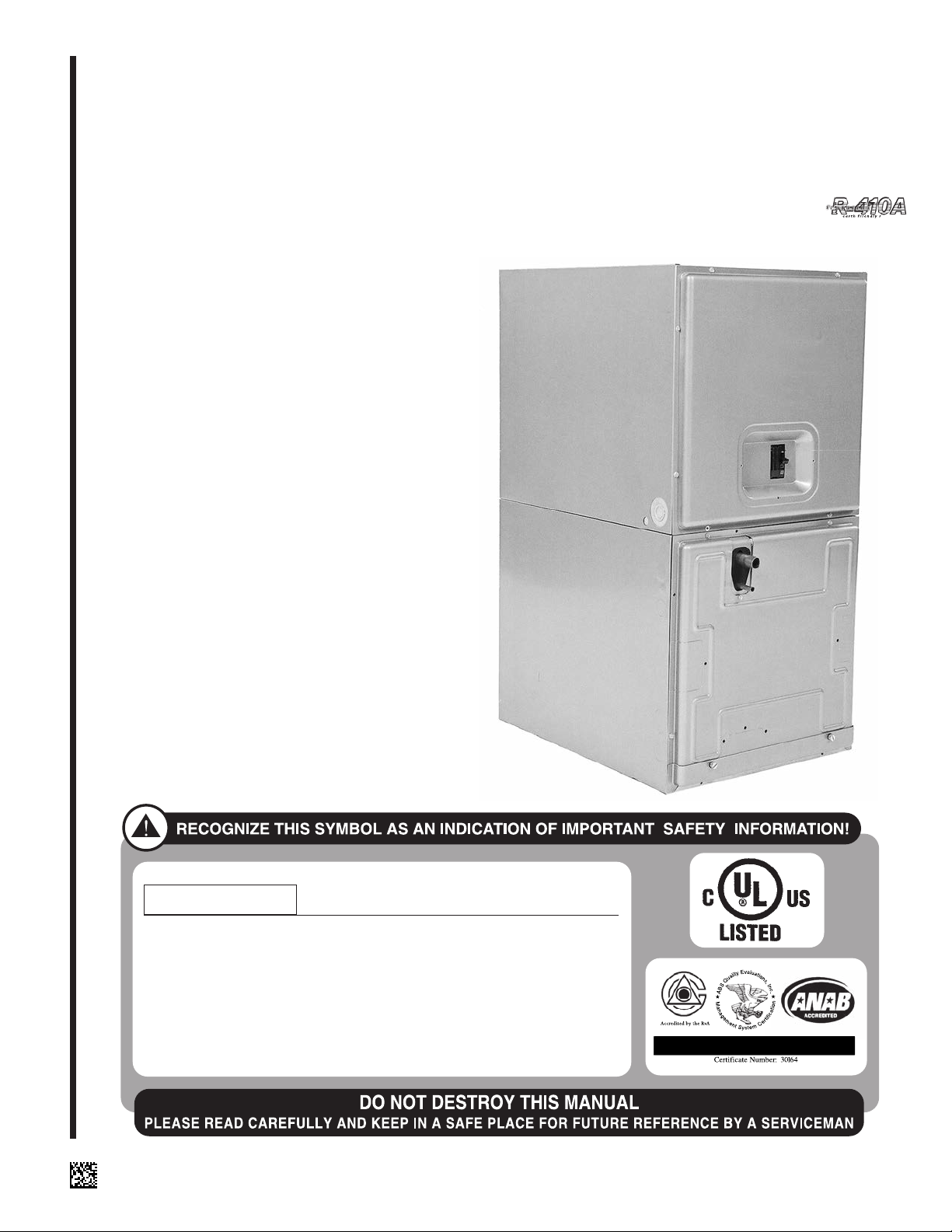

Rheem RBHP-21J06SH2, RBHP-17J07SH1, RBHP-17J11SH1, RBHP-17J06SH1, RBHP-21A00NH2 Installation Instructions Manual

...Page 1

INSTALLATION INSTRUCTIONS

WARNING

ISO 9001:2008

AIR HANDLERS

(-)BHP

• MODELS FEATURING R-22 REFRIGERANT

• MODELS FEATURING EARTH-FRIENDLY R-410A REFRIGERANT

• MODELS FEATURING ELECTRIC HEAT WITHOUT INDOOR

COOLING COIL

!

▲WARNING

These instructions are intended as an aid to qualified licensed

service personnel for proper installation, adjustment and

operation of this unit. Read these instructions thoroughly before

attempting installation or operation. Failure to follow these

instructions may result in improper installation, adjustment,

service or maintenance possibly resulting in fire, electrical

shock, property damage, personal injury or death.

SUPERSEDES 92-20521-44-05

92-20521-44-06

Page 2

TABLE OF CONTENTS

1.0 SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.0 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Important Information About Efficiency and Indoor Air Quality. . . . . . . . . . . . 7

2.2 Receiving. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Model Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

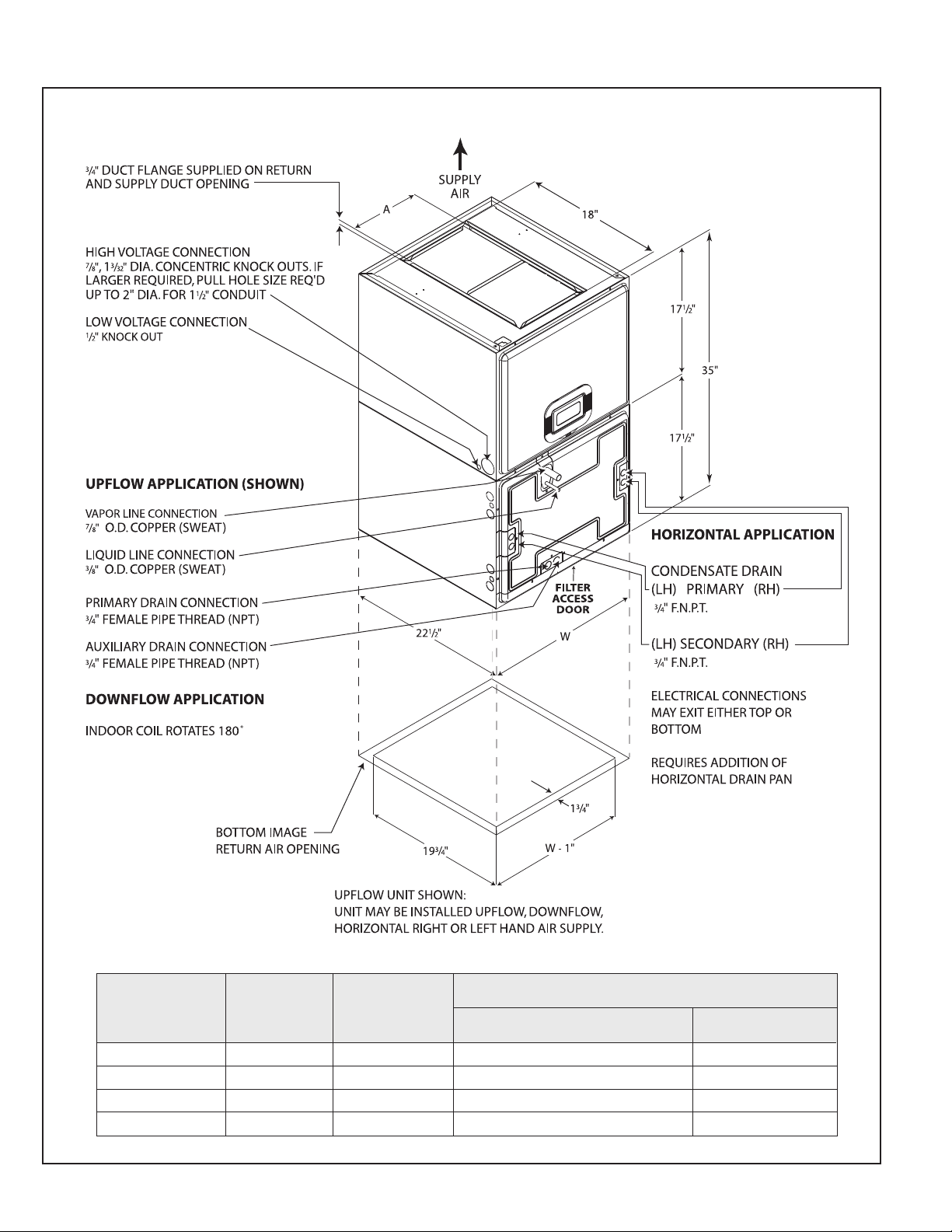

2.5 Dimensions and Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6 Unit Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.7 Vertical Upflow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.8 Vertical Downflow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.9 Horizontal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.0 ELECTRICAL WIRING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4 Blower Motor Electrical Data: “A” Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5 Blower Motor Electrical Data: “J” Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.6 Electric Heat Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.0 DUCTWORK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.0 REFRIGERANT CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 Flowcheck Pistons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.0 CONDENSATE DRAIN TUBING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.0 AIR FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.0 AIRFLOW PERFORMANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.1 Airflow Operatng Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.2 Airflow Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9.0 SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.1 Cooling (cooling only or heat pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.2 Heating (electric heat only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.3 Heating (heat pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.4 Watt Restrictor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.5 Defrost Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.6 Emergency Heat (Heating of Heat Pump) . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9.7 Room Thermostat (Anticipator Setting) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.0 CALCULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.1 Calculating Temperature Rise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.2 Calculating BTUH Heating Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.3 Calculating Airflow CFM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.4 Calculating Correction Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11.0 PRE-START CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12.1 Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12.2 Indoor Coil-Drain Pan-Drain Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

12.3 Blower Motor and Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

12.4 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

12.5 Blower Assembly Removal and Replacement. . . . . . . . . . . . . . . . . . . . . . . 28

12.6 Electric Heater Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

12.7 Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

13.0 REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

14.0 ACCESSORIES - KITS - PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2

Page 3

1.0 SAFETY INFORMATION

Improper installation, or installation not made in accordance with the Underwriters

Laboratory certification or these instructions, can result in unsatisfactory operation

and/or dangerous conditions and are not covered by the unit warranty.

WARNING

!

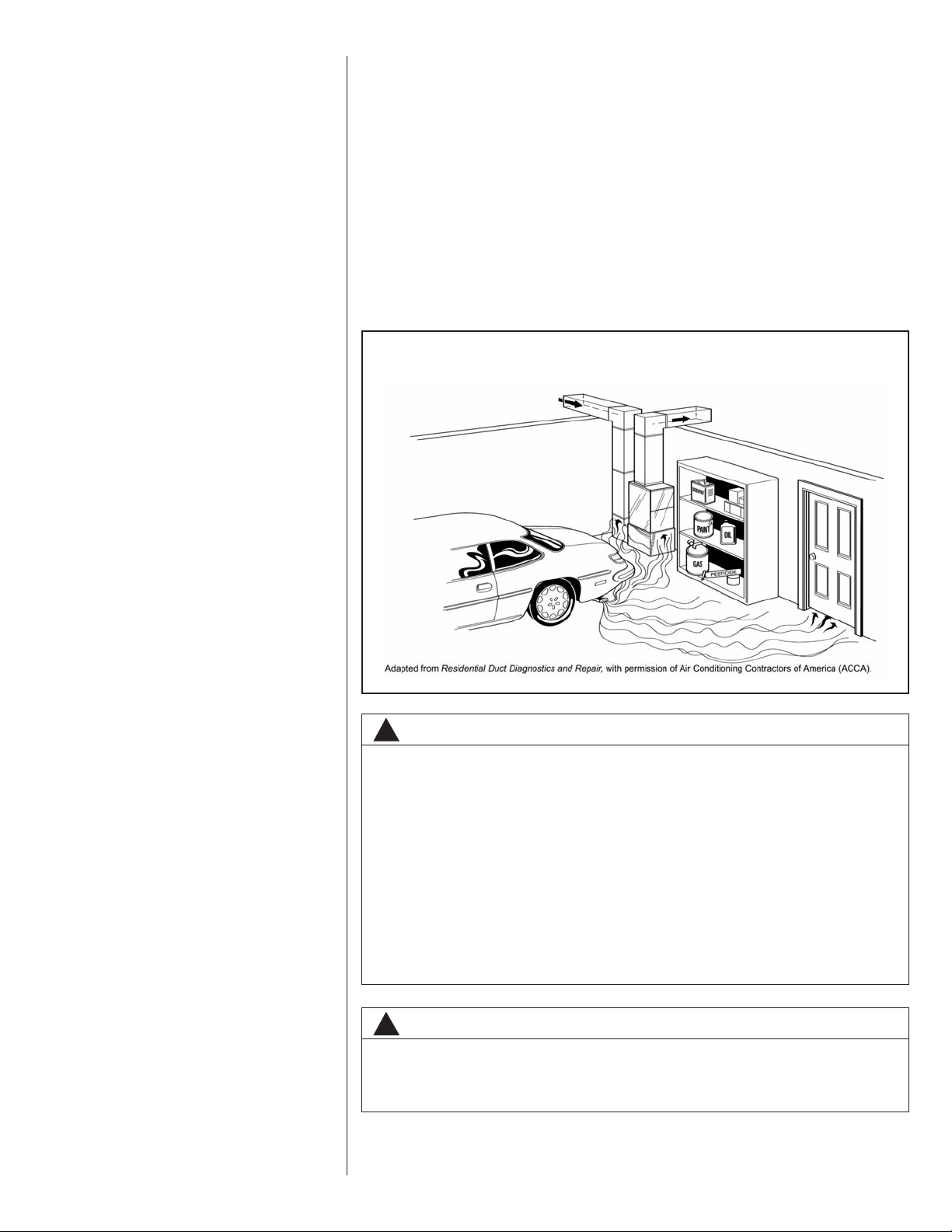

Duct leaks can create an unbalanced system and draw pollutants such as dirt,

dust, fumes and odors into the home causing property damage. Fumes and

odors from toxic, volatile or flammable chemicals, as well as automobile

exhaust and carbon monoxide (CO), can be drawn into the living space

through leaking ducts and unbalanced duct systems causing personal injury

or death (see Figure 1).

• If air-moving equipment or ductwork is located in garages or off-garage storage areas - all joints, seams, and openings in the equipment and duct must

be sealed to limit the migration of toxic fumes and odors including carbon

monoxide from migrating into the living space.

• If air-moving equipment or ductwork is located in spaces containing fuel

burning appliances such as water heaters or boilers - all joints, seams, and

openings in the equipment and duct must also be sealed to prevent depressurization of the space and possible migration of combustion byproducts

including carbon monoxide into the living space.

WARNING

!

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED, LICENSED

SERVICE PERSONNEL FOR PROPER INSTALLATION, SET UP AND OPERATION OF THIS UNIT. READ THESE INSTRUCTIONS THOROUGHLY BEFORE

ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO FOLLOW THESE

INSTRUCTIONS MAY RESULT IN IMPROPER INSTALLATION, SET UP, SERVICE

OR MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK,

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

PROPOSITION 65: THIS APPLIANCE CONTAINS FIBERGLASS INSULATION. RESPIRABLE PARTI CLES OF FIBERGLASS ARE KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER.

WARNING

!

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT RETURN DUCTWORK TO

ANY OTHER HEAT PRODUCING DEVICE SUCH AS FIREPLACE INSERT,

STOVE, ETC. UNAUTHORIZED USE OF SUCH DEVICES MAY RESULT IN FIRE,

CARBON MONOXIDE POISONING, EXPLOSION, PERSONAL INJURY OR PROPERTY DAMAGE.

CAUTION

!

When installing a unit with cooling coil over a finished ceiling and/or living

space, installation of an auxiliary drain pan under the entire unit, to avoid damage to ceiling, is recommended.

WARNING

!

DISCONNECT ALL POWER TO UNIT BEFORE INSTALLING OR SERVICING.

MORE THAN ONE DISCONNECT SWITCH MAY BE REQUIRED TO DE-ENERGIZE THE EQUIPMENT. HAZARDOUS VOLTAGE CAN CAUSE SEVERE PERSONAL INJURY OR DEATH.

WARNING

!

BECAUSE OF POSSIBLE DAMAGE TO EQUIPMENT OR PERSONAL INJURY,

INSTALLATION, SERVICE AND MAINTENANCE SHOULD BE PERFORMED BY

A TRAINED, QUALIFIED SERVICE PERSON. CONSUMER SERVICE IS RECOMMENDED ONLY FOR FILTER CLEANING/ REPLACEMENT. NEVER OPERATE

THE UNIT WITH THE ACCESS PANELS REMOVED.

3

Page 4

WARNING

!

DO NOT INSTALL THIS UNIT IN MANUFACTURED (MOBILE) HOMES.

IMPROPER INSTALLATION IS MORE LIKELY IN MANUFACTURED HOUSING

DUE TO DUCTWORK MATERIAL, SIZE, LOCATION, AND ARRANGEMENT.

INSTALLATIONS IN MANUFACTURED HOUSING CAN CAUSE A FIRE RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

EXCEPTION: MANUFACTURED HOUSING INSTALLATIONS ARE APPROVED

ONLY WITH DOCUMENTATION BY A RECOGNIZED INSPECTION AUTHORITY

THAT THE INSTALLATION HAS BEEN MADE IN COMPLIANCE WITH THE

INSTRUCTIONS AND ALL WARNINGS HAVE BEEN OBSERVED.

WARNING

!

IF UNIT IS TO BE INSTALLED WITHOUT AN INDOOR COIL, RETURN DUCT OR

PLENUM, IT MUST NOT BE IN STALLED DIRECTLY OVER COMBUSTIBLE MATERIAL. IF INSTALLED WITHOUT AN INDOOR COIL WITH A RETURN DUCT OR

PLENUM, THE AIR PLENUM OR DUCT MUST HAVE A SOLID SHEET METAL

BOTTOM WITH NO RETURN AIR OPENINGS, REGISTERS OR FLEXIBLE AIR

DUCTS LOCATED DIRECTLY UNDER THE UNIT. EXPOSING COMBUSTIBLE

MATERIAL TO THE RETURN OPENING OF AN UPFLOW UNIT WITHOUT AN

INDOOR COIL CAN CAUSE A FIRE RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

THE RXBB-AA COMBUSTIBLE FLOOR BASE IS REQUIRED WHEN SOME

UNITS WITH ELECTRIC HEAT ARE APPLIED DOWNFLOW ON COMBUSTIBLE

FLOORING. FAILURE TO USE THE BASE CAN CAUSE A FIRE RESULTING IN

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH. SEE CLEARANCES

FOR UNITS REQUIRING A COMBUSTIBLE FLOOR BASE.

(SEE WARNINGS IN REGARD TO DUCTWORK)

WARNING

!

THE FIRST 36 INCHES OF SUPPLY AIR PLENUM AND DUCTWORK MUST BE

CONSTRUCTED OF SHEET METAL AS REQUIRED BY NFPA 90B. THE SUPPLY

AIR PLENUM OR DUCT MUST HAVE A SOLID SHEET METAL BOTTOM

DIRECTLY UNDER THE UNIT WITH NO OPENINGS, REGISTERS OR FLEXIBLE

AIR DUCTS LOCATED IN IT. IF FLEXIBLE SUPPLY AIR DUCTS ARE USED THEY

MAY BE LOCATED ONLY IN THE VERTICAL WALLS, OF A RECTANGULAR

PLENUM, A MINIMUM OF 6 INCHES FROM THE SOLID BOTTOM. METAL

PLENUM OR DUCT MAY BE CONNECTED TO THE COMBUSTIBLE FLOOR

BASE, IF NOT, IT MUST BE CONNECTED TO THE UNIT SUPPLY DUCT

FLANGES SUCH THAT COMBUSTIBLE FLOOR OR OTHER COMBUSTIBLE

MATERIAL IS NOT EXPOSED TO THE SUPPLY AIR OPENING FROM THE

DOWNFLOW UNIT. EXPOSING COMBUSTIBLE (NON-METAL) MATERIAL TO

THE SUPPLY OPENING OF A DOWNFLOW UNIT CAN CAUSE A FIRE RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

EXCEPTIONS TO DOWNFLOW WARNINGS:

• INSTALLATIONS ON CONCRETE FLOOR SLAB WITH SUPPLY AIR PLENUM

AND DUCTWORK COMPLETELY ENCASED IN NOT LESS THAN 2 INCHES OF

CONCRETE (SEE NFPA 90B).

• INSTALLATIONS OF UNITS WITHOUT ELECTRIC HEATERS.

WARNING

!

THE SUPPLY AIR PLENUM OR DUCT MUST HAVE A SOLID SHEET METAL

BOTTOM WITH NO SUPPLY AIR OPENINGS, REGISTERS OR FLEXIBLE AIR

DUCTS LOCATED IN IT FOR THE FIRST 36 INCHES OF HORIZONTAL SURFACE

ON UNITS WITH ELECTRIC HEATERS. FAILURE TO OBSERVE SUPPLY

PLENUM, DUCT WARNINGS CAN CAUSE A FIRE RESULTING IN PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

4

Page 5

WARNING

!

THE UNIT MUST BE PERMANENTLY GROUNDED. FAILURE TO DO SO CAN

RESULT IN ELECTRICAL SHOCK CAUSING PERSONAL INJURY OR DEATH.

WARNING

!

UNITS ARE FOR DUCTED APPLICATIONS ONLY. A MINIMUM OF 36 INCHES OF

SUPPLY AIR PLENUM AND DUCTWORK IS REQUIRED. NO SUPPLY AIR OPENINGS, REGISTERS OR FLEXIBLE AIR DUCTS MAY BE LOCATED WITHIN THE

FIRST 36 INCHES OF SUPPLY PLENUM AND DUCTWORK ON UNITS WITH

ELECTRIC HEATERS. FAILURE TO OBSERVE SUPPLY PLENUM/DUCT WARNINGS CAN CAUSE A FIRE RESULTING IN PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

WARNING

!

UNITS WITH CIRCUIT BREAKER(S) MEET REQUIREMENTS AS A SERVICE

DISCONNECT SWITCH, HOWEVER, IF ACCESS IS REQUIRED TO THE LINE

SIDE (COVERED) OF THE CIRCUIT BREAKER, THIS SIDE OF THE BREAKER(S)

WILL BE ENERGIZED WITH THE BREAKER(S) DE-ENERGIZED. CONTACT WITH

THE LINE SIDE CAN CAUSE ELECTRICAL SHOCK RESULTING IN PERSONAL

INJURY OR DEATH.

WARNING

!

IF REMOVAL OF THE BLOWER ASSEMBLY IS REQUIRED, ALL DISCONNECT

SWITCHES SUPPLYING POWER TO THE AIRHANDLER MUST BE DE-ENERGIZED AND LOCKED (IF NOT IN SIGHT OF UNIT) SO THE FIELD POWER

WIRES CAN BE SAFELY REMOVED FROM THE BLOWER ASSEMBLY. FAILURE

TO DO SO CAN CAUSE ELECTRICAL SHOCK RESULTING IN PERSONAL

INJURY OR DEATH.

(SEE SPECIFIC AIRFLOW POSITION FOR ADDITIONAL

WARNINGS)

5

Page 6

CAUTION

!

When used on cooling applications, excessive sweating may occur when unit

is installed in an unconditioned space. This can result in property damage.

• Some building codes require extra cabinet insulation and gasketing when

unit is installed in attic applications.

• If installed in an unconditioned space, apply caulking around the power

wires, control wires, refrigerant tubing and condensate line where they enter

the cabinet. Seal the power wires on the inside where they exit conduit

opening. Caulking is required to prevent air leakage into and condensate

from forming inside the unit, control box, and on electrical controls.

• Install the unit in such a way as to allow free access to the coil/filter compartment and blower/control compartment.

• Install the unit in a level position to ensure proper condensate drainage.

Make sure unit is level in both directions within 1/8”.

• Install the unit in accordance with any local code which may apply and the

national codes. Latest editions are available from: “National Fire Protection

Association, Inc., Batterysmarch Park, Quincy, MA 02269.” These publications

are:

• ANSI/NFPA No. 70-(Latest Edition) National Electrical Code.

• NFPA90A Installation of Air Conditioning and Ventilating Systems.

• NFPA90B Installation of warm air heating and air conditioning systems.

• The equipment has been evaluated in accordance with the Code of Federal

Regulations, Chapter XX, Part 3280.

CAUTION

!

HORIZONTAL UNITS MUST BE CONFIGURED FOR RIGHT HAND AIR SUPPLY

OR LEFT HAND AIR SUPPLY. HORIZONTAL DRAIN PAN MUST BE LOCATED

UNDER INDOOR COIL. FAILURE TO USE THE DRAIN PAN CAN RESULT IN

PROPERTY DAMAGE.

NOTICE

!

Improper installation, or installation not made in accordance with the

Underwriters Laboratory (UL) certification or these instructions, can result

in unsatisfactory operation and/or dangerous conditions and are not covered by the unit warranty.

NOTICE

!

In compliance with recognized codes, it is recommended that an auxiliary

drain pan be installed under all evaporator coils or units containing evaporator coils that are located in any area of a structure where damage to the

building or building contents may occur as a result of an overflow of the

coil drain pan or a stoppage in the primary condensate drain piping. See

accessories section of these instructions for auxiliary horizontal overflow

pan information (model RXBM).

6

Page 7

2.0 GENERAL INFORMATION

2.1 IMPORTANT INFORMATION ABOUT EFFICIENCY AND INDOOR

2.1 AIR QUALITY

Central cooling and heating equipment is only as efficient as the duct system that carries the cooled or heated air. To maintain efficiency, comfort and good indoor air quality,

it is important to have the proper balance between the air being supplied to each room

and the air returning to the cooling and heating equipment.

Proper balance and sealing of the duct system improves the efficiency of the heating

and air conditioning system and improves the indoor air quality of the home by reducing

the amount of airborne pollutants that enter homes from spaces where the ductwork and

/ or equipment is located. The manufacturer and the U.S. Environmental Protection

Agency’s Energy Star Program recommend that central duct systems be checked by a

qualified contractor for proper balance and sealing.

FIGURE 1

MIGRATION OF DANGEROUS SUBSTANCES, FUMES, AND ODORS INTO LIVING SPACES

WARNING

!

Duct leaks can create an unbalanced system and draw pollutants such as

dirt, dust, fumes and odors into the home causing property damage.

Fumes and odors from toxic, volatile or flammable chemicals, as well as

automobile exhaust and carbon monoxide (CO), can be drawn into the living space through leaking ducts and unbalanced duct systems causing

personal injury or death (see Figure 1).

• If air-moving equipment or ductwork is located in garages or off-garage

storage areas - all joints, seams, and openings in the equipment and

duct must be sealed to limit the migration of toxic fumes and odors

including carbon monoxide from migrating into the living space.

• If air-moving equipment or ductwork is located in spaces containing fuel

burning appliances such as water heaters or boilers - all joints, seams,

and openings in the equipment and duct must also be sealed to prevent

depressurization of the space and possible migration of combustion

byproducts including carbon monoxide into the living space.

NOTICE

!

Improper installation, or installation not made in accordance with the

Underwriters Laboratory (UL) certification or these instructions, can result

in unsatisfactory operation and/or dangerous conditions and are not covered by the unit warranty.

7

Page 8

NOTICE

!

In compliance with recognized codes, it is recommended that an auxiliary

drain pan be installed under all evaporator coils or units containing evaporator coils that are located in any area of a structure where damage to the

building or building contents may occur as a result of an overflow of the

coil drain pan or a stoppage in the primary condensate drain piping. See

accessories section of these instructions for auxiliary horizontal overflow

pan information (model RXBM).

2.2 RECEIVING

Immediately upon receipt, all cartons and contents should be inspected for transit damage. Units with damaged cartons should be opened immediately. If damage is found, it

should be noted on the delivery papers, and a damage claim filed with the last carrier.

• After unit has been delivered to job site, remove carton taking care not to damage

unit.

• Check the unit rating plate for unit size, electric heat, coil, voltage, phase, etc. to be

sure equipment matches what is required for the job specification.

• Read the entire instructions before starting the installation.

• Some building codes require extra cabinet insulation and gasketing when unit is

installed in attic applications.

• If installed in an unconditioned space, apply caulking around the power wires, control

wires, refrigerant tubing and condensate line where they enter the cabinet. Seal the

power wires on the inside where they exit conduit opening. Caulking is required to

pre-vent air leakage into and condensate from forming inside the unit, control box,

and on electrical controls.

• Install the unit in such a way as to allow necessary access to the coil/filter rack and

blower/control compartment.

• Install the unit in a level position to ensure proper condensate drainage. Make sure

unit is level in both directions within 1/8”.

• Install the unit in accordance with any local code which may apply and the national

codes. Latest editions are available from: “National Fire Protection Association, Inc.,

Batterysmarch Park, Quincy, MA 02269.” These publications are:

• ANSI/NFPA No. 70-(Latest Edition) National Electrical Code.

• NFPA90A Installation of Air Conditioning and Ventilating Systems.

• NFPA90B Installation of warm air heating and air conditioning systems.

• The equipment has been evaluated in accordance with the Code of Federal

Regulations, Chapter XX, Part 3280.

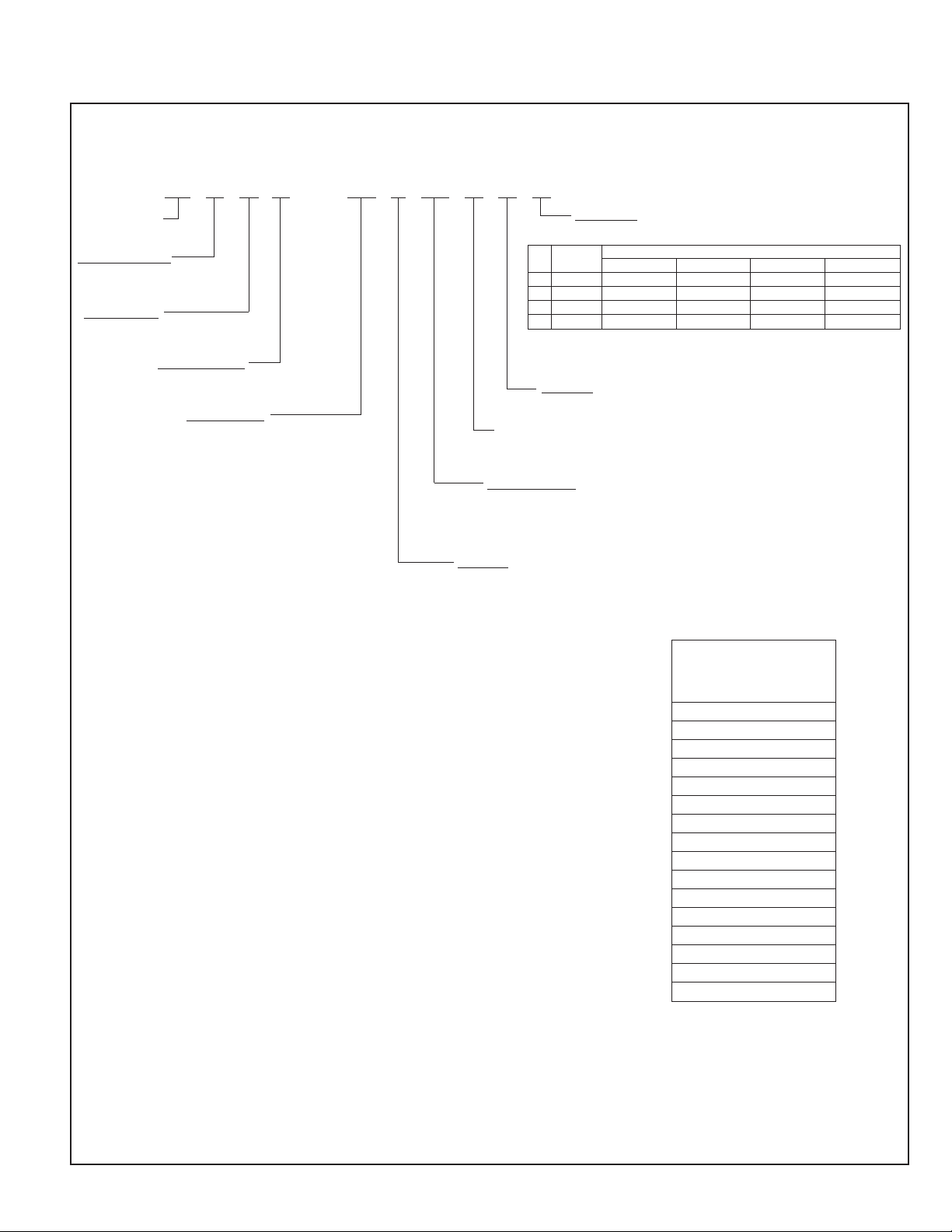

2.3 CLEARANCES

• All units are designed for “0” inches clearance to combustible material on all cabinet

surfaces.

• Some units require supply duct clearances and combustible floor bases depending on

the heating kW. The following table should be used to determine these requirements:

Model Cabinet Size 17 21 24 25

Model Designation kW 11 11 18 18

Units with electric heating kW above

ance to combustible material for the first three feet of supply plenum and ductwork.

Additionally, if these units are installed downflow, a combustible floor base is

required.

Units with electric heating kW equal to

not require supply ductwork clearances or combustible floor bases.

• Vertical units require clearance on at least one side of the unit for electrical connec-

tions. Horizontal units require clearance on either top or bottom for electrical connections. Refrigerant and condensate drain connections are made on the front of the unit.

• All units require 24 inches minimum access to the front of the unit for service.

• These units may be installed in either ventilated or nonventilated spaces.

8

that listed in the table require a one inch clear-

or less than the values listed in the table do

Page 9

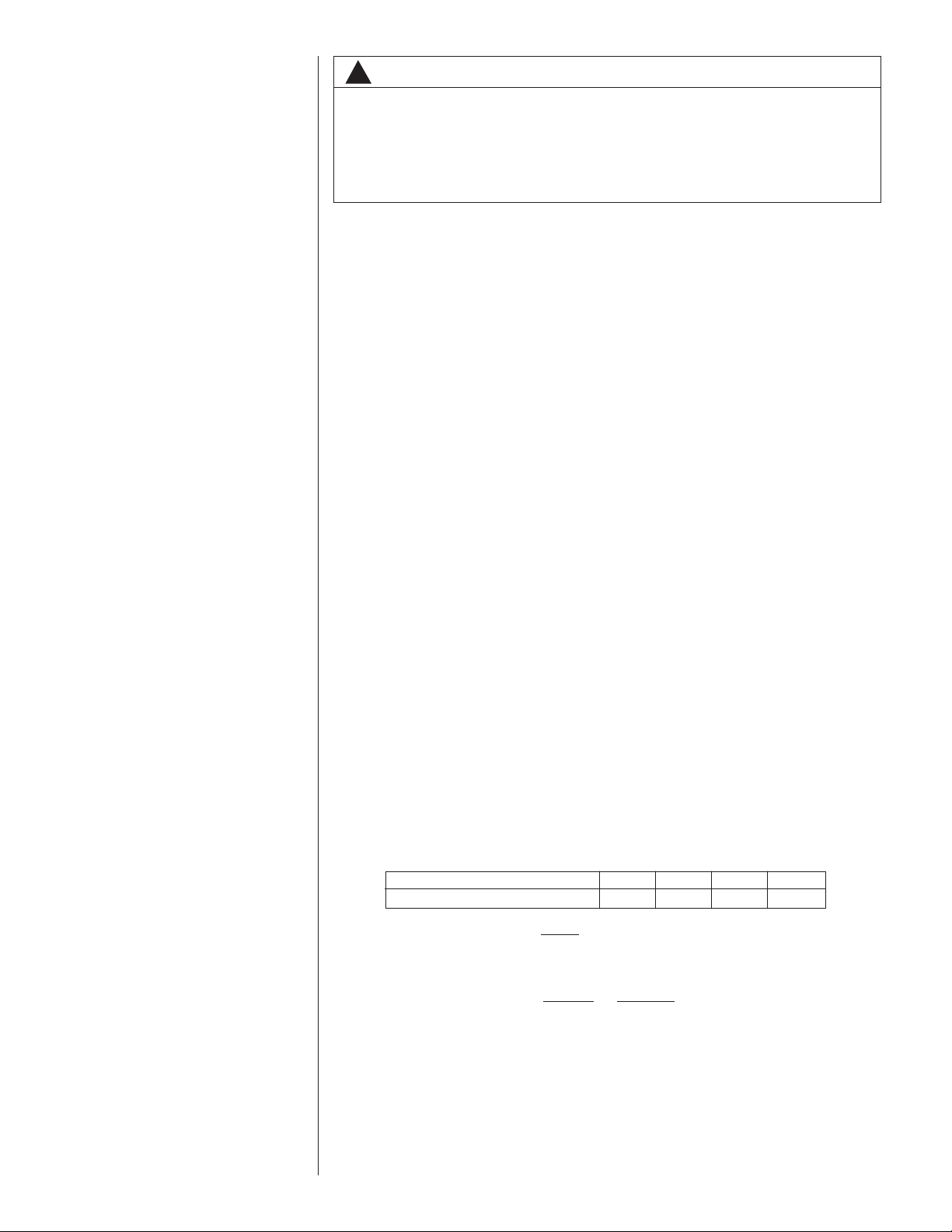

2.4 UNIT MODEL EXPLANATION

FIGURE 2

MODEL NUMBER EXPLANATION

(-) BHP—17 J 00 NHD

TRADEBRAND

CLASSIFICATION

B = BLOWER UNIT

APPLICATION

H = HEAT PUMP AIR HANDLER

DESIGN SERIES

P = X-13 MOTOR

CABINET SIZE

17 = 17.5”

21 = 21.0”

24 = 24.5”

25 = 24.5”

COIL CODE

A = NO COIL

Coil Refrigerant Cabinet Width

Code Type 17 21 24 25

1 R-410A RCHL-24A2GH17

2 R-410A RCHL-36A1GH21

4 R-410A RCHL-48A1GH24

7 R-410A RCHL-60A1GH24

AIRFLOW

HORIZONTAL MULTI-POSITION

CONTROL

N = NO CIRCUIT PROTECTION (SINGLE CIRCUIT)

S = CIRCUIT BREAKER (SINGLE CIRCUIT)

ELECTRIC HEAT

00 = NO HEAT 14 = 14.0 KW

06 = 4.9 KW 18 = 17.5 KW

07 = 7.0 KW 21 = 21.0 KW

11 = 10.0 KW

VOLTAGE

A = 115V-1-60

J = 208/240V-1-60

AVAILABLE MODELS

FEATURING R-410A

REFRIGERANT

(-)BHP-17A00NH1

(-)BHP-17J06SH1

(-)BHP-17J07SH1

(-)BHP-17J11SH1

(-)BHP-21A00NH2

(-)BHP-21J06SH2

(-)BHP-21J07SH2

(-)BHP-21J11SH2

(-)BHP-24A00NH4

(-)BHP-24J06SH4

(-)BHP-24J07SH4

(-)BHP-24J11SH4

(-)BHP-24J18SH4

(-)BHP-25A00NH7

(-)BHP-25J11SH7

(-)BHP-25J18SH7

9

Page 10

2.5 DIMENSIONS AND WEIGHTS

FIGURE 3

DIMENSIONS AND WEIGHTS

NOTE: 24” CLEARANCE REQUIRED

IN FRONT OF UNIT FOR FILTER

AND COIL MAINTENANCE.

10

DIMENSIONAL DATA

MODEL

CABINET SIZE

17 17

21 21" 97⁄16" 109/117 [383.3/411.5] 79/87 [277.8/306]

24 241⁄2" 113⁄4" 125/134 [439.6/471.3] 88/97 [309.5/341.1]

25 241⁄2" 113⁄4" 125/134 [439.6/471.3] 88/97 [309.5/341.1]

UNIT

WIDTH

“W” IN.

1

⁄2"7

SUPPLY

DUCT

“A” IN.

9

⁄16" 92/99 [323.6/348.2] 66/75 [232.1/263.8]

UNIT WEIGHT / SHIPPING WEIGHT (LBS.)*

UNIT WITH COIL

(MAX. kw.)

UNIT WITHOUT COIL

(MAX. kw.)

Page 11

WARNING

!

DO NOT INSTALL THIS UNIT IN MANUFACTURED (MOBILE) HOMES.

IMPROPER INSTALLATION IS MORE LIKELY IN MANUFACTURED HOUSING

DUE TO DUCTWORK MATERIAL, SIZE, LOCATION, AND ARRANGEMENT.

INSTALLATIONS IN MANUFACTURED HOUSING CAN CAUSE A FIRE RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

EXCEPTION: MANUFACTURED HOUSING INSTALLATIONS ARE APPROVED

ONLY WITH DOCUMENTATION BY A RECOGNIZED INSPECTION AUTHORITY

THAT THE INSTALLATION HAS BEEN MADE IN COMPLIANCE WITH THE

INSTRUCTIONS AND ALL WARNINGS HAVE BEEN OBSERVED.

CAUTION

!

When used on cooling applications, excessive sweating may occur when unit

is installed in an unconditioned space. This can result in property damage.

• Some building codes require extra cabinet insulation and gasketing when

unit is installed in attic applications.

• If installed in an unconditioned space, apply caulking around the power

wires, control wires, refrigerant tubing and condensate line where they enter

the cabinet. Seal the power wires on the inside where they exit conduit

opening. Caulking is required to prevent air leakage into and condensate

from forming inside the unit, control box, and on electrical controls.

• Install the unit in such a way as to allow free access to the coil/filter compartment and blower/control compartment.

• Install the unit in a level position to ensure proper condensate drainage.

Make sure unit is level in both directions within 1/8”.

• Install the unit in accordance with any local code which may apply and the

national codes. Latest editions are available from: “National Fire Protection

Association, Inc., Batterysmarch Park, Quincy, MA 02269.” These publications

are:

• ANSI/NFPA No. 70-(Latest Edition) National Electrical Code.

• NFPA90A Installation of Air Conditioning and Ventilating Systems.

• NFPA90B Installation of warm air heating and air conditioning systems.

• The equipment has been evaluated in accordance with the Code of Federal

Regulations, Chapter XX, Part 3280.

(SEE WARNINGS IN REGARD TO DUCTWORK)

FIGURE 4

DIMENSIONS FOR FRONT CONNECT COIL

153/4”

133/4”

91/2”

71/2”

NOTE: FOR “W”

MEASUREMENT,

SEE FIGURE 3.

C

1

L

3

/4”

1.5”

2.0”

C

L

W

2.6 UNIT CONFIGURATION

All units are modular construction allowing installer to disassemble unit into two 17-1/2”

high components, coil casing and blower unit, for ease of installation, then reassemble

in location.

TO DISASSEMBLE:

Remove both access panels and remove six screws holding coil casing to blower unit,

lift blower unit from coil casing.

11

Page 12

TO REASSEMBLE:

To attach coil casing to blower unit, make sure 3/4” flanges on back and sides of

return air opening of blower casing are bent along perforated edge to inside of casing.

Clearance holes in flange should match up with drive holes on inside of blower casing. Make sure 3/4” flanges on coil casing are bent up (back and 2 sides only) on supply air side of coil casing along perforated edge. Do not bend flange on front of coil

casing. Set supply air side of coil casing (3/4” flanges) into return air opening of blower casing. Replace 6 - #8 screws through flange in coil casing, flange in blower casing

and into drive holes on inside of blower casing, two screws in back and two screws in

each side. Do not overtighten sheet metal screws, they will strip easily if overtightened.

IMPORTANT: Configure the unit with the indoor coil casing installed on air inlet

(return) side of the blower section. Do not try to configure unit with indoor coil on

discharge (supply) side of blower section.

2.7 VERTICAL UPFLOW

• Electrical connections can be made from either the left or right side of the unit.

Refrigerant and condensate drain connections are made on the front of the unit (see

Figures 3 & 4).

• If return air is to be ducted, install duct flush with floor. Use fireproof resilient gasket 1/8

to 1/4 in. thick between duct, unit and floor. Set unit on floor over opening.

WARNING

!

IF UNIT IS TO BE INSTALLED WITHOUT AN INDOOR COIL, RETURN DUCT OR

PLENUM, IT MUST NOT BE IN STALLED DIRECTLY OVER COMBUSTIBLE MATERIAL. IF INSTALLED WITHOUT AN INDOOR COIL WITH A RETURN DUCT OR

PLENUM, THE AIR PLENUM OR DUCT MUST HAVE A SOLID SHEET METAL

BOTTOM WITH NO RETURN AIR OPENINGS, REGISTERS OR FLEXIBLE AIR

DUCTS LOCATED DIRECTLY UNDER THE UNIT. EXPOSING COMBUSTIBLE

MATERIAL TO THE RETURN OPENING OF AN UPFLOW UNIT WITHOUT AN

INDOOR COIL CAN CAUSE A FIRE RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

2.8 VERTICAL DOWNFLOW

Conversion to Vertical Downflow: A vertical upflow unit may be converted to vertical

downflow. (See Figure 3)

• Remove the indoor coil.

• Install coil rails in the top of the coil box (supplied).

• Rotate unit into the downflow position, with the coil compartment on top and the blower compartment on bottom.

• Reinstall the indoor coil in its new position.

• Rotate the circuit breaker(s) 180° (see instructions for rotating breaker(s) that follow).

IMPORTANT NOTE:

• In a downflow configuration the internal air filter must not be used.

• A remote air filter should be installed in the return air system

• The remote air filter should be sized for a maximum of 300 feet per minute of air velocity for the CFM required.

12

Page 13

FIGURE 5

ROTATING CIRCUIT BREAKER

IMPORTANT: To comply with certification agencies and the National Electric

Code, units with circuit breaker(s) on vertical units must have circuit breakers

installed so that the breaker switch “on” position and marking is up and, “off”

position and marking is down.

- To turn breaker(s): Rotate one breaker pair (circuit) at a time starting with the one on the

right. Loosen both lugs on the load side of the breaker. Wires are bundles with wire ties,

one bundle going to the right lug and one bundle going to the left lug.

- Using a screwdriver or pencil, lift white plastic tab with hole away from breaker until

breaker releases from mounting opening (see Figure 5).

- With breaker held in hand, rotate breaker so that “on” position is up, “off” position is down

with unit in planned vertical mounting position. Insert right wire bundle into top right

breaker lug, ensuring all strands of all wires are inserted fully into lug, and no wire insulation is in lug.

- Tighten lug as tight as possible while holding circuit breaker. Check wires and make sure

each wire is secure and none are loose. Repeat for left wire bundle in left top circuit

breaker lug.

- Replace breaker by inserting breaker mounting tab opposite white pull tab in opening,

hook mounting tab over edge in opening.

- With screwdriver or pencil, pull white tab with hole away from breaker while setting that

side of breaker into opening. When breaker is in place, release tab, locking circuit breaker into location in opening.

- Repeat above operation for remaining breaker(s) (if more than one is provided).

- Replace single point wiring jumper bar, if it is used, on line side of breaker and tighten

securely.

- Double check wires and lugs to make sure all are secure and tight. Check to make sure

unit wiring to circuit breaker load lugs match that shown on the unit wiring diagram.

• Electrical connections can be made from either the left or right side of the unit.

Refrigerant and condensate drain connections are made on the front of the unit (see

Figure 4).

• RXBB-AA combustible floor base is used for all unit sizes. Unit must be centered on

combustible base in the width dimension (14

WARNING

!

THE RXBB-AA COMBUSTIBLE FLOOR BASE IS REQUIRED WHEN SOME

UNITS WITH ELECTRIC HEAT ARE APPLIED DOWNFLOW ON COMBUSTIBLE

FLOORING. FAILURE TO USE THE BASE CAN CAUSE A FIRE RESULTING IN

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH. SEE CLEARANCES

FOR UNITS REQUIRING A COMBUSTIBLE FLOOR BASE.

3

/8”).

13

Page 14

WARNING

!

THE FIRST 36 INCHES OF SUPPLY AIR PLENUM AND DUCTWORK MUST BE

CONSTRUCTED OF SHEET METAL AS REQUIRED BY NFPA 90B. THE SUPPLY

AIR PLENUM OR DUCT MUST HAVE A SOLID SHEET METAL BOTTOM

DIRECTLY UNDER THE UNIT WITH NO OPENINGS, REGISTERS OR FLEXIBLE

AIR DUCTS LOCATED IN IT. IF FLEXIBLE SUPPLY AIR DUCTS ARE USED THEY

MAY BE LOCATED ONLY IN THE VERTICAL WALLS, OF A RECTANGULAR

PLENUM, A MINIMUM OF 6 INCHES FROM THE SOLID BOTTOM. METAL

PLENUM OR DUCT MAY BE CONNECTED TO THE COMBUSTIBLE FLOOR

BASE, IF NOT, IT MUST BE CONNECTED TO THE UNIT SUPPLY DUCT

FLANGES SUCH THAT COMBUSTIBLE FLOOR OR OTHER COMBUSTIBLE

MATERIAL IS NOT EXPOSED TO THE SUPPLY AIR OPENING FROM THE

DOWNFLOW UNIT. EXPOSING COMBUSTIBLE (NON-METAL) MATERIAL TO

THE SUPPLY OPENING OF A DOWNFLOW UNIT CAN CAUSE A FIRE RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

EXCEPTIONS TO DOWNFLOW WARNINGS:

• INSTALLATIONS ON CONCRETE FLOOR SLAB WITH SUPPLY AIR PLENUM

AND DUCTWORK COMPLETELY ENCASED IN NOT LESS THAN 2 INCHES OF

CONCRETE (SEE NFPA 90B).

• INSTALLATIONS OF UNITS WITHOUT ELECTRIC HEATERS.

2.9 HORIZONTAL

Units with an “H” (left-hand air supply) in the airflow direction position in the model number

have factory configured evaporator coils for installation in the horizontal position.

Conversion to Horizontal: A vertical upflow evaporator coil may be converted to horizontal by removing the indoor coil and installing horizontal drain pan on coil as shown for right

hand or left hand air supply. Reinstall coil in unit as shown for right or left hand air supply.

See Figures 6 & 7.

Conversion in Horizontal Direction: Evaporator coils configured for horizontal left-hand

supply can be changed to horizontal right-hand supply by removing the indoor coil and

installing the drain pan as shown in Figures 6 & 7 for appropriate air supply direction.

FIGURE 6

INDOOR COIL AND DRAIN PAN SET-UP

HORIZONTAL LEFT-HAND AIR SUPPLY

CAUTION

!

HORIZONTAL UNITS MUST BE CONFIGURED FOR RIGHT HAND AIR SUPPLY

OR LEFT HAND AIR SUPPLY. HORIZONTAL DRAIN PAN MUST BE LOCATED

UNDER INDOOR COIL. FAILURE TO USE THE DRAIN PAN CAN RESULT IN

PROPERTY DAMAGE.

Horizontal Drain Pan Model RXBD-CB: This drain pan is used on all coil models and

fits all unit sizes either right or left hand air supply.

• Install horizontal drain pan as shown for right hand or left hand supply. Drain pan connections must be toward front of coil (header connection end). Install coil assembly

FIGURE 7

INDOOR COIL AND DRAIN PAN SET-UP

HORIZONTAL RIGHT-HAND AIR SUPPLY

14

I156

I156

Page 15

into horizontal pan as shown with coil endplates fitting into “V” shaped supports in the

front and back of the horizontal pan. Mounting tabs on vertical drain pan fit over the

air inlet side of the horizontal pan with vertical pan inside horizontal drain pan.

Horizontal pan must be under indoor coil when in the installed position. Note primary

and auxiliary drain pan positions for horizontal right vs. horizontal left. Drain connection with 3/4” hole must be connected to primary drain. Connection with 3/8” knockout

is the secondary drain connection.

Electrical connections may be made from the top or bottom of the unit. Refrigerant

and condensate drain connections must be made on the front of the unit. (See unit

dimensions and horizontal right hand supply and horizontal left hand supply, Figures

3, 6 & 7.)

IMPORTANT: Units cannot be installed horizontally laying on or suspended from the

back of the unit. Horizontal units must be supported or suspended from one side or the

other when in the horizontal position.

• Support along the length of the unit, all units installed horizontally. Do not support or

suspend unit from both ends without support in the center of the cabinet. If unit is to

be supported or suspended from corners, run two reinforcing rails length of unit and

support or suspend from reinforcing rails.

NOTE: When converting a vertical upflow to horizontal, the foam tape must be removed

from both sides of the vertical pan going into the horizontal pan. When converting a

horizontal left-hand to horizontal right-hand, the foam tape must be moved to the

appropriate location.

WARNING

!

THE SUPPLY AIR PLENUM OR DUCT MUST HAVE A SOLID SHEET METAL

BOTTOM WITH NO SUPPLY AIR OPENINGS, REGISTERS OR FLEXIBLE AIR

DUCTS LOCATED IN IT FOR THE FIRST 36 INCHES OF HORIZONTAL SURFACE

ON UNITS WITH ELECTRIC HEATERS. FAILURE TO OBSERVE SUPPLY

PLENUM, DUCT WARNINGS CAN CAUSE A FIRE RESULTING IN PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

3.0 ELECTRICAL WIRING

Field wiring must comply with the National Electric Code (C.E.C. in Canada) and any

applicable local ordinance.

3.1 POWER WIRING

It is important that proper electrical power is available for connection to the unit model

being installed. See the unit nameplate, wiring diagram and electrical data in the installation instructions.

• If required, install a branch circuit disconnect of adequate size, located within sight of,

and readily accessible to the unit.

• Units with factory installed circuit breaker(s) meet UL and CSA requirements as a service disconnect and should make above requirement for a field installed branch circuit

disconnect unnecessary.

• IMPORTANT: Units may be equipped with one, two, or three 60 amp. circuit breakers.

These breaker(s) protect the internal wiring in the event of a short circuit and serve as

a disconnect. Circuit breakers installed within the unit do not provide over-current protection of the supply wiring and therefore may be sized larger than the branch circuit

protection.

• Supply circuit power wiring must be 75°C minimum copper conductors only. See electrical data for ampacity, wire size and circuit protector requirement. Supply circuit protective devices may be either fuses or “HACR” type circuit breakers.

• Power wiring may be connected to either the right or left side (vertical) top or bottom

(horizontal). A 7/8”, 1-3/32” dia. concentric knockout is provided for connection of

power wiring to unit. If a larger opening is required, dependent upon kW electric heat

supplied, pull appropriate size hole required for conduit size being used. Using a conduit hole punch (Greenlee type), center punch using outside cabinet around 7/8”

knockout as a template to center punch location and punch desired hole size. Holes

may be punched for any size conduit up to a 2” hole for 1-1/2” con duit.

• Power wiring is connected to either the power terminal block or circuit breaker(s) in

unit control compartment.

•Single phase units above 10.5 kW may be supplied with circuit breaker(s) requiring

separate supply circuits. Units come standard with a jumper bar assembly connecting

separate circuits into one single supply circuit (excluding 18 kW and 21 kW “C” voltage units).

15

Page 16

• Jumper bar assemblies are connected to the line side lugs of the circuit breakers.

Jumper bar is assembled for left (upflow) cabinet power wiring entrance. To convert to

right (upflow) power entrance: Remove jumper cover, remove jumper bar from circuit

breakers, remove screw on back holding left lug in upper hole to bar, reassemble lug

in lower hole and retighten screw. Use the same procedure to move the right lug to

the upper mounting hole. Reassemble jumper bar into circuit breakers and tighten

lugs. Jumper bar is now ready for wiring from the opposite side.

• If a factory supplied jumper bar for single supply circuit is removed from unit to make

multiple supply circuits the line side of the individual circuit breakers must be covered

with finger safe covers. (See information on accessories for part numbers.)

• After wiring is complete, make sure finger safe cover(s) are replaced over circuit

breaker(s) lugs covering lug where field connections are made. On units with jumper

bar, make sure jumper bar cover is replaced and secured in place. Covers provided

for jumper bar must have side of cover broken off on the side wiring has been connected so that field supply will clear under appropriate side of cover. Units with circuit

breakers must have covers in place to meet requirements as a service disconnect.

3.2 CONTROL WIRING

IMPORTANT: Class 2 low voltage control wire should not be run in conduit with

power wiring and must be separated from power wiring, unless class 1 wire of

proper voltage rating is used.

• Low voltage control wiring should be 18 AWG color-coded (105°C minimum). For

lengths longer than 100 ft., 16 AWG wire should be used.

• Control wiring should be routed through 1/2” dia. knockout near power wiring

entrance on either left or right side of unit. After opening selected knockout, install

bushing (supplied in parts bag) in openings.

• If control wiring is routed through right side (upflow), it must be routed through extruded holes in lower front of blower housing behind power raceway to the left side of

blower housing. If routed through left side (upflow), it should be routed through

extruded hole in lower front left blower side.

• Field control connections are made to terminals extending from left side of control

compartment (upflow position).

• See wiring diagrams attached to indoor and outdoor sections to be connected, control

wiring diagram booklet supplied with outdoor heat pump section, or Figures 8 and 9.

• Do not leave excess field control wiring inside unit, pull excess control wire to outside

of unit and provide strain relief for field control wiring on inside of cabinet at point

wiring penetrates cabinet.

• Make sure, after installation, separation of control wiring and power wiring has been

maintained.

16

3.3 GROUNDING

WARNING

!

THE UNIT MUST BE PERMANENTLY GROUNDED. FAILURE TO DO SO CAN

RESULT IN ELECTRICAL SHOCK CAUSING PERSONAL INJURY OR DEATH.

• Grounding may be accomplished by grounding metal conduit when installed in accordance with electrical codes to the unit cabinet.

• Grounding may also be accomplished by attaching ground wire(s) to ground lug(s)

provided in the unit wiring compartment.

• Ground lug(s) are located close to wire entrance on left side of unit (upflow). Lug(s)

may be moved to marked locations near wire entrance on right side of unit (upflow), if

alternate location is more convenient.

• Use of multiple supply circuits require grounding of each circuit to lug(s) provided in

unit.

Page 17

3.4 BLOWER MOTOR ELECTRICAL DATA: “A” VOLTAGE (115V)

MODEL

SIZE/ELEC.

DESIGNATION

(-)BHP-17A00NH* 115 1 60 1/3 [249] 300-1100 5 3.3 5.0 15

(-)BHP-21A00NH* 115 1 60 1/2 [373] 300-1100 5 5.0 7.0 15

(-)BHP-24A00NH* 115 1 60 3/4 [559] 300-1100 5 5.8 8.0 15

(-)BHP-25A00NH* 115 1 60 3/4 [559] 300-1100 5 7.7 10.0 15

VOLTAGE

HERTZPHASE

HP

[W]

SPEEDSRPM

CIRCUIT

AMPS.

MINIMUM

CIRCUIT

AMPACITY

MAXIMUM

PROTECTOR

3.5 BLOWER MOTOR ELECTRICAL DATA: “J” VOLTAGE (208/240V)

MODEL

SIZE/ELEC.

DESIGNATION

(-)BHP-17J00NH* 208/240 1 60 1/3 [249] 300-1100 5 2.0 3.0 15

(-)BHP-21J00NH* 208/240 1 60 1/2 [373] 300-1100 5 3.1 4.0 15

(-)BHP-24J00NH* 208/240 1 60 3/4 [559] 300-1100 5 4.2 6.0 15

(-)BHP-25J00NH* 208/240 1 60 3/4 [559] 300-1100 5 5.7 8.0 15

VOLTAGE

HERTZPHASE

HP

[W]

SPEEDSRPM

CIRCUIT

AMPS.

MINIMUM

CIRCUIT

AMPACITY

MAXIMUM

PROTECTOR

3.6 ELECTRIC HEAT ELECTRICAL DATA

Model Size/

Elec./KW

Designation

(-)BHP-17J06SH* 3.7/4.9 1/60 2/2.5 Single Circuit 19.8/22.4 25/29 25/30

(-)BHP-17J07SH* 5.3/7.0 1/60 2/3.5 Single Circuit 27.5/31.2 35/39 40/40

(-)BHP-17J11SH* 7.5/10.0 1/60 3/3.3 Single Circuit 38.1/43.7 48/55 50/60

(-)BHP-21J06SH* 3.7/4.9 1/60 2/2.5 Single Circuit 20.9/23.5 27/30 30/30

(-)BHP-21J07SH* 5.3/7.0 1/60 2/3.5 Single Circuit 28.6/32.3 36/41 40/45

(-)BHP-21J11SH* 7.5/10.0 1/60 3/3.3 Single Circuit 39.2/44.8 49/56 50/60

(-)BHP-24J06SH* 3.7/4.9 1/60 2/2.5 Single Circuit 22.0/24.6 28/31 30/35

(-)BHP-24J07SH* 5.3/7.0 1/60 2/3.5 Single Circuit 29.7/33.4 38/42 40/45

(-)BHP-24J11SH* 7.5/10.0 1/60 3/3.3 Single Circuit 40.3/45.9 51/58 60/60

(-)BHP-24J18SH* 5.3/7.0 1/60 2/3.5 Multiple Ckt. 1 29.7/33.4 38/42 40/45

(-)BHP-25J11SH* 7.5/10.0 1/60 3/3.3 Single Circuit 91.8/47.4 53/60 60/60

(-)BHP-25J18SH* 5.3/7.0 1/60 2/3.5 Multiple Ckt. 1 31.2/39.9 39/44 40/45

Heater

KW

Volts

208/240

13.2/17.5 5/3.5 Single Circuit 67.7/77.1 85/97 90/100

7.9/10.5 3/3.5 Multiple Ckt. 2 39.0/43.8 48/55 50/60

13.2/17.5 5/3.5 Single Circuit 69.2/78.6 87/99 90/100

7.9/10.5 3/3.5 Multiple Ckt. 2 38.0/43.8 48/55 50/60

PH/HZ

Heater

No./KW

@ 240V

Type Supply Circuit

Single Circuit

Multiple Circuit

Circuit

Amps.

Minimum

Circuit

Ampacity

Maximum

Circuit

Protector

CIRCUIT

CIRCUIT

Supply circuit protective devices may be fuses or “HACR” type circuit breakers. Largest motor load is included in single circuit and circuit 1 multiple circuit. If nonstandard fuse size is specified, use next size larger standard fuse size.

17

Page 18

w

W2

G

Y

W1

B

C

R

Air Handler

Control Board

G

Y

C

R

Single-Stage A/C Thermostat

A/C Outdoor Unit

Y

C

Y

G/BK

BR

R

Y

BR

FIGURE 8

B

W2

G

Y

W1

B

C

R

Air Handler

Control Board

Y

G

W2

E

Heat Pump Thermostat

Heat Pump

Outdoor Unit

C

R

Y

B

C

R

D

Y

G/BK

BR

W/BL

W/BK

BL

BR

R

Y

BL

R

P

*

TYPICAL THERMOSTAT WIRING – STRAIGHT COOLING WITH ELECTRIC HEAT

FIGURE 9

HEAT PUMP WITH ELECTRIC HEAT

Purple

*Recommitted to jump W1 and W2 together for maximum temperature rise

18

Page 19

4.0 DUCTWORK

Field ductwork must comply with the National Fire Protection Association NFPA 90A,

NFPA 90B and any applicable local ordinance.

WARNING

!

UNITS ARE FOR DUCTED APPLICATIONS ONLY. A MINIMUM OF 36 INCHES OF

SUPPLY AIR PLENUM AND DUCTWORK IS REQUIRED. NO SUPPLY AIR OPENINGS, REGISTERS OR FLEXIBLE AIR DUCTS MAY BE LOCATED WITHIN THE

FIRST 36 INCHES OF SUPPLY PLENUM AND DUCTWORK ON UNITS WITH

ELECTRIC HEATERS. FAILURE TO OBSERVE SUPPLY PLENUM/DUCT WARNINGS CAN CAUSE A FIRE RESULTING IN PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

Sheet metal ductwork run in unconditioned spaces must be insulated and covered with a

vapor barrier. Fibrous ductwork may be used if constructed and installed in accordance

with SMACNA Construction Standard on Fibrous Glass Ducts. Ductwork must comply

with National Fire Protection Association as tested by U/L Standard 181 for Class I Air

Ducts. Check local codes for requirements on ductwork and insulation.

• Duct system must be designed within the range of external static pressure the unit is

designed to operate against. It is important that the system airflow be adequate. Make

sure supply and return ductwork, grills, special filters, accessories, etc. are accounted

for in total resistance. See airflow performance tables in this manual.

• Design the duct system in accordance with “ACCA” Manual “D” Design for Residential

Winter and Summer Air Conditioning and Equipment Selection. Latest editions are

available from: “ACCA” Air Conditioning Contractors of America, 1513 16th Street,

N.W., Washington, D.C. 20036. If duct system incorporates flexible air duct, be sure

pressure drop information (straight length plus all turns) shown in “ACCA” Manual

“D” is accounted for in system.

• Supply plenum is attached to the 3/4” duct flanges supplied on the unit around the

blower outlet. Flanges are flat for shipping purposes and must be bent up along perforated edge around blower opening. Be sure to bend flanges completely up so they do

not interfere with air being discharged from blower.

IMPORTANT: Flanges around blower opening for attaching supply duct must be

bent up out of blower discharge even if not used so they do not restrict airflow

from blower.

• Supply plenum should be the same size as the flanges provided around the blower

outlet. Ideally, it should extend 3 feet from the unit before turning or branching off

plenum into duct runs. The plenum forms an extension of the blower housing and

minimizes air expansion losses from the blower. Changing the size, shape or length

will degrade blower performance. If supply discharges directly into a larger duct or

plenum as much as .1” W.C., static pressure will be lost. If 3 feet is not possible, even

6, 12 or 18 inches will help.

IMPORTANT: If an elbow is included in the plenum close to the unit, it must not be

smaller than the dimensions of the supply duct flange on the unit.

• Some units with electric heaters require 1 in. clearance to supply plenum and branch

ducts to combustible material for the first 3 feet from the unit. See CLEARANCES.

• A 3/4” return duct flange is supplied on all sides of the air inlet opening of the unit coil

casing. If the unit is to be installed without a coil casing (no indoor coil), a 3/4” flange

is supplied on the back and sides of the air inlet opening of the blower casing. No

flange is provided on the front of the opening to the blower casing. If return duct is

attached to the inlet of the blower casing, the front flange of the duct should be run up

into the opening or 90° brake made on the front flange to tape to the front of the blower casing.

• IMPORTANT: The front flange on the return duct if connected to the blower cas-

ing must not be screwed into the area where the power wiring is located. Drills

or sharp screw points can damage insulation on wires located inside unit.

• Return duct flanges on blower or coil casing are flat for shipping purposes and must

be bent out along perforated edge around opening.

• Secure the supply and return ductwork to the unit flanges, using proper fasteners for

the type of duct used and tape the duct-to-unit joint as required to prevent air leaks.

(SEE SPECIFIC AIRFLOW POSITION FOR ADDITIONAL

WARNINGS)

19

Page 20

5.0 REFRIGERANT CONNECTIONS

Keep coil connections sealed until refrigerant connections are to be made. See outdoor

unit manual for details on line sizing, tubing installation, evacuation and charging information.

• To install the refrigerant connections, first install the refrigerant block-off plate (located in the Parts Bag, see Figure 10) around the refrigerant connections. Braze all fittings. When refrigerant lines have cooled, insert the foam gasket (located in the parts

bag, see Figure 10) around the refrigerant lines, between the coil and the refrigerant

block-off plate.

IMPORTANT: The refrigerant block-off plate MUST be installed around the refrigerant connections before brazing.

• When making braze connections close to outside of cabinet, use a brazing shield to

protect cabinet paint from being damaged from torch flame.

• If the installation is in a tight location, it might be convenient to make some external

tubing connections before setting unit in place.

IMPORTANT: Install refrigerant tubing so it does not block service access to front of unit.

24 in. clearance is required for filter, coil or blower removal and service access.

FIGURE 10

REFRIGERANT BLOCK-OFF PLATE AND FOAM GASKET

20

5.1 FLOWCHECK PISTONS

See outdoor unit installation instructions for correct flowcheck piston sizes and proper

piston installation instructions.

• Indoor coil piston size is indicated by the digits underscored in the indoor coil model

number.

IMPORTANT: It is important that the proper piston sizes be used dependent on

indoor coil, outdoor unit combination and application.

Page 21

6.0 CONDENSATE DRAIN TUBING

Consult local codes or ordinances for specific requirements that may apply.

• The coil door is shipped from the factory with the condensate drain knockout

attached. Knockout must be removed and the condensate block-off plate (included in

parts bag, see Figure 11) must be installed to access the front drain.

• Vertical units (vertical drain pan) are supplied with a 3/4” female pipe thread primary

drain connection and a 3/4” female pipe thread auxiliary drain connection. (See unit

dimensions figures for drain locations.)

IMPORTANT: Side drain connections on vertical drain pans have a plastic web

covering opening. Connection(s) used must be broken out before connection(s)

are made. Break out only connection(s) to be used. Front drain connections have

removable threaded plastic plugs factory installed. Plugs must be removed before

connections are made; do not remove plugs if these connections are not used.

• Horizontal units (horizontal drain pan) are supplied with a 3/4” female pipe thread primary drain connection and a 3/4” female pipe thread auxiliary drain connection. (See

unit dimensions and position figures for drain locations).

IMPORTANT: All horizontal pans have plastic web over the secondary drain connection. Plastic web covering secondary connection must be broken out if used.

Secondary connection is lowered by 3/8”. Do not get primary and secondary connections interchanged.

• Removal of door knockouts required for drain connections can be made much easier

with the door removed from the cabinet.

• Install drain lines so they do not block service access to front of unit. 24 in. clearance

is required for filter, coil or blower removal and service access.

• Make sure unit is level or pitched slightly toward primary drain connection so that

drain pan will drain completely without water standing in pan.

FIGURE 11

CONDENSATE BLOCK-OFF PLATE

IMPORTANT: 2-6" PVC lengths are provided for making drain connection. When

making drain fitting connections to drain pan, use a thin layer of teflon paste, silicone or teflon tape and install hand tight.

IMPORTANT: When making drain fitting connections to drain pan, do not over

torque. Overtorquing fittings can split pipe connections on drain pan.

• Do not reduce drain line size less than connection size provided on condensate drain

pan.

• All drain lines must be pitched downward away from the unit a minimum of 1/8 in. per

foot of line to ensure proper drainage.

• Do not connect condensate drain line to a closed or open sewer pipe. Run condensate to an open drain or outdoors.

• The drain line should be insulated where necessary to prevent sweating and damage

due to condensate forming on the outside surface of the line.

21

Page 22

• Make provisions for disconnecting and cleaning of the primary drain line should it

become necessary.

• Install a 2 in. trap in the primary drain line as close to the unit as possible. Make sure

that the top of the trap is below connection to the drain pan to allow complete

drainage of pan.

IMPORTANT: Do not operate unit without a drain trap (see Figure 12). The condensate drain is on the negative side of the blower, therefore, air being pulled in

through the condensate line will prevent positive drainage without a proper trap.

• Auxiliary drain if used should be run to a place where it will be noticeable if it become

operational. Occupant should be warned that a problem exists if water should begin

running from the auxiliary drain line.

• Test condensate drain pan and drain line after installation is complete. Pour several

quarts of water into drain pan, enough to fill drain trap and line. Check to make sure

drain pan is draining completely, no leaks are found in drain line fittings, and water is

draining from the termination of the primary drain line.

FIGURE 12

CONDENSATE DRAIN TRAP

ST-A1244-01-01

7.0 AIR FILTER

The unit internal air filter should only be used if the unit is readily accessible for filter

cleaning or replacing.

• If unit is not readily accessible for filter maintenance, a remote filter should be

installed in the return air system.

• If a remote filter is installed, it should be sized for a maximum of 300 feet/min. air

velocity for the CFM required..

IMPORTANT: Do not operate system without a filter. A filter is required to protect

the coil, blower and internal parts from excessive dirt and dust.

• See unit position figures for location of filter in unit cabinet and service panel giving

access to unit filter.

IMPORTANT NOTE:

• In a downflow configuration the internal air filter must not be used.

• A remote air filter should be installed in the return air system

• The remote air filter should be sized for a maximum of 300 feet per minute of air velocity for the CFM required.

8.0 AIRFLOW PERFORMANCE

Airflow performance data is based on cooling performance with a coil and filter in

place. Select performance table for appropriate unit size, voltage and number of electric

heaters to be used. Make sure external static applied to unit allows operation within the minimum and maximum limits shown in table on next page for both cooling and electric heat

operation. For optimum blower performance, operate the unit in the .2” to .5” in. W.C. external static range. In general, the indoor motor speed tap should be as shown in table for the

appropriate cooling capacity shown. Always check to make sure proper motor speed tap is

connected as units are shipped from the factory connected for high speed operation (Speed

Tap 5).

22

Page 23

8.1 AIRFLOW OPERATING LIMITS

Nominal

Speed Tap

Volts 0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17] 0.8 [.20] 0.9 [.23] 1.0 [.25]

none 2 208/240

659 [311]

(74)

625 [294] (80)

581 [274]

(84)

539 [254]

(88)

------

none 3 208/240

790 [372]

(98)

759 [358]

(105)

722 [340]

(113)

687 [324]

(119)

650 [306]

(126)

615 [290]

(131)

573 [270]

(139)

552 [260]

(145)

507 [239]

(150)

460 [217]

(155)

3 (max.) 2 208/240

649 [306]

(79)

615 [290] (84)

571 [269]

(88)

529 [249]

(92)

------

3 (max.) 3 208/240

773 [365]

(110)

736 [347]

(113)

699 [330]

(118)

677 [320]

(126)

640 [302]

(132)

605 [286]

(141)

563 [266]

(146)

542 [256]

(154)

497 [235]

(157)

450 [212]

(162)

none 2 115

651 [307]

(76)

627 [295] (82)

583 [275]

(86)

541 [255]

(90)

------

none 3 115

776 [366]

(105)

743 [351]

(109)

724 [342]

(118)

687 [324]

(122)

658 [311]

(131)

617 [291]

(136)

595 [281]

(144)

555 [262]

(148)

517 [244]

(152)

460 [217]

(162)

none 4 208/240

844 [398]

(141)

819 [386]

(146

799 [377]

(155)

764 [360]

(160)

------

none 5 208/240

958 [452]

(162)

934 [440]

(172)

914 [431]

(176)

888 [419]

(186)

855 [403]

(189)

816 [380]

(210)

785 [370]

(204)

760 [358]

(214)

708 [334]

(223)

672 [317]

(226)

3 (max.) 4 208/240

834 [393]

(146)

809 [831]

(150)

789 [372]

(159)

754 [355]

(164)

------

3 (max.) 5 208/240

946 [446]

(179)

922 [435]

(189)

902 [426]

(193)

876 [413]

(203)

843 [398]

(206)

804 [380]

(216)

773 [365]

(221)

748 [353]

(231)

696 [328]

(240)

660 [311]

(243)

none 4 115

846 [399]

(143)

821 [387]

(148)

801 [378]

(157)

766 [361]

(162)

------

none 5 115

964 [455]

(167)

945 [446]

(178)

914 [431]

(181)

888 [419]

(191)

861 [406]

(196)

821 [387]

(205)

787 [372]

(210)

761 [359]

(218)

726 [342]

(220)

690 [326]

(230)

none 2 208/240

1068 [504]

(138)

1041 [491]

(147)

1001 [472]

(153)

972 [458]

(161)

------

none 3 208/240

1187 [560]

(180)

1162 [548]

(188)

1125 [530]

(192)

1099 [518]

(200)

1058 [499]

(208)

1013 [478]

(215)

982 [463]

(223)

951 [448]

(232)

899 [424]

(234)

855 [403]

(237)

4 (max.) 2 208/240

1035 [488]

(143)

1007 [475]

(152)

966 [455]

(158)

936 [441]

(169)

------

4 (max.) 3 208/240

1157 [546]

(182)

1132 [534]

(192)

1095 [517]

(198)

1069 [505]

(209)

1028 [485]

(218)

983 [464]

(228)

952 [449]

(239)

921 [435]

(250)

869 [410]

(255)

825 [389]

(262)

none 2 115

1070 [504]

(138)

1043 [492]

(147)

1004 [473]

(153)

974 [459]

(161)

------

none 3 115

1138 [537]

(175)

1113 [525]

(186)

1075 [507]

(191)

1053 [497]

(203)

1004 [474]

(210)

957 [451]

(216)

932 [440]

(226)

901 [425]

(231)

855 [404]

(242)

800 [378]

(252)

none 4 208/240

1269 [598]

(207)

1236 [583]

(219)

1174 [554]

(226)

1149 [542]

(236)

------

none 5 208/240

1397 [659]

(287)

1377 [649]

(307)

1346 [635]

(317)

1318 [622]

(320)

1291 [609]

(322)

1264 [596]

(319)

1234 [582]

(312)

1190 [561]

(326)

1155 [545]

(351)

1126 [531]

(368)

4 (max.) 4 208/240

1241 [585]

(222)

1208 [570]

(234)

1174 [554]

(241)

1149 [542]

(251)

------

4 (max.) 5 208/240

1366 [645]

(302)

1346 [635]

(313)

1315 [621]

(323)

1287 [608]

(331)

1260 [595]

(341)

1233 [582]

(346)

1203 [568]

(358)

1159 [547]

(371)

1124 [530]

(381)

1095 [517]

(387)

none 4 115

1269 [598]

(207)

1236 [583]

(219)

1174 [554]

(226)

1149 [542]

(236)

------

none 5 115

1370 [646]

(292)

1343 [634]

(302)

1309 [618]

(309)

1285 [607]

(319)

1258 [594]

(330)

1221 [576]

(336)

1182 [558]

(348)

1147 [542]

(357)

1117 [527]

(366)

1080 [510]

(375)

3.0-ton Air

Flow

Model

Cabinet

Size

Electric

Heaters

Blower Motor

CFM [L/s] (Watts)/External Static Pressure-Inches W.C. [kPa] with filter & indoor coil

Tonnage

-17

-21

2.0-ton Air

Flow

1.5-ton Air

Flow

2.5-ton Air

Flow

Model/Cabinet Size 17 21 24 25

Cooling BTU/H 18000 24000 30000 36000 42000 48000 60000 60000

Cooling Tons Nominal 1.5 2 2.5 3 3.5 45 5

Heat Pump or Air Conditioning

Maximum Heat/Cool CFM 675 900 1125 1350 1575 1800 2025 2250

(37.5 CFM/1,000 BTUH)

(450 CFM/Ton Nominal)

Heat Pump or Air Conditioning

Nominal Heat/Cool CFM 600 800 1000 1200 1400 1600 1800 2000

(33.3 CFM/1,000 BTUH)

(400 CFM/Ton Nominal)

Heat Pump or Air Conditioning

Minimum Heat/Cool CFM 540 720 900 1080 1260 1440 1620 1800

(30.0 CFM/1,000 BTUH)

(360 CFM/Ton Nominal)

Maximum kW Electric Heating 11 11 11 11 18 18 18 18

& Minimum Electric Heat CFM 560 560 900 1220 1220 1220 1460 1460

Maximum Electric Heat Rise °F 85 85 35 35 65 65 43 43

See Airflow Performance Data for recommended blower motor speed.

8.2 AIRFLOW PERFORMANCE DATA

23

Page 24

none 2 208/240

1438 [678]

(205)

1409 [664]

(217)

1375 [648]

(229)

1341 [632]

(252)

------

none 3 208/240

1568 [740]

(279)

1538 [725]

(290)

1507 [711]

(303)

1471 [694]

(313)

1435 [677]

(333)

1403 [662]

(338)

1362 [642]

(358)

1318 [622]

(365)

1287 [607]

(374)

1250 [589]

(405)

5 (max.) 2 208/240

1414 [667]

(230)

1384 [653]

(242)

1350 [637]

(254)

1315 [620]

(277)

------

5 (max.) 3 208/240

1548 [730]

(304)

1518 [716]

(316)

1487 [701]

(328)

1451 [684]

(338)

1415 [667]

(358)

1383 [653]

(368)

1342 [633]

(388)

1298 [612]

(395)

1267 [597]

(409)

1230 [580]

(455)

none 2 115

1448 [683]

(205)

1419 [669]

(217)

1385 [653]

(229)

1351 [637]

(252)

------

none 3 115

1559 [735]

(294)

1527 [720]

(308)

1497 [706]

(322)

1466 [691]

(335)

1431 [675]

(349)

1378 [650]

(367)

1349 [636]

(379)

1306 [606]

(393)

1271 [599]

(406)

1250 [589]

(417)

none 4 208/240

1640 [773]

(311)

1604 [757]

(326)

1587 [748]

(335)

1559 [735]

(376)

------

none 5 208/240

1789 [844]

(413)

1762 [831]

(427)

1731 [816]

(433)

1699 [801]

(449)

1667 [786]

(462)

1635 [771]

(482)

1602 [756]

(498)

1546 [729]

(516)

1515 [715]

(529)

1465 [691]

(542)

5 (max.) 4 208/240

1613 [761]

(331)

1574 [742]

(346)

1557 [734]

(355)

1529 [721]

(396)

------

5 (max.) 5 208/240

1759 [830]

(433)

1732 [817]

(447)

1701 [802]

(453)

1669 [787]

(469)

1637 [772]

(482)

1605 [757]

(502)

1572 [741]

(518)

1516 [715]

(536)

1485 [700]

(549)

1435 [677]

(562)

none 4 115

1642 [774]

(311)

1606 [757]

(326)

1589 [749]

(335)

1561 [736]

(376)

------

none 5 115

1811 [854]

(423)

1791 [845]

(436)

1760 [830]

(451)

1730 [816]

(464)

1700 [802]

(479)

1669 [787]

(492)

1606 [757]

(516)

1573 [742]

(529)

1538 [725]

(542)

1462 [689]

(555)

none 2 208/240

1872 [883]

(373)

1837 [866]

(393)

1798 [848]

(407)

1763 [832]

(419)

------

none 3 208/240

2075 [979]

(497)

2036 [960]

(511)

2017 [951]

(533)

1984 [936]

(553)

1944 [917]

(563)

1910 [901]

(582)

1889 [891]

(599)

1846 [871]

(617)

1805 [851]

(626)

1783 [841]

(638)

5 (max.) 2 208/240

1831 [854]

(393)

1795 [847]

(413)

1756 [828]

(427)

1720 [811]

(439)

------

5 (max.) 3 208/240

2043 [964]

(517)

2004 [945]

(531)

1985 [936]

(553)

1951 [920]

(573)

1912 [901]

(583)

1878[886]

(602)

1857 [876]

(619)

1814 [856]

(637)

1773 836]

(646)

1751[826]

(658)

none 2 115

1872 [883]

(373)

1837 [866]

(393)

1798 [848]

(407)

1763 [832]

(419)

------

none 3 115

2075 [979]

(497)

2036 [960]

(511)

2017 [951]

(533)

1984 [936]

(553)

1944 [917]

(563)

1910 [901]

(582)

1889 [891]

(599)

1846 [871]

(617)

1805 [851]

(626)

1783 [841]

(638)

none 4 or 5 208/240

2102 [992]

(550)

2072

[977](568)

2042 [963]

(584)

2011 [949]

(593)

1974 [931]

(610)

1949 [919]

(631)

1916 [904]

(644)

1884 [889]

(662)

1851 [873]

(669)

1810 [854]

(692)

5 (max.) 4 or 5 208/240

2070 [976]

(560)

2040

[962](578)

2010 [948]

(594)

1979 [933]

(613)

1942 [916]

(620)

1917 [904]

(641)

1884 [889]

(654)

1852 [874]

(672)

1819 [858]

(679)

1778 [839]

(702)

none 4 or 5 115

2102 [992]

(550)

2072

[977](568)

2042 [963]

(584)

2011 [949]

(593)

1974 [931]

(610)

1949 [919]

(631)

1916 [904]

(644)

1884 [889]

(662)

1851 [873]

(669)

1810 [854]

(692)

3

3.5-ton Air

Flow

4.0-ton Air

Flow

5.0-ton Air

Flow

For external static exceeding 0.5", move the blue wire from the x-13 motoer to appropriate high static speed tab 3 (Lower tonnage)

or speed tab 5 (Higher tonnage)

-24

-25

are lower tonnage. Speed tab 4 (Low static) and Speed tab 5 (High static) are for higher tonnage.

The lower static speed 2 (lower tonnage) and speed tab 4 (Higher tonnage) are used for external static below 0.5"

X-13 NOTES (X-13 Motor Speed Changes)

X-13 Motors require no voltage change between 208 and 240 volts.

If appliction exceeds 0.5" of static, aduust the motor speed to the high static speed as described below:

All X-13 motors have 5 speed tabs. Speed tab 1 is for continuous fan. Speed 2 (Low static) and speed tab 3 (High Static)

8.2 AIRFLOW PERFORMANCE DATA – continued

24

Page 25

9.0 SEQUENCE OF OPERATION

9.1 Cooling (cooling only or heat pump)

• When the thermostat “calls for cooling,” the circuit between R, G and Y is completed,

causing the blower to energize. This circuit also closes the contactor (CC) in the outdoor unit starting the compressor (COMP) and outdoor fan motor (OFM).

9.2 Heating (electric heat only)

• When the thermostat “calls for heat,” the circuit between R and W1is completed, and

the heater sequencer (HR

elements (HE) and the indoor blower motor (IBM) will come on. Units with a second

heater sequencer (HR

thermostat sub-base or connected to a second stage W

on the furnace board MUST be connected for heating blower operation.

W

1

9.3 Heating (heat pump)

• When the thermostat “calls for heat,” the circuits between R and G are completed.

Circuit R and B energizes the reversing valve (RV) switching it to the heating position

(remains energized as long as system switch is in “heat” position). Circuit R and Y

energizes the contactor (CC) starting the outdoor fan motor (OFM), compressor

(COMP), and the indoor blower motor (IBM).

• If the room temperature should continue to fall, circuit R and W

second-stage heat room thermostat. Circuit R-W

The completed circuit will energize supplemental electric heat. Units with a second

heater sequencer (HR

stat or connected to a third heating stage W

the thermostat indicates when supplemental heat is being energized.

9.4 WATT RESTRICTOR

(Heating - Heat Pump)

• Heat pump air handlers with supplemental electric heat above a specific kW dependent on unit size and total heater kW are equipped with a patented watt restrictor.

Models so equipped are Cabinet Model Size -14 with more than 6 kW Cabinet Model

Size -17, -21 and -24 with more than 11 kW Watt restrictor (WR) may directly control

a heater element in the heater circuit or may be in the control circuit controlling heater

sequencer (HR

wiring diagram).

• The watt restrictor (WR) will restrict the amount of supplemental electric heat that can

be energized dependent on the heat output of the heat pump (temperature of the air

leaving the indoor heat pump coil).

Since the heat output of the heat pump is dependent upon the outdoor air temperature,

this control performs the same function as a field installed outdoor thermostat,.

An additional benefit of the watt restrictor is that it can sense a degradation in heat pump

performance due to causes other than outdoor temperature and react accordingly to

bring on more supplemental electric heat.

2) indirectly controlling two or three heater elements (HE) (see unit

) is energized. A time delay will follow then: The heating

1

) can be connected with the first sequencer (HR1) to W on the

2

2 energizes a heat sequencer (HR1).

2) can be connected with first sequencer (HR1) to W2 on thermo-

3 on the thermostat sub-base. A light on

on the sub-base.

2

2 is completed by the

9.5 DEFROST SEQUENCE

• For sequence of operation for defrost controls, see outdoor heat pump installation

instructions.

• Supplemental heat during defrost can be provided by connecting the purple (PU) pigtail in the outdoor unit to P on the indoor unit control board. This will complete the circuit between R and W through a set of contacts in the defrost relay (DR) when the

outdoor heat pump is in defrost. This circuit, if connected, will temper air being discharged from the indoor unit during defrost.

• Defrost heat control (DHC) is wired in series in the circuit described above on units

where the supplemental heat is more than would be required to offset the defrost

cooling capacity. Defrost heat control (DHC) is provided on the same models

described above having watt restrictors.

• When the outdoor unit goes into defrost, the circuit between R and W is completed

through a set of contacts on the defrost relay (DR) in series with the contacts on the

defrost heat control (DHC). Purple (PU) pigtails on the indoor unit and outdoor units

must be connected to make circuit. During defrost, the defrost heat control (DHC)

senses the air temperature leaving the indoor unit and cycles the supplemental electric heat to maintain comfort (75° to 85°) air temperature and prevent objectable cold