Page 1

High Efficiency Commercial Gas Water Heater

USE & CARE MANUAL

WITH INSTALLATION INSTRUCTIONS FOR THE CONTRACTOR

This Use & Care Manual covers the following model numbers:

OFF

ON

Recognize this symbol as an Indication of Important

Safety Information!

!

NOTICE: This water heater is designed for use in a commercial application.The installation and

maintenance of it should be performed by qualified, licensed service personnel.

!

WARNING: Read and review this entire manual with special emphasis on the Venting and Operation

Sections prior to any installation work.

!

CALIFORNIA PROPOSITION 65 WARNING: This product contains chemicals known to the State of California

to cause cancer, birth defects or other reproductive harm.

!

WARNING: If the information in these instructions are not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

!

HE45-100N HE119-130N HE45-199LP

HE45-130N HE119-160N HE80-130LP

HE45-160N HE119-199N HE80-160LP

HE45-199N HE80-199LP

HE80-130N HE45-100LP HE119-130LP

HE80-160N HE45-130LP HE119-160LP

HE80-199N HE45-160LP HE119-199LP

Do Not Destroy this Manual. Please read carefully

and keep in a safe place for Future Reference.

!

FOR YOUR SAFETY!

!

— Do not store or use gasoline or other flammable

vapors or liquids or other combustible materials in

the vicinity of this or any other appliance.To do so

may result in an explosion or fire.

— WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any

•

phone in your building.

Printed in the USA

Immediately call your gas supplier from a neigh-

•

bor's phone. Follow the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire

•

department.

Do not return to your building until authorized by

•

the gas supplier or fire department.

— Improper installation, adjustment, alteration, ser-

vice or maintenance can cause injury, property

damage or death. Refer to this manual. Installation

and service must be performed by a qualified

installer, service agency or the gas supplier.

AP12158-2 (04/05)

Page 2

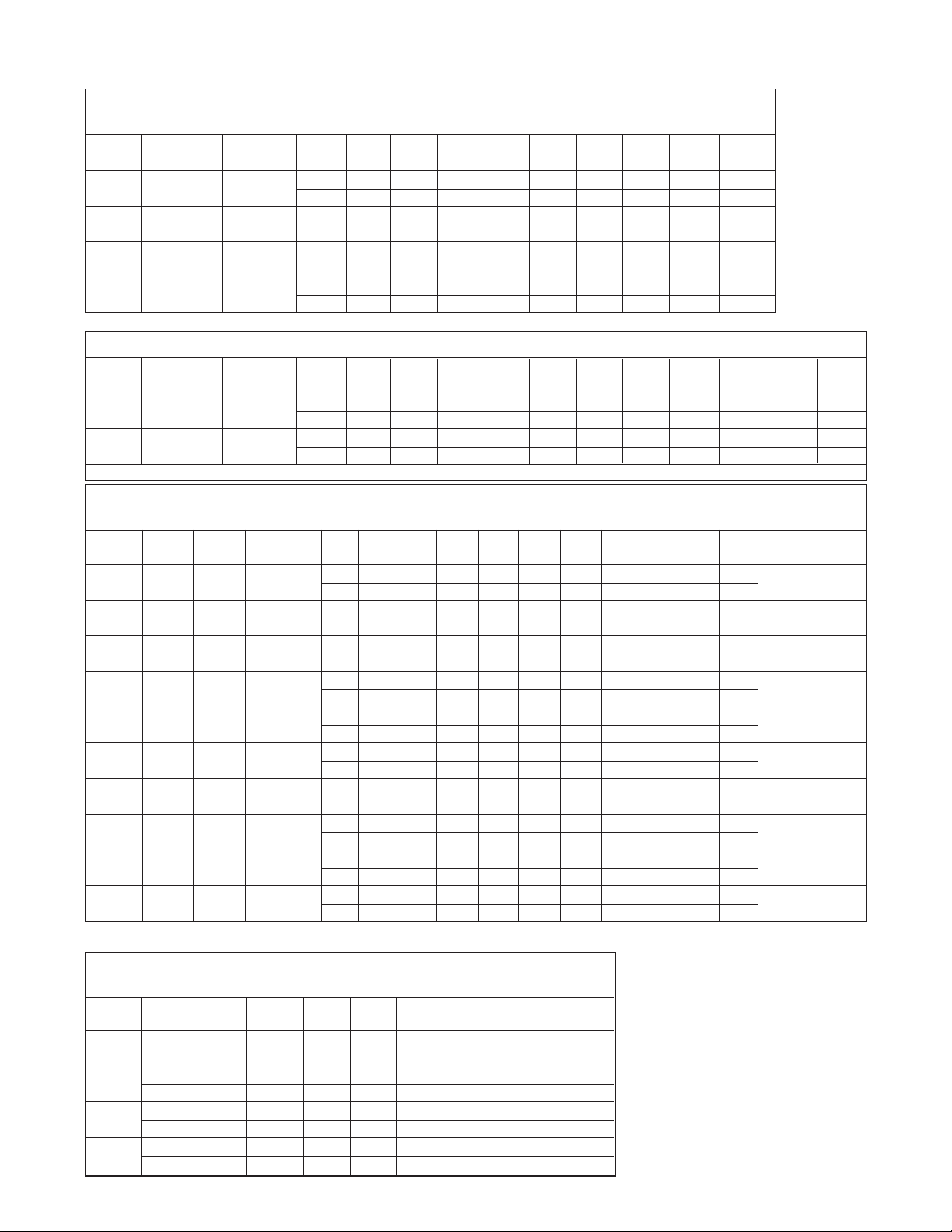

SPECIFICATIONS

RECOVERY CAPACITIES

Recovery in U.S. Gallons/Hr. (GPH) and Liters/Hr. (LPH) at Various Temperature Rises

MODEL INPUT (BTU/HR) THERMAL

NUMBER NAT. & LP EFFICIENCY UNITS

HE45-100

HE45-130

HE80-130

HE119-130

HE80-160

HE119-160

HE80-199

HE119-199

Recovery rating is based on thermal efficiencies obtained in an AGA certified laboratory.

BOOSTER MODELS

MODEL INPUT (BTU/HR) THERMAL

NUMBER NAT. & LP EFFICIENCY UNITS

HE45-160 160,000 95%

HE45-199 199,000 95%

All models exceed the minimum NAECA energy efficiency requirements of ASHRAE 90.1b-1989, 1992 requirements.

100,000 95%

130,000 95%

160,000 95%

199,000 95%

Recovery in U.S. Gallons/Hr. (GPH) and Liters/Hr. (LPH)

MAXIMUM DELIVERY

In U.S. Gallons and Liters

MODEL

NUMBER

HE45-100

HE45-130

HE80-130

HE119-130

HE45-160

HE80-160

HE119-160

HE45-199

HE80-199

HE119-199

All models have a maximum setpoint of 160°F with the exception of the HE45-160 and HE45-199 booster models. The HE45-160 and HE45-199 have a maximum setpoint of 180°F.

* NOTE: The 180º F models are shipped with all necessary components for an approved installation (see Booster Installation Kit for component list.)

GALLONS/

LITERS

MAX.

SETPOINT

45

45

80

45

80

45

80

160º 100,000

160º 130,000

160º 130,000

160º 130,000

180º* 160,000

160º 160,000

160º 160,000

180º* 199,000

160º 199,000

160º 199,000

170 55.6°C LTR. 156 192 228 265 337 446 555 991 1427

170 55.6°C LTR. 166 214 261 308 403 544 686 1253 1819

303 55.6°C LTR. 259 306 354 401 495 637 779 1345 1912

119

450 55.6°C LTR. 363 410 457 504 599 750 882 1449 2015

170 55.6°C LTR. 177 235 294 352 468 642 817 1514 2211

303 55.6°C LTR. 270 328 386 444 561 735 909 1607 2304

119

450 55.6°C LTR. 373 432 490 548 664 838 1013 1710 2408

170 55.6°C LTR. 192 264 336 408 553 770 987 1854 2721

303 55.6°C LTR. 284 357 429 501 646 863 1079 1947 2814

119

450 55.6°C LTR. 338 460 532 604 749 966 1183 2050 2918

(Includes useable storage and recovery for indicated times)

INPUT (BTU/HR)

NAT. & LP

DIMENSIONAL INFORMATION

All dimensions shown in English and Metric

MODEL

NUMBER UNITS

HE45-100

HE45-130

HE45-160

HE45-199

HE80-130

HE80-160

HE80-199

HE119-130

HE119-160

HE119-199

All models require a 120V power source.

* 130,000 Btu models are certified to be installed with 2” venting.

inches 42 23 1/2 32 2 1 1 175 lbs.

inches 42 23 1/2 32 3 1 1 175 lbs.

inches 72 23 1/2 32 3* 1-1/2 1-1/2 235 lbs.

inches 73 27 36 3* 1-1/2 1-1/2 405 lbs.

HEIGHT WIDTH DEPTH VENT

mm 1067 597 813 51 25 25 79 kgs

mm 1067 597 813 76 25 25 79 kgs

mm 1854 597 813 76 38 38 106 kgs

mm 1854 686 914 76 38 38 184 kgs

40°F 50°F 60°F 70°F 80°F 90°F 100°F 110°F 120°F

(22.2°C) (27.8°C) (33.3°C) (38.9°C) (44.4°C) (50.0°C) (55.6°C) (61.1°C) (66.7°C)

GPH 288 230 192 165 144 128 115 105 96

LPH 1090 872 726 623 545 484 436 396 363

GPH 374 299 249 214 187 166 150 136 125

LPH 1417 1133 944 809 708 630 567 515 472

GPH 461 368 307 263 230 205 184 167 154

LPH 1744 1395 1162 996 872 775 697 634 581

GPH 573 458 382 327 286 255 229 208 191

LPH 2169 1735 1446 1239 1084 964 867 789 723

40°F 50°F 60°F 70°F 80°F 90°F 100°F 110°F 120°F 130°F 140°F

(22.2°C) (27.8°C) (33.3°C) (38.9°C) (44.4°C) (50.0°C) (55.6°C) (61.1°C) (66.7°C) (72.2°C) (77.8°C)

GPH 461 368 307 263 230 205 184 167 154 142 132

LPH 1744 1395 1162 996 872 775 697 634 581 536 498

GPH 573 458 382 327 286 255 229 208 191 176 164

LPH 2169 1735 1446 1239 1084 964 867 789 723 667 620

TEMP. 5 10 15 20 30 45 1 2 3 MIN. TO RECOVER

RISE UNITS MIN. MIN. MIN. MIN. MIN. MIN. HR. HR. HR. CONTENTS

100°F GAL. 41 51 60 70 89 118 147 262 377

100°F GAL. 44 56 69 81 106 144 181 331 481

100°F GAL. 68 81 93 106 131 168 206 355 505

100°F GAL. 96 108 121 133 158 196 233 383 532

100°F GAL. 47 62 78 93 124 170 216 400 584

100°F GAL. 71 87 102 117 148 194 240 424 609

100°F GAL. 99 114 129 145 175 221 268 452 636

100°F GAL. 51 70 89 108 146 203 261 490 719

100°F GAL. 75 94 113 132 171 228 285 514 743

GAL. 102 121 141 160 198 255 312 542 771

100°F

WATER CONNECTIONS APPROX

INLET OUTLET

SHIPPING WT.

0" CLEARANCE TO

COMBUSTIBLES ON ALL

ADVANTAGE PLUS UNITS,

HOWEVER, A 24"

CONTROL PANEL SERVICE CLEARANCE IS

RECOMMENDED.

2

23

18

32

48

15

26

39

12

21

31

Page 3

General Safety Precautions

!

Be sure to read and understand the entire Use & Care Manual before attempting to install or operate this water heater.

Pay particular attention to the following General Safety Precautions. Failure to follow these warnings could result in a fire

or explosion, causing property damage, bodily injury or death. Should you have any problems understanding the instructions in this manual, STOP, and get help from a qualified installer or service technician or the gas supplier.

DANGER

WARNING

!

Gasoline, as well as other flammable materials and liq-

!

LIQUEFIED PETROLEUM MODELS

uids (adhesives, solvents, etc.), and the vapors they produce, are extremely dangerous. DO NOT handle, use or

store gasoline or other flammable or combustible materials anywhere near or in the vicinity of a water heater. Be

sure to read and follow the warning label pictured below

and other labels on the water heater, as well as the warnings printed in this manual. Failure to do so can result in

property damage, bodily injury, or death.

- Propane, or LP gas, must be used with great caution.

· It is heavier than air and will collect first in lower areas

making it hard to detect at nose level.

· Make sure to look and smell for LP leaks before

attempting to light appliance. Use a soapy solution to

check all gas fittings and connections. Bubbling at a connection indicates a leak that must be corrected. When

smelling to detect an LP leak, be sure to sniff near the

floor.

DANGER

!

· Gas detectors are recommended in LP applications and

their installation should be in accordance with the manuFailure to install and properly vent the water heater to the

outdoors as outlined in the Venting Section of this manual can result in unsafe operation of the water heater. To

avoid the risk of fire, explosion, or asphyxiation from car-

facturer's recommendations and/or local laws, rules, reg-

ulations or customs.

· It is recommended that more than one method be used

to detect leaks in LP applications.

bon monoxide, never operate this water heater unless it

is properly vented and has an adequate air supply for

IF LP GAS IS PRESENT OR SUSPECTED:

proper operation. Be sure to inspect the vent system for

proper installation at initial start-up and at least annually

thereafter. Refer to maintenance section of this manual

for more information regarding vent system inspections.

· DO NOT attempt to find the cause yourself;

· DO NOT try to light any appliance;

· DO NOT touch any electrical switch;

· DO NOT use any phone in your building.

!

DANGER

· Leave the house immediately and make sure your fam-

ily and pets leave also.

· Leave the doors open for ventilation and contact the gas

supplier, a qualified service agency or the fire depart-

ment.

· Keep the area clear until the service call has been

made, the leak is corrected, and a qualified agency has

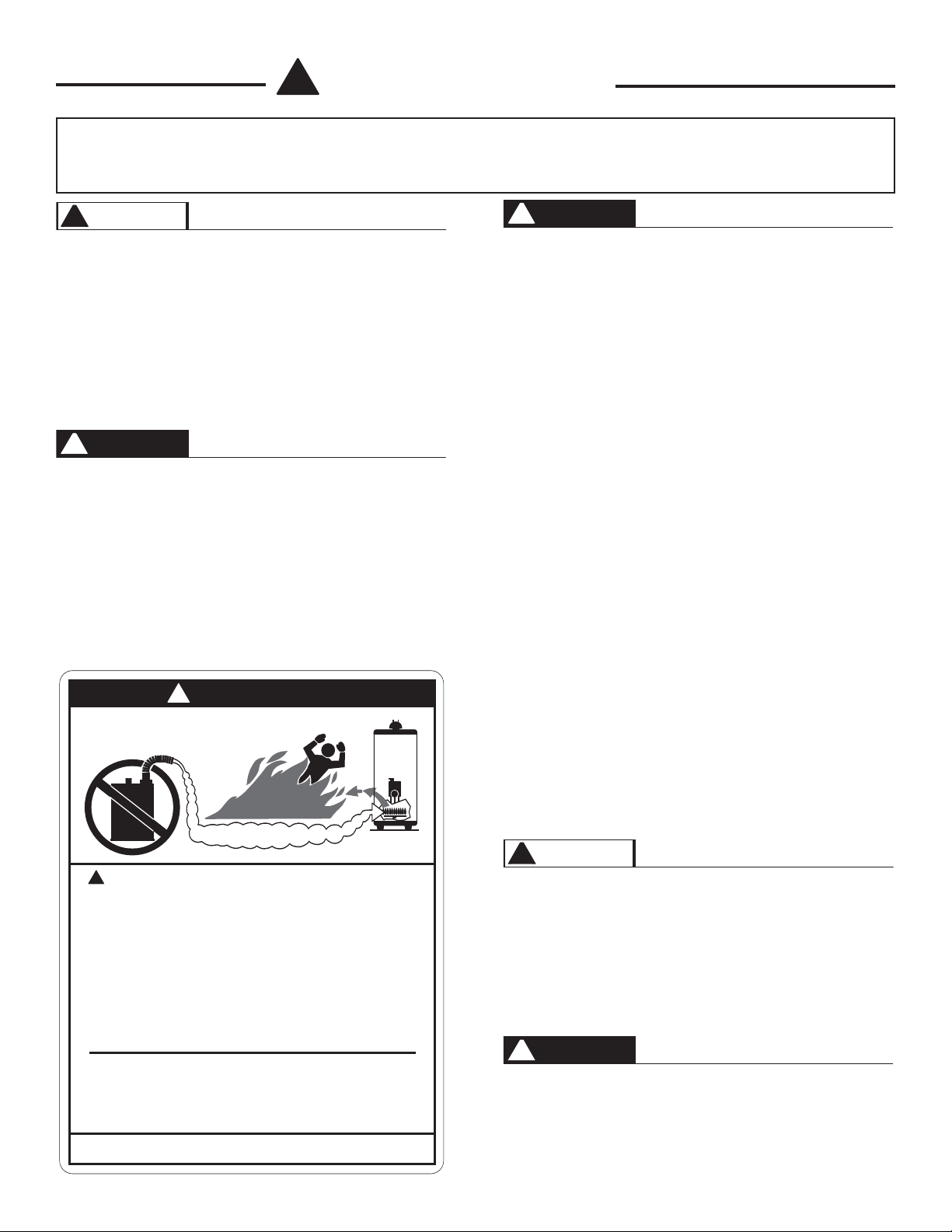

FLAMMABLES

!

Vapors from flammable

liquids will explode and

catch fire causing death or

severe burns.

Do not use or store flammable

products such as gasoline,

solvents or adhesives in the

same room or area near the

water heater.

Keep flammable products:

1. far away from heater,

2. in approved containers,

3. tightly closed and

4. out of children's reach.

Installation:

Do not install water heater

where flammable products will

be stored or used unless the

main burner and pilot flames

Read and follow water heater warnings and instructions. If owners

manual is missing, contact the retailer or manufacturer.

Flammable Vapors

Water heater has a main

burner and pilot flame.

The pilot flame:

1. which can come on at

2. will ignite flammable

Vapors:

1. cannot be seen,

2. are heavier than air,

3. go a long way on the

4. can be carried from

flame by air currents.

are at least 18" above the

floor. This will reduce, but not

eliminate, the risk of vapors

being ignited by the main

burner or pilot flame.

any time and

vapors.

floor and

other rooms to the pilot

determined the area to be safe.

WARNING

!

Both LP and natural gas have an odorant added to help

detection. Some people may not physically be able to

smell or recognize this odorant. If unsure or unfamiliar

about the smell associated with LP or natural gas, ask

the gas supplier. Other conditions, such as "Odorant

Fade", which causes the odorant to "fade", or diminish in

intensity can also hide or camouflage a gas leak.

DANGER

!

Water heaters utilizing Liquefied Petroleum gas (LP) are

different from natural gas models. A natural gas heater

will not function safely on LP gas and vice versa. No

attempt should ever be made to convert a heater from

natural gas to LP gas. To avoid possible equipment dam-

3

Page 4

General Safety Precautions

!

age, personal injury or fire: DO NOT connect this water

heater to a fuel type not in accordance with unit rating

plate. Propane gas for propane units. Natural gas for

natural gas units. These units are not certified for any

other type fuel.

WARNING

!

LP appliances should not be installed below-grade (for

example, in a basement) if such installation is prohibited

by federal, state and/or local laws, rules, regulations, or

customs.

To meet commercial water use needs, the thermostat on

this water heater is adjustable up to 160

els have a maximum setpoint of 180°F). However, water

temperatures over 125

instantly or death from scalds. This is the preferred starting point for setting the controls for supplying general

purpose hot water.

Safety and energy conservation are factors to be considered when setting the water temperature on the thermostat. The most energy efficient operation will result when

the temperature setting is the lowest that satisfies the

needs consistent with the application.

!

DANGER

0

F can cause severe burns

0

F (Booster mod-

Maximum water temperatures occur just after burner has

shut off. To find temperature of the water being delivered, turn on a hot water faucet and place a thermometer in the hot water stream and read the thermometer.

The following chart details the relationship of water temperature and time with regard to scald injury and may be

used as a guide in determining the safest water temperature for your applications.

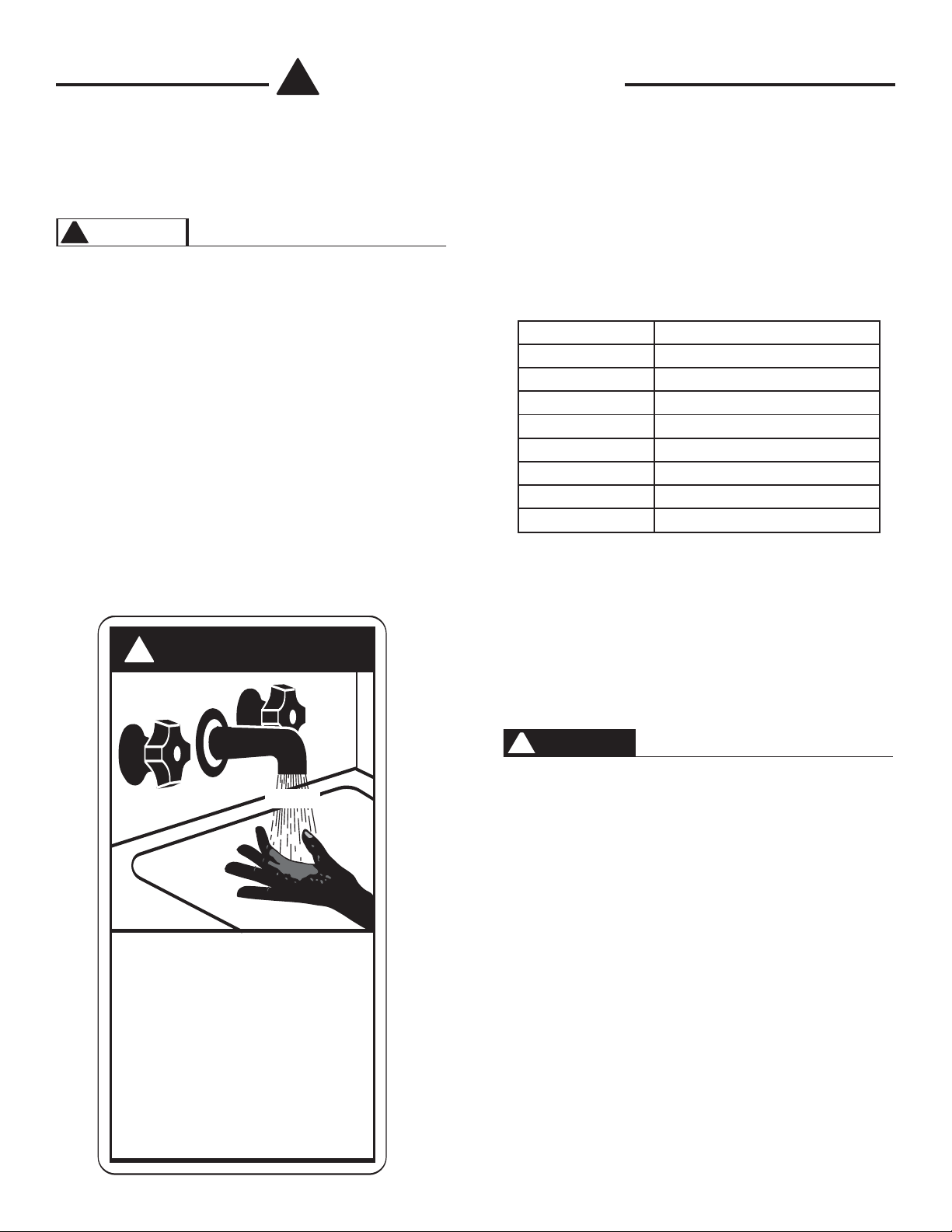

TIME / TEMPERATURE RELATIONSHIPS IN SCALDS

Temperature Time to Produce Serious Burn

120˚F More than 5 minutes

125˚F 1½ to 2 minutes

130˚F About 30 seconds

135˚F About 10 seconds

140˚F Less than 5 seconds

145˚F Less than 3 seconds

150˚F About 1½ seconds

155˚F About 1 second

Table courtesy of Shriners Burn Institute

The temperature of the water in the heater can be regulated by setting the temperature on the electronic thermostat. To comply with safety regulations, the thermostat

was set at its lowest setting before the water heater was

shipped from the factory. See the section titled SET

POINT ADJUSTMENT PROCEDURE to set the electronic thermostat.

HOT

BURN

Water temperature over 125°F can

cause severe burns instantly or

death from scalds.

Children, disabled and elderly are

at highest risk of being scalded.

See instruction manual before

setting temperature at water

heater.

Feel water before bathing or

showering.

Temperature limiting valves are

available, see manual.

DANGER

!

There is a Hot Water SCALD Potential if the thermostat is set too high.

NOTE: When this water heater is supplying general purpose hot water requirements for use by individuals, a

thermostatically controlled mixing valve for reducing point

of use water temperatures is recommended to reduce the

risk of scald injury. Contact a licensed plumber or the

local plumbing authority for further information.

4

Page 5

INSTALLATION

WARNING

!

Read and review this entire manual with special

emphasis on the Venting Sections and Operation

Sections prior to any installation work.

LOCAL INSTALLATION REGULATIONS

This water heater must be installed in accordance with

these instructions, local codes, utility company requirements, and/or in the absence of local codes, the latest

edition of the American National Standard / National Fuel

Gas Code, a copy of which can be purchased from either

American Gas Association, 1515 Wilson Blvd., Arlington,

VA 22209 as booklet Z223.1 or National Fire Prevention

Association, 1 Batterymarch Park, Quincy, MA 02269 as

booklet NFPA 54.

The water heater must be located or protected so it is not

subject to physical damage, for example, by moving

objects, area flooding, etc.

CAUTION

!

The water heater should not be located in an area

where leakage of the tank or connections will result

in damage to the area adjacent to it or to lower floors

of the structure. When such areas cannot be avoided, it is recommended that a suitable catch pan, adequately drained, be installed under the water heater.

The pan MUST NOT restrict the flow of combustion

air flow.

NOTE: Auxiliary catch pan installation MUST conform to the applicable local codes

service clearance minimum. This front service may be

achieved by a non-rated or combustible door or access

panel; providing the 24" service clearance is achieved

when the door is opened or panel is removed. This water

heater must not be located near flammable liquids

such as gasoline, adhesives, solvents, paint thinners, butane, liquefied propane, etc. as the controls

of this appliance could ignite those vapors, causing

an explosion.

TEMPERATURE AND PRESSURE RELIEF VALVE

A new combination temperature and pressure relief

valve, complying with the Standard for Relief Valves and

Automatic Gas Shutoff Devices for Hot Water Supply

Systems, ANSI Z21.22, must be installed in the opening

provided on the water heater at the time of installation.

No valve is to be placed between the relief valve and the

water heater. For circulating tank installation, the separate storage tank(s) must have similar protection. The

pressure rating of the relief valve must not exceed the

maximum working pressure as marked on the front of the

water heater. The Btu/h rating of the relief valve must

equal or exceed the Btu/h input of the water heater as

noted on its rating plate. Connect the outlet of the relief

valve to a suitable open drain. The discharge line must

pitch downward from the valve to allow complete draining

(by gravity) of the relief valve and discharge line, and

must be no smaller than the outlet of the relief valve. The

end of the discharge line should not be threaded or concealed and should be protected from freezing. No valve

of any type, restriction or reducer coupling should be

installed in the discharge line. Local codes shall govern

the installation of the relief valves.

LOCATION

Choose a location for your water heater centralized to the

piping system, along with consideration to vent pipe

length. As the length of vent pipe increases, the firing

rate of the appliance decreases. You must also locate

the Advantage Plus where it will not be exposed to below

freezing temperatures. Additionally, you will need to

place the water heater so that the controls, drain,

inlet/outlet, and gas valve are easily accessed. This

appliance must not be installed outdoors, as it is certified

as an indoor appliance, and must be kept vertical and on

a level surface. Also, care must be exercised when

choosing the location of this appliance where leakage

from the relief valve, leakage from related piping, or leakage from the tank or connections, will not result in damage to the surrounding areas or to the lower floors of the

building. A water heater should always be located in

an area with a floor drain or installed in an adequately drained catch pan suitable for water heaters.

Proper clearance must be provided around the

AdvantagePlus as follows: Sides, bottom, top, and back

are 0" (zero clearance). Front of the appliance needs 24"

EXPANSION TANK

A potable hot water expansion tank may be required to

offset the water expansion as the water is heated. In

most city plumbing systems, the water meter has a no

return or back flow device built into the system to prevent

back flowing of water back into city mains. Back flow preventers may be found on all incoming water supplies.

Under these circumst

expansion tank listed for potable water use. The expansion tank should be located on the cold inlet piping close

to the water heater. The expansion tank must be suit-

able for hot potable water.

WARNING

!

The manufacturer’s warranty does not cover any

damage or defect caused by installation or attachment or use of any special attachments such as energy saving devices (other than those authorized by

the manufacturer) into, onto, or in conjunction with

the water heater. The use of such unauthorized

5

ances, you will need a hot water

Page 6

devices may shorten the life of the water heater and

may endanger life and property. The manufacturer

disclaims any responsibility for such loss or injury

resulting from the use of such unauthorized devices.

DOMESTIC WATER CONNECTIONS

The water connections must be installed in accordance

with all national and local plumbing codes, or any prevailing standard. NEVER USE DIELECTRIC UNIONS

OR GALVANIZED STEEL FITTINGS ON ADVANTAGE

PLUS CONNECTIONS. The inlet and outlet connections

are 1" on the 45 gallon models and 1-1/2" on the 80 and

119 gallon models. On the cold inlet, install a 1" brass

tee on the 45 gallon models, or a 1-1/2" brass tee on the

80 and 119 gallon models. On the run of the 1" brass tee

install, with pipe sealant, compound a 1" brass drain cock

or it's equivalent (not supplied). Into the branch of the 1"

or 1-1/2" brass tee install a copper male adapter to match

with the copper plumbing system. For convenience, you

may install a shut off valve and a union in the cold inlet

piping to ease servicing in the future. If there is a back

flow preventer, or any type of a no return valve in the system, then you must install an additional tee for a suitable

potable thermal expansion tank. (See section on

Expansion Tank.) In the hot outlet connection, (top left),

install a suitable adapter to match the copper tubing of

the plumbing system. A thermal trap or heat trap loop

may be installed here to provide additional energy savings and prevent thermal siphoning of domestic hot

water. A domestic hot water tempering/ anti-scald valve

should be installed into the hot water line to prevent the

maximum outlet water temperature from exceeding 125°

Fahrenheit to prevent scald injury.

SPECIAL INSTRUCTIONS FOR BOOSTER

INSTALLATIONS

All booster heaters are supplied with the "Booster

Installation" kit. In order to maintain proper temperature,

this kit must be correctly installed. The Booster kit contains the following list of parts:

#01 - Nibco Tee - 1"x 1"x 1/2" (2 pcs.)

#02 - Female Adapter - 1" (2 pcs.)

#03 - Dial Thermometer (2 pcs.)

#04 - Expansion Tank - 4-1/2 Gal.

#05 - Grundfos 3 Speed Pump w/ Check Valve

#06 - Nibco 1.2" x 12" Fitting Air Chamber

#07 - Vacuum Relief Valve

#08 - Pressure Gauge - 0 - 200 PSI

#09 - Nibco Tee 712R - 1"x 1" x 3/4" (2 pcs.)

#10 - Nibco Tee 714RR - 1"x 1/2"x 1"

#11 - Nibco Tee - 1"x 1/2"x 1" Copper

#12 - Reducing Coupling

#13 - Pressure Reducing Valve

#14 - Nibco Male Adapter - 1"

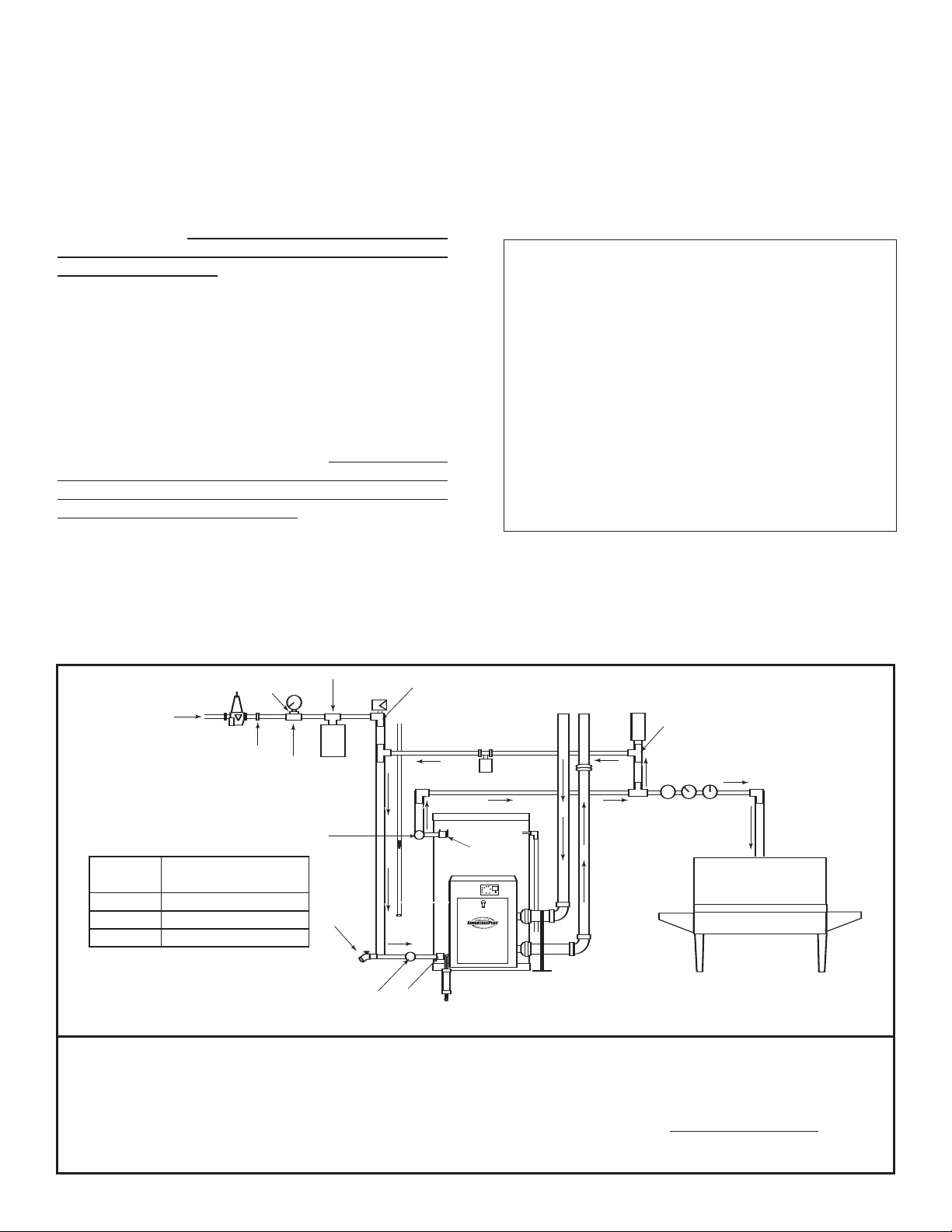

See the following drawing for a typical "Booster" installation. Please note that those items marked with an asterisk in the drawing are not included with the Booster kit,

but are items that should be installed in a typical dishwasher package.

120˚ F TO

140˚ F SUPPLY

1" COPPER

CIRCULATOR

SETTING

1

2

#08

#12

#13

#14

#09

#01

#03

DISTANCE TO DISHWASHER

(ONE WAY)

1 - 19 FT.

20 - 59 FT.

DRAIN

VALV E

#09

#04

1" SUPPLY

#07

#11

3/4" GAS

3/4" RETURN

3 60 - 100 FT.

#01

#02

#03

The booster heater is equipped with a circulating pump to provide the

minimum water flow in the booster and maintain a uniform water temperature in the tank. Depending on the physical distance from the

booster to the dishwasher, and the length of time between washes, it

may be necessary to run an empty rack to purge the supply line of

water that has cooled below 180ºF. For this reason it is best to locate

the booster as close as possible to the dishwasher. The circulator is

equipped with three speeds to increase flow rate and reduce heat

CONDENSATE

DRAIN

1" SUPPLY

3" PVC

180˚F

RETURN

3" ABS MIN.

#06

180˚F

WATER

84" REQ'D

#10

* PRESS. REGULATOR

* PRESS. GAUGE

* THERMOMETER

DISHWASHER

ances should the

3" PVC

#05

#02

INTAKE

EXHAUST

loss. Reference the "Distance" chart to determine the appropriate circulator speed setting.

All piping should be installed with suitable pipe insulation to avoid

temperature loss on the re-circulation line. A minimum of 1" thick pipe

insulation is recommended. Under no circumst

booster be installed without a circulating pump.

6

Page 7

WARNING

!

Tank MUST be full of water before power is turned

on. Heat exchanger coil WILL BE DAMAGED if energized even for a short time while the tank is dry. The

water heater’s warranty does not cover damage or

failure resulting from operation with an empty or partially empty tank. (Reference is made to the limited

warranty for complete terms and conditions)

ELECTRICAL CONNECTION

The electrical connection for the AdvantagePlus is on the

left side of the combustion shroud. There is a 1/2" knockout location for electrical connection. All electrical wiring

must be performed by a qualified licensed electrician,

and in accordance with National Electrical Code, or to the

applicable local codes and standards. The electrical

requirements are for standard 120 volts, 60 Hz., 10 amp

service. It is recommended that an electrical disconnect

switch be placed near the water heater, and that the connection to the AdvantagePlus be made using 3/8" extraflex, or 3/8" greenfield (or equivalent). This unit must be

wired with #14 AWG, and fused for no more than 15

amps.

properly grounded! Ground the water heater by con-

necting the green wire in the electrical access compartment directly to the main building ground system. It is

very important that the building system ground is

inspected by a qualified electrician prior to making

this connection. Once all connections have been

made, the electrical access may be closed. It is very

important that the electrical power is not turned on until

gas and venting connections are completed and the tank

is full of water.

A green LED is provided on the main control board.

This LED must be illuminated when appliance is

turned on for proper operation. Failure to illuminate

means bad or missing ground or reverse polarity.

GAS CONNECTION

Gas supply shall not exceed a maximum inlet pressure of

14" water column (350 mm), 1/2 pound pressure (3.4

kPa), and a minimum of 7" water column (natural and

propane). The entire piping system, gas meter, and regulator must be sized properly to prevent a pressure drop

greater than 0.5" of water column as stated in the

National Fuel Gas Code. Gas pressure information is

listed on the rating plate. It is very important that you

are connected only to the type of gas noted on the

rating plate; "LP" or propane gas or "Nat" natural

gas or city gas. All gas connections must be approved

by the local gas supplier or utility in addition to the governing authority prior to turning the gas supply on. The

nipple provided for the inlet gas connection is 1/2", and it

is mandatory that a 3/4" to 1/2" reducing bushing (provided) is used, threaded into the branch of a 3/4" tee, and

a drip leg fabricated, as per the National Fuel Gas Code.

It is of extreme importance that this unit be

You must ensure that the entire gas line to the reducing bushing connection at the Advantage Plus is no

smaller than 3/4".

CAUTION

!

THE USE OF FLEXIBLE GAS CONNECTORS IS NOT RECOMMENDED. HOWEVER, IF USED, IT IS IMPERATIVE THAT THEY ARE

SIZED CORRECTLY. FLEXIBLE GAS CONNECTORS MUST HAVE A

MINIMUM ID OF 3/4". A MINIMUM 3/4" ID MUST BE MAINTAINED

TO AVOID RESTRICTION OF GAS FLOW! NEVER REDUCE THE

GAS SUPPLY LINE BELOW 3/4"!

Once all the inspections have been performed, the piping

system must be leak tested. If the leak test pressure is

higher than the maximum permissible inlet pressure, you

must isolate the AdvantagePlus from the gas line before

testing. In order to do this, you must disconnect the

union and cap the inlet gas line. In the event the gas

valve is exposed to a pressure greater than 1/2 PSI, 14"

water column, the gas valve must be replaced.

Failure to follow all precautions could result in fire,

explosion or death! It is recommended that a soapy

solution be used to detect leaks. Bubbles will appear and

indicate a leak is present. The gas piping must be sized

for the proper flow and length of pipe to avoid unacceptable pressure drop. Both the gas meter and the gas regulator must be properly sized for the total gas load. If you

experience a pressure drop greater than 1" W.C., the

meter or regulator or gas line may be undersized or in

need of service. On the inlet side of the gas valve, there

is a 1/8" NPT plug. This plug can be removed to attach a

manometer. You can attach a meter to the incoming gas

drip leg by removing the cap and installing the meter. The

gas pressure must remain between 7" and 14" of water

column during stand-by and unit running heat cycle. If an

in-line regulator is used, it must be a minimum of 10 feet

from the AdvantagePlus. It is very important that the

gas line is properly purged by the gas supplier or

utility. Failure to properly purge the lines or improper line sizing, will result in the failure of the

AdvantagePlus lighting off. The gas valve is a special

gas valve which has a Pressure Augmented Regulator

feature, as well as negative outlet pressure. This valve

must not be replaced with a conventional valve under any

circumstances. Make sure valve is in the “OFF” position

prior to turning gas supply on. As an additional safety

feature, this valve has a left hand thread on the outlet

end, and a special tamper resistant electrical connector.

WARNING

!

Never use open flame to test for gas leaks, as

bodily injury or property damage could result.

WARNING

!

DO NOT exceed input shown on water heater rating

plate.

7

Page 8

VENTING WHEN USING 3" VENT PIPE

(ONLY MODELS WITH INPUTS OF 100,000 BTU AND 130,000 BTU

ARE CERTIFIED TO USE 2" VENT PIPE, SEE SPECIAL VENTING

INSTRUCTIONS SECTION)

For inlet air supply, top pipe on the right of the shroud,

use 3" PVC schedule 40. It is very important that you plan

the location properly to eliminate long pipe runs and

excessive fittings. Inlet pipe size must not be reduced.

Do not combine the inlet air with any other inlet pipe

including an inlet to an additional similar appliance.

The joints must be properly cleaned, primed, and

cemented. The piping must also be properly supported

as per local and national standard plumbing codes. It is

important that the piping be clean and free from burs,

debris, ragged ends, and particles of PVC.

For exhaust piping, lower pipe on the right of the shroud,

use only ABS schedule 40 or CPVC schedule 40 or 80,

NON FOAM CORE

, in the first 84" (7 feet) of vent length.

The balance of the inlet and exhaust piping may be PVC

schedule 40, ABS schedule 40 or CPVC schedule 40 or

80, NON FOAM CORE ONL

Y, as required to meet local

venting codes.

Exhaust piping should be sloped back to the connection

on the AdvantagePlus, at least 1/4 inch per foot of pipe,

to remove the condensate that forms within the pipe. The

total combined length of pipe, (inlet air piping plus

exhaust piping) including allowances for elbows, should

not exceed 85 equivalent feet. The total combined length

of pipe, including allowances for elbows, should not be

less than 22 equivalent feet (minimum length of 12 feet of

piping, including allowances for elbows, on the inlet and

the exhaust). Choose your vent termination locations

carefully. You must make certain that exhaust gas does

not re-circulate back into the air inlet pipe. You must

place your vent terminations in an open area, according

to the following guidelines.

V

enting Guidelines

1) Never vent into a walkway or patio area, or an alley,

or otherwise public area less than 7' from the ground.

2) Allow four (4) feet below or four (4) feet horizontally

from any door, window or gravity air inlet to the building

or other appliance.

3) Never install a heat saver or similar product to capture waste heat from exhaust.

4) Always have vent location at least 1' above maximum

snow level.

5) Always have vent 1' above ground level, away from

shrubs and bushes.

6) Follow local gas codes in your region or refer to

National Fuel Gas Code, or Can B149.

7) Always have vent at least 3' from an inside corner of

outside walls.

8) Maintain at least 4' clearance to electric meters, gas

meters and exhaust fans or inlets.

9) Inlet air must be taken from outside of building next

to exhaust outlet, no closer than 8".

10) Always place 1/2 inch x 1/2 inch 16 gauge galvanized steel screen in the intake and exhaust openings to

prevent foreign matter from entering the AdvantagePlus.

11) The vent system must be balanced by friction loss

equivalent (See table on page 10).

12) The same method must be used for both intake and

exhaust termination. DO

NOT terminate one horizontal-

ly and the other vertically.

13) Roof Venting: The vent intake and exhaust must be

properly cleaned and glued, for pressure tight joints.

Several methods for venting the AdvantagePlus can be

found on pages 22 and 23. Use the layout as a guideline. Certain site conditions such as multiple roof

lines/pitches may require venting modifications-consult

factory. The air inlet must be a minimum of 1' vertically

above the maximum snow level or 24" whichever is

greater. The air inlet must also be a minimum of 10' horizontally from the roof and terminated with a tee. The

exhaust must be a minimum of 24" above the air inlet

opening and terminated with a coupling. It is very important that there are no other vents, chimneys, or air inlets

in any direction for at least 4'. All venting must be

properly supported, as the AdvantagePlus is not

intended to support any venting whatsoever. All pip-

ing, glue, solvents, cleaners, fittings, and components

must conform to ASTM (American Society for Testing and

Materials), and ANSI (American National Standard

Institute).

14) It is recommended that you use vent kits specifically

designed for AdvantagePlus installations.

PIPE / FITTINGS WHEN USING 3” VENT PIPE

The first 84" (7’) of exhaust piping, must be of 3" ABS

solid only (provided) or CPVC; (NEVER use cellular

foam core pipe on exhaust piping), and conform to

ASTM D-3965 for ABS or ASTM F-441 for CPVC, and fittings to ASTM D2661 & D3311 for ABS and ASTM F-439

for CPVC. The balance of exhaust piping, and all of

intake piping, use standard 3" PVC schedule 40 or 3"

ABS schedule 40, conforming to ASTM D2665, or ABS

conforming to ASTM D-3965 & ASTM R-441 for ABS; and

fittings conforming to ASTM D-2665 & D331. ABS may

also be used for intake venting as long as pipe conforms

to ASTM D3965 & D2661 and fittings meet ASTM D2661

& D3311.

FOR LONGER VENT LENGTHS WHEN USING 3”

VENT PIPE

All venting must be 3", both intake and exhaust. NEVER

use any piping less than 3", or different size pipe on

the intake and exhaust. You may use 4" venting on

both intake and exhaust to lower the pressure drop and

provide additional venting length. It is imperative when

using 4" venting to follow these instructions very

carefully. For longer venting lengths, the first 10' of

both the intake and exhaust piping are 3". For the

intake, use 10' of 3" PVC plus one 90 degree or two

45 degree elbows. For the exhaust, use 10' of ABS

solid NON FOAM CORE, or CPVC plus one 90 degree

8

Page 9

or two 45 degree elbows. Then use a 4" x 3" PVC or 4"

x 3" ABS reducing coupling. Then proceed with PVC 4"

NON FOAM CORE pipe and fittings for both the intake

and exhaust piping. On 4" piping you may go an additional 125 equivalent feet of pipe and fittings, combined

total length. The 4" fittings have a friction loss allowance

as follows:

4" 90 degree = 3' and a 4" 45 degree = 1'.

The total maximum venting length can be 125', plus the

first 10' of each 3", and a maximum fitting allowance of

the 3", total two 90 degree or four 45 degree before

increasing to 4". Total equivalent would be 30' of 3" plus

125' of 4". Never

use different pipe sizes for intake and

exhaust.

SPECIAL VENTING INSTRUCTIONS USING 2" VENT

PIPE

(ONLY MODELS WITH INPUTS OF 100,000 BTU AND 130,000 BTU

ARE CERTIFIED FOR 2" VENTING) HE45-100, HE45-130, HE80-130,

HE119-130

For inlet air supply, top pipe on the right of the shroud,

use 2 inch PVC schedule 40. It is very important that you

plan the location properly, to eliminate long pipe

runs and excessive fittings. Inlet pipe size must not be

reduced. Do not combine the inlet air with any other inlet

pipe, including an inlet to an additional similar appliance.

The joints must be properly cleaned, primed and cemented. The piping must also be properly supported as per

local and national standard plumbing codes. It is important that the piping be clean and free from burs, debris,

ragged ends and particles of PVC.

For exhaust piping, lower pipe on the right of the shroud,

use 2 inch PVC schedule 40 NON FOAM CORE. Use 2

inch ABS NON FOAM CORE or 2 inch CPVC schedule

40 or 80 only when required to meet local venting codes.

Exhaust piping should be sloped back to the connection

on the AdvantagePlus, at least 1/4 inch per foot of pipe,

to remove the condensate that forms within the pipe. The

total combined length of pipe, (inlet air piping plus

exhaust piping) including allowances for elbows, should

not exceed 85 equivalent feet. The total combined length

of pipe, including allowances for elbows, should not be

less than 22 equivalent feet (minimum length of 12 feet of

piping, including allowances for elbows, on the inlet and

the exhaust). Choose your vent termination locations

carefully. You must make certain that exhaust gas does

not re-circulate back into the air inlet pipe. You must

place your vent terminations in an open area, according

to the venting guidelines section on page 8.

PIPE / FITTINGS WHEN USING 2" VENT PIPE

All inlet air and exhaust venting may use standard PVC

schedule 40 piping, conforming to ASTM D-1785, and fittings conforming to ASTM D-2466, or ABS pipe conforming to ASTM D-3965 and ASTM D-2661, and fittings conforming to ASTM D-3311 and ASTM D-2661. (NEVER

use cellular foam core pipe on exhaust piping)

FOR LONGER VENT LENGTHS WHEN USING

2" VENT PIPE

You may use 3 inch venting on both the intake and

exhaust to lower the pressure drop and provide additional vent length. It is imperative when using 3 inch venting

to follow these instructions carefully. For longer vent

lengths, the first 10 feet of both the intake and exhaust

piping must be 2 inches. For the first 10 foot use 2 inch

PVC schedule 40 NON FOAM CORE, 2 inch ABS NON

FOAM CORE or 2 inch CPVC schedule 40 or 80 plus one

90 degree or two 45 degree elbows. Then use a 2" x 3"

reducing coupling of like material. Then proceed with 3

inch PVC schedule 40 NON FOAM CORE, 3 inch ABS

NON FOAM CORE or 3 inch CPVC schedule 40 or 80

pipe and fittings for both the intake and exhaust piping.

On 3 inch pipe you may go an additional 125 equivalent

feet of pipe and fittings, combined total length. The total

combined equivalent vent length would be 30 equivalent

feet of 2-inch vent and 125 equivalent feet of 3-inch vent,

for a maximum equivalent vent length of 155 feet. Never

use different pipe sizes for intake and exhaust.

CLEANER / CEMENT

Cement for all venting must be ALL PURPOSE Cement,

and must conform to ASTM D-2235, D-2564 and F-493,

and cleaner for the piping and fittings must conform to

ASTM F-656.

NOTE

:

THE METHODS DESCRIBED ARE SUGGESTED

GENERIC METHODS ONLY. SPECIFIC JOB SITE

OBSERVATIONS AND SIZING MAY REQUIRE ALTERNATE INSTALLATION METHODS. CONSULT THE

FACTORY WITH SPECIFIC JOB REQUIREMENTS

FOR ADDITIONAL RECOMMENDATIONS.

VERY IMPORTANT SET-UP INSTRUCTIONS!

IF YOU HAVE A COMBUSTION ANALYZER, THE FOLLOWING RATINGS WILL BE VERY HELPFUL IN SETTING UP YOUR ADVANTAGE PLUS:

FOR NATURAL GAS -

CO2reading should be between (9 1/2% – 10%)

O2reading should be between (3 1/2% – 4 1/2%)

CO reading should be under 10 PPM

FOR PROPANE GAS -

CO2reading should be between (10 1/2% – 11 1/2%)

O2reading should be between (3 1/2% – 4 1/2%)

CO reading should be under 10 PPM

9

Page 10

FRICTION LOSS EQUIVALENCE TABLES

R

3" VENTED MODELS 2" VENTED MODELS

FITTING

DESCRIPTION

3" 90˚ 4" 90˚

3" 45˚

3" Coupling

3" Tee

3" Pipe

3" Concentric vent kit

3" V1000 vent kit

EQUIVALENT

FEET OF PIPE

5'

3'

0'

0'

1' = 1'

3'

0'

FITTING

DESCRIPTION

2" 90˚

2" 45˚

2" Coupling

2" Tee

2" Pipe

2" Concentric vent kit

EQUIVALENT

FEET OF PIPE

5'

3'

0'

0'

1' = 1'

3'

AFTER THE FIRST 10' OF 3" ONLY

4" EQUIVALENT TABLE

FITTING

DESCRIPTION

4" 45˚

4" Coupling

4" Tee

4" Pipe

VENTING EXAMPLES (NOTE: SHOWN AS INTAKE & EXHAUST PIPE FITTINGS ADDED TOGETHE

* = MINIMUM VENT LENGTH ** = MAXIMUN VENT LENGTH

GRAND TOTAL

TOTAL COMBINED

VENT LENGTH

(FEET) INTAKE &

EXHAUST

*12

20

20

20

20

20

20

20

20

20

20

20

20**

30

30

30

30

30

30

30

30

30**

40

40

40

40

40

40

40**

50

50

50

50

50**

60

60

60**

70**

QTY. OF 90˚

ELBOWS

2

2

3

4

5

6

7

8

9

10

11

12

13

3

4

5

6

7

8

9

10

11

3

4

5

6

7

8

9

3

4

5

6

7

3

4

5

3

EQUIVALENT

FRICTION LOSS

(FEET) FOR EACH

ELBOW

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

TOTAL FRICTION

LOSS FOR

ELBOWS

10

10

15

20

25

30

35

40

45

50

55

60

65

15

20

25

30

35

40

45

50

55

15

20

25

30

35

40

45

15

20

25

30

35

15

20

25

15

VENT LENGTH

(FEET) WITH

FITTING FRICTION

LOSS ADDED

22

30

35

40

45

50

55

60

65

70

75

80

85**

45

50

55

60

65

70

75

80

85**

55

60

65

70

75

80

85**

65

70

75

80

85**

75

80

85

85

EQUIVALENT

FEET OF PIPE

3'

1'

0'

0'

1' = 1'

10

Page 11

OPERATION

CONTROL DESCRIPTION

The fully integrated water heater control is an all electronic, fully automatic controller which will provide many

years of trouble free service. The control requires no

periodic maintenance and includes a built-in microprocessor which performs a number of diagnostic tests to

verify proper appliance and control operation. Should an

unsafe condition occur, the burner will shut down and the

appropriate status indicators will illuminate indicating the

need for service. Consisting of two printed circuit board

assemblies, the controller's main board is attached to the

inside left of the shroud while the display board is mounted to the front top of the shroud. This arrangement simplifies access for the user adjustments while enhancing

the visibility of the temperature display and status indicators. A power step-down transformer and blower pressure switch are also mounted on the inside left of the

shroud. The controller display functions include a high

visibility three digit LED readout which is used to display

the actual water temperature within the tank along with

the programmed desired water temperature (set point

temperature). Nine individual LED indicators are also

mounted on the display board which are used to determine the operating status of the appliance and provide

assistance when troubleshooting any problems which

may occur. All indicators are of the solid state variety and

should last for the life of the appliance. The controller

has sufficient built-in memory to retain the programmed

temperature set point in the event power is ever interrupted. The final component of the control system

includes a temperature sensing probe which is threaded

into the side of the tank. This probe is of unique construction in that both the temperature sensing/control and

safety limit functions are performed by this single device.

All probe components are of solid state construction to

provide extended operational life.

START UP PROCEDURE

(NEVER APPLY POWER TO AN ADVANTAGEPLUS

UNIT THAT IS NOT COMPLETELY FILLED WITH

WATER)

1. Make sure that the AdvantagePlus has been installed

to these instruction procedures along with all applicable

state and local codes.

2. Make sure all gas piping and connections have been

verified and inspected by all applicable inspectors. Turn

on gas supply. Ensure that the gas line and the LP tank,

if applicable, has been properly purged. Failure to properly purge the gas lines will result in failure to

operate.

3. Make sure that the cold water supply has been turned

on and the AdvantagePlus is completely filled with water.

Verify by opening a hot water faucet, or purging at the

dishwasher, and allowing water to flow until all air is

removed and a clear water flow is present.

.

VALVE.

0

F and

0

F and

NEVER PURGE FROM THE T&P

4. Turn on electrical supply.

5. The control will first display "102", then "88.8", which is

the control test, and finally the actual tank temperature at

the probe.

TEMPERATURE SET POINT ADJUSTMENT

PROCEDURE

WARNING

!

When this water heater is supplying general purpose

hot water requirements for individuals, a thermostatically controlled mixing valve for reducing point of

use water temperature is recommended. Contact a

licensed plumber or the local plumbing authority for

further instructions.

The three digit LED display will illustrate actual water

temperature within the tank under normal operating conditions. However, this display is also used to indicate the

temperature set point when in the programming mode.

The controller has a temperature set point range of 70°F

to 160°F (Booster models have a maximum set point of

180°F), with a factory setting of 120°F.

NOTE: Power must be applied to the controller prior

to any programming operations.

To change or access the programmed temperature set

point value, utilize the red button on the display panel.

Momentarily depressing the button will briefly illustrate

the existing set point value. If the button is held down for

more than one second, the programming mode is

entered and the set point value will begin incrementing by

one degree per second. When the desired set point

value is reached, simply release the button and the controller will automatically retain this value in temporary

memory. After 30 seconds, this new set point will be

retained in permanent memory

NOTE: If power is interrupted during this 30 second

period, the new set point will not be retained in permanent memory. It is a good practice to re-check the

set point value approximately 60 seconds after a new

value has been entered.

If the button is held down, the maximum set point will

reach 160°F (180°F on Booster models) and stop. This is

the maximum value. At this point, if the desired set point

has not been obtained, release the button and depress it

again, the set point will decrement down to 70

stop. The set point value will now restart at 70

once again increase in value for as long as the button is

pressed.

11

Page 12

DANGER

CAUTION

!

!

There is a hot water SCALD POTENTIAL if the

thermostat is set too high.

THERMOSTAT DIFFERENTIAL ADJUSTMENT

PROCEDURE

8. If flame is present, the control will enter the heating

mode where it will continue heating the tank water until

the set point temperature plus 4°F is reached. At this

point, the gas valve is closed and the control enters the

post-purge cycle. The flame can be viewed through a

window on the lower right of combustion blower flange.

To allow proper water heater operation, the control has

an 8°F "window" around the set point. This means that

the burner will be turned on when the water temperature

drops to 4°F below the set point, and it will be turned off

when the water temperature reaches 4°F above the set

point. Thus, if the set point is set to 120°F., the control

will turn on the burner when the water temperature drops

to 116°F., and will continue to heat the water until the

temperature reaches 124°F. The differential is factory set

to 8°F (+ or- 4°F.) If another differential is required, the

value of the differential can be field adjusted by holding

the set point button when power is applied to the control.

Shut off power to the control. Next hold in the set point

button. Now reapply power to the control. Using the set

point button, the value of the differential can be incremented or decremented as above. When the proper

value is reached, release the button and wait for the display to show "00". This indicates the new differential has

been stored into permanent memory. Remove power

and restart control by applying power for normal operation.

OVERALL APPLIANCE AND CONTROL OPERATION

9. The post purge cycle continues to run the combustion

blower for an additional 30 seconds to purge the system

of all combustion gases. After this time period, the blower is de-energized and will coast to a stop.

10. The control will now enter the idle state while continuing to monitor internal tank water temperature. If the

temperature drops to 4°F below the set point value, the

control will automatically return to step 1.

STATUS INDICATORS

Pages 16-20 contain nine individual diagrams which illustrate the various operating states of the appliance and

their relation to the LED status indicators found on the

controller. These diagrams reflect normal water heater

operation.

MAINTENANCE

In unusually dirty or dusty conditions, care must

be taken to keep appliance door in place. Failure

to do so VOIDS WARRANTY!

A normal operating sequence is as follows:

1. The control determines that the actual water temperature inside the tank is 4 degrees F below the programmed temperature set point.

2. The control performs selected system diagnostic

checks.

3. If all checks are successfully passed, the combustion

blower is energized for the 40 second pre-purge cycle.

4. After the pre-purge cycle is complete, power is applied

to the ignitor element for the ignitor warm-up period

(blower should continue to run).

5. The ignitor warm-up period will last for 30 seconds,

then gas valve will be opened, allowing gas to enter the

burner chamber.

6. The ignitor will remain on for an additional 4 seconds,

then it will be turned off.

7. After an additional 2 seconds, the control will verify the

presence of flame. If the flame was not established, the

gas valve will be closed, power will be removed from the

ignitor element, and the control will run the blower for 30

seconds. This removes excess fuel from the combustion

chamber. At this point, the control will return to step 2.

The control system requires no periodic maintenance

under normal conditions. However, in unusually dirty or

dusty conditions, periodic vacuuming of the cover to

maintain visibility of the display and indicators is recommended.

INTERNAL WIRING

For specific wiring information, please refer to the diagrams on pages 21 and 22.

SHUTDOWN PROCEDURE

If the burner is operating, lower the set point value to

70°F and wait for the burner to shut off. Continue to wait

for the combustion blower to stop so all latent

combustion gases are purged from the system.

This should take a maximum of 40 to 90 seconds.

Disconnect the electrical supply. If the burner is not operating, disconnect the electrical supply.

VACATION PROCEDURE

If there is danger of freezing, change the set point to

70°F. DO NOT

danger of freezing, follow the "Shutdown Procedure".

12

turn off electrical power. If there is no

Page 13

FAILURE TO OPERATE

CORROSIVE ATMOSPHERES

Should the burner fail to light, the control will perform two

more ignition trials prior to entering a lockout state (flashing “LOC”). Note that each subsequent ignition trial will

not occur immediately. After a failed ignition trial, the

blower must run for approximately 10 seconds to purge

the system, then the ignitor element must complete a 30

second warm-up period. Therefore, a time period of

approximately 40 to 90 seconds will expire between each

ignition trial. If the burner lights during any one of these

three ignition trials, normal operation will resume. If the

burner lights, but goes off in about 4 seconds, check the

polarity of the wiring. See electrical on page 6. If the

burner does not light after the third ignition trial, the

control will enter a lockout state. This lockout state

indicates that a problem exists with either the appliance, the controls, or the gas supply. Under such cir-

cumstances, a qualified service technician should be

contacted immediately to properly service the appliance

and correct the problem. If a technician is not available,

depressing the red button once will remove the lockout

state so additional trials for ignition can be performed.

Any time flashing double zero’s are shown, you must

look for an LED out, or flashing. The LED that is out

or flashing will assist you in diagnosing lock out condition.

FUEL CONVERSIONS

This product may be converted from L.P. gas (propane)

to Natural gas or from Natural gas to L.P. gas (propane).

For information and requirements about this procedure

call the Technical Service Department at 1-800-432-

8373.

WARNING

!

Should overheating occur or the gas supply fail to shut

off, turn off the manual gas control valve to the appliance.

The heater should not be installed near an air supply containing halogenated hydrocarbons. For example, the air

in beauty salons, dry cleaning establishments, photo processing labs, and storage areas for liquid and powdered

bleaches or swimming pool chemicals often contain

hydrocarbons. The air there may be safe to breathe, but

when it passes through a gas flame, corrosive elements

are released that will shorten the life of any gas burning

appliance. Propellants from common spray cans or gas

leaks from refrigeration equipment are highly corrosive

after passing through a flame. The limited warranty is

voided when failure of water heater is due to a corrosive

atmosphere. (Reference is made to the limited warranty

for complete terms and conditions.)

CONDENSATE

This is a condensing high efficiency appliance, therefore

this unit has a condensate removal system. Condensate

is nothing more than water vapor, derived from the combustion products, similar to an automobile when it is initially started. This condensate does have a low pH and

should be treated with a condensate filter. This filter contains either lime crystals or marble crystals, which will

neutralize the condensate. The outlet of the filter is sized

for 5/8" ID (inside diameter) plastic tubing. It is very

important that the condensate line is sloped away from

and down to a suitable inside drain. If the condensate

outlet on the AdvantagePlus is lower than the drain, you

must use a condensate removal pump. It is also very

important that the condensate line is not exposed to

freezing temperatures, or any other type of blockage.

Plastic tubing should be the only material used for the

condensate line. Steel, brass, copper, or other metals will

be subject to corrosion and deterioration. A second vent

may be necessary to prevent condensate line vacuum

lock if a long horizontal run is used. Also an increase to

1" tubing may be necessary.

WARNING

!

DO NOT use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace the water heater if

the control system or any gas control which has been

under water.

INSTALLATION OF A CONDENSATE NEUTRALIZER AND PUMP (Not Supplied)

CONDENSATE LINE CONDENSATE LINE WITH PUMP

FROM ADVANTAGE PLUS

TO DRAIN

CONDENSATE LINE MUST BE PITCHED AT LEAST 1/4" PER FOOT TO PROPERLY DRAIN.

IF THIS CANNOT BE DONE OR A VERY LONG LENGTH OF CONDENSATE HOSE IS USED

YOU MUST INCREASE THE CONDENSATE HOSE TO A MINIMUM OF 1" I.D. AND PLACE A

TEE IN THE LINE AFTER THE CONDENSATE NEUTRALIZER TO PROPERLY REDUCE

VACUUM LOCK IN THE DRAIN LINE.

NOTE: Always check local codes for proper

evacuation of condensate.

FROM ADVANTAGE PLUS

TO DRAIN

CONTACT YOUR LOCAL WHOLESALE PLUMBING SUPPLY

STORE FOR MORE INFORMATION ON CONDENSATE

NEUTRALIZERS AND PUMPS

13

Page 14

Components of the AdvantagePlus

1. 1/2” NPT x 6” Gas Inlet Nipple

2. Gas Valve

3. Gas Valve Elbow

4. Gas Orifice Union

5. Gas Orifice

6. Union Connector Nipple

7. Main Control PC Board

8. Display PC Board

9. Pressure Switch

10. Transformer

11. ECO / Temperature Probe

12. Carborundum Ignitor

13. Flame Rectification Probe

14. Over Temperature Switch

15. Combustion Blower

16. Glass Sight Window

17. Air Inlet Adapter

18. Air Inlet Connector

19. Air Inlet Manifold

20. Exhaust Outlet Connector

21. Exhaust Elbow and Drain

22. Condensate Connector Hose

23. 1/2” barb x 1/2” M Adapter

24. 15/16” Hose Clamp

25. 90 degree Street Elbow

26. Combination 90 degree Elbow

27. Conduit 1/32” locknut

28. Combination 90 degree Elbow

REPLACEMENT PARTS NOT SHOWN

Low Voltage Cable Assembly

Interconnect Ribbon Cable

Line Cable

Blower Cable

Gasket Burner Mounting Flange

Gasket Blower Outlet Flange

Gasket Air Inlet

Gasket Burner Mounting Flange White

14

Page 15

GAS VALVE ADJUSTMENT

ON

OFF

W

R

Let the unit start to cycle and listen carefully to the ignition. If the ignition was quiet, the valve will need no

adjustment. If it was a loud ignition, the unit rumbles, or

there was no ignition at all, follow these steps:

SEESIDE WARNING

LABEL

M

PRESS

MAX

1/2

PSI

P

C

WR

1

3

2

IF THERE WAS NO IGNITION:

1. Make sure the gas valve is in the "on" position, gas is

on to the unit, and the gas valve wiring harness is

plugged into the gas valve and into the control board.

2. Turn the adjustment screw under the brass cap. Turn

one full turn clockwise with a small flathead screwdriver.

Turning the adjustment screw clockwise increases the

amount of gas.

3. If the unit still does not ignite, turn the adjustment

screw two full turns counterclockwise.

IF IGNITION WAS POOR:

1. Look at the color of the flame through the sight glass

while the unit is running. If it is green or red in color, or

the heater whistles on ignition, turn the adjustment screw

counterclockwise at 1/8” turn intervals until the flame

turns blue/light blue in color or the whistling at ignition

stops. If the flame is very weak or pulsing, turn the

adjustment screw clockwise until the flame steadies.

2. Put the gas valve adjustment screw cover back in

place and tighten.

Gas Valve

Adjustment

Screw

CAUTION

!

PILOT ADJ

THERE ARE NO USER SERVICEABLE PARTS WITHIN THE CONTROL SYSTEM. TO MAINTAIN SAFETY

AND PROPER APPLIANCE PERFORMANCE, REFER

ALL TROUBLESHOOTING TO QUALIFIED SERVICE

PERSONNEL.

TROUBLESHOOTING

The appliance controller has many inherent diagnostic

and fault detection routines built into its operating software and hardware. These routines, along with the three

digit LED display and nine LED status indicators present

on the display panel, can greatly assist the service person in quickly pinpointing the source of problems that

may occur with the appliance. In certain circumstances,

multiple LED's may be lit or flashing to better pinpoint the

problem. The following charts, diagrams, and information can be used during troubleshooting procedures. See

also Trouble Shooting Guides and Sequence of

Operations at the end of this Use and Care Manual.

3. Put the AdvantagePlus cabinet door back into place.

NOTES

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

15

Page 16

LINE

K1

COMB

BLOWER

K5

IGNITER

ELEMENT

STATUS INDICATIONS UNDER NORMAL CONDITIONS

K4K3

SWITCH

ELECTRONICS

PRESSURE

SWITCH

CONTROL

GAS

VALVE

RLY 1

GAS

VALVE

GAS

VALVE

RLY 2

K1

K5

K3

K4

24

VAC

ECO/VENT

LINE

K1

COMB

BLOWER

K5

IGNITER

ELEMENT

CONTROL

HEALTH

1. Idle Status

ECO/VENT

24

SWITCH

VAC

ELECTRONICS

CONTROL

HEALTH

2. Call for Heat

WATER

TEMPERATURE

PRESSURE

SWITCH

CONTROL

WATER

TEMPERATURE

GAS

VALVE

RLY 1

GAS

VALVE

K4K3

GAS

VALVE

RLY 2

K1

K5

K3

K4

K4K3

LINE

K1

COMB

BLOWER

K5

IGNITER

ELEMENT

24

VAC

ECO/VENT

SWITCH

ELECTRONICS

CONTROL

HEALTH

PRESSURE

SWITCH

CONTROL

WATER

TEMPERATURE

GAS

VALVE

RLY 1

GAS

VALVE

GAS

VALVE

RLY 2

KEY:

Lamp ON

K1

K5

K3

K4

Lamp OFF

Lamp Flashing

3. Combustion Blower Powered

NOTICE:

If an error message is still indicated after removal of the replaceable 3 amp fuse on the CONTROL,

there is a problem with the transformer. The TRANSFORMER has an internal non-replaceable fuse.

The transformer must be replaced. Please contact your local distributor or service professional.

16

Page 17

LINE

K1

COMB

BLOWER

K5

IGNITER

ELEMENT

24

VAC

ECO/VENT

SWITCH

ELECTRONICS

PRESSURE

SWITCH

CONTROL

GAS

VALVE

RLY 1

GAS

VALVE

K4K3

GAS

VALVE

RLY 2

K4K3

PRESSURE

ECO/VENT

LINE

24

VAC

SWITCH

SWITCH

K1

COMB

K1

K5

K3

K4

BLOWER

K5

IGNITER

ELEMENT

CONTROL

ELECTRONICS

GAS

VALVE

RLY 1

GAS

VALVE

GAS

VALVE

RLY 2

K1

K5

K3

K4

CONTROL

HEALTH

TEMPERATURE

4. Pressure Switch Closes,

Pre-purge Cycle Starts

LINE

24

VAC

SWITCH

SWITCH

PRESSURE

ECO/VENT

K1

COMB

BLOWER

K5

IGNITER

ELEMENT

ELECTRONICS

CONTROL

HEALTH

CONTROL

TEMPERATURE

6. Burner Light-off

WATER

WATER

GAS

VALVE

RLY 1

GAS

VALVE

K4K3

GAS

VALVE

RLY 2

CONTROL

HEALTH

WATER

TEMPERATURE

5. Igniter Element Warmup

K4K3

PRESSURE

ECO/VENT

LINE

24

VAC

SWITCH

SWITCH

VALVE

K1

COMB

K1

K5

K3

K4

BLOWER

K5

IGNITER

ELEMENT

ELECTRONICS

CONTROL

HEALTH

CONTROL

WATER

TEMPERATURE

GAS

RLY 1

GAS

VALVE

GAS

VALVE

RLY 2

K1

K5

K3

K4

7. Water Heating

ECO/VENT

LINE

24

SWITCH

VAC

K1

COMB

BLOWER

K5

IGNITER

ELEMENT

CONTROL

HEALTH

8. End Call for Heat

Start Post-purge Cycle

STATUS INDICATIONS UNDER NORMAL OPERATING CONDITIONS

PRESSURE

SWITCH

CONTROL

ELECTRONICS

WATER

TEMPERATURE

GAS

VALVE

RLY 1

GAS

VALVE

K4K3

GAS

VALVE

RLY 2

K4K3

PRESSURE

ECO/VENT

LINE

24

VAC

SWITCH

SWITCH

VALVE

K1

COMB

K1

K5

K3

K4

BLOWER

K5

IGNITER

ELEMENT

ELECTRONICS

CONTROL

HEALTH

CONTROL

WATER

TEMPERATURE

GAS

RLY 1

GAS

VALVE

GAS

VALVE

RLY 2

K1

K5

K3

K4

9. End of Sequence, Idle State

17

Page 18

LINE

K1

COMB

BLOWER

K5

IGNITER

ELEMENT

LINE

K1

COMB

BLOWER

K5

IGNITER

ELEMENT

VAC

VAC

24

24

ECO/VENT

SWITCH

ELECTRONICS

CONTROL

HEALTH

ECO/VENT

SWITCH

ELECTRONICS

CONTROL

HEALTH

PRESSURE

SWITCH

CONTROL

WATER

TEMPERATURE

PRESSURE

SWITCH

CONTROL

WATER

TEMPERATURE

GAS

VALVE

RLY 1

GAS

VALVE

RLY 1

GAS

VALVE

GAS

VALVE

K4K3

GAS

VALVE

RLY 2

K4K3

GAS

VALVE

RLY 2

NO INCOMING LINE VOLTAGE OR 24 VOLT

Line LED & 24 VAC LED Off

POSSIBLE CAUSE

1. No Input power.

2. Wiring disconnected

3. One or more wiring recep-

K1

K5

K3

K4

tacles disconnected from

control.

4. LED burned out.

5. Defective transformer.

6. Transformer wiring problem.

1. Apply Power

2. Check all wiring

3. Reconnect plugs on control.

Confirm all are fully seated.

4. Replace display board.

5. Replace transformer.

6. Repair transformer wiring.

REMEDY

NOTE:

The transformer is of Class II variety and has an internal nonreplaceable fuse. If blown, a problem may exist with the control

which is affecting the transformer. In such cases, it is recommended the control should be replaced as well.

IGNITOR LOCKOUT

Ignitor Element LED Flashing

POSSIBLE CAUSE

1. Broken ignitor element.

2. Ignitor unplugged.

3. Insufficient ignitor current

K1

K5

K3

K4

draw.

NOTE:

The ignitor current is monitored by pressing the blue button to

1. Replace ignitor element.

2. Plug in ignitor.

3. Monitor ignitor current draw.

See note below.

the left of the LEDs during the ignitor warm-up period or when

the ignitor element LED is illuminated. The 3-segment LED

display will show the actual ignitor current draw. The expected

ignitor current draw is from 2.5 to 4.5 amps.

REMEDY

18

Page 19

LINE

K1

COMB

BLOWER

K5

IGNITER

ELEMENT

VAC

24

ECO/VENT

SWITCH

ELECTRONICS

CONTROL

HEALTH

PRESSURE

SWITCH

CONTROL

WATER

TEMPERATURE

GAS

VALVE

RLY 1

GAS

VALVE

K4K3

GAS

VALVE

RLY 2

IGNITION LOCKOUT

Gas Valve LED Flashing

This condition results from a failure to establish burner ignition

after three successive trials. In such cases:

First - Investigate the possible cause and remedy any

observations.

Second - Momentarily press the red button on the display panel

to reset the lockout condition.

Third - Confirm the proper appliance operation.

POSSIBLE CAUSE

1. Burner ground wire broken

or corroded.

2. Connectors unplugged.

K1

K5

K3

K4

3. Flame probe faulty.

4. Gas shut off.

5. Clogged gas valve.

6. Faulty gas valve.

7. Defective control.

8. Burner improperly adjusted.

9. Dirty burner.

10. Improper line connection.

1. Check wire and connection

at burner.

2. Check connectors.

3. Replace flame probe.

4. Turn on gas supply

5. Replace gas valve.

6. Replace gas valve.

7. Replace control.

8. Adjust burner.

9. Clean burner.

10. Verify green LED on the-

control board is illuminated

when power is applied.

11. Insufficient flame current.

11. Montior flame current.

See note below.

NOTE:

The flame current (flame rectification) is monitored by pressing

the blue button to the left of the LEDs during the heat cycle or

when the gas valve LED is illuminated. The 3-segment LED

display will show the actual flame curent. The expected flame

current draw is 4.0 to 5.1 micro-amps.

REMEDY

LINE

K1

COMB

BLOWER

K5

IGNITER

ELEMENT

VAC

24

ECO/VENT

SWITCH

ELECTRONICS

CONTROL

HEALTH

PRESSURE

SWITCH

CONTROL

WATER

TEMPERATURE

GAS

VALVE

RLY 1

GAS

VALVE

K4K3

GAS

VALVE

RLY 2

ECO SWITCH OPEN

ECO LED Flashing

POSSIBLE CAUSE

1. Temperature probe is

unplugged.

2. Temperature probe wiring

damaged.

K1

K5

K3

K4

3. Water in tank is too hot.

ECO is tripped.

1. Check connectors.

2. Repair wiring.

3. Normal condition when

water temperature exceeds

safety limit. Alow tank to cool

or admit cold water into tank.

Manually reset the control.

Determine cause for overtemp

condition.

4. Low water cutoff device is

tripped.

4. Make sure tank is full of

water.

19

REMEDY

Page 20

LINE

K1

COMB

BLOWER

K5

IGNITER

ELEMENT

VAC

24

ECO/VENT

SWITCH

ELECTRONICS

PRESSURE

SWITCH

CONTROL

GAS

VALVE

RLY 1

GAS

VALVE

K4K3

GAS

VALVE

RLY 2

CONTROL HEALTH

Control Health LED Flashing

POSSIBLE CAUSE

This indicates that the main

control board has failed one or

more of its internal diagnostic

K1

K5

K3

K4

self-tests.

REMEDY

Press red reset button on the

display board to reset the control. If this error occurs repeatedly, replace the main control

board.

LINE

K1

COMB

BLOWER

K5

IGNITER

ELEMENT

VAC

24

CONTROL

HEALTH

ECO/VENT

SWITCH

ELECTRONICS

CONTROL

HEALTH

WATER

TEMPERATURE

PRESSURE

SWITCH

CONTROL

WATER

TEMPERATURE

GAS

VALVE

RLY 1

GAS

VALVE

K4K3

GAS

VALVE

RLY 2

COMBUSTION AIR BLOCKAGE

Pressure Switch LED Flashing

POSSIBLE CAUSE

1. Combustion air blockage.

2. Blower not operating:

K1

K5

K3

K4

3. Defective air switch

a. Blower wiring

b. Blower motor

4. One of the gas valve wiresmay be disconnected during ignition sequence.

5. Poly hose between the

blower and air pressure