Page 1

Gas Hot Water Supply Heaters

Available in Indoor and Outdoor Models

136,000 thru 1,826,000 BTU/Hr.

Rheem-Ruud hot water supply heaters are designed to provide hot water service to a variety of commercial applications

when used in conjunction with an appropriately sized storage

tank. These models are particularly suited for applications that

require high inputs and large volumes of stored hot water.

Construction Features:

• Reliable heat exchanger

Design – The all copper

heat exchanger is a single

bank, straight-through

design with a floating

return header immune to

thermal shock.

• Energy saving pump

control – The energy

saving pump control is an

electric device that allows

the operator to set the

desired time for the pump

to run after the water

heater shuts off. With the

energy saving pump control the water heater pump

is programmed to continue running for an optimum

period of time in order to

absorb the residual heat

from the combustion

chamber and use it in the

system.

• Compact design –

The low water heater

mass design offers

substantial savings in

weight and cube over

most cast iron, steel tube

and storage-type water

heaters making it ideal

for rooftop installations

and in tight quarters.

• Minimal heat loss design

– Spark-to-pilot (IID)

system is standard on

all models.

• Glasslined cast iron

headers –

To handle aggressive

water conditions. (Models

GBBP/GBB136 feature

bronze headers.)

Certifications and Ratings:

•

Efficiency – These models have been tested according to ANSI

test procedures, and meet or exceed the 80% thermal efficiency

requirement of current ASHRAE standards (Part of the Federally

mandated Energy Policy Act (EPact)). Also exceeds energy

efficiency codes of all states.

•

Safety and Construction – These products are design certified

by the CSA: a) As a Hot Water Supply Water Heater equipped

with on/off controls for use in conjunction with a storage tank. b)

For operation at 180°F. c) To meet all safety and construction

requirements of ANSI Z21.10.3.c) For installation on combustible

flooring when used with a combustible floor base, and, or e) for

alcove installation. ASME construction is standard on all models.

Certified for a 160 PSI Maximum Working Pressure.

Continued next page.

Indoor and Outdoor

Models

Pump Mounted Models

Available

5 Year Limited Warranty

Indoor Models

Page 2

Reliability

• Like all of our water heating products,

Rheem-Ruud hot water supply

heaters are crafted to exacting standards. Each detail of design, engineering and construction must meet

our criteria for performance and durability.

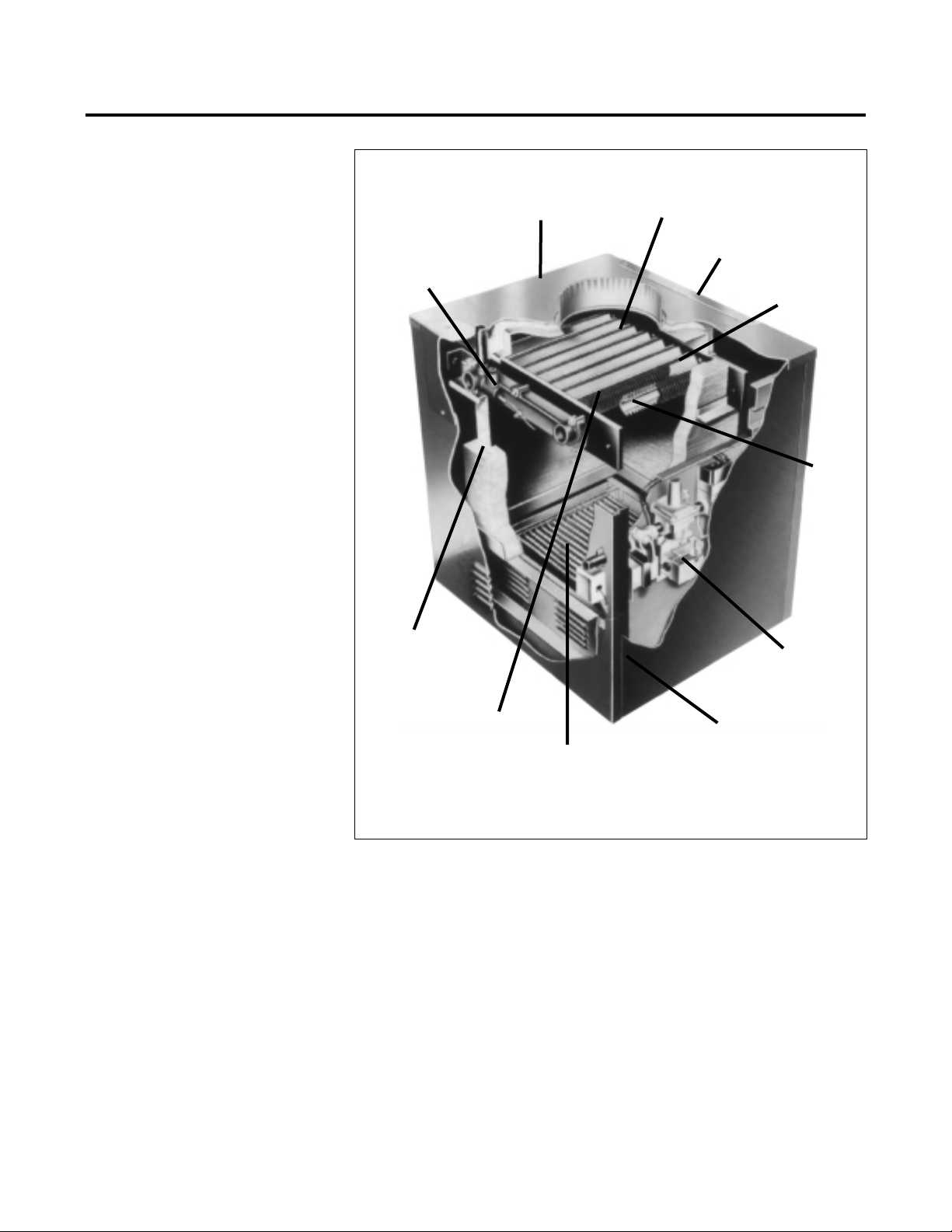

• The heat exchanger (1), for example,

is constructed of 100% copper. High

Velocity hydraulics (2) virtually eliminates problems of scaling and corrosion within its waterways. The cast

iron headers (3) are glass-lined to

assure that the entire heat exchanger

assembly is resistant to corrosion.

• Every Rheem-Ruud hot water supply

heater features titanium stainless

steel burners (4). They operate quietly, will not clog or corrode, and have

far greater temperature resistance

than cast iron. The controls (5) are

factory adjusted and completely

enclosed for reliable, automatic

operation.

• The outer jacket (6) is galvanized

and enamel baked for lasting

aesthetics.

Efficiency

• Today’s demands for volume hot water

must be met economically, so we’ve

attempted to use every fuel saving

technique conceivable. The resulting

82% efficiency will save you money in

fuel costs for years to come.

• The integral finned copper tubing

(7) in the heat exchanger provides

nine times more heat transfer area

than smooth tubing. Efficiency is

boosted even further by V-baffles (8),

which redirect the heat across the

finned tubing. The insulated combus-

tion chamber (9) features corner

sealed and interlocking refractory

panels to minimize chamber radiation

losses.

• Economy is further enhanced with a

special energy saving pump control.

This automatic control continues to

pump operation until all usable heat

has been absorbed from the combustion chamber and stored in the tank.

• Access to water heater for inspection

is simple. All Rheem-Ruud hot water

supply heaters feature a heat

exchanger inspection panel (10)

and a removable door to access the

slide out burner drawer (11).

Flexibility

• You’ll find that Rheem-Ruud hot

water supply heaters are perfectly

suited for many commercial, industrial and special application needs

requiring economical, reliable supplies of hot water. The optional factory supplied pump is designed to

handle nearly all water conditions

• Our standard sized water heaters –

nine models ranging from 136,000 to

825,000 BTU – are designed for hot

water supply in commercial applications. Each model is available for

indoor and outdoor installation. The

outdoor models feature a special

draft system which is wind, rain and

debris-proof.

• Our large sized water heaters –

seven indoor and seven outdoor

models ranging from 926,000 to

1,825,600 BTU – meet the heavier

demand of larger multi-family housing and commercial applications.

They are ideal for use as summer

replacement water heaters, eliminating the need to fire large central

heating water heaters merely to supply domestic hot water.

• All of these Rheem-Ruud hot water

supply heaters are compact and

convenient; they save space, fuel

and installation cost.

1

100% copper

heat exchanger

10

heat exchanger

inspection panel

6

galvanized and

baked enamel jacket

3

cast-iron glasslined headers,

easily removable

8

high efficiency

“V” baffles

7

integral

finned

copper

tubing

5

totally

enclosed

automatic

controls

11

removable door

for access to

slide out

burner drawer

4

precision titanium

stainless steel

burners

2

high velocity

hydraulics

9

corner sealed

and interlocked

combustion

chamber

Three Important Reasons to Choose Hot Water Supply Heaters

from Rheem-Ruud Commercial Water Heaters

Page 3

JACKET INSULATED STORAGE TANKS BY RHEEM-RUUD (All dimensions shown in inches)

Connections Approx. Shipping

Capacity Overall Connection Circulating Relief Valve Weight (Lbs.)

Model Gallons Height Diameter Hot Outlet Line Connection Standard ASME

ST80(A) 80 58-5/16 24-7/16

221

220 260

ST120(A) 115 59-1/4 28-1/4 2 2 1 260 340

ST175(A) 175 67-1/4 32-1/4 2-1/2 2-1/2 1 600 600

ST200A 200 77-1/4 32 2 2-1/2 1 N/A 500

ST260A 257 95-1/2 34 2 3 1-1/4 N/A 1108

ST320A 318 84-1/2 40 2 3 1-1/4 N/A 1290

ST430A 432 84-1/2 46 2 3 1-1/4 N/A 1626

ST500A 504 94-1/2 46 2 3 1-1/4 N/A 1765

ST750A 752 107-1/2 54 2 3 1-1/4 N/A 2330

ST950A 940 131-1/2 54 2 3 1-1/4 N/A 3010

These storage tanks meet standby loss requirements of ASHRAE 90.1b-1992.

(A) ASME code constructed tanks available as an option.

Consult specification sheet for complete details.

RECIRCULATION

PUMP

(BY OTHERS)

RECIRCULATION

DRAIN

OPENING

THERMOMETER

HOT WATER SUPPLY

INDOOR

MODELS

OUTDOOR

MODELS

•• OPTIONAL

INTEGRAL PUMP

ON MODELS 512 - 1826

COLD WATER

A

TANKSTAT

LOCATION

Example System

MINIMUM PIPE SIZE

Model Dimension

Size A

136 1-1/4"

186-399 1-1/2"

512-825 2"

926-1826 2-1/2"

WATER HEATER

SHOWN REPRESENTS VARIOUS

MODELS.

BECAUSE MODELS WILL VARY IN

DRAFT HOOD

DESIGN AND SIZE.

SEE SPECIFIC

WATER HEATER

INFORMATION

FOR DETAILS.

Guaranteed 80% draw without temperature drop,

using Rheem-Ruud water heaters, tanks, sizing tables and hook-up data.

PUMP AND BALL VALVE LOCATION ON

MODELS 136 THRU 399

•• OPTIONAL ON MODELS

512 THRU 1826 WITHOUT INTEGRAL PUMP

PRESSURE

RELIEF VALVE

UNION

BALL VALVE

GATE VALVE

CHECK VALVE

PUMP

KEY

NOTES:

1. PLUMB SWING CHECK VALVE IN GRAVITY CLOSED POSITION.

2. MINIMUM PIPE EQUAL TO WATER HEATER INLET/OUTLET

CONNECTION SIZE BETWEEN WATER HEATER AND TANK(S)

3. PIPE ALL RELIEF VALVES TO DRAIN, OR AS LOCAL CODES

REQUIRE

Page 4

SPECIFICATIONS AND DIMENSIONS

MODEL NUMBER STYLE MBTUH NATURAL GAS (X 1000) DIMENSIONS (INCHES) SHIPPING WEIGHT††

Ref. With- Height Jacket Gas Flue

to out With In- Out- (indoor) (outdoor) Width Overall Height Conn. Dia.

Dwg. Pump Pump door door Input Output Input Output A B C G J K L M N (Indoor) (Outdoor)

1 GBB136* GBBP136* • • 136.0 112.0 136.0 112.0 241⁄8 45.0 301⁄81⁄2 –691⁄4 101⁄4 31⁄2 195 195

GBC186** GBCP186** • • 181.0 148.0 181.0 148.0 18

1

⁄

4 40.0 38

3

⁄

4 12

1

⁄

16 6 – – – 191 200

GBC264** GBCP264** • • 264.0 216.0 264.0 216.0 22

3

⁄8 40.0 38

3

⁄4 111⁄8 7 – – – 214 220

2

GBC331** GBCP331** • • 334.0 274.0 334.0 274.0 25

3

⁄4 40.0 38

3

⁄4 103⁄4 8 – – – 234 240

GBC399** GBCP399** • • 399.0 327.0 399.0 327.0 29

1

⁄

4 40.0 38

3

⁄

4 12

1

⁄

2 9 – – – 253 260

GBC512 GBCP512 • • 511.5 419.4 511.5 419.4 32

3

⁄4 57.0 33 1 – 10 253⁄8 – – 510 535

GBC627 GBCP627 • • 627.0 514.1 627.0 514.1 37

1

⁄2

57.0 33 1 – 12 29

1

⁄2

– – 520 545

3

GBC726 GBCP726 • • 726.0 595.4 726.0 595.4 41

5

⁄8

57.0 33 1 – 12 34

1

⁄4

– – 630 685

GBC825 GBCP825 • • 825.0 676.5 825.0 676.5 45

3

⁄4

57.0 33 1 – 14 38

1

⁄2

– – 660 720

GBC926 GBCP926 – • – – 926.0 759.3 52

3

⁄8

– – 1––––– – 790

GBC962 GBCP962 • – 961.7 788.6 – – 52

3

⁄8

68

3

⁄4

33

1

⁄2

1 18 14 28 – – 760 –

GBC1083 GBCP1083 – • – – 1083.0 888.1 59

1

⁄4

– – 1––––– – 850

GBC1125 GBCP1125 • – 1124.7 922.2 – – 59

1

⁄4

74

1

⁄2

33

1

⁄2

125

5

⁄8

16 32 – – 800 –

GBC1178 GBCP1178 – • – – 1178.0 966.0 63

5

⁄8

– – 1––––– – 910

GBC1223 GBCP1223 • – 1222.5 1002.4 – – 63

5

⁄8

74

1

⁄2

33

1

⁄2

123

5

⁄8

16 32 – – 860 –

GBC1287 GBCP1287 – • – – 1287.0 1055.3 68

5

⁄

8 ––1

1

⁄

4 – – – – – – 975

4

GBC1337 GBCP1337 • – 1336.6 1096.0 – – 68

5

⁄

8 76

1

⁄

2 33

1

⁄

2 1

1

⁄

4 23

5

⁄

8 18 36 – – 930 –

GBC1413 GBCP1413 – • – – 1413.0 1158.7 74

7

⁄8 ––1

1

⁄4 – – – – – – 1065

GBC1467 GBCP1467 • – 1467.0 1202.9 – – 74

7

⁄8 761⁄2 331⁄2 11⁄4 235⁄8 18 36 – – 1000 –

GBC1570 GBCP1570 – • – – 1570.0 1287.4 81

1

⁄

8 ––1

1

⁄

4 – – – – – – 1120

GBC1630 GBCP1630 • – 1630.0 1336.5 – – 81

1

⁄8 791⁄2 361⁄2 11⁄4 235⁄8 18 36 – – 1040 –

GBC1758 GBCP1758 – • – – 1758.0 1441.6 89

3

⁄8 ––1

1

⁄4 – – – – – – 1150

GBC1826 GBCP1826 • – 1825.6 1496.9 – – 89

3

⁄

8 81

1

⁄

2 36

1

⁄

2 1

1

⁄

4 23

5

⁄

8 20 40 – – 1090 –

* Equipped with bronze headers, all other models have glasslined cast iron headers. GBC – cast iron headers. GBB – bronze headers.

†† Subtract 55 lbs. when ordering GBC models.

** Low NOx models add “N” after model number. Outdoor models add “-O” after model number.

Indicate Natural or LP when ordering.

MBTUH PROPANE GAS†

Model

Size Multiplier

136-399 Same as natural gas

512-825 .94

926-1826 .92 Indoor

.955 Outdoor (input)

.92 Outdoor (output)

† Multiplier x Nat. MBTUH = Pro. MBTUH

ELECTRICAL RATINGS

Model

Size With Pump

136-399 3.7 amps @ 120V (1/8 hp pump)

331-399 3.6 amps @ 120V (1/6 hp pump)

512-1826 7.2 amps @ 120V (1/2 hp pump)

MIN. CLEARANCES TO COMBUSTIBLE SURF.

Model Left Right

Top

Size Rear Side Side Indoor Outdoor

136 12" 12" 6" 42" Unobstr.

186-399 12" 12" 12" 39" Unobstr.

512-825 12" 18" 6" 36" Unobstr.

926-1826 24" 24" 24" 24" Unobstr.

For servicing provide 24" minimum unobstructed clearance

in front of unit.

OUTLET

INLET

REAR VIEW

B

L

14

1

/2

10

1

/2

3

1

/4

15

3

/8

7

1

/4

1

1

/4

38

1

/2

24

1

/4

FRONT VIEW

4

7

/8

4

3

/4

C

K

A

G

GAS

ELEC.

CONN.

INDOOR OUTDOOR

UP FRONT

CONTROLS

2

2

OPTIONAL

ON INDOOR

COMBUSTIBLE

FLOOR SHIELD

OUTLET INLET

OUTDOORINDOOR

B

C

28

1

/4

44

1

/8

29

1

/2

11

1

/8

2

1

/4

6

14

3

/4

17

G

GAS

2

K

A

18

14

1

/2

2

1

/4

5

L

A

2

COMBUSTIBLE

FLOOR SHIELD

ELEC

CONN

OPTIONAL

ON INDOOR

K

68-3/4

INDOOR

DRAFT

(B)

STACKLESS

OUTDOOR TOP

PUMP COVER

(OPTIONAL

OUTDOOR

MODELS ONLY)

21-1/4

ELECTRIC

CONNECTION

13-1/4

GAS

CONNECTION

3/4 NPT

GAS

CONNECTION

1-1/2 NPT

WATER

CONNECTION

J

(C)

26-1/2

26-1/2

8-1/2

3-7/8

A

10-1/4

9-7/8

PUMP

(OPTIONAL)

OUTLET

INLET

A

K

B

A

2

18

14

1

/2

11/8

51/8

21/2

273/4

21/2

463/4

321/2

111/4

113/4

111/8

C

J

14

6

G

GAS

5

/8

5

18

OUTDOOR

OPTIONAL

ON INDOOR

OUTLET INLET

COMBUSTIBLE

FLOOR SHIELD

ELEC

CONN

INDOOR

DRAWING 1 DRAWING 2

DRAWING 3 DRAWING 4

Page 5

RECOVERY CAPACITIES

MODEL NUMBER STYLE

INPUT BTU/Hr.

TEMPERATURE RISE – DEGREES F – GALLONS PER HOUR

wo/Pump w/Pump Indoor Outdoor

NATURAL

40° 50° 60° 70° 80° 90° 100° 110° 120° 130° 140°

GBB136 GBBP136 * * 136,000 330 264 220 188 165 147 132 120 110 101 94

GBC186 GBCP186 * * 181,000 440 352 293 251 220 195 176 160 147 135 126

GBC264 GBCP264 * * 264,000 640 512 427 366 320 284 256 233 213 197 183

GBC331 GBCP331 * * 334,000 811 649 541 463 406 360 324 295 270 250 232

GBC399 GBCP399 * * 399,000 967 774 645 553 484 430 387 352 322 298 276

GBC512 GBCP512 * * 511,500 1240 992 827 709 620 551 496 451 413 382 354

GBC627 GBCP627 * * 627,000 1520 1216 1013 869 760 676 608 553 507 468 434

GBC726 GBCP726 * * 726,000 1760 1408 1173 1006 880 782 704 640 587 542 503

GBC825 GBCP825 * * 825,000 2000 1600 1333 1143 1000 889 800 727 667 615 571

GBC926 GBCP926 * 926,000 2245 1796 1497 1283 1122 998 898 816 748 691 641

GBC962 GBCP962 * 961,700 2331 1865 1554 1332 1166 1036 933 848 777 717 665

GBC1083 GBCP1083 * 1,083,000 2625 2100 1750 1500 1313 1167 1050 955 875 808 750

GBC1125 GBCP1125 * 1,124,700 2727 2181 1818 1558 1363 1212 1091 991 909 839 779

GBC1178 GBCP1178 * 1,178,000 2856 2285 1904 1632 1428 1269 1142 1038 952 879 816

GBC1223 GBCP1223 * 1,222,500 2964 2371 1976 1694 1482 1317 1185 1078 988 912 847

GBC1287 GBCP1287 * 1,287,000 3120 2496 2080 1783 1560 1387 1248 1135 1040 960 891

GBC1337 GBCP1337 * 1,336,600 3240 2592 2160 1852 1620 1440 1296 1178 1080 997 926

GBC1413 GBCP1413 * 1,413,000 3425 2740 2284 1957 1713 1522 1370 1246 1142 1054 979

GBC1467 GBCP1467 * 1,467,000 3556 2845 2371 2032 1778 1581 1423 1293 1185 1094 1016

GBC1570 GBCP1570 * 1,570,000 3806 3045 2537 2175 1903 1692 1522 1384 1269 1171 1087

GBC1630 GBCP1630 * 1,630,000 3952 3161 2634 2258 1976 1756 1581 1437 1317 1216 1129

GBC1758 GBCP1758 * 1,758,000 4262 3409 2841 2435 2131 1894 1705 1550 1421 1311 1218

GBC1826 GBCP1826 * 1,825,600 4426 3541 2950 2529 2213 1967 1770 1609 1475 1362 1264

GENERAL FLOW AND PIPING SPECIFICATIONS

Water Hardness

MODELS SOFT MEDIUM HARD

0-4 Grains Per Gallon 5-15 Grains Per Gallon 16 & Over Grains Per Gallon

Indoor Outdoor

T GPMP MPS SHL

T GPMP MPS SHL

T GPMP MPS SHL

136 136 22 10 3.4 1-1/4 5.09 17 13 5.5 1-1/4 8.2 10 22 14.7 1-1/4 22

186 186 15 20 1.82 1-1/2 4.48 11 26 3 1-1/2 7.5 7 40 6.8 1-1/2 17

264 264 21 20 1.85 1-1/2 4.51 16 26 3.1 1-1/2 7.6 10 42 8.3 1-1/2 18.8

331 331 27 20 1.9 1-1/2 4.56 20 26 3.2 1-1/2 7.7 13 42 8.5 1-1/2 19

399 399 30 22 2.1 1-1/2 5.08 25 26 3.3 1-1/2 7.8 15 43 9 1-1/2 19.5

512 512 20 42 1.8 2 4.4 16 52 2.9 2 7 10 84 6.8 2 16.6

627 627 25 41 1.9 2 4.5 19 54 3.1 2 7.2 11 90 8.5 2 20.4

726 726 29 41 2 2 4.6 20 60 4 2 9.3 13 90 9 2 20.8

825 825 30 45 2.5 2 5.7 20 68 5.2 2 11.7 15 90 9.3 2 21.1

962 926 30 53 3.5 2-1/2 4.9 20 79 7.5 2-1/2 10.5 17 90 10.1 2-1/2 14.3

1125 1083 30 61 5.5 2-1/2 7.5 20 90 11.8 2-1/2 16 20 90 11.8 2-1/2 16

1223 1178 30 67 6.5 2-1/2 8.8 22 90 12 2-1/2 16.2 22 90 12 2-1/2 16.2

1337 1287 30 73 8.4 2-1/2 11 24 90 13.3 2-1/2 17.5 24 90 13.3 2-1/2 17.5

1467 1413 30 80 10.8 2-1/2 14.1 26 90 13.8 2-1/2 18 26 90 13.8 2-1/2 18

1630 1570 30 89 13.7 2-1/2 17.6 29 90 14.8 2-1/2 19 29 90 14.8 2-1/2 19

1826 1758 32 90 15.5 2-1/2 19.7 32 90 15.5 2-1/2 19.7 32 90 15.5 2-1/2 19.7

NOTE: Additional pipe fittings will increase the system head loss. Select a pump based on the water hardness, flow and system head loss. If water heater is

more than two stories above the tank, consult the pump manufacturer.

T – Temperature Rise, Degree F @ GPM Flow

GPM – Gallons per Minute Flow

P – Pressure Drop, Ft. thru Heat Exchanger

MPS – Minimum Pipe Size, NPT

SHL – System Head Loss

Sizing based on water heater and tank being placed 5 feet apart. The

equivalent length of pipe valves and fittings in the system is as follows.

1-1/4" NPT = 65 Ft (136)

1-1/2" NPT = 70 Ft (186-399)

2" NPT = 75 Ft (512-825)

2-1/2" NPT = 80 Ft (926-1826)

Page 6

Gas Hot Water Supply Heaters

Heat Exchanger

• Finned Copper Tubes

• ASME Steel Tubesheet

• Silicon O-Rings

• 125 PSIG ASME Pressure Relief Valve

• Glasslined Cast Iron Headers

Controls

• Energy Saving Pump Control

• Flow Switch

• Spark-to-Pilot Ignition System

• High Limit Control

• On/Off Switch

• Flue Gas Spillage Sensor

• Flame Roll-Out Sensor

Gas Control Train

• Manual Gas Shut-Off Cock

• Main Gas Pressure Regulator

• Safety Shut-Off Valve, Redundant

• Control Valve

Construction

• Vent Terminal

• Front Controls Enclosed

• Stainless Steel Burners

• Polytuf Powder Coat Finish

When ordering specify:

■■ wo/Pump (GBC) or ■■ w/Pump (GBCP)

■■ Natural Gas or ■■ L.P.

■■ Indoor or ■■ Outdoor

Hot Water Supply Heater(s) shall be model ________________, manufactured by RHEEM-RUUD,

having gas input of __________ Btu/hr. and recovery rate of _____________ GPH at a 100°F temperature rise when tested and certified at ____________ thermal efficiency. Water heaters(s) shall have the

CSA seal of certification and supplied with a factory installed 125 PSIG ASME pressure relief valve.

Water heater(s) shall meet or exceed the thermal efficiency requirements of ASHRAE. Water heater(s)

shall be ASME inspected and stamped for 160 PSI working pressure complete with manufacturer’s data

report. Water tube heat exchanger shall be constructed of straight integral copper fin tubes with fins

spaced at seven fins per inch. Tube sheets shall be ASME fire box steel. Headers shall be of glasslined

cast iron and joined to the copper tubes and tube sheets by means of silicone “O” rings to form a positive seal between the copper tubes and the headers to 1200 PSI hydrostatic pressure. Headers shall be

secured to the tube sheets by properly spaced bolts and flange nuts. Heat exchanger shall be readily

cleanable from either the right or left sides (or rear) of the water heater by removing header(s), and on

the right side, cleanable without removing external piping. Heat exchanger to be explosion proof on the

water side. Waterways to be 100% copper and glasslined cast iron to prevent galvanic action within the

water heater by positively sealing off water contact between ferrous and non-ferrous metals. Pump, flow

switch, and energy saving pump control are to be factory supplied and units over 400,000 Btu/Hr. must

have electronic intermittent pilot ignition.

Water heater to be equipped with remote bulb electric high limit control adjustable to 200°F. Main

electric gas valve to be 24 volt with 110/24 volt transformer. Gas pressure regulator to be factory set

at 4" W.C. Flame supervision shall be either 60 second thermopilot or 1-4 second electronic shut down.

Burners to be raised port and die formed from stainless steel alloy, mounted on a removable drawer,

capable of quiet ignition and extinction, and equipped with fixed primary air ports.

Models above 330,000 Btu/Hr. shall be CSA design certified for a minimum efficiency of 82% on indoor

and outdoor models.

Limited Warranty

All GB models feature a five year limited warranty on the

copper heat exchanger and glasslined cast iron header.

Please refer to Commercial Warranty Information brochure

for complete limited warranty information.

COMMERCIAL

WATER HEATERS

Rheem Water Heating • 101 Bell Road, Montgomery, Alabama 36117-4305 • www.rheem.com

PRINTED IN U.S.A 10/06 WP FORM NO. RR102C-6 Rev. 11

In keeping with its policy of continuous progress and product improvement, Rheem-Ruud reserves the right to make changes without notice.

Standard Equipment:

Recommended Specifications:

Loading...

Loading...