Page 1

PROJECT NAME ______________________________________________________________________________

LOCATION __________________________________________________________________________________

ARCHITECT__________________________________________________________________________________

ENGINEER __________________________________________________________________________________

CONTRACTOR ______________________________________________________________________________

SUBMITTED BY ______________________________ DATE ________________________________________

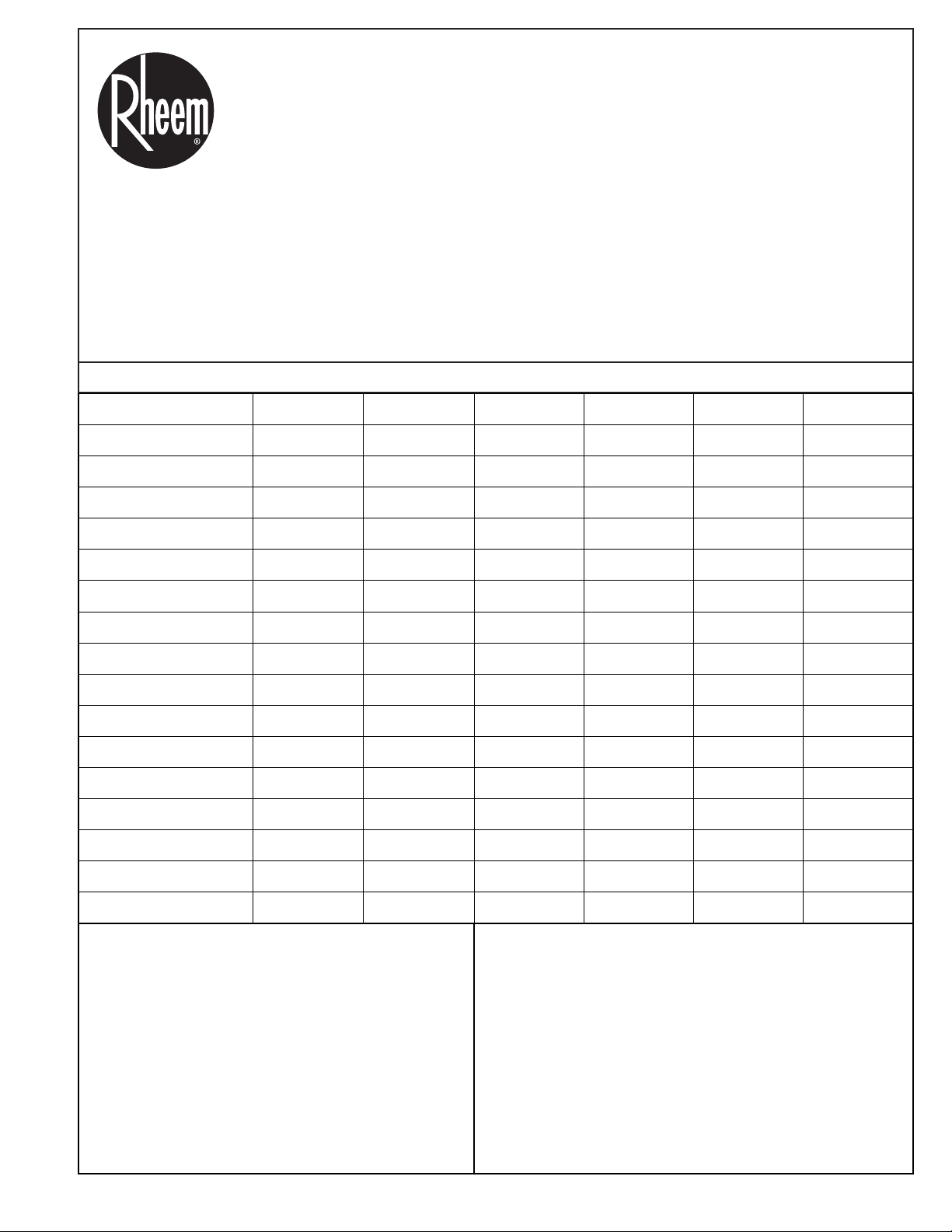

UNIT SUMMARY

SUBMITTAL COVER SHEET

Quantity

Unit Designation

Model No.

Total Cooling

Sensible Cooling

Air Ent. Evaporator

Air Lvg. Evaporator

Heating Input

Heating Output

CFM/ESP

EER/SEER

Electrical

Minimum Ampacity

Min.-Max. Breaker

Net Unit Weight

Accessory

Catalog Form Number

ACCESSORIES: NOTES:

PRINTED IN U.S.A. 10-06 DC FORM NO. X11-1123 REV. 2

Supersedes Form No. X11-1123 Rev. 1

Page 2

FORM NO. X33-1259 REV. 2

Supersedes Form No. X33-1259 Rev. 1

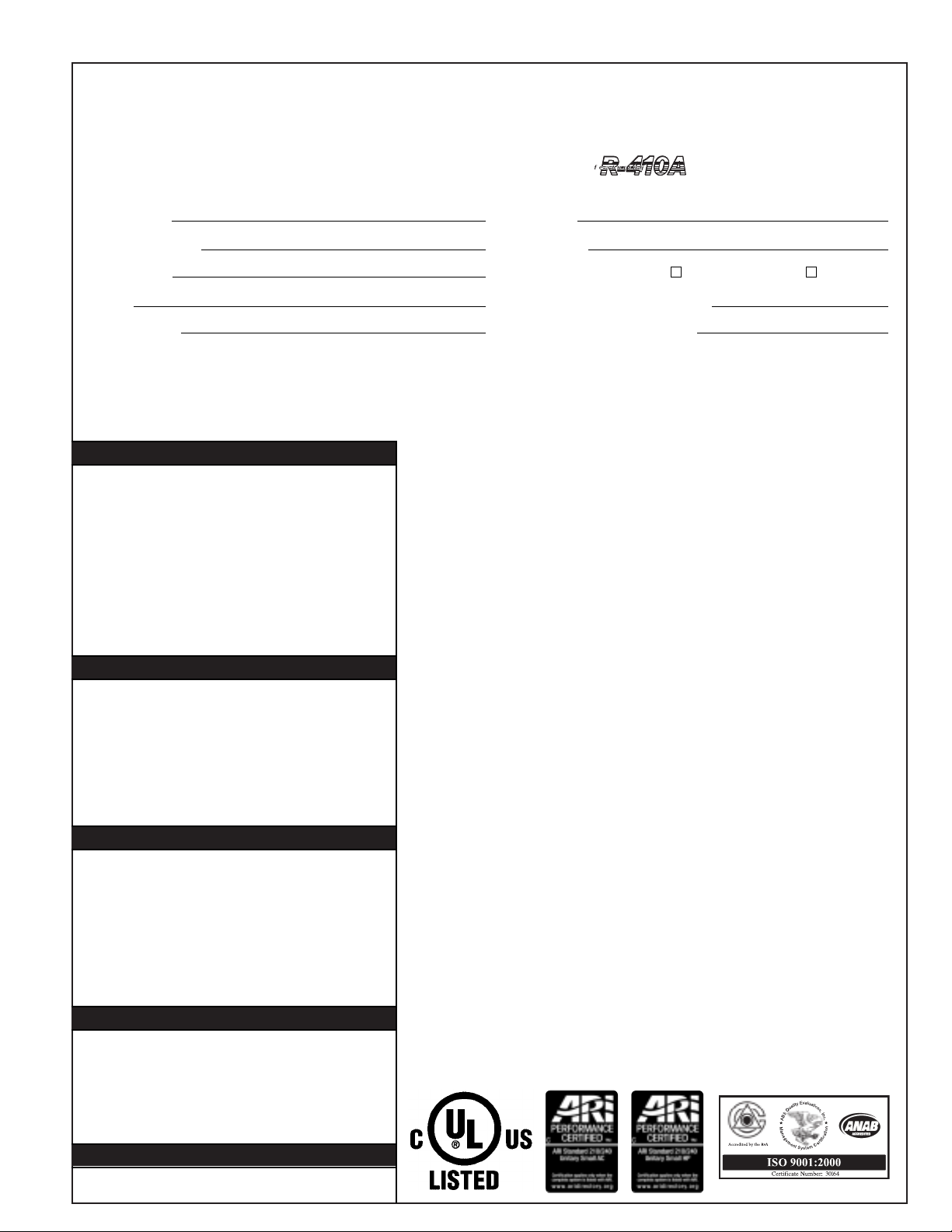

JOB NAME LOCATION

CONTRACTOR ORDER NO.

ENGINEER SUBMITTED FOR APPROVAL RECORD

DATE OUTDOOR UNIT MODEL NO.

MODEL NO. INDOOR COIL MODEL NO.

SUBMITTAL SHEET FOR HEAT PUMP AIR HANDLERS AND

FAN COIL UNIT: RBHP

• Models featuring R-22 Refrigerant

• Models featuring Earth-Friendly R-410A Refrigerant

• Models featuring Electric Heat without Indoor Cooling Coil

UNIT DATA

COOLING PERFORMANCE

TOTAL CAPACITY*..................

_______

MBH [kW]

SENSIBLE CAPACITY*............

_______

MBH [kW]

OUTDOOR DESIGN TEMP. ....

_______

°F [°C] DB

TOTAL SUPPLY AIR ................

_______

CFM [L/s]

TEMP. OF AIR ENTERING

EVAPORATOR COIL............

_______

°F [°C] DB

_______

°F [°C] WB

POWER INPUT REQUIREMENT ........

_______

kW

(*uses blower motor heat)

HEATING PERFORMANCE

TOTAL CAPACITY*..................

_______

MBH [kW]

OUTDOOR DESIGN TEMP. ....

_______

°F [°C] DB

TEMP. OF AIR ENTERING

EVAPORATOR COIL............

_______

°F [°C] DB

ELECTRIC HEAT CAPACITY ............

_______

kW

POWER INPUT REQUIREMENT ........

_______

kW

(*uses blower motor heat)

SUPPLY AIR BLOWER PERFORMANCE

TOTAL AIR SUPPLY ................

_______

CFM [L/s]

TOTAL RESISTANCE EXTERNAL

TO UNIT......................................

_______

IWG

BLOWER SPEED ..........................

_______

RPM

POWER OUTPUT REQUIREMENT ..

_______

BHP

MOTOR RATING ........................

_______

HP [W]

POWER INPUT REQUIREMENT ........

_______

kW

ELECTRICAL DATA

POWER SUPPLY ........................

____/____/____

TOTAL UNIT AMPACITY................

_______

AMPS

MINIMUM WIRE SIZE ....................

_______

AWG

MAXIMUM OVERCURRENT DEVICE

FUSES/HACR BREAKER ..........

_______

AMPS

CLEARANCES

SERVICE ACCESS FRONT 24" [609.6 mm]

FEATURES FOR RBHP AIR HANDLERS

■ Quiet, efficient X-13 motor technology providing nominal airflow to 0.5 inch

[12 kPa] of external static pressure.

■ Field selectable airflow to meet the requirements of particular applications.

■ Low continuous speed fan.

■ The most compact unit design available.

■ Attractive pre-painted cabinet exterior.

■ Rugged double wall steel cabinet construction, designed for added strength

and versatility.

■ .5" foil faced insulation mechanically retained in blower compartment.

■ Four leg rubber insulated wire motor mount.

■ Circuit breakers standard on models above 11 kW and optional on models with

11 kW or less.

■ Models supplied with circuit breakers meet UL and cUL requirements as a

service disconnect switch.

■ Provisions for field electrical connections from either side of air handler

cabinet.

■ Tab lock blower housing with integrated electric heaters, controls, motor and

blower. Slide out design for service and maintenance convenience.

■ Exclusive dependable Incoloy sheath type electric heating elements located in

the blower housing provide mixed warm air.

■ Field convertible for vertical upflow, vertical downflow, horizontal left hand or

right hand air supply.

■ Common combustible floor base accessory fits all model sizes when required

for downflow installations on combustible floors.

■ Durable framed cleanable air filter provided as standard in unit filter rack.

■ Factory-Installed MultiFlex

®

indoor coil design provides low air side pressure

drop, high performance and extremely compact size. All coils come with PVC

condensate elbow standard.

■ All indoor coils have copper tubing and aluminum fins.

■ Molded polymer corrosion resistant condensate drain pan is provided on all

indoor coils.

■ Both supply and return duct flanges provided as standard on air handler

cabinet.

■ Connection points for both high voltage and low voltage control wiring inside

air handler cabinet.

■ Concentric knockouts are provided for power connection to cabinet. Installer

may pull desired hole size up to 2 inches [51 mm] for 1

1

/2 inch [38 mm]

conduit.

■ Patented watt restrictor on heat pump models to control electric heat during

heating operation.

■ Internal checked TX valves are used on the RCHJ & RCHL Heat Pump indoor

coil for more quiet refrigerant metering.

■ Front refrigerant and drain connections.

■ Factory limited warranty on parts as follows:

Indoor Coil leaks caused by factory defects ................................Five (5) Years

Electric Heating Element ..............................................................Five (5) Years

Any Other Part..............................................................................Five (5) Years

earth friendly refrigerant

Page 3

FIELD INSTALLED ACCESSORIES

Unit Dimensions & Weights

Dimensions for Front Connection

Coils. For “W”, see Unit Dimensions.

(Single Indoor Coil Units Only)

[ ] Designates Metric Conversions

( ) Designates Unit with Double Coil Cabinet

Combustible Floor Base RXBB-AA ................

Jumper Bar Kit 3 Ckt. to 1 Ckt. RXBJ-A31 ......

Jumper Bar Kit: 2 Ckt to 1 Ckt. RXBJ-A21 ....

Finger Safe Circuit Breaker Cover ................

Replacement Filters ....................................

Auxiliary Horizontal Drain Pan RXBM-AA06....

Horizontal Drain Pan Model RXBD-CB ..........

Before proceeding with installation, refer

to installation instructions packaged

with each model, as well as complying

with all Federal, State, Provincial, and

Local codes, regulations, and practices.

Rheem Sales Company, Inc.

P.O. Box 17010, Fort Smith, AR 72917

“In keeping with its policy of continuous progress and product improvement, Rheem reserves the right to make changes without notice.”

PRINTED IN U.S.A. 4-08 DC FORM NO. X33-1259 REV. 2

Supersedes Form No. X33-1259 Rev. 1

Model Number

Cabinet Size

17 171/

21 21 [533] 97/16 [240] 109/117 [49/53]

24

25 241/2 [622] 113/4 [298] 125/134 [57/61]

Unit

Width

“W” In. [mm]

2 [445]

241/2 [622] 113/4 [298]

Supply

Duct

“A” In. [mm]

16 [192]

79/

Unit Weight/Shipping Weight (Lbs.) [kg]

Unit With

Coil (Max. KW)

92/99 [42/45]

125/134 [57/61]

Unit Without

Coil (Max. KW)

66/75 [30/31]

79/87 [36/39]

88/97 [40/44]

88/97 [40/44]

Loading...

Loading...