Page 1

Rheem High Efficiency Air Handler

FORM NO. H11-554

RH1V/RH2V- Series

ECM Motor

Efficiencies up to 16 SEER

• Includes an energy efficient ECM®Motor, which in most applications, enhances the SEER rating of the outdoor unit. It also

slowly ramps its speed up for quiet operation and enhanced

customer satisfaction.

• Versatile 4-way convertible design for upflow, downflow,

horizontal left and horizontal right applications.

• Nominal airflow up to 1.0" external static pressure.

• Factory-installed indoor coil.

• Sturdy cabinet construction with 1.0 inch [25.4 mm] of foil faced

insulation for excellent sound and insulating characteristics.

• Field-installed auxiliary electric heater kits provide exact heat

for indoor comfort. Kits include circuit breakers which meet

U.L. and cUL requirements for service disconnect.

• Dip switch settings for selectable, customized cooling airflow

over a wide variety of applications.

• On-demand dehumidification terminal that adjusts airflow to

help control humidity for unsurpassed comfort in cooling mode.

• External filter required.

• Evaporator coil is constructed of aluminum fins bonded to

internally grooved aluminum tubing.

Air

Air Handlers

RH1V/RH2V Series

Page 2

Air

Table of Contents

RH1V/RH2V Series

2

TABLE OF CONTENTS

Engineering Features ......................................................................................3

Model Number Identification ............................................................................4

Dimensional Data ........................................................................................5-6

Airflow Directional Data ..................................................................................7

Airflow Performance Data (-)H1V ..................................................................8-9

Electrical Data (-)H1V ..............................................................................10-11

Airflow Performance Data (-)H2V ....................................................................12

Electrical Data (-)H2V ..............................................................................13-14

Electrical Wiring ............................................................................................15

Accessories ............................................................................................................15

Limited Warranty ..........................................................................................16

Page 3

Air

Engineering Features

RH1V/RH2V Series

3

Engineering Features

RH1V/RH2V- Series

• Quiet, efficient ECM motor technology providing nominal

airflow up to 1.0 inch [25 kPa] of external static pressure.

• Interface board with dip switches conveniently located in the

blower compartment allows for precise, field selectable airflow to meet the requirements of particular applications.

• Selectable continuous fan “on” options.

• The most compact unit design available.

• Attractive pre-painted cabinet exterior.

• Rugged steel cabinet construction, designed for added

strength and versatility.

• 1.0" foil faced insulation mechanically retained in blower

compartment.

• Four leg rubber insulated motor mount.

• Field-installed auxiliary heater kit includes circuit breakers

that meet UL and cUL requirements as a service disconnect

switch.

• Blower housing with integrated controls, motor and blower.

Slide out design for service and maintenance convenience.

• Field convertible for vertical upflow, vertical downflow, horizontal left hand or right hand air supply.

• Combustible floor base accessory available when required for

downflow installations on combustible floors.

• Indoor coil design provides low air side pressure drop, high

performance and extremely compact size. All coils come with

PVC condensate elbow standard.

• Coils are constructed of aluminum fins bonded to internally

grooved aluminum tubing.

• Coils are tested at the factory with an extensive refrigerant

leak check.

• Coils have copper sweat refrigerant connections.

• Coils utilize chatleff metering device connections.

• Molded polymer corrosion resistant condensate drain pan is

provided on all indoor coils.

• Supply duct flanges provided as standard on air handler

cabinet.

• Provisions for field electrical connections available from either

side or top of the air handler cabinet.

• Connection point for high voltage wiring is inside the air handler cabinet. Low voltage connection is made on the outside

of the air handler cabinet.

• Concentric knockouts are provided for power connection to

cabinet. Installer may pull desired hole size up to 2 inches

[51 mm] for 1

1

/2 inch [38 mm] conduit.

• Front refrigerant and drain connections.

[ ] Designates Metric Conversions

Page 4

Air

Model Number Identification

RH1V/RH2V Series

4

(-) H 1 V 24 17 S T A N A A ***

Option Code (see ADS-3803)

Blank = None

Minor Series

A = First

Voltage

A = 115/1/60

D = 480/3/60

J = 208/240/1/60

T = 220/240/1/50

Controls

C = Communicating

N = Non-Communicating

Major Series

A = First

Metering Device

T = TEV

E = EEV

P = Piston

Coil Efficiency

S = Standard

M= Medium

H = High

Width

17 = 17.5" [431.8 mm] (600-1200 CFM)

21 = 21" [533.4 mm] (800-1600 CFM)

24 = 24.5" [609.6 mm] (1400-1800 CFM)

Nominal Capacity

24 = 18,000 [5.27 kW]-24,000 [7.03 kW] BTU/H

36 = 30,000 [8.79 kW]-36,000 [10.55 kW] BTU/H

48 = 42,000 [12.31 kW]-48,000 [14.06 kW] BTU/H

60 = 60,000 [17.58 kW]

Motor Type

V = ECM

Stages of Air Flow

1 = Single

2 = Two Stage

Product Category

H = Air Handler

Rheem

[ ] Designates Metric Conversions

Available Models

RH1V2417STANJA

RH1V3617STANJA

RH1V3621MTANJA

RH1V4821STANJA

RH1V4824STANJA

RH1V6024STANJA

RH2V2421HTACJA

RH2V3624HTACJA

RH2V4824HTACJA

RH2V6024HTACJA

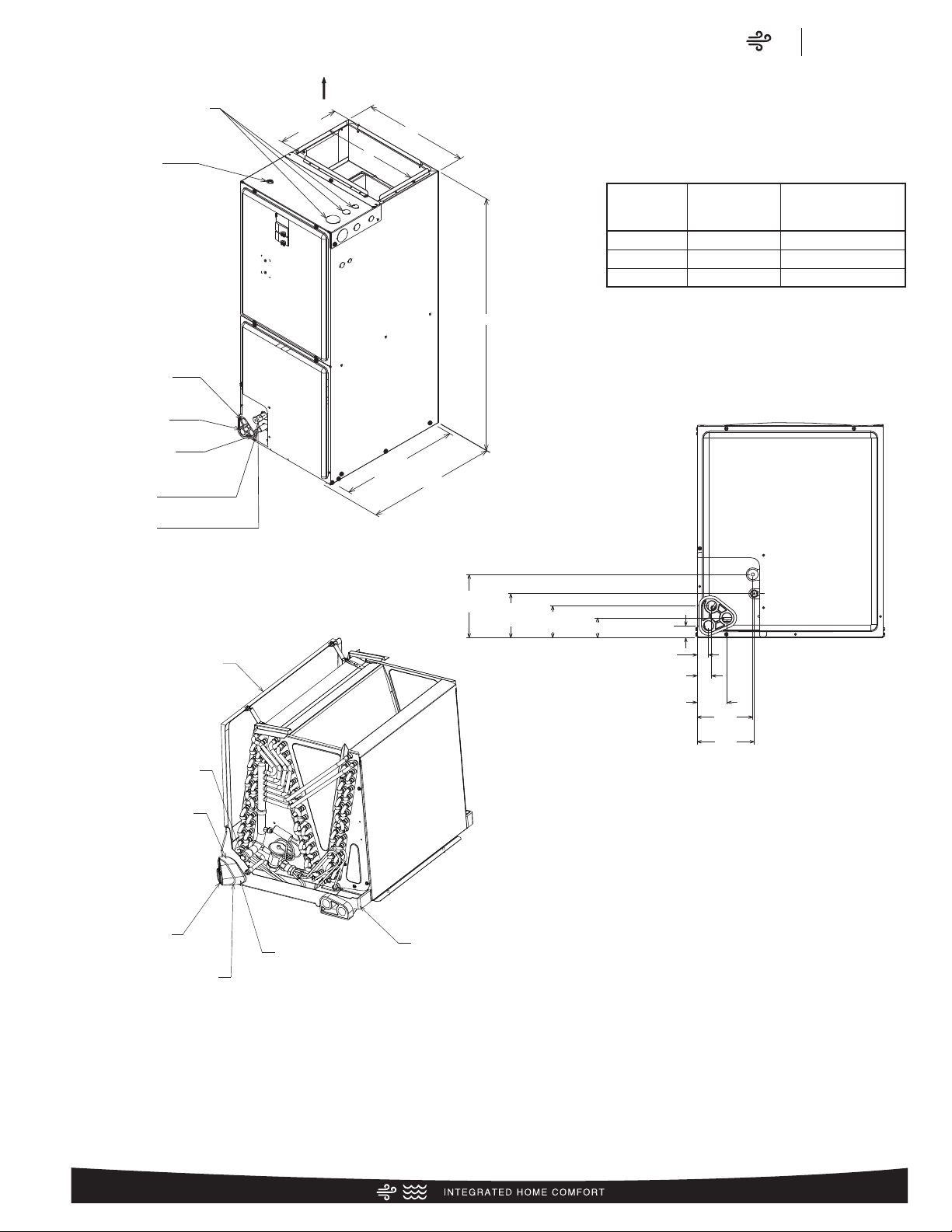

Page 5

Air

Dimensional Data

RH1V/RH2V Series

5

ELECTRICAL CONNECTIONS

Unit Dimensions

[ ] Designates Metric Conversions

( ) Designates Unit with Double Coil Cabinet

UPFLOW UNIT SHOWN:

UNIT MAY BE INSTALLED UPFLOW,

DOWNFLOW, HORIZONTAL RIGHT

OR LEFT AIR SUPPLY.

Return Air Opening Dimensions

[ ] Designates Metric Conversions

( ) Designates Unit with Double Coil Cabinet

HORIZONTAL ADAPTER KIT

VAPOR LINE

CONNECTION

AUXILIARY HORIZONTAL

DRAIN CONNECTION

PRIMARY DRAIN

CONNECTION

AUXILIARY UPFLOW/DOWNFLOW

DRAIN CONNECTION

LIQUID LINE

CONNECTION

VERTICAL DRAIN PAN

MAY EXIT TOP OR EITHER SIDE

HIGH VOLTAGE CONNECTION

3

/32 [27.8 mm], 131/32 [50 mm] DIA. KNOCKOUTS.

1

LOW VOLTAGE CONNECTION

5

/8 [15.9 mm] AND 7/8 [22.2 mm] KNOCKOUT

AUXILIARY DRAIN CONNECTION

3

/4 [19.1 mm] FEMALE PIPE THREAD (NPT)

HORIZONTAL APPLICATION ONLY

PRIMARY DRAIN CONNECTION

3

/4 [19.1 mm] FEMALE PIPE THREAD (NPT)

AUXILIARY DRAIN CONNECTION

3

/4 [19.1 mm] FEMALE PIPE THREAD (NPT)

UPFLOW/DOWNFLOW APPLICATION ONLY

LIQUID LINE CONNECTION

COPPER (SWEAT)

VAPOR LINE CONNECTION

COPPER (SWEAT)

7

/8 [22.2 mm],

SUPPLY AIR

5

/16

10

[262 mm]

A

191/2 [495 mm]

RETURN AIR

OPENING

UPFLOW UNIT SHOWN:

UNIT MAY BE INSTALLED UPFLOW, DOWNFLOW,

HORIZONTAL RIGHT OR LEFT AIR SUPPLY.

NOTE: 24 CLEARANCE REQUIRED IN FRONT OF

UNIT FOR FILTER AND COIL MAINTENANCE.

W

H

11

/16

21

[551 mm]

Model

Cabinet Size

Return Air

Opening Width

(Inches)

17 157/8 193/4

21 193/8 193/4

24 227/8 193/4

Return Air Opening

Depth/Length

(Inches)

515/16

[151 mm]

1

/8

4

[105 mm]

1

3

/16

[76 mm]

3

1

/16 [48 mm]

1

1

/8 [29 mm]

1

/16

1

[27 mm]

1

[35 mm]

2

[71 mm]

3

/8

13

/16

1

/4

5

[133 mm]

3

5

/8

[136 mm]

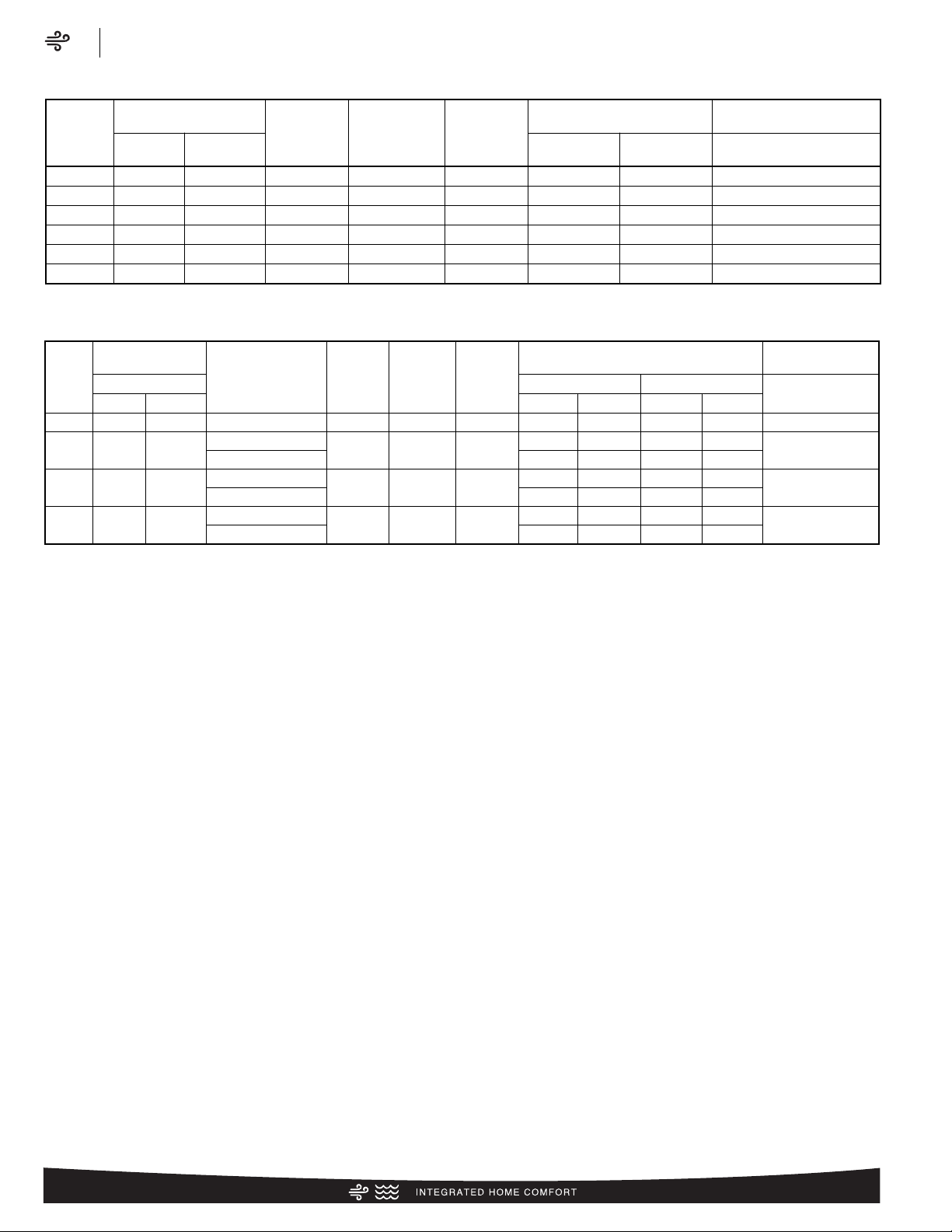

Page 6

Air

Dimensional Data

RH1V/RH2V Series

6

Unit Dimensions & Weights

Model

Size

RH1V

Refrigerant Connections

Sweat (In.) [mm] ID

Unit

Width

“W” In. [mm]

Unit

Height

“H” In. [mm]

Supply

Duct

“A” In. [mm]

Air Flow

CFM (Nom.) [L/s]

Unit Weight/Shipping Weight

(Lbs.) [kg]

Liquid Vapor

Lo Hi

Unit With

Coil (Max. KW)

2417ST

3

/8 [9.53]

3

/4 [19.05] 171/2 [445] 421/2 [1080] 161/2 [406]

600 [283] 800 [378] 82/96 [37/44]

3617ST

3

/8 [9.53]

3

/4 [19.05] 171/2 [445] 421/2 [1080] 161/2 [406]

1000 [472] 1200 [566] 90/104 [41/47]

3621MT

3

/8 [9.53]

7

/8 [22.23] 211/2 [533] 501/2 [1282] 191/2 [495] 1000 [472] 1200 [566] 126/142 [57/64]

4821ST

3

/8 [9.53]

7

/8 [22.23] 211/2 [533] 501/2 [1282] 191/2 [495] 1400 [661] 1600 [755] 130/146 [59/66]

4824ST

3

/8 [9.53]

7

/8 [22.23] 241/2 [622] 501/2 [1282] 231/2 [584] 1600 [755] — 142/160 [64/72]

6024ST

3

/8 [9.53]

7

/8 [22.23] 241/2 [622] 551/2 [1410] 231/2 [584]

— 1800 [850] 162/179 [73/81]

Unit Dimensions & Weights

Model

Size

RH2V

Refrigerant

Connections

Matched

to

Outdoor Unit

Unit

Width

“W” In.

[mm]

Unit

Height

“H” In.

[mm]

Supply

Duct

“A” In.

[mm]

Nominal Coil

Airflow [L/s]

Unit Weight/Shipping

Weight (Lbs.) [kg]

Sweat (in.) [mm] ID

1st Stage 2nd Stage

Unit With

Coil (Max. KW)

Liquid Vapor

ODD* Normal ODD* Normal

2421HT

3

/8 [9.53]3/4 [19.05] (-)ARL/(-)ASL-024JEC 211/2 [533] 421/2 [1080] 191/2 [495] 500 [236] 600 [283] 650 [307] 775 [366] 99/117 [45/51]

3624HT

3

/8 [9.53]7/8 [22.23]

(-)ASL-039JEC

241/2 [622] 551/2 [1410] 231/2 [584]

725 [342] 825 [389] 975 [460] 1175 [555]

129/146 [59/66]

(-)ARL/(-)ASL-0935JEC 825 [389] 950 [448] 1000 [472] 1175 [555]

4824HT3/8 [9.53]7/8 [22.23]

(-)ASL-048JEC

241/2 [622] 551/2 [1410] 231/2 [584]

825 [389] 1000 [472] 1300 [614] 1600 [755]

143/160 [65/72]

(-)ARL-048JEC 1000 [472] 1200 [566] 1350 [637] 1600 [755]

6024HT3/8 [9.53]7/8 [22.23]

(-)ASL-060JEC

241/2 [622] 551/2 [1410] 231/2 [584]

925 [437] 1050 [496] 1325 [625] 1700 [802]

159/176 [72/80]

(-)ARL-060JEC 1025 [484] 1275 [602] 1400 [661] 1700 [802]

*Maximum dehumidification airflow.

[ ] Designates Metric Conversions

Page 7

Air

Airflow Directional Data

RH1V/RH2V Series

7

UPFLOW DOWNFLOW

Airflow Directional Data

HORIZONTAL RIGHT

HAND AIRFLOW

HORIZONTAL LEFT

HAND AIRFLOW

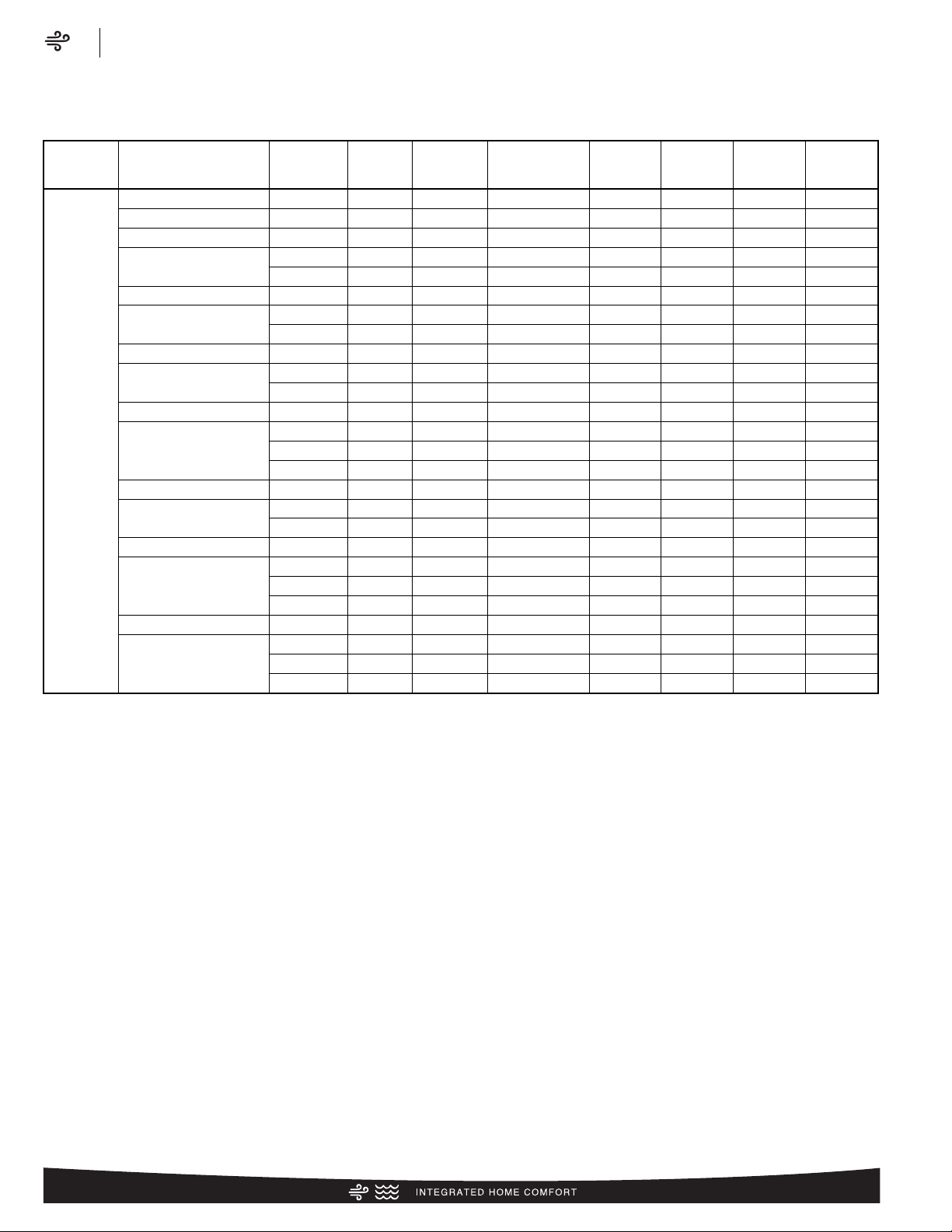

Page 8

Air

Airflow Performance Data

RH1V/RH2V Series

8

Airflow Performance

Airflow performance data is based on cooling performance

with a coil and no filter in place. Select performance table for

appropriate unit size, voltage and number of electric heaters to

be used. Make sure external static applied to unit allows operation within the minimum and maximum limits shown in table

below for both cooling and electric heat operation. For optimum blower performance, operate the unit in the .3 [8 mm] to

.7 inches [18 mm] W.C. external static range. Units with coils

should be applied with a minimum of .1 inch [3 mm] W.C.

external static range.

Airflow Performance and Electrical Data RH1V

External Static Pressure—Inches W.C. [kPa]

ECM

CFM Air Delivery/RPM/Watts—230 Volts

Blower

Size/

Motor

HP [W]

Tonnage

Application

Nominal

Air-Flow

CFM

0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17]

RPM 522 609 673 757 815 869 938

Model

No.

RH1V

Watts 57 74 89 115 130 144 169

10x8

1/3 [249]

5 Speed

1.5 Ton 600*

CFM [L/s] 597 [282] 608 [287] 607 [286] 616 [291] 616 [291] 618 [292] 613 [289]

Motor

Speed

From

Factory

High

190

995

608 [287]

0.8 [.20]

212

1051

600 [283]

0.9 [.22]

232

1097

594 [280]

1.0 [.24]

209

1047

595 [281]

233

1104

587 [277]

254

1149

577 [272]

RPM 536 608 723 805 864 919 989

Watts 65 85 100 129 145 160 186

10x8

1/3 [249]

5 Speed

1.5 Ton 600*

CFM [L/s] 588 [278] 598 [282] 596 [281]

605 [286]

603 [285] 605 [286] 600 [283]

High

259

1017

810 [382]

289

1070

809 [382]

311

1112

805 [380]

RPM 614 682 763 818 868 917 972

Watts 97 113 144 167 191 209 239

10x8

1/3 [249]

5 Speed

2.0 Ton 800

CFM [L/s] 787 [371] 805 [380] 815 [385]

819 [387]

810 [382] 807 [381] 811 [383]

High

298

1044

798 [377]

332

1098

797 [376]

357

1141

793 [374]

RPM 630 700 783 839 891 941 997

Watts 111 130 165 192 798 240 275

10x8

1/3 [249]

5 Speed

2.0 Ton 800

CFM [L/s] 775 [366] 793 [374] 803 [379]

807 [381]

798 [377] 795 [375] 799 [377]

High

320

1065

1029 [486]

341

1090

1029 [486]

357

1118

1023 [483]

RPM 652 752 812 845 923 945 1007

Watts 134 166 193 212 244 266 280

10x8

1/2 [373]

2.5 Ton 1000*

CFM [L/s]

1001 [472] 1030 [486] 1030 [486] 1035 [488] 1035 [488] 1029 [486] 1029 [486]

High

362

1127

1008 [476]

383

1152

1008 [476]

399

1180

1002 [473]

RPM 714 814 874 907 985 1007 1069

Watts 176 208 235 254 286 308 322

10x8

1/2 [373]

2.5 Ton 1000*

CFM [L/s]

980 [463] 1009 [476] 1009 [476] 1014 [479] 1014 [479] 1008 [476] 1008 [476]

High

426

1108

1238 [584]

472

1156

1233 [582]

496

1194

1228 [580]

RPM 732 831 875 930 981 1005 1077

Watts 215 253 282 314 348 362 409

10x8

1/2 [373]

3.0 Ton 1200*

CFM [L/s]

1220 [576] 1229 [580] 1229 [580] 1229 [580] 1229 [580] 1229 [580] 1238 [584]

High

385

1102

1197 [565]

416

1144

1180 [557]

RPM 646 740 783 851 911 958 1013

3.0 Ton

Watts

1200*

147

CFM [L/s]

1199 [566] 1208 [570] 1208 [570] 1208 [570] 1208 [570] 1208 [570] 1217 [574]

186 207 240 270 296 334

10x10

3/4 [559]

3.0 Ton 1200*

CFM [L/s]

1175 [555] 1200 [566] 1203 [568] 1200 [566] 1200 [566] 1199 [566] 1202 [567]

High

416

1122

1145 [540]

450

1172

1137 [537]

487

1219

1114 [526]

RPM 680 779 826 899 963 1015 1074

Watts 168 213 239 278 313 345 388

10x10

3/4 [559]

3.0 Ton 1200*

CFM [L/s]

1159 [546] 1178 [556] 1176 [555] 1167 [551] 1162 [548] 1155 [545] 1153 [544]

High

287

1026

468

1170

1217 [574]

994 [496]

301

514

1218

1212 [572]

1058

970 [458]

538

1256

1207 [570]

323

1099

967 [456]

RPM 593 650 737 801 867 914 980

Watts 103 124 155 177

RPM 794 893 937 992 1043 1067 1139

207 224 258

10x10

3/4 [559]

Watts 257 295 324 356 390 404 451

10x8

1/2 [373]

2.5 Ton 1000*

CFM [L/s]

1000 [472] 1001 [472] 1011 [477] 1009 [476] 1005 [474] 1000 [472] 996 [470]

High

347

1092

939 [443]

366

1128

910 [429]

394

1174

901 [425]

RPM 627 689 780 849 919 971 1041

Watts 124 151 187 215 250 273 312

10x10

3/4 [559]

2.5 Ton 1000*

CFM [L/s]

984 [464] 979 [462] 984 [464] 976 [461] 967 [456] 956 [451] 947 [447]

High

356

1056

1200 [566]

High

3821MT

with

18 kW

Heat

3621MT

No Heat

3621MT

with

15 kW

Heat

3621MT

No Heat

3617ST

with

18 kW

Heat

3617ST

No Heat

3617ST

with

18 kW

Heat

3617ST

No Heat

2417ST

No

Heater

2417ST

with

13 kW

Heat

2417ST

No Heat

2417ST

with

13 kW

Heat

WARNING: Observe airflow operating limits. Do not operate above 1.0 in. W.C. system external static.

*The airflow for continuous fan is set at 50% of the cooling airflow.

[ ] Designates Metric Conversions

Page 9

Air

Airflow Performance Data

RH1V/RH2V Series

9

Model

No.

RH1V

Voltage Phase Hertz HP [W] RPM Speeds

Circuit

Amps.

Minimum

Circuit

Ampacity

Maximum

Circuit

Protector

2417ST 208/240 1 60 1/3 [249] 300-1100 2 2.8 4.0 15

3617ST 208/240 1 60 1/2 [373] 300-1100 2 4.3 6.0 15

6024ST 206/240 1 60 3/4 [559] 300-1100 2 4.4 6.0 15

3621MT/4821ST/

4824ST/6024ST

208/240 1 60 3/4 [559] 300-1100 2 6.8 9.0 15

Blower Motor Electrical Data RH1V

External Static Pressure—Inches W.C. [kPa]

ECM

CFM Air Delivery/RPM/Watts—230 Volts

Blower

Size/

Motor

HP [W]

Tonnage

Application

Nominal

Air-Flow

CFM

0.1 [.02] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17]

RPM 731 807 859 910 968 1016 1057

Model

No.

RH1V

4821ST

No Heat

Watts 240 273 308 349 383 411 436

10x10

3/4 [559]

3.5 Ton 1400*

CFM [L/s]

1395 [658] 1404 [663] 1413 [667] 1413 [667] 1411 [666] 1411 [666] 1402 [662]

Motor

Speed

From

Factory

High

468

1100

1391 [656]

0.8 [.20]

496

1128

1380 [651]

0.9 [.22]

513

1158

1371 [647]

1.0 [.24]

614

1176

1547 [730]

616

1219

1539 [726]

RPM 826 879 933 984 1025 1067 1119

4821ST

No Heat

Watts 342 375 410 454 486 523 552

10x10

3/4 [559]

4.0 Ton 1600*

CFM [L/s]

1583 [747] 1583 [747] 1583 [747] 1590 [750] 1582 [747] 1566 [739] 1572 [742]

High

653

1222

1484 [700]

688

1255

1467 [692]

697

1304

1452 [685]

RPM 860 919 978 1035 1082 1129 1187

4821ST

with

25 kW

Heat

Watts 363 403 444 495 534 577 613

10x10

3/4 [559]

4.0 Ton 1600*

CFM [L/s]

1567 [740] 1559 [736] 1551 [732] 1550 [732] 1534 [724] 1510 [713] 1508 [712]

High

502

950

1614 [762]

532

981

1606 [758]

568

1018

1583 [747]

RPM 612 698 747 788 835 870 914

4824ST

No Heat

Watts 225 297 334 359 410 439 469

11x11

3/4 [559]

4.0 Ton 1600*

CFM [L/s]

1607 [758] 1615 [762] 1622 [765] 1630 [769] 1637 [773] 1629 [769] 1621 [765]

High

572

1027

1549 [731]

609

1062

1534 [724]

652

1104

1505 [710]

528

1166

1336 [631]

561

1198

1319 [622]

584

1233

1305 [616]

RPM 765 846 902 958 1020 1073 1118

4821ST

with

20 kW

Heat

Watts 261 300 340 387 426 460 490

10x10

3/4 [559]

3.5 Ton 1400*

CFM [L/s]

1379 [651] 1382 [652] 1385 [654] 1380 [651] 1372 [648] 1367 [645] 1352 [638]

High

585

1148

1556 [734]

RPM 658 748 802 847 899 938 987

4824ST

with

25 kW

Heat

Watts 246 325 369 401 459 495 532

11x11

3/4 [559]

4.0 Ton 1600*

CFM [L/s]

1587 [749] 1589 [750] 1589 [750] 1591 [751] 1591 [751] 1577 [744] 1562 [737]

High

624

994

1800 [850]

662

1028

1786 [843]

694

1050

1772 [836]

RPM 676 739 787 840 871 923 950

6024ST

No Heat

Watts

330 376 416 465 504 554 576

11x11

3/4 [559]

5.0 Ton 1800*

CFM [L/s]

1794 [847] 1808 [853] 1808 [853] 1807 [853] 1807 [853] 1807 [853] 1807 [853]

High

676

1047

1762 [832]

717

1083

1748 [825]

752

1107

1734 [818]

RPM 713 778 828 884 917 971 1000

6024ST

with

30 kW

Heat

Watts 361 410 453 505 547 600 625

11x11

3/4 [559]

5.0 Ton 1800*

CFM [L/s]

1756 [829] 1770 [835] 1770 [835] 1769 [835] 1769 [835] 1769 [835] 1769 [835]

High

502

950

1614 [762]

532

981

1606 [758]

568

1018

1583 [747]

RPM 612 698 747 788 835 870 914

6024ST

No Heat

Watts

225 297 334 359 410 439 469

11x11

3/4 [559]

5.0 Ton 1600*

CFM [L/s]

1607 [758] 1615 [762] 1622 [765] 1630 [769] 1637 [773] 1629 [769] 1621 [765]

High

572

1027

1549 [731]

609

1063

1534 [724]

652

1104

1505 [710]

RPM 658 748 802 847 899 938 987

6024ST

with

25 kW

Heat

Watts

246 325 369 401 459 495 532

11x11

3/4 [559]

5.0 Ton 1600*

CFM [L/s]

1587 [749] 1589 [750] 1589 [750] 1591 [751] 1591 [751] 1577 [744] 1562 [737]

High

WARNING: Observe airflow operating limits. Do not operate above 1.0 in. W.C. system external static.

*The airflow for continuous fan is set at 50% of the cooling airflow.

[ ] Designates Metric Conversions

Airflow Performance and Electrical Data (Cont.) RH1V

Page 10

Air

Electrical Data

RH1V/RH2V Series

10

Air Handler

Model

RH1V

Heater Model No.

Heater kW

(208/240V)

PH/HZ

No. Elements

kW Per

Type Supply

Circuit Single

Circuit Multiple

Circuit

Amps.

Motor

Ampacity

Minimum

Circuit

Ampacity

Maximum

Circuit

Protector

2417ST

RXBH-1724?03J 2.25/3.0 1/60 1-3.0 SINGLE

10.8/12.5 2.2 17/19 20/20

RXBH-1724?05J 3.6/4.8 1/60 1-4.8 SINGLE

17.3/20.0 2.2 25/28 25/30

RXBH-1724?07J 5.4/7.2 1/60 2-3.6 SINGLE

26.0/30.0 2.2 36/41 40/45

RXBH-1724?10J 7.2/9.6 1/60 2-4.8 SINGLE

34.6/40.0 2.2 46/53 50/60

RXBH-1724A13J

9.4/12.5 1/60 3/4/17 SINGLE

45.1/52.1 2.2 60/68 60/70

3.1/4.2 1/60 1/4/17 MULTIPLE CKT 1

15.0/17.4 2.2 22/25 25/25

6.3/8.3 1/60 2/4/17 MULTIPLE CKT 2

30.1/34.7 0 38/44 40/45

RXBH-1724A07C 5.4/7.2 3/60 3-2.4 SINGLE

15.0/17.3 2.2 22/25 25/25

RXBH-1724A10C 7.2/9.6 3/60 3-3.2 SINGLE

20.0/23.1 2.2 28/32 30/35

RXBH-1724A13C 9.4/12.5 3/60 3/4/17 SINGLE

26.1/30.1 2.2 36/41 40/45

3617ST

RXBH-1724?03J 2.25/3.0 1/60 1-3.0 SINGLE

10.8/12.5 3.1 18/20 20/20

RXBH-1724?05J 3.6/4.8 1/60 1-4.8 SINGLE

17.3/20.0 3.1 26/29 30/30

RXBH-1724?07J 5.4/7.2 1/60 2-3.6 SINGLE

26.0/30.0 3.1 37/42 40/45

RXBH-1724?10J 7.2/9.6 1/60 2-4.8 SINGLE

34.6/40.0 3.1 48/54 50/60

RXBH-1724A13J

9.4/12.5 1/60 3/4/17 SINGLE

45.1/52.1 3.1 61/69 70/70

3.1/4.2 1/60 1/4/17 MULTIPLE CKT 1

15.0/17.4 3.1 23/26 25/30

6.3/8.3 1/60 2/4/17 MULTIPLE CKT 2

30.1/34.7 0 38/44 40/45

RXBH-1724A15J

10.8/14.4 1/60 3-4.8 SINGLE

51.9/60.0 3.1 69/79 70/80

3.6/4.8 1/60 1-4.8 MULTIPLE CKT 1

17.3/20.0 3.1 26/29 30/30

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 2

34.6/40.0 0 44/50 45/50

RXBH-1724A18J

12.8/17.0 1/60 3/5/68 SINGLE

61.6/70.8 3.1 81/93 90/100

4.3/5.7 1/60 1/5/68 MULTIPLE CKT 1

20.5/23.6 3.1 30/34 30/35

8.5/11.3 1/60 2/5/68 MULTIPLE CKT 2

41.1/47.2 0 52/59 60/60

RXBH-1724A07C 5.4/7.2 3/60 3-2.4 SINGLE

15.0/17.3 3.1 23/26 25/30

RXBH-1724A10C 7.2/9.6 3/60 3-3.2 SINGLE

20.0/23.1 3.1 29/33 30/35

RXBH-1724A13C 9.4/12.5 3/60 3/4/17 SINGLE

26.1/30.1 3.1 37/42 40/45

RXBH-1724A15C 10.8/14.4 3/60 3-4.8 SINGLE

30.0/34.6 3.1 42/48 45/50

RXBH-1724A18C 12.8/17.0 3/60 3/5/68 SINGLE

35.5/41.0 3.1 49/56 50/60

3821MT

4821ST

RXBH-1724?05J 3.6/4.8 1/60 1-4.8 SINGLE

17.3/20.0 4.0 27/30 30/30

RXBH-1724?07J 5.4/7.2 1/60 2-3.6 SINGLE

26.0/30.0 4.0 38/43 40/45

RXBH-1724?10J 7.2/9.6 1/60 2-4.8 SINGLE

34.6/40.0 4.0 49/55 50/60

RXBH-1724A15J

10.8/14.4 1/60 3-4.8 SINGLE

51.9/60.0 4.0 70/80 70/80

3.6/4.8 1/60 1-4.8 MULTIPLE CKT 1

17.3/20.0 4.0 27/30 30/30

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 2

34.6/40.0 0.0 44/50 45/50

RXBH-1724A18J

12.8/17.0 1/60 4/4/26 SINGLE

61.6/70.8 4.0 82/94 90/100

6.4/8.5 1/60 2/4/26 MULTIPLE CKT 1

30.8/35.4 4.0 44/50 45/50

6.4/8.5 1/60 2/4/26 MULTIPLE CKT 2

30.8/35.4 0.0 39/45 40/45

RXBH-24A20J

(3

1

/2

, 4-ton only)

14.4/19.2 1/60 4-48 SINGLE

69.2/80 4.0 92/105 100/110

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 1

34.6/40.0 4.0 49/55 50/60

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 2

34.6/40.0 0.0 44/50 45/50

RXBH-24A25J

(4-ton only)

18.0/24.0 1/60 6-4.0 SINGLE

86.4/99.9 4.0 113/130 125/150

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 1

28.8/33.3 4.0 42/47 45/50

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 2

28.8/33.3 0.0 36/42 40/45

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 3

28.8/33.3 0.0 36/42 40/45

Electrical Data – With Electric Heat RH1V

Installation of the U.L. Listed original equipment manufacturer provided heater kits listed in the following table is recommended for all

auxiliary heating requirements.

• Supply circuit protective devices may be fuses or “HACR” type circuit breakers.

• Largest motor load is included in single circuit and multiple circuit 1.

• If non-standard fuse size is specified, use next size larger standard fuse size.

• J Voltage (230V) single phase air handler is designed to be used with single or three phase 230 volt electric heaters. In the case of connecting 3-phase power to the air handler terminal block

without the heater, bring only two leads to the terminal block cap, insulate and fully secure the third lead.

[ ] Designates Metric Conversions

Page 11

Air

Electrical Data

RH1V/RH2V Series

11

Electrical Data – With Electric Heat RH1V (Cont.)

Installation of the U.L. Listed original equipment manufacturer provided heater kits listed in the following table is recommended for all

auxiliary heating requirements.

Air Handler

Model

RH1V

Heater Model No.

Heater kW

(208/240V)

PH/HZ

No. Elements

kW Per

Type Supply

Circuit Single

Circuit Multiple

Circuit

Amps.

Motor

Ampacity

Minimum

Circuit

Ampacity

Maximum

Circuit

Protector

3821MT

4821ST

RXBH-1724A07C 5.4/7.2 3/60 3-2.4 SINGLE

15.0/17.3 4.0 24/27 25/30

RXBH-1724A10C 7.2/9.6 3/60 3-3.2 SINGLE

20.0/23.1 4.0 30/34 30/35

RXBH-1724A15C 10.8/14.4 3/60 3-4.8 SINGLE

30.0/34.6 4.0 43/49 45/50

RXBH-1724A18C 12.8/17.0 3/60 3/2/84 SINGLE

35.6/41.0 4.0 50/57 50/60

RXBH-24A20C*

(3

1

/2

, 4-ton only)

14.4/19.2 3/60 3-3.2 SINGLE

40.0/46.2 4.0 55/63 60/70

7.2/9.6 3/60 3-3.2 MULTIPLE CKT 1

20.0/23.1 4.0 30/34 30/35

7.2/9.6 3/60 3-3.2 MULTIPLE CKT 2

20.0/23.1 0.0 25/29 25/30

RXBH-24A25C*

(4-ton only)

18.0/24.0 3/60 6-4.0 SINGLE

50.0/57.8 4.0 68/78 70/80

9.0/12.0 3/60 3-4.0 MULTIPLE CKT 1

25.0/28.9 4.0 37/42 40/45

9.0/12.0 3/60 3-4.0 MULTIPLE CKT 2

25.0/28.9 0.0 32/37 35/40

4824ST

6024ST

RXBH-1724?05J 3.6/4.8 1/60 1-4.8 SINGLE

17.3/20.0 4.4 28/31 30/35

RXBH-1724?07J 5.4/7.2 1/60 2-3.6 SINGLE

26.0/30.0 4.4 38/43 40/45

RXBH-1724?10J 7.2/9.6 1/60 2-4.8 SINGLE

34.6/40.0 4.4 49/56 50/60

RXBH-1724A15J

10.8/14.4 1/60 3-4.8 SINGLE

51.9/60.0 4.4 71/81 80/90

3.6/4.8 1/60 1-4.8 MULTIPLE CKT1

17.3/20.0 4.4 28/31 30/35

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 2

34.6/40.0 0 44/50 45/50

RXBH-1724A18J

12/8/17 1/60 4/4/26 SINGLE

61.6/70.8 4.4 83/94 90/100

6.4/8.5 1/60 2/4/26 MULTIPLE CKT 1

30.8/35.4 4.4 44/50 45/50

6.4/8.5 1/60 2/4/26 MULTIPLE CKT 2

30.8/35.4 0 39/45 40/45

RXBH-24A20J

14.4/19.2 1/60 4-4.8 SINGLE

69.2/80 4.4 93/106 100/110

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 1

34.6/40.0 4.4 49/56 50/60

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 2

34.6/40.0 0 44/50 45/50

RXBH-24A25J

18.0/24.0 1/60 6-4.0 SINGLE

86.4/99.9 4.4 114/131 125/150

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 1

28.8/33.3 4.4 42/48 45/50

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 2

28.8/33.3 0 36/42 40/45

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 3

28.8/33.3 0 36/42 40/45

RXBH-24A30J

(1800 CFM only)

21.6/28.8 1/60 6-4.8 SINGLE

103.8/120. 4.4 136/156 150/175

RXBH-24A30J

(5-ton only)

(1800 CFM only)

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 1

34.6/40.0 4.4 49/56 50/60

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 2

34.6/40.0 0 44/50 45/50

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 3

34.6/40.0 0 44/50 45/50

RXBH-1724A07C 5.4/7.2 3/60 3-2.4 SINGLE

15.0/17.3 4.4 25/28 25/30

RXBH-1724A10C 7.2/9.6 3/60 3-3.2 SINGLE

20.0/23.1 4.4 31/35 35/35

RXBH-1724A15C 10.8/14.4 3/60 3-4.8 SINGLE

30.0/34.6 4.4 43/49 45/50

RXBH-1724A18C 12.8/17.0 3/60 3/2/84 SINGLE

35.6/41.0 4.4 50/57 50/60

RXBH-24A20C*

14.4/19.2 3/60 3-3.2 SINGLE

40.0/46.2 4.4 56/64 60/70

7.2/9.6 3/60 3-3.2 MULTIPLE CKT 1

20.0/23.1 4.4 31/35 35/35

7.2/9.6 3/60 3-3.2 MULTIPLE CKT 2

20.0/23.1 0 25/29 25/30

RXBH-24A25C*

18.0/24.0 3/60 6-4.0 SINGLE

50.0/57.8 4.4 68/78 70/80

9.0/12.0 3/60 3-4.0 MULTIPLE CKT 1

25.0/28.9 4.4 37/42 40/45

9.0/12.0 3/60 3-4.0 MULTIPLE CKT 2

25.0/28.9 0 32/37 35/40

RXBH-24A30C*

(1800 CFM only)

21.6/28.8 3/60 6-4.8 SINGLE

60.0/69.4 4.4 81/93 90/100

RXBH-24A30C

(5-ton only) (1800 CFM only)

10.8/14.4 3/60 3-4.8 MULTIPLE CKT 1

30.0/34.7 4.4 43/50 45/50

10.8/14.4 3/60 3-4.8 MULTIPLE CKT 2

30.0/34.7 0 38/44 40/45

• Supply circuit protective devices may be fuses or “HACR” type circuit breakers.

• Largest motor load is included in single circuit and multiple circuit 1.

• If non-standard fuse size is specified, use next size larger standard fuse size.

• J Voltage (230V) single phase air handler is designed to be used with single or three phase 230 volt electric heaters. In the case of connecting 3-phase power to the air handler terminal block

without the heater, bring only two leads to the terminal block cap, insulate and fully secure the third lead.

[ ] Designates Metric Conversions

Page 12

Air

Airflow Performance Data

RH1V/RH2V Series

12

Airflow Performance

Airflow performance data is based on cooling performance

with a coil and no filter in place. Select performance table for

appropriate unit size, voltage and number of electric heaters to

be used. Make sure external static applied to unit allows operation within the minimum and maximum limits shown in table

below for both cooling and electric heat operation. For optimum blower performance, operate the unit in the .3 [8 mm] to

.7 inches [18 mm] W.C. external static range. Units with coils

should be applied with a minimum of .1 inch [3 mm] W.C.

external static range.

Airflow Performance Data RH2V

Outdoor

Unit

Blower

Nominal

Airflow

CFM

0.20 0.40 0.60 0.80

RARL-024

or

RASL-024

10 x 8

1/3

600

CFM 575 [271] 600 [283] 625 [295] 600 [283]

RPM 540 695 825 940

0.90

575 [271]

985

0.70

625 [295]

885

0.50

625 [295]

760

0.30

600 [283]

620

External Static Pressure - In. W.C.

CFM [L/s] Air Delivery/RPM/Watts-230 Volts

External Static Pressure – Inches W.C. [kPa]

0.10

550 [260]

455

1.00

550 [260]

1030

170

825 [389]

1020

250

135

825 [389]

925

205

105

800 [378]

810

160

70

775 [366]

685

115

40

775 [366]

540

70

185

825 [389]

1065

270

Watts 55 85 120 150

775

CFM 775 [366] 800 [378] 825 [389] 825 [389]

RPM 615 750 870 975

Watts

90 135 180 225

Air

Handler

RH2V

2421HT

First

Stage

Second

Stage

Size

Motor HP

Unit

Operation

3624HT

RARL-036

or

RASL-036

11 x 11

3/4

First

Stage

950

CFM

950 [448] 950 [448] 1000 [472] 975 [460] 975 [460] 975 [460] 925 [437] 925 [437] 925 [437] 925 [437]

RPM 495 555 610 665 720 770 820 865 910 955

Watts 95 115 140 165 185 210 240 265 290 320

Second

Stage

1175

CFM 1150 [543] 1150 [543] 1175 [555] 1175 [555] 1175 [555] 1150 [543] 1150 [543] 1150 [543] 1125 [531] 1125 [531]

RPM 550 600 650 700 750 800 850 900 925 975

Watts 125 175 200 225 250 275 300 325 375 400

RASL-039

First

Stage

825

CFM 825 [389] 825 [389] 875 [413] 875 [413] 850 [401] 850 [401] 825 [389] 825 [389] 800 [378] 800 [378]

RPM 455 515 575 630 680 730 780 830 875 915

Watts 70 90 115 135 155 180 205 230 255 280

Second

Stage

1175

CFM 1150 [543] 1150 [543] 1175 [555] 1175 [555] 1175 [555] 1150 [543] 1150 [543] 1150 [543] 1125 [531] 1125 [531]

RPM 550 600 650 700 750 800 850 900 925 975

Watts

125 175 200 225 250 275 300 325 375 400

4824HT

RARL-048

11 x 11

3/4

First

Stage

1200

CFM

1275 [602] 1275 [602] 1250 [590] 1250 [590] 1275 [602] 1250 [590] 1250 [590] 1225 [578] 1225 [578] 1225 [578]

RPM 533 593 649 702 752 798 841 881 917 950

Watts 131 161 191 221 250 279 307 335 363 390

Second

Stage

1600

CFM 1650 [779] 1650 [779] 1675 [791] 1700 [802] 1700 [802] 1700 [802] 1675 [791] 1675 [791] 1675 [791] 1675 [791]

RPM 635 698 761 824 887 950 1013 1075 1120 1006

Watts 244 293 340 384 425 464 500 533 564 592

RASL-048

First

Stage

1000

CFM 1000 [472] 1000 [472] 1025 [484] 1025 [484] 1000 [472] 1000 [472] 975 [460] 975 [460] 975 [460] 975 [460]

RPM 500 575 625 675 725 775 825 875 925 950

Watts 100 125 150 175 200 225 250 275 300 325

Second

Stage

1600

CFM 1650 [779] 1650 [779] 1675 [791] 1700 [802] 1700 [802] 1700 [802] 1675 [791] 1675 [791] 1675 [791] 1675 [791]

RPM 635 698 761 824 887 950 1013 1075 1120 1006

Watts

244 293 340 384 425 464 500 533 564 592

6024HT

RARL-060

11 x 11

3/4

First

Stage

1275

CFM

1275 [602] 1275 [602] 1275 [602] 1275 [602] 1275 [602] 1275 [602] 1275 [602] 1250 [590] 1250 [590] 1250 [590]

RPM 577 633 687 738 786 831 874 914 951 986

Watts 159 189 218 248 279 310 341 372 404 436

Second

Stage

1700

CFM 1625 [767] 1625 [767] 1650 [779] 1675 [791] 1675 [791] 1650 [779] 1650 [779] 1625 [767] 1625 [767] 1625 [767]

RPM 691 742 790 835 877 916 953 986 1016 1044

Watts 289 334 377 417 456 493 529 562 593 623

RASL-060

First

Stage

1050

CFM 1050 [496] 1050 [496] 1075 [507] 1075 [507] 1050 [496] 1025 [484] 1025 [484] 1025 [484] 1025 [484] 1000 [472]

RPM 525 575 625 675 750 800 825 875 925 975

Watts 100 125 150 175 225 250 275 300 325 350

Second

Stage

1700

CFM 1625 [767] 1625 [767] 1650 [779] 1675 [791] 1675 [791] 1650 [779] 1650 [779] 1625 [767] 1625 [767] 1625 [767]

RPM 691 742 790 835 877 916 953 986 1016 1044

Watts 289 334 377 417 456 493 529 562 593 623

Cabinet

Size

24

21

24

24

IMPORTANT: Observe airflow operating limits. Do not operate above 1.0 in. W.C. system external static.

[ ] Designates Metric Conversions

Page 13

Air

Electrical Data

RH1V/RH2V Series

13

Air Handler

Model

RH2V

Heater Model No.

Heater kW

(208/240V)

PH/HZ

No. Elements

kW Per

Type Supply

Circuit Single

Circuit Multiple

Circuit

Amps.

Motor

Ampacity

Minimum

Circuit

Ampacity

Maximum

Circuit

Protection

2421HT

RXBH-1724?05J 3.6/4.8 1/60 1 - 4.8 SINGLE

17.3/20.0 1.7 24/28 25/30

RXBH-1724?07J 5.4/7.2 1/60 2 - 3.6 SINGLE

26.0/30.0 1.7 35/40 35/40

RXBH-1724?10J 7.2/9.6 1/60 2 - 4.8 SINGLE

34.6/40.0 1.7 46/53 50/60

3624HT

RXBH-1724?05J 3.6/4.8 1/60 1 - 4.8 SINGLE

17.3/20.0 4.9 28/32 30/35

RXBH-1724?07J 5.4/7.2 1/60 2 - 3.6 SINGLE

26.0/30.0 4.9 39/44 40/45

RXBH-1724?10J 7.2/9.6 1/60 2 - 4.8 SINGLE

34.6/40.0 4.9 50/57 50/60

RXBH-1724A13J 9.4/12.5 1/60 3-4.17 SINGLE

45.1/52.1 4.9 63/72 70/80

RXBH-1724A13J

3.1/4.2 1/60 1-4.17 MULTIPLE CKT 1

15.0/17.4 4.9 25/28 25/30

6.3/8.3 1/60 2-4.17 MULTIPLE CKT 2

30.1/34.7 0.0 38/44 40/45

RXBH-1724A15J 10.8/14.4 1/60 3-4.8 SINGLE

51.9/60.0 4.9 71/82 80/90

RXBH-1724A15J

3.6/4.8 1/60 1 - 4.8 MULTIPLE CKT 1

17.3/20.0 4.9 28/32 30/35

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2

34.6/40.0 0.0 44/50 45/50

RXBH-1724A18J 12.8/17 1/60 3-5.68 SINGLE

61.6/70.8 4.9 84/95 90/100

RXBH-1724A18J

4.3/5.7 1/60 1 - 5.68 MULTIPLE CKT 1

20.5/23.6 4.9 32/36 35/40

8.7/11.3 1/60 2 - 5.86 MULTIPLE CKT 2

41.1/47.2 0.0 52/59 60/60

RXBH-24A20J 14.4/19.2 1/60 4-4.8 SINGLE

69.2/80 4.9 93/107 100/110

RXBH-24A20J

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 1

34.6/40.0 4.9 50/57 50/60

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2

34.6/40.0 0.0 44/50 45/50

4824HT

RXBH-1724?05J 3.6/4.8 1/60 1 - 4.8 SINGLE

17.3/20.0 4.9 28/32 30/35

RXBH-1724?07J 5.4/7.2 1/60 2 - 3.6 SINGLE

26.0/30.0 4.9 39/44 40/45

RXBH-1724?10J 7.2/9.6 1/60 2 - 4.8 SINGLE

34.6/40.0 4.9 50/57 50/60

RXBH-1724A13J 9.4/12.5 1/60 3-4.17 SINGLE

45.1/52.1 4.9 63/72 70/80

RXBH-1724A13J

3.1/4.2 1/60 1-4.17 MULTIPLE CKT 1

15.0/17.4 4.9 25/28 25/30

6.3/8.3 1/60 2-4.17 MULTIPLE CKT 2

30.1/34.7 0.0 38/44 40/45

RXBH-1724A15J 10.8/14.4 1/60 3-4.8 SINGLE

51.9/60.0 4.9 71/82 80/90

RXBH-1724A15J

3.6/4.8 1/60 1 - 4.8 MULTIPLE CKT 1

17.3/20.0 4.9 28/32 30/35

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2

34.6/40.0 0.0 44/50 45/50

RXBH-1724A18J 12.8/17 1/60 3-5.68 SINGLE

61.6/70.8 4.9 84/95 90/100

RXBH-1724A18J

4.3/5.7 1/60 1 - 5.68 MULTIPLE CKT 1

20.5/23.6 4.9 32/36 35/40

8.7/11.3 1/60 2 - 5.86 MULTIPLE CKT 2

41.1/47.2 0.0 52/59 60/60

RXBH-24A20J 14.4/19.2 1/60 4-4.8 SINGLE

69.2/80 4.9 93/107 100/110

RXBH-24A20J

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 1

34.6/40.0 4.9 50/57 50/60

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2

34.6/40.0 0.0 44/50 45/50

RXBH-24A25J (4-ton only) 18.0/24.0 1/60 6-4.0 SINGLE

86.4/99.9 5.2 115/132 125/150

RXBH-24A25J (4-ton only)

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 1

28.8/33.3 5.2 43/49 45/50

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 2

28.8/33.3 0.0 36/42 40/45

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 3

28.8/33.3 0.0 36/42 40/45

Electrical Data – With Electric Heat RH2V

Installation of the U.L. Listed original equipment manufacturer provided heater kits listed in the following table is recommended for all

auxiliary heating requirements.

• Supply circuit protective devices may be fuses or “HACR” type circuit breakers.

• Largest motor load is included in single circuit and multiple circuit 1.

• If non-standard fuse size is specified, use next size larger standard fuse size.

• J Voltage (230V) single phase air handler is designed to be used with single or three phase 230 volt electric heaters. In the case of connecting 3-phase power to the air handler terminal block

without the heater, bring only two leads to the terminal block cap, insulate and fully secure the third lead.

[ ] Designates Metric Conversions

Model

RH2V

Voltage Phase HertzHP [W] RPM

Circuit

Amps.

Minimum

Circuit

Ampacity

Maximum

Circuit

Protector

2421HT 208/230 1 601/3 [249] 300-1100 1.7 4.0 15

3624HT 208/230 1 603/4 [559] 300-1100 4.9 9.0 15

4824HT 208/230

1

603/4 [559] 300-1100

4.9

9.0 15

6024HT 208/230 603/4 [559] 300-1100 9.0 15

1 4.9

Electrical Data (-)H2V

Page 14

Air

Electrical Data

RH1V/RH2V Series

14

Air Handler

Model

RH2V

Heater Model No.

Heater kW

(208/240V)

PH/HZ

No. Elements

kW Per

Type Supply

Circuit Single

Circuit Multiple

Circuit

Amps.

Motor

Ampacity

Minimum

Circuit

Ampacity

Maximum

Circuit

Protection

6024HT

RXBH-1724?07J 5.4/7.2 1/60 2 - 3.6 SINGLE

26.0/30.0 4.9 39/44 40/45

RXBH-1724?10J 7.2/9.6 1/60 2 - 4.8 SINGLE

34.6/40.0 4.9 50/57 50/60

RXBH-1724A15J 10.8/14.4 1/60 3-4.8 SINGLE

51.9/60.0 4.9 71/82 80/90

RXBH-1724A15J

3.6/4.8 1/60 1 - 4.8 MULTIPLE CKT 1

17.3/20.0 4.9 28/32 30/35

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2

34.6/40.0 0.0 44/50 45/50

RXBH-1724A18J 12.8/17 1/60 3-5.68 SINGLE

61.6/70.8 4.9 84/95 90/100

RXBH-1724A18J

4.3/5.7 1/60 1 - 5.68 MULTIPLE CKT 1

20.5/23.6 4.9 32/36 35/40

8.7/11.3 1/60 2 - 5.86 MULTIPLE CKT 2

41.1/47.2 0.0 52/59 60/60

RXBH-24A20J 14.4/19.2 1/60 4-4.8 SINGLE

69.2/80 4.9 93/107 100/110

RXBH-24A20J

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 1

34.6/40.0 4.9 50/57 50/60

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2

34.6/40.0 0.0 44/50 45/50

RXBH-24A25J 18.0/24.0 1/60 6-4.0 SINGLE

86.4/99.9 4.9 115/131 125/150

RXBH-24A25J

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 1

28.8/33.3 4.9 43/48 45/50

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 2

28.8/33.3 0.0 36/42 40/45

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 3

28.8/33.3 0.0 36/42 40/45

RXBH-24A20J 14.4/19.2 1/60 4-4.8 SINGLE

69.2/80 4.9 93/107 100/110

RXBH-24A20J

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 1

34.6/40.0 4.9 50/57 50/60

7.2/9.6 1/60 2 - 4.8 MULTIPLE CKT 2

34.6/40.0 0.0 44/50 45/50

RXBH-24A25J 18.0/24.0 1/60 6-4.0 SINGLE

86.4/99.9 4.9 115/131 125/150

RXBH-24A25J

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 1

28.8/33.3 4.9 43/48 45/50

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 2

28.8/33.3 0.0 36/42 40/45

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 3

28.8/33.3 0.0 36/42 40/45

RXBH-24A30J 21.6/28.8 1/60 6-4.8 SINGLE

103.8/120 4.9 136/156 150/175

RXBH-24A30J

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 1

34.6/40.0 4.9 50/57 50/60

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 2

34.6/40.0 0.0 44/50 45/50

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 3

34.6/40.0 0.0 44/50 45/50

Electrical Data – With Electric Heat RH2V (con’t.)

Installation of the U.L. Listed original equipment manufacturer provided heater kits listed in the following table is recommended for all

auxiliary heating requirements.

• Supply circuit protective devices may be fuses or “HACR” type circuit breakers.

• Largest motor load is included in single circuit and multiple circuit 1.

• If non-standard fuse size is specified, use next size larger standard fuse size.

• J Voltage (230V) single phase air handler is designed to be used with single or three phase 230 volt electric heaters. In the case of connecting 3-phase power to the air handler terminal block

without the heater, bring only two leads to the terminal block cap, insulate and fully secure the third lead.

[ ] Designates Metric Conversions

Page 15

Air

Electrical Wiring

RH1V/RH2V Series

15

Electrical Wiring

Power Wiring

• Field wiring must comply with the National Electrical Code

(C.E.C. in Canada) and any applicable local ordinance.

• Supply wiring must be 75°C minimum copper conductors only.

• See electrical data for product Ampacity rating and Circuit

Protector requirement.

Grounding

• This product must be sufficiently grounded in accordance with

National Electrical Code (C.E.C. in Canada) and any applicable

local ordinance.

• A grounding lug is provided.

RXHF-

Accessories

• Auxiliary Horizontal Overflow Pan Accessory RXBM-

• Combustible Floor Base RXHB-

• Jumper Bar Kit 3 Ckt. to 1 Ckt. RXBJ-A31 is used to convert

single phase multiple three circuit units to a single supply

circuit. Kit includes cover and screw for line side terminals.

• Jumper Bar Kit 2 Ckt. to 1 Ckt. RXBJ-A21 is used to convert

single phase multiple two circuit units to a single supply circuit.

Kit includes cover and screw for line side terminals.

• Note: No jumper bar kit is available to convert three phase

multiple two circuit units to a single supply circuit.

• Auxiliary Electric Heater Kits RXBH-

Heater Kits include circuit breakers which meet UL and cUL

requirements for service disconnect. See the Electric Heat

Electrical Data in this specification sheet for specific Heater Kit

Model numbers.

• External Filter Rack RXHF-B17, B21, B24

*Accommodates 1" filter

[ ] Designates Metric Conversions

17

21

24

RXHB-17

RXHB-21

RXHB-24

Model Cabinet Size

Combustible Floor

Base Model Number

Nominal Cooling

Capacity-Tons

Auxiliary Horizontal Overflow Pan

Accessory Model Number

11/2 - 3

RXBM-AC48

31/2 - 5 RXBM-AC61

RXHF-B

B

A

B

A

11/2⬙

[38 mm]

• External Filter Base RXHF-

*Accommodates 1" or 2" filter

• Horizontal Adapter Kit RXHH-

This horizontal adapter kit is used to convert Upflow/Downflow

only models to horizontal flow. See the following table to order

proper horizontal adapter kit.

Model Cabinet Size Filter Size In. [mm]

21 20 x 20 [508 x 508]

Part Number*

RXHF-21

RXHF-2424 25 x 20 [635 x 508] 22.70

19.20

A

25.5

21.0

B

Model Cabinet Size Part Number*

RXHF-B17

RXHF-B21

Filter Size In. [mm]

RXHF-B24

24

25 x 20 [635 x 508]

17

16 x 20 [406 x 508]

21

20 x 20 [508 x 508]

A

16.90

20.40

25.00

B

20.77

20.77

21.04

• External Filter Base RXHF-

*Accommodates 1" or 2" filter

Model Cabinet Size Filter Size In. [mm]

17 16 x 20 [406 x 508]

21 20 x 20 [508 x 508]

Part Number*

RXHF-17

RXHF-21

RXHF-2424 25 x 20 [635 x 508] 22.70

19.20

15.70

A

25.5

21.0

17.5

B

Coil Model

Horizontal Adapter Kit

Model Number (10-Pack Qty.)

RXHH-A01 x 10

RXHH-A02 x 10

Horizontal Adapter Kit

Model Number (Single Qty.)

RXHH-A03 x 103617/3621 RXHH-A03

2414 RXHH-A01

2417 RXHH-A02

3821/4821/4824 RXHH-A04 RXHH-A04 x 10

6024 RXHH-A05 RXHH-A05 x 10

Page 16

Air

Limited Warranty

RH1V/RH2V Series

16

GENERAL TERMS OF LIMITED WARRANTY*

Rheem will furnish a replacement for any part of this product

which fails in normal use and service within the applicable

periods stated, in accordance with the terms of the limited

warranty.

Conditional Parts (Registration Required) ..........Ten (10) Years

*For complete details of the Limited and Conditional Warranties, including

applicable terms and conditions, contact your local contractor or the

Manufacturer for a copy of the product warranty certificate.

Page 17

Air

Notes

RH1V/RH2V Series

17

Page 18

Air

Notes

RH1V/RH2V Series

18

Page 19

19

Air

Notes

RH1V/RH2V Series

Page 20

The new degree of comfort.

™

Rheem Heating, Cooling & Water Heating • P.O. Box 17010

Fort Smith, Arkansas 72917 • www.rheem.com

In keeping with its policy of continuous progress and product improvement, Rheem reserves the right to make changes without notice.

PRINTED IN U.S.A 4/14 QG FORM NO. H11-554

Rheem Canada Ltd./Ltée • 125 Edgeware Road, Unit 1

Brampton, Ontario • L6Y 0P5

Loading...

Loading...