Page 1

PowerPack ASME

Electric Commercial Water Heaters

Available in 12, 20, 30, and 40 Gallon Tank-Type Models

3 KW thru 36 KW

Electric Commercial Water Heaters are suitable for general commercial hot water

applications and are also ideal for point-of-use installations. Small volume ASME

models are designed to meet engineering specifications.

Construction Features:

• System Sentinel

immersion thermostat models employ

an element diagnostic panel, utilizing

light emitting diodes (L.E.D.), corresponding to the number and location

of each heating element. This system

monitors the on-off function of the

electric heating elements.

• Long life ASME tank design

proprietary steel formulation with

high temperature porcelain enamel

to maximize corrosion resistance

resulting in a superior tank design.

• LIFEGUARD heating elements

separate screw-in type elements

feature a stainless steel outer sheath

of INCO-LOY 840, surrounding a

Nichrome wire filament, to resist water

chemical corrosion and burn-out even

in air or sediment…for long element

life and long life performance.

Elements are directly immersed in the

water for maximum recovery efficiency

(98%) and are easily changed by

simply screwing new ones into the

tank. LIFEGU

ARD elements feature

a three (3) year limited warranty.

• Full port, full flow brass drain

valve

• Minimal heat loss design

85% of the tank surface area on all

Rheem-Ruud Commercial Electric

products are insulated with 2-1/2" of

rigid polyurethane foam insulation

providing superior insulating qualities.

Unlike other designs, Rheem-Ruud

Commercial Electrics can achieve 85%

because of the unique compact layout

of the heating elements. This results

in heat losses less than the energy

used by a 75 watt light bulb during

a 48 hour standby period!

Certifications and Ratings:

• Efficiency –

in accordance with ANSI test procedures, these models tested below

the maximum allowable standby loss levels of ASHRAE Standard 90.1b-2001

(Part of the Federally mandated Energy Policy Act (EPact)). Also exceeds energy

efficiency codes of all states including California Energy Commission (CEC).

• Safety and construction –

These products are design certified by Underwriters

Laboratories (UL) to meet UL standard 1453 as electric booster and commercial

storage tank water heaters. All models are North Carolina and Massachusetts code

compliant.

CERTIFIED FOR A

160 PSI MAXIMUM WORKING PRESSURE.

• ASME construction –

standard on E12A, E20A, E30A, and E40A models.

Continued next page.

208, 240,

277 and 480

Voltages

Immersion

Thermostat

Models

®

Page 2

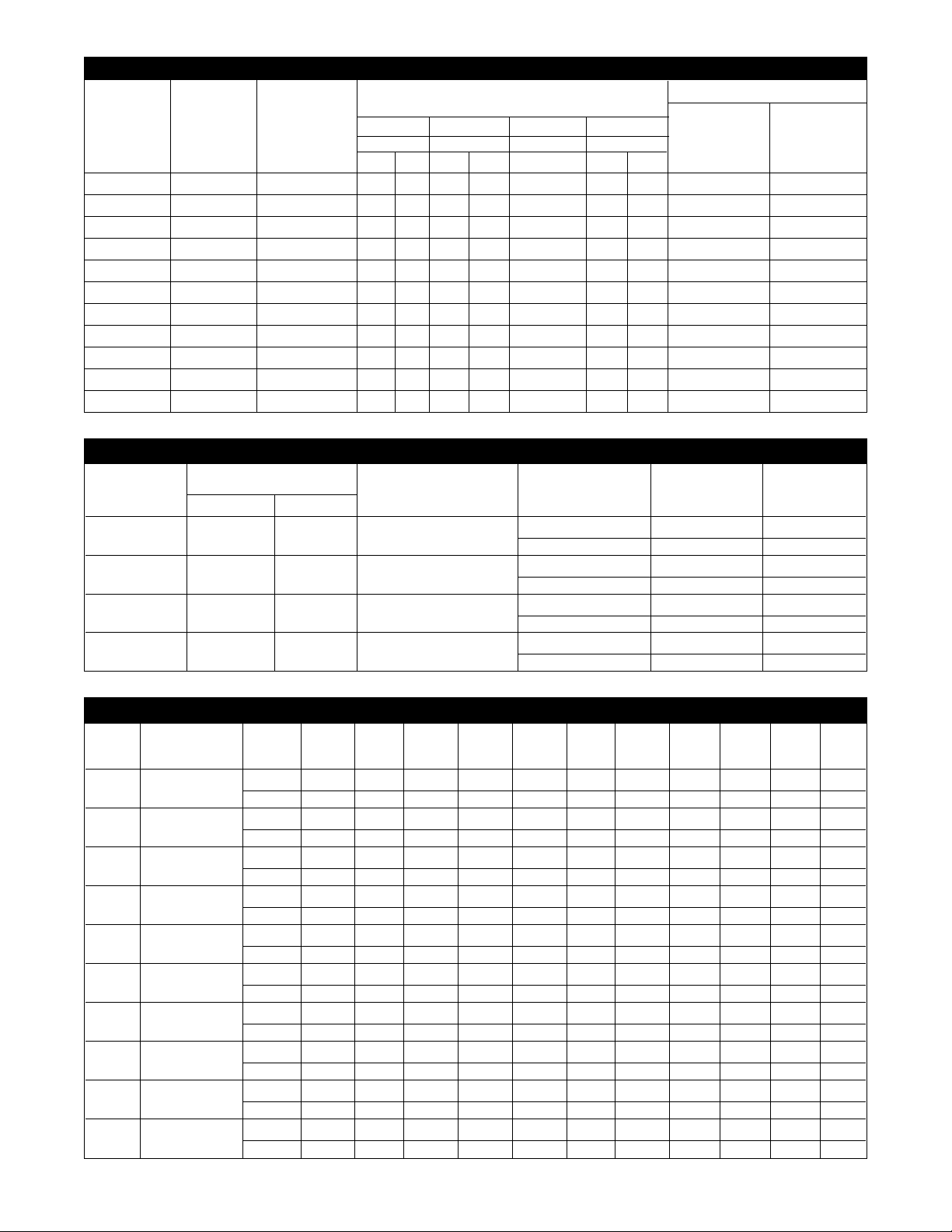

RECOVERY CAPACITIES Recovery in U.S. Gallons/Hr. (GPH) and Liters/Hr. (LPH) at Various Temperature Rises

INPUT EQUIVALENT 40°F 50°F 60°F 70°F 80°F 90°F 100°F 110°F 120°F 130°F 140°F

KW BTU/HR. UNITS (22°C) (28°C) (33°C) (39°C) (45°C) (50°C) (56°C) (61°C) (67°C) (72°C) (78°C)

3 10,236 GPH 31 25 21 18 16 14 12 11 10 10 9

LPH 117 95 80 68 61 53 45 42 38 38 34

6 20,473 GPH 62 50 41 35 31 28 25 23 21 19 18

LPH 235 188 157 134 117 104 94 85 78 72 67

9 30,709 GPH 93 74 62 53 47 41 37 34 31 29 27

LPH 352 282 235 201 176 157 141 128 117 108 101

12 40,946 GPH 124 99 83 71 62 55 50 45 41 38 35

LPH 470 376 313 268 235 209 188 171 157 145 134

15 51,183 GPH 155 124 103 89 78 69 62 56 52 48 44

LPH 587 470 391 335 294 261 235 213 196 181 168

18 61,420 GPH 186 149 124 106 93 83 74 68 62 57 53

LPH 705 564 470 403 352 313 282 256 235 217 201

24 81,893 GPH 248 199 165 142 124 110 99 90 83 76 71

LPH 939 751 626 537 470 417 376 342 313 289 268

27 92,129 GPH 279 223 186 160 140 124 112 102 93 86 80

LPH 1057 845 705 604 528 470 423 384 352 325 302

30 102,366 GPH 310 248 207 177 155 138 124 113 103 95 89

LPH 1174 939 783 671 587 522 470 427 391 361 335

36 122,839 GPH 372 298 248 213 186 165 149 135 124 115 106

LPH 1409 1127 939 805 705 626 564 512 470 434 403

ELECTRICAL CHARACTERISTICS

INPUT

KW

NUMBER

OF

ELEMENTS

ELEMENT

WATTAGE

FULL LOAD CURRENT

IN AMPERES

208V

Phase

1 3

240V

Phase

1 3

277V

Phase

1

480V

Phase

1 3

IMMERSION THERMOSTATS

No. of

T’Stats

Number

of

Fuses

WATER TEMPERATURE RATINGS

Minimum Maximum High

Model

Tank Capacity

Thermostat Delivered Delivered Temperature

Number Gallons Liters Type Temperature Temperature Limit

E12A 13 49 Immersion 90°F 190°F 200°F

32.2°C 87.8°C 93.3°C

E20A 19.9 75 Immersion 90°F 190°F 200°F

32.2°C 87.8°C 93.3°C

E30A 30 114 Immersion 90°F 190°F 200°F

32.2°C 87.8°C 93.3°C

E40A 40 152 Immersion 90°F 190°F 200°F

32.2°C 87.8°C 93.3°C

3 1 3000 15 – 13 – 11 7 – 2 1

6 3 2000 29 17 25 14 22 13 8 6 1

9 3 3000 44 25 38 22 33 19 11 6 1

12 3 4000 58 34 50 29 44 25 15 6 1

15 3 5000 73 42 63 37 55 32 18 6 1

18 3 6000 87 50 75 44 65 38 22 6 1

18 6 3000 87 50 75 44 65 38 22 12 1

24 6 4000 116 67 100 58 87 50 29 12 1

27 6 4500 130 75 113 65 98 57 33 12 1

30 6 5000 145 84 125 73 109 63 37 12 1

36 6 6000 173 100 150 87 130 75 44 12 1

PowerPack continued.

Page 3

MODEL NUMBERS

• Fuse type

the “G” in the model number

represents Class G fuses.

• UL Sanitation compliance

all models are UL Sanitation

(NSF5) compliant when

equipped with the optional

ring seal kits. E12A, E20A,

E30A-(AS39827),

E40A-(AS39828) Solid State

Low Water Cut-off – units may

be ordered with probe type

cut-off for field installations

(AP8408).

IMMERSION THERMOSTATS

Tank Capacity In Gallons

12 20 30 40

E12A-3-G E20A-3-G E30A-3-G E40A-3-G

E12A-6-G E20A-6-G E30A-6-G E40A-6-G

E12A-9-G E20A-9-G E30A-9-G E40A-9-G

N/A E20A-12-G E30A-12-G E40A-12-G

N/A E20A-15-G E30A-15-G E40A-15-G

N/A E20A-18-G E30A-18-G E40A-18-G

N/A N/A E30A-24-G E40A-24-G

N/A N/A E30A-27-G E40A-27-G

N/A N/A E30A-30-G E40A-30-G

N/A N/A E30A-36-G E40A-36-G

INPUT

KW

3

6

9

12

15

18

24

27

30

36

DIMENSIONAL INFORMATION All dimensions shown in English and Metric

MODEL

APPROX. SHIPPING

WEIGHT (LBS.)/(KG)

NUMBER UNITS

ABCD E

ASME

E12A inches 28-1/2 19 24-1/4 14-3/4 26-1/4 135

mm 724 483 616 375 667 61

E20A inches 36-1/2 19 24-1/4 14-3/4 26-1/4 160

mm 927 483 616 375 667 73

E30A inches 49-1/4 19 24-1/4 14-3/4 32-1/2 192

mm 1251 483 616 375 826 87

E40A inches 53-3/4 21 26-3/4 16-1/2 32-1/2 228

mm 1365 583 679 419 826 104

B

8"

D

A

E

3

/4"

T&P

4

1

/4"

2

1

/2"

SYSTEM SENTINEL

AUTOMATIC

TEMPERATURE

CONTROL

C

• System Sentinel

all models employ a

diagnostic panel utilizing

light emitting diodes (L.E.D.),

corresponding to the number

and location of each heating

element. L.E.D.’s are

energized when the electric

elements are operating. An

unlit L.E.D. pinpoints the

exact location of a nonfunctioning element, making

element operation diagnosis

simple and positive.

PowerPack continued.

Page 4

Water heater(s) shall be model ________________, manufactured by RHEEM-RUUD, having electrical input of __________

kW and a recovery rate of _____________ GPH at a 100°F temperature rise. Water heater(s) shall have a storage capacity of

___________ gallons. Water heater(s) shall have the UL seal of certification and be factory equipped with an AGA/ASME rated

temperature and pressure relief valve. Water heater(s) shall be constructed in accordance with the requirements of the ASME

Boiler and Pressure Vessel Code, Section IV Part HLW. Tank(s) shall have a coating of high temperature porcelain enamel and

furnished with two (2) magnesium anode rods rigidly supported. Water heater(s) shall meet or exceed the standby loss requirements of ASHRAE Standard 90.1b-2001. Tank(s) shall have a working pressure of 160 psi, and shall be completely assembled. Water heater(s) shall be approved-listed and constructed in accordance with UL Sanitation (NSF5). Water heater(s) shall

be equipped with LIFEGUARD “screw-in” type elements featuring a stainless steel outer sheath of INCO-LOY 840 material.

Tank shall be insulated with 2-1/2" of rigid polyurethane foam insulation. Water heater(s) shall be constructed with a SYSTEM

SENTINEL element diagnostic panel utilizing light emitting diodes. Each LED will correspond to the number and location of the

heating elements and monitor their on-off function. Water heater(s) shall be provided with internal power circuit fusing, control

circuit fusing, magnetic contactors, 120 volt control circuit transformer and immersion thermostat(s) with manual reset high limit

control. 3/4" inlet and outlet water connections shall be provided. Water heater(s) shall be covered by a three year limited

warranty against tank leaks.

This product features a three year limited warranty against tank leaks.

Please refer to Commercial Warranty Information brochure for complete warranty information.

Recommended Specifications:

Limited Warranty:

COMMERCIAL

WATER HEATERS

Rheem Water Heating • 101 Bell Road, Montgomery, Alabama 36117-4305 • www.rheem.com

Rheem Canada Ltd./Ltée,128 Barton Street West, Hamilton, Ontario L8N 3P3

PRINTED IN U.S.A 02/06 WP FORM NO. RR102CE-5 Rev. 5

In keeping with its policy of continuous progress and product improvement, Rheem-Ruud reserves the right to make changes without notice.

PowerPack continued.

Other Features:

• Integral Fusing

all models have integral fusing for each element.

• Anode Rods

two (2) magnesium anodes are installed in each tank

to ensure long life and corrosion resistance.

• Temperature and Pressure Relief Valve

AGA/ASME rated and factory installed.

• Electrical Connections

pre-wired, accessible control box with multiple

knock-outs on side in size selections to match the

National Electric Code. Sizes range from 1/2" to 2".

A grounding screw is provided for attaching an

equipment grounding conductor.

• Single Panel Control Box

with hinged door, provides immediate access to all

electrical components and elements.

• Terminal Block

all models are equipped with U.L. listed terminal

blocks for simplicity of installation. The terminal

block will accept either copper or aluminum field

connect wire.

• 120 Volt Control Circuit

all units are furnished with a fused 120 volt control

circuit. This circuit is created by an internal multi-tap

transformer of unique design that has four (4) taps

for the primary voltages, 208, 240, 277 and 480.

• Water Connections

hot outlet and cold inlet are 3/4" NPT plastic lined

nipples which prevent excessive turbulence of

heated water and results in optimum tank draw.

Loading...

Loading...