Page 1

TANKLESS GAS

TR UBLESHOOTING

POCKET MANUAL

SVC 820P

For Mid & High Efficiency Platforms

Rheem.com

Page 2

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 1

This manual is specific to the following model numbers:

MID EFFICIENCY

64DV, 64X / 68DV / 68X

84DV, 84X / 95DV, 95X

150DV, 150X / 180DV, 180X / 200DV, 200X

2-20RDV, 2-20ROF / 2-25RDV, 2-25ROF

2-28RDV, 2-28ROF

-

HIGH EFFICIENCY

(Condensing)

H-84DV, H-84X / H-95DV, H-95X

H-160DV, H-160X / H-200DV, H-200X

H-25RDV, H-25ROF / H-32RDV, H-32ROF

DASH 2 REVISION

1

1

1

1

1

-

Page 3

2 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

2

TABLE OF CONTENTS

General Information

Installation Guidelines……………………………………………….. 8

Mid & High-Efficiency Flow Rates…………………………….. 12

Control Board Connectors………………………………………… 14

Diagnostic Points (Voltage & Resistance Readings)……16

Maintenance Mode Instructions………………………………. 21

Altitude Settings on Control Board…………………………… 25

Reset Procedures……………………………………………………..26

Clearing Fault History……………………………………………….27

Error Code Diagnostics

No Error Code & No Hot Water 28

P1 Warning Code 31

1L Warning Code 32

03 Error Code 34

05 Warning Code 35

10 Warning Code 37

11 Error Code 40

12 Error Code 46

13 Error Code 48

14 Error Code 50

15 Error Code 52

16 Error Code 53

24 Error Code 54

29 Error Code

High-Efficiency ONLY (A)…………………………….. 55

Mid & High-Efficiency (B)…………………………… 56

31 Error Code 58

32 Error Code 60

33 Error Code 62

34 Error Code 64

35 Error Code 66

51 Error Code 67

52 Error Code 70

Page 4

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 3

3

61 Error Code 73

65 Error Code 76

66 Error Code 78

71 Error Code 79

72 Error Code 81

76 Error Code 84

79 Error Code 85

80 Error Code 89

82 Error Code 92

90 Error Code 94

92 Warning Code 95

93 Error Code 95

99 Error Code 94

HOW TO REMOVE COMPONENTS

Section 1: Control Board Bracket…98

Section 2: Blower Motor…100

Section 3: Flame Rod; Igniter Rod; Igniter Coil…102

Section 4: Orifice Assembly…104

Section 5: Burner Assembly…106

Section 6: Gas Control Valve…107

Section 7: Water Control Valves…111

Section 8: Heat Exchanger Thermistor…114

Section 9: Outlet Thermistor…116

Section 10: Inlet Thermistor…118

Section 11: Ambient Thermistor…120

Section 12: Control Board…122

How to Program Control Board…123

Page 5

4 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

4

Important Safety Information

READ the Safety Information

Before inspecting, diagnosing, repairing or operating

any water heater, be sure to examine all of the safety

and warning labels on the water heater. Follow the

instruction on these warning labels. Read and

understand the Use and Care Manual that was

shipped with the water heater. Failure to do so can

result in unsafe operation of the water heater resulting

in property damage, bodily injury, or death. Should

you have any problems reading or following the

instructions in the Use and Care Manual, seek the

help of a licensed and qualified professional.

ELECTRICAL SHOCK

Troubleshooting and repairing this water heater can

expose you to electrical shock. Some of the

diagnostic procedures require the presence of AC and

DC volt electricity. Use extreme caution when

performing these procedures. When replacing an

unserviceable component, turn off all power to the

water heater and check for the presence of power

with a multi-meter or test lamp. The ignition cable

carries more than 10,000 volts of electrical energy.

Use extreme caution when diagnosing the Tankless

Gas Water Heater.

FLAMMABLE LIQUIDS AND VAPORS

Gasoline, as well as other flammable material and

Page 6

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 5

5

liquids (adhesives, solvents, etc.), and vapors they

produce are extremely dangerous.

DO NOT handle, use or store gasoline or other

flammable or combustible materials anywhere near or

in the vicinity of a water heater. The spark ignition and

burner assembly in the water heater controls can

ignite these vapors. Failure to do so can result in

property damage, bodily injury or death.

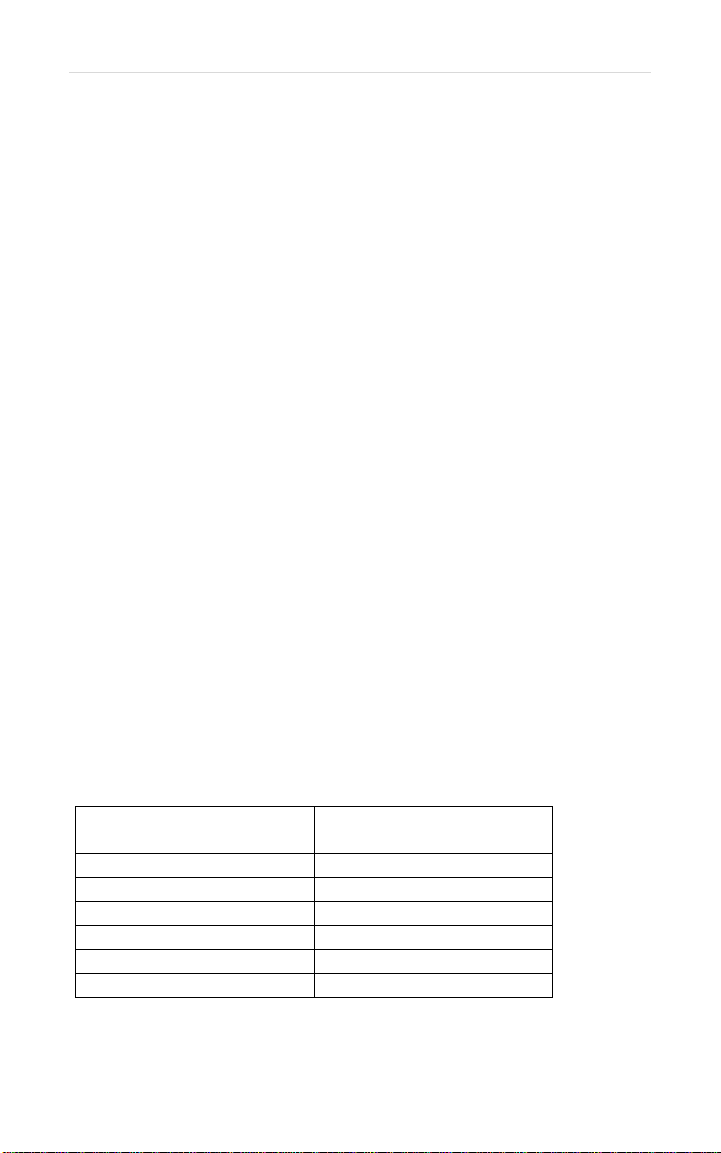

WATER TEMPERATURE ADJUSTMENT

Safety and energy conservation are factors to be

considered when selecting the water temperature

setting on the thermostat. Water temperatures above

125° F can cause severe burns or death from

scalding. The chart shown here may be used as a

guide in determining the proper water temperature for

your application.

Page 7

6 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

6

Multi-Meter

Used to

measure

Resistance &

Voltage

Multi-Meter

Needle Set

Used on meter

test leads to

access

connectors

while measuring

Resistance &

Voltage

Manometer

Used to

measure gas

pressure

during standby

and operation

WARNING: WHILE MEASURING VOLTAGE, DO NOT touch any

grounding areas on unit (unless specified in

SAFETY FIRST

Your safety and safety of others is very important.

This manual is only intended for qualified service

technicians. ALWAYS USE CAUTION while testing

voltages and/or gas supply.

Troubleshooting Tools

Page 8

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 7

7

WARNING: WHILE MEASURING VOLTAGE, DO NOT cross/touch

multi-meter leads together. This will cause damage to electrical

components.

WHEN INSERTING LEADS INTO WIRING CONNECTOR, insert on the

wiring side to prevent damage to connector.

BEFORE MEASURING RESISTANCE, TURN OFF all electrical power

and make sure to REMOVE CONNECTOR from the circuit

(control board). Check resistance on connector that was

removed.

WHEN MEASURING VOLTAGE, DO NOT REMOVE CONNECTOR;

insert multi-meter leads prior to operating unit.

WHEN MEASURING DC VOLTAGE, if the meter displays the dash (--) symbol, swap the position of your black and red leads on the

connector.

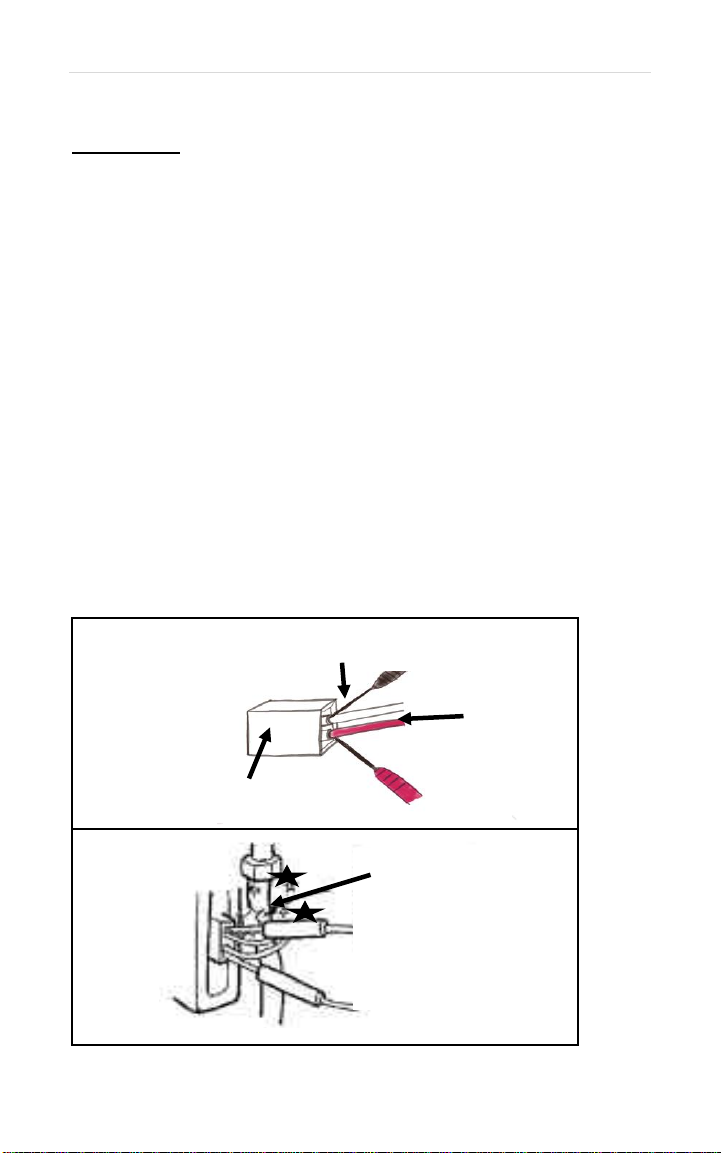

Multi-Meter Needle Leads

Wiring

Connector

Do NOT touch any

grounding areas

while measuring

voltage

MEASURING VOLTAGE & RESISTANCE

Page 9

8 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

8

Installation Guidelines for

HIGH-Efficiency ONLY:

GAS TYPE: Liquid Propane (LP) or Natural (NG)

NG MAX INLET GAS PRESSURE: 10.5 (In. of w.c.)

NG MIN INLET GAS PRESSURE: 4.0 (In. of w.c)

LP MAX INLET GAS PRESSURE: 13.0 (In. of w.c.)

LP MIN INLET GAS PRESSURE: 8.0 (In. of w.c.)

MAX INPUT RATE: 199,900 (Btu/hr)

MIN INPUT RATE: 11,000 (Btu/hr)

GAS CONNECTION: 3/4” NPT

ELECTRICAL CONSUMPTION:

Normal: 100 W

Standby: 3-5 W

Antifreeze Protection: 200 W

MINIMUM ACTIVATION FLOW RATE (gpm): 0.4

EXTINCTION FLOW RATE (gpm): 0.25

VENT SIZE (Indoor ONLY): 2” or 3”

Page 10

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 9

9

The vent exhaust and air intake must be vented outside as

described in the use and care manual. DO NOT vent this water

heater through a chimney. It must be vented seperately from all

other appliances.

NOTICE: The unit can be vented using only the following

recommended pipe material.

Use only 2 – or 3-inch diameter pipe. Refer to local codes for

restrictions on the use of PVC, CPVC, or ABS pipe and fittings. All

exhaust venting materials for product installed in Canada must

meet ULC-S636.

Acceptable materials or equivalent:

PVC (Schedule 40, ASTM D-1785

CPVC (Schedule 40, ASTM F-441)

ABS (Schedule 40, ASTM D-2661) (Not permitted in Canada)

The fittings other than the VENT TERMINAL should be equivalent

to the following:

PVC (Schedule 40, DMW, ASTM D-2665

CPVC (Schedule 40, DMW, ASTM F-438)

ABS (Schedule 40, DMW, ASTM D-2661) (Not permitted in

Canada)

Category III Stainless Steel

DO NOT USE Schedule 20, Cell Core, Drain Pipe, Galvanized,

Aluminum, or B-Vent.

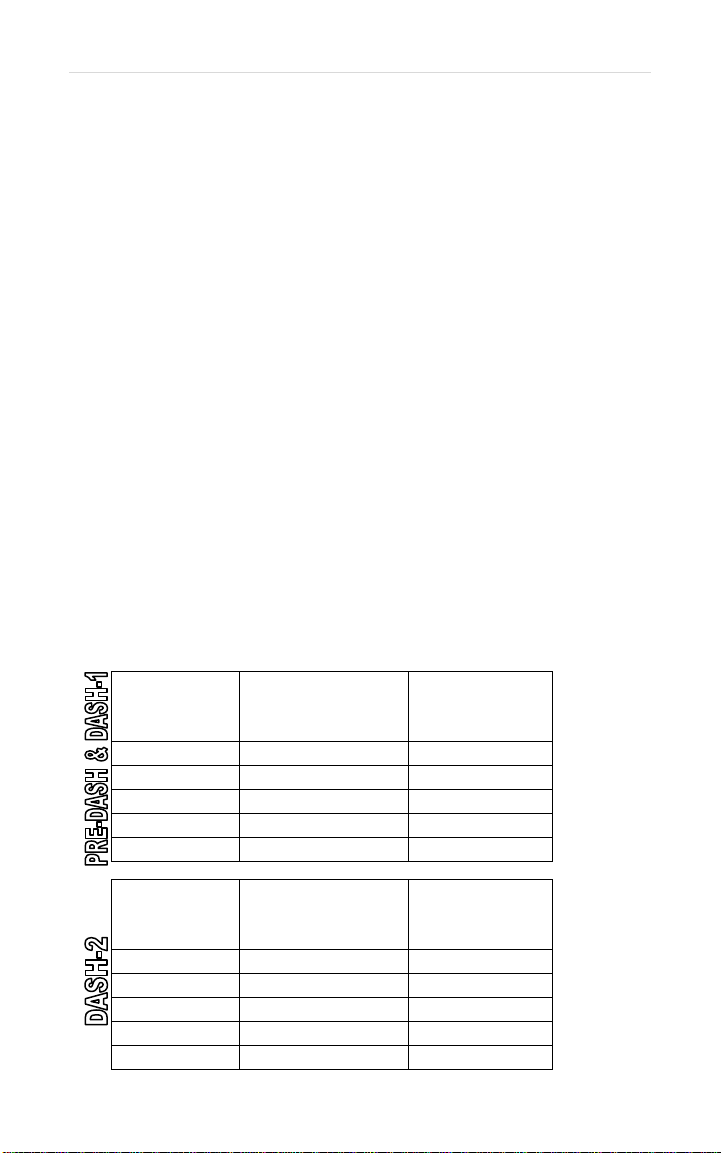

Installation Guidelines for

HIGH-Efficiency ONLY:

Number of

90 Degree

Elbows

Maximum

Length of 2”

Straight Pipe

Maximum

Length of 3”

Straight Pipe

0 or 1

5 ft.

38’ 2 3.5 ft.

36’ 6”

3

2.0 ft.

35’

4

Not available

33’ 6”

5

Not available

32’

Number of

90 Degree

Elbows

Maximum

Length of 2”

Straight Pipe

Maximum

Length of 3”

Straight Pipe

0 or 1

60’

150’ 2 58’ 6”

148’6” 3 57’

147’ 4 55’ 6”

145’ 6” 5 54’

144’

Page 11

10 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

10

Installation Guidelines for

MID-Efficiency ONLY:

GAS TYPE: Liquid Propane (LP) or Natural (NG)

NG MAX INLET GAS PRESSURE: 10.5 (In. of w.c.)

NG MIN INLET GAS PRESSURE: 4.0 (In. of w.c)

LP MAX INLET GAS PRESSURE: 13.0 (In. of w.c.)

LP MIN INLET GAS PRESSURE: 8.0 (In. of w.c.)

MAX INPUT RATE: 199,900 (Btu/hr)

MIN INPUT RATE: 11,000 (Btu/hr)

GAS CONNECTION: 3/4” NPT

ELECTRICAL CONSUMPTION:

Normal: 100 W

Standby: 3-5 W

Antifreeze Protection: 200 W

MINIMUM ACTIVATION FLOW RATE (gpm): 0.4

EXTINCTION FLOW RATE (gpm): 0.25

VENT SIZE (Indoor ONLY): 3”/5” concentric

Page 12

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 11

11

WARNING:

Use 3-in. /5-in. UL-approved Category III

Stainless Steel vent materials or water heater

manufacturer-approved vent material. No

other vent material is permitted for use with

this appliance.

Venting Requirements

The installation of the venting must comply with

national codes, local codes and the vent

manufacturer’s instructions.

The water heater must be vented to the outdoors.

DO NOT vent this water heater through a chimney. It

must be vented separately from all other appliances.

All coaxial vent components (adapters, pipe, elbows,

terminals, etc.) should be water heater manufacturerapproved Stainless Steel Venting Material (e.g.,

AL29-4C).

Number of 90 Degree

Elbows (bends)

Maximum Length of

Straight Pipe

1

39’

2

37’ 6”

3

36’

4

34’ 6”

5

33’

6

31’ 6”

Installation Guidelines for

MID-Efficiency ONLY:

Page 13

12 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

12

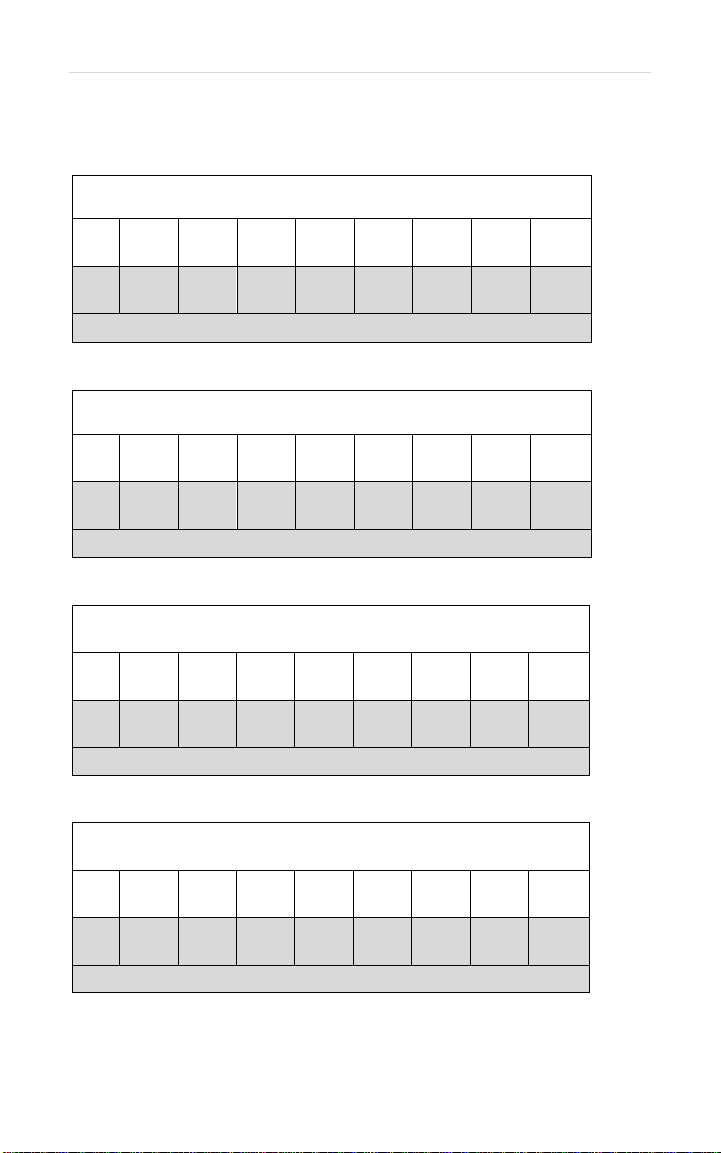

Temperature Rise ( ° F)

35

45

50

60

70

77

80

90

100

6.4

5.6

5.1

4.2

3.6

3.3

3.2

2.8

2.5

Max Water Flow - GPM (gallons per minute)

Temperature Rise ( ° F)

35

45

50

60

70

77

80

90

100

6.6

5.1

4.6

3.8

3.4

3.3

2.9

2.6

2.3

Max Water Flow - GPM (gallons per minute)

Temperature Rise ( ° F)

35

45

50

60

70

77

80

90

100

8.4

6.7

6.1

5.1

4.3

3.9

3.8

3.4

3.0

Max Water Flow - GPM (gallons per minute)

Temperature Rise ( ° F)

35

45

50

60

70

77

80

90

100

9.5

7.4

6.6

5.5

4.7

4.3

4.1

3.7

3.3

Max Water Flow - GPM (gallons per minute)

MID-EFFICIENCY FLOW RATES

64DV & 64X

95DV & 95X

84DV & 84X

68DV & 68X

Page 14

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 13

13

Temperature Rise ( ° F)

35

45

50

60

70

77

80

90

100

8.4

6.6

6.0

5.0

4.3

3.9

3.7

3.3

3.0

Max Water Flow - GPM (gallons per minute)

Temperature Rise ( ° F)

35

45

50

60

70

77

80

90

100

9.5

8.4

7.6

6.3

5.4

4.9

4.7

4.2

3.8

Max Water Flow - GPM (gallons per minute)

H95DV & H95X

H84DV & H84X

HIGH-EFFICIENCY FLOW RATES

(Condensing)

Page 15

14 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

14

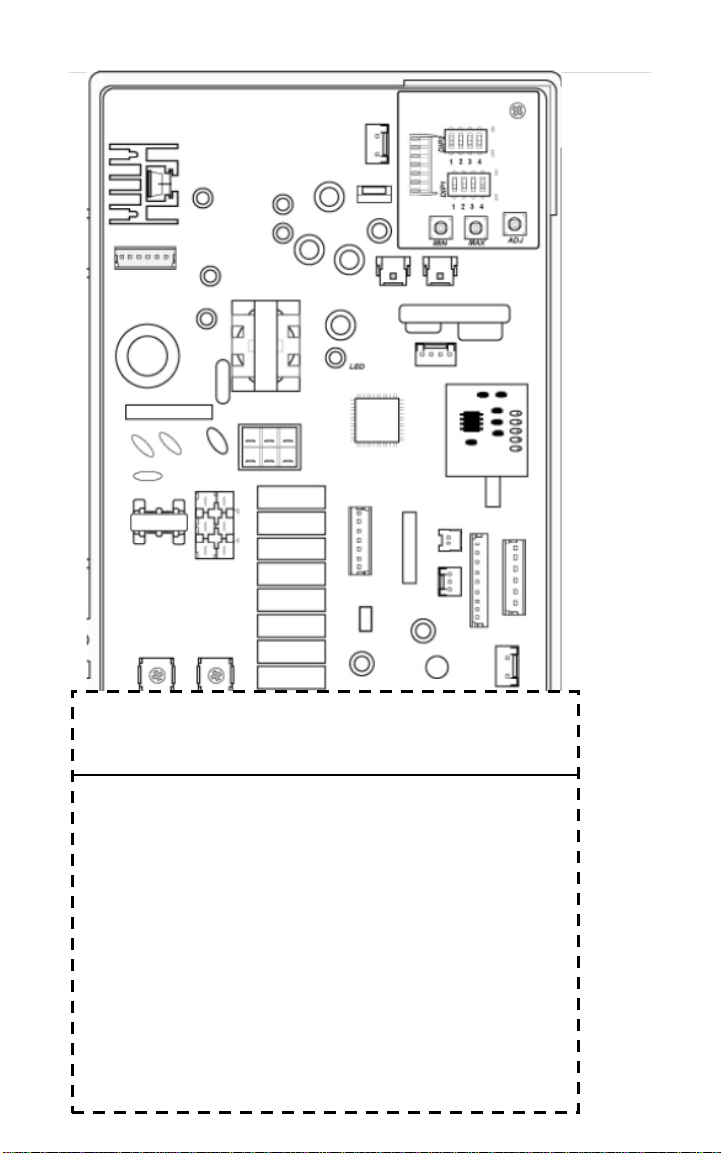

G

C

S

U

R

H

K

B

T

M

P

***FUEL TYPE CHIP*** – When replacing Control Board, you

must use the original chip on the new Control Board. New

Control Board must be programmed (refer to page 122).

P – Red, Red (High Efficiency ONLY)

M – White Molex: Grey

T – Blue Molex: Blue (Indoor Models ONLY)

K – Red, Black, Green, Yellow, White, Grey, Blue

H – White, White, Grey, Grey

U – White, White

S – Brown, Black, Red

C – Brown, White, Orange, Blue, Yellow, Green, Red, Black

B - Brown, White, Orange, Blue, Yellow, Green, Red, Black

G – Indoor Units: Blue, Yellow, White, Black, Red

G – Outdoor Units: Yellow, Orange, Red, Blue, White

R – Mid Efficiency: Red, Black, Black, Red, Yellow, White, Blue

R – High Efficiency: Red, Black, Black, Red, Green, White, Blue

Control Board

Connectors

Connector Wire

Colors

Fuel Type Chip

Page 16

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 15

15

CONTROL BOARD CONNECTORS

M

T

P

F

A

R

U

C

B

S

V

FUSES

(3A)

POWER

LED

DIP1

DIP2

MIN

MAX

ADJ

H

K

G

Page 17

16 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

16

Diagnostic Points on Control Board

Connection

Wire

Color

Normal Value

What are

you

checking?

I – J

W1-BK2

AC108-132V

Do you have

power to the

control

board?

U

W1-W2

50KΩ-500KΩ

Is the

overheat film

wrap OK?

S

BR1-BK2

DC 2-5V

(Pulse)

More than 1,310

pulses/minute

Does the

water flow

sensor send

a pulse?

(Only when

water is

flowing thru

the unit)

S

R3-BK2

DC 11-17V

Does the

water flow

sensor have

voltage?

(Power ON;

no water

flow)

Page 18

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 17

17

Connection

Wire Color

Normal Value

What are

you

checking?

G

BK4-R6

DC 144-192V

Does the

fan motor

have the

proper

voltage?

W3-BK4

DC 12-18V

Is the

overheat

film wrap

OK?

BR1-BK2

DC 4-10V

(Pulse)

Is the fan

motor

producing

regular

pulse?

R

W6-BK3

68°F=10.3KΩ

104°F=4.9KΩ

Is the water

inlet

thermistor

working?

R

Mid-

Efficiency:

Y5-BK3

High-

Efficiency

(condensing):

G5-BK3

68°F=10.3KΩ

104°F=4.9KΩ

Is the heat

exchanger

thermistor

working?

Page 19

18 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

18

Connection

Wire Color

Normal Value

What are

you

checking?

R

R4-BK3

68°F=10.3KΩ

104°F=4.9KΩ

Is the water

outlet

thermistor

working?

R

BL7-BK4

Mid-Efficiency

INDOOR

Units:

68°F=10.3KΩ

104°F=4.9KΩ

Is the

ambient air

thermistor

working?

ALL

OUTDOOR &

ALL

CONDENSING

units:

68°F=10.3KΩ

104°F=4.9KΩ

Page 20

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 19

19

Connection

Wire

Color

Normal Value

What are

you

checking?

R

R1-BK2

DC1.5-14V

40Ω-80Ω

Is the

P.G.F.R.

valve

operating?

(Proportional

Gas Flow

Regulator –

full

modulating

valve)

M

W1-GND

AC 1-100 V

Flame rod

detecting

flame?

T

BL1-GND

AC 1-100 V

Flame rod

detecting

flame?

H

GY3-GY4

AC 108-132 V

Is the igniter

working

properly?

Page 21

20 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

20

Connection

Wire

Color

Normal Value

What are

you

checking?

K

Y1-BK6

DC 90-120 V

0.8KΩ-2.4KΩ

Gas inlet

solenoid

valve OK?

K

W2-BK6

DC 90-120 V

0.8KΩ-2.4KΩ

Solenoid

valve 1 OK?

K

GY3-BK6

DC 90-120 V

0.8KΩ-2.4KΩ

Solenoid

valve 2 OK?

K

R5-BK6

DC 90-120 V

0.8KΩ-2.4KΩ

Solenoid

valve 3 OK?

K

BL4-BK6

DC 90-120 V

0.8KΩ-2.4KΩ

Solenoid

valve 4 OK?

Page 22

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 21

21

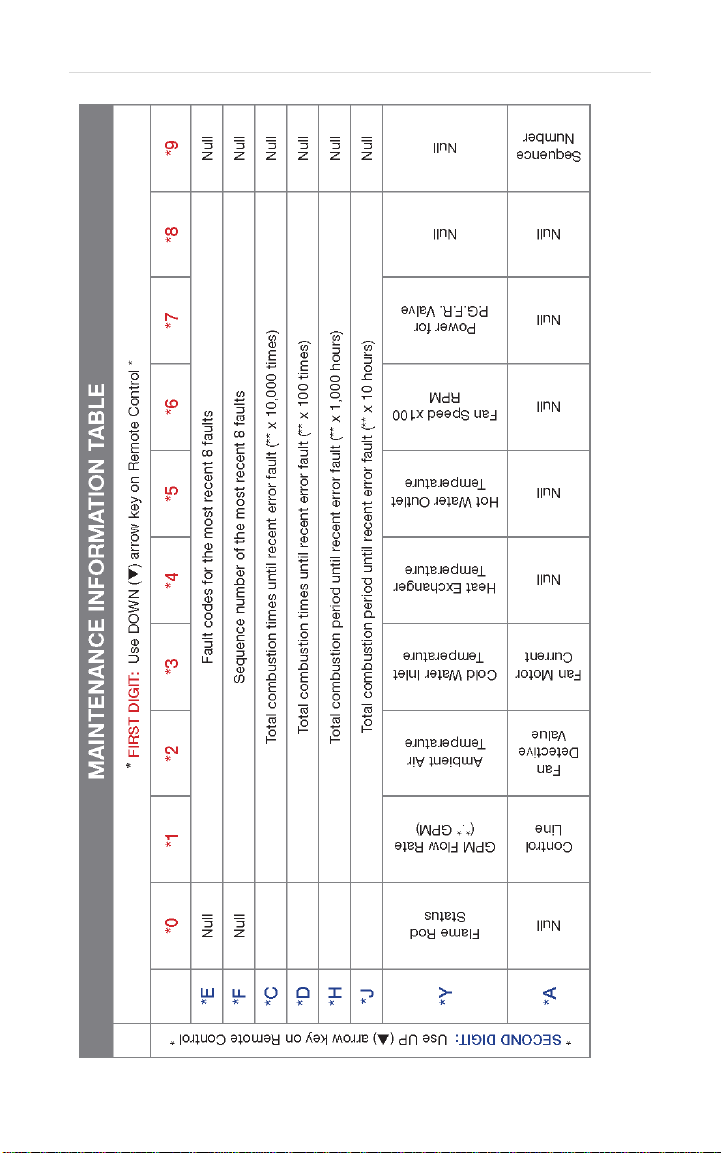

Maintenance Mode Panel Display

INSTRUCTIONS

The Rheem/Ruud Tankless has a maintenance mode

chart on the remote control. To access the

maintenance mode, turn the unit OFF at remote

control and make sure water flow is OFF. Then hold

down the UP and DOWN arrow keys at the same

time for 5 seconds. You will hear an audible beep and

see the display go to 1E (NOTE: Unit will default to

120° F). By pressing the UP and DOWN arrow keys

on the remote control, you can access a variety of

information about the water heater. To activate the

unit while displaying the maintenance panel: push

the power button once, open a hot water fixture, and

the green LED will illuminate. This will allow you to

access a variety of real time information while the unit

is in operation.

Shortcut: (See Diagram on Page 22) DIP1 - Lift dip

switch #1 to the up position to go immediately

into maintenance mode. This can be done while

the water heater is in operation.

(NOTE: Unit will maintain the set temperature)

While in maintenance mode you want to push the UP

arrow key to select the table you wish to view. The

table is designated by a letter and is always displayed

as the second digit. Then push the DOWN arrow key

to display the number item in the table you selected.

The number is always displayed as the first digit. You

can select as many as 8 readings for each table.

To perform diagnostics in this service manual, press

the UP arrow until you get to table1Y.

Now using your DOWN arrow you can change the

number in front of Y. As you move through the

diagnostic readings, the selected table will flash first

and then the diagnostic reading.

(Maintenance Mode Table on Page 23)

Page 23

22 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

22

You will see the following as you navigate the Y

table in maintenance mode:

0Y = Flame rod status

1Y = Water flow in gallons per minute

2Y = Ambient air temperature

3Y = Water inlet temperature

4Y = Heat exchanger temperature

5Y = Hot water outlet temperature

6Y = Fan speed (x 100 rpm)

7Y = Power for modulating gas valve

8Y = Null (no reading)

9Y = Null (no reading)

control board

DIP1

Page 24

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 23

23

Page 25

24 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

24

NOTES:

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

Page 26

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 25

25

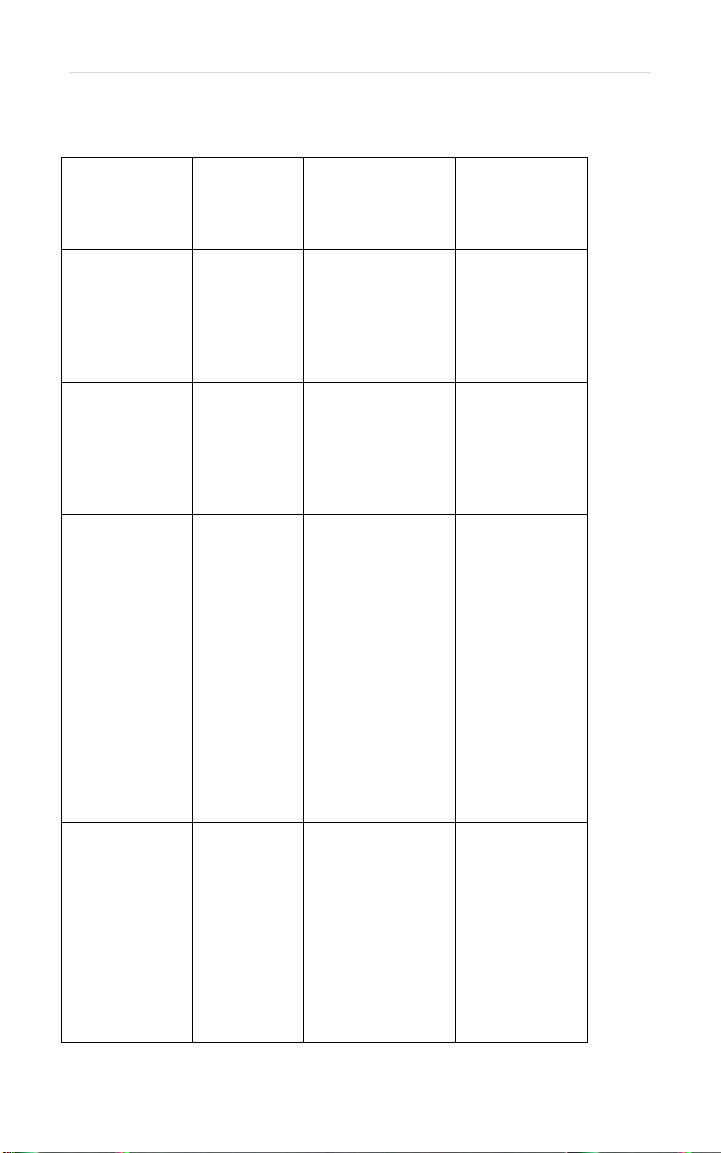

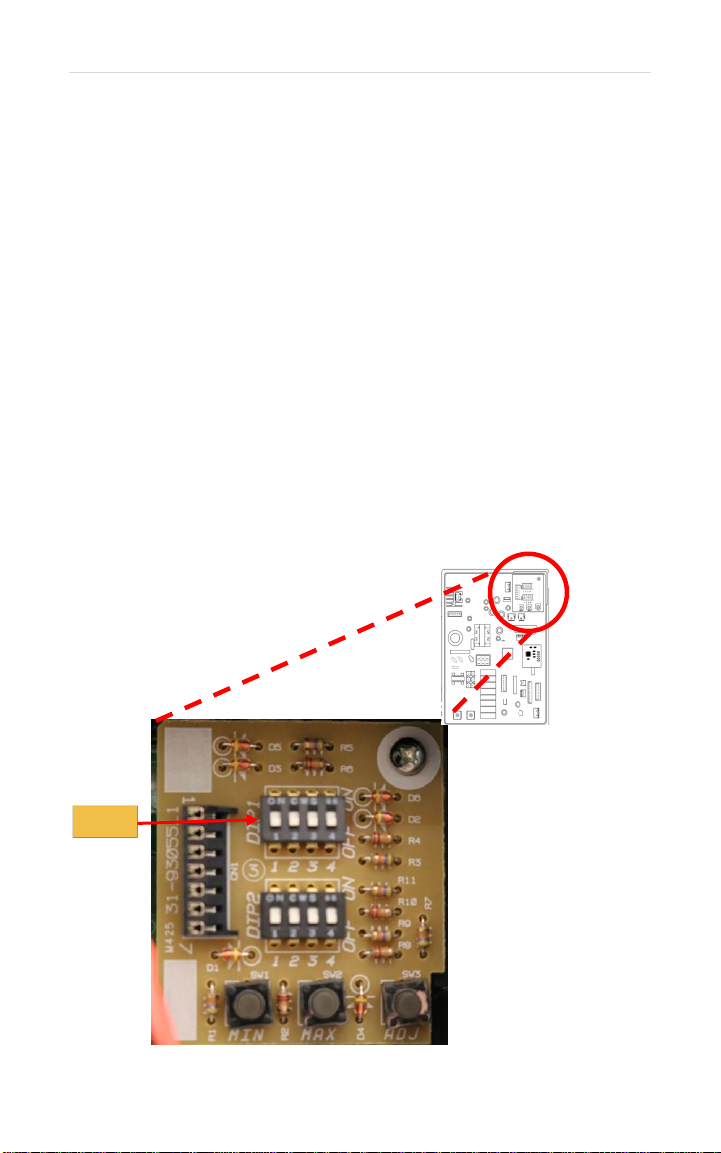

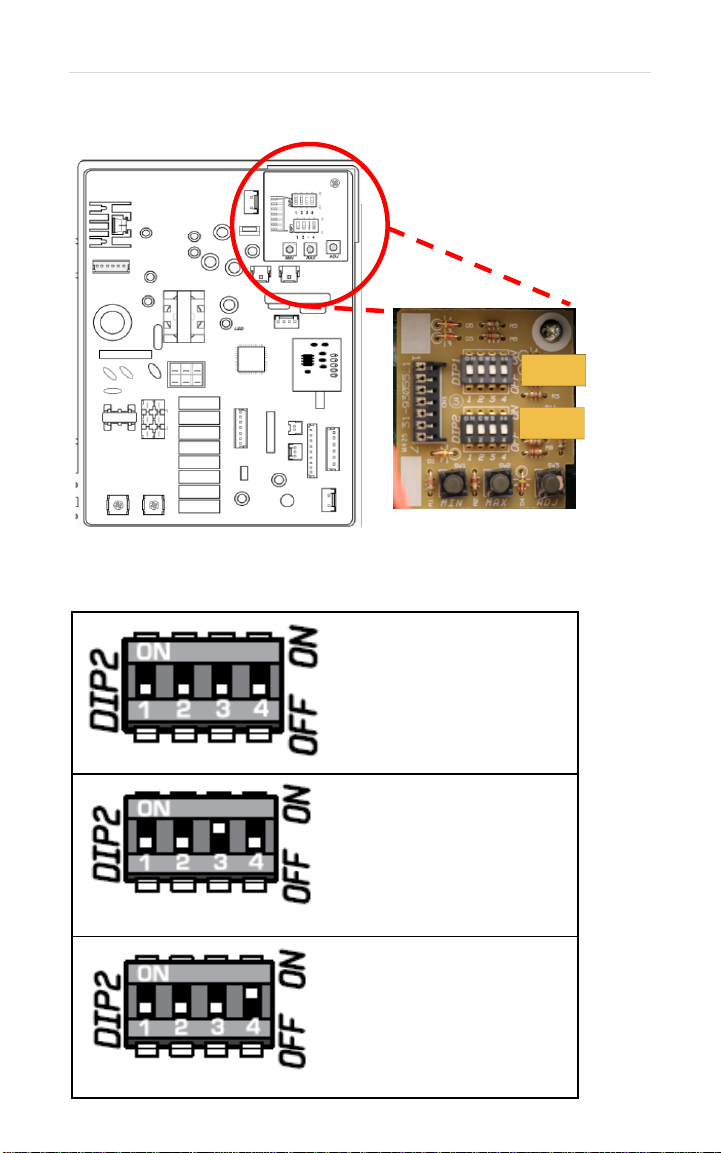

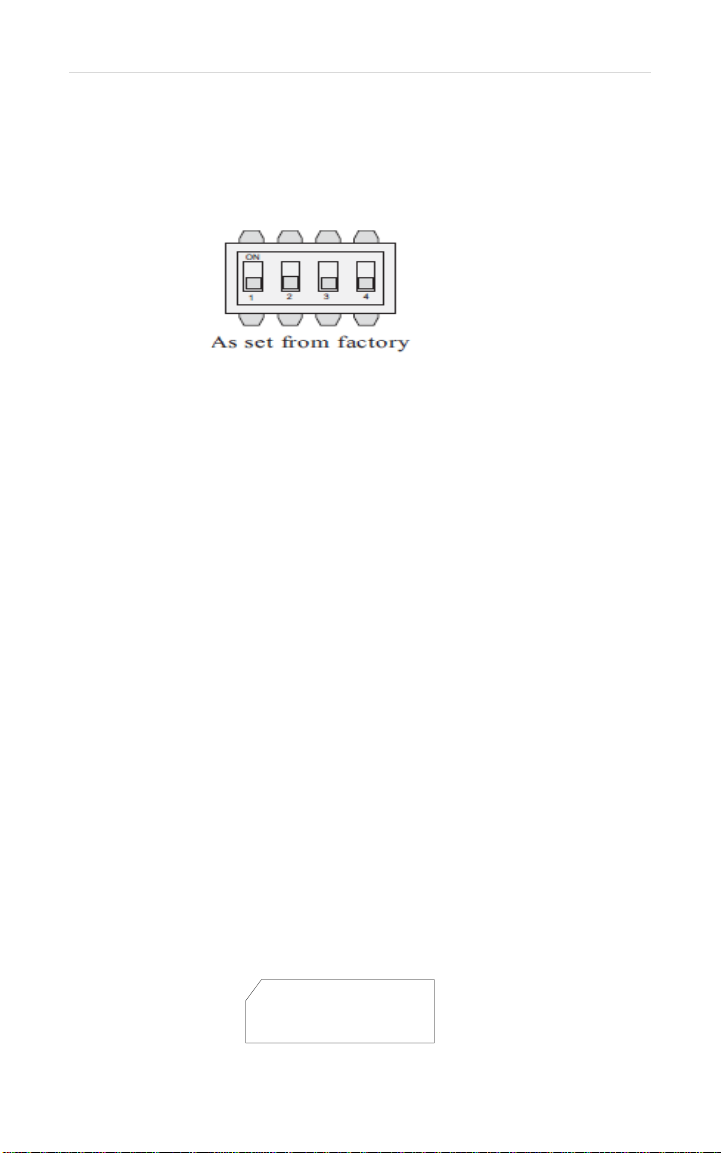

Altitude Settings on Control Board

Locate the two DIP switches at top right of Control Board.

Switch labeled DIP2 is the bottom switch. Altitude

adjustments must be performed on DIP2 ONLY.

Sea Level (0ft – 2000ft)

All switches should be in the

OFF position (DOWN)

2000ft – 5400ft

3RD switch should be in the

ON position (UP)

5400ft –8500ft

4TH switch should be in the

ON position (UP)

DIP1

DIP2

Page 27

26 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

26

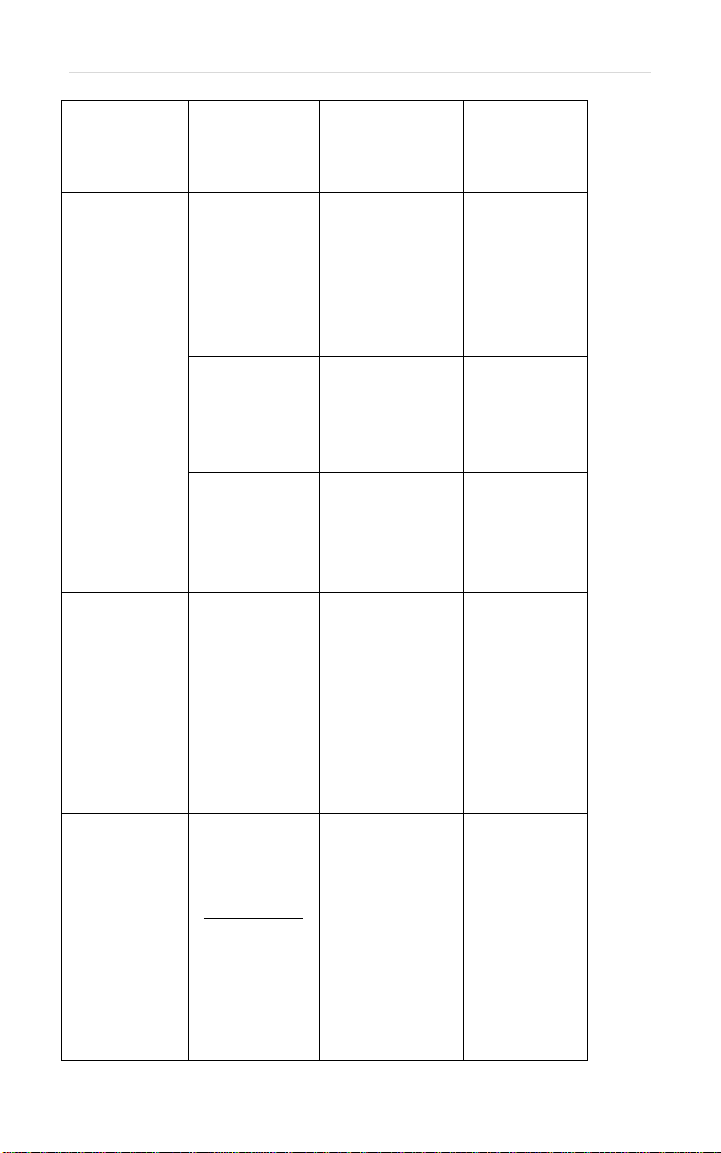

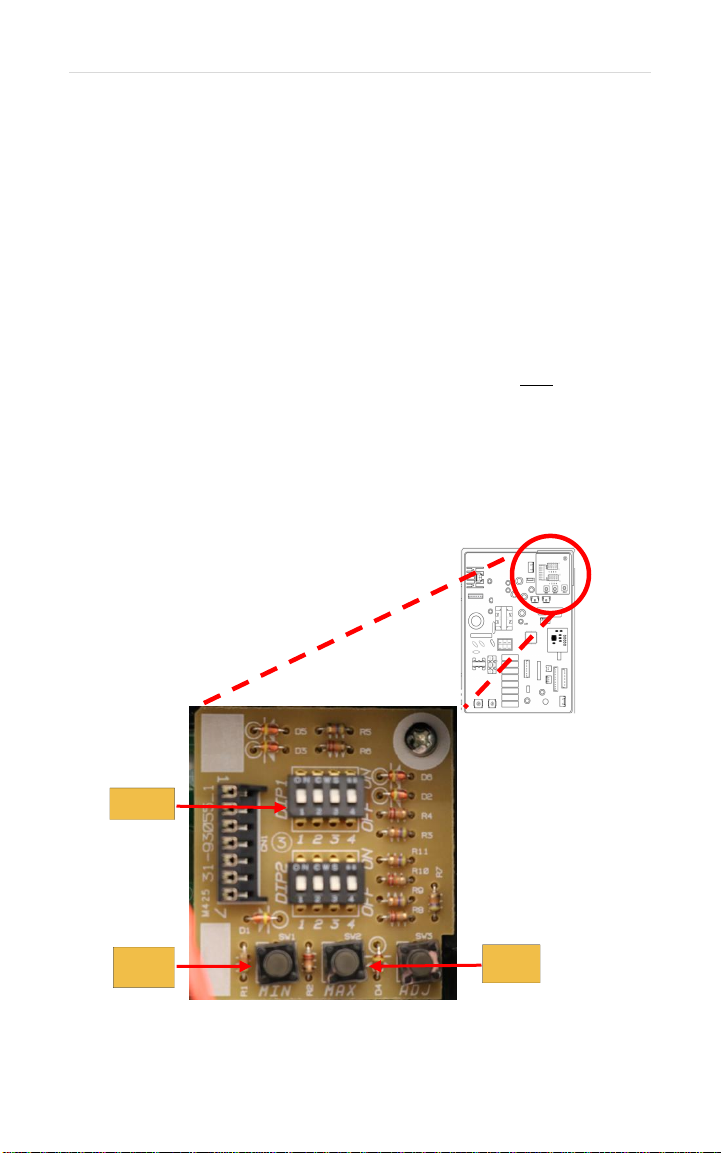

ONLY for ‘Hard Lockouts’ - Error Codes: 10, 13 & 99

1. Turn remote control OFF; leave unit plugged in. Remove

front cover. Locate the DIP Switches (Upper Right on the

control board).

2. Make sure all the DIP Switches are OFF (down position).

3. Locate DIP1 – Switch #2 and turn it ON (up position)

then immediately turn it OFF.

4. Within 5 seconds, press and hold the MIN and MAX

buttons for at least 2 seconds.

5. The remote control will flash “UL” then it will go solid.

This indicates the heater has been reset.

6. Release the buttons.

7. Turn remote control ON. You may operate unit.

control board

RESET PROCEDURE

DIP1

MIN

MAX

Page 28

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 27

27

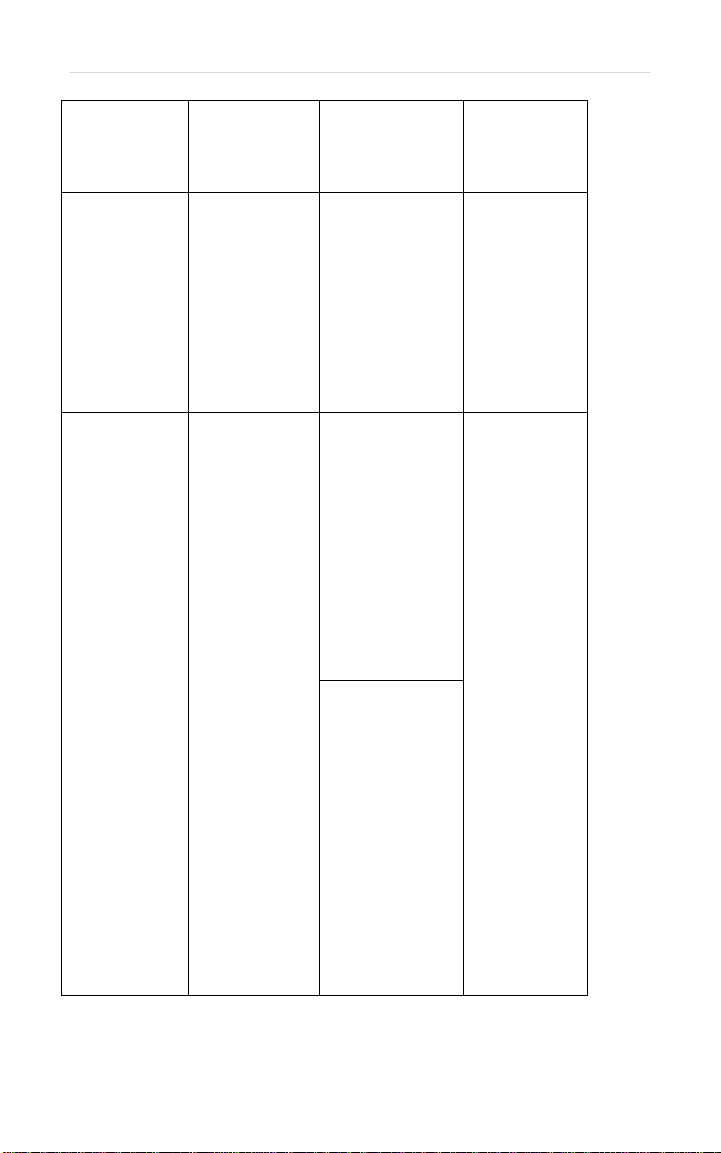

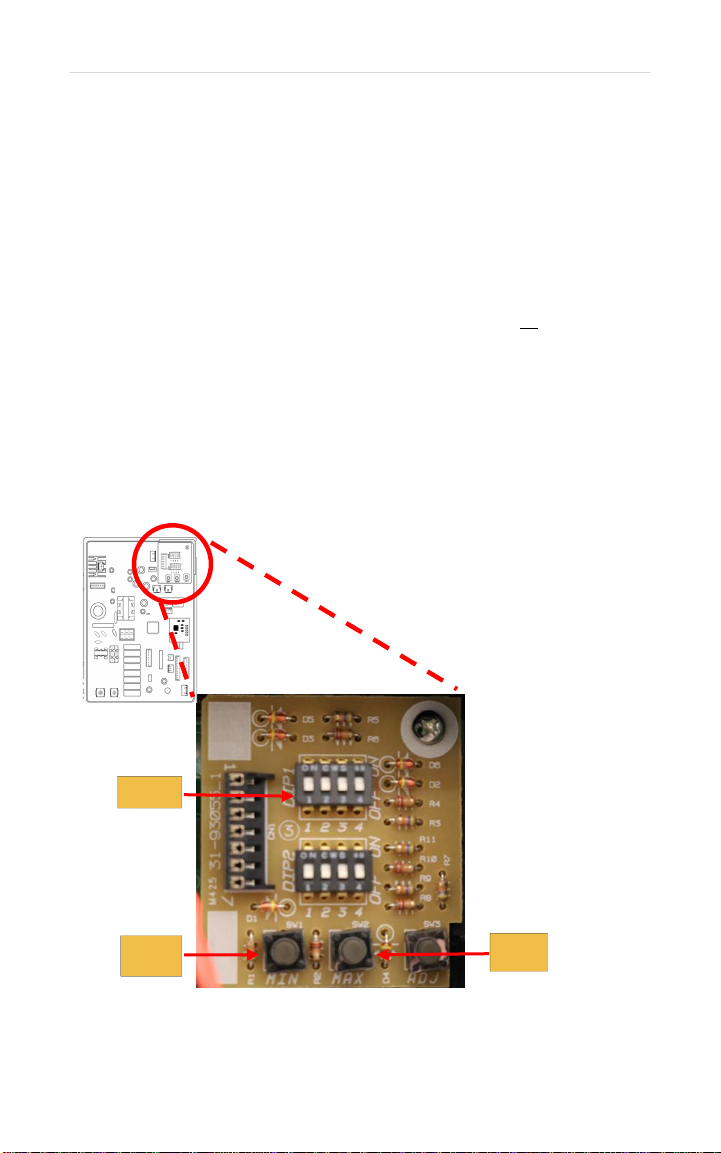

1. Turn remote control OFF; leave unit plugged in. Remove

front cover. Locate the DIP Switches (Upper Right on the

control board).

2. Make sure all the DIP Switches are OFF (down position).

3. Locate DIP1 – Switch #1 and turn it ON (up position)

then immediately turn it OFF.

4. Within 5 seconds, press and hold the MIN or MAX button

for at least 2 seconds.

5. The remote control will flash “CL” then it will go solid.

This indicates the fault history has been cleared.

6. Release the buttons.

7. You can verify clearing history by entering maintenance

mode and check the code at location 1E. Should read

NULL (- - two dashes).

8. Turn remote control ON. You may operate unit.

control board

CLEARING FAULT HISTORY

DIP1

MIN

MAX

Page 29

28 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

28

No Error Code & No Hot Water

Explanation: No hot water is delivered when water is

flowing through unit and remote control displays the

hot water temperature setting. [For ‘NO POWER’

complaint (remote control will not turn on) – check

wall outlet for 120 volts. If voltage is present, check

the two 3-amp fuses at the control board]

Possible Causes:

Water flow (0.4 GPM to activate)

DIP1 setting on main control board

Water flow sensor

Water Flow:

1. Use cold water shutoff valve to turn OFF

water supply to unit. Turn remote control

OFF; unplug power cord at wall outlet. Wait

10 seconds; plug power cord back into outlet;

wait 20 seconds; turn the remote control ON.

Turn water supply ON; check the nearest hot

water fixture for hot water.

2. Open multiple hot water fixtures. If unit fires

then there is not enough water flow to

engage the unit at a particular fixture. Check

your fixture aerator screen(s) for debris.

Clean if necessary.

3. Your water flow may be restricted by debris in

water filter. Remove the water filter and

inspect. Clean if necessary.

4. Your water lines might be crossed. Make

sure your hot and cold water supply lines are

connected to the appropriate hot and cold

water assembly connections on the unit.

Page 30

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 29

29

FINAL CHECK: Water flow sensor in water volume

control valve.

Check connector ‘S’ between the Red and Black

wires. With the unit ON and no water flow, you

should read 11-17 DC volts. If not, replace the control

board. IF you have voltage, then.......

With the water flowing, measure 2-5 DC volts

between the Brown and Black wire. (This is

measuring water flow thru the control). IF you have a

reading and no main burner, replace the control

board. If you do not have a reading, remove any

debris from water volume control valve.

Single Unit Installations ONLY:

All DIP1 switches must be in the ‘OFF’ position

(DOWN).

DIP 1

Manifold (Multiple) Unit Installations

ONLY:

Go to 03 - Error Code to verify proper DIP1 setting.

Water Flow Sensor:

Connector Location

On Page 14

Page 31

30 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

30

NOTES:

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

Page 32

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 31

31

1. Turn the water supply to the unit OFF. Turn the remote

control OFF, wait 10 seconds and turn the remote

control ON. Turn the water supply to the unit ON and

check the nearest hot water fixture for hot water. If you

have hot water, then the unit needed to be reset.

2. Your water lines might be crossed. Make sure your hot

and cold water supply lines are connected to the

appropriate hot and cold water connections on the unit.

3. Your water flow may be restricted by a dirty In-Line

Water Filter. Remove the water filter and inspect. Clean

if necessary.

4. Possible plumbing cross-over in the home. Turn OFF

hot water valve to the water heater. Go to each water

fixture in the home and turn ON the hot water ONLY

(test washing machine by setting it to hot ONLY). If

water flows freely through the hot water side of the

fixture, this is a plumbing crossover. HINT: During this

test, to prevent scalding, pressure-balancing valves on

single-handle fixtures will not allow any water to flow if

there is a plumbing crossover.

5. Water flow might be too low. Open multiple hot water

fixtures. If unit fires then there is not enough water flow

to engage the unit at a particular fixture. Check your

fixture aerator screen(s) for debris. Clean if necessary.

FOR RECIRCULATION LINES: check pump size, aquastat, check valve, and operation.

P1 - Warning Code

Explanation: No hot water is delivered when water

is flowing through unit and remote control displays

P1 - Warning Code.

Possible Causes:

Not Enough Water Flow

Page 33

32 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

32

.

1L - Warning Code

Explanation: The control board has detected lime

build-up inside the heat exchanger. To prevent

permanent damage to the unit, the unit must be

drained and flushed.

Flushing procedures may need to be repeated for

excessive lime and scale build-up.

*To reset 1L Code, hold down the MIN and MAX

buttons at the same time for 10 seconds

NOTE: Flushing instructions utilize a

submersible utility pump (provided with the

Rheem/Ruud Tankless Flush Kit – RTG20124)

Tankless Water Heater

Gas Supply

Valve

Cold Water

Service

Valve

(cold water side)

Hot Water

Service

Valve

(hot water side)

Drain Hose

(cold water side)

Drain Hose

(hot water side)

5-Gallon

Bucket

Utility Pump

Page 34

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 33

33

1. Turn OFF gas and both the cold and hot water supply to

the water heater. The gas must remain OFF during the

flushing process.

2. At the remote control, turn OFF the power and wait 10

seconds. Turn ON the power and wait 10 seconds.

Disconnect the water heater from the electrical source.

3. Connect a hose to the hose connections on the service

valves under the water heater.

4. Place the loose end of the hoses into a 5-gallon bucket.

5. Open the service port valve on each side of the service

valves, to allow the heater to drain. Connect the cold

water side hose to the outlet side of the utility pump and

set the pump into the bottom of the bucket.

6. Pour 2 gallons of virgin food grade white vinegar into

the bucket and turn the pump ON.

7. Allow the pump to circulate the vinegar for 45 to 60

minutes. (time will vary depending upon mineral build-up

and hardness of the water)

8. Turn OFF the pump and remove the hose from the

pump. Allow the vinegar to drain from water heater into

the bucket.

9. Place the hot water side hose in another bucket or route

it to a suitable drain.

10. Close the service port valve on the cold water side and

disconnect the cold water hose from the service valve.

11. Follow instructions in the Use & Care manual, supplied

with the water heater, to clean the water inlet filter.

12. Turn ON the cold water supply to the heater. DO NOT

TURN ON THE HOT WATER SUPPLY TO THE

HEATER. Water will begin to flow through the heater;

this will rinse out any remaining vinegar from the water

heater. Allow the water to run for approximately 5

minutes.

13. Close the hot water service port valve and disconnect

the drain hose.

14. Open a hot water fixture in the home, such as a tub.

Allow the water to flow for a minute to ensure there is no

air remaining in the system. Turn OFF the hot water

fixture.

15. Reconnect power to water heater, turn ON gas supply,

and turn ON power at the remote control.

16. Turn ON a hot water fixture to ensure the water

heater is operating.

Page 35

34 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

34

Only for manifold (multiple) unit installations: EZLink; MIC-6; or MIC-185 manifold controllers.

Explanation: Communication failure between water heaters,

remote control, and/or manifold controller.

Diagnostic Checks:

DIP1 setting on main control board (PCB)

DIP1 SETTING:

Manifold units only: DIP1, switch #4 must be in the ‘ON’ position

(UP) for each unit.

Check ALL Molex connections on ALL control boards.

If 03 - Error Code is displayed after completing all checks:

Call Technical Support (800)-432-8373

03 - Error Code

Page 36

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 35

35

Make sure DIP2 on control board is set to the correct altitude. Refer to

Page 25 for altitude settings.

`

05 – Warning Code

Explanation: The flame rod has detected improper

burner combustion (Indoor Units ONLY). This

warning code is commonly caused by VENTING

and/or GAS SUPPLY.

Diagnostic Checks:

GAS SUPPLY & VENTING (refer to pages 8-11)

DIP2 setting on main control board

DIP1

DIP2

Page 37

36 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

36

NOTES:

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

Page 38

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 37

37

10 – Warning Code

Explanation: Unit was operated prior to vent

installation OR blower motor is not creating enough

ventilation.

First: Follow reset procedure on page 26.

Next: Check VENTING.

Diagnostic Checks:

VENTING (refer to pages 8-11)

Blower motor

Remove control board bracket. (How to remove: Section 1)

Remove blower motor. (How to remove: Section 2)

Clean blower motor and blower motor housing.

Reassemble & operate unit.

Does 10-Warning Code appear?

Locate MIN & MAX buttons

on upper right-hand corner of

control board.

Continue diagnostics on next

page.

YES

Blower motor needed to be

cleaned or you had a loose

connection.

Unit appears to be operating

OK.

NO

MIN & MAX

BUTTONS

CONTROL

BRACKET

Page 39

38 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

38

Blower Motor Diagnostics: INDOOR Models ONLY

Upper Right-Hand Corner of Control Board

Test DC voltage across

Black and Red wires

on connector G:

144 – 192 DC Volts

YES

Remove & re insert G.

Operate unit again.

IF Code 10 appears:

Replace control board.

NO

Hold down MAX button.

Test DC voltage across

Black & White wires

on connector G:

12 – 18 DC Volts

YES

Remove & reinsert G.

Operate unit again.

IF Code 10 appears:

Replace control board.

NO

Hold down MAX button.

Test DC voltage across

Black & Blue wires

on connector G:

4 – 10 DC Volts

YES

Remove & reinsert G.

Operate unit again.

IF Code 10 appears:

Replace blower motor .

NO

Control board and blower

motor are OK.

CHECK VENTING.

IMPORTANT: While performing voltage checks, DO NOT touch

multimeter leads across BLUE & White wires. Damage may occur

to blower motor and control board.

Connector Location

On Page 14

MIN

MAX

Page 40

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 39

39

Blower Motor Diagnostics: OUTDOOR Models ONLY

Test DC voltage across

Blue and White wires

on connector G:

144 – 192 DC Volts

YES

Remove & re insert G.

Operate unit again.

IF Code 10 appears:

Replace control board.

NO

Hold down MAX button.

Test DC voltage across

Blue & Red wires

on connector G:

12 – 18 DC Volts

YES

Remove & reinsert G.

Operate unit again.

IF Code 10 appears:

Replace control board.

NO

Hold down MAX button.

Test DC voltage across

Blue & Yellow wires

on connector G:

4 – 10 DC Volts

YES

Remove & reinsert G.

Operate unit again.

IF Code 10 appears:

Replace blower motor .

NO

Control board and blower

motor are OK.

CHECK VENTING.

IMPORTANT: While performing voltage checks, DO NOT touch

multimeter leads across YELLOW & RED wires. Damage may

occur to blower motor and control board.

Connector Location

On Page 14

Upper Right-Hand Corner of Control Board

MIN

MAX

Page 41

40 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

40

Igniter Rod Diagnostics (spark is NOT visible)

11 – Error Code

Explanation: Flame rod(s) does not detect flame.

Commonly GAS SUPPLY and/or VENTING.

IMPORTANT: If all water heater components test OK , you must

thoroughly inspect your GAS SUPPLY & VENTING.

Diagnostic Checks:

GAS SUPPLY & VENTING (refer to pages 8-11)

Igniter rod

Flame rod(s)

Gas control valve

Connector Location

On Page 14

HINT: Make sure DIP2 (altitude setting) is properly

set – see Page 25

Turn Power OFF.

Remove and reinsert: connector H(White Molex on

bottom of igniter coil) & black insulated igniter

cable on igniter rod.

Turn Power ON.

Operate unit and determine IF spark is visible

through sight glass.

You had a loose connection.

Igniter is OK.

YES

Continue diagnostic on next

page.

NO

SIGHT GLASS

IGNITER ROD

IGNITER COIL

Page 42

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 41

41

While attempting to ignite,

test AC Volts across 2 Grey

wires on connector H:

108 – 132 AC Volts

YES

Remove & reinsert H.

Operate unit again.

IF Code 11 appears:

Replace control board.

NO

Turn GAS OFF.

Remove and hold igniter

cable 1/8 inch from igniter

connection. With GAS OFF,

operate unit. Determine IF

there is a spark

at igniter connection.

YES

Replace igniter coil..

NO

Turn power OFF.

Remove and clean igniter

rod. Reassemble & operate

unit. Is spark visible through

sight glass?

YES

Replace igniter rod.

NO

Igniter rod needed to be

cleaned and is OK. Turn GAS

ON and check for normal

operation.

Igniter Rod Diagnostics (spark is NOT visible)

IGNITER ROD

IGNITER COIL

IGNITER

CABLE

WHITE MOLEX

Page 43

42 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

42

Turn Power OFF.

Remove and reinsert connector M, T, and

terminal on flame rod(s).

Turn Power ON.

While viewing through sight glass, operate unit to determine

IF flame is touching the flame rod(s).

Indoor models – 2 flame rods (Connectors M& T).

Outdoor models – 1 flame rod (Connector M).

Access maintenance mode

to check flame rod status &

continue to diagnostic chart

on next page.

YES

Remove any foreign debris.

IF foreign debris is not

present: CHECK GAS

SUPPLY & VENTING.

NO

(See maintenance mode instructions on page 21)

Flame Rod Diagnostics (flame IS visible)

SIGHT GLASS

FLAME ROD(S)

Page 44

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 43

43

Flame Rod(s) Diagnostics

Outdoor: 1 flame rod

White Molex – Grey Wire

Indoor: 2 flame rods

White Molex – Grey Wire

Blue Molex – Blue Wire

Test AC volts on

connector M

(Grey wire to Ground)

1 – 100 AC Volts

YES

Remove & reinsert M.

Operate unit again.

IF code 11 appears:

Replace control board.

NO

Test AC volts on connector

T(Blue wire to Ground)

1 – 100 AC Volts

YES

Remove & reinsert T.

Operate unit again.

IF code 11 appears:

Replace control board.

NO

Cycle unit ON; while in

maintenance mode, check

flame rod status under

table 0Y.

IF flame rod(s) is detecting

flame, maintenance mode

will display:

Indoor Models – 05

Outdoor Models - 01

YES

Clean flame rod(s). Operate

unit again. IF still does not

detect flame:

Replace flame rod(s).

NO

Flame rod(s) test OK.

CHECK GAS SUPPLY,

VENTING, & GROUND.

Page 45

44 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

44

Gas Control Valve Diagnostics

(Igniter Rod Sparks & NO flame)

IMPORTANT: DURING VOLTAGE CHECKS – CONNECTOR KONLY

(water is flowing and unit is attempting to ignite):

IF you do NOT get a voltage reading, push and hold the MAX button on

upper right hand corner of control board to activate unit at full BTUs.

This will force voltage to ALL gas valve solenoids during diagnostics.

CAUTION: DO NOT hold MAX button down for more than 5 Seconds

*MAY CAUSE DAMAGE TO THE HEAT EXCHANGER*.

Connector Location

On Page 14

Turn Power OFF.

Remove and reinsert connectors K& R.

(Connector Kis Gas Valves.

Connector Ris PGFR valve.)

Locate PGFR valve on lower right side of unit

(round black piece on bottom of gas valve.

PGFR is a full modulating gas valve).

Remove and reinsert Molex connectors with

Red and Black wires on PGFR.

Turn Power ON.

While viewing through sight glass, operate unit to

determine IF flame is visible.

You had a loose connection.

Gas control valve is OK.

YES

Continue diagnostics on

next page.

NO

MAX

GAS VALVE

PGFR

Page 46

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 45

45

Gas Control Valve Diagnostics

While attempting to ignite

test DC volts across #1 wire

(Red) & #2 wire (Black) on

connector R:

1.5 – 14 DC Volts

YES

Remove & reinsert R.

Operate unit again.

IF Code 11 appears:

Replace control board.

NO

Turn power OFF. Remove

connector R& measure

resistance across same

wires:

40 – 80 OHMS

YES

Remove & reinsert PGFR

connectors. Retest R.

IF resistance test fails:

Replace gas control valve.

NO

Turn power OFF.

Remove connector K.

On connector K: Using the

BLACK WIRE as the

common – individually check

resistance for Yellow, White,

Grey, Red, & Blue wires:

0.8K – 2.4K OHMS

YES

Make sure all wires are

connected to Gas Control

Valve. Retest connector K.

IF test fails: Replace gas

control valve.

NOTE: IF Grey wire failed

ohms test, replace manifold

assembly.

NO

Gas control valve is OK.

Reconnect connector K.

Turn power ON.

While unit is attempting to

ignite - On connector K:

Using the BLACK WIRE as

the common – Individually

check DC volts for Yellow,

White, Grey, Red, & Blue

wires:

90 – 120 DC Volts

Remove & reinsert K.

Operate unit again. IF 11-

Error Code appears:

Replace control board.

NO

Control board is OK.

IF ALL components tested

OK: CHECK GAS SUPPLY,

VENTING, & GROUND.

YES

Page 47

46 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

46

.

12 – Error Code

Explanation: Commonly GAS SUPPLY and/or

VENTING. Unit detected the presence of flame and

then lost it.

Diagnostic Checks:

GAS SUPPLY & VENTING (refer to pages 8-11)

Flame rod(s)

(See maintenance mode instructions on page 21)

Connector Location

On Page 14

Turn Power OFF.

Remove and reinsert connector M; T;

and terminal on flame rod(s).

Turn Power ON.

While viewing through sight glass, operate unit to determine

IF flame is touching the flame rod(s).

Indoor models – 2 flame rods (Connectors M& T).

Outdoor models – 1 flame rod (Connector M).

Access maintenance mode

to check flame rod status &

continue to diagnostic chart

on next page.

YES

Remove any foreign debris.

IF foreign debris is not

present: CHECK GAS

SUPPLY & VENTING.

NO

HINT:: Make sure DIP2 (altitude setting) is properly

set – see Page 25

SIGHT GLASS

FLAME ROD(S)

Page 48

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 47

47

Test AC volts on

connector M

(Grey wire to Ground)

1 – 100 AC Volts

YES

Remove & reinsert M.

Operate unit again.

IF code 12 appears:

Replace control board.

NO

Test AC volts on connector

T(Blue wire to Ground)

1 – 100 AC Volts

YES

Remove & reinsert T.

Operate unit again.

IF code 12 appears:

Replace control board.

NO

Cycle unit ON; while in

maintenance mode, check

flame rod status under

table 0Y.

IF flame rod(s) is detecting

flame, maintenance mode

will display:

Indoor Models – 05

Outdoor Models - 01

YES

Clean flame rod(s). Operate

unit again. IF still does not

detect flame:

Replace flame rod(s).

NO

Flame rod(s) test OK.

CHECK GAS SUPPLY,

VENTING, & GROUND.

Outdoor: 1 flame rod

White Molex – Grey Wire

Indoor: 2 flame rods

White Molex – Grey Wire

Blue Molex – Blue Wire

Page 49

48 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

48

13 – Error Code

Explanation: Indoor units ONLY. Flame rod is

detecting poor combustion. This is commonly caused

by inadequate GAS SUPPLY and/or VENTING.

Diagnostic Checks:

GAS SUPPLY & VENTING (refer to pages 8-11)

Flame rod FL-2

(See maintenance mode instructions on page 21)

Turn Power OFF.

Remove and reinsert connector Tand

Terminals on flame rods.

Turn Power ON.

While viewing through sight glass, operate unit to determine

IF flame is touching the flame rod(s).

Indoor models – 2 flame rods

(Connectors M& T).

Access maintenance mode

to check flame rod status &

continue to diagnostic chart

on next page.

YES

Remove any foreign debris.

IF foreign debris is not

present: CHECK GAS

SUPPLY & VENTING.

NO

HINT: Make sure DIP2 (altitude setting) is properly

set – see Page 25

(If unit shuts down 5 times within a 4 hour period

due to 13 – Error Code, the unit must be

reset by performing reset procedure

on page 26).

Connector Location

On Page 14

SIGHT GLASS

FLAME ROD(S)

Page 50

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 49

49

Test AC volts on

connector T

(Blue wire to Ground)

1 – 100 AC Volts

YES

Remove & reinsert T.

Operate unit again.

IF code 13 appears:

Replace control board.

NO

Cycle unit ON; while in

maintenance mode, check

flame rod status under table

0Y. IF flame rod(s) is

detecting flame, maintenance

mode will display: 05

YES

Unit is operating correctly.

Burner and/or manifold

needed to be cleaned.

CHECK the area around the

air intake for the possible

cause of dirty manifold and/

or burner.

Flame rod(s) test OK.

Remove and clean the

manifold assembly and

burner assembly (How to

Remove: Sections 4 & 5).

Reassemble and operate

unit again.

Did Error Code - 13 appear?

YES

Clean flame rod(s). Operate

unit again. IF still does not

detect flame:

Replace flame rod(s).

NO

CHECK GAS SUPPLY,

VENTING, & GROUND.

Indoor: 2 flame rods

White Molex – Grey Wire

Blue Molex – Blue Wire

Page 51

50 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

50

14 – Error Code

Explanation: OHL (Over Heat Limiter) or Over Temp Limit

Switch activated. IF the OHL or Over Temp Limit Switch has

been activated, this is normally caused by inadequate/wrong

GAS SUPPLY and/or VENTING.

CHECK GAS SUPPLY & VENTING (refer to pages 8-11).

Diagnostic Checks:

OHL

High-Efficiency ONLY: Over Temp Limit

Switch (monitors vent temperature)

High-Efficiency Indoor (condensing) ONLY:

Locate the Over Temp Limit Switch (circled in red)

Connector Location

On Page 14

Turn Power OFF.

Remove & reinsert connector U.

Attempt to operate unit.

Does 14 – Error Code appear?

Continue to diagnostic chart

on next page.

YES

Unit had a loose connection

or over temp limit switch

cooled down. Unit appears

to be operating OK.

NO

Page 52

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 51

51

Turn power OFF. Remove

connector U. Measure

resistance across both White

wires:

50K – 500K OHMS

YES

Mid Efficiency ONLY:

Replace Unit.

High Efficiency

Indoor ONLY:

Continue to over

temp switch diagnostics.

(bottom of page)

NO

Reconnect connector U.

Attempt to operate unit.

YES

Unit had a loose connection.

Operation appears to be

normal.

IF error code 14 appears:

Replace control board.

NO

Over Temp Limit Switch - High Efficiency Indoor

(Condensing) ONLY:

Disconnect two White Molex

connectors for the over temp

limit switch.

On female end of Molex,

check continuity across both

Black wires.

YES

Switch automatically resets

once it cools down.

Allow limit switch to

cool down. IF switch does

NOT have continuity

once unit cools down:

Replace over temp

limit switch.

IF switch automatically

resets, check VENTING.

Limit switch possibly cooled

down. Operate unit.

IF error code 14 appears and

you have continuity through

Over Temp Limit Switch:

Replace Unit.

Page 53

52 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

52

15 – Error Code

Explanation: The hot water temperature and/or heat

exchanger temperature reached 207 degrees F for

more than 15 seconds.

Diagnostic Checks:

GAS SUPPLY & VENTING (refer to pages 8-11)

Sediment build-up in heat exchanger

Heat exchanger thermistor

Sediment Build-Up Diagnostics

Go to Error Code 1L for flushing instructions.

Heat Exchanger Thermistor Diagnostics

Go to Error Code - 32 for heat exchanger thermistor

diagnostic instructions.

IMPORTANT: Inadequate GAS SUPPLY and/or VENTING

will create hot spots in the heat exchanger.

Page 54

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 53

53

16 – Error Code

Explanation: Outlet water temperature is above the

set point on the remote control.

Diagnostic Checks:

Outlet thermistor

Water bypass valve

Outlet Thermistor Diagnostics:

Go to Error Code 33 for outlet thermistor diagnostic

instructions.

Water Bypass Valve Diagnostics:

Go to Error Code 66 for water bypass valve

diagnostic instructions.

IMPORTANT: Check the outlet thermistor FIRST.

Page 55

54 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

54

24 – Error Code

Explanation: Remote control buttons were

depressed for more than 20 seconds, release buttons

and operate unit. IF error code 24 appears again,

continue to remote control diagnostics.

Diagnostic Checks:

Remote control

Visually inspect remote

control wiring for damaged

or loose connections.

Is wiring OK?

YES

Tighten loose

Connections or replace

damaged wiring.

NO

Turn Power OFF & unplug

unit from power source.

Remove wires from wiring

terminals on remote control

and bottom of unit. Use a

new short piece of wire to

connect remote control

directly to wiring terminals at

bottom of unit.

Plug unit in, turn power ON

and open a hot water source.

Does 24 – Error Code

appear?

YES

Replace remote control.

Replace remote control

wiring

NO

Page 56

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 55

55

29 – Error Code (A)

Explanation: High-Efficiency (condensing) Units

ONLY: Condensation is NOT draining.

Diagnostic Checks:

Plug not removed from condensate drain

Pinch in condensate drain line

Blockage in condensate drain line

Drain line has unnecessary “P” trap

Condensate Drain Diagnostics:

1. Ensure you removed the condensate

protection plug located at bottom of unit &

attached a condensate drain line to the unit.

2. Check condensate drain line for internal or

external blockage. Make sure drain line is

NOT pinched.

3. Remove “P” trap on condensate drain line.

BOTTOM OF UNIT

Page 57

56 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

56

29 – Error Code (B)

Explanation: Heat exchanger temperature too low

for more than 3 minutes.

Diagnostic Checks:

Inlet & heat exchanger thermistors

Gas control valve

Water volume control valve

Inlet thermistor Diagnostics:

Go to 31 – Error Code.

Heat Exchanger thermistor Diagnostics:

Go to 32 – Error Code.

Turn power OFF.

Remove connector Rand

measure resistance across #1 wire (Red)

and #2 wire (Black):

40-80 OHMS

Remove connector K. Using the BLACK WIRE

as the common – Individually check resistance for

Yellow, White, Red, & Blue wires:

0.8K – 2.4K OHMS

Continue to diagnostic chart

on next page.

YES

Replace gas control valve.

NO

Connector Location

On Page 14

HINT: High-Efficiency (condensing) Units ONLY:

make sure condensate is draining properly

prior to continuing diagnostics

(go to previous page for diagnostics).

HINT: ALWAYS diagnose thermistors before

continuing to next steps.

Page 58

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 57

57

Calculate Temperature Rise & Gallons per Minute:

1. Enter maintenance mode & select table 3Y. Turn on

water flow to determine inlet water temperature.

2. Using the formula below, determine temperature rise.

Remote control temp - Incoming water temp = Temperature Rise

3. Select table 1Y. Using the incoming water shut off valve

Turn OFF incoming water at the unit. Turn ON ALL hot

water fixtures in the home/business to full flow. Using the

incoming water shut-off valve, turn ON incoming water at

unit. Determine MAX GPM flowing through unit.

*BEFORE continuing - Refer to pages 12 & 13 to obtain

MAX GPM possible for appropriate model number.

Maintenance Mode

Instructions on Page 21

With ALL hot water fixtures

turned ON full flow, will the

unit EXCEED MAX GPM it

can produce?

YES

Remove & reinsert C.

Operate unit again.

IF Code 29 appears:

Replace control board.

NO

Turn water & remote control

OFF. Turn remote control

ON. Open ALL hot water

fixtures. Measure DC Volts

across Black & White wires

on connector C:

8 – 16 DC Volts

YES

NO

Measure DC Volts across

black & red wires on

connector C:

8 – 16 DC Volts

YES

NO

Replace water volume

control valve.

Remove & reinsert C.

Operate unit again.

IF Code 29 appears:

Replace control board.

Remove & reinsert C.

Operate unit again.

IF Code 29 appears:

Replace control board.

Page 59

58 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

58

31 – Error Code

Explanation: Inlet thermistor malfunction.

Diagnostic Checks:

Inlet thermistor

Connector Location

On Page 14

Turn Power OFF.

Remove connector R. Measure resistance

between #3 wire (Black) & #6 wire (White):

7K – 23K Ohms

Reinsert connector R.

Operate unit.

IF Error Code 31 appears:

Replace control board.

YES

Remove control board

bracket to access inlet

thermistor Molex near

blower motor

(How to Remove: Section 1).

Continue diagnostics

on next page.

NO

CONTROL

BRACKET

Page 60

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 59

59

Locate & separate WHITE

Molex (located near blower

motor). Check resistance

across White wires on female

end of Molex:

7K – 23K Ohms

YES

Clean scale build-up on inlet

thermistor. Operate unit. IF

Error Code 31 appears:

Replace inlet thermistor.

NO

Reconnect Molex. Check

resistance on connector R

between #3 wire (Black) and

#6 wire (White):

7K – 23K Ohms

YES

Replace wiring harness for

connector R.

NO

Reinsert connector R.

Operate unit.

IF 31 - Error Code

appears:

Replace control board.

Blower Motor

Molex Connectors

Page 61

60 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

60

32 – Error Code

Explanation: Heat exchanger thermistor malfunction.

Diagnostic Checks:

Heat exchanger thermistor

Connector Location

On Page 14

Turn Power OFF. Remove connector R:

Mid-Efficiency Units ONLY: Measure resistance between

#3 wire (Black) & #5 wire (YELLOW):

High-Efficiency Units ONLY: Measure resistance between

#3 wire (Black) & #5 wire (GREEN):

7K – 23K OHMS

Reinsert connector R.

Operate unit.

IF Error Code 32 appears:

Replace control board.

YES

Remove control board

bracket to access heat

exchanger thermistor Molex

near

blower motor

(How to Remove: Section 1).

Continue diagnostics

on next page.

NO

CONTROL

BRACKET

Page 62

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 61

61

Locate & separate Yellow or

Green Molex (located near

blower motor). Check

resistance across White

wires on female end of

Molex:

7K – 23K Ohms

YES

Clean scale build-up on heat

exchanger thermistor.

Reassemble and operate

unit. IF Error Code 32

appears:

Replace heat exchanger

thermistor.

Reconnect Molex. Check

resistance on connector R

between #3 wire (Black) and

#5 wire (Yellow) OR #3 wire

(Black) and #5 wire (Green):

7K – 23K Ohms

YES

Replace wiring harness for

connector Ron control

board.

NO

Reinsert connector R.

Operate unit.

IF 32 - Error Code

appears:

Replace control board.

Blower Motor

Molex Connectors

Page 63

62 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

62

33 – Error Code

Explanation: Outlet thermistor malfunction.

Diagnostic Checks:

Outlet thermistor

Turn Power OFF.

Remove connector R:

Measure resistance between

#3 wire (Black) & #4 wire (RED):

7K – 23K OHMS

Reinsert connector R.

Operate unit.

IF Error Code 33 appears:

Replace control board.

YES

Remove control board

bracket to access outlet

thermistor Molex near

blower motor

(How to Remove: Section 1).

Continue diagnostics

on next page.

NO

Connector Location

On Page 14

CONTROL

BRACKET

Page 64

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 63

63

Blower Motor

Molex Connectors

Locate & separate Black

Molex (located near blower

motor). Check resistance

across White wires on female

end of Molex:

7K – 23K Ohms

YES

Clean scale build-up outlet

thermistor. Reassemble and

operate unit. IF Error Code

33 appears:

Replace outlet thermistor.

Reconnect Molex. Check

resistance on connector R

between #3 wire (Black) and

#4 wire (Red):

7K – 23K Ohms

YES

Replace wiring harness for

connector Ron control

board.

NO

Reinsert connector R.

Operate unit.

IF 33 - Error Code

appears:

Replace control board.

Page 65

64 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

64

34 – Error Code

Explanation: Ambient thermistor malfunction.

Diagnostic Checks:

Ambient thermistor

Turn Power OFF. Remove connector R:

Measure resistance between

#3 wire (Black) & #7 wire (Blue):

64DV; 84DV; 95DV: 7K – 23K Ohms

64X; 84X; 95X; H95X; H95DV: 2K – 72K Ohms

Reinsert connector R.

Operate unit.

IF Error Code 34 appears:

Replace control board.

YES

Remove control board

bracket to access ambient

thermistor Molex near

blower motor

(How to Remove: Section 1).

Continue diagnostics

on next page.

NO

Connector Location

On Page 14

CONTROL

BRACKET

Page 66

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 65

65

Locate & separate Blue

Molex (located near blower

motor). Check resistance

across White wires on female

end of Molex:

2K – 72K Ohms

7K – 23K Ohms

YES

Clean scale build-up ambient

thermistor. Reassemble and

operate unit. IF Error Code

34 appears:

Replace ambient thermistor.

NO

Reconnect Molex. Check

resistance on connector R

between #3 wire (Black) and

#7 wire (Blue):

2K – 72K Ohms

7K – 23K Ohms

YES

Replace wiring harness for

connector Ron control

board.

NO

Reinsert connector R.

Operate unit.

IF 34 - Error Code

appears:

Replace control board.

Blower Motor

Molex Connectors

Page 67

66 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

66

35 – Error Code

Explanation: Improper thermistor connection. Unit

has four thermistors; one or more possibly has a poor

connection or not connected in proper location.

Diagnostic Checks:

Inlet, heat exchanger, outlet, & ambient

thermistors

Connector Location

On Page 14

Turn Power OFF. Remove connector R.

Turn Power ON. Operate Unit.

Does 35 – Error Code Appear?

Test ALL thermistors.

Follow Instructions for:

31 – Error Code

32 – Error Code

33 – Error Code

34 – Error Code

YES

Unit had a loose connection.

Thermistors appear to be

OK.

NO

Page 68

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 67

67

(See maintenance mode instructions on page 21)

51 – Error Code

Explanation: Gas control valve malfunction. Unit

detected the presence of flame when demand for hot

water terminated & the unit turned OFF.

Diagnostic Checks:

Flame rod(s)

Gas control valve

Connector Location

On Page 14

Turn Power OFF.

Remove and reinsert connector M, T,

and terminal on flame rod(s).

Turn Power ON. Operate unit.

Did 51 – Error Code appear?

Indoor models – 2 flame rods (Connectors M& T).

Outdoor models – 1 flame rod (Connector M).

Access maintenance mode

to check flame rod status.

Locate sight glass.

Continue to diagnostic chart

on next page

YES

Unit had a loose connection

or foreign debris that is no

longer present.

Thermistors appear to be

OK.

NO

Connector Location

On Page 14

SIGHT GLASS

FLAME ROD(S)

Page 69

68 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

68

While viewing burner

chamber through sight glass:

In 10 second intervals, cycle

unit 3 times -

ON-OFF; ON-OFF; ON-OFF

Determine if flame is visible

when OFF.

YES

Follow maintenance mode

instructions at bottom of

page & continue to

diagnostics on next page.

NO

Visually inspect burner

chamber through sight glass

for foreign debris.

YES

Operate unit.

IF 51 – Error Code appears &

flame IS visible while unit has

been OFF longer than 5

seconds:

Replace gas control valve.

NO

Remove and clean

burner assembly

On remote control, go to maintenance mode 0Y table. For

maintenance mode instructions go to page 21.

All maintenance mode ‘0Y’ readings should be done

immediately after turning the unit OFF. IF Flame Rod(s) is

detecting flame, maintenance mode will display:

Indoor Units: 05

Outdoor Units: 01

Outdoor: 1 flame rod

Indoor: 2 flame rods

Open a hot water fixture

and use shut-off

valve at the unit to

cycle unit On-Off.

Page 70

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 69

69

In 10 second intervals, cycle

unit 3 times by turning unit:

ON-OFF; ON-OFF; ON-OFF

Does 0Y status in

maintenance mode indicate

presence of flame while unit

has been off >5 seconds?

YES

Follow maintenance mode

instructions at bottom of

page & continue to

diagnostics on next page.

NO

Disconnect wires at flame

rod(s). While viewing burner

chamber through sight glass:

In 10 second intervals, cycle

unit 3 times by turning unit:

ON-OFF; ON-OFF; ON-OFF

Does 0Y status in

maintenance mode indicate

presence of flame while unit

has been off >5 seconds?

YES

Clean flame rod(s).

IF 51 – Error Code appears

after cleaning flame rod(s):

Replace flame rod(s).

Replace control board.

On remote control, go to maintenance mode 0Y table.

For maintenance mode instructions go to page 21.

All maintenance mode ‘0Y’ readings should be done

immediately after turning the unit OFF.

IF Flame Rod(s) is detecting flame, maintenance mode will

display:

Indoor Units: 05

Outdoor Units: 01

Page 71

70 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

70

52 – Error Code

Explanation: PGFR malfunction. The PGFR is

the only modulating valve in the gas control valve.

Diagnostics: PGFR (Proportional Gas Flow Regulator)

Connector Location

On Page 14

Turn Power OFF.

Remove and reinsert connector R.

Locate PGFR valve on lower right side of

unit (round black piece on bottom of gas control valve).

Remove and reinsert Molex connectors with Red and Black

wires on PGFR.

Operate unit.

While viewing through sight glass,

determine if flame is visible.

Unit had a loose connection

Gas control valve is OK.

_______________________

IF 52 – Error Code appears

and flame IS visible:

Replace gas control valve

YES

Continue diagnostics on

next page.

NO

PGFR

Page 72

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 71

71

While unit is attempting to

ignite:

Check DC volts across

#1 wire (Red) and #2 wire

(Black) on connector R:

1.5 – 14 DC Volts

YES

Remove & reinsert R.

Operate unit.

If 52 – Error Code appears:

Replace control board.

NO

While unit is attempting to

ignite:

Check DC volts across Red

and Black wires at PGFR:

1.5 – 14 DC Volts

YES

Replace wiring harness for

connector Ron control

board.

NO

Make sure Black & Red wires

are properly connected to

PGFR. Operate unit.

IF 52 - Error Code appears:

Replace gas control valve.

PGFR

RED & BLACK

WIRES

Page 73

72 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

72

NOTES:

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

_________________________

Page 74

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 73

73

Explanation: The Blower motor speed was not

appropriate to allow proper combustion.

Diagnostic Checks:

Blower motor

61 – Error Code

Turn Power OFF.

Remove control board bracket (How to Remove: Section 1).

Remove blower motor (How to Remove: Section 2).

Clean blower motor and blower motor housing.

Reassemble & operate unit.

Does 61 – Error Code appear?

Locate MIN & MAX buttons

on upper right- hand corner

of control board.

Continue diagnostics on next

page

YES

Unit had a loose connection.

Unit appears to be operating

OK.

NO

MIN & MAX

BUTTONS

CONTROL

BRACKET

Page 75

74 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

74

Blower Motor Diagnostics:

Indoor Models ONLY

Upper Right-Hand Corner of Control Board

Test DC voltage across

Black and Red wires

on connector G:

144 – 192 DC Volts

YES

Remove & reinsert G.

Operate unit again.

IF Code 61appears:

Replace control board.

NO

Hold down MAX button.

Test DC voltage across

Black & White wires

on connector G:

12 – 18 DC Volts

YES

Remove & reinsert G.

Operate unit again.

IF Code 61 appears:

Replace control board.

NO

Hold down MAX button.

Test DC voltage across

Black & Blue wires

on connector G:

4 – 10 DC Volts

YES

Remove & reinsert G.

Operate unit again.

IF Code 61 appears:

Replace blower motor.

NO

Control board and blower

motor are OK.

CHECK GAS SUPPLY AND

VENTING.

IMPORTANT: While performing voltage checks, DO NOT touch

multimeter leads across BLUE & White wires. Damage may occur

to blower motor and control board.

Connector Location

On Page 14

MIN

MAX

Page 76

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 75

75

Blower Motor Diagnostics:

Outdoor Models ONLY

Upper Right-Hand Corner of Control Board

IMPORTANT: While performing voltage checks, DO NOT touch

multimeter leads across YELLOW & RED wires. Damage may

occur to blower motor and control board.

Test DC voltage across

Blue and White wires

on connector G:

144 – 192 DC Volts

YES

Remove & reinsert G.

Operate unit again.

IF Code 61 appears:

Replace control board.

NO

Hold down MAX button.

Test DC voltage across

Blue & Red wires

on connector G:

12 – 18 DC Volts

YES

Remove & reinsert G.

Operate unit again.

IF Code 61 appears:

Replace control board.

NO

Hold down MAX button.

Test DC voltage across

Blue & Yellow wires

on connector G:

4 – 10 DC Volts

YES

Remove & reinsert G.

Operate unit again.

IF Code 61 appears:

Replace blower motor.

NO

Control board and blower

motor are OK.

CHECK VENTING.

Connector Location

On Page 14

MIN

MAX

Page 77

76 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

76

Turn on all hot water fixtures to activate water control valve

(refer to 29 – ErrorCode (B) Page 56).

Explanation: Water volume control valve

malfunction.

Diagnostic Checks:

Water volume control valve

65 – Error Code

Blower Motor

Connector Location

On Page 14

Turn Power Off, Remove & Reinsert connector C.

Remove control board bracket. (How to remove: Section 1)

Visually inspect water volume control valve for

loose or damaged connections

Reassemble & operate unit.

Does 10-Warning Code appear?

Locate MIN & MAX buttons

on upper right-hand corner of

control board.

Continue diagnostics on next

page.

YES

Blower motor needed to be

cleaned or you had a loose

connection.

Unit appears to be operating

OK.

NO

IMPORTANT: The water volume control valve will only activate IF

demand for hot water EXCEEDS the units limitations. If water flow

is within the units limitations, you will not get a voltage reading for

diagnostics.

Water volume control

valve, located to right of

blower motor, connected

directly to water inlet.

Page 78

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 77

77

While water is flowing & unit

is attempting to ignite; check

DC volts across White &

Black wires at connector C:

8 – 16 DC Volts

YES

Check connector C.

Operate unit again. IF code

65 appears:

Replace control board.

NO

Turn Power OFF then ON.

While water is flowing & unit

is attempting to ignite; check

DC volts across Red & Black

wires at connector C:

8 – 16 DC Volts

YES

Check connector C.

Operate unit again. IF code

65 appears:

Replace control board.

NO

Turn Power OFF then ON.

While water is flowing & unit

is attempting to ignite; check

DC volts across Green &

Black wires at connector C:

4 – 6 DC Volts

YES

Check connector C.

Operate unit again. IF code

65 appears:

Replace control board.

NO

Operate unit. IF 65 – Error

Code appears:

Replace water volume

control valve..

CAUTION: Hot water temperatures above

120 will scald. Return to original setting

once test is complete.

If voltages are NOT

registering, ATTEMPT to

activate water volume control

valve by turning remote control

to highest temperature

setting & opening all

hot water fixtures.

Page 79

78 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

78

Turn Power OFF. Remove

and reinsert connector B.

Remove control board

bracket (How to Remove:

Section 1). Visually inspect

water bypass valve for loose

or damaged connections.

Reassemble & operate unit.

Does 66 – Error Code

appear?

YES

Unit had a loose connection.

Unit appears to be operating

OK

NO

Turn remote control OFF;

unplug unit. Plug unit in.

Turn Power ON. Operate

unit. Check DC volts across

Red & Black wires at

connector B:

8 – 16 DC Volts

YES

Check connector B.

Operate unit again.

IF 66 – Error Code appears:

Replace control board.

NO

Operate unit.

IF 66 – Error Code appears:

Replace water bypass valve.

IMPORTANT: Prior to measuring voltage, turn remote

temperature down to 102 degrees. Water bypass valve will

activate at this time.

66 – Error Code

Explanation: Water by-pass valve malfunction.

Diagnostic Checks:

Water bypass valve

For water bypass valve

location: Refer to 65 -

Error Code diagram.

Water bypass valve is

located right of blower

motor; connected directly

to bottom of two copper

pipes.

Connector Location

On Page 14

Page 80

S V C 8 2 0 ( P ) P o c k e t M a n u a l P a g e 79

79

Explanation: Gas control valve malfunction

(inlet solenoid).

Diagnostic Checks:

Gas control valve

71 – Error Code

Connector Location

On Page 14

Turn Power OFF. Remove

and reinsert connector K.

Operate unit.

Does 71 – Error Code

appear?

YES

Unit had a loose connection.

Unit appears to be operating

OK

NO

While unit is attempting to

ignite; check DC voltage

across Yellow & black wires

on connector K:

90 – 120 DC Volts

YES

Check connector K.

Operate unit again.

IF 71 – Error Code appears:

Replace control board.

NO

Operate unit.

IF 71 – Error Code appears:

Replace gas control valve.

GAS VALVE

Page 81

80 | P a g e S V C 8 2 0 ( P ) P o c k e t M a n u a l

80

NOTES:

_________________________