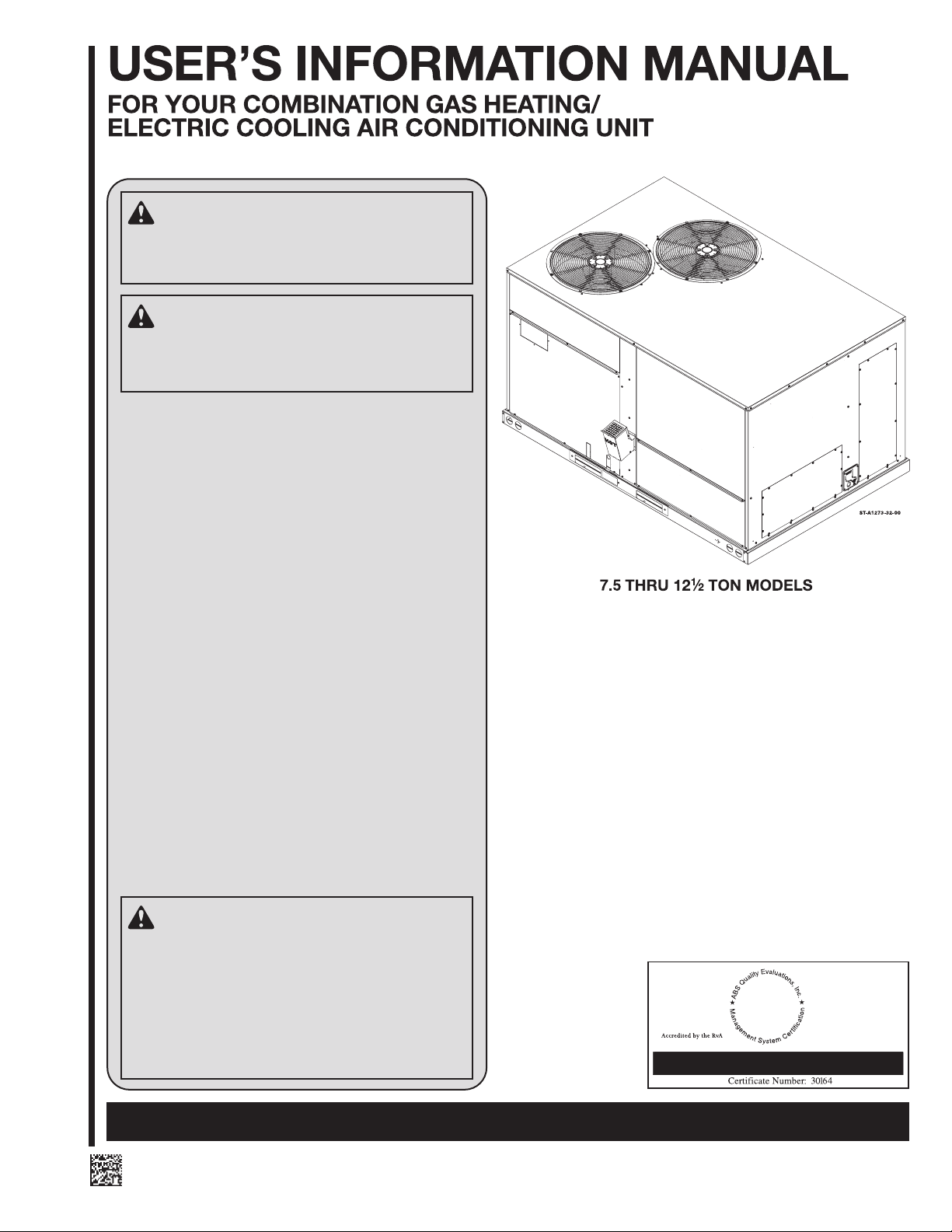

Page 1

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result, causing property damage, personal injury or loss of life.

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result

in serious injury, death or property damage.

— Do not store or use gasoline or other flammable

vapors and liquids, or other combustible materials in

the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

• Do not return to your home until authorized by the

gas supplier or fire department.

— DO NOT RELY ON SMELL ALONE TO DETECT LEAKS.

DUE TO VARIOUS FACTORS, YOU MAY NOT BE ABLE

TO SMELL FUEL GASES.

• U.L. and/or C.S.A. recogniz

bon monoxide) detectors are recommended in all

applications, and their installation should be in accordance with the manufacturer’s recommendations and/or local laws, rules, regulations, or

customs.

— Improper installation, adjustment, alteration, service

or maintenance can cause injury, property damage or

death. Refer to this manual. Installation and service

must be performed b

agency or the gas supplier. In the commonwealth of

Massachusetts, installation must be performed by a licensed plumber or gas filter for appropriate fuel.

building.

ed fuel gas and CO (car-

y a qualified installer, service

WARNING

PROPOSITION 65: THIS FURNACE CONTAINS

FIBERGLASS INSULATION. RESPIRABLE PARTICLES OF FIBERGLASS ARE KNOWN TO THE

STATE OF CALIFORNIA TO CAUSE CANCER. EXHAUST GAS FROM THIS FURNACE CONTAINS

CHEMICALS, INCLUDING CARBON MONOXIDE,

KNOWN TO THE STATE OF CALIFOR NIA TO

CAUSE BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

DO NOT DESTROY. PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE.

SUPERSEDES 92-106167-01-00

ISO 9001:2015

92-106167-01-01

Page 2

IMPROPER INSTALLA TION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, PERSONAL INJURY

OR DEATH. FOR ASSISTANCE OR

ADDITIONAL INFORMATION CONSULT A QUALIFIED INSTALLER,

SERVICE AGENCY OR THE GAS

SUPPLIER.

Should the gas supply fail to shut

8.

off or if overheating occurs, shut

off the gas valve to the furnace

before shutting off the electrical

supply.

DUCT LEAKS CAN CREATE AN UNBALANCED SYSTEM AND DRAW POLLUTANTS SUCH AS DIRT, DUST, FUMES

AND ODORS INTO THE HOME CAUSING

PROPERTY DAMAGE. FUMES AND

ODORS FROM TOXIC, VOLATILE OR

FLAMMABLE CHEMICALS, AS WELL AS

AUTOMOBILE EXHAUST AND CARBON

MONOXIDE (CO), CAN BE DRAWN INTO

THE LIVING SPACE THROUGH LEAKING

DUCTS AND UNBALANCED DUCT

SYSTEMS CAUSING PERSONAL INJURY

OR DEATH.

IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN SPACES

CONTAINING FUEL BURNING APPLIANCES SUCH AS WATER HEATERS OR

BOILERS, ALL JOINTS, SEAMS, AND

OPENINGS IN THE EQUIPMENT AND

DUCT MUST ALSO BE SEALED TO

PREVENT DEPRESSURIZATION OF THE

SPACE AND POSSIBLE MIGRATION OF

COMBUSTION BYPRODUCTS INCLUDING CARBON MONOXIDE INTO THE

LIVING SPACE.

Page 3

NOTICE

IMPROPER INSTALLATION, OR

INSTALLATION NOT MADE IN ACCORDANCE WITH THE CSA INTERNATIONAL (CSA) CERTIFICATION OR THESE

INSTRUCTIONS, CAN RESULT IN

UNSATISFACTORY OPERATION

AND/OR DANGEROUS CONDITIONS

AND ARE NOT COVERED BY THE

UNIT WARRANTY.

IMPORTANT INFORMATION

ABOUT EFFICIENCY AND

INDOOR AIR QUALITY

Central cooling and heating equipment is

only as efficient as the duct system that

carries the cooled or heated air. To

maintain efficiency, comfort and good

indoor air quality, it is important to have

the proper balance between the air

being supplied to each room and the air

returning to the cooling and heating

equipment.

Proper balance and sealing of the duct

system improves the efficiency of the

heating and air conditioning system and

improves the indoor air quality of the

occupied space by reducing the amount

of airborne pollutants that enter

occuplied spaces from spaces where the

ductwork and / or equipment is located.

The manufacturer and the U.S. Environ-

mental Protection Agency’s Energy Star

Program recommend that central duct

systems be checked by a qualified

contractor for proper balance and

sealing.

NOTE: The time delays vary depending

on how the wires are connected.

a preselected time of

a preselected time.

a preselected time to extract

CARBON MONOXIDE (CO) IS A COLORLESS, ODORLESS, POISONOUS GAS

THAT CAN CAUSE SEVERE PERSONAL

INJURY OR DEATH. CARBON MONOXIDE CAN BE PRODUCED BY ANY

FUEL-BURNING DEVICE.

CARBON MONOXIDE FROM ANY FUEL

BURNING DEVICES CAN BE INADVERTENTLY DRAWN INTO AND DISTRIBUTED THROUGH THE LIVING SPACE BY

THE NORMAL OPERATION OF THE

CENTRAL HEATING / AIR CONDITIONING SYSTEM.

APPLIANCES AND FUEL BURNING

DEVICES MUST BE INSTALLED, OPERATED AND MAINT AINED IN ACCOR-

DANCE WITH THE MANUFACTURER’S

INSTRUCTIONS.

EVEN WITH DOORS AND WINDOWS OR

VENTS OPEN, CARBON MONOXIDE

CAN BUILD UP AND SEEP INTO THE

LIVING SPACE THROUGH CRACKS

AND OPENINGS IN THE STRUCTURE.

TOXIC FUMES, INCLUDING CARBON

MONOXIDE, CAN ALSO BE DRAWN

INTO THE LIVING SPACE THROUGH

OPENINGS AND SEAMS IN THE

CENTRAL HEATING AND AIR CONDITIONING EQUIPMENT AND / OR

DUCTWORK.

FOR THESE REASONS, THE U.S.

CONSUMER PRODUCT SAFETY COMMISSION (CPSC) RECOMMENDS THAT

EVERY HOME HAVE AT LEAST ONE

CARBON MONOXIDE ALARM

INSTALLED IN THE HALLWAY NEAR

THE BEDROOMS IN EACH SEPARATE

SLEEPING AREA OF THE HOME.

CARBON MONOXIDE ALARMS SHOULD

BE CERTIFIED TO THE REQUIREMENTS

OF THE MOST RECENT UL, IAS OR CSA

STANDARD, AND SHOULD BE

INSTALLED, OPERATED AND MAINTAINED IN ACCORDANCE WITH THE

ALARM MANUFACTURER’S INSTRUCTIONS.

Page 4

WHITE RODGERS 36H54-473

TWO STAGE GAS VALVE

Used on (-)GED Models with Fuel Code: 3A, 3B, 3C

Use only your hand to move the gas

control switch. Never use tools. If the

switch will not move by hand, don’t

try to repair it; call a qualified service

technician. Force or attempted repair

may result in a fire or explosion.

HONEYWELL VR8305Q

TWO STAGE GAS VALVE

ST-A1273-36-00

Used on (-)GED Models with Fuel Code: 3D, 3E, 3F

Page 5

NORMAL FURNACE

OPERATING SEQUENCE

This unit is equipped with a two stage

integrated direct spark ignition control.

NORMAL HEAT MODE

A. Call For First Stage (low fire) Only:

1. Zone thermostat contacts close, a call

for first stage (low fire) heat is initiated.

2. Control runs self check.

3. Control checks the high-limit switch

for normally closed contacts, the

pressure switch for normally open

contacts, and all flame rollout

switches for continuity.

4. Control energizes the inducer.

5. Control checks the low-fire pressure

switch for closure.

6. If the pressure switch is closed, the

control starts a 30 second prepurge.

If the pressure switch is still open

after 180 seconds, the inducer will be

energized until closure.

7. After prepurge timeout, control

initiates spark for 2 seconds

minimum, 7 second maximum ignition

trial, initiates 45 second, second

stage (high fire) warm up timing.

8. Control detects flame, de-energizes

spark and initiates 45 s econd delay

on blower timing.

9. After a fixed 45 s econds indoor

blower delay on, t

the indoor blower.

10. After the 45 second s econd stage

warmup period control checks

thermostat input. If only W1 is called

for, W2 is de-energized.

11. Control enters normal operating loop

where all inputs are continuously

checked.

B. Call For Second Stage, After First

Stage Established; Starting from A.11:

1. If a call for second stage (high fire) is

initiated after a call f or f irst stage heat

is established, the control assures the

pressure switch is closed and

energizes the second stage of the

gas valve.

2. Control enters normal operating loop

where all inputs are continuously

checked.

C. Second Stage Satisfied; First Stage

Still Called For; Starting From B.2:

1. Once the call for second stage is

satisfied, the control reduces the gas

valve to first stage.

2. Control enters normal operating loop

where all inputs are continuously

checked.

D. First Stage Satisfied:

1. Zone thermostat is satisfied.

2. Control de-energizes gas valve.

3. Control senses loss of flame.

4. Control initiates 5 second inducer

postpurge and 90 second indoor

blower delay off.

5. Control de-energizes inducer blower.

6. Control de-energizes indoor blower.

7. Control in the stand by mode with

solid red LED.

he control energizes

E. First Stage and Second Stage Called

Simultaneously:

1. Zone thermostat contacts close, a call

for first stage (low fire) and second

stage (high fire) heat is initiated.

2. Control runs self check.

3. Control checks the limit switch for

normally closed contacts, the switch

for normally open contacts, and t he

flame rollout switch for continuity.

4. Control energizes the inducer.

5. Control checks the pressure switch for

closure.

6. If the pressure switch is closed, the

control starts a 30 second prepurge. If

the switch is still open after 180

seconds, the inducer will be energized

until closure.

7. After prepurge timeout, control

initiates spark for 2 seconds minimum,

7 second maximum ignition trial, and

initiates 45 second s econd stage

warm up timing.

8. Control detects flame, de-energizes

spark and starts a 45 second indoor

blower delay on timing.

9. After a fixed 45 s econds indoor blower

delay on

indoor blower.

10. After the 45 seconds second stage

warmup period control checks the

thermostat input. If W1 and W2 is

present control enters normal

operating loop where all inputs are

continuously checked.

F. First Stage and Second Stage

Removed Simultaneously:

1. Upon a loss of W1 and W2 the gas

valve is de-energized.

2. Upon a loss of flame, the inducer will

complete a 5 s econd postpurge and

the indoor blower will complete a 90

second delay off.

3. Control in the stand by mode with

solid red LED.

The integrated control is a four-ignition

system.

After a total of four cycles without sensing

main burner flame, the system goes into a

100% lockout mode. After one hour, the

ignition control repeats the prepurge and

ignition cycles for 4 tries and then go into

100% lockout mode again. It continues

this sequence of cycles and lockout each

hour until ignition is successful or power is

interrupted. During the lockout mode,

neither the ignitor or gas valve will be

energized until the system is reset by

turning the thermostat to the “OFF”

position or interrupting t he electrical power

to the

induced draft blower and main burner will

shut off when t he t hermostat is satisfied.

The circulating air blower will start and run

on the heating speed if the thermostat fan

switch is in the “ON” position.

, the control energizes the

unit for 3 seconds or longer. The

All integrated furnace c ontrols come

standard with a 7 s egment diagnostic

display. During standby mode with no f ault

codes present, the display will read “0”

(zero). During normal thermostat heating,

cooling or continuous fan operations a letter

will be displayed to describe t he mode of

operation outlined in the “Installation and

Operating Manual” normal operation codes.

OPERATING INSTRUCTIONS

This appliance is equipped with integrated

furnace control. This device lights the main

burners each time the room thermostat

(closes) calls for heat. See operating

instructions on the back of the

furnace/controls access panel.

!

WARNING

DO NOT ATTEMPT TO MANUALLY

LIGHT THIS FURNACE WITH A MATCH

OR ANY OPEN FLAME. ATTEMPTING

TO DO SO CAN CAUSE AN EXPLOSION

OR FIRE RESULTING IN PROPERTY

DAMAGE, PERSONAL INJURY OR

DEATH.

TO START THE FURNACE

1. Set the thermostat to its lowest setting.

2. Turn off all electric power to the

applianc

3. This appliance does not have a pilot. It

is equipped with an ignition device

which automatically lights the burner.

Do not

4. Remove control door.

5. Move control switch/knob on the gas

valve to the “OFF” position.

6. Wait five (5) minutes to clear out any

gas. Then smell for gas, including

near the floor. If you smell gas, STOP!

Follow B in the safety information on

the Operating Instructions located on

the back of the controls/access panel.

If you don’t smell gas, go to the next

step.

7. Move the gas control switch/knob on

the gas valve from “OFF” position to

“ON” position. Operate this appliance

with the gas control switch/knob on the

gas valve in the “ON” position only.

8. Replace the control door.

9. Turn on all electric power to the

appliance.

10. Set the thermostat to the desired

setting.

11. If the appliance will not operate, follow

the instructions below on how to shut

down the furnace.

e.

try to light the burner by hand.

5

Page 6

!

WARNING

THE SPARK IGNITOR AND IGNITION

LEAD FROM THE IGNITION

CONTROL ARE HIGH VOLTAGE.

KEEP HANDS OR TOOLS AWAY TO

PREVENT ELECTRICAL SHOCK.

SHUT OFF ELECTRICAL POWER

BEFORE SERVICING ANY OF THE

CONTROLS. FAILURE TO ADHERE

TO THIS WARNING CAN RESULT IN

PERSONAL INJURY OR DEATH.

The initial start-up on a new installation

may require the control system to be

energized for some time until air has

bled through the system and fuel gas is

available at the burners.

TO SHUT DOWN FURNACE

1. Set the thermostat to the lowest

setting.

2. Turn off all electric power to the

appliance if service is to be

performed.

3. Remove control door.

4. Move control switch/knob on the

gas valve to the “OFF” position.

5. Replace control door.

!

WARNING

SHOULD OVERHEATING OCCUR OR

THE GAS SUPPLY FAIL TO SHUT OFF,

SHUT OFF THE MANUAL GAS VALVE

TO THE APPLIANCE BEFORE

SHUTTING OFF THE ELECTRICAL

SUPPLY. FAILURE TO DO SO CAN

RESULT IN AN EXPLOSION OR FIRE

CAUSING PROPERTY DAMAGE,

SEVERE PERSONAL INJURY OR

DEATH!

BURNERS

Burners for these units have been

designed so that field adjustment is not

required. Burners are tray-mounted and

accessible for easy cleaning when

required.

MANUAL RESET

OVERTEMPERATURE

CONTROL

Two manual reset overtemperature

controls are located on the burner shield.

These devices senses blockage in the

heat exchanger or insufficient combustion

air. This shuts off the main burners if

excessive temperatures occur in the

burner compartment.

Operation of this control indicates an

abnormal condition. Therefore, the unit

should be examined by a qualified

installer, service agency, or the gas

supplier before being placed back into

operation.

!

WARNING

DO NOT ATTEMPT TO DEFEAT THIS

IMPORTANT SAFETY DEVICE. DO NOT

RESET THE OVERTEMPERATURE

CONTROL WITHOUT TAKING

CORRECTIVE ACTION TO ASSURE

THAT AN ADEQUATE SUPPLY OF

COMBUSTION AIR IS MAINTAINED

UNDER ALL CONDITIONS OF OPERATION

AND THAT NO HEAT EXCHANGER TUBES

ARE BLOCKE

REPLACE THIS CONTROL ONLY WITH

THE IDENTICAL REPLACEMENT PART.

FAILURE TO ADHERE TO THIS WARNING

CAN RESULT IN PERSONAL INJURY

OR DEATH.

D OR PERFORATED.

PRESSURE SWITCH

This furnace has two pressure switches for

sensing a blocked exhaust or a failed

induced draft blower. They are normally

open and close when the induced draft

blower starts, indicating air flow through t he

combustion chamber.

LIMIT CONTROL

The supply air high temperature limit cut-off

is set at the factory and cannot be adjusted.

It is calibrated to prevent the air

temperature leaving the furnace from

exceeding the maximum outlet air

temperature.

!

WARNING

DO NOT JUMPER THIS DEVICE! DOING

SO CAN CAUSE A FIRE OR EXPLOSION

RESULTING IN PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

IMPORTANT: Replace this control only

with the identical replacement part.

6

Page 7

Page 8

CAN RESULT IN BODILY INJURY,

SEVERE ELECTRICAL SHOCK, OR

DEATH.

Filter quantity: 4

Filter size: 2” × 20” × 20”

CM 1217

Loading...

Loading...