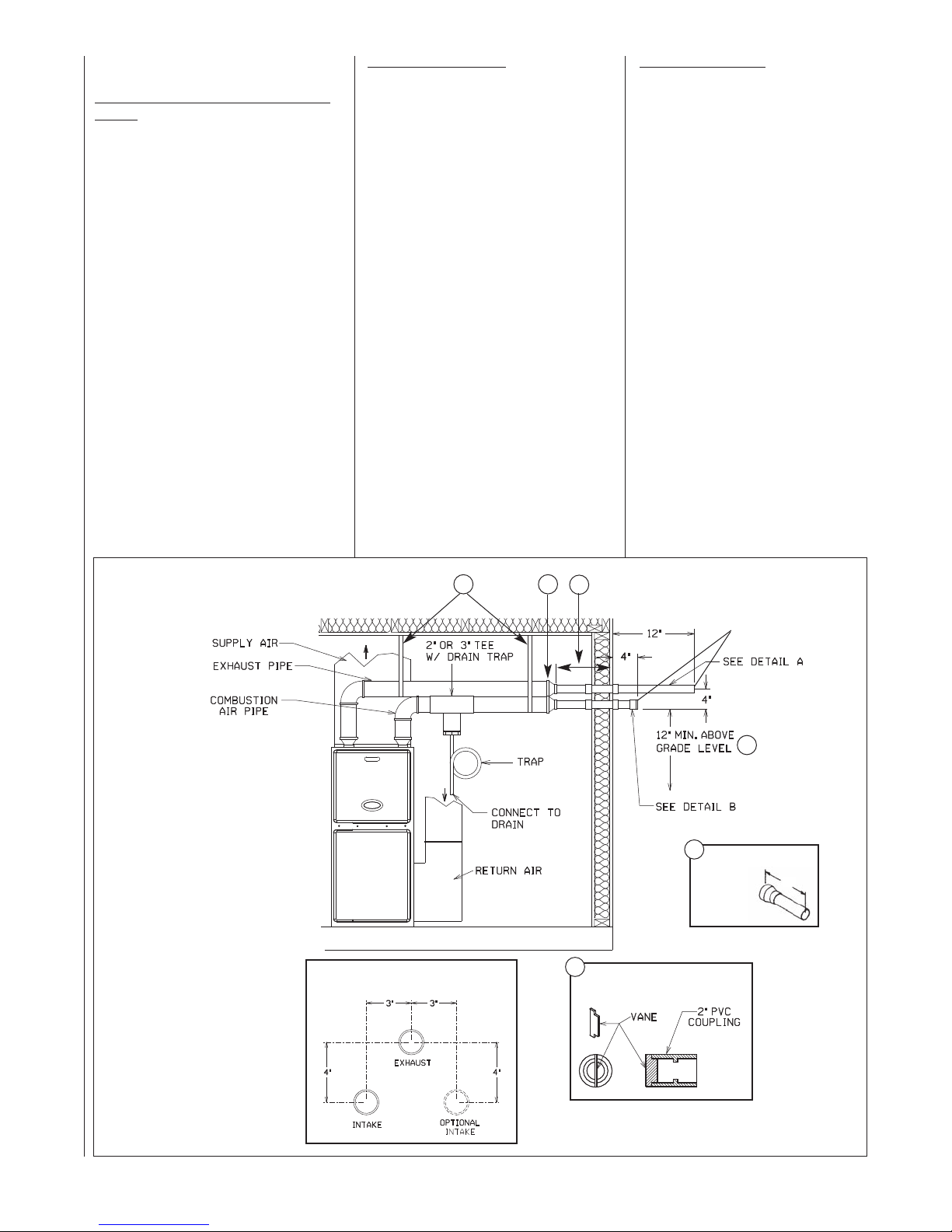

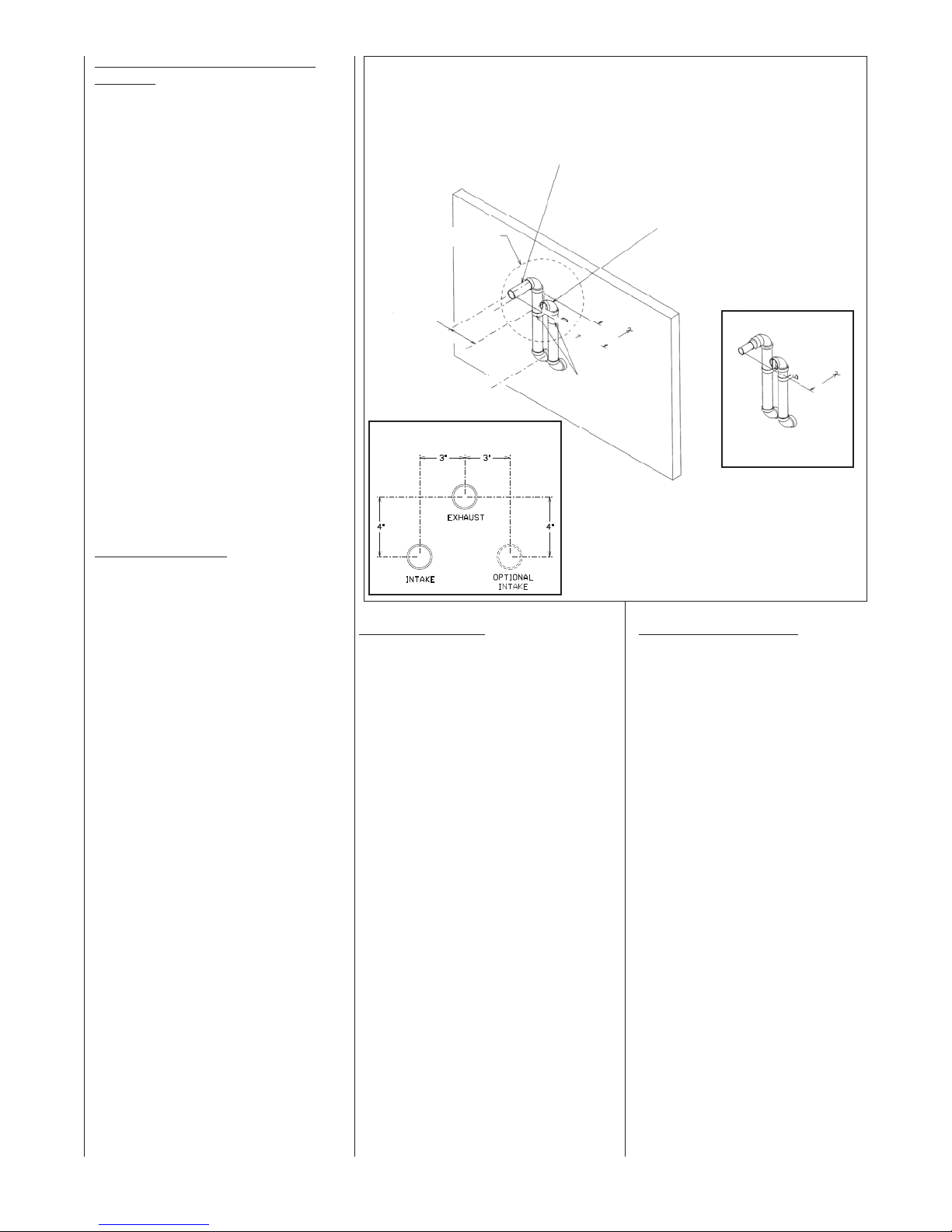

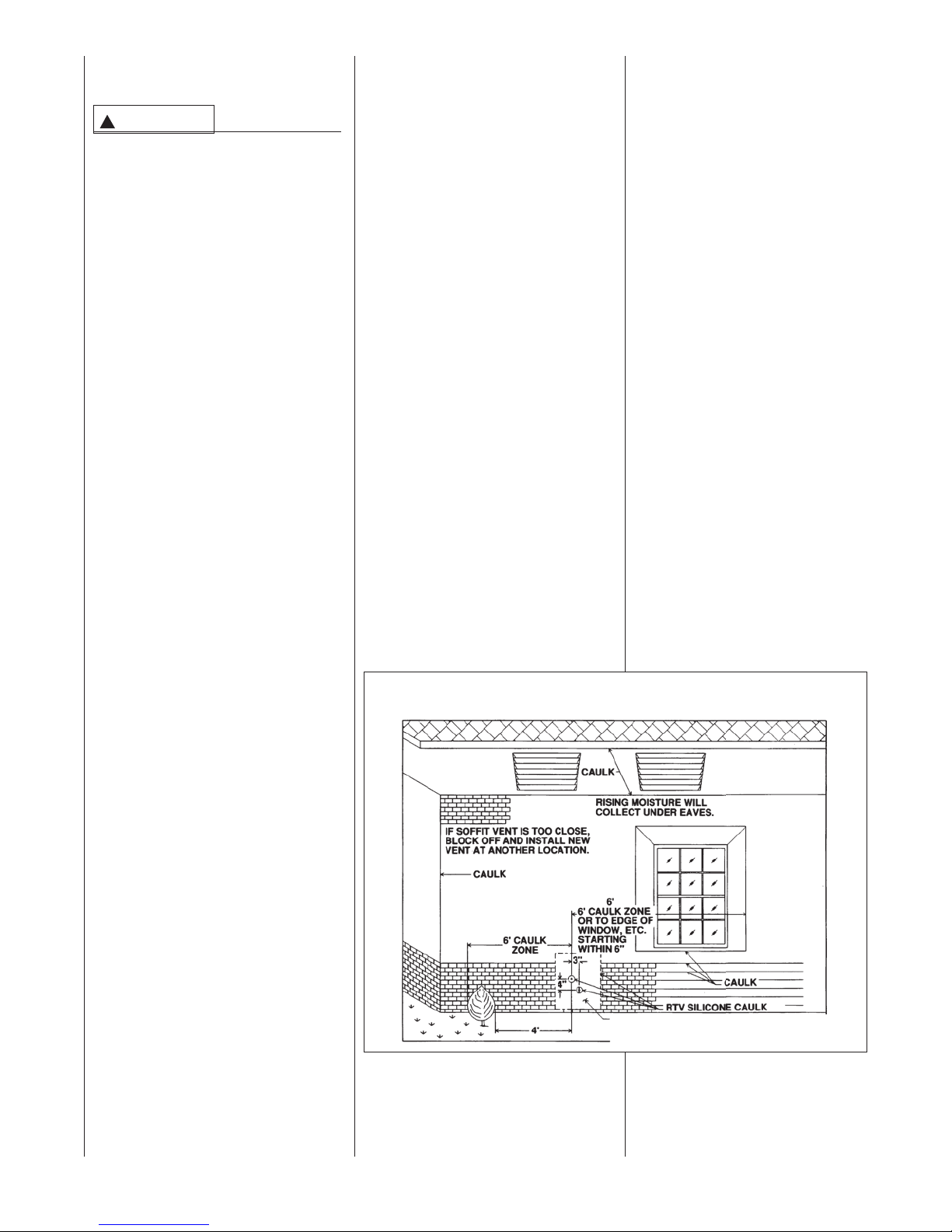

HORIZONTALTERMINATIONS...................................................................................................................28

CONDENSATE DRAIN / OPTIONAL NEUTRALIZER ..........................................................................................34

CONVERTING DOWNFLOW/HORIZONTAL MODELS TO HORIZONTAL CONFIGURATION.........................36

GAS SUPPLYAND PIPING ....................................................................................................................................39

GAS VALVE...................................................................................................................................................40

LP CONVERSION.........................................................................................................................................42

ELECTRICAL WIRING............................................................................................................................................45

ACCESSORIES.......................................................................................................................................................47

ELECTRONIC AIR CLEANER......................................................................................................................47

HUMIDIFICATIONAND DEHUMIDIFICATION............................................................................................47

OTHER ACCESSORIES ..............................................................................................................................49

TYPICAL WIRING ACCESSORIES FOR COMMUNICATING RESIDENTIAL SYSTEMS............49-50

HIGH ALTITUDE INSTALLATIONS ........................................................................................................................51

LP GAS AT HIGH ALTITUDE ELEVATIONS................................................................................................53

ZONING SYSTEMS......................................................................................................................................54

INSTALLATION WITH NON-COMMUNICATING, HIGH-EFFICIENCY PREMIUM COOLING

SYSTEMS ...................................................................................................................................................54

INTEGRATED FURNACE CONTROL ...................................................................................................................55

CONNECTORS AND COMPONENTS OF FURNACE CONTROL ...........................................................55

SPECIAL CONFIGURATION – COMM T-STAT AND NON-COMM CONDENSER ..................................56

MEMORY CARD...........................................................................................................................................60

RULES FOR WRITING, DISTRIBUTION AND ARBITRATION OF MULTIPLE COPIES OF

FURNACE SHARED DATA FOR COMMUNICATING-CAPABLE FURNACES ..............................60

REPLACING THE FURNACE CONTROL...................................................................................................63

DIPSWITCHES .............................................................................................................................................66

FURNACE OPERATION USING NON-COMMUNICATING MODULATING,

MODULATING AND TWO-STAGE T-STATS.....................................................................................69

COMMUNICATING SYSTEMS....................................................................................................................73

WIRING FOR COMMUNICATIONS...................................................................................................73

STARTUP FOR SYSTEMS CONFIGURED WITH COMMUNICATIONS........................................74

CONTINUOUS FAN OPERATION IN COMMUNICATING MODE...................................................75

ACTIVE FAULT CODES WITH COMMUNICATING SYSTEMS.......................................................75

FURNACE USER MENUS ...........................................................................................................................75

STATUS 1 ............................................................................................................................................76

STATUS 2 ............................................................................................................................................78

2 WK HIST...........................................................................................................................................78

LIFE HIST............................................................................................................................................79

FAULT HISTORY.................................................................................................................................79

UNIT INFO...........................................................................................................................................79

SETUP.................................................................................................................................................79

DIPSWITCH.........................................................................................................................................80

DUAL-FUEL OPERATION ............................................................................................................................80

START-UP PROCEDURES ....................................................................................................................................81

SEQUENCE OF OPERATION.....................................................................................................................83

SETTING INPUT RATE................................................................................................................................83

MAINTENANCE.......................................................................................................................................................84

TROUBLESHOOTING CHART ..............................................................................................................................87

NORMAL OPERATING CODES (TABLE 20) ........................................................................................................89

FURNACE FAULT CODES WITH DESCRIPTIONS AND SOLUTIONS (TABLE 21)..................................90-105

WIRE DIAGRAM – STEPPER / SERVO MODULATING VALVE (FUEL CODES HA OR HB).........................106

WIRE DIAGRAM – SOLENOID CONTROLLED MODULATING VALVE (FUEL CODES HG OR HH)............107

THERMOSTATS ....................................................................................................................................................108

NON-COMMUNICATING THERMOSTATS...............................................................................................108

THERMOSTAT WIRING (WITH WIRING DIAGRAMS) ............................................................................109

APPLICATIONS.....................................................................................................................................................112

MODULATING, TOUCH-SCREEN, NON-COMMUNICATING THERMOSTAT ((-)HC-TST412MDMS)..112

COMMUNICATING THERMOSTATS.........................................................................................................122

(-)HC-TST501CMMS PROGRAMMABLE COMMUNICATING THERMOSTAT............................124

(-)HC-TST550CMMS FULL COLOR, PROGRAMMABLE COMMUNICATING THERMOSTAT...128

2

IMPORTANT: To insure proper installation and operation of this product, completely read all instructions prior to attempting to assemble, install, operate, maintain or repair this product. Upon unpacking of the furnace, inspect all parts for

damage prior to installation and start-up.

Page 3

SAFETY INFORMATION

IMPORTANT!

THE COMMONWEALTH OF MASSACHUSETTS REQUIRES COMPLIANCE

WITH REGULATION 248 CMR 4.00

AND 5.00 FOR INSTALLATION OF

THROUGH-THE-WALL VENTED GAS

APPLIANCES AS FOLLOWS:

(a) For all side wall horizontally vented

gas fueled equipment installed in every

dwelling, building or structure used in

whole or in part for residential purposes,

including those owned or operated by

the Commonwealth and where the side

wall exhaust vent termination is less than

seven (7) feet above finished grade in

the area of the venting, including but not

limited to decks and porches, the following requirements shall be satisfied:

1. INSTALLATION OF CARBON

MONOXIDE DETECTORS. At the time of

installation of the side wall horizontal

vented gas fueled equipment, the

installing plumber or gasfitter shall

observe that a hard wired carbon

monoxide detector with an alarm and

battery back-up is installed on the floor

level where the gas equipment is to be

installed. In addition, the installing

plumber or gasfitter shall observe that a

battery operated or hard wired carbon

monoxide detector with an alarm is

installed on each additional level of the

dwelling, building or structure served by

the side wall horizontal vented gas

fueled equipment. It shall be the responsibility of the property owner to secure

the services of qualified licensed professionals for the installation of hard wired

carbon monoxide detectors.

a. In the event that the side wall horizon-

tally vented gas fueled equipment is

installed in a crawl space or an attic, the

hard wired carbon monoxide detector

with alarm and battery back-up may be

installed on the next adjacent floor level.

b. In the event that the requirements of

this subdi

time of completion of installation, the

owner shall have a period of thirty (30)

days to comply with the above requirements; provided, however, that during

said thirty (30) day period, a battery

operated carbon monoxide detector with

an alarm shall be installed.

2. APPROVED CARBON MONOXIDE

DETECTORS. Each carbon monoxide

detector as required in accordance with

the above provisions shall comply with

NFPA 720 and be ANSI/UL 2034 listed

and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be permanently mount-

ed to the exterior of the building at a

minimum height of eight (8) feet above

grade directly in line with the exhaust

vent terminal for the horizontally vented

gas fueled heating appliance or equip-

ment. The sign shall read, in print size

no less than one-half (1/2) inch in size,

“GAS VENT DIRECTLY BELOW. KEEP

CLEAR OF ALL OBSTRUCTIONS”.

vision can not be met at the

4. INSPECTION. The state or local gas

inspector of the side wall horizontally

vented gas fueled equipment shall not

approve the installation unless, upon

inspection, the inspector observes car-

bon monoxide detectors and signage

installed in accordance with the provisions of 248 CMR 5.08(2)(a) 1 through

4.

(b) EXEMPTIONS: The following equip-

ment is exempt from 248 CMR

5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10

entitled “Equipment Not Required To Be

Vented” in the most current edition of

NFPA 54 as a

2. Product Approved side wall horizon-

tally vented gas fueled equipment

installed in a room or structure separate from the dwelling, building or structure used in whole or in part for residential purposes.

(c) MANUFACTURER REQUIREMENTS – GAS EQUIPMENT VENTING SYSTEM PROVIDED. When the

manufacturer of Product Approved side

wall horizontally vented gas equipment

provides a venting system design or

venting system components with the

equip

ment, the instructions provided by

the manufacturer for installation of the

equipment and the venting system shall

include:

1. Detailed instructions for the installation of the venting system design or the

venting system components; and

2. A complete parts list for the venting

system design or venting system.

(d) MANUFACTURER REQUIREMENTS – GAS EQUIPMENT VENTING SYSTEM NOT PROVIDED. When

the manufacturer of a Product

Approved side wall horizontally vented

gas fue

the parts for venting the flue gases, but

identifies “special venting systems”, the

following requirements shall be satisfied by the manufacturer:

1. The referenced “special venting system” instructions shall be included with

the appliance or equipment installation

instructions; and

2. The “special venting systems” shall

be Product Approved by the Board, and

the instructions for that system shall

include a parts list and detailed in

tion instructions.

(e) A copy of all installation instructions

for all Product Approved side wall hori-

zontally vented gas fueled equipment,

all venting instructions, all parts lists for

venting instructions, and/or all venting

design instructions shall remain with

the appliance or equipment at the completion of the installation.

dopted by the Board; and

led equipment does not provide

stalla-

WARNING

!

INSTALL THIS FURNACE ONLY IN

A LOCATION AND POSITION AS

SPECIFIED IN THE LOCATION

REQUIREMENTS AND CONSIDERATIONS SECTION OF THESE

INSTRUCTIONS. PROVIDE ADEQUATE COMBUSTION AND VENTILATION AIR TOTHE FURNACE

SPACE AS SPECIFIED IN THE

VENTING SECTION OF THESE

INSTRUCTIONS.

WARNING

!

PROVIDE ADEQUATE COMBUSTION AND VENTILATION AIR TO

THE FURNACE SPACE AS SPECIFIED IN THE COMBUSTION AND

VENTILATION AIR SECTION OF

THESE INSTRUCTIONS.

WARNING

!

COMBUSTION PRODUCTS MUST

BE DISCHARGED OUTDOORS.

CONNECT THIS FURNACE TO AN

APPROVEDVENT SYSTEM ONLY,

AS SPECIFIED IN VENT PIPE

INSTALLATION SECTION OF

THESE INSTRUCTIONS.

WARNING

!

NEVER TEST FOR GAS LEAKS

WITH AN OPEN FLAME. USE A

COMMERCIALLY AVAILABLE

SOAP SOLUTION MADE SPECIFICALLY FOR THE DETECTION OF

LEAKS TO CHECK ALL CONNECTIONS, AS SPECIFIED IN GAS

SUPPLY AND PIPING SECTION OF

THESE TION INSTRUCTIONS.

WARNING

!

THIS FURNACE IS NOT

APPROVED OR RECOMMENDED

FOR INSTALLATION ON ITS BACK,

WITH ACCESS DOORS FACING

UPWARDS, ORWITH SUPPLY AIR

DISCHARGING TO THE RIGHTHAND SIDE WHEN FACING THE

FRONT OF THE FURNACE. SEE

FIGURES 6 AND 7 FOR PROPER

INSTALLATION OF HORIZONTAL

MODELS.

WARNING

!

DO NOT INSTALL THIS FURNACE

IN A MOBILE HOME!! THIS FURNACE IS NOT APPROVED FOR

INSTALLATION IN A MOBILE

HOME. DOING SO COULD CAUSE

FIRE, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

USE ONLY WITH TYPE OF GAS

APPROVED FORTHIS FURNACE.

REFER TO THE FURNACE RATING

PLATE.

3

Page 4

WARNING

!

WHEN THIS FURNACE IS INSTALLED

IN A RESIDENTIAL GARAGE, IT

MUST BE INSTALLED SO THE BURNERS AND IGNITION SOURCE ARE

LOCATED NO LESS THAN 18 INCHES ABOVE THE FLOOR. THIS ISTO

REDUCE THE RISK OF IGNITING

FLAMMABLE VAPORS WHICH MAY

BE PRESENT IN A GARAGE.

ALSO,THE FURNACE MUST BE

LOCATED OR PROTECTED TO

AVOID PHYSICAL DAMAGE BY VEHICLES. FAILURETO FOLLOW THESE

WARNINGS CAN CAUSE A FIRE OR

EXPLOSION, RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY

OR DEATH.

WARNING

!

USE OF THIS FURNACE IS

ALLOWED DURING CONSTRUCTION

IF THE FOLLOWING TEMPORARY

INSTALLATION REQUIREMENTS

ARE MET. INSTALLATION MUST

COMPLY WITH ALL INSTALLATION

INSTRUCTIONS INCLUDING:

• PROPER VENT INSTALLATION;

• FURNACE OPERATING UNDER

THERMOSTATIC CONTROL;

• RETURN AIR DUCT SEALED TO

THE FURNACE;

• AIR FILTERS IN PLACE;

• SET FURNACE INPUT RATE AND

TEMPERATURE RISE PER RAT-

ING PLATE MARKING;

• MEANS FOR PROVIDING OUT-

DOOR AIR REQUIRED FOR COM-

BUSTION;

• RETURN AIR TEMPERATURE

MAINTAINED BETWEEN 55°F

(13°C) AND 80°F (27°C); AND;

• CLEAN FURNACE, DUCT WORK

AND COMPONENTS UPON SUBSTANTIAL COMPLETION OF THE

CONSTRUCTION PROCESS, AND

VERIFY FURNACE OPERATING

CONDITIONS INCLUDING IGNITION, INPUT RATE,TEMPERATURE RISE AND VENTING,

ACCORDINGTO THE INSTRUCTIONS.

WARNING

!

DO NOT JUMPER OR OTHERWISE

BYPASS OVERTEMPERATURE OR

ANY OTHER LIMITS OR SWITCHES

ON THE FURNACE. IF ONE OF

THESE LIMITS OR SWITCHES

SHOULD TRIP OR OPEN, THE USER

IS TO BE INSTRUCTED TO CALL A

QUALIFIED INSTALLER, SERVICE

AGENCY OR THE GAS SUPPLIER.

FOR MANUALLY RESETABLE

SWITCHES,THE USER IS FURTHER

INSTRUCTED TO NEVER RESET THE

SWITCH, BUT TO CALL A QUALIFIED

TECHNICIAN. MANUAL RESET

SWITCHES MAY REQUIRE FURTHER

CORRECTIVE ACTIONS. FAILURE TO

FOLLOWTHIS WARNING COULD

RESULT IN CARBON MONOXIDE

POISONING, SERIOUS INJURY OR

DEATH. IF THE UNIT IS INSTALLED

IN A CLOSET,THE DOOR MUST BE

CLOSED WHEN MAKINGTHIS

CHECK. INSTALLERS AND TECHNICIANS ARE INSTRUCTED TO

REPLACE ANY LIMIT OR SAFETY

SWITCH/DEVICE ONLY WITH IDENTICAL REPLACEMENT PARTS.

WARNING

!

DUCT LEAKS CAN CREATE AN

UNBALANCED SYSTEM AND DRAW

POLLUTANTS SUCH AS DIRT, DUST,

FUMES AND ODORS INTO THE

HOME CAUSING PROPERTY DAMAGE. FUMES AND ODORS FROM

TOXIC, VOLATILE OR FLAMMABLE

CHEMICALS, AS WELL AS AUTOMOBILE EXHAUST AND CARBON

MONOXIDE (CO), CAN BE DRAWN

INTOTHE LIVING SPACETHROUGH

LEAKING DUCTS AND UNBALANCED DUCT SYSTEMS CAUSING

PERSONAL INJURY OR DEATH (SEE

FIGURE 5).

• IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN

GARAGES OR OFF-GARAGE

STORAGE AREAS - ALL JOINTS,

SEAMS, AND OPENINGS IN THE

EQUIPMENT AND DUCT MUST BE

SEALED TO LIMIT THE MIGRATION

OF TOXIC FUMES AND ODORS

INCLUDING CARBON MONOXIDE

FROM MIGRATING INTO THE LIVING SPACE.

• IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN

SPACES CONTAINING FUEL

BURNING APPLIANCES SUCH AS

WATER HEATERS OR BOILERS ALL JOINTS, SEAMS, AND OPENINGS IN THE EQUIPMENT AND

DUCT MUST ALSO BE SEALED TO

PREVENT DEPRESSURIZATION

OF THE SPACE AND POSSIBLE

MIGRATION OF COMBUSTION

BYPRODUCTS INCLUDING CARBON MONOXIDE INTOTHE LIVING

SPACE.

WARNING

!

ALWAYS INSTALL FURNACETO

OPERATE WITHIN THE FURNACE'S INTENDED TEMPERATURE-RISE RANGE WITH A DUCT

SYSTEM WHICH HAS AN EXTERNAL STATIC PRESSURE WITHIN

THE ALLOWABLE RANGE, AS

SPECIFIED IN DUCTING SECTION

OF THESE INSTRUCTIONS. SEE

ALSO FURNACE RATING PLATE.

WARNING

!

WHEN A FURNACE IS INSTALLED

SO THAT SUPPLY DUCTS CARRY

AIR CIRCULATED BYTHE FURNACETO AREAS OUTSIDE THE

SPACE CONTAINING THE FURNACE,THE RETURN AIR SHALL

ALSO BE HANDLED BY DUCT(S)

SEALED TO THE FURNACE CASING AND TERMINATING OUTSIDE

THE SPACE CONTAININGTHE

FURNACE.

NOTICE

IMPROPER INSTALLATION, OR

INSTALLATION NOT MADE IN

ACCORDANCE WITH THE CSA

INTERNATIONAL (CSA) CERTIFICATION OR THESE INSTRUCTIONS, CAN RESULT IN UNSATISFACTORY OPERATION AND/OR

DANGEROUS CONDI-TIONS AND

ARE NOT COVERED BY THE UNIT

WARRANTY.

NOTICE

IN COMPLIANCE WITH RECOGNIZED CODES, IT IS RECOMMENDED THAT AN AUXILIARY

DRAIN PAN BE INSTALLED

UNDER ALL EVAPORATOR COILS

OR UNITS CONTAINING EVAPORATOR COILS THAT ARE LOCATED IN ANY AREA OF A STRUCTURE WHERE DAMAGE TO THE

BUILDING OR BUILDING CONTENTS MAY OCCUR AS A RESULT

OF AN OVERFLOW OF THE COIL

DRAIN PAN OR A STOPPAGE IN

THE PRIMARY CONDENSATE

DRAIN PIPING. SEE ACCESSORIES SECTION OF THESE

INSTRUCTIONS FOR AUXILIARY

HORIZONTAL OVERFLOW PAN

INFORMATION (MODEL RXBM).

WARNING

!

DO NOT EXCHANGE MEMORY

CARDS BETWEEN 2 OR MORE

DIFFERENT FURNACES. DOING

SO COULD RESULT IN UNEXPECTED OPERATION – INCLUDING INADEQUATE AIRFLOW DURING HEATING (AND OTHER

MODES OR A LOSS OF HEAT).

4

Page 5

INSTALLATION CHECK LIST

REFER TO INSTALLATION INSTRUCTIONS

GAS SUPPLY

Adequate pipe size

Correct supply pressure (during furnace operation)

Manifold pressure

No gas leaks

ELECTRICAL

115 V.A.C. supply (Single Circuit)

Polarity observed

Furnace properly grounded (Earth ground)

Adequate wire size

FURNACE INSTALLATION

Adequate clearance to combustibles

Adequate clearance for service (at front)

DUCT STATIC PRESSURE

in. w.c. on heating speed

in. w.c. on cooling spe

Air temperature rise

CONDENSATE LINE

Trap filled with water

Vented

Sloped toward drain

Condensate drain line hoses connected

and clamped

ed

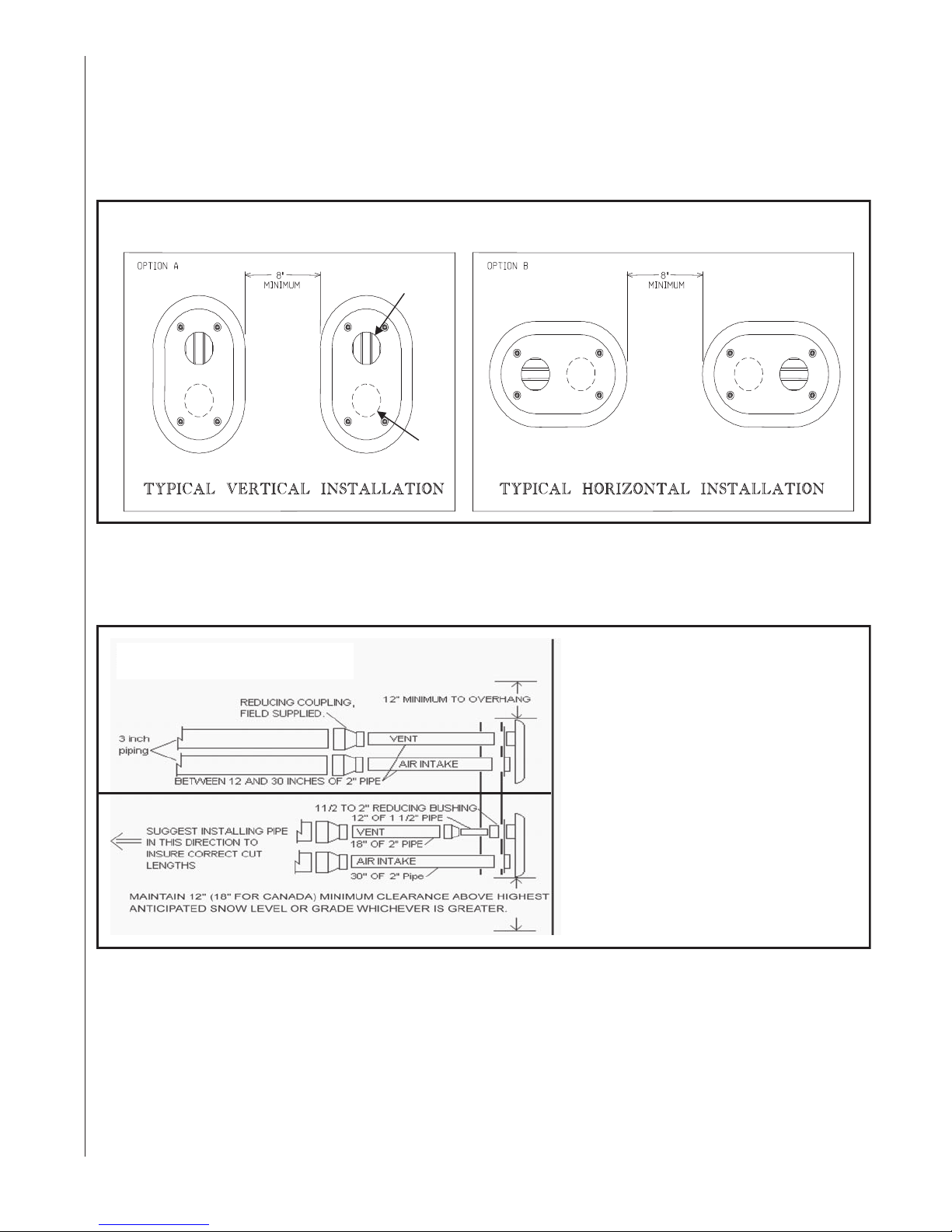

TERMINATIONS – DIRECT VENT

VERTICAL

Intake – 12" min. above roof/snow level

Correct relationship – exhaust to intake

VERTICAL – CONCENTRIC (RXGY-E03A)

Intake – 12" min. above roof/snow level

HORIZONTAL – STANDARD (RXGY-D02, -D02A, -D03,

-D03A)

Correct relationship – exhaust to intake

12" min. above grade/snow level

H

ORIZONTAL – ALTERNATE (RXGY-D02, -D02A, -D03,

-D03A, -D04 OR -D04A)

Correct relationship – exhaust to intake

Above anticipated snow level

HORIZONTAL – CONCENTRIC (RXGY-E03A)

12" min. above grade/snow level

Intake “Y” rotated above center

Exhaust sloped toward furnace

VENTING – NON-DIRECT VENT (VERTICAL ONLY)

in. diameter – exhaust pipe

ft. of pipe – exhaust

no. of elbows

TERMINATION – NON-DIRECT VENT (VERTICAL ONLY)

12" min. above roof/snow level

Freeze protection (if necessary)

______ Neutralizer (if needed)

VENTING – DIRECT VENT

in. diameter – intake pipe

in. diameter – exhaust pipe

ft. of pipe – intake air

no. of elbows – intake air

ft. of pipe – exhaust pipe

no. of elbows – exhaust pipe

HORIZONTAL – STANDARD

12" min. above grade/snow level

HORIZONTAL – ALTERNATE

Above anticipated snow level

Model #

Serial #

Date

of installation

5

Page 6

GENERAL INFORMATION

The RGFE, RGGE and RGJF series

furnaces are design-certified by CSA

for use with natural and L.P. gases as

follows:

• As direct vent, central forced air

furnaces with all combustion air

supplied directly to the furnace

burners through a special air intake

system outlined in these instructions.

• As non-direct, central forced air fur-

nace taking combustion air from

the installation area or using air

ducted from the outside.

• IMPORTANT: Proper application,

installation and maintenance of this

furnace are required if consumers

are to receive the full benefits for

which they have paid.

Install this furnace in accordance with

the American National Standard

Z223.1 – latest edition entitled

“National Fuel Gas Code” (NFPA54,

90A and 90B) and requirements or

codes of the local utilities or other

authorities having jurisdiction. This is

available from the following:

National Fire Protection

Association, Inc.

Batterymarch Park

Quincy, MA 02269

CSA International - U.S.

8501 East Pleasant Valley Road

Cleveland, Ohio, 44131

Canadian installations must be

installed in accordance with CSA,

local installation codes and

authorities having jurisdiction.

CSA is available from:

CSA International - Canada

178 Rexdale Blvd.

Etobicoke (Toronto), Ontario,

Canada M9W-1R3

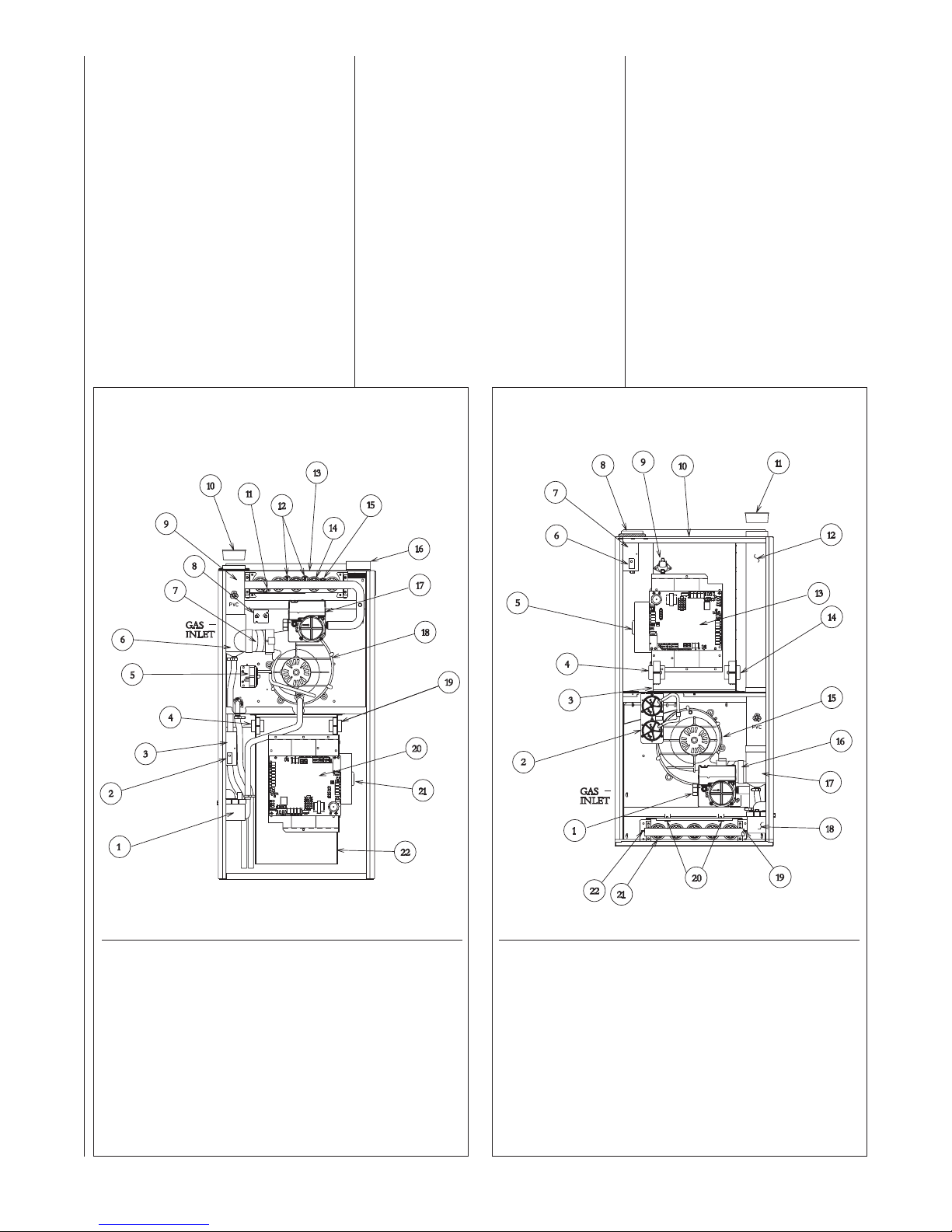

FIGURE 1

UPFLOW FURNACE RGFE

(GAS VALVE MAY BE DIFFERENT THAN SHOWN)

➤ FIGURE 2

DOWNFLOW FURNACE RGGE

(GAS VALVE MAY BE DIFFERENT THAN SHOWN)

ITEM

NO. PART NAME

1 CONDENSATE TRAP

2 DOOR SWITCH

3 JUNCTION BOX

4 TRANSFORMER

5 PRESSURE SWITCH ASSEMBLY

6 EXHAUST TRANSITION

7 CONNECTOR

8 MAIN LIMIT

9 EXHAUST AIR PIPE

10 VENT CAP SHIPPING PLUG

11 FLAME SENSOR

12 OVERTEMPERATURE SWITCH

ITEM

NO. PART NAME

13 TOP PLATE

14 BURNER

15 IGNITER

16 COMBUSTION AIR INLET

17 GAS VALVE

18 INDUCED DRAFT BLOWER

19 POWER FACTOR CHOKE

20 INTEGRATED FURNACE CONTROL

21 BLOWER MOTOR

22 BLOWER HOUSING

6

ITEM

NO. PART NAME

1 GAS VALVE

2 PRESSURE SWITCH ASSEMBLY

3 BLOWER HOUSING

4 POWER FACTOR CHOKE

5 BLOWER MOTOR

6 DOOR SWITCH

7 JUNCTION BOX

8 COMBUSTION AIR INLET

9 HALC

10 TOP PLATE

11 VENT CAP SHIPPING PLUG

ST-A1123-01_1 ST-A1123-01_2

12 OUTLET AIR PIPE

ITEM

NO. PART NAME

13 INTEGRATED FURNACE CONTROL

14 TRANSFORMER

15 INDUCED DRAFT BLOWER

16 CONNECTOR

17 EXHAUST TRANSITION

18 CONDENSATE TRAP

19 IGNITER

20 OVERTEMPERATURE SWITCH

21 BURNER

22 FLAME SENSOR

Page 7

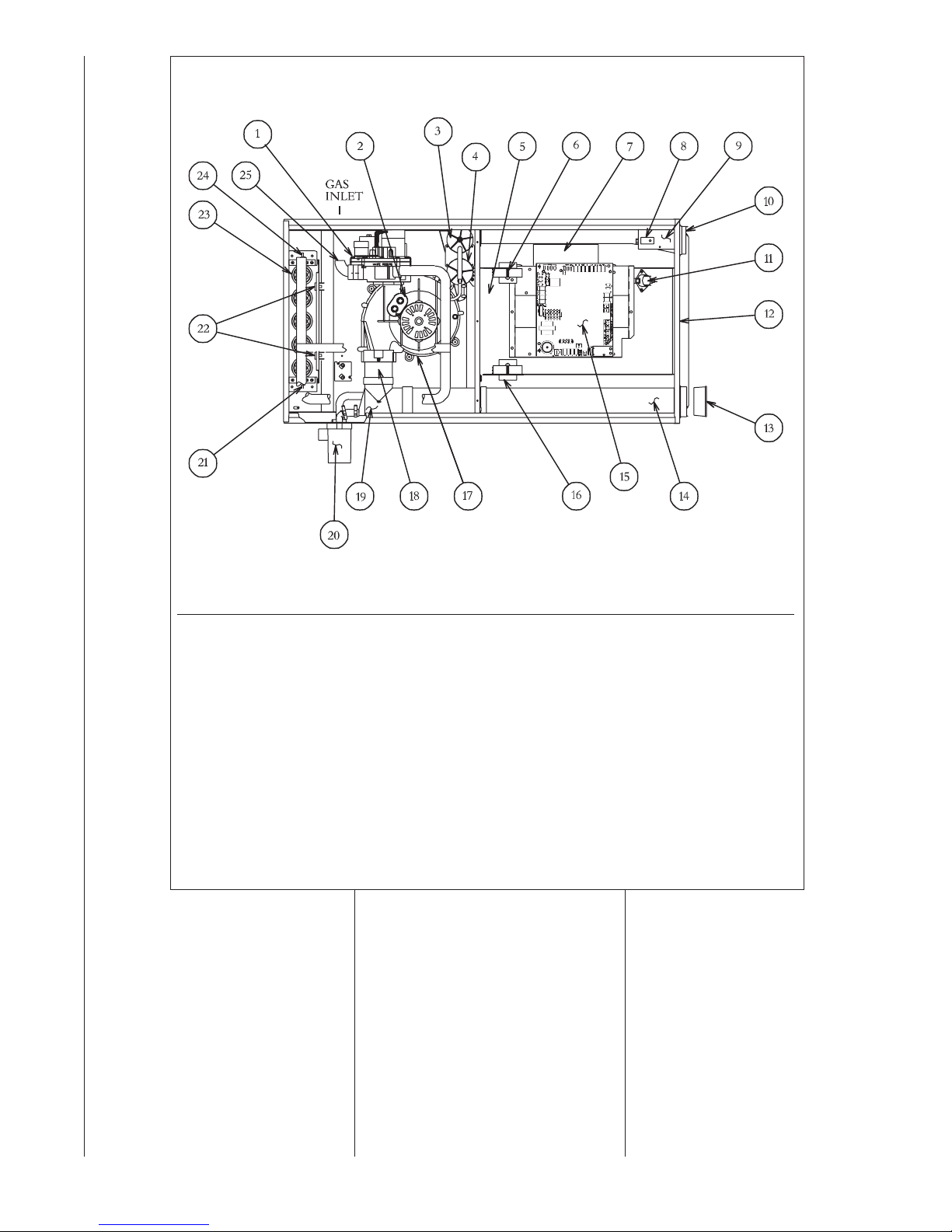

➤ FIGURE 3

DEDICATED HORIZONTAL FURNACE RGJF

(GAS VALVE MAY BE DIFFERENT THAN SHOWN)

ITEM

NO. PART NAME

1 GAS VALVE

2 CAPACITOR (FOR INDUCER)

3 LOW PRESSURE SWITCH

4 HIGH PRESSURE SWITCH

5 BLOWER HOUSING

6 POWER FACTOR CHOKE

7 BLOWER MOTOR

8 DOOR SWITCH

9 JUNCTION BOX

10 COMBUSTION AIR INLET

11 HALC

12 TOP PLATE

13 VENT CAP PLUG

ITEM

NO. PART NAME

14 OUTLET AIR PIPE

15 INTEGRATED FURNACE CONTROL

16 TRANSFORMER

17 INDUCED DRAFT BLOWER

18 CONNECTOR

19 EXHAUST TRANSITION

20 CONDENSATE TRAP

21 IGNITER

22 OVERTEMPERATURE SWITCH

23 BURNER

24 FLAME SENSOR

25 FACTORY-INST

ALLED STREET ELBOW

ST-A107801.S01

7

Page 8

IMPORTANT INFORMATION ABOUT EFFICIENCY

AND INDOOR AIR

QUALITY

Central cooling and heating equipment is only as efficient as the duct

system that carries the cooled or

heated air. To maintain efficiency,

comfort and good indoor air quality, it

is important to have the proper balance between the air being supplied

to each room and the air returning to

the cooling and heating equipment.

Proper balance and sealing of the

duct system improves the efficiency

of the heating andair conditioning

system and improves the indoor air

quality of the home by reducing the

amount of airborne pollutants that

enter homes from spaces where the

ductwork and / or equipment is located. The manufacturer and the U.S.

Environmental Protection Agency’s

Energy Star Program recommend

that central duct systems be checked

by a qualified contractor for proper

balance and sealing.

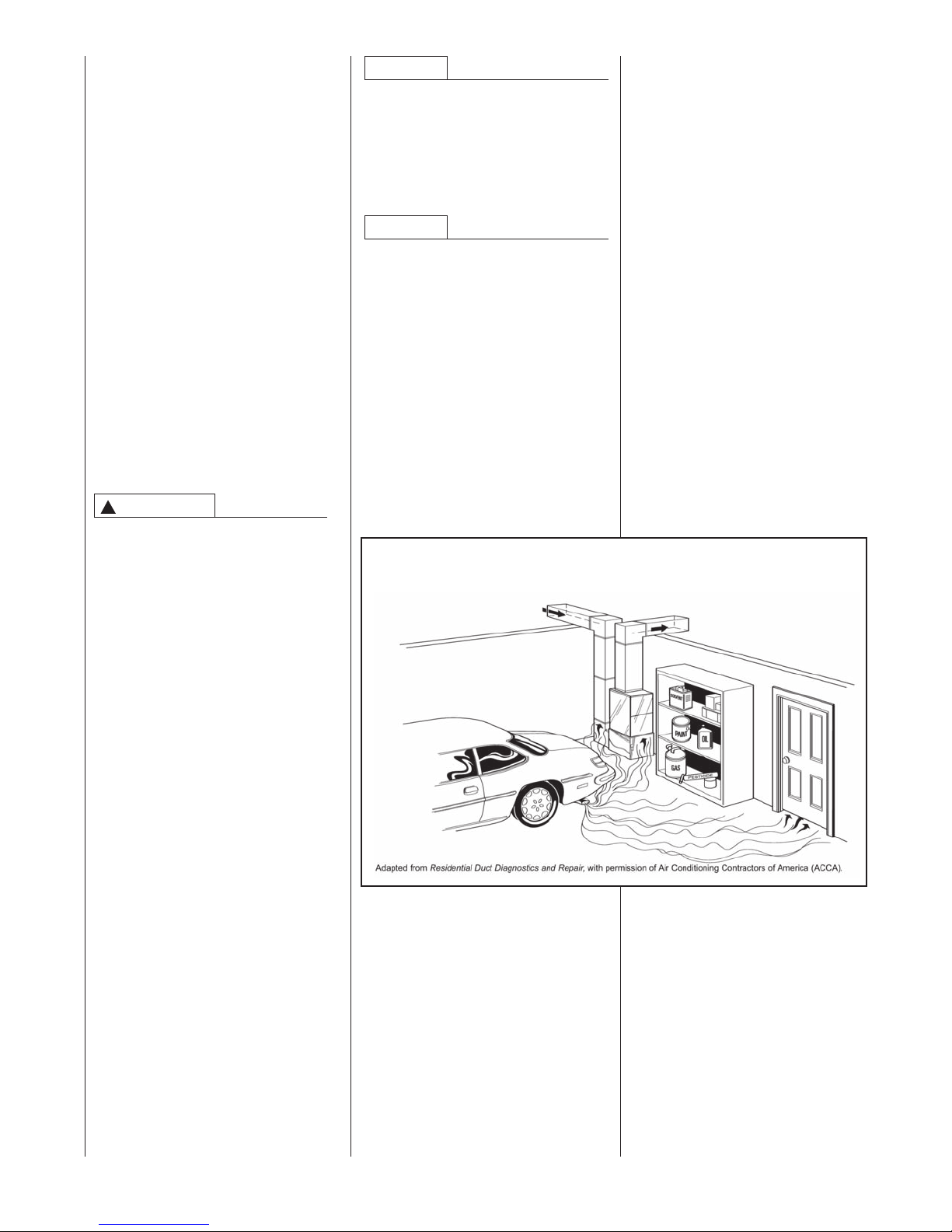

WARNING

!

DUCT LEAKS CAN CREATE AN

UNBALANCED SYSTEM AND

DRAW POLLUTANTS SUCH AS

DIRT, DUST, FUMES AND ODORS

INTOTHE HOME CAUSING PROPERTY DAMAGE. FUMES AND

ODORS FROM TOXIC,VOLATILE

OR FLAMMABLE CHEMICALS, AS

WELL AS AUTOMOBILE EXHAUST

AND CARBON MONOXIDE (CO),

CAN BE DRAWN INTO THE LIVING

SPACE THROUGH LEAKING

DUCTS AND UNBALANCED DUCT

SYSTEMS CAUSING PERSONAL

INJURY OR DEATH (SEE FIGURE

4).

• IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN

GARAGES OR OFF-GARAGE

STORAGE AREAS - ALL JOINTS,

SEAMS, AND OPENINGS IN THE

EQUIPMENT AND DUCT MUST

BE SEALED TO LIMIT THE

MIGRATION OF TOXIC FUMES

AND ODORS INCLUDING CARBON MONOXIDE FROM MIGRATING INTO THE LIVING SPACE.

• IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN

SPACES CONTAINING FUEL

BURNING APPLIANCES SUCH

AS WATER HEATERS OR BOILERS - ALL JOINTS, SEAMS, AND

OPENINGS IN THE EQUIPMENT

AND DUCT MUST ALSO BE

SEALED TO PREVENT DEPRESSURIZATION OF THE SPACE

AND POSSIBLE MIGRATION OF

COMBUSTION BYPRODUCTS

INCLUDING CARBON MONOXIDE INTO THE LIVING SPACE.

NOTICE

IMPROPER INSTALLATION,OR

INSTALLATION NOT MADE IN

ACCORDANCE WITH THE CSA

INTERNATIONAL (CSA) CERTIFICATION OR THESE INSTRUCTIONS,

CAN RESULT IN UNSATISFACTORY

OPERATION AND/OR DANGEROUS

CONDI-TIONS AND ARE NOT COVERED BY THE UNIT WARRANTY.

NOTICE

IN COMPLIANCE WITH RECOGNIZED CODES, IT IS RECOMMEND-

ED THAT AN AUXILIARY DRAIN PAN

BE INSTALLED UNDER ALL EVAPORATOR COILS OR UNITS CONTAINING EVAPORATOR COILS THAT ARE

LOCATED IN ANY AREA OF A

STRUCTURE WHERE DAMAGE TO

THE BUILDING OR BUILDING CON-

TENTS MAY OCCUR AS A RESULT

OF AN OVERFLOW OF THE COIL

DRAIN PAN OR A STOPPAGE IN THE

PRIMARY CONDENSATE DRAIN PIP-

ING. SEE ACCESSORIES SECTION

OF THESE INSTRUCTIONS FOR

AUXILIARY HORIZONTAL OVER-

FLOW PAN INFORMATION (MODEL

RXBM).

FIGURE 4

MIGRATION OF DANGEROUS SUBSTANCES, FUMES, AND ODORS INTO LIVING SPACES

RECEIVING

Immediately upon receipt, all cartons

and contents should be inspected for

transit damage. Units with damaged

cartons should be opened immedi-

ately. If damage is found, it should

be noted on the delivery papers, and

a damage claim filed with the last

carrier.

• After unit has been delivered to

job site, remove carton taking care

not to damage unit.

• Check the unit rating plate for unit

size, electric heat, coil, voltage,

phase, etc. to be sure equipment

matches what is required for the

job specification.

• Read the entire instructions before

starting the installation.

• Some building codes require extra

cabinet insulation and gasketing

when unit is installed in attic applications.

• If

installed in an unconditioned

space, apply caulking around the

power wires, control wires, refrigerant tubing and condensate line

where they enter the cabinet. Seal

the power wires on the inside

where they exit conduit opening.

Caulking is required to prevent air

leakage into and condensate from

forming inside the unit, control box,

and on electrical controls.

• Install the unit in such a way as to

allow necessary access to the

coil/filter rack and blower/control

compartment.

• Install the unit in a level position to

ensure proper condensate

drainage. Make sure unit is level in

both directions within 1/8”.

• Install the unit in accordance with

any local code which may apply

and the national codes. Latest edi-

tions are available from: “National

Fire Protection Association, Inc.,

Batterymarch Park, Quincy, MA

02269.” These publications are:

• ANSI/NFPA No. 70-(Latest Edition)

National Electrical Code.

• NFPA90A Installation of Air

Conditioning and Ventilating

Systems.

• NFPA90B Installation of warm air

heating and air conditioning systems.

• The equipment has been evaluat-

ed in accordance with the Code of

Federal Regulations, Chapter XX,

Part 3280.

8

Page 9

LOCATION REQUIREMENTS AND CONSIDERATIONS

GENERAL INFORMATION

!

CAUTION

DO NOT USE THIS FURNACE

DURING CONSTRUCTION IF

AIR LADEN CORROSIVE COMPOUNDS ARE PRESENT SUCH

AS CHLORINE AND FLUORINE.

OTHERWISE, PROVISIONS

MUST BE TAKEN TO PROVIDE

CLEAN, UNCONTAMINATED

COMBUSTION AND VENTILATION AIR TO THE FURNACE.

FURNACE COMBUSTION AND

VENTILATION AIR CONTAMINATED WITHTHESE COMPOUNDS FORMS ACIDS DURING COMBUSTION WHICH CORRODES THE HEAT EXCHANGER

AND COMPONENT PARTS.

SOME OF THESE CONTAMINANTS ARE FOUND IN, BUT

NOT LIMITED TO, PANELING,

DRY WALL, ADHESIVES,

PAINTS, STAINS, VARNISHES,

SEALERS, AND MASONRY

CLEANING MATERIALS.

WARNING

!

DO NOT INSTALL THIS FURNACE IN A MOBILE HOME!!

THIS FURNACE IS NOT

APPROVED FOR INSTALLATION

IN A MOBILE HOME. DOING SO

COULD CAUSE FIRE, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

WARNING

!

WHEN THIS FURNACE IS

INSTALLED IN A RESIDENTIAL

GARAGE, IT MUST BE

INSTALLED SO THE BURNERS

AND IGNITION SOURCE ARE

LOCATED NO LESS THAN 18

INCHES ABOVE THE FLOOR.

THIS IS TO REDUCE THE RISK

OF IGNITING FLAMMABLE

VAPORS WHICH MAY

BE PRESENT IN A GARAGE.

ALSO,THE FURNACE MUST BE

LOCATED OR PROTECTED TO

AVOID PHYSICAL DAMAGE BY

VEHICLES. FAILURE TO FOLLOWTHESE WARNINGS CAN

CAUSE A FIRE OR EXPLOSION,

RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH.

1. IMPORTANT: If installing the unit

over a finished ceiling or living

area, be certain to install an auxil-

iary condensate drain pan under

the entire unit. Extend this auxil-

iary drain pan under any evaporator coil installed with the furnace

and the open portion of the con-

densate drain assembly. See

“Condensate Drain/Neutralizer”

section for more details.

2. IMPORTANT: If using a cooling

evaporator coil with this furnace.

Be sure the air passes over the

heat exchanger before passing

over the cooling coil. The cooled

air passing over the warm ambient

air inside the heat exchanger

tubes can cause condensation

inside the

sion and eventual failure.

3. IMPORTANT: Install the furnace

level. If it is not level, condensate

cannot drain properly, possibly

causing furnace shut down.

NOTE: These furnaces are approved

for installation in attics, as well as

alcoves, utility rooms, closets and

crawlspaces. Make provisions to pre-

vent freezing of condensate.

4. IMPORTANT: If this furnace is

installed in a garage, attic or any

other unconditioned space, a selfregulating heat tape must be

installed around the condensate

trap and along the entire length of

the condensate drain in the unconditioned space.

The heat tape should meet the following requirements:

a. The heat tape must be UL listed.

b. Install the heat tape per the

c. The heat tape should be rated

FIGURE 5

DOWNFLOW HORIZONTAL FURNACE WITH HEAT TAPE ON CONDENSATETRAP

DRAIN

PIPE

A086701

tubes resulting in corro-

manufacturer’s instructions for

the entire length of drain pipe in

the unconditioned space.

at 3 or 5 watts per foot at 120V.

SUPPLY

AIR

HEAT

TAPE

TRAP

5. IMPORTANT: If installing in a

utility room, be sure the door is

wide enough to:

a. allow the largest part of the

furnace to pass; or

b. allow any other appliance

(such as a water heater)

to pass.

6. Install the furnace level and

plumb. If it is not level, condensate cannot drain properly, possibly causing furnace to shut

down.

IMPORTANT: Do not attempt to twin

the modulating furnace. The characteristics of the ECM blower motor

preclude twinning applications.

RETURN

AIR

9

Page 10

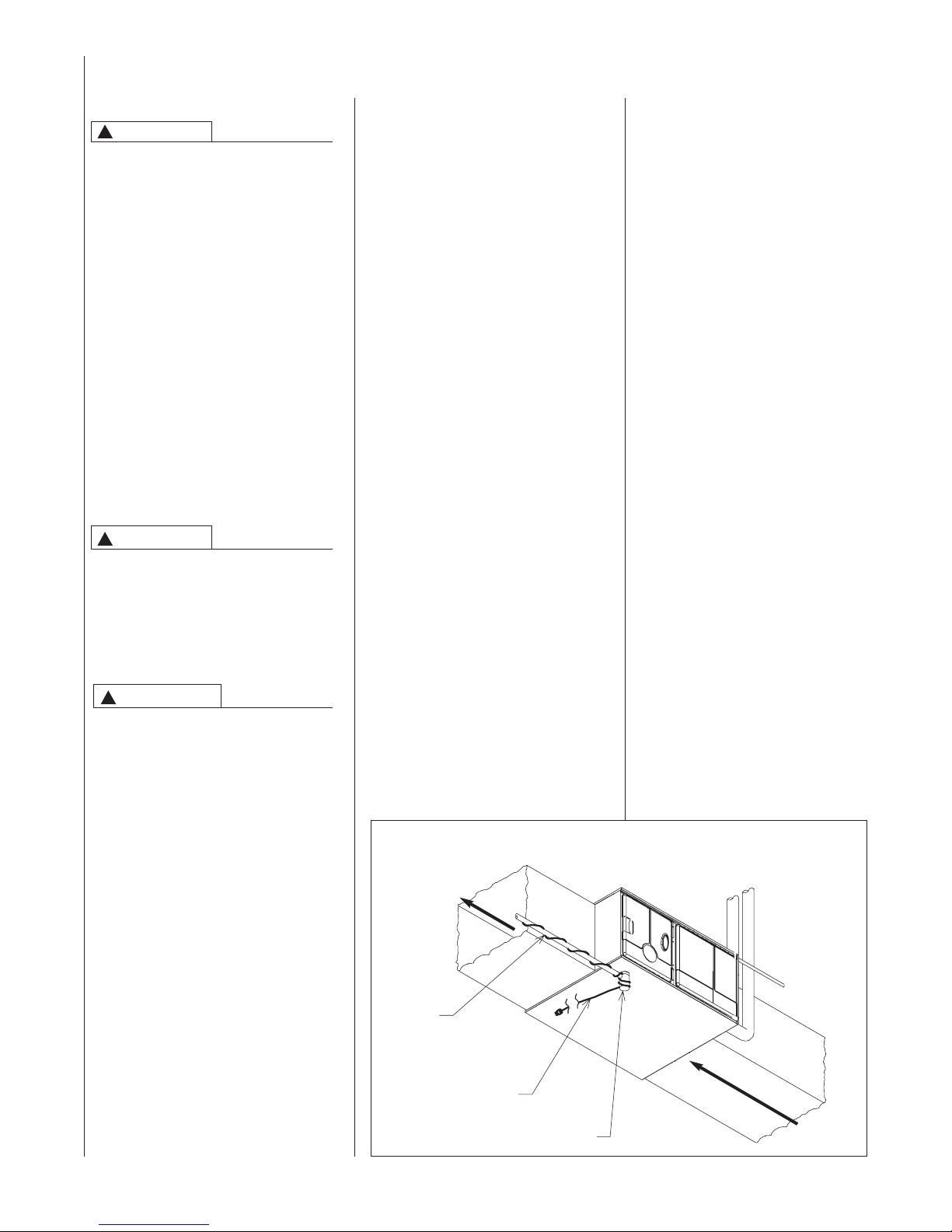

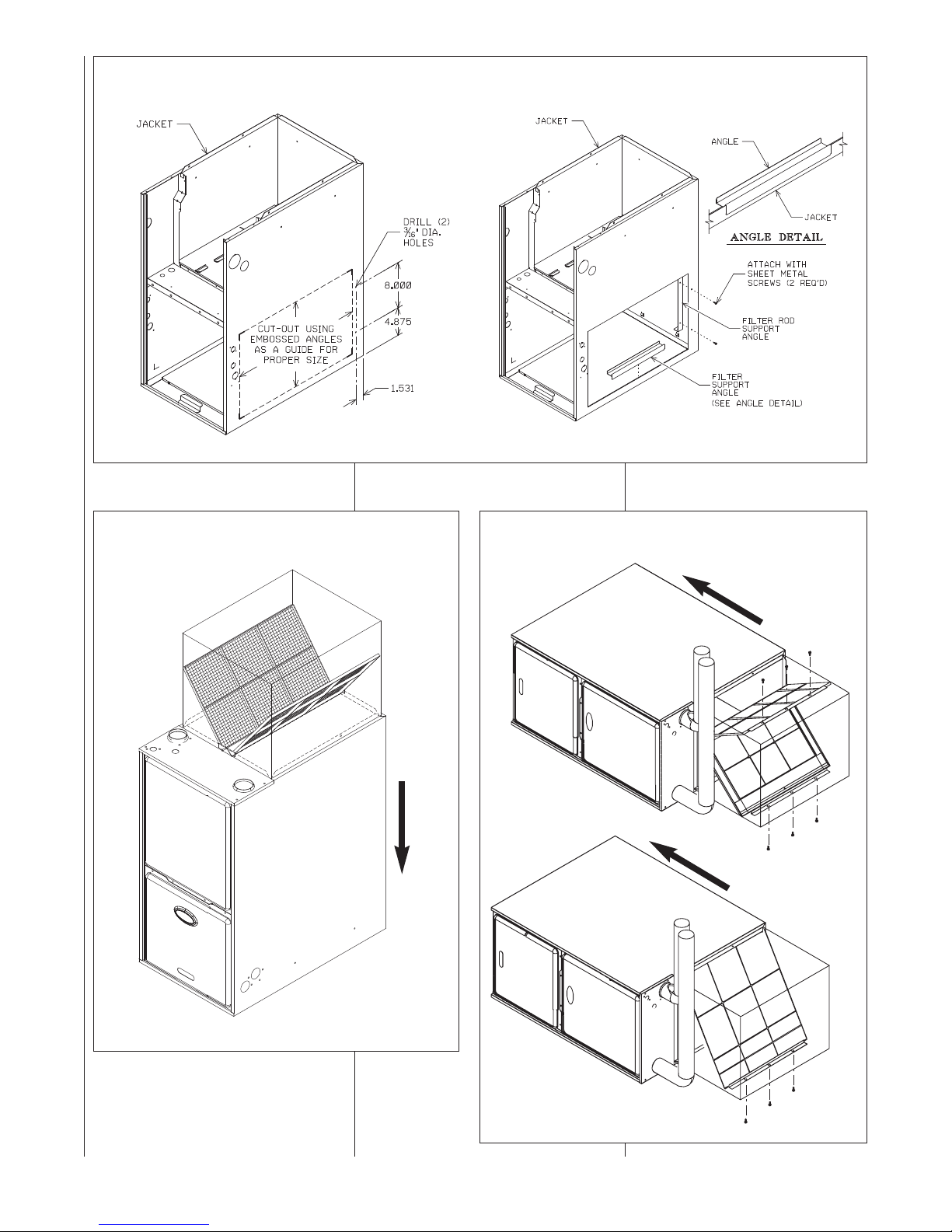

FIGURE 6

DOWNFLOW/HORIZONTAL FURNACE INSTALLED IN HORIZONTAL POSITION W/SUPPORT

BRACKETS

!

THIS FURNACE IS NOT

APPROVED OR RECOMMENDED

FOR INSTALLATION ON ITS BACK,

WITH ACCESS DOORS FACING

UPWARDS, ORWITH SUPPLY AIR

DISCHARGING TO THE RIGHT

GAS

PIPE

TRAP

CAUTION

SUPPLY

AIR

INTAKE

VENT

ELECTRICAL

CONDUIT

EXHAUST

VENT

RETURN

AIR

TH

E FOLLOWING MODELS INCLUDE

THE ADDITIONAL BRACKET (WHICH

MUST BE REMOVED) ON THE

BLOWER ASSEMBLY:

RGFE/RGGE/RGJF-09EZCMS

RGFE/RGGE/RGJF-10EZCMS

RGFE/RGGE/RGJF-12ERCMS

HAND SIDE WHEN FACING THE

FRONT OF THE FURNACE.

SEE FIGURES 6 AND 7 FOR PROPER INSTALLATION OF HORIZONTAL MODELS.

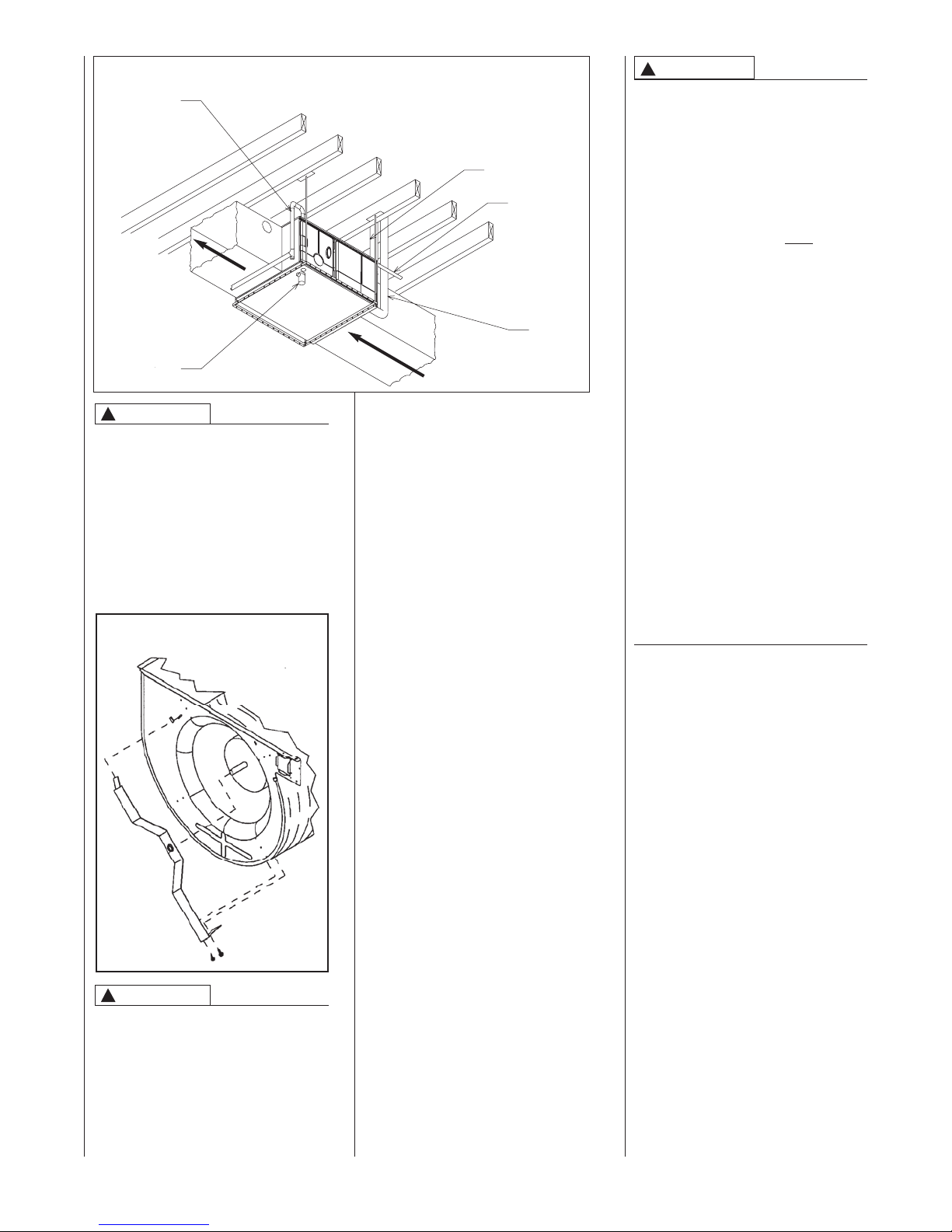

FIGURE 7

REMOVING SHIPPING BRACKET

CLEARANCE ACCESSIBILITY

The design of forced air furnaces with

models as listed in the tables under

Figures 9 and 10 are certified by CSA

Laboratories for the clearances to combustible materials shown in inches.

See name/rating plate and clearance

label for specific model number and

clearance information.

Service clearance of at least 24 inches

is recommended in front of

all furnaces.

FOR PURPOSES OF SERVICING

THIS APPLIANCE, ACCESSIBILITY

CLEARANCES, WHERE GREATER,

SHOULD TAKE PRECEDENCE OVER

FIRE PROTECTION CLEARANCES.

A086801

WARNING

!

FURNACES MUST NOT BE

INSTALLED DIRECTLY ON CARPET,

TILE OR OTHER COMBUSTIBLE

MATERIAL. INSTALLATION ON A

COMBUSTIBLE MATERIAL OTHER

THAN WOOD FLOORING MAY

RESULT IN FIRE CAUSING DAMAGE, PERSONAL INJURY OR

DEATH.

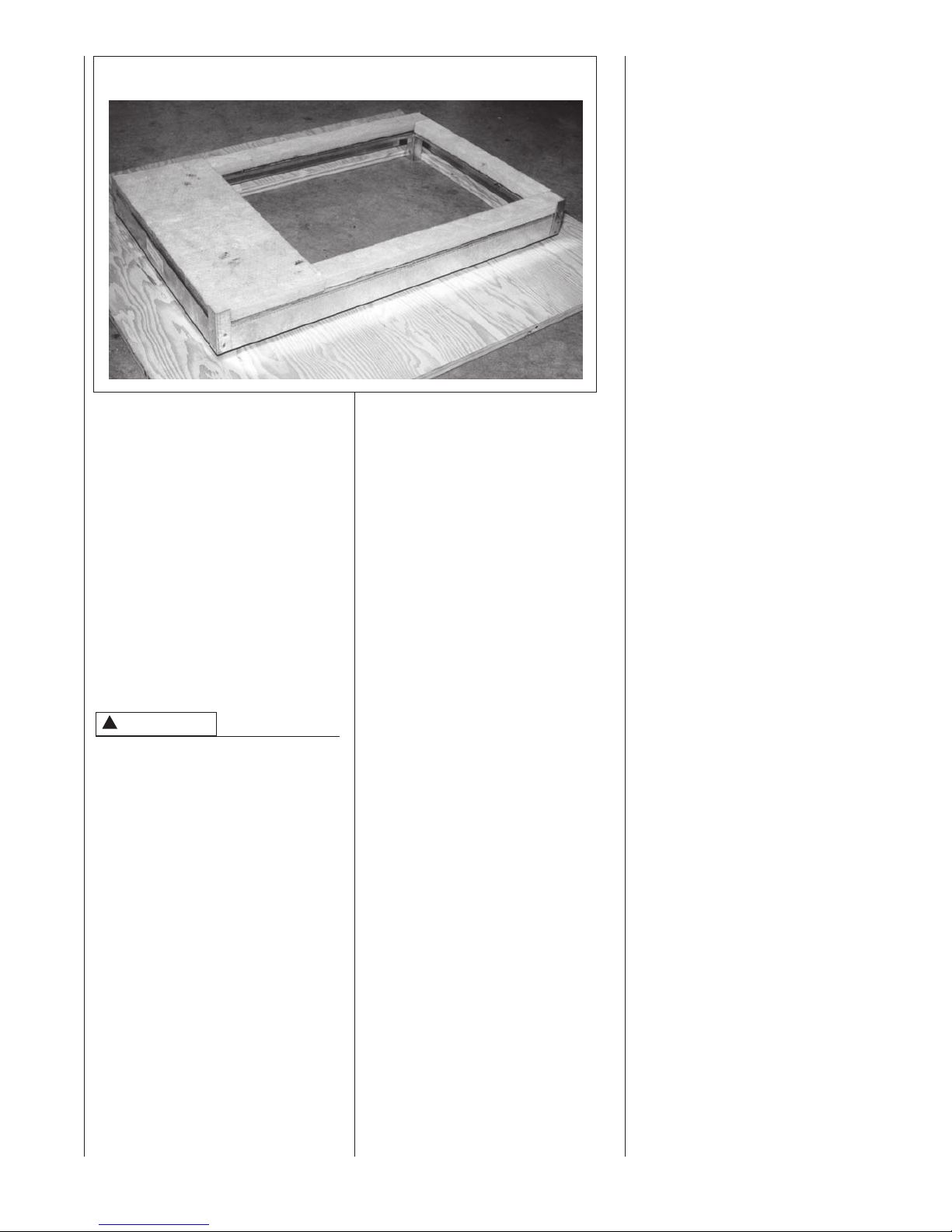

-GGE FURNACES MAY NOT

BE

INSTALLED DIRECTLYTO A COMBUSTIBLE FLOOR. A SPECIAL

FLOOR BASE IS REQUIRED.

-GFE upflow furnaces and -GGE

downflow furnaces are designed

and certified for installation on

combustible (wood only) floors.

-GGE downflow furnaces may be

installed on a cased evaporator coil

mounted on a combustible (wood

only) floor or (for installations without an evaporator coil) installed on

a special base for combustible

floors mounted to a combustible

(wood only) floor.The nece

ssary

floor base for installing a -GGE furnace in the downflow configuration

to a combustible (wood only) floor

is an accessory sold through finished goods. Following is a list of

floor base models by furnace input

size (see Figure 8).

RGGE

Furnace Special Base For

BTU’s Combustible Floors

60, 75 RXGC-B17

90, 105 RXGC-B21

120 RXGC-B24

Upflow furnaces are shipped with

a bottom closure panel installed.

When bottom return air is used,

remove the panel by removing the

two screws attaching the panel to

the front base angle. See filter section for details (see Figure 12).

92-24379-01

!

CAUTION

SOME MODELS HAVE A SHIPPING

BRACKET INSTALLED TO PROTECT THE BLOWER ASSEMBLY

DURING SHIPPING.

LOCATE AND REMOVE THE SHIPPING BRACKET FROM THE SIDE

OF THE BLOWER HOUSING

BEFORE OPERATING UNIT. SEE

FIGURE 7.

10

Page 11

FIGURE 8

BASE FOR COMBUSTIBLE FLOORS

SITE SELECTION

1. Select a site in the building near

the center of the proposed, or exist-

ing, duct system.

2. Give consideration to the vent system piping when selecting the furnace location. Vent from the furnace to the termination with minimal length and elbows.

3. Locate the furnace near the exist-

ing gas piping. If running a new gas

line, locate the furnace to minimize

the length and elbows in the gas

piping.

4. Locate the furnace to maintain

proper clearance to combu

as shown in Figures 9, 10 & 11.

stibles

!

WARNING

COMBUSTIBLE MATERIAL MUST

NOT BE PLACED ON OR AGAINST

THE FURNACE JACKET. THE AREA

AROUND THE FURNACE MUST BE

KEPT CLEAR AND FREE OF ALL

COMBUSTIBLE MATERIALS

INCLUDING GASOLINE AND OTHER

FLAMMABLE VAPORS AND LIQUIDS. PLACEMENT OF COMBUSTIBLE MATERIALS ON,

AGAINST OR AROUND THE FURNACE JACKET CAN CAUSE AN

EXPLOSION OR FIRE RESULTING IN

PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH. THE HOMEOWNER SHOULD BE CAUTIONED THAT

THE FURNACE A

USED AS A BROOM CLOSET OR

FOR ANY OTHER STORAGE PURPOSES.

REA MUST NOT BE

11

Page 12

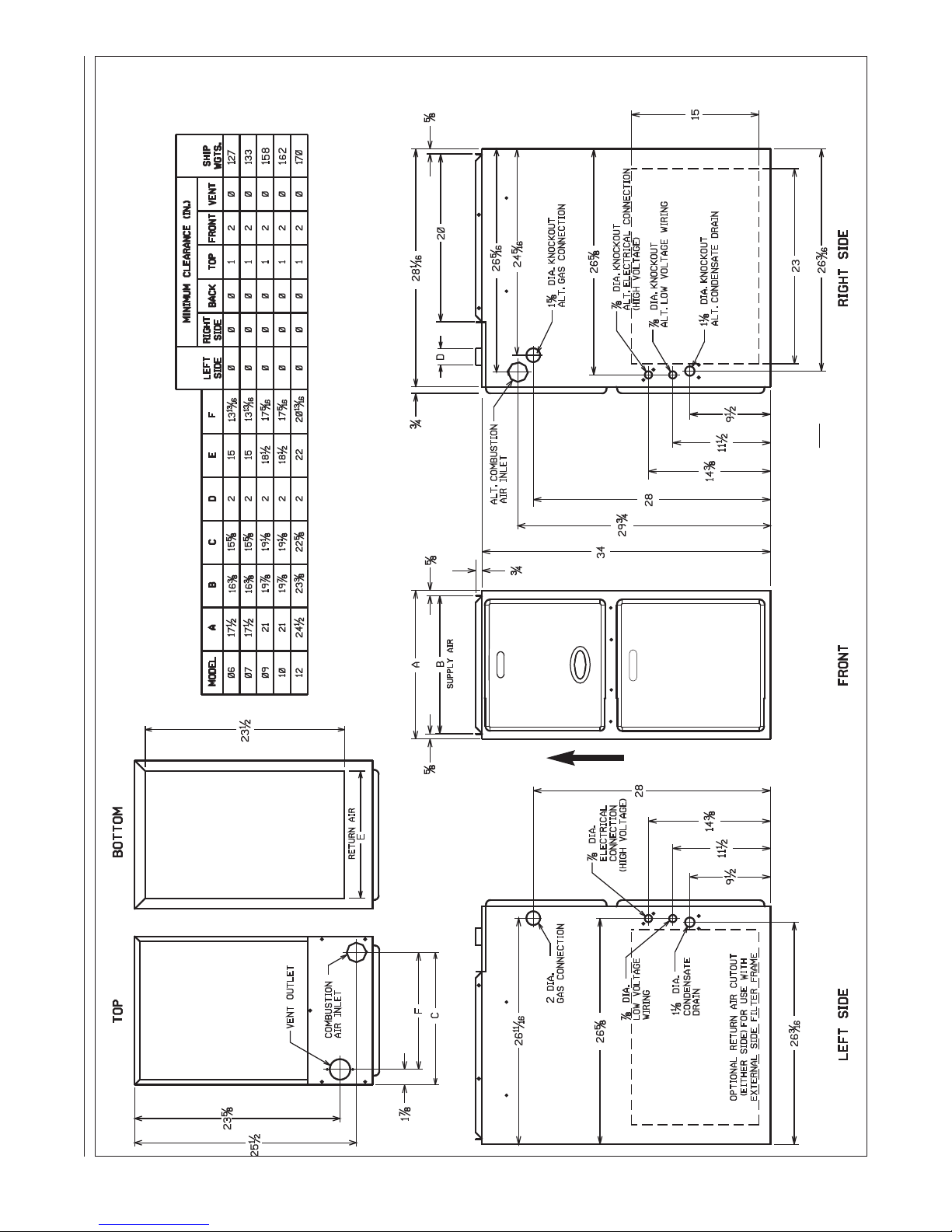

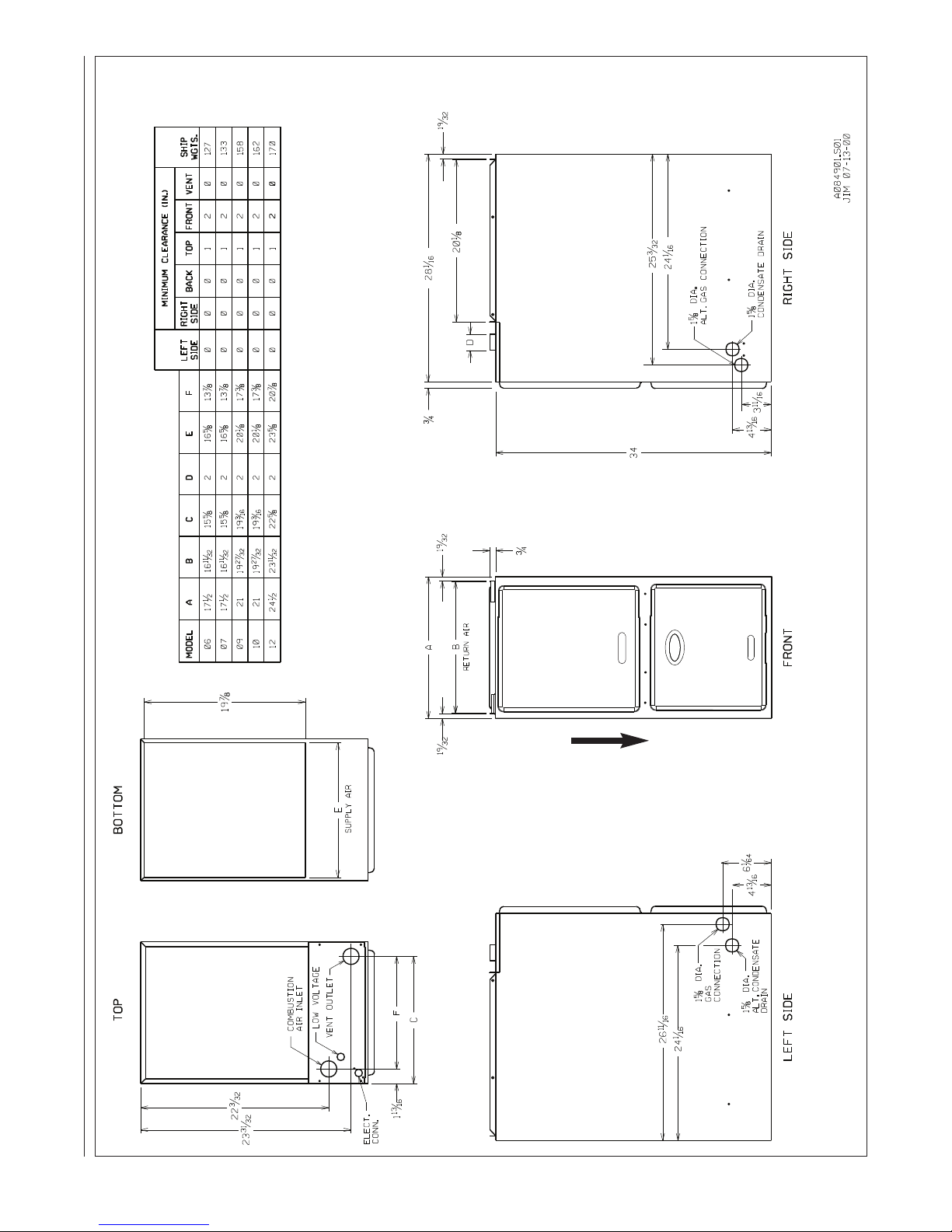

FIGURE 9

PHYSICAL DIMENSIONS AND CLEARANCE TO COMBUSTIBLES, UPFLOW MODELS

A039201

RGFE

UPFLOW MODELS

AIRFLOW

NOTE: For 1800 or more CFM, both side

returns must be used when not using a

bottom return configuration.

12

AO39201

Page 13

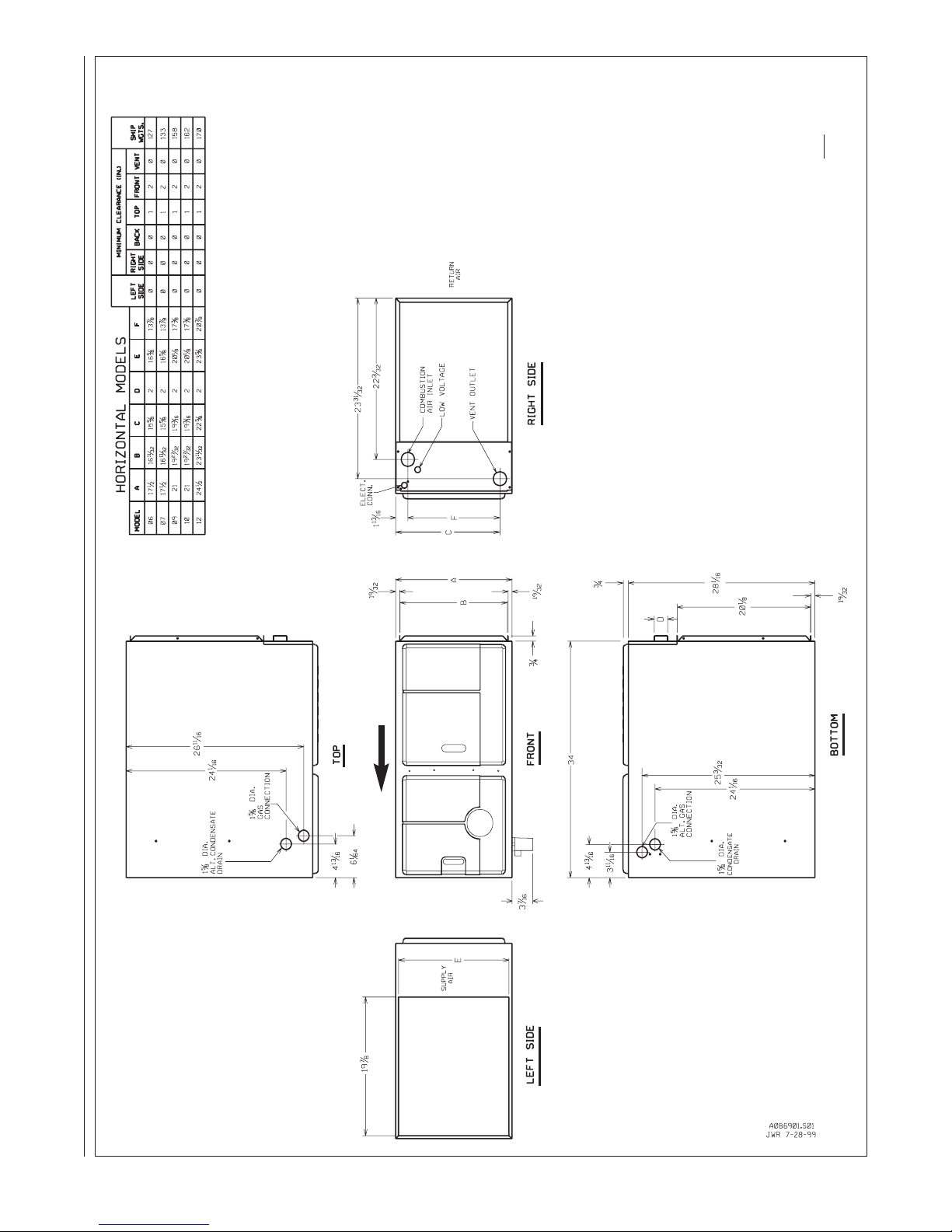

FIGURE 10

DIMENSIONS AND CLEARANCES TO COMBUSTIBLES, DOWNFLOW MODELS

RGGE

(Downflow Configuration)

FOR MODELS INSTALLED AS DOWNFLOW ONLY

AIRFLOW

13

Page 14

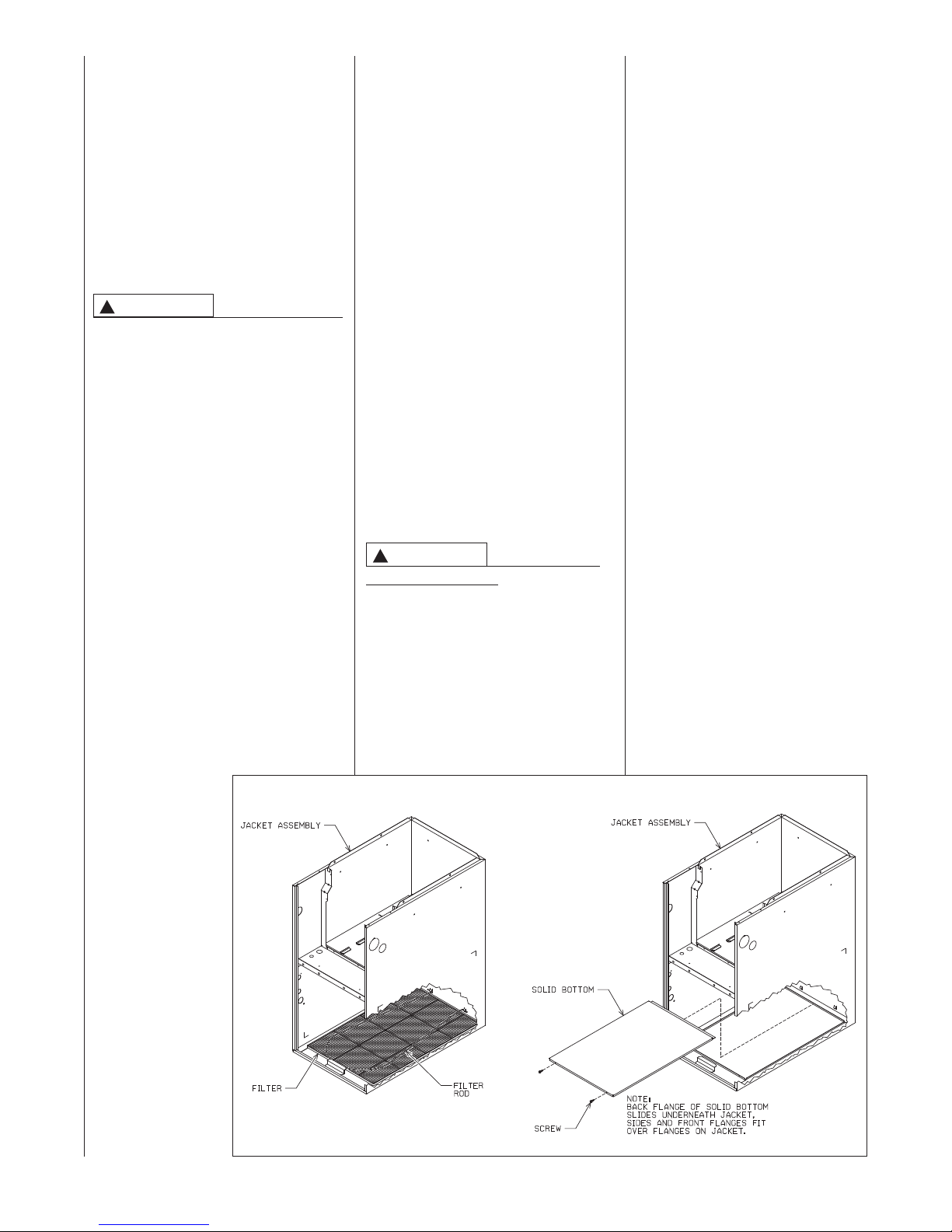

FIGURE 11

DIMENSIONS AND CLEARANCES TO COMBUSTIBLES, HORIZONTAL MODELS

NOTE: For 1800 or more CFM, both side

returns must be used when not using a

FACING THE FRONT OF THE FUR-

ONLY BE INSTALLED SO AS WHEN

IMPORTANT:THIS FURNACE MAY

NACE, SUPPLY AIR IS DIS-

CHARGED ON THE LEFT HAND

SIDE.

(RETURN)(SUPPLY)

bottom return configuration.

INSTALLED AS

configuration.)

(FUEL CODE HB ONLY)

HORIZONTAL ONLY

RGJF (ALL) & RGGE

14

on RGGE models – only

(Be sure to check the fuel code

furnaces with HB fuel codes

can be installed in horizontal

AIRFLOW

Page 15

DUCTING

Proper airflow is required for the correct

operation of this furnace.

Too little airflow can cause erratic operation and can damage the heat

exchanger. The supply and return duct

must carry the correct amount of air for

heating and cooling if summer air conditioning is used.

Size the ducts according to acceptable

industry standards and methods. The

total static pressure drop of the supply

and return duct should not exceed 0.2"

w.c.

WARNING

!

NEVER ALLOWTHE PRODUCTS

OF COMBUSTION FROMTHE

FLUE TO ENTER THE RETURN

AIR DUCTWORK ORTHE CIRCULATED AIR SUPPLY. ALL RETURN

DUCTWORK MUST BE ADEQUATELY SEALED AND

SECURED TO THE FURNACE

WITH SHEET METAL SCREWS;

AND JOINTS,TAPED. SECURE

ALL OTHER DUCT JOINTS WITH

APPROVED CONNECTIONS AND

SEAL AIRTIGHT.WHEN A FURNACE IS MOUNTED ON A PLATFORM WITH RETURN THROUGH

THE BOTTOM, IT MUST BE

SEALED AIRTIGHT BETWEEN

THE FURNACE ANDTHE RETURN

AIR PLENUM.THE FLOOR OR

PLATFORM MUST PROVIDE

PHYSICAL SUPPORT OFTHE

FURNACEWITHOUT SAGGING,

CRACKS, OR GAPS AROUND THE

BASE, PROVIDING A SEAL

BETWEEN THE SUPPORT AND

THE BASE.

FAILURE TO PREVENT PRODUCTS OF COMBUSTION FROM

BEING CIRCULATED INTOTHE

LIVING SPACE CAN CREATE

POTENTIALLY HAZARDOUS CONDITIONS, INCLUDING CARBON

MONOXIDE POISONINGTHAT

COULD RESULT IN PERSONAL

INJURY OR DEATH.

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT RETURN OR

SUPPLY DUCTWORK TO OR

FROM ANY OTHER HEAT PRODUCING DEVICE SUCH AS A

FIREPLACE INSERT, STOVE, ETC.

DOING SO MAY RESULT IN FIRE,

CARBON MONOXIDE POISONING,

EXPLOSION, PERSONAL INJURY

OR PROPERTY DAMAGE.

IMPORTANT: Some high efficiency filters

have a greater than normal resistance to

airflow. This can adversely affect furnace

operation. Be sure to check airflow if

using any filter other than the factory-provided filter.

UPFLOW UNITS

1. Position the unit to minimize long

runs of duct or runs of duct with

many turns and elbows.

WARNING

!

UPFLOW FURNACE:

BASE PLATE MUST BE INSTALLED IN

THE FURNACE BOTTOM WHEN USING

SIDE AIR RETURN. FAILURE TO

INSTALL A BASE PLATE COULD

CAUSETHE PRODUCTS OF COMBUSTION TO CIRCULATE INTOTHE LIVING

SPACE AND CREATE POTENTIALLY

HAZARDOUS CONDITIONS, INCLUDING CARBON MONOXIDE POISONING

OR DEATH.

A SOLID METAL

2. Open the return air compartment.

a. If using side return air, do not

remove the bottom base.

b. Cut an opening in the side .

The opening should be cut the

full width of the knockouts on

the

unit.

NOTE: When using side

return, return air plenums,

RXGR-C17B, C21B and C24B

are available from the factory.

c. Remove the bottom base, if

using bottom return air.

Remove the panel by removing the two screws attaching

the base to the front base

angle. See Figure 12.

NOTE: Where the maximum

airflow is 1800 CFM or more,

both sides or the bottom must

be used for return air.

3. Connect the return duct or return

air cabinet to the unit. Make the

connection air tight to prevent

entra

ining combustion gases from

an adjacent fuel-burning appli-

ance.

4. Be sure to have adequate

space for the unit filter.

NOTE: DO NOT take return air

from bathrooms, kitchens, furnace

rooms, garages, utility or laundry

rooms, or cold areas. DO NOT

use a rear air return.

5. If summer air conditioning is

desired, position the indoor coil on

the supply air side of the unit.

Insure that no air can bypass this

coil.

6. Connect the supply air plenum to

the furnace plenum opening.

IMPOR

TANT: If a flexible duct

connector must be used, it MUST

be rated for a minimum temperature of 250°F. continuous.

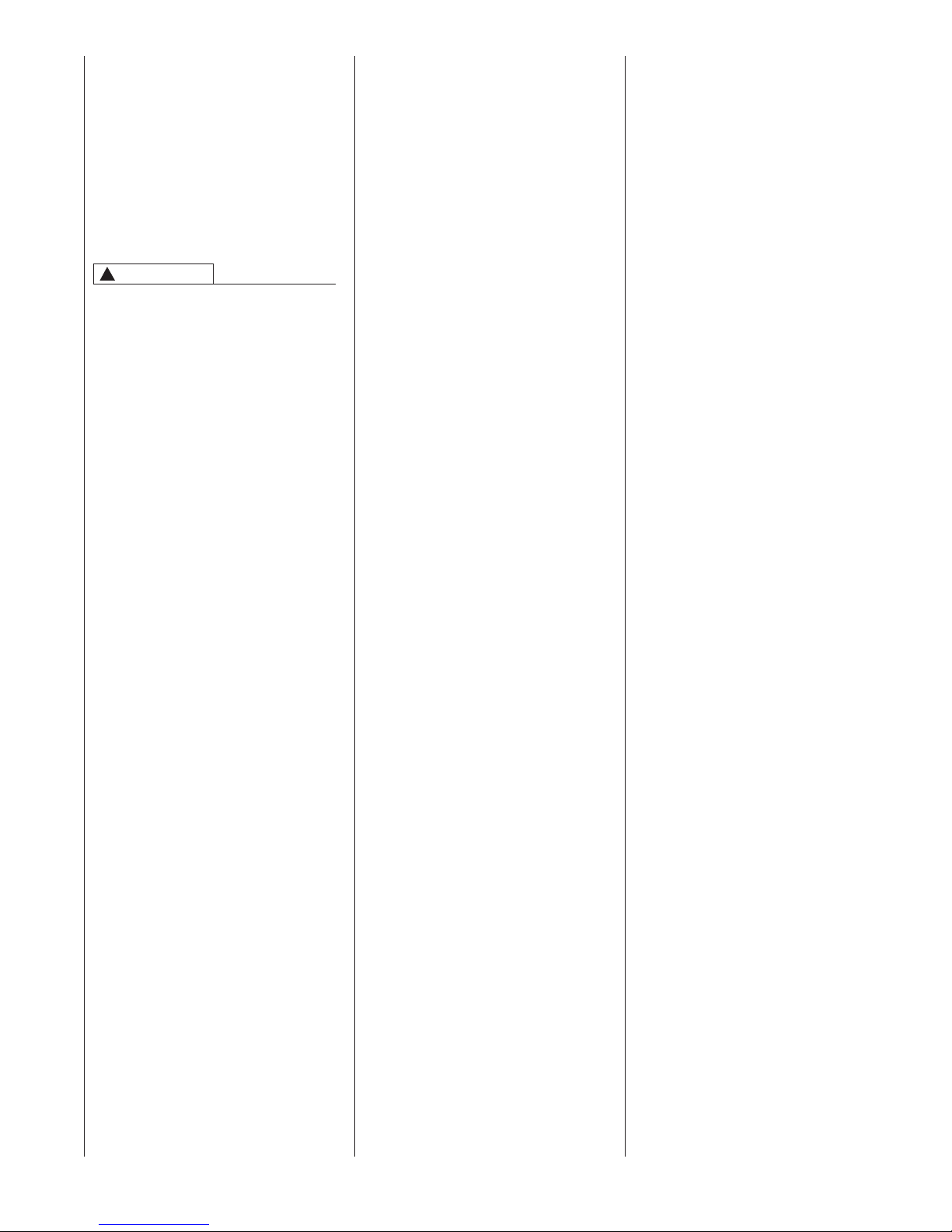

FIGURE 12

BOTTOM PANEL REMOVAL

NOTE: FILTERAND FILTER-ROD ARE SHIPPED

ON TOP OF SOLID BOTTOM. REMOVE FILTER

AND FILTER ROD TO ACCES SOLID BOTTOM

ADS-5422-01

15

Page 16

DOWNFLOW UNITS

1. Position the unit to minimize long

runs of duct or runs of duct with

many turns and elbows.

2. If summer air conditioning is desired,

position the indoor coil on the supply

air side of the unit. Insure that no air

can bypass this coil.

3. If installing on a combustible floor

and not using an air conditioning

plenum, install the special base for

combustible floors. See Figure 8.

!

WARNING

THE DOWNFLOW FURNACE DESIGN

IS CERTIFIED FOR INSTALLATION

ON A NON-COMBUSTIBLE FLOOR

USE THE SPECIAL BASE SPECIFIED

ON THE FURNACE CLEARANCE

LABEL. FAILURE TO INSTALLTHE

SPECIAL BASE MAY RESULT IN

FIRE, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.THIS

SPECIAL BASE IS SHIPPED FROM

THE FACTORY AS AN ACCESSORY.

4. Connect the furnace to the supply

air plenum.

5. Connect the return air ducting to

the return air opening at the top of

the unit. Make the connection air

tight to prevent entraining combus-

tion gases from an adjacent fuel-

burning appliance.

6. Be sur

eto have adequate space

for the unit filter.

NOTE: DO NOT take return air

from bathrooms, kitchens, furnace

rooms, garages, utility or laundry

rooms, or cold areas.

.

Return air can come from : (1) outside the building, (2) from return air

ducting from several inside rooms, or (3)

a combination of the two. When using

outside air, design and adjust the sys-

tem to maintain a return air temperature

above 55°F during the heating season.

If return air comes from both inside and

outside the building, design the ducting

system with a diverting damper so that

the volume of return air entering the furnace equals that which would normally

enter thr

furnace. Any duct opening pulling return

air from the outside must not be any

higher nor closer than 10 feet to the fur-

nace exhaust vent.

ough the return air intake of the

16

Page 17

SUPPLY AIR SENSOR

Each furnace comes shipped from the

factory with a supply air sensor. Install

the sensor, in the supply air plenum

trunk, with two, field supplied, #8 sheet

metal screws, using the following guidelines:

1. 12” downstream of the evaporator

coil, if installed.

2. If no evaporator coil is used, locate

the sensor out of direct line-of-site

of the heat exchanger and not closer than 18” downstream of the furnace outlet.

3. Attach the supply air sensor wires

onto the terminals marked “SA

Sensor” on the integrated furnace

control board (See Figure 13).

4. Do not extend the supply-air sensor

wire.

NOTE: Improper placement of the

supply air sensor can adversely

affect furnace temperature rise.

NOTE: In downflow circumstances

where building construction does not

allow for the placement of the sensor to

fall within these parameters, the supply

air sensor should not be connected.

This means that the furnace will run

under default parameters. When running under default parameters, the “82”

code will appear for 90 seconds. After

that, the fault code will be stored in the

control board’s memory and will show

only upon power cycling. Default airflow

parameters can be manually adjusted.

See section discussing Integrated

Furnace Control (IFC) board in this

manual.

For communicating systems, the

supply air se

off so that a fault code will not be

displayed at all. This can be done in

the furnace setup menu of a communicating thermostat. See the section

of this manual titled Communicating

Systems under sub-section titled

Furnace User Menus (Setup).

nsor input can be turned

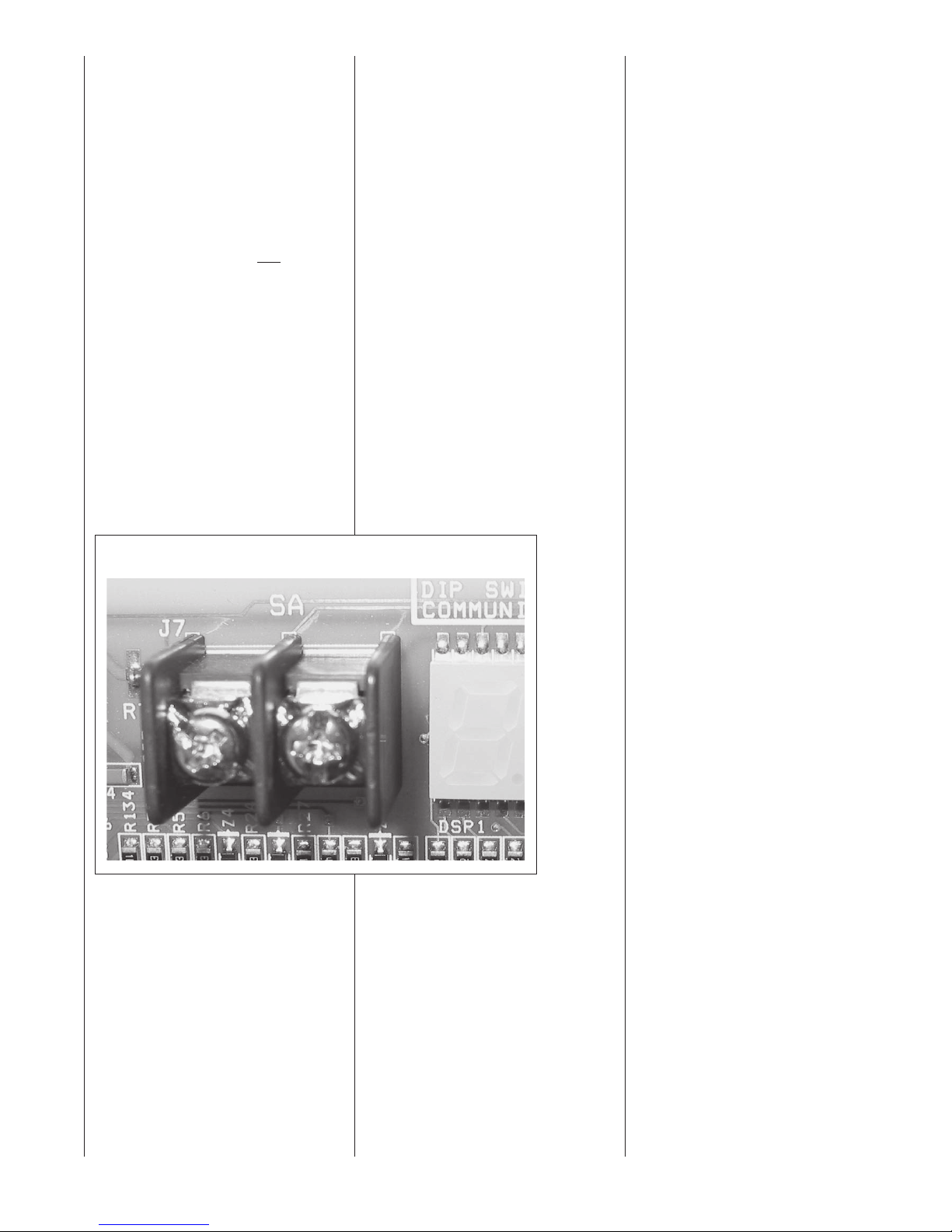

FIGURE 13

SUPPLY AIR SENSOR TERMINALS

17

Page 18

VENTING AND COMBUSTION AIR PIPING

GENERAL INFORMATION

WARNING

!

READ AND FOLLOW ALL

INSTRUCTIONS IN THIS SECTION. FAILURETO PROPERLY

VENT THIS FURNACE OR PROTECT IT FROM INADEQUATE

COMBUSTION AIR CAN CAUSE

CARBON MONOXIDE POISONING, AN EXPLOSION OR FIRE,

RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH.

OVERTEMPERATURE

SAFETY SWITCHES

Furnaces are equipped with safety

switches in the burner compartment to

protect against over temperature conditions. If a switch is tripped, it must be

manually reset.

WARNING

!

DO NOT JUMPER OVERTEMPERATURE OR ANY OTHER

SAFETY SWITCHES! IF ONE OF

THESE OVER TEMPERATURE

SWITCHES SHOULD TRIP, CALL

A QUALIFIED INSTALLER, SERVICE AGENCY OR THE GAS

SUPPLIER. DO NOT RESET THE

SWITCHES WITHOUTTAKING

CORRECTIVE ACTION. FAILURE

TO DO SO CAN RESULT IN CARBON MONOXIDE POISONING OR

DEATH. IF THIS UNIT IS

INSTALLED IN A CLOSET, THE

DOOR MUST BE CLOSEDWHEN

MAKING THIS CHECK.

REPLACETHE OVER TEMPERATURE SAFETY SWITCHES ONLY

WITH THE IDENTICAL REPLACEMENT PART.

WARNING

!

IN CANADA, PRODUCTS CERTIFIED FOR INSTALLATION AND

INTENDED TO BE VENTEDWITH

PLASTIC VENT SYSTEMS (PVC,

CPVC) MUST USE VENT SYSTEMS THAT ARE CERTIFIED TO

THE STANDARD FOR TYPE BH

GAS VENTING SYSTEMS, ULC

S636.

THE COMPONENTS OF THE

CERTIFIED MATERIAL MUST

NOT BE INTERCHANGED WITH

OTHER VENT SYSTEMS OR

UNLISTED PIPE/FITTINGS.

PLASTIC COMPONENTS AND

SPECIFIED PRIMERS AND

GLUES OF THE CERTIFIED SYSTEM MUST BE FROM A SINGLE

SYSTEM MANUFACTURER AND

NOT INTERMIXED WITH OTHER

SYSTEM MANUFACTURER’S

PARTS.

NOTE: INLET AIR PIPING IS NOT

CONSIDERED TO BE A PART OF

THE “VENTING SYSTEM”.THE

REQUIREMENT THATVENT MATERIAL BE CERTIFIED TO ULC S636

DOES NOT APPLY TO INLET AIR

PIPING.

INSTALLATION WITH

PRE-EXISTING VENT

SYSTEMS

When the installation of this furnace

replaces an existing furnace that is

removed from a vent system serving

other appliances (such as a water

heater), the existing vent system is likely

to be too large to proper

remaining attached appliances.

Follow the steps below with each appliance remaining connected to the original common vent system. Place the

appliance to be tested in operation,

while the other appliances remaining

connected to the common vent system

are not in operation. Test the operation

of each appliance individually by the following method.

1. Permanently seal any unused

openings in the common venting

system.

2. Visually inspect the venting system

f

or proper size and horizontal pitch

and determine that there is no

blockage, restriction, leakage, corrosion or other deficiencies which

could cause an unsafe condition.

3. If practical, close all building doors,

windows and all doors between the

space where the appliances

remaining connected to the common venting system are located.

Turn on clothes dryers and any

appliance not connected to the

ly vent the

common venting system. Turn

on any exhaust fans, such as

range hoods and ba

exhausts, so they will operate at

maximum speed. Do not operate

a summer exhaust fan. Close

fireplace dampers.

4. Follow the lighting instructions.

Place the appliance being

inspected into operation. Adjust

the thermostat so the appliance

will operate continuously.

5. Test for spillage at the draft hood

relief opening after 5 minutes of

main burner operation. Use the

flame of a match or candle, or

smoke from a cigarette, cigar

or pipe.

6. After it has been determined

each appliance that remains connected to the common venting

system properly vents (when

tested as outlined above), return

doors, windows, exhaust fans,

fireplace dampers and any other

gas-burning appliance to their

previous conditions of use.

7. If improper venting is observed

during any of the above tests,

resize the common venting sys-

tem. Refer to latest edition of the

National Fuel Gas Code ANSI

Z223.1, or the CSA-GAMA venting tables for Category I furnaces

.

NOTE: For U.S. installations

only. Schedule 40 ABS-DWV

pipe and fittings may be used as

an alternate to PVC pipe for the

combustion air inlet and vent

pipes.

NOTE: For U.S. installations

only. Cellular core PVC is also

approved for use. It must be

schedule 40 PVC-DWV cellular

pipe manufactured under ASTM

F-891.

throom

that

18

Page 19

JOINING PIPE AND

FITTINGS

WARNING

!

PVC SOLVENT CEMENTS AND

PRIMERS ARE HIGHLY FLAMMABLE. PROVIDE ADEQUATE

VENTILATION AND DO NOT

ASSEMBLE COMPONENTS

NEAR HEAT SOURCE OR AN

OPEN FLAME. DO NOT

SMOKE. AVOID SKIN OR EYE

CONTACT. OBSERVE ALL CAUTIONS AND WARNINGS PRINTED ON MATERIAL CONTAINERS. FAILURETO FOLLOW

THESE GUIDELINES MAY

RESULT IN FIRE, EXPLOSION

OR ASPHYXIATION CAUSING

PERSONAL INJURY OR DEATH.

All pipe, fittings, solvent cement,

primers and procedures must conform

to American National Standard

Institute and American Society for

Testing and Materials (ANSI/ASTM)

standards as shown below:

IMPORTANT: The plastic combustion

air and venting components are MADE

of PVC. If using ABS piping, ensure that

the solvent cement is compatible for

joining PVC to ABS components or use

a mechanical connection that can withstand the vent temperatures and is corrosion resistant.

CEMENTING JOINTS

Properly seal all joints in the PVC vent

using the following materials and procedures:

PVC CLEANER-PRIMER AND

PVC MEDIUM-BODY SOLVENT

CEMENT

IMPORTANT: After cutting pipe, remove

all ragged edges and burrs. This is

important to prevent increase in pressure drop throughout the system.

1. Cut pipe end square. Chamfer edge

of pipe. Clean fitting socket and

pipe joint area of all dirt, grease and

moisture.

2. After checking pipe and socket for

proper fit, wipe socket

cleaner-primer. Apply

a liberal coat of primer to inside surface of socket and outside of pipe.

READ INSTRUCTIONS INCLUDED

WITH THE PRIMER FOR PROPER

INSTALLATION.

and pipe with

3. Apply a thin coat of cement

evenly in the socket. Quickly

apply a heavy coat of cement to

the pipe end and insert pipe into

fitting with a slight twisting movement until it bottoms out.

NOTE: Cement must be fluid; if

not, recoat.

4. Hold the pipe in the fitting for 30

seconds to prevent the tapered

socket from pushing the pipe out

of the fitting.

5. Wipe all excess cement from the

joint with a rag. Allow 15 minutes

before handling. Cure time varies

according to fit, temperature and

humidity.

NOTE: Stir the solvent cement

frequently while using. Use a

natural bristle, one inch wide

brush or the applicator supplied

with the can.

IMPORTANT: For Proper Installation

DO NOT use solvent cement that has

become curdled, lumpy or thickened.

DO NOT thin. Observe shelf precautions printed on containers. For application below 32°F, use only low-temperature-type solvent cement.

For correct installation of the vent

pipe, follow the instructions provided

by the manufacturers of the pipe,

primer and solvent.

PIPE & FITTING MATERIAL

Schedule 40 PVC (Pipe) D1785

Schedule 40 PVC (Cellular Core Pipe) F891

Schedule 40 PVC (Fittings) D2466

SDR-21PVC (Pipe) D2241

SDR-26 PVC (Pipe) D2241

Schedule 40 ABS Cellular Core DWV (Pipe) F628

Schedule 40 ABS (Pipe) D1527

Schedule 40 ABS (Fittings) D2468

ABS-DWV (Drain Waste & Vent)

(Pipe & Fittings)

PVC-DWV (Drain Waste & Vent)

(Pipe & Fittings)

ASTM

SPECIFICATION

D2661

D2665

19

Page 20

NON-DIRECT VENT PIPE INSTALLATION

(FOR VERTICALTERMINATIONS ONLY)

COMBUSTION AIR

WARNING

!

ALWAYS PROVIDE THIS FURNACE AND ANY OTHER FUEL

BURNING APPLIANCE WITH

ENOUGH FRESH AIR FOR

PROPER COMBUSTION AND

VENTILATION OF THE FLUE

GASES. MOST BUILDING

CODES REQUIRE THAT OUTSIDE AIR BE SUPPLIED INTO

THE FURNACE AREA. FAILURE TO DO SO CAN CAUSE

DEATH FROM CARBON

MONOXIDE POISONING.

Provide adequate facilities for combustion and ventilation air in accordance with section 5.3, Air for

Combustion and Ventilation of the

National Fuel Gas Code, ANS

Z223.1 - latest edition; CAN/CGA

B149.1 and .2, or applicable provisions of the local building codes.

These combustion and ventilation

facilities must not be obstructed.

IMPORTANT: Air for combustion and

ventilation must not come from a

corrosive atmosphere. Any furnace

failure due to corrosive elements in

the atmosphere is excluded from

warranty coverage.

I

The following types of installation (but

not limited to the following) REQUIRE

OUTDOOR AIR for combustion, d

to chemical exposures:

• Commercial buildings

• Buildings with indoor pools

• Furnaces installed in laundry

rooms

• Furnaces in hobby or craft rooms

• Furnaces installed near chemical

storage areas.

Exposure to the following substances

in the combustion air supply (but not

limited to the following) also

REQUIRE OUTDOOR AIR for combustion:

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine-based swimming pool

chemicals

• Water softening chemica

• De-icing salts or chemicals

• Carbon Tetrachloride

• Halogen type refrigerants

• Cleaning solvents (such as per-

chloroethylene)

• Printing inks, paint removers,

varnishes, etc.

• Hydrochloric acid

• Cements and glues

• Anti-static fabric softeners for

clothes dryers

• Masonry acid washing materials

Combustion air must be free of acid

forming chemicals such as sulphur,

fluorine, and chlorine. These elements are found in aerosol sprays,

detergents, bleaches, cl

vents, air fresheners, paint and varnish removers, refrigerants and many

other commercial and household

products. Vapors from these products

when burned in a gas flame form acid

compounds. The acid compounds

increase the dew point temperature

of the flue products and produce

highly corrosive condensate.

eaning sol-

ue

ls

WARNING

!

ALL FURNACE INSTALLATIONS

MUST COMPLY WITHTHE

NATIONAL FUEL GAS CODE AND

LOCAL CODES TO PROVIDE ADEQUATE COMBUSTION AND VENTILATION AIR FOR THE FURNACE.

FAILURE TO DO SO CAN RESULT

IN EXPLOSION, FIRE, PROPERTY

DAMAGE, CARBON MONOXIDE

POISONING, PERSONAL INJURY

OR DEATH.

Combustion air requirements are

determined by whether the furnace

is in an open (unconfined) area or in

a confined space such as a closet or

small room.

FURNACE LOCA

UNCONFINED SPACE

Using indoor air for combustion.

An unconfined space must have at

least 50 cubic feet for each 1,000

BTUH of the total input for all

appliances in the space. Here are a

few examples of the room sizes

required for different inputs. The

sizes are based on 8 foot ceilings.

See Table 1.

TABLE 1

UNCONFINED SPACE DIMENSIONS

BTUH Minimum Sq. Feet Typical Room Size

Input With 8 foot Ceiling

60,000 375 15' x 25' OR 19' x 20'

75,000 469 15' x 32' OR 20' x 24'

90,000 563 20' x 28' OR 24' x 24'

105,000 657 20' x 33' OR 26' x 25'

120,000 750 25' x 30' OR 24' x 32'

If the open space containing the furnace is in a building constructed to

severely limit outside air infiltration

(contemporary energy efficient construction methods), o

still be required for the furnace to

operate and vent properly. Outside

air openings should be sized the

same as for a confined space.

TED IN AN

utside air may

20

Page 21

FURNACE LOCATED IN A

CONFINED SPACE.

A confined space (any space smaller than shown before as “unconfined”) must have openings into

the space, which are located in

accordance with the requirements set forth in the following

subsections A and B. The open-

ings must be sized by how they

connect to the heated area or to the

outside, and by the input of all

appliances in the space.

If the confined space is within a

building with tight construction,

combustion air must be taken fro

m

outdoors or areas freely communicating with the outdoors.

TABLE 2

INDOOR AIR OPENING DIMENSIONS

BTUH Free Area

Input Each Opening

60,000 100 square inches

75,000 100 square inches

90,000 100 square inches

105,000 105 square inches

120,000 120 square inches

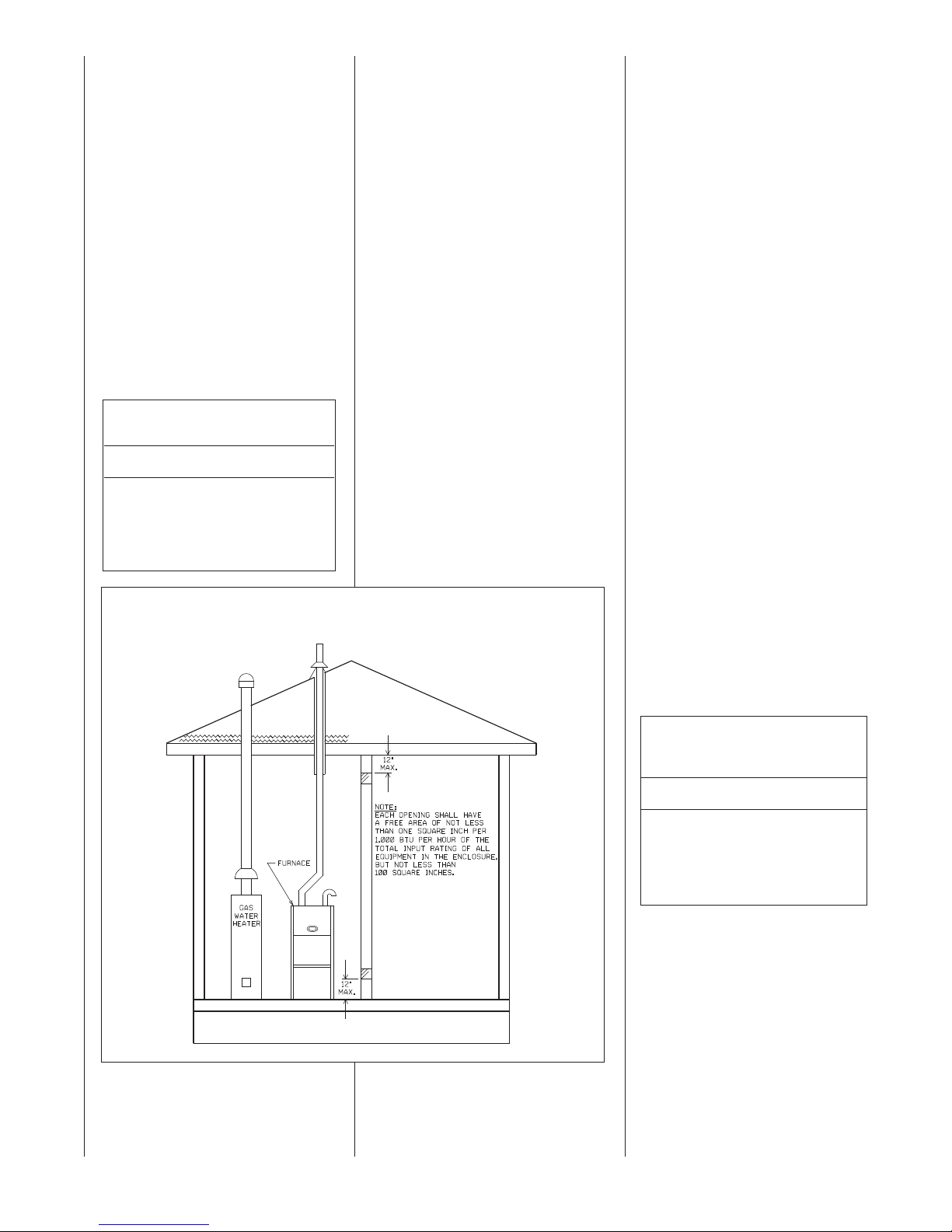

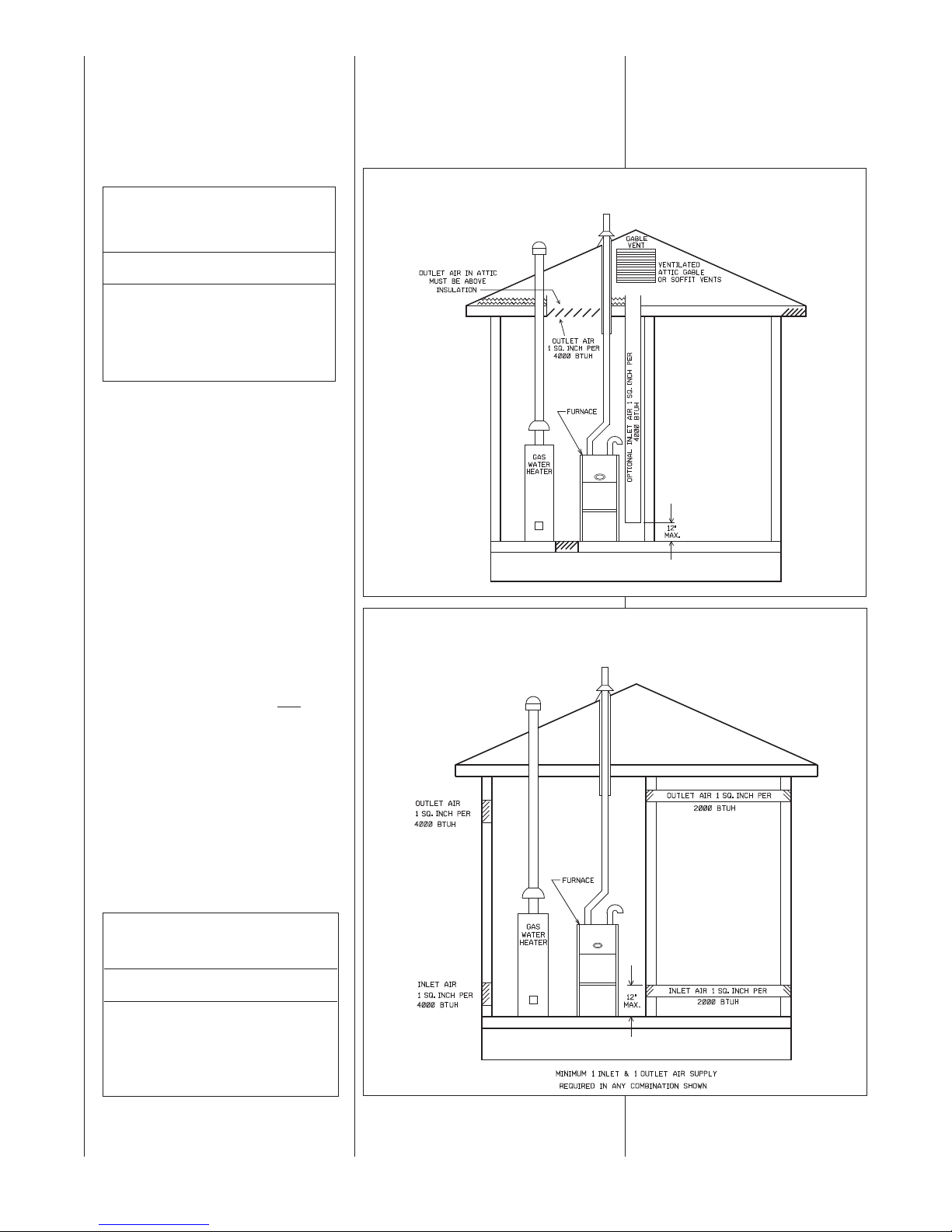

FIGURE 14

AIR FROM HEATED SPACE

A. USING INDOOR AIR FOR

COMBUSTION

IMPORTANT: DO NOT take air from

a heated space with a fireplace,

exhaust fan or other device that may

produce a negative pressure.

If combustion air is taken from the

heated area (see Figure 14), the

openings must each have at least

100 square inches of free area.

Each opening must have at least

one square inch of free area for

each 1,000 BTUH of total input in

the space. See Table 2.

B. USING OUTDOOR AIR FOR

COMBUSTION

IMPORTANT: Do not take air from

an attic space that is equipped with

power ventilation.

The confined space must communicate with the outdoors in accordance

with Methods 1 or 2. The minimum

dimension of air openings shall not

be less than 3 inches. Where ducts

are used, they shall be of the same

cross-sectional area as the free area

of the openings to which they connect.

Method 1

Two permanent openings, one locat-

ed within 12 inches of the top and

one located within 12 inches of the

bottom of the enclosure, shall be pro-

vided. The openings shall communi-

cate directly, or by ducts, with the out-

doors or spaces (crawl or attic) that

freely communicate with the out-

doors.

a. Where directly communicating

with the outdoors or where communicating to the outdoors

through vertical ducts as shown in

Figure 15, each opening shall

have a minimum free area of 1

square inch for each 4000 BTUH

of total appliance input rating in

the enclosure. See Table 3.

A077501

TABLE 3

VERTICAL OUTDOOR AIR OPENING

DIMENSIONS

BTUH Free Area Round Pipe

Input Each Opening Size

60,000 15.00 square inches 5"

75,000 18.75 square inches 5"

90,000 22.50 square inches 6"

105,000 26.25 square inches 6"

120,000 30.00 square inches 7"

21

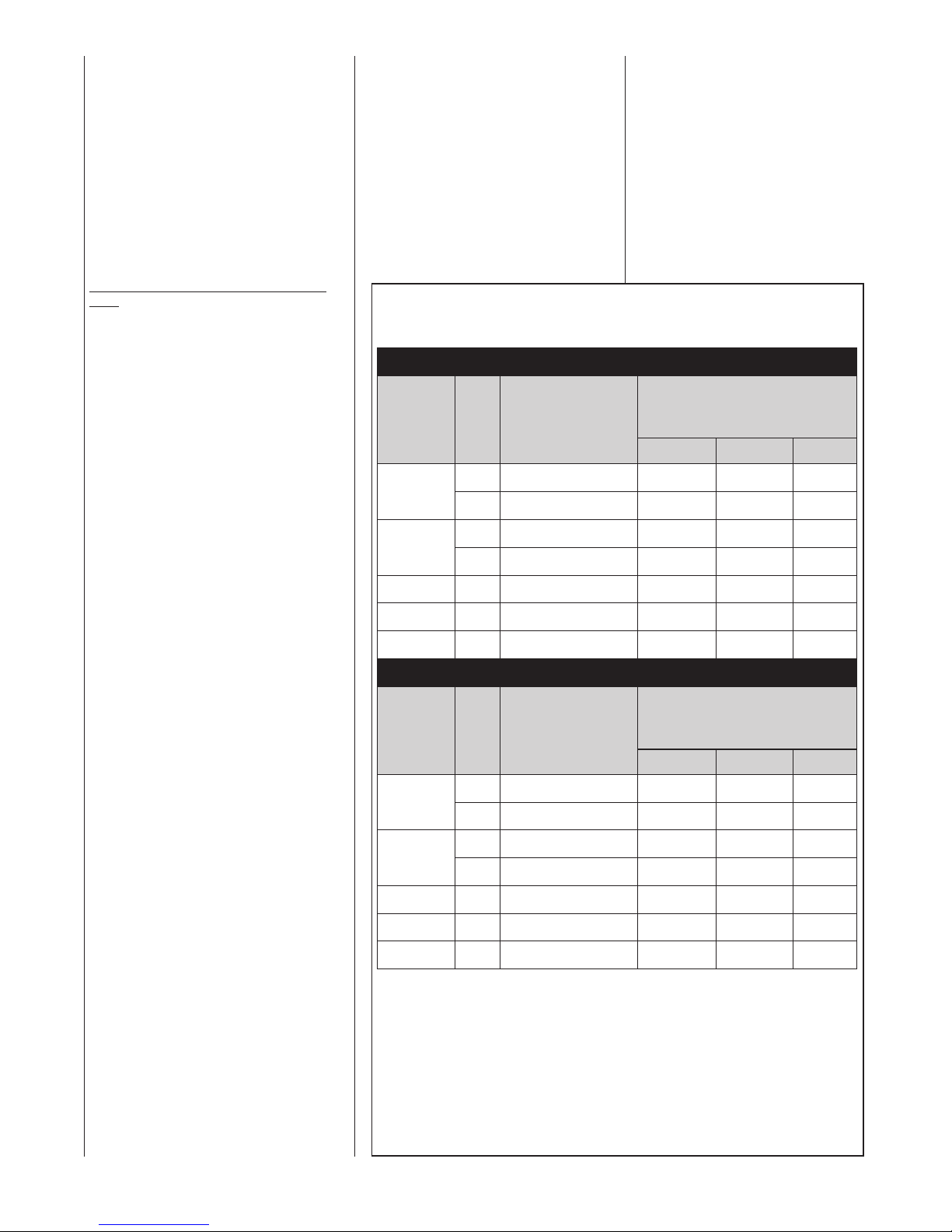

Page 22

b. Where communicating with out-

doors through horizontal ducts,

each opening shall have a minimum

free area of 1 square inch for each

2000 BTUH of total input rating of

all equipment in the enclosure. See

Table 4 and Figure 16.

TABLE 4

HORIZONTAL OUTDOOR AIR

OPENING DIMENSIONS

BTUH Free Area Round Pipe

Input Each Opening Size

60,000 30.00 square inches 7"

75,000 37.50 square inches 7"

90,000 45.00 square inches 8"

105,000 52.50 square inches 9"

120,000 60.00 square inches 9"

Method 2

One permanent opening, located

within 12 inches of the top of the

enclosure, shall be permitted where

the equipment has clearances of at

least 1 inch from the sides and back

and 6 inches from the front of the

appliance. The opening shall directly

communicate with the outdoors or

communicate through a vertical or

horizontal duct to the outdoors or

spaces (crawl or attic) that freely

communicate with the outdoors, and

shall have a minimum free area of:

a. One square inch for each 3000

BTUH of the total input rating of

all equipment located in the

enclosure (see Table 5), and

Combustion air openings must not be

restricted in any manner.

CONSULT LOCAL CODES FOR SPECIAL REQUIREMENTS.

FIGURE 15

AIR FROM ATTIC/CRAWL SPACE

A077601

FIGURE 16

OUTSIDE AIR USING A HORIZONTAL INLET & OUTLET

b. Not less than the sum of the

areas of all vent connectors in the

confined space.

If the unit is installed where there is

an exhaust fan, sufficient ventilation

must be provided to prevent the

exhaust fan from creating a negative

pressure.

TABLE 5

VERTICAL OR HORIZONTAL

OUTDOOR AIR OPENING DIMENSIONS

BTUH Free Area Round Pipe

Input Each Opening Size

60,000 20.00 square inches 6"

75,000 25.00 square inches 6"

90,000 30.00 square inches 7"

105,000 35.00 square inches 7"

120,000 40.00 square inches 8"

22

A077701

Page 23

INSTALLATION GUIDELINES

IMPORTANT: When installed as a non-

direct furnace, only vertical terminations

are allowed. Do not use horizontal termi-

nations when the furnace is installed with

a non-direct vent.

All exhaust vent piping must be installed

in compliance with Part 7, Venting of

Equipment, of the latest edition of the

National Fuel Gas Code NFPA 54/ANSI

A223.1, or CAN/CGA-B149.1 and .2,

local codes or ordinances and these

instructions.

7. The minimum vent length is 5 feet.

8. All piping through the roof is 2".

When using 3" pipe, reduce to

2" within 18" of the inside of the

roof.

9. Vertical through-the-roof installations do not require any special

vent termination. Use 2" PVC

pipe extending a minimum of 12

inches above the anticipated

level of snow accumulation.

10. Elbows must be a mini

mum of

15” apart.

11. No screens may be used to

cover combustion air or

exhaust.

VENTING GUIDELINES - Non-

Direct

Vent

1. IMPORTANT: Do not common vent

with any other appliance. Do not

install in the same chase or chimney with a metal or high temperature plastic pipe from another gas or

fuel-burning appliance unless the

required minimum clearances to