Rheem Commercial Water Heaters User Manual

SURFACE MOUNTED ELECTRIC TANK-TYPE

WATER HEATERS 9 KW THRU 36 KW

RHEEM-RUUD line of commercial electric

water heaters come in a broader range of

models. Our completely redesigned single panel

control center with hinged door features ready

access to all controls and elements. With single

or three phase operation, these units provide the

most versatile and dependable operation we’ve

ever offered in a commercial electric water

heater.

Thick, R-Foam

®

insulation completely surrounds

the tank, maximizing heat retention while improving energy costs.

Features the Lifeguard®high-efficiency stainlesssteel clad elements for long element life and

performance.

Seven different inputs from 9 KW to 36 KW to

meet most commercial and industrial needs.

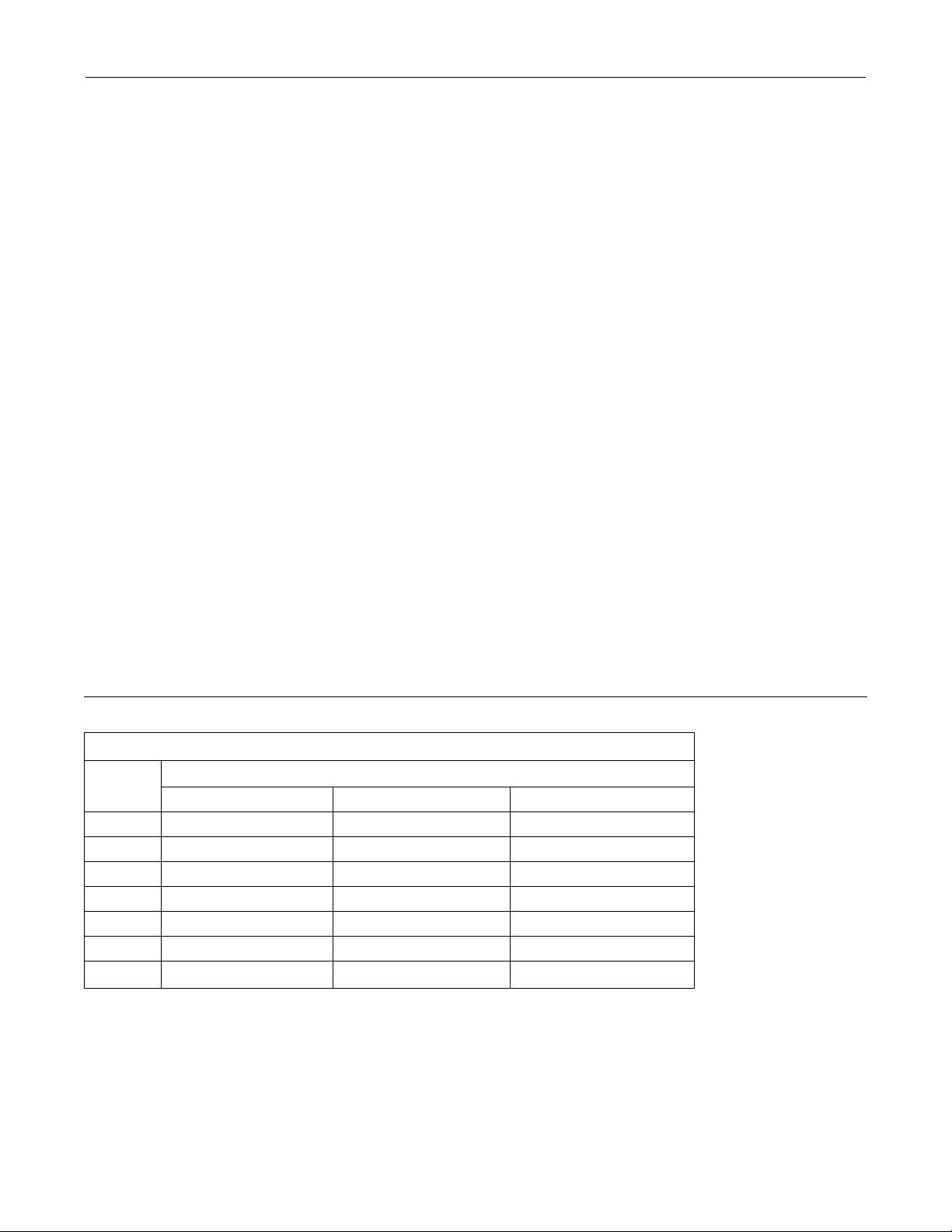

Model Applications

In addition to being suitable for general commercial hot water applications, these units are also

ideal for point-of-use installations, eliminating

costly temperature loss in long piping runs. A

single unit can be used as a booster heater to

satisfy the hot water requirements of commercial

dishwashers. A single temperature storage unit,

when installed with a mixing valve, will supply

two temperatures in food service establishments.

For larger volume hot water requirements, 2, 3 or

4 units can be parallel manifolded, using optional

factory kits.

Energy Information

Rheemglas®commercial electric water heaters are quality engineered to provide the maximum amount of hot

water available from storage capacity of the tank and energy input of heating elements. Surface mounted

thermostat models provide water from 120°F to 160°F (50°C to 71°C). Detailed Engineering Information for

208, 240 and 600 volt models with single or three phase operation will be found in Table A, B or C.

These units have been tested according to procedures specified by CSA and meet or exceed the energy

efficiency requirements of ASHRAE Standard 90.1b 1992 requirements for energy conservation.

50, 85

AND

120 U.S.

GALLON

CAPACITIES

208, 240,

AND 600

VOLTAGES

EGS-SURFACE MOUNTED

THERMOSTAT MODELS

TANK CAPACITY

50 Gal. (190 L) 85 Gal. (321 L) 120 Gal. (454 L)

EGS50-C-9 EGS85-C-9 EGS120-C-9

EGS50-C-12 EGS85-C-12 EGS120-C-12

EGS50-C-15 EGS85-C-15 EGS120-C-15

EGS50-C-18 EGS85-C-18 EGS120-C-18

EGS50-C-24 EGS85-C-24 EGS120-C-24

EGS50-C-30 EGS85-C-30 EGS120-C-30

EGS50-C-36 EGS85-C-36 EGS120-C-36

INPUT

KW

9

12

15

18

24

30

36

Construction Features

GLASS LINED STORAGE TANK – Heavy

duty steel tank protects with double coating of

exclusive Rheemglas

®

to resist the corrosive

action of hot water. Designed for 150 PSI working

pressure. Each tank is supplied with factory

installed anode rods or cathodic protection.

WATER CONNECTIONS – Hot outlet and

cold inlet are 1-1/2" NPS brass nipples which prevent excessive turbulence of heated water and

result in optimum tank draw.

R-FOAM®INSULATION – A rigid

polyurethane foam insulation provides superior

insulating qualities and improves efficiency.

Exceeds R-16 insulation factor. Our patented

process of injecting R-Foam directly into the insulating cavity adds additional durability and toughness to the heater jacket. Fiberglass insulation

guards against heat loss in the heating element

compartment, and provides easy service access.

SINGLE PANEL CONTROL BOX – With

hinged door, provides immediate access to all

electrical components and elements.

HEATING ELEMENTS – Separate screw-in

type LIFEGUARD

®

elements on 50, 85 and 120

gallon models feature a stainless steel outer

sheath of INCO-LOY

®

800, surrounding a

Nichrome wire filament, to resist water chemical

corrosion and burn-out even in air or sediment…

for long element life and long life performance.

Elements are directly immersed in the water for

efficient transfer of heat, and are easily changed

by simply screwing new ones into the tank.

TERMINAL BLOCK – All models are

equipped with CSA listed terminal blocks for

simplicity of installation. This new terminal block

will accept either copper or aluminum field

connect wire.

ELECTRICAL CONNECTIONS – Pre-wired,

accessible control box with multiple knock-outs on

top and side in size selections to match the

Canadian Electrical Code. Sizes range from 1/2"

to 2". A grounding screw is provided for attaching

an equipment grounding conductor.

AUTOMATIC TEMPERATURE

CONTROL – Temperature is maintained by a

surface mounted thermostat adjustable to provide

water 120°F to 160°F (50°C to 71°C) that insure

instant shut off at the selected temperature for

safety and economy of operation. Over temperature protection is provided by surface mounted

high temperature limit controls, one per heating

element, factory set at 190°F (88°C).

STANDARD EQUIPMENT ASME T&P

RELIEF VALVE – This is a double safety valve

that relieves when temperature or pressure

becomes excessive.

MODEL NUMBERS

Loading...

Loading...