Rheem Residential Solar Water Heater with Heat Exchanger, Residential Solar Heat Exchang Use & Care Manual

Residential Solar Water Heater with Heat Exchanger

USE & CARE MANUAL

WITH INSTALLATION INSTRUCTIONS FOR THE CONTRACTOR

The purpose of this manual is twofold: one, for the installing

contractor, to provide requirements and recommendations

for the proper installation and adjustment of the water

heater; and two, for the owner-operator, to explain the

features, operation, safety precautions, maintenance and

trouble shooting of the water heater. This manual also

includes a parts list.

It is imperative that all persons who are expected to install,

operate or adjust this water heater read the instructions

carefully so that they may understand how to do so.

ALTERNATE-ENERGY WATER-STORAGE TANK

52L6

Do Not Destroy this Manual. Please read carefully

!

and keep in a safe place for Future Reference.

CALIFORNIA PROPOSITION 65 WARNING: This product contains chemicals known to the State of California to cause

!

cancer, birth defects or other reproductive harm.

Printed in USA

Recognize this symbol as an Indication of Important

!

Safety Information!

AP12816-4 (06/11)

!

!

!

General Safety Precautions

Be sure to read and understand the entire Use & Care Manual before attempting to install

or operate this water heater.

low these warnings could result in serious bodily injury or death. Should you have problems understanding the instructions in this manual, or have any

questions, STOP, and get help from a qualified installer, service technician, or the local electric utility.

It may save you time and cost. Pay particular attention to the General Safety Precautions. Failure to fol-

DANGER!

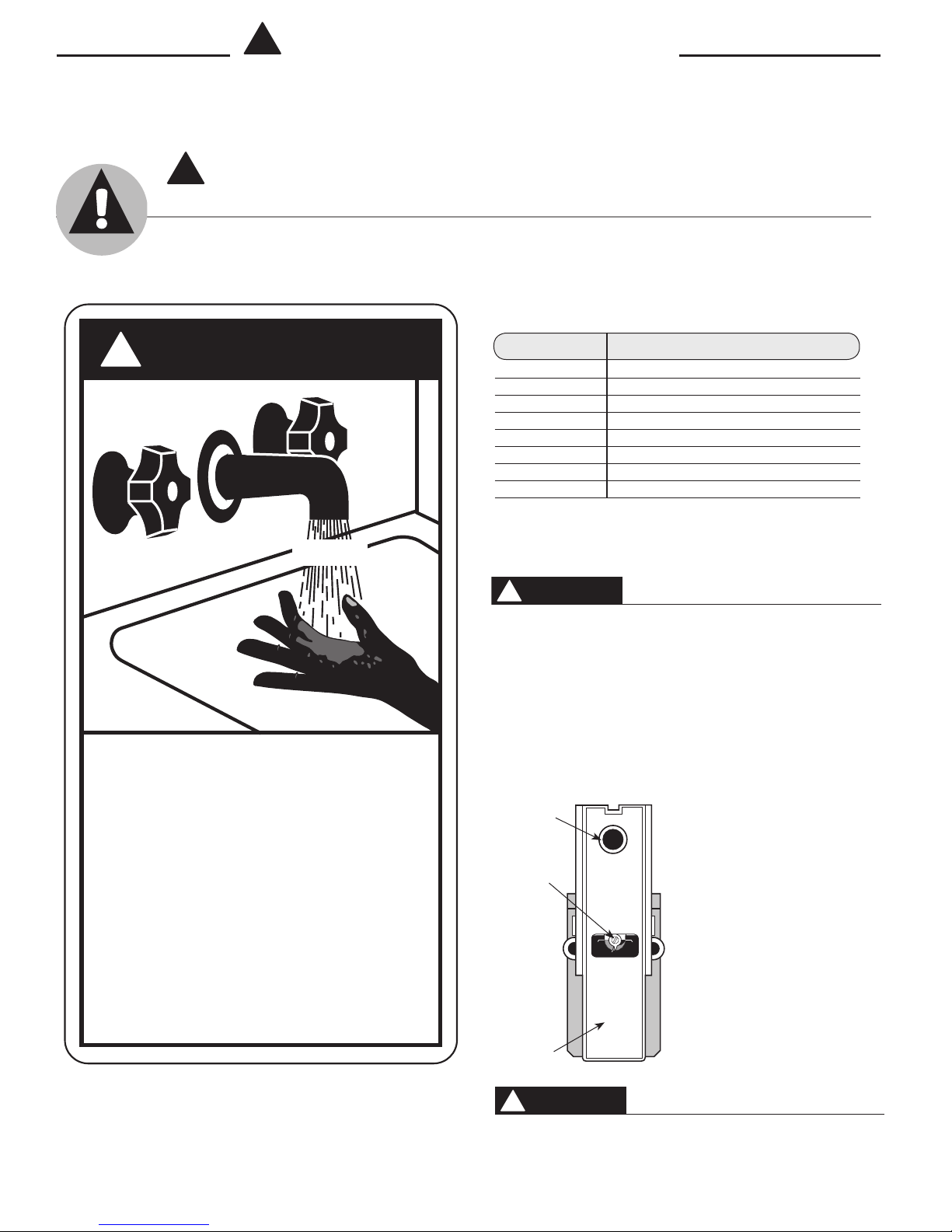

WATER TEMPERATURE SETTING

Safety and energy conservation are factors to be considered when selecting the water temperature setting of a

water heater’s gas control. Water temperatures above 125°F can cause severe burns or death from scalding. Be

sure to read and follow the warnings outlined on the label pictured below. This label is also located on the water

heater.

Time/Temperature Relationship in Scalds

!

D A N G E R

HOT

BURN

Water temperature over 125°F can

cause severe burns instantly or

death from scalds.

Children, disabled and elderly are

at highest risk of being scalded.

See instruction manual before

setting temperature at water

heater.

Feel water before bathing or

showering.

Temperature limiting valves are

available, see manual.

Water Temperature Time To Produce a Serious Burn

120°F (49°C) More than 5 minutes

125°F (52°C) 11/2 to 2 minutes

130°F (54°C) About 30 seconds

135°F (57°C) About 10 seconds

140°F (60°C) Less than 5 seconds

145°F (63°C) Less than 3 seconds

150°F (66°C) About 11/2 seconds

155°F (68°C) About 1 second

Table courtesy of Shriners Burn Institute

The chart shown above may be used as a guide in determining the proper

water temperature for your home.

DANGER

NOTICE: Households with small children, disabled, or

elderly persons may require a 120°F or lower thermostat setting to prevent contact with “HOT” water.

The temperature of the water in the heater is regulated by the adjustable

surface mounted thermostat located behind the Jacket Access Panel. To

comply with safety regulations the thermostat was set at 120° F before the

water heater was shipped from the factory.

Reset

Button

Thermostat Dial

Pointer

Thermostat

Protective

Cover

(66°C)

TURN OFF

SERVICING

T

E

S

E

R

125°F

POWER

BEFORE

R

E

S

E

T

90°F150°F

(32°C)

(52°C)

The illustration at left shows the

temperature adjustment dial used for

setting the water temperature. Refer

to Operation section of this manual

for detailed instructions in how to

adjust the thermostat.

Notice: Mixing valves are available for reducing

point of use water temperature by mixing hot and

cold water in branch water lines. Contact a licensed

plumber or the local plumbing authority for further

information.

DANGER

!

There is a Hot Water SCALD Potential if the thermostat is

set too high.

2

Introduction

The location chosen for the water heater must take into consideration the following:

LOCAL INSTALLATION REGULATIONS

Solar storage or solar electric storage water heaters must be installed in accordance with these instructions, local codes, utility

company requirements or, in the absence of local codes, the latest

edition of the National Electrical Code. It is available from some

local libraries or can be purchased from the National Fire Prevention Association, 1 Batterymarch Park, Quincy, MA 02269 as

booklet ANSI/NFPA 70.

LOCATION

Locate the water heater or storage tank as determined by the type

of solar system that is being installed. The area should be clean,

dry and as near as practical to the area of greatest heated water

demand. The piping should be insulated. Long uninsulated hot

water lines can waste energy and water. Place the water heater in

such a manner that the thermostat and element access panels can

be removed to permit inspection and servicing such as removal of

elements or checking controls. The water heater and water lines

should be protected from freezing temperatures. Do not install the

water heater in outdoor, unprotected areas.

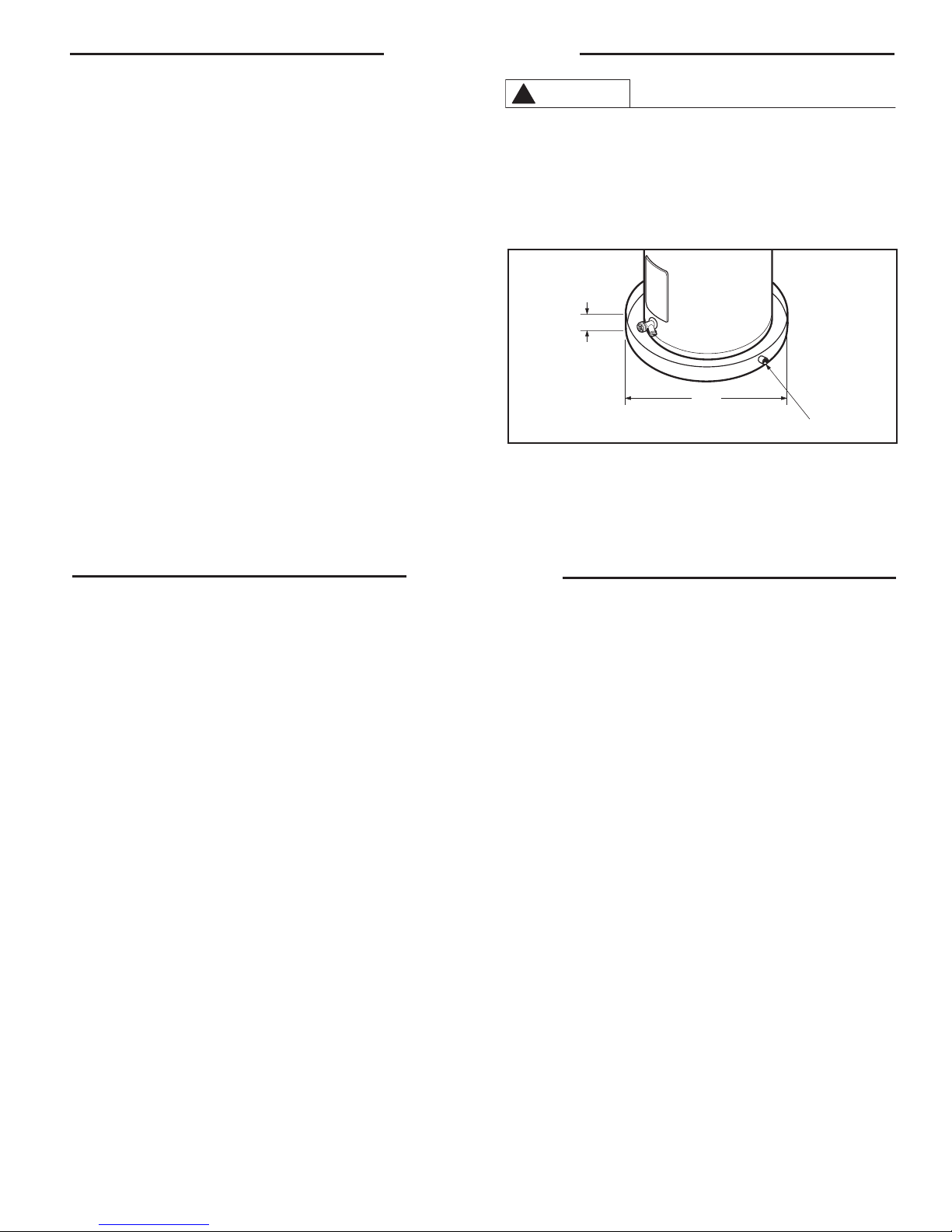

CAUTION

!

The water heater should not be located in an area

where leakage of the tank or connections will result

in damage to the area adjacent to it or to lower floors

of the structure. Where such areas cannot be avoided, it is recommended that a suitable catch pan, adequately drained, be installed under the water heater.

B

A — Diameter of water

heater plus 2" min.

B — Maximum 2"

Figure 1 - Auxiliary Catch Pan

A

To open drain, line

should be at least

3

/4" ID and pitched

for proper drainage.

NOTICE: Auxiliary catch pan installation MUST conform to local codes

Catch Pan Kits are available from the distributor or store where

the water heater was purchased.

.

Installation

This product is for the use in indirect domestic solar water heat-

ing systems — other applications, made without written factory

approval, will void the warranty.

The design and install at ion of solar water heating systems

should only be undertaken by qualified individuals, as such systems involve components and operating principles not found in

standard household plumbing installations. Often high-temperature or toxic fluids are an integral part of solar systems —failure

to understand good design and installation practices can affect

the health and safety of the system user.

Solar storage and solar electric storage water heaters must be

installed in accordance with federal and local codes. The location

chosen for the water heater or storage tank should be as close

as possible to the hot water faucet(s) that are most frequently

used, and the piping should be insulated.

1. INSPECT SHIPMENT — Inspect water heater for possible damage. Check the markings on the rating plate of the water heater

to be cer tain the power supply (Solar Electric Only) corresponds

to that for which the water heater is equipped.

2. THERMAL EXPANSION — Determine if a check valve exists in the

inlet water line. It may have been installed in the cold water line

as a separate back flow preventer, or it may be part of a pressure

reducing valve, water meter or water softener. A check valve

located in the cold water inlet line can cause what is referred

to as a ”closed water system”. A cold water inlet line with no

check valve or back flow prevention device is referred to as an

”open” water system.

As water is heated, it expands in volume and creates an increase

in the pressure within the water system. This action is referred to

as ”thermal expansion”. In an ”open” water system, expanding

water which exceeds the capacity of the water heater flows back

into the city main where the pressure is easily dissipated.

A ”closed water system”, however, prevents the expanding

water from flowing back into the main supply line, and the result of ”thermal expansion” can create a rapid, and dangerous

pressure increase in the water heater and system piping. This

rapid pressure increase can quickly reach the safety setting of

the relief valve, causing it to operate during each heating cycle.

Thermal expansion, and the resulting rapid, and repeated expansion and contraction of components in the water heater and

piping system can cause premature failure of the relief valve,

and possibly the heater itself. Replacing the relief valve will not

correct the problem!

The suggested method of controlling thermal expansion is to install

an expansion tank in the cold water line between the water heater

and the check valve. (refer to Figure 2.) The expansion tank is designed with an air cushion built in that compresses as the system

pressure increases, thereby relieving the over pressure condition

and eliminating the repeated operation of the relief valve. Other

methods of controlling thermal expansion are also available. Contact your installing contractor, water supplier, or plumbing inspector

for additional information regarding this subject.

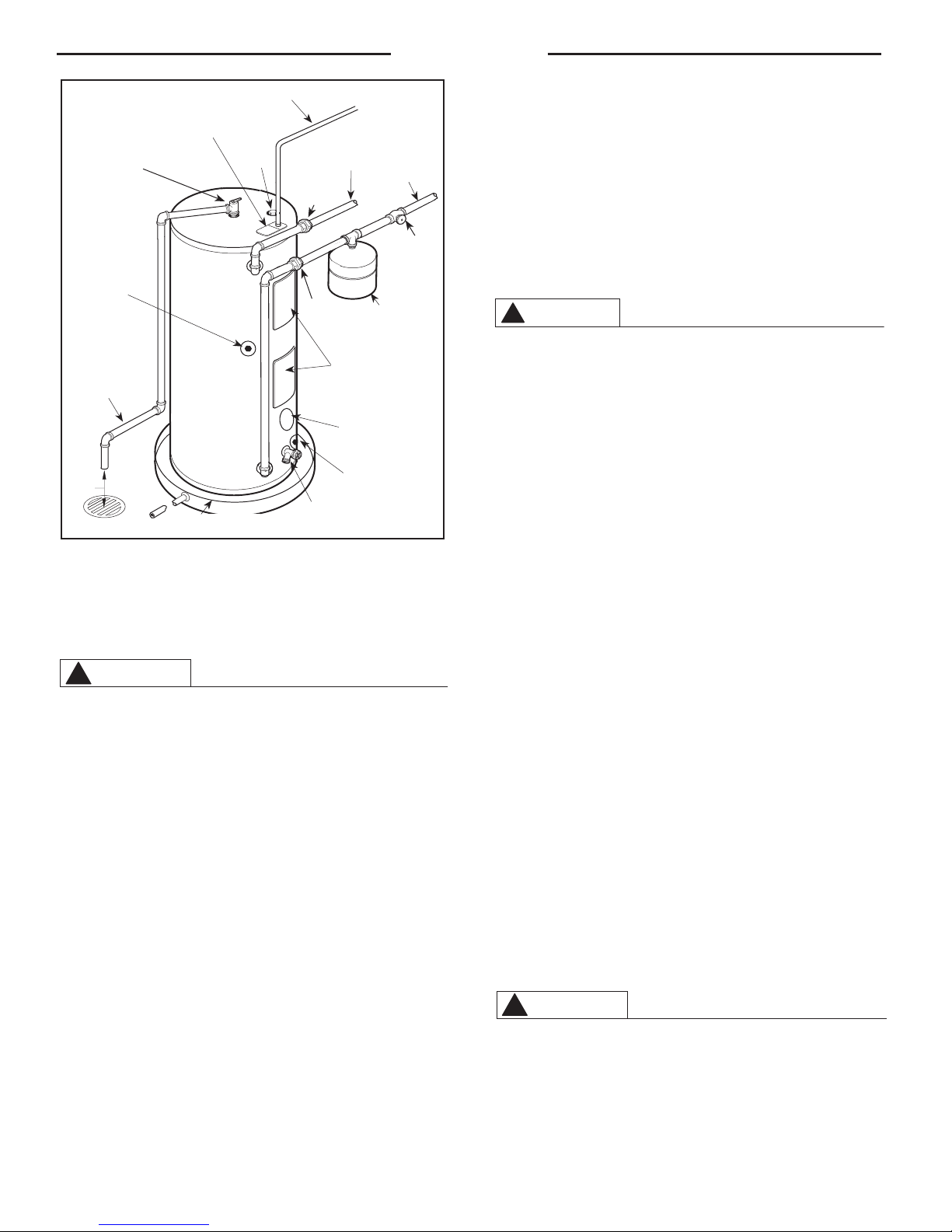

3. HEAT EXCHANGER LOOP & SOLAR CONNECTIONS — This

heater contains a wrap-around, vented, double wall heat exchanger that provides positive leak detection. Passageways for

the heat transfer fluid are of copper and brass — to prevent

dissimilar-metals corrosion, use only copper panels, piping, and

fittings in the heat exchanger loop. Flow rates through the heat

exchanger should be less than 3 gpm to limit the effects of corrosion.

3

Installation

E

L

I

E

F

V

A

L

V

E

**

Temperature

& Pressure Relief

Valve

*Collector Return

Line Connection

Relief Valve

Discharge Line

to Suitable Open

Drain.

Air Gap

6”

*

These connections are for non-potable heat transfer fluid loop. Do not make potable water

connections to these fittings. Do not introduce non-potable heat transfer fluids into any other

tank fitting.

**

Temperature and Pressure Relief Valve has alternate location on top of heater for 65 Gallon

heaters.

Electrical Junction

Box (Use Copper

Conductors Only)

Auxiliary Catch Pan

To Electrical Distribution Panel

Anode

Hot Water Outlet

to Fixtures

Union

Union

Jacket

Access

Panel

Solar Sensor Access

Cover (Solar Sensor Not

*

System

Drain

Valve

To Cold

Water

Supply

Shut-Off

Valve

Thermal Expansion

Tank (if required)

Provided)

To Solar Collector

Figure 2 - Typical Installation

WARNING

!

Many heat transfer fluids are classified as toxic. Do not

introduce heat transfer fluids into any fitting on the heater

except those clearly marked for that purpose.

Any of the commonly accepted solar heat transfer fluids may

be used in the exchanger, provided they contain appropr iate

corrosion inhibitors for copper systems. Anti-freeze fluids will

turn acidic when exposed to prolonged high temperatures, causing corrosion damage in solar systems. A regular maintenance

schedule must be established to monitor and maintain the proper

pH level of the heat transfer fluid in the system to protect the

heat exchanger and other metallic par ts.

When making connections to the heat exchanger, do not use

standard pipe dope. Use teflon tape, teflon joint compound or

fuorosilicone rubber sealant to prevent anti-freeze leaks. Do not

apply heat to heat exchanger fittings when making sweat connections. Sweat tubing to adapter before fitting to solar connections.

To protect the tank and heat exchanger from damage, the solar

loop must contain a pressure relief valve, and a check valve to

prevent thermosyphoning.

A 1/2” npt fitting is provided on the tank surface (beneath the

plastic snap cap on lower front of jacket) for installation of a solar

control sensor. The solar control should incorporate a recycling

shut-off switch that limits the temperature of the stored water

to 180°F. Also , a mixing valve should be provided to limit water

temperature at fixtures to 140°F. The solar sensor and mixing

valve are not included with the tank. It must be purchas ed

seperately. Please contact the place of purchase for details.

4. POTABLE WATER SUPPLY CONNECTIONS — Refer to Fig.

2 for suggested typical installation. The installation of unions

or flexible copper connectors is recommended on the hot and

cold water connections so that the water heater may be easily

disconnected for servicing if necessar y. The HOT and COLD

water connections are clearly marked and are 3/4” NPT on all

models. Install a shut-off valve in the cold water line near the

water heater.

CAUTION

!

Do not introduce heat transfer fluids into any potable water connection.

IMPORTANT!! Do not apply heat to the hot or cold water connections. If sweat connections are used, sweat tubing to adapter before

fitting adapter to hot or cold water connections on heater. Any heat

applied to the hot or cold water supply fittings will permanently damage them.

5. RELIEF VALVE — A new combination temperature and pressure

relief valve, complying with the Standard for Relief Valves and Automatic Gas Shutoff Devices for Hot Water Supply Systems, ANSI

Z21.22, must be installed in the opening provided and marked

for the purpose on the water heater. (Refer to Fig. 2.) No valve

of any type should be installed between the relief valve and the

tank. Local codes shall gover n the installation of relief valves.

The pressure rating of the relief valve must not exceed 150 PSI,

the maximum working pressure of the water heater as marked

on the rating plate. The Btu/h rating of the relief valve must not be

less than the input rating of the water heater as indicated on the

rating label located on front of the heater (1 watt = 3.412 Btu/h).

Connect the outlet of the relief valve to a suitable open drain

so that the discharge water cannot contact live electrical parts

and to eliminate potential water damage. Piping used should

be of a type approved for hot water distribution. The discharge

line must be no smaller than the outlet of the valve and must

pitch downward from the valve to allow complete drainage (by

gravity) of the relief valve and discharge line. The end of the

discharge line should not be threaded or concealed and should

be protected from freezing. No valve of any type, restriction or

reducer coupling should be installed in the discharge line.

6. TO FILL WATER HEATER — Make cer tain drain valve is completely closed. Open shut-off valve in cold water supply line.

Open each hot water faucet slowly to allow air to vent from the

water heater and piping. A steady flow of water from the hot

water faucet(s) indicates a full water heater.

WARNING

!

Tank MUST BE full of water before power is turned on.

Heating element WlLL BE DAMAGED if energized for

even a short time while tank is dry. The water heater’s

warranty does not cover damage or failure resulting

from operation with an empty or partially empty tank.

(Reference is made to the limited warranty for complete terms and conditions.)

4

Installation

CAUTION

!

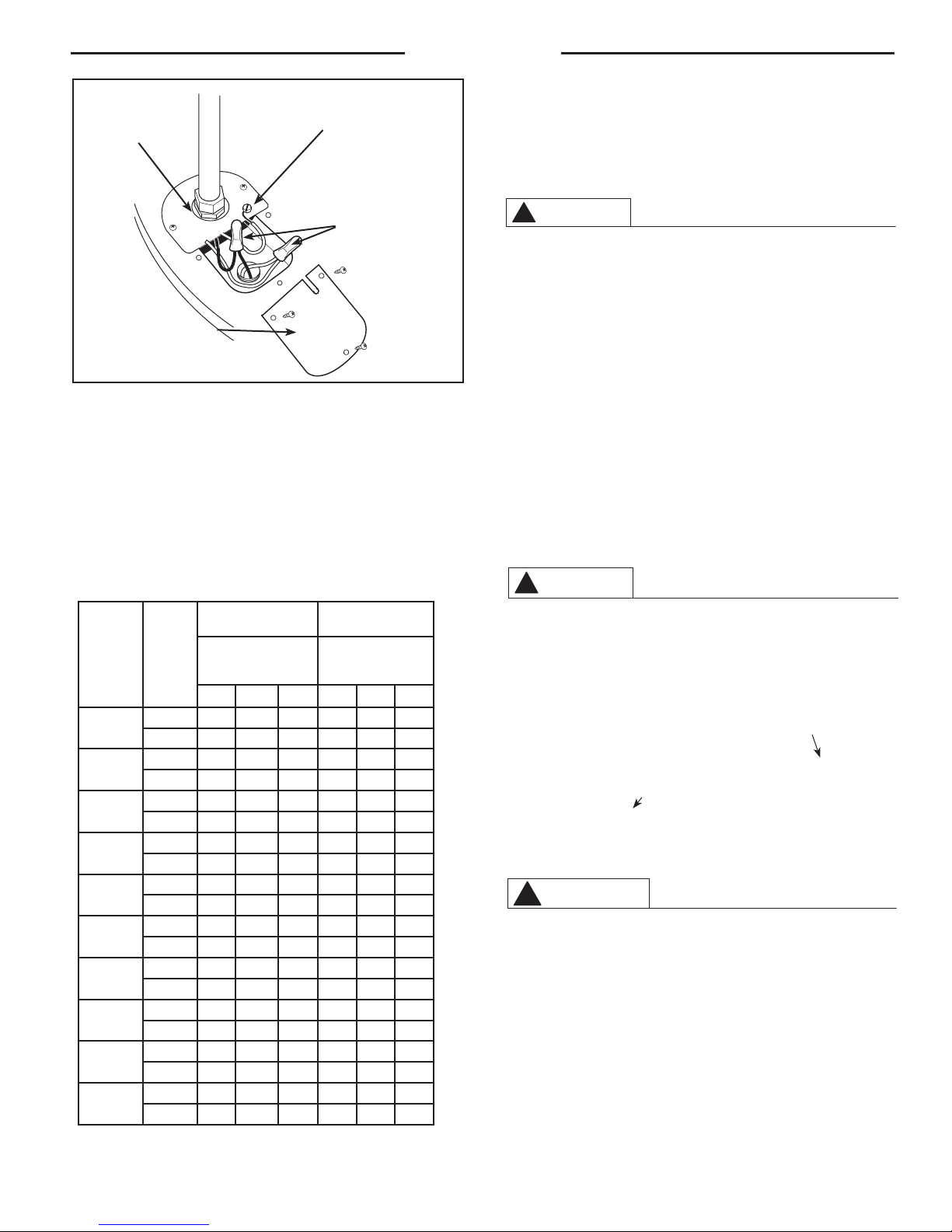

Conduit

Connector

Ground Screw

(See Text)

Wire Connectors

WARNING

Junction Box

Figure 3 - Water Heater Junction Box.

7. ELECTRICAL CONNECTIONS for Electric Element Solar Only— A

separate branch circuit with copper conductors, overcurrent protective device and suitable disconnecting means must be provided

by a qualified electrician. All wiring must conform to local codes or

latest edition of the National Electrical Code ANSI/NFPA 70.

The water heater is completely wired to the junction box inside

jacket at top front of water heater. An opening for 1/2" or 3/4”

electrical fitting is provided for field wiring connections. (Refer to

Fig. 3)

Recommended Over

Total

Water

Heater

Wattage

1,500

2,000

2,500

3,000

3,500

4,000

4,500

5,000

5,500

6,000

Table 1-Branch Circuit Sizing and Wire Size Guide

Phase

Based on N.E.C. ANSI / NFPA 70

Current Protection

(Fuse or Circuit

Breaker)

Amperage Rating

120V 208V 240V 120V 208V 240V

1 20 15 15 12 14 14

---- --- --- --- ---

1 25 15 15 10 14 14

--- --- --- --- --- ---

1 30 20 15 10 12 14

--- --- --- --- --- ---

1 35 20 20 8 12 12

--- --- --- --- --- ---

1 --- 25 20 --- 10 12

--- --- --- --- --- ---

1 --- 25 25 --- 10 10

--- --- --- --- --- ---

1 --- 30 25 --- 10 10

--- --- --- --- --- ---

1 --- 35 30 --- 8 10

--- --- --- --- --- ---

1 --- 35 30 --- 8 10

--- --- --- --- --- ---

1 --- 40 35 --- 8 10

--- --- --- --- --- ---

Copper Wire Size -

AWG Based on

N.E.C.

Table 310-16 (75°C.)

The voltage requirements and wattage load for the water heater

is specified on the rating plate on front of heater.

Table 1 recommends minimum branch circuit sizing based on

National Electric Code. Refer to wir ing diagram on back cover

of this manual for field wiring connections.

CAUTION

!

The presence of water in the piping and water heater

does not provide sufficient conduction for a ground.

Non-metallic piping, dielectric unions, flexible connectors etc. can cause the water heater to be electrically isolated.

The branch circuit wiring should include either:

A. Metallic conduit or metallic sheathed cable approved for use

as a grounding conductor and installed with fittings approved

for the purpose.

B. Non-metallic sheathed cable or metallic conduit or metallic

sheathed cable not approved for use as a ground conductor

shall include a separate conductor for grounding. It should

be attached to the ground ter minals of the water heater and

the electrical distribution box. (Refer to Fig. 3)

The manufacturer’s warranty does not cover any

damage or defect caused by installation, attachment

or use of any type of energy sav i ng or oth er

unapproved devices (other than those authorized by

the manufacturer) into, onto or in conjunction with the

water heater. The use of unauthorized energy saving

devices may shorten the life of the water heater and

may endanger life and property. The manufacturer

disclaims any responsibility for such loss or injury

resulting from the use of such unauthorized devices.

If local codes require external application of insulation

blanket kits the manufacturer’s instructions included with

the kit must be carefully followed.

WARNING

!

Application of any external insulation to this water heater

will require careful attention to the following:

• Do Not cover the temperature and pressure relief

valve.

• Do Not cover jacket access panel to thermostat

and heating element.

• Do Not cover electrical junction box of water

heater.

• Do Not cover operating or warning labels at-

tached to the water heater nor attempt to relocate

them on exterior of insulation blanket.

5

Loading...

Loading...