Rheem Raypak R207A, Raypak R337A, Raypak R267A, Raypak R407A Installation And Operation Manual

INSTALLATION AND

OPERATION MANUAL

Gas-Fired Pool

and Spa Heater

Low NOx Models 207A, 267A,

337A and 407A

WARNING: If the information is not followed exactly, a re or explosion may result causing property

damage, personal injury or death.

— Do not store or use gasoline or other flammable vapors and liquids or other combustible materials

in the vicinity of this or any other appliance. To do so may result in an explosion or fire.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

— Installation and service must be performed by a qualified installer, service agency or the gas supplier.

This manual should be maintained in legible condition and kept adjacent to the heater or in a safe place for future

reference.

Catalog No. 6000.592

Eective: 10-01-19

Replaces: New

P/N 241793 Rev 0

QUICK START GUIDE

CLEARANCES

Space required: See page 12.

Minimum and service clearances: See page 7 for

clearances table. Note that local codes prevail.

PIPING

Pressure relief valve: See page 18 for recommended

PRV orientation.

Flow rates: See page 15 for ow rate values.

GAS

Distance to regulator (pipe lengths) and gas inlet

sizes: See page 15.

Required pressure for Natural Gas:

Min = 5" WC, Max = 10.5" WC

Sediment trap is required for all installations.

See page 14.

WATER CHEMISTRY

Water chemistry requirements: See page 5.

POWER

Supply voltage: See page 21 for acceptable input

voltages.

VENTING

Materials: See pages 9, 11 and 13.

D-2 Power Vent Kit: See page 13.

Indoor Stack kit: See page 11.

CONTROLS INTERFACE

Wiring diagram: See page 23.

User interface: See page 24.

Remote operation: See page 28.

2

CONTENTS

1. WARNINGS ............................................................. 4

Pay Attention to These Terms ................................. 4

2. WATER CHEMISTRY ............................................. 5

Automatic Chlorinators and Chemical Feeders....... 5

3. BEFORE INSTALLATION ...................................... 6

Receiving equipment............................................... 6

Rating and certications .......................................... 6

Elevation ................................................................. 7

Ambient Temperature Rating .................................. 7

4. INSTALLATION ....................................................... 7

Installation Codes ................................................... 7

Clearances .............................................................. 7

Outdoor Heater Installation ..................................... 8

Combustion and Ventilation Air ............................. 11

Vent Piping ............................................................ 13

D-2 Power Vent Kit ................................................ 13

Gas Supply Connections....................................... 14

Flow Rates ............................................................ 15

ProTek Shield Assembly........................................ 16

Unitherm Governor Operation ............................... 17

Internal Automatic Bypass Valve ........................... 17

External Auxiliary Bypass Valve ............................ 18

Auxiliary Bypass Valve Adjustment .......................18

Pressure Relief Valve Installation .......................... 18

Plumbing Diagram................................................. 19

Heat Exchanger Reversal ..................................... 20

5. ELECTRICAL WIRING ......................................... 21

Electrical Power Draw ........................................... 21

Transformer Wiring ...............................................21

6. WIRING DIAGRAM ............................................... 23

7. CONTROLS ........................................................... 24

Control Panel Removal ......................................... 24

Control Adjustments – Digital Models ...................24

Operation .............................................................. 25

Status and Diagnostics ......................................... 27

Remote Control Installation and Operation ........... 28

Remote Control Wiring .......................................... 28

8. OPERATING INSTRUCTIONS ............................ 34

Before Start-Up ..................................................... 34

Start-Up Procedures ............................................. 34

9. MAINTENANCE AND CARE ............................... 36

Cold Weather Operation .......................................36

10. TROUBLESHOOTING ......................................... 37

Digital - Flow Chart................................................ 38

Control Logic - Flow Chart .................................... 39

11. REPLACEMENT PARTS ..................................... 40

12. ILLUSTRATED PARTS LIST .............................. 41

3

1. WARNINGS

Pay Attention to These Terms

DANGER

AA

WARNING

AA

CAUTION

AA

CAUTION

NOTE

DANGER: Failure to install the drafthood on indoor

AA

installation and properly vent the heater to the outdoors

as outlined in the venting section of this manual can

result in unsafe operation of the heater. To avoid the risk

of re, explosion, or asphyxiation from carbon monoxide,

never operate this heater unless it is properly vented

and has an adequate air supply for proper operation. Be

sure to inspect the vent system for proper installation at

initial start-up, and at least annually thereafter. Refer to

the venting section of this manual for more information

regarding vent system inspections.

Indicates the presence of immediate hazards which will cause severe personal injury, death or

substantial property damage if ignored.

Indicates the presence of hazards or unsafe practices which could cause severe personal injury,

death or substantial property damage if ignored.

Indicates the presence of hazards or unsafe practices which could cause minor personal injury

or product or property damage if ignored.

CAUTION used without the warning alert symbol indicates a potentially hazardous condition

which could cause minor personal injury or product or property damage if ignored.

Indicates special instructions on installation, operation, or maintenance which are important but

not related to personal injury hazards.

WARNING: Improper installation, adjustment,

AA

alteration, service, or maintenance can cause property

damage, personal injury or loss of life. Installation

and service must be performed by a qualied installer,

service agency, or the gas supplier.

WARNING: Gasoline, as well as other ammable

AA

materials and liquids (adhesives, solvents, etc.), and

the vapors they produce, are extremely dangerous. Do

not handle, use, or store gasoline or other ammable or

combustible materials in the vicinity of a heater.

WARNING: To minimize the possibility of improper

AA

operation, serious personal injury, re, or damage to the

heater:

• Always keep the area around the heater free of

combustible materials, gasoline, and other ammable

liquids and vapors.

• Heater should never be covered or have any blockage

to the ow of fresh air to the heater.

WARNING: This unit contains refractory ceramic

AA

ber (RCF) insulation in the combustion chamber. RCF,

as manufactured, does not contain respirable crystalline

silica. However, following sustained exposure to very

high temperatures [>2192°F (1200°C)], the RCF can

transform into crystalline silica (cristabolite). The

International Agency for Research on Cancer (IARC) has

classied the inhalation of crystalline silica (cristabolite)

as carcinogenic to humans.

When removing the burners or heat exchangers, take

precautions to avoid creating airborne dust and avoid

inhaling airborne bers. When cleaning spills, use wet

sweeping or High Eciency Particulate Air (HEPA)

ltered vacuum to minimize airborne dust. Use feasible

engineering controls such as local exhaust ventilation

or dust collecting systems to minimize airborne dust.

Wear appropriate personal protective equipment

including gloves, safety glasses with side shields, and

appropriate NIOSH certied respiratory protection,

to avoid inhalation of airborne dust and airborne ber

particles.

WARNING: Both natural gas and propane have

AA

an odorant added to aid in detecting a gas leak. Some

people may not physically be able to smell or recognize

this odorant. If you are unsure or unfamiliar with the

smell of natural gas or propane, ask your local gas

supplier. Other conditions, such as “odorant fade,”

which causes the odorant to diminish in intensity, can

also hide, camouage, or otherwise make detecting a

gas leak by smell more dicult.

WARNING: UL-recognized fuel gas detectors are

AA

recommended in all enclosed propane and natural

gas applications wherein there is a potential for an

explosive mixture of fuel gas to accumulate and their

installation should be in accordance with the detector

manufacturer’s recommendations and/or local laws,

rules, regulations, or customs.

WARNING: Do not install within 3 feet (0.9 m) of

AA

a heat pump or an outdoor condensing unit. Strong

air intake from this type of equipment can disturb the

combustion process and cause damage or personal

injury.

WARNING: The heater shall not be located in an

AA

area where water sprinklers, or other devices, may cause

water to spray through the cabinet louvers and into the

heater. This could cause internal rusting or damage

electrical components, and void the warranty.

4

CAUTION: Elevated water temperature can be

AA

hazardous. The U.S. Consumer Product Safety

Commission has these guidelines:

1. Spa water temperatures should never exceed

104°F (40°C). A temperature of 100°F (38°C) is

considered safe for a healthy adult. Special caution

is suggested for young children.

2. Drinking of alcoholic beverages before or during spa

or hot tub use can cause drowsiness which could

lead to unconsciousness and subsequently result in

drowning.

3. Pregnant Women Beware! Soaking in water over

102°F (39°C) can cause fetal damage during the rst

three months of pregnancy resulting in the birth of a

brain-damaged or deformed child. Pregnant women

should stick to the 100°F (38°C) maximum rule.

4. Before entering the spa or hot tub, users should

check the water temperature with an accurate

thermometer; spa or hot tub thermostats may err

in regulating water temperatures by as much as 4°F

(2.2°C).

5. Persons with a medical history of heart disease,

circulatory problems, diabetes, or blood pressure

problems should obtain a physician’s advice before

using pools or hot tubs.

6. Persons taking medications which induce

drowsiness, such as tranquilizers, antihistamines,

or anticoagulants, should not use spas or hot tu

bs.

2. WATER CHEMISTRY

NOTE: Corrosive water voids all warranties.

Chemical imbalance can cause severe damage to your

heater and associated equipment. Maintain your water

chemistry according to Table A. If the mineral content

and dissolved solids in the water become too high, scale

forms inside the heat exchanger tubes, reducing heater

eciency and damaging the heater. If the pH drops below

7.2, this will cause corrosion of the heat exchanger and

severely damage the heater. Heat exchanger damage

resulting from chemical imbalance is not covered by

the warranty.

For your health and the protection of your pool equipment,

it is essential that your water be chemically balanced. The

following levels must be used as a guide for balanced

water.

CAUTION: Free chlorine must not exceed 5 ppm

AA

which can damage the heater and is not covered under

warranty.

• Occasional chemical shock dosing of the pool or spa

water should not damage the heater providing the

water is balanced.

• Automatic chemical dosing devices and salt

chlorinators are usually more efficient in heated

water, unless controlled, they can lead to excessive

chlorine level which can damage your heater.

• Check valve should be installed between the heater

outlet and a chlorinator or other chemical dosing

device.

• Further advice should be obtained from your pool

or spa builder, accredited pool shop, or chemical

supplier for the correct levels for your water.

Automatic Chlorinators and Chemical Feeders

All chemicals must be introduced and completely diluted

into the pool or spa water before being circulated through

the heater. Do not place sanitizing chemicals in the

skimmer. High chemical concentrations will result when

the pump is not running (e.g. overnight).

Chlorinators must feed downstream of the heater and

have an anti-siphoning device to prevent chemical backup

into the heater when the pump is shut o.

See "Plumbing Diagram" on page 19.

NOTE: High chemical concentrates from feeders and

chlorinators that are out of adjustment will cause rapid

corrosion to the heat exchanger. Such damage is not

covered under the warranty.

Recommended Level(s) Fiberglass Pools Fiberglass Spas Other Pool and Spa Types

Water Temperature 68-88°F (20-31°C) 89-104°F (31-40°C) 68-104°F (20-40°C)

pH 7.3-7.4 7.3-7.4 7.6-7.8

Total Alkalinity (ppm) 120-150 120-150 80-120

Calcium Hardness (ppm) 200-300 150-200 200-400

Salt (ppm) 4500 Maximum 4500 Maximum 4500 Maximum

Free Chlorine (ppm)* 2-3 2-3 2-3

Total Dissolved Solids (ppm) 3000 Maximum** 3000 Maximum** 3000 Maximum**

*Free Chlorine MUST NOT EXCEED 5 ppm!

**In saltwater chlorinated pools, the total TDS can be as high as 6000 ppm.

Table A. Pool Water Chemistry

5

3. BEFORE INSTALLATION

Be sure that you receive the number of packages indicated

on the Bill of Lading.

Receiving equipment

The manufacturer recommends that this manual be

reviewed thoroughly before installing the pool/spa heater. If

there are any questions that this manual does not answer,

please contact the factory or your local representative.

On receipt of your equipment it is suggested that you

visually check for external damage to the carton. If the

carton is damaged, a note should be made on the Bill

of Lading when signing for the equipment. Remove the

heater from the carton. If it is damaged, report the damage

to the carrier immediately. Save the carton.

These items are shipped inside a box in the carton with

the heater:

Standard Unit (POLYMER HEADERS)

1. “Pagoda” top

2. 2" CPVC union half with "O" rings (2)

3. Plastic pipe finish flange for gas line

4. Bonding lug with mounting screw

ASME Unit (BRASS HEADERS)

1. “Pagoda” top

2. 2" CPVC union half with "O" rings (2)

3. Plastic pipe finish flange for gas line

4. Bonding lug with mounting screw

5. Pressure Relief Valve

6. ProTek Shield Adapter with ProTek Shield Assembly

and wing nut

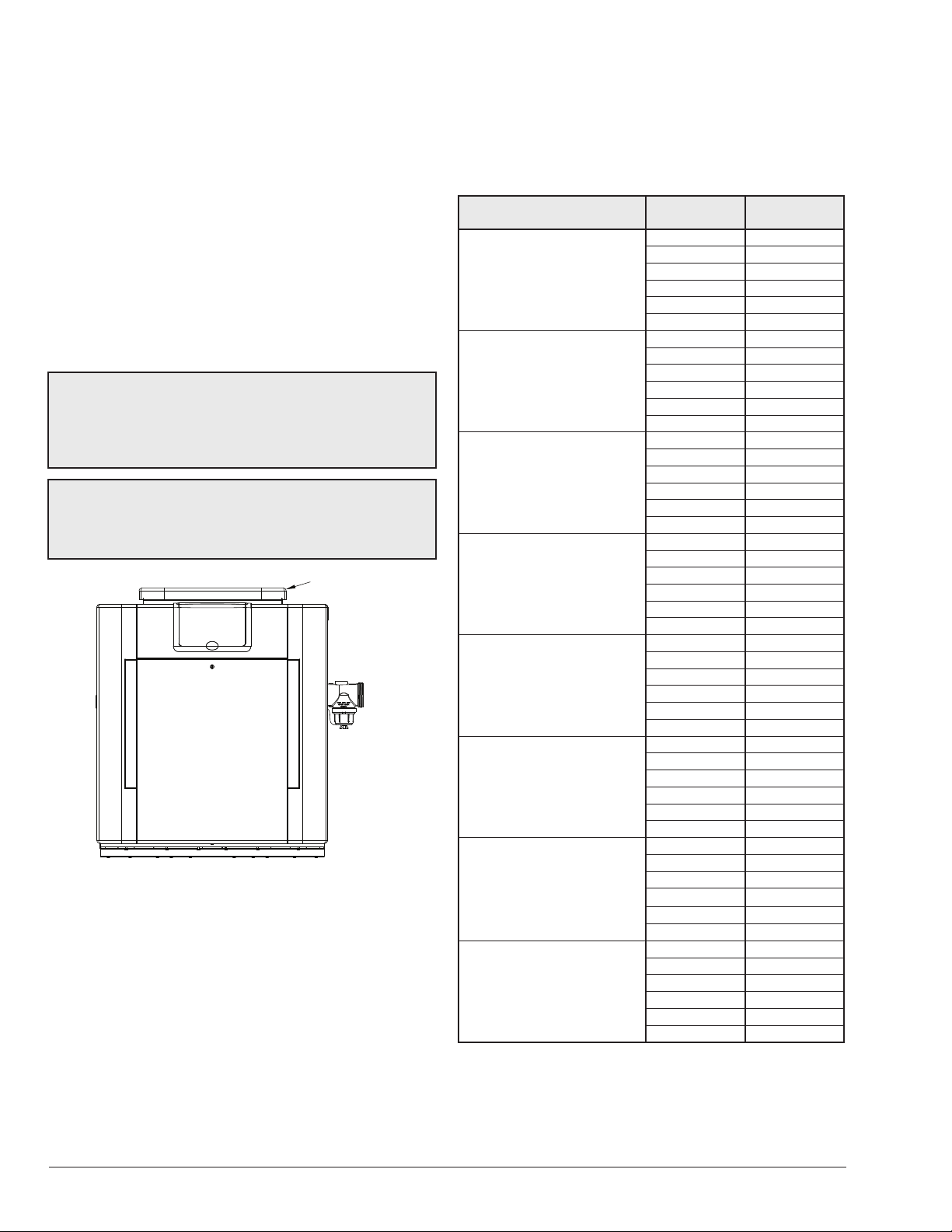

THE MODEL AND SERIAL NO.

CAN ALSO BE FOUND INSIDE

THE BEZEL ABOVE THE DISPLAY

Model Identication Number

The model number of a pool heater can be found on the

Sales Order and the pool heater rating plate. The example

below identies what the characters of the model number

represent.

B - _ 207A - E N - C # 26

#

Burner Orice Size

C Copper tubes

X Cupronickel tubes

N Natural gas

E Electronic ignition

207A input 199,500 BTUH (58.4 kw)

267A input 266,000 BTUH (77.9 kw)

337A input 332,500 BTUH (97.4 kw)

407A input 399,000 BTUH (116.9 kw)

_ Brand designation with letter

B Bronze headers

P Polymer headers

†

For commercial installations, ASME-Certied.

† †

Units with polymer headers do not meet building code requirements for

commercial installations. Consult local code authorities before using any

unit with polymer headers in a commercial environment.

(for residential use ONLY)

†

† †

When ordering parts, you must specify the model and

serial numbers of the heater. See Figure 1 for location of

serial number. When ordering under warranty conditions,

you must also specify date of installation.

Model:

P-R 207A-EN-C #26

POLYMER

Fuel: Ignition

NAT IID

Item Number:

MODEL AND SERIAL NO.

LOCATED ON RATING PLATE

Figure 1. Rating Plate Location

6

F10639-1

009240

Serial Number:

91001010

Note:

Figure 2. Model and Serial Number

Rating and certications

These heaters are design-certied and tested under the

latest requirements of the ANSI Z21.56 / CSA 4.7 Standard

for Gas-Fired Pool Heaters. All heaters can be used either

indoor or outdoors when appropriate venting is installed.

The appropriate top designated for each type of use is

Serial No.

required. If necessary, the top can be changed at a later

date to change from outdoor to indoor or vice versa.

Elevation

Rated inputs are suitable for up to 5,000 feet (1524 m)

elevation. For elevations above 5,000 feet (1524 m),

consult the factory.

Ambient Temperature Rating

Heater Components

Electronic Ignition Heater* -32°F to 175°F (-35°C to 79°C)

*Requires 120 or 240VAC, 1 Ph, 60 Hz Power Supply

4. INSTALLATION

WARNING: This unit contains refractory ceramic

AA

ber (RCF) insulation in the combustion chamber. RCF,

as manufactured, does not contain respirable crystalline

silica. However, following sustained exposure to very

high temperatures (>2192°F), the RCF can transform

into crystalline silica (cristabolite). The International

Agency for Research on Cancer (IARC) has classied

the inhalation of crystalline silica (cristabolite) as

carcinogenic to humans.

When removing the burners or heat exchangers, take

precautions to avoid creating airborne dust and avoid

inhaling airborne bers. When cleaning spills, use wet

sweeping or High Eciency Particulate Air (HEPA)

ltered vacuum to minimize airborne dust. Use feasible

engineering controls such as local exhaust ventilation

or dust collecting systems to minimize airborne dust.

Wear appropriate personal protective equipment

including gloves, safety glasses with side shields, and

appropriate NIOSH certied respiratory protection,

to avoid inhalation of airborne dust and airborne ber

particles.

IMPORTANT NOTICE: These instructions are intended

only for the use by qualied personnel, specically

trained and experienced in the installation of this type

of heating equipment and related system components.

Installation and service personnel may be required by

some states to be licensed. If your state is such, be sure

your contractor bears the appropriate license. Persons

not qualied shall not attempt to x the equipment nor

attempt repairs according to these instructions.

WARNING: Improper installation, adjustment,

AA

alteration, service or maintenance may damage the

equipment, create a hazard resulting in asphyxiation,

explosion or re, and will void the warranty.

NOTE: The heater should not be located in an area where

possible water leakage will result in damage to the area

adjacent to the heater or to the structure. When such

locations cannot be avoided, it is recommended that a

suitable drain pan, with adequate drainage, be installed

under the heater. The pan must not restrict combustion

air ow.

Installation Codes

Installation must be in accordance with local codes, or,

in the absence of local codes, with the latest edition of

the National Fuel Gas Code, ANSI Z223.1/NFPA54 and

National Electrical Code, ANSI/NFPA 70, and for Canada,

the latest edition of CAN/CSA-B149 Installation Codes,

and Canadian Electrical Code, CSA C22.1 Part 1 and

Part 2.

Clearances

All Heaters

For indoor and outdoor clearances from combustible

surfaces, see the chart below.

Location Indoor Installation

Top * 30" (762 mm) Drafthood

Front Alcove (Open)

Vent 6" (152 mm)

Floor ** 0"

Back 6" (152 mm)

Right Side 12" (305 mm) Water Side

Left Side 6" (152 mm) Opposite Water Side

Location Outdoor Installation

Top * Unobstructed (Outdoor Stack)

Top *** 36" (914 mm) (Stackless Top)

Floor 0"

Back 6" (152 mm)

Right Side 12" (305 mm) Water Side

Left Side 6" (152 mm) Opposite Water Side

* Clearance from top of vent terminal

** Do not install on carpeting

*** Clearance from top of heater

Table B. Minimum Clearances from Combustible Surfaces

When installed according to the listed minimum clearances

from combustible construction, the pool heater can still be

serviced without removing permanent construction around

the heater.

However for ease of servicing, we recommend a clearance

of at least 24" (610 mm) in the front, and at least 18"

(457 mm) on the water connection side. This will enable

the heater to be serviced in its installed location, that is,

without movement or removal of the heater.

7

Clearances less than these may require removal of the

heater to service either the heat exchanger or the burner

tray. In either case, the heater must be installed in a manner

that will enable the heater to be serviced without removing

any structure around the heater.

Flooring

This heater can be installed on combustible ooring. The

combustible clearances listed can be reduced by protecting

the exposed combustible surfaces as shown in Table C.

Outdoor Heater Installation

These heaters are design-certied for outdoor installation,

when equipped with the approved tops designated for

outdoor use.

WARNING: The heater shall not be located in an

AA

area where water sprinklers, or other devices, may cause

water to spray through the cabinet louvers and into the

heater. This could cause internal rusting or damage

electrical components, and void the warranty.

WARNING: Do not install within 3' (0.9 m) of a heat

AA

pump or an outdoor condensing unit. Strong air intake

from this type of equipment can disturb the combustion

process and cause damage or personal injury.

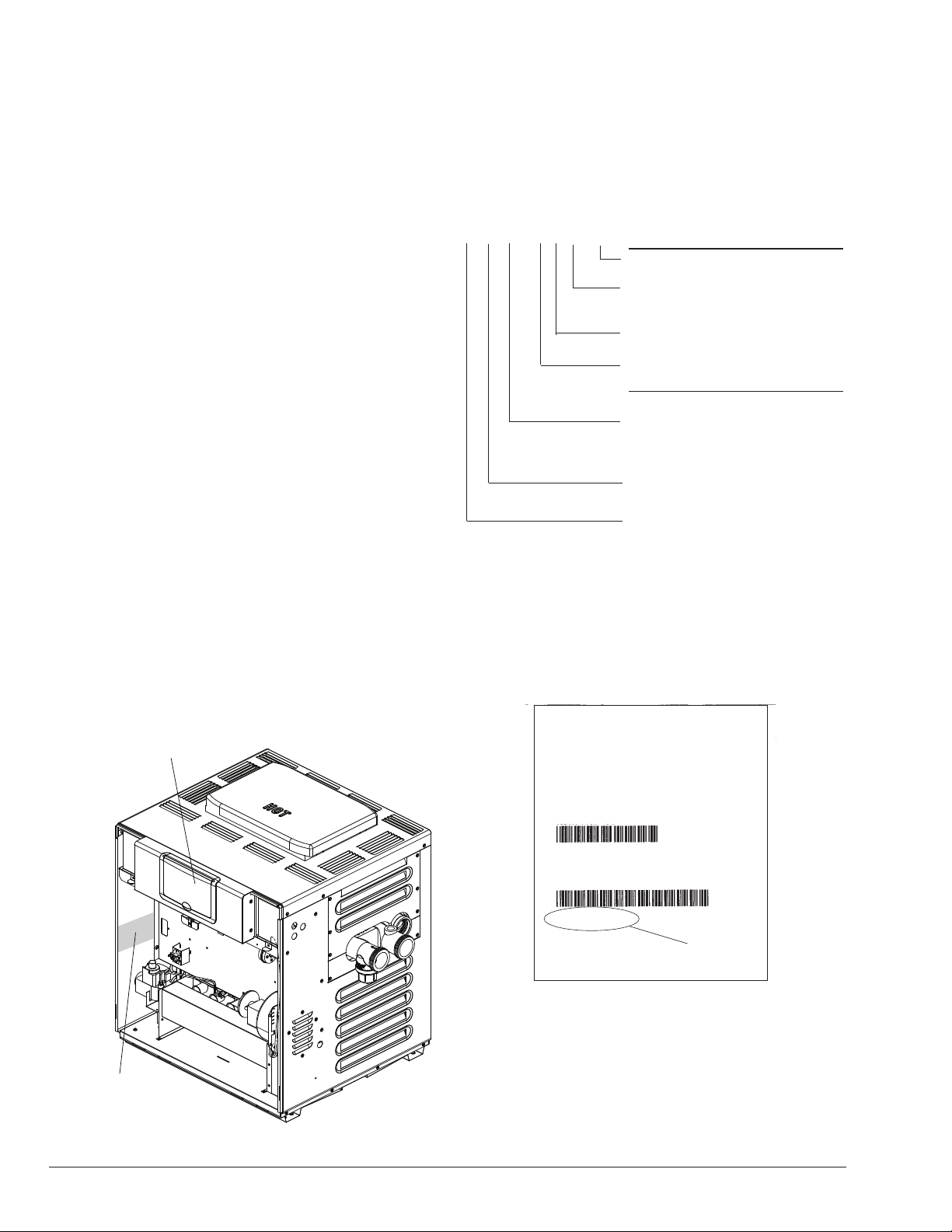

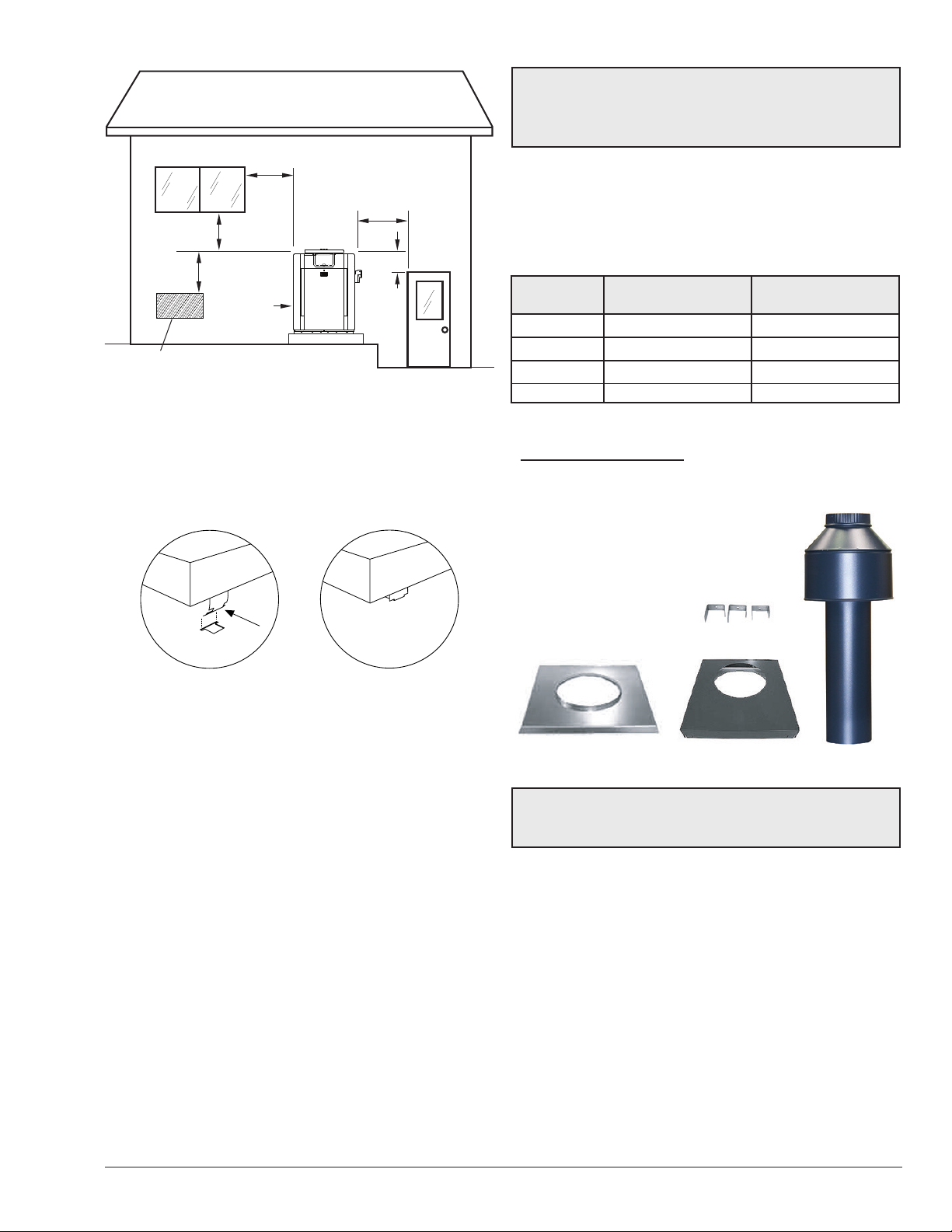

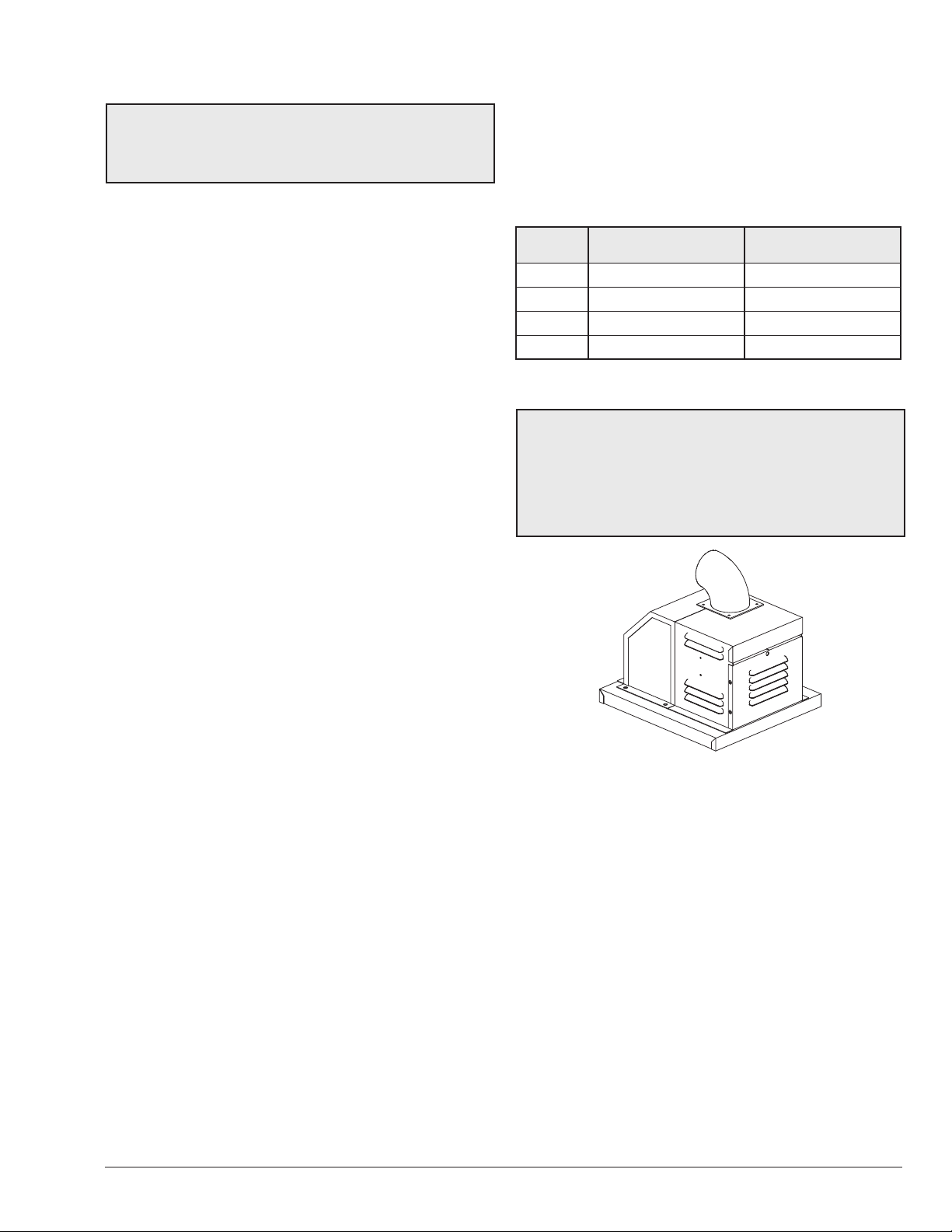

PAGODA TOP

INSTALLATION

F10647-2

Figure 3. Heater with Outdoor Stackless Top

Heaters must not be installed under an overhang of less

than three 3' (0.9 m) from the top of the heater. Three sides

must be open in the area under the overhang. Roof water

drainage must be diverted away from the heaters installed

under overhangs with the use of gutters.

For U.S. installations, the point from where the ue

products exit the heater must be a minimum of 4' (1.2 m)

below, 4' (1.2 m) horizontally from, or 1' (0.3 m) above any

door, window or gravity inlet into any building. The top

surface of the heater shall be at least 3' (0.9 m) above

any forced air inlet, or intake ducts located within 10' (3 m)

horizontally.

For Canadian installations, pool heaters shall not be

installed with the top of the vent assembly within 10' (3 m)

below, or to either side, of any opening into the building.

Refer to the latest revisions of CAN/CSA-B149.

A minimum of 6' (1.8 m) is required from the heater to an

inside corner wall for proper outdoor venting.

Description Location

Back 9 (229)

a. 3-1/2" (89 mm) thick

masonry walls without

ventilated air space

b. 1/2" (13 mm)insulation

board over 1" (25 mm)

glass ber or mineral

wool batts

c. 0.024 sheet metal over

1" (25 mm) glass ber

or mineral wool batts

reinforced with wire on

rear face with ventilated

air space

d. 3-1/2" (89 mm) thick

masonry wall with

ventilated air space

e. 0.024 sheet metal with

ventilated air space

f. 1/2" (13 mm) thick

insulation board with

ventilated air space

g. 0.024 sheet metal with

ventilated air space over

0.024 sheet metal with

ventilated air space.

h. 1" (25 mm) glass ber

or mineral wool batts

sandwiched between two

sheets 0.024 sheet metal

with ventilated air space

Derived from National Fuel Gas Code, Table 10.2.3

Table C. Reduction of Clearances to Protected Surfaces

Right 9 (229)

Left 9 (229)

Vent 5 (127)

Indoor Top 39 (991)

Outdoor Top Unobstructed

Back 6 (152)

Right 6 (152)

Left 6 (152)

Vent 3 (76)

Indoor Top 30 (762)

Outdoor Top Unobstructed

Back 4 (102)

Right 4 (102)

Left 4 (102)

Vent 3 (76)

Indoor Top 24 (610)

Outdoor Top Unobstructed

Back 6 (152)

Right 6 (152)

Left 6 (152)

Vent 6 (152)

Indoor Top 39 (991)

Outdoor Top Unobstructed

Back 4 (102)

Right 4 (102)

Left 4 (102)

Vent 2 (51)

Indoor Top 24 (610)

Outdoor Top Unobstructed

Back 4 (102)

Right 4 (102)

Left 4 (102)

Vent 3 (76)

Indoor Top 24 (610)

Outdoor Top Unobstructed

Back 4 (102)

Right 4 (102)

Left 4 (102)

Vent 3 (76)

Indoor Top 24 (610)

Outdoor Top Unobstructed

Back 4 (102)

Right 4 (102)

Left 4 (102)

Vent 3 (76)

Indoor Top 24 (610)

Outdoor Top Unobstructed

Distance

in. (mm)

8

4' (1.2 m)

Minimum

4' (1.2 m)

Minimum

4' (1.2 m)

Minimum

3' (0.9 m)

Minimum

10' (3 m)

Minimum

Forced Air Inlet

Figure 4. Clearances

1' (0.3 m)

Minimum

Pagoda Top Installation

1. Insert tabs into keyhole (4 places). See Figure 5,

detail A.

2. Snap tabs into keyholes so as not to pull out. See

Figure 5, detail B.

WARNING: Indoor heaters require a drafthood that

AA

must be connected to a vent pipe and properly vented to

the outside. Failure to follow this procedure can cause

re or fatal carbon monoxide poisoning.

Outdoor and Indoor Stacks

The outdoor and indoor stacks are optional equipment

and do not come standard with the heater. Refer to

installation instructions inside box for instructions on

how to install outdoor/indoor stack.

Outdoor Stack Indoor Stack

Model Part No Part No.

207A 009834 009838

267A 009835 009839

337A 009836 009840

407A 009837 009841

Table D. Outdoor and Indoor Stack Kit Number

OUTDOOR STACK KIT

(1) Outdoor stack, painted

(1) Adapter plate

(3) Mounting brackets (clips)

(1) Top panel cover

(2) 1-foot sections of metal tape

(3) Screws

(1) Instructions

Clips

DETAIL A DETAIL B

OUTDOOR TOP

(SHIPPED LOOSE WITH HEATER)

Figure 5. Outdoor Top Installation

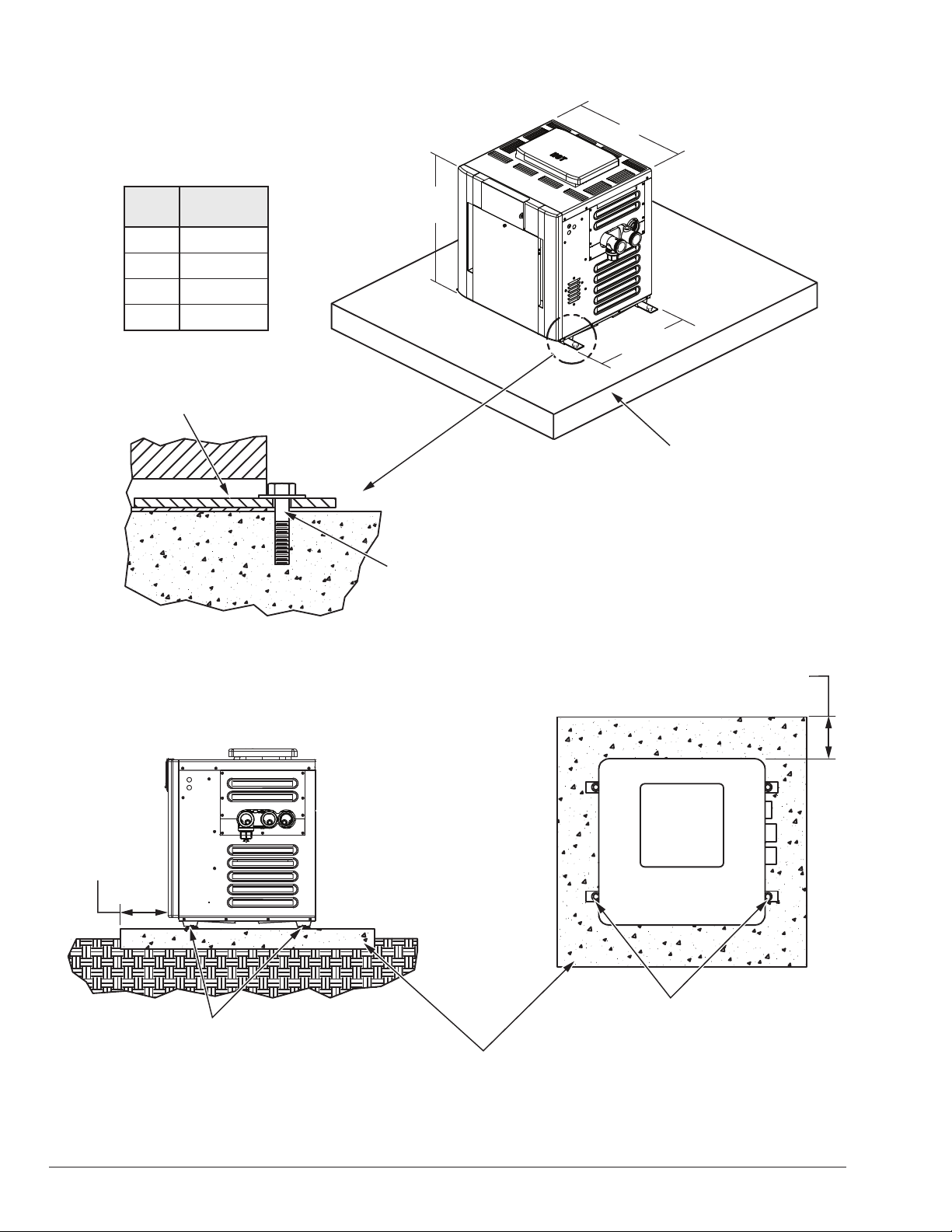

For installations in Florida and Texas, that must

comply with the Florida or Texas Building Code, follow

the directions shown in Figure 7 for the installation of

hurricane tie-down brackets for all models.

Indoor Heater Installation

The heater is also design-certied for indoor installation

when equipped with the approved drafthood.

For Canada, indoor installation is restricted to an enclosure

that is not occupied and does not directly communicate

with an occupied area. Refer to the latest edition of CAN/

CSA-B149 for specic requirements. Locate heater as

close as is practical to a chimney or gas vent. Heater

must always be vented to the outside. See section "Vent

Piping" on page 13 for details. Minimum allowable

space is shown on the nameplate.

Figure 6. Outdoor Stack Kit Components

NOTE: The outdoor drafthood kit does not require any

additional vent pipe for proper operation. This drafthood

functions as the vent termination.

9

Florida and Texas Building Code:

Wind Speed = 150 mph 3 sec gust

Exposure = C

B

Model

B

in. (mm)

207A 20 (508)

267A 23 (584)

337A 26 (660)

407A 29 (737)

2" x 6" x 1/8" Pallet

Anchor Bracket (4 Total) (Kit# 011636)

31-13/16"

(792 mm)

F10649

28"

(709 mm)

3" (76 mm)

Min. Conc.

Pad by others

1/4" x 1-3/4" S.S.

Tapcon Bolt and Washer (Field-Supplied)

NOTE: Use hole closest to unit with

washer overlapping edge of unit.

Min. Edge

Distance

6"

(152 mm)

Min. Edge

Distance

6"

(152 mm)

(1)–1/4" x 1-3/4" S.S. Tapcon

Bolt & Washer (Field-Supplied)

Ea. Pallet Anchor Bracket

Use hole closest to unit (4 total)

10

(1)–1/4" x 1-3/4" S.S.

Tapcon Bolt & Washer (Field-Supplied)

Ea. Pallet Anchor Bracket

3" (76 mm)

Min. Conc.

Pad by others

Use hole closest to unit (4 total)

Figure 7. Hurricane Tie-Down Bracket Installation

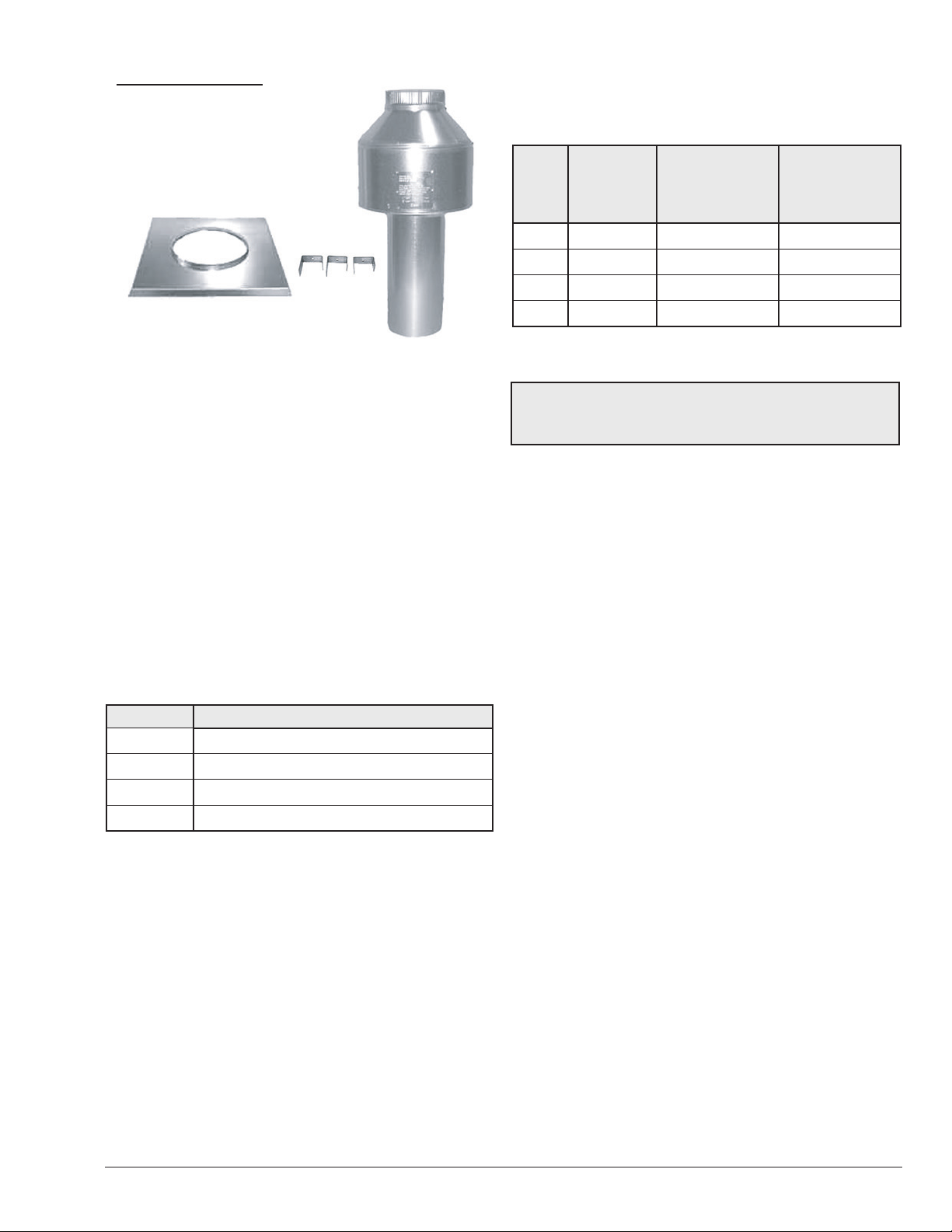

TOH

INDOOR STACK KIT

(1) Drafthood, unpainted

(1) Adapter plate

(3) Mounting brackets (clips)

(3) Screws

(1) Instructions

Clips

All Air from Outdoors:

When air is supplied directly from outside the building, each

opening shall have a minimum net free area as noted:

Unrestricted

Model

207A 50 (0.03) 75 (0.05) 100 (0.1)

267A 67 (0.04) 101 (0.06) 134 (0.09)

337A 84 (0.05) 126 (0.08)

407A 100 (0.06) 150 (0.1)

Opening

sq. in. (m2)

Typical Screened

or Louvered

Opening

sq. in. (m2)

Typical Screened

and Louvered

Opening

sq. in. (m2)

168 (0.11)

200 (0.13)

Figure 8. Indoor Stack Kit Components

Combustion and Ventilation Air

Indoor Units Only

The heater must have both combustion and ventilation

air. The minimum requirements are listed in the latest

edition of the National Fuel Gas Code (U.S. ANSI Z223.1

or Canada CAN/CSA-B149) and any local codes that

may have jurisdiction. The most common approach is

the "2-opening" method, with combustion air opening no

more than 12" from the oor and the ventilation opening

no more than 12" from the ceiling. For opening sizes using

this method, see below.

All Air from Inside the Building:

Each opening shall have a minimum net free area as

noted:

Model Sq. in. (m2)

207A 200 (0.13)

267A 266 (0.17)

337A 333 (0.21)

407A 399 (0.26)

Table F. Opening Minimum Net Free Requirements -

Outdoor Air

CAUTION: Combustion air must not be contaminated

AA

by corrosive chemical fumes which can damage the

heater. Such damage will not be covered by the warranty

Table E. Opening Minimum Net Free Requirements -

Indoor Air

11

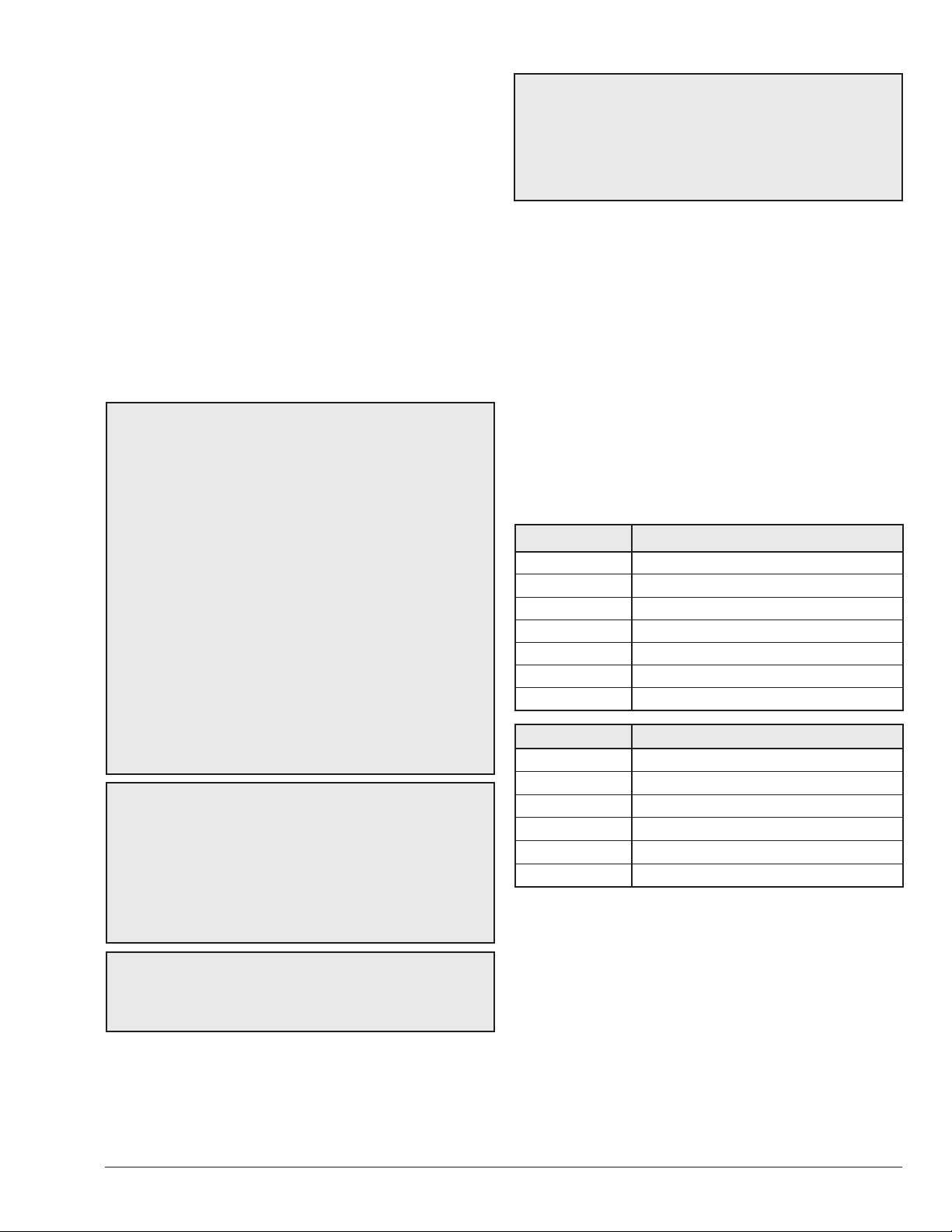

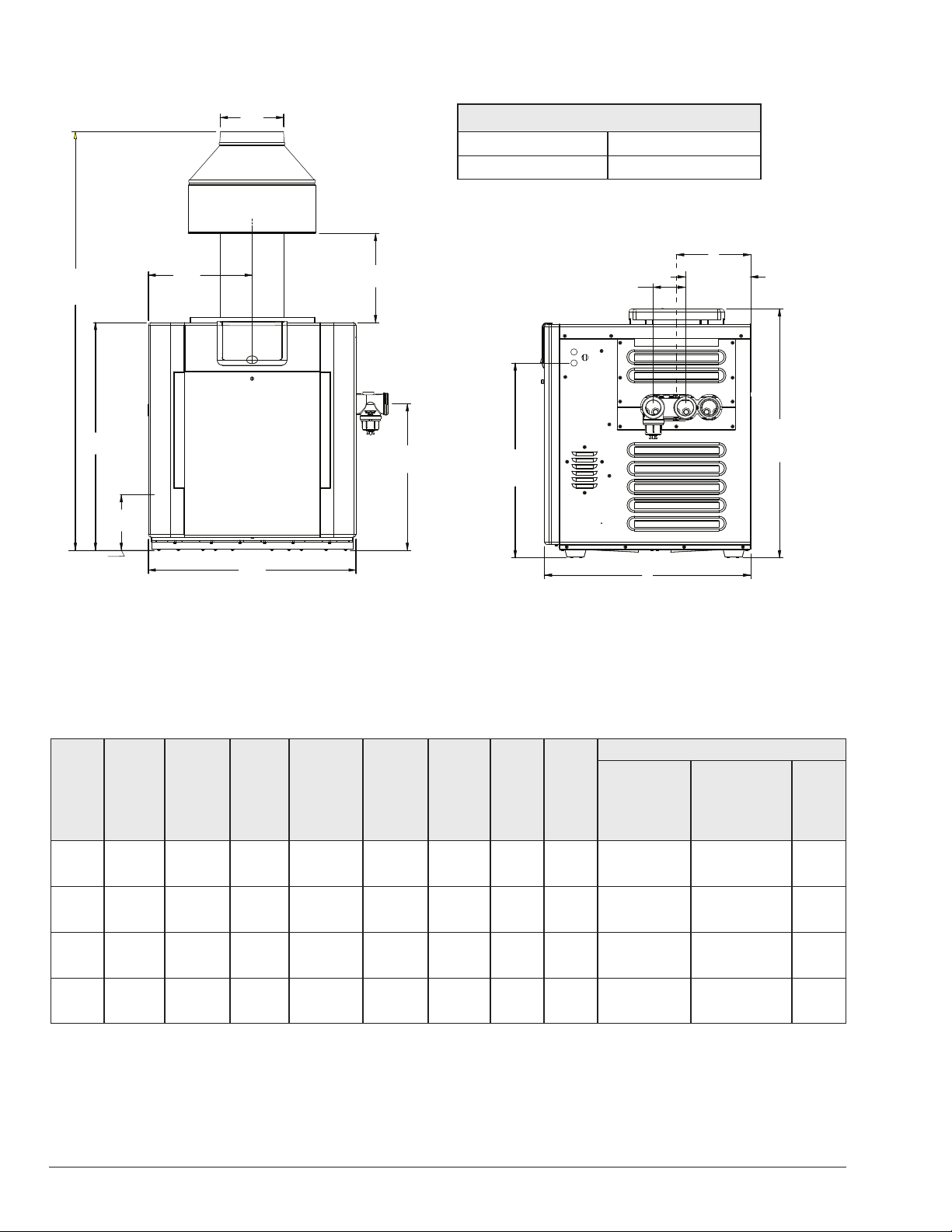

Specications and Dimensions

(711 mm)

F10647-1

C

L

FLUE

C

INDOOR

DRAFTHOOD

31-13/16"

(792 mm)

GAS

CONNECTION

7-3/4"

(197 mm)

B

Amp Draw

120 VAC, 1 Ph, 60 Hz 240 VAC, 1 Ph, 60 Hz

6 3

10"

(254 mm)

J*D

20-1/2"

(521 mm)

A

F10647

26-1/2"

(673 mm)

ELECTRICAL

CONNECTION

4-3/8"

(111 mm)

28"

8-7/8"

(225 mm)

(6-5/8" ASME)

(168 mm ASME)

34"

(867 mm)

STACKLESS

OUTDOOR

TOP

Figure 9. Front View

*Note: For outdoor stack, use J dimension in the table below for appropriate size plus 6" (152 mm).

Heater

Model

R207A

R267A

R337A

R407A

BTUH

Input

(000)

(kw)

199.5

(58.4)

266.0

(77.9)

332.5

(97.4)

399

(116.9)

(A)

Cabinet

Width

in. (mm)

20

(508)

23

(584)

26

(660)

29

(737)

(B)

Flue

Dia.

in.

6

7

8

9

(C)

Indoor

Drafthood

in. (mm)

55-5/8

(1413)

56

(1422)

57

(1448)

58-1/2

(1486)

(D)

in. (mm)

10.0

(254)

11.5

(292)

13.0

(330)

14.5

(368)

(J)*

Min.

in. (mm)

11-3/4

(298)

11

(279)

10-5/8

(270)

12-1/2

(318)

Gas

Conn.

in.

3/4 2

3/4 2

3/4 2

3/4 2

Water

Conn.

in.

Table G. Heater Specications and Dimensions

Figure 10. Side View

Shipping Weights - lbs (kg)

Standard

Heater

w/Stackless

w/Stackless

Top

174

(79)

197

(89)

219

(99)

237

(108)

ASME

Heater

Top

193

(88)

216

(98)

238

(108)

256

(116)

Indoor

Draft-

hood

14

(6.4)

16

(7.3)

19

(8.6)

21

(9.5)

12

Vent Piping

WARNING: Indoor heaters require a drafthood that

AA

must be connected to a vent pipe and properly vented to

the outside. Failure to follow this procedure can cause

re or fatal carbon monoxide poisoning.

When properly installed outdoors, only the outdoor

stackless top, provided, is required. If installed indoors,

a drafthood is required, connected to a CATEGORY

I (a heater that operates with a non-positive vent static

pressure and a vent gas temperature that avoids excessive

condensate production in the vent) vent per the National

Fuel Gas Code and local requirements.

Vent piping the same size as the drafthood outlet is

recommended, however, when the total vent height is at

least 10 ft (3 m) (drafthood relief opening to vent terminal),

the vent pipe size may be reduced by no more than one

size as specied in Chapter 13 of the National Fuel Gas

Code, ANSI Z223.1 (Canada - CAN/CSA-B149).

As much as possible, avoid long horizontal runs of vent

pipe and too many elbows. If installation requires horizontal

runs, the vent pipe must have a minimum of 1/4 in. per ft

rise (20.8 mm per meter rise) and should be supported at

not more than 5 ft (1.5 m) intervals.

maintained. However single-wall metal vent pipe may be

used as specied in the latest edition of the National Flue

Gas Code, ANSI Z223.1 (Canada - CAN/CSA-B149).

D-2 Power Vent Kit

Another option for an installation that requires horizontal

runs is using the D-2 power vent kit option.

Model 120 VAC P/N 240 VAC P/N

207A 010744 009832

267A 010744 009832

337A 010745 009833

407A 010745 009833

Table H. Power Vent Kit Part Numbers

NOTE: The D-2 Power Vent operates with a positive

vent static pressure and with a vent gas temperature

that prevents excessive condensate production in the

vent, and as such, is a CATEGORY III appliance. For

more information consult the D-2 Power Vent manual

6000.57.1. CATEGORY I vent material such as B-vent

must not be used under CATEGORY III conditions.

Plumber's tape, criss-crossed, will serve to space both

horizontal and vertical piping. Gas vents supported only

by the ashing and extending above the roof more than 5

ft (1.5 m) should be securely guyed or braced to withstand

snow and wind loads. We recommend use of insulated

vent pipe spacers through the roof and walls.

For protection against rain or blockage by snow, the vent

pipe must terminate with a vent cap which complies with

the local codes or, in the absence of such codes, to the

latest edition of the National Fuel Gas Code, ANSI Z223.1

(Canada - CAN/CSA-B149).

The discharge opening must be a minimum of 2' (0.6

m) vertically from the roof surface and at least 2' (0.6 m)

higher than any part of the building within 8' (2.4 m). Vent

stack shall be at least 5' (1.5 m) in vertical height above

the drafthood outlet. The vent cap location shall have a

minimum clearance of 4' (1.2 m) horizontally from, and in

no case below, unless a 4' (1.2 m) horizontal distance is

maintained, from electric meters, gas meters, regulators

and relief equipment.

The weight of the vent stack or chimney must not rest on the

heater drafthood. Support must be provided in compliance

with applicable codes. The heater top and drafthood must

be readily removable for maintenance and inspection.

Vent pipe should be adequately supported to maintain

proper clearances from combustible construction.

Flue materials must be certied to CATEGORY I or

better. Type “B” double-wall or equivalent vent pipe is

recommended. A draft of -0.01" to -0.08" WC must be

Figure 11. D-2 Power Vent Option

The power vent system is a fan-assisted combustion

system designed for application to models 207A-407A.

The power vent system, when installed as directed, is

capable of operating in applications such as through-thewall venting with reduced horizontal and vertical vent pipe

sizes in new and current installations. The unit is factorywired for 240 VAC, with capability of eld-rewiring for 120

VAC.

For more information consult the D-2 Power Vent manual,

(Catalog No. 6000.57.1).

13

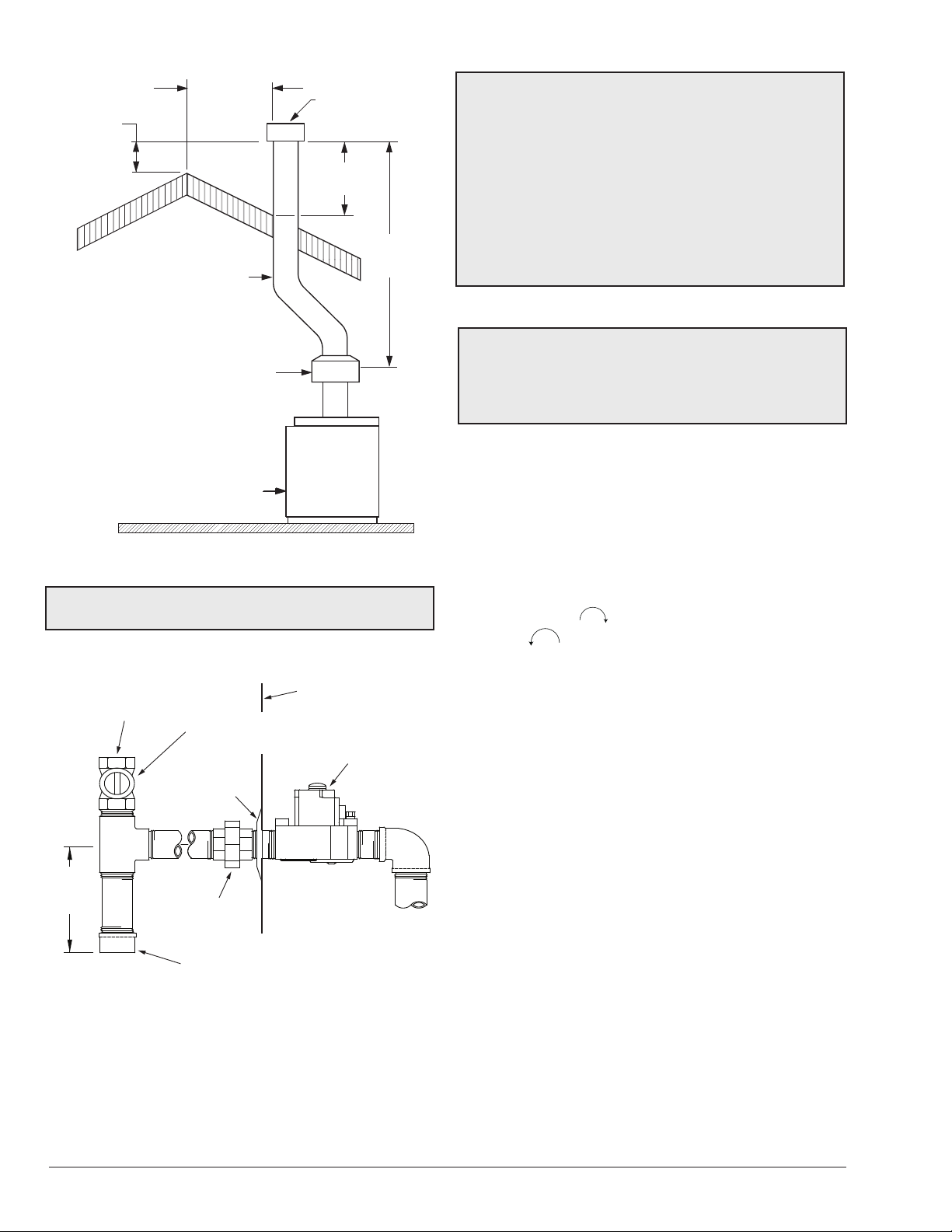

8' (2.4 m)

OR LESS

HEATER JACKET

2' MIN

(0.6 m)

VENT PIPE

DRAFT HOOD

HEATER

VENT CAP

2' MIN

(0.6 m)

5' MIN

(1.5 m)

Figure 12. Venting Clearances

NOTE: With venting application of two or more heaters,

contact the factory.

CAUTION: The heater and its manual shut-o valve

AA

must be disconnected from the gas supply during any

pressure testing of that system at test pressures in

excess of 1/2 psi (3.45 kPa). Dissipate test pressure in

the gas supply line before reconnecting the heater and

its manual shut o valve to gas supply line. FAILURE

TO FOLLOW THIS PROCEDURE MAY DAMAGE THE

GAS VALVE. OVER PRESSURIZED GAS VALVES ARE

NOT COVERED BY WARRANTY. The heater and its gas

connections shall be leak tested before placing the

appliance in operation. Use soapy water for leak test. DO

NOT use open ame.

Supply Pressure

CAUTION: Do not use teon tape on gas line pipe

AA

thread. Only sealant tape or a pipe compound rated for

use with natural and propane gases is recommended.

Apply sparingly only on male pipe ends, leaving the two

end threads bare.

A minimum of 5 in. WC and a maximum of 10.5 in. WC

upstream pressure under load and no-load conditions

must be provided for natural gas.

Gas Pressure Regulator

The gas pressure regulator is preset at 3.1 in. WC for

natural gas. The pressure at the gas valve, taken with a

manometer, should be about 3.1 in. WC natural gas. If an

adjustment is needed, remove seal and turn adjustment

screw clockwise

clockwise to decrease pressure.

to increase pressure or counter-

Gas Supply Connections

GAS INLET

3" MIN

(76 mm)

Typical

Figure 13. Gas Supply Plumbing

Gas piping must have a sediment trap ahead of the

heater gas controls, and a manual shut-o valve located

outside the heater jacket. All gas piping should be tested

after installation in accordance with local codes.

MANUAL SHUT-OFF VALVE

FINISH FLANGE

UNION

(Field supplied)

SEDIMENT TRAP

(Field supplied)

(Field supplied)

GAS VALVE

14

MANUAL

F10638-1

SHUT-OFF

VALV E

UNION

F10639-4

Figure 14. Manual Shut-O Valve Installation

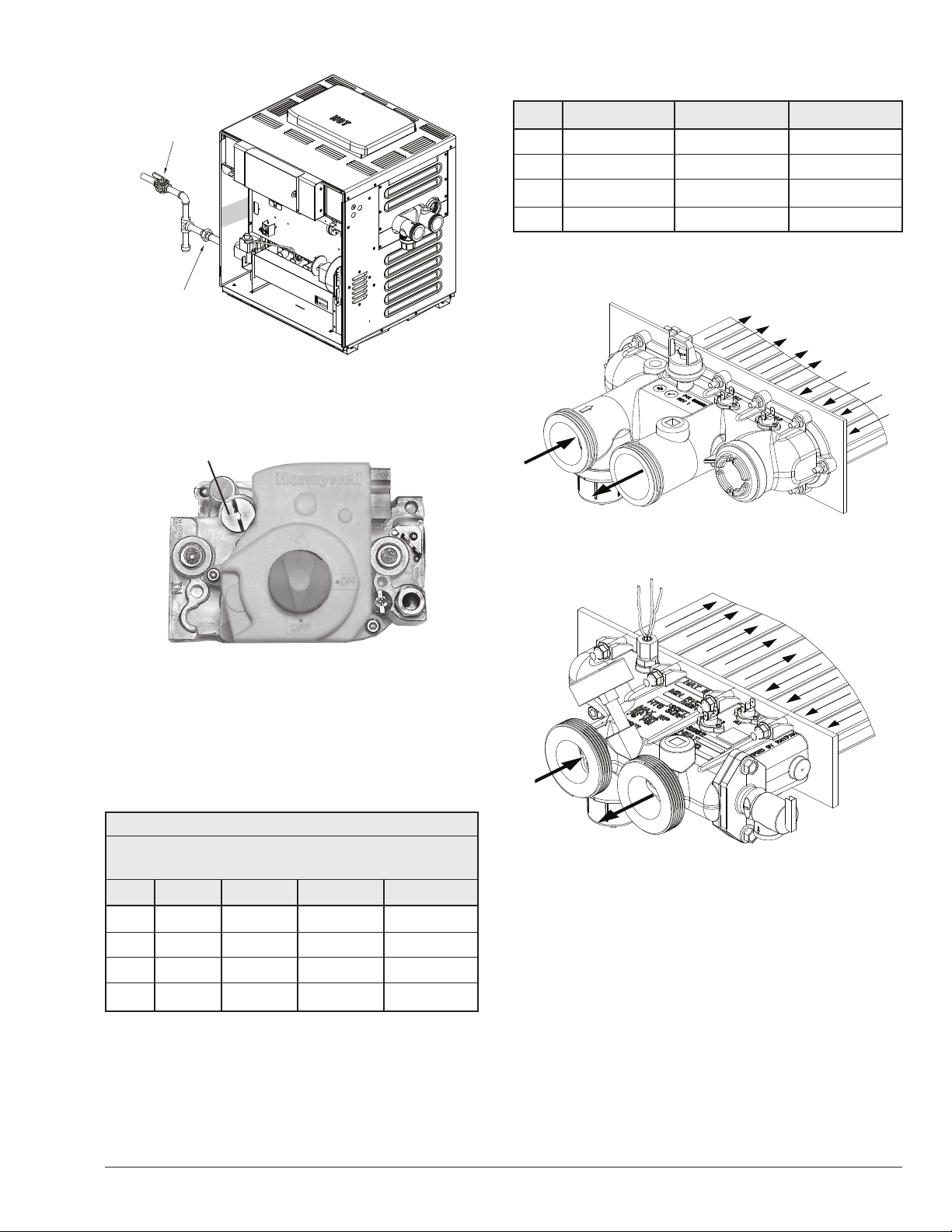

Gas Pressure Adjustment Locations

Gas Pressure Adjustment

Flow Rates

Model Pipe Size Min. GPM (lpm) Max. GPM (lpm)

207A 1-1/4"–1-1/2"–2" 20 (75) 125 (473)

267A 1-1/4"–1-1/2"–2" 25 (95) 125 (473)

337A 1-1/4"–1-1/2"–2" 35 (132) 125 (473)

407A 1-1/4"–1-1/2"–2" 40 (151) 125 (473)

* When ow rates exceed maximum GPM an external auxiliary bypass valve is

required. See external bypass valve section for details.

Table J. Min/Max Flow Rates

Figure 15. Honeywell VR8340)

Pipe Sizing for Gas Connection

The capacities shown below are based on using SCH

40 black iron pipe. For capacities using other materials,

consult local codes.

Maximum Equivalent Pipe Length (ft) (m)

3

Natural Gas 1000 BTU/FT

in. WC Pressure Drop

Model 3/4" 1" 1-1/4" 1-1/2"

207A 25 (7.6) 90 (27.4) 360 (109.7) n/a

267A 15 (4.6) 50 (15.2) 210 (64.0) 445 (135.6)

337A 10 (3.0) 30 (9.1) 140 (42.7) 290 (88.4)

0.60 Specic Gravity @ 0.5

Figure 16. Polymer Headers Water Flow

F10637-1

Figure 17. Brass Headers (ASME) Water Flow

407A * 20 (6.1) 95 (29.0) 215 (65.5)

* A 3/4" gas line can be used for up to 5' (1.5 m) maximum length from the gas

valve in addition to the sediment trap.

Table I. Gas Pipe Sizing

15

Loading...

Loading...