Page 1

PROJECT NAME ______________________________________________________________________________

LOCATION __________________________________________________________________________________

ARCHITECT__________________________________________________________________________________

ENGINEER __________________________________________________________________________________

CONTRACTOR ______________________________________________________________________________

SUBMITTED BY ______________________________ DATE ________________________________________

UNIT SUMMARY

SUBMITTAL COVER SHEET

Quantity

Unit Designation

Model No.

Total Cooling

Sensible Cooling

Air Ent. Evaporator

Air Lvg. Evaporator

Heating Input

Heating Output

CFM/ESP

EER/SEER

Electrical

Minimum Ampacity

Min.-Max. Breaker

Net Unit Weight

Accessory

Catalog Form Number

ACCESSORIES: NOTES:

PRINTED IN U.S.A. 10-06 DC FORM NO. X11-1123 REV. 2

Supersedes Form No. X11-1123 Rev. 1

Page 2

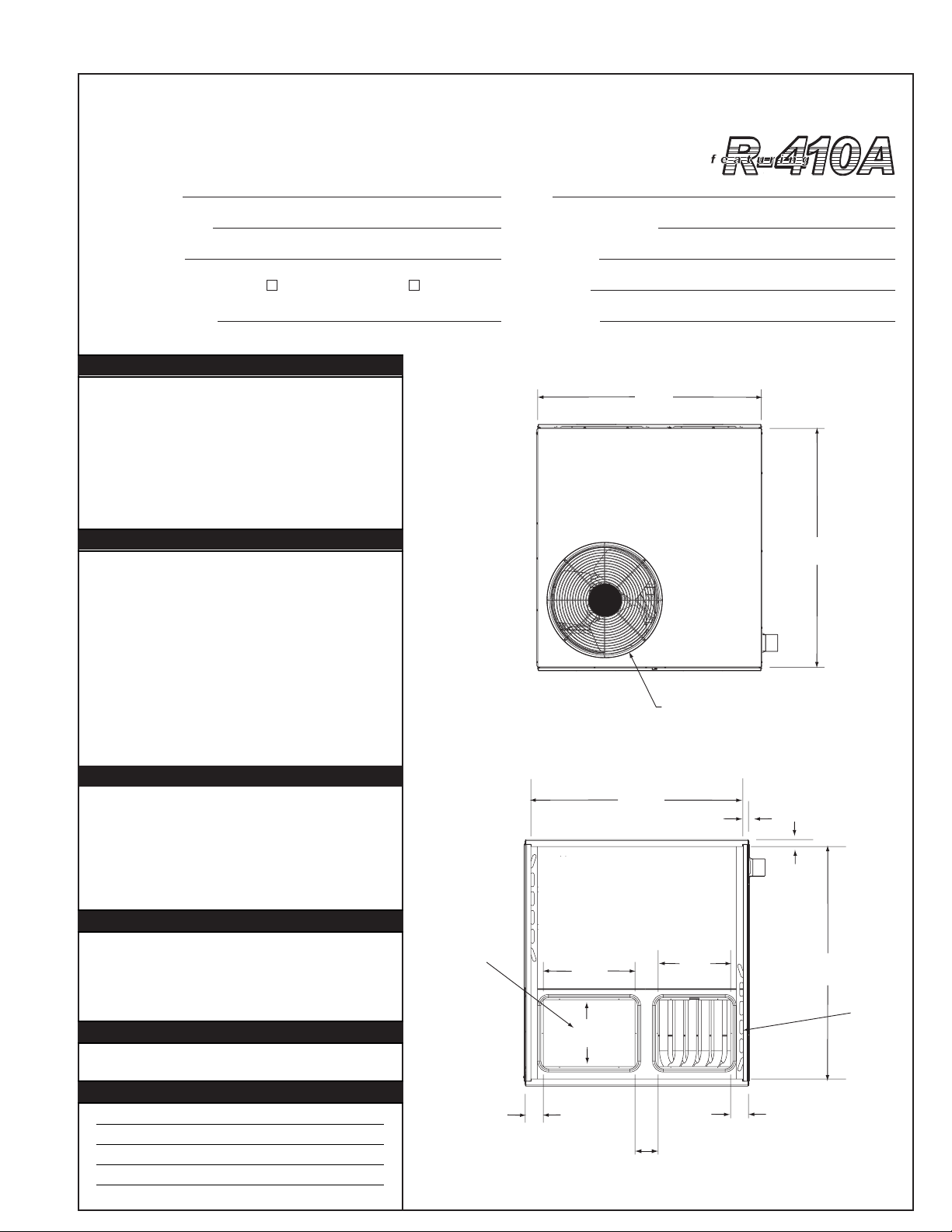

SUBMITTAL SHEET FOR RQPW PACKAGE DUAL FUEL UNITS

FEATURING NEW INDUSTRY STANDARD R-410A REFRIGERANT

Nominal Sizes 2 Thru 4 Tons [7.0 thru 14.0 kW]

JOB NAME DATE

CONTRACTOR UNIT DESIGNATION

ENGINEER MODEL NO.

SUBMITTED FOR APPROVAL RECORD LOCATION

SUBMITTED BY ORDER NO.

[ ] Designates Metric Conversions

FORM NO. X33-1235 REV. 1

Supersedes Form No. X33-1235

OUTDOOR FAN

GRILLE &

COMPRESSOR ACCESS

5013/16

"

[1290 mm]

47

9

/16

"

[1208 mm]

TOP VIEW

BOTTOM

RETURN

DUCT

OPENING

451/16

"

[1145 mm]

INSIDE

1

3

/16

"

[30 mm]

TYP.

1

1

/2

"

[38 mm]

TYP.

BOTTOM

SUPPLY

DUCT

OPENING

497/16

"

[1256 mm]

INSIDE

313/16

"

[97 mm]

33/16

"

[97 mm]

191/2

"

[495 mm]

153/8

"

[391 mm]

141/4

"

[362 mm]

TYP.

49/10

"

[125 mm]

BOTTOM VIEW

UNIT DATA

COOLING PERFORMANCE

TOTAL CAPACITY* ........................

_______

MBH

SENSIBLE CAPACITY* ..................

_______

MBH

OUTDOOR DESIGN TEMP.

_______

°F [°C] DB/WB

TOTAL SUPPLY AIR ................

_______

CFM [L/s]

TEMP. OF AIR ENTERING

EVAPORATOR COIL......

_______

°F [°C] DB/WB

POWER INPUT REQUIREMENT ......

_______

KW

SEER RATING........................................

_______

(*uses blower motor heat)

HEATING PERFORMANCE

GAS HEAT INPUT CAPACITY..........

_______

MBH

GAS HEAT OUTPUT CAPACITY...... ________MBH

STEADY STATE EFF........................ ________MBH

AFUE ..........................................

_______

C.O.P.

HEAT PUMP HEATING PERFORMANCE

CAPACITY @ 47°F .......................... ________MBH

CAPACITY @ 17°F .......................... ________MBH

COEFFICIENT OF PERFORMANCE

@ 47°F............................................ ________C.O.P.

@ 17°F............................................ ________C.O.P.

ELECTRIC HEAT CAPACITY ............

_______

KW

H.S.P.F. ...................................................... _______

SUPPLY AIR BLOWER PERFORMANCE

TOTAL SUPPLY AIR ................

_______

CFM [L/s]

TOTAL RESISTANCE EXTERNAL

TO UNIT......................................

_______

IWG

BLOWER SPEED ..........................

_______

RPM

POWER OUTPUT REQUIREMENT ..

_______

BHP

MOTOR RATING ........................

_______

HP [W]

POWER INPUT REQUIREMENT ......

_______

KW

ELECTRICAL DATA

POWER SUPPLY......................

____________ Hz

TOTAL UNIT AMPACITY................

_______

AMPS

MINIMUM WIRE SIZE ....................

_______

AWG

MAXIMUM OVERCURRENT DEVICE

FUSES HACR BREAKER ........

_______

AMPS

TOTAL UNIT WEIGHT

TOTAL OPERATING WEIGHT ....

_______

LBS [kg]

(including field-installed accessories)

CLEARANCES

SIDE “A”

(WITHOUT ECONOMIZER)

2" [50.8 mm]

SIDE “B”

(WITHOUT ECONOMIZER)

12" [304.8 mm]

SIDE “C”

(WITHOUT ECONOMIZER)

48" [1,219.2 mm]

SIDE “D”

(WITHOUT ECONOMIZER)

24" [610 mm]

ABOVE UNIT

(WITHOUT ECONOMIZER)

60" [1,524 mm]

Page 3

FIELD INSTALLED ACCESSORIES

Roof Curb (14" [356 mm & 24" [610 mm]

Sloped Platform) ..............................................

Filter Kit ................................................................

Lift Kit (For Rigging) ..............................................

Low Ambient Control ..............................................

Economizer (Downflow Only) ..................................

Economizer (Sideflow Only) ....................................

Fresh Air Damper ..................................................

L.P. (Conversion) Kit ..............................................

Transition Rectangular-Round (Downflow) ................

Concentric Diffuser and Grille ..................................

High Pressure Control ............................................

Thermostat with Outdoor Sensor..............................

BACK VIEW

FRONT VIEW

FILTER ACCESS PANEL (FOR UNIT

MOUNTED FILTER ACCESSORY)

OUTDOOR

COIL PROTECTIVE

GRILLE

52

7

/16

"

[1332 mm]

SIDE VIEW

SIDE VIEW

Model # “A” Height

B024, B025

3515/16"

B030, B036

B042, B048

41"

[ ] Designates Metric Conversions

BLOWER/

EVAPORATOR

ACCESS PANEL

FLUE

EXHAUST

HOOD

GAS SUPPLY

ENTRANCE

1

11

/16

"

[42.9 mm]

1015/16

"

[278 mm]

Sloped Curb

Before proceeding with installation, refer

to installation instructions packaged

with each model, as well as complying

with all Federal, State, Provincial, and

Local codes, regulations, and practices.

Rheem Sales Company, Inc.

P.O. Box 17010, Fort Smith, AR 72917

“In keeping with its policy of continuous progress and product improvement, Rheem reserves the right to make changes without notice.”

PRINTED IN U.S.A. 9-09 DC FORM NO. X33-1235

Supersedes Form No. X33-1235 Rev. 1

1

/2

"

2

[63.5 mm]

THREADED PVC

CONDENSATE DRAIN

CONNECTION (

3

/4" N.P.T.)

1

/2

47

[1207 mm]

"

7

20

[530 mm]

11

22

/16

[576 mm]

/8

"

"

[186 mm]

LIQUID PRESSURE

SERVICE PORT

SUCTION PRESSURE

SUCTION PORT

FIELD POWER

WIRE ENTRANCE

FIELD CONTROL

WIRE ENTRANCE

22

[581 mm]

15

13

/16

"

[338 mm]

5

7

/16

"

9

3

/16

"

[90 mm]

SIDE SUPPLY

DUCT OPENING

191/8

/16

[486 mm]

[124 mm]

"

"

7

/8

"

4

SIDE RETURN

DUCT OPENING

15

"

[381 mm]

15

35

/16

[897 mm]

"

131/4

[337 mm]

7

/16

4

[113 mm]

"

"

1

/2

"

8

[216 mm]

TYP.

SHOWN WITH DUCT COVERS REMOVED.

3

14

[360 mm]

TYP.

7

/8

"

3

/4

13

[349 mm]

TYP.

"

Loading...

Loading...