Rheem R801TA050314MSA, (-)(-)80MSX100C50SA, (-)(-)80MSX075B40SA, (-)(-)80MSX050A30SA, R801TA075417MSA Installation Instructions Manual

...Page 1

INSTALLATION INSTRUCTIONS

FOR UPFLO W/HORIZONTAL SINGLE STA GE

GAS FURNA CES

(-)801S UPFLOW/HORIZONTAL SERIES

(-)801P UPFLOW/HORIZONTAL SERIES

(-)(-)80MSS UPFLOW/HORIZONTAL SERIES

(-)(-)80MSP UPFLOW/HORIZONTAL SERIES

U.L. and/or C.S.A. recognized fuel gas and CO (carbon monoxide) detectors are recommended in all applications, and their installation should be in accordance with the

manufacturer’s recommendations and/or local laws, rules, regulations, or customs.

92-24161-142-04

SUPERSEDES 92-24161-142-03

Factory Use Only

ISO 9001:2008

ST-A1220-01-X0

Page 2

2

Contents

TABLE OF CONTENTS

1 TABLE OF CONTENTS. . . . . . . . . . . . . . . . . . . . . . . 2

2 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . 3

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

California Proposition 65 Note . . . . . . . . . . . . . . . . . . 4

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 SAFETY INFORMATION. . . . . . . . . . . . . . . . . . . . . . 6

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Important Information About Ef ficiency and Quality. . 7

4 LOCATION REQUIREMENTS . . . . . . . . . . . . . . . . . 8

Site Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Clearance –Accessibility . . . . . . . . . . . . . . . . . . . . . . 8

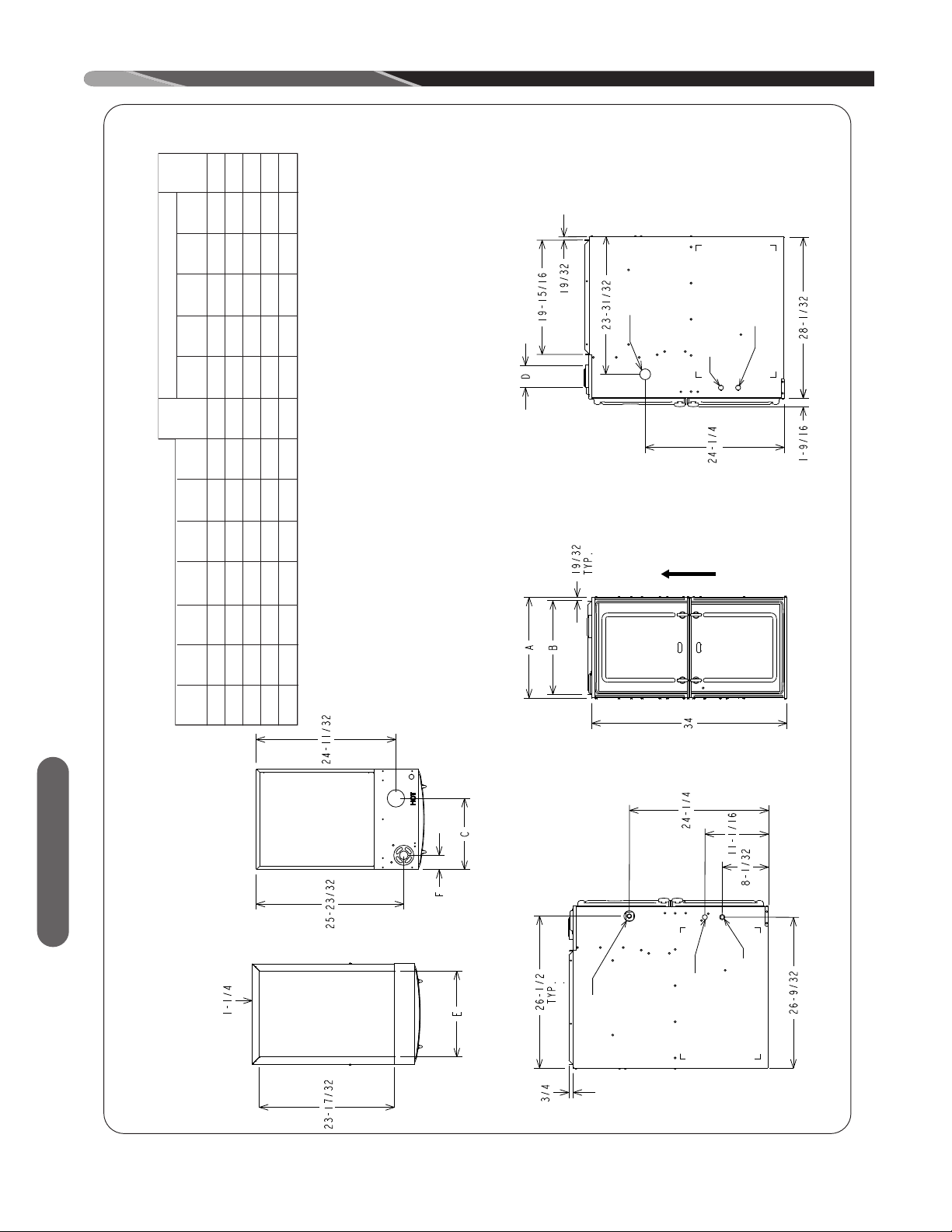

Upflow Dimensions and Clearance Table . . . . . . . . . 9

5 DUCTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Upflow Installations. . . . . . . . . . . . . . . . . . . . . . . . . . 11

Horizontal Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 COMBUSTION AND VENTILA TION AIR. . . . . . . . 14

Combustion Air Requirements. . . . . . . . . . . . . . . . . 14

Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

“B-1” Vertical Venting . . . . . . . . . . . . . . . . . . . . . . . . 19

Special Vent Systems (SVS) . . . . . . . . . . . . . . . . . . 20

Power Vent Systems . . . . . . . . . . . . . . . . . . . . . . . . 22

Existing Vent Systems . . . . . . . . . . . . . . . . . . . . . . . 22

7 GAS SUPPLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Gas Supply and Piping. . . . . . . . . . . . . . . . . . . . . . . 23

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Gas Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Setting Gas Pressure . . . . . . . . . . . . . . . . . . . . . . . . 26

Supply Gas Pressure Measurement . . . . . . . . . . . . 26

Manifold Gas Pressure Measurement. . . . . . . . . . . 26

8 LP CONVERSION . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9 ELECTRICAL WIRING . . . . . . . . . . . . . . . . . . . . . . 28

Reversing The Electrical Connection. . . . . . . . . . . . 28

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

10 ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Field Installed Option Accessories. . . . . . . . . . . . . . 30

Electronic Air Cleaner. . . . . . . . . . . . . . . . . . . . . . . . 30

Humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

RXGW-B01 Chimney Adapter . . . . . . . . . . . . . . . . . 30

RXGW-C01 Four Inch Flue Adapter . . . . . . . . . . . . 30

11 TWINNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Furnace T winning Installations. . . . . . . . . . . . . . . . . 32

Control Boards . . . . . . . . . . . . . . . . . . . . . . . . . . 33-34

12 HIGH ALTITUDE . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Natural Gas at High Altitudes. . . . . . . . . . . . . . . . . . 35

LP Gas at High Altitudes. . . . . . . . . . . . . . . . . . . . . . 37

13 STARTUP PR OCEDURES . . . . . . . . . . . . . . . . . . . 38

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . 38

14 DIAGNOSTICS AND F AULT CODES. . . . . . . . . . . 39

15 LOCKOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

16 FIELD SELECTIONS & ADJUSTMENTS . . . . . . . 41

Field Selections – Dipswitches. . . . . . . . . . . . . . . . . 41

17 FA ULT CLEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

18 FA ULT RECALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

19 FLAME STATUS L.E.D.. . . . . . . . . . . . . . . . . . . . . . 42

20 TIMING DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . 42

21 ADJUSTING OR CHECKING FURNACE INPUT . 43

22 SETTING INPUT RATE. . . . . . . . . . . . . . . . . . . . . . 44

23 AIRFLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Blower Speed Selection. . . . . . . . . . . . . . . . . . . . . . 46

24 SAFETY FEATURES. . . . . . . . . . . . . . . . . . . . . . . . 47

25 MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

26 SYSTEM OPERATION INFORMATION . . . . . . . . . 49

27 ANNUAL INSPECTION. . . . . . . . . . . . . . . . . . . . . . 49

28 REPLACEMENT P AR TS. . . . . . . . . . . . . . . . . . . . . 49

24 TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . 50

30 WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . 51

IMPORTANT: TO INSURE PROPER INSTALLATION AND OPERATION OF THIS PRODUCT, COMPLETELY READ ALL INSTRUC-

TIONS PRIOR TO ATTEMPTING TO ASSEMBLE, INSTALL, OPERATE, MAINTAIN OR REP AIR THIS PRODUCT. UPON UNPACKING

OF THE FURNA CE, INSPECT ALL PARTS FOR DAMAGE PRIOR TO INSTALLATION AND START-UP.

Page 3

3

General Information

GENERAL INFORMATION

NOTE: A heat loss calculation should be performed to properly

determine the required furnace BTU size for the structure. Also,

the duct must be properly designed and installed for proper airflow. Existing ductwork must be inspected for proper size and to

make sure that it is properly sealed. Proper airflow is necessary

for both user comfort and equipment performance.

Before opening the furnace carton, verify that the data tags on

the carton specify the furnace model number that was ordered

from the distributor and are correct for the installation. If not,

return the unit without opening the carton. If the model number

is correct, open the carton and verify that the furnace rating

label specifies the same furnace model number that is specified on the carton label. If the model numbers do not match, return the furnace to the distributor .

IMPORTANT: Proper application, installation and maintenance of

this furnace and system is a must if consumers are to receive the full

benefits for which they have paid.

The (-)801S/(-)801P series furnaces are design certified by CSA

for use with natural and propane gases as follows:

As a Category I furnace, it may be vented vertically with type B1 vent pipe and also may be common vented as described in

these instructions.

This furnace should be installed in accordance with the American

National Standard Z223.1 - latest edition booklet entitled “National

Fuel Gas Code” (NFPA 54), and the requirements or codes of the

local utility or other authority having jurisdiction including local

plumbing or waste water codes.

With the introduction of higher efficiency furnaces, special attention

must be paid to the venting system. Only listed venting systems

may be used as stated in the installation instructions and the

Na-

tional Fuel Gas Code, ANSI Z223.1 (NFPA 54),.

Since furnace

technology and venting requirements are changing, awareness of

local, state, and federal codes and industry changes is imperative.

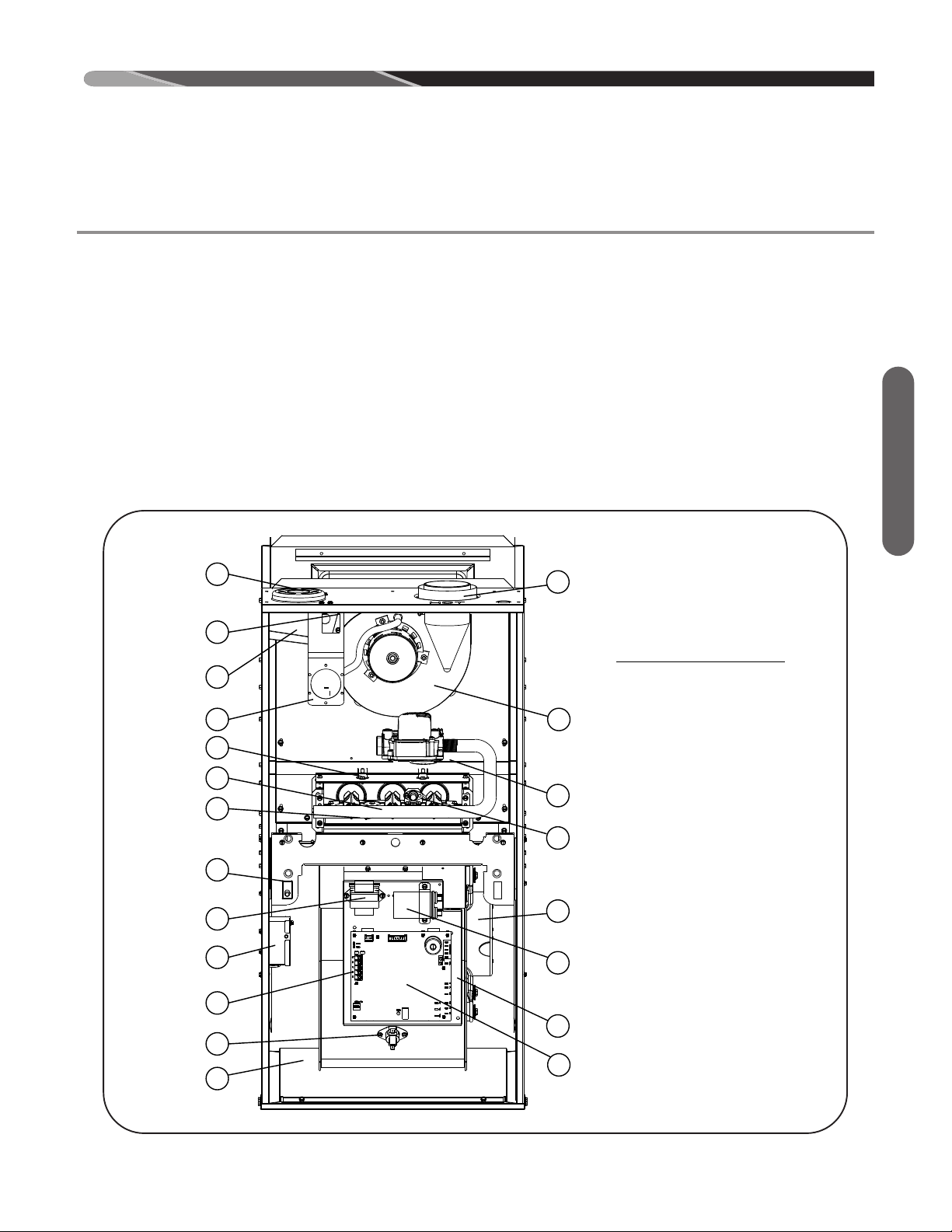

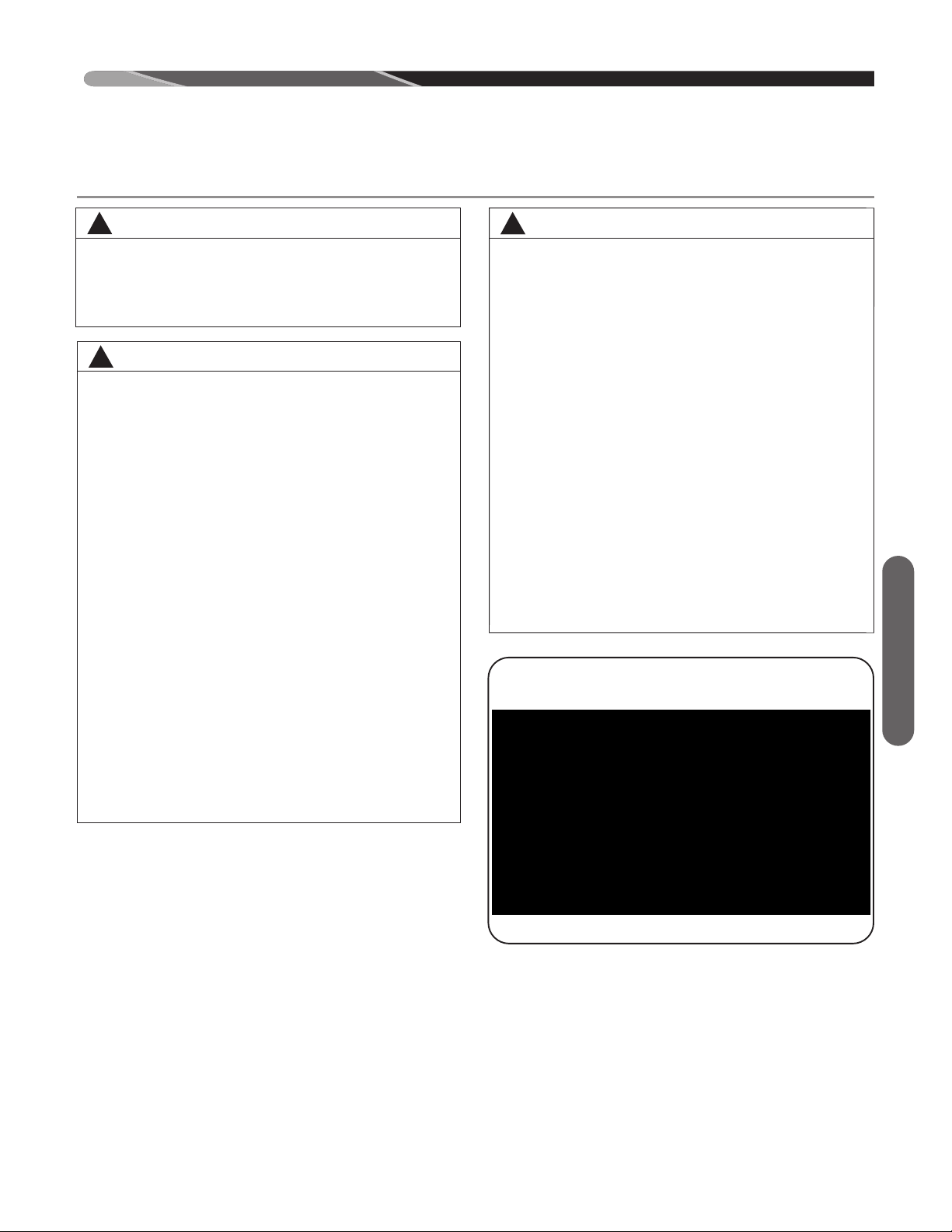

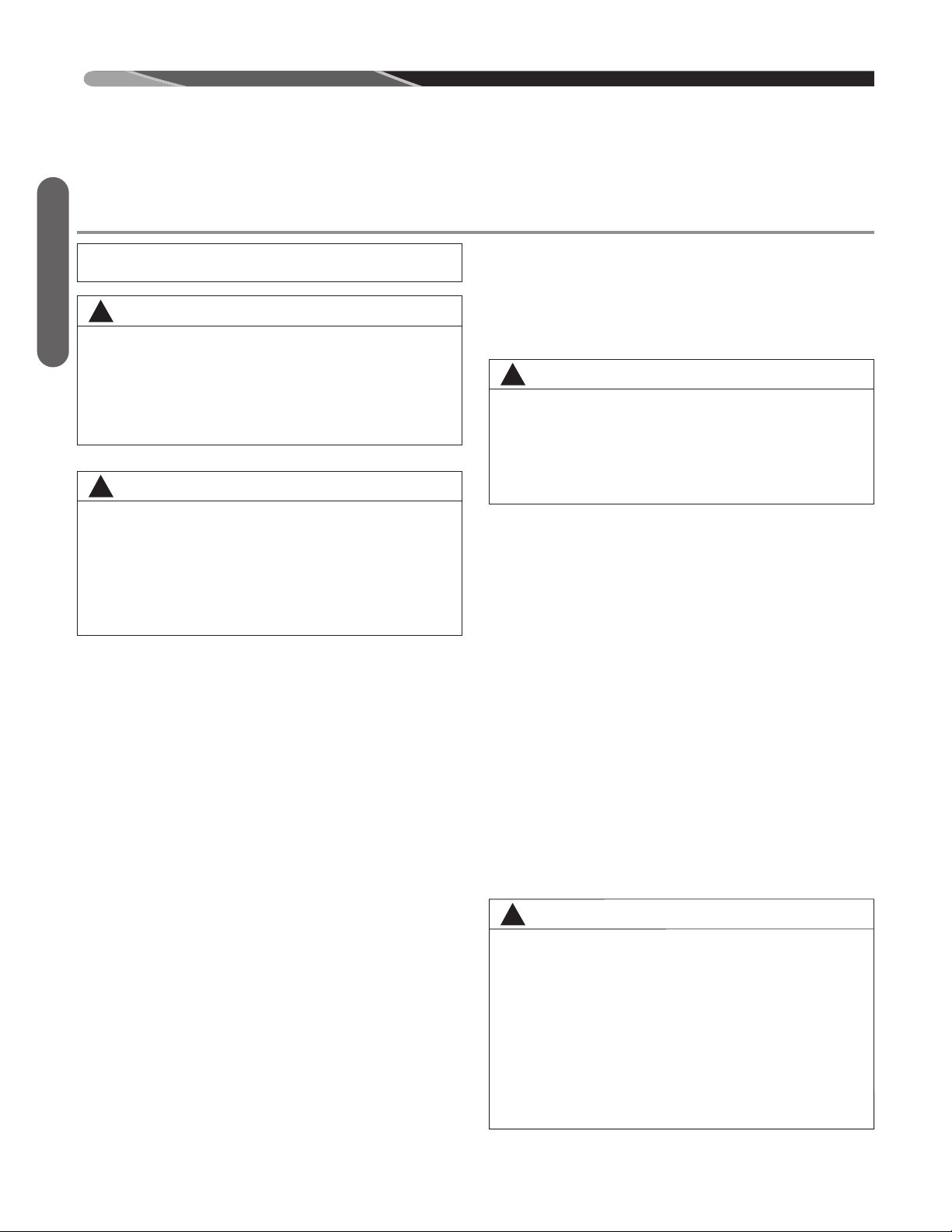

ST-A1220-02

FIGURE 1

FURNACE COMPONENTS

14

15

16

17

21

18

19

1

2

3

4

20

5

13

ITEM

NO.

12

11

10

9

8

DESCRIPTION

1

DOOR SWITCH

2

TRANSFORMER

3

JUNCTION BOX

4

LOW VOLTAGE TERMINAL

5

SOLID METAL BASE PAN ((-) 801P ONLY)

6

FURNACE CONTROL

7

CONTROL MOUNTING PLATE

8

CAPACITOR

9

BLOWER

10

IGNITER

11

GAS VALVE

12

INDUCED DRAFT BLOWER

13

4” FLUE ADAPTER (OPTIONAL)

14

COMBUSTION AIR INLET

15

MAIN LIMIT

16

COMBUSTION AIR DIFFUSER

17

MAIN PRESSURE SWITCH

18

BURNER

19

FLAME SENSOR

20

HEAT ASSISTED LIMIT CONTROL (HALC)

21

OVER TEMPERATURE SWITCH

7

6

ST-A1220-02-03

Page 4

4

Install this furnace in accordance with the American National Standard Z223.1 – latest edition entitled “National Fuel Gas Code”

(NFPA54) and requirements or codes of the local utilities or other

authorities having jurisdiction. This is available from the following:

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

RECEIVING

Immediately upon receipt, all cartons and contents should be inspected for transit damage. Units with damaged cartons should

be opened immediately. If damage is found, it should be noted on

the delivery papers, and a damage claim filed with the last carrier.

• After unit has been delivered to job site, remove carton taking

care not to damage unit.

• Check the unit rating plate for unit size, electric heat, coil, voltage, phase, etc. to be sure equipment matches what is required for the job specification.

• Read the entire instructions before starting the installation.

• Some building codes require extra cabinet insulation and gasketing when unit is installed in attic applications.

• If installed in an unconditioned space, apply caulking around

the power wires, control wires, refrigerant tubing and condensate line where they enter the cabinet. Seal the power wires on

the inside where they exit conduit opening. Caulking is required to prevent air leakage into and condensate from forming

inside the unit, control box, and on electrical controls.

• Install the unit in such a way as to allow necessary access to

the coil/filter rack and blower/control compartment.

• Install the unit in accordance with any local code which may

apply and the national codes. Latest editions are available

from: “National Fire Protection Association, Inc., Batterymarch

Park, Quincy, MA 02269.” These publications are:

• ANSI/NFPA No. 70-(Latest Edition) National Electrical Code.

• NFPA90A Installation of Air Conditioning and Ventilating Systems.

• NFPA90B Installation of warm air heating and air conditioning

systems.

• The equipment has been evaluated in accordance with the

Code of Federal Regulations, Chapter XX, Part 3280.

CALIFORNIA RESIDENTS ONLY

IMPORTANT: All manufacturer products meet current Federal

OSHA Guidelines for safety. California Proposition 65 warnings

are required for certain products, which are not covered by the

OSHA standards.

California's Proposition 65 requires warnings for products sold in

California that contain, or produce, any of over 600 listed chemicals known to the State of California to cause cancer or birth defects such as fiberglass insulation, lead in brass, and combustion

products from natural gas.

All “new equipment” shipped for sale in California will have labels

stating that the product contains and/or produces Proposition 65

chemicals. Although we have not changed our processes, having

the same label on all our products facilitates manufacturing and

shipping. We cannot always know “when, or if” products will be

sold in the California market.

You may receive inquiries from customers about chemicals found

in, or produced by, some of our heating and air-conditioning equipment, or found in natural gas used with some of our products.

Listed below are those chemicals and substances commonly associated with similar equipment in our industry and other manufacturers.

• Glass Wool (Fiberglass) Insulation

• Carbon Monoxide (CO)

• Formaldehyde

• Benzene

More details are available at the Websites for OSHA (Occupa-

tional Safety and Health Administration), at www.osha.gov

and the

State of California's OEHHA (Office of Environmental Health Hazard Assessment), at www.oehha.org.

Consumer education is important since the chemicals and substances on the list are found

in our daily lives. Most consumers are aware that products present safety and health risks, when improperly used, handled and

maintained.

GENERAL INFORMATION (cont.)

General Information

Page 5

5

Installation Checklist

REFER TO INSTALLATION INSTRUCTIONS

GAS SUPPLY

______ Correct pipe size (record size)

______ Correct supply pressure (during furnace operation) (record pressure)

______ Manifold pressure (record upstream pressure)

______ No gas leaks

______ L.P. Kit Number (if applicable) (record kit number)

ELECTRICAL

______ 115 V.A.C. supply (Dedicated Circuit) (record voltage)

______ Polarity observed

______ Furnace properly grounded

______ Correct wire size (record type and gauge)

FURNACE INSTALLATION

______ Correct clearance to combustibles (record clearance)

______ Correct clearance for service (at front) (record clearance)

DUCT STATIC PRESSURE

______ in. w.c. on heating speed (record static pressure)

______ in. w.c. on cooling speed (record static pressure)

______ Air temperature rise in heat (record air temperature rise)

______ Air temperature rise in cool (record air temperature rise)

VENTING

______ Correct vent pipe diameter and length (according to NFGC tables) _________________ Vent connection size

______ Correct venting material (according to NFGC tables)

______ Correct lining for masonry chimneys

______ Adequate clearance from combustibles

______ Proper negative pressure reading in the vent

______ Vent pipe secured to induced draft blower housing

COMBUSTION AIR

______ Proper source of combustion air

______ Correct combustion air opening size

______ Optional attic combustion air pull

______ Non-attic combustion air pull

Checklist

Installation Instructions remain with the furnace as a reference guide to the servicing contractor. We recommend

that performance and installation data be recorded for future ref erence on this sheet to meet service and warranty

obligations so that job site information is available when required.

Page 6

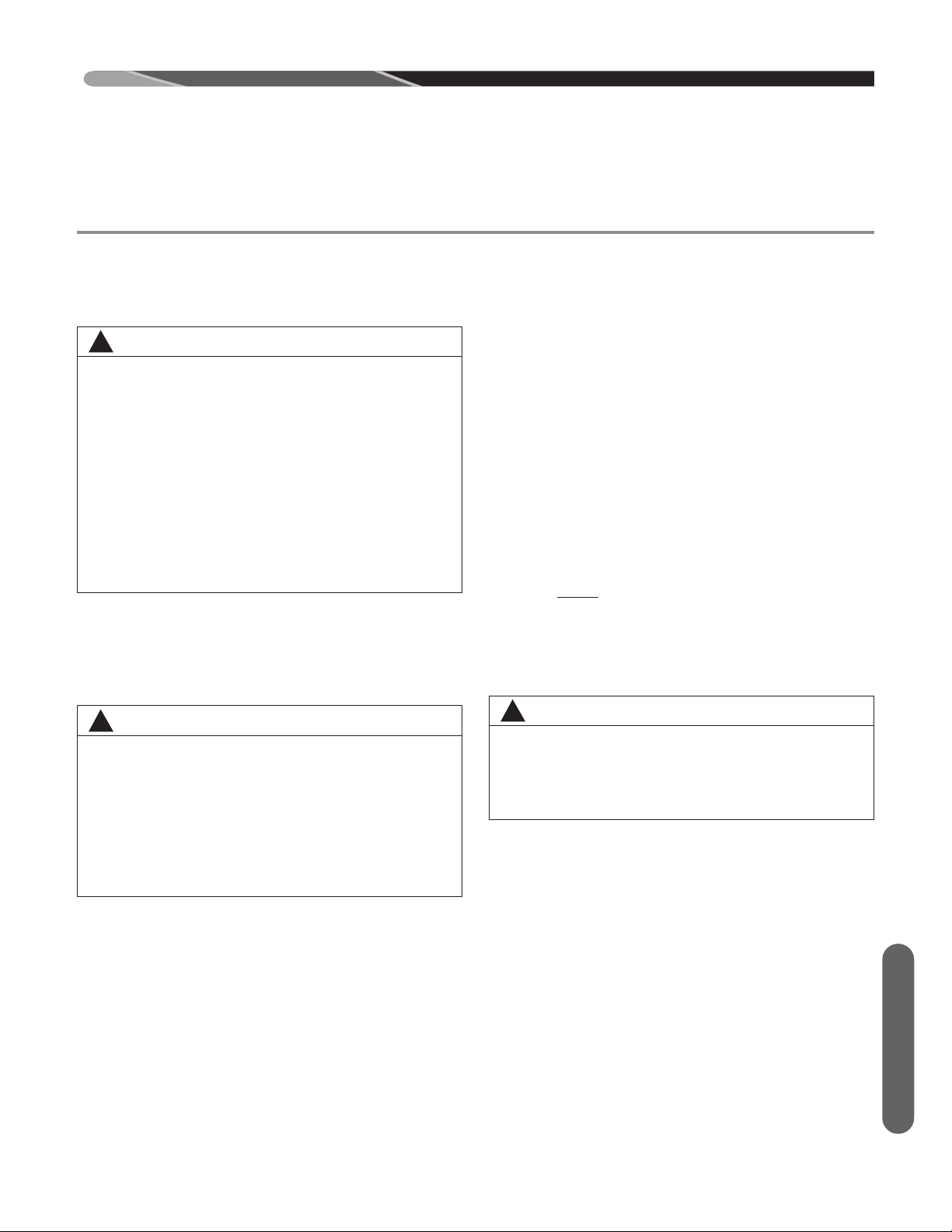

Safety Information

SAFETY INFORMATION

!

WARNING

IN COMPLIANCE WITH RECOGNIZED CODES, IT IS RECOMMENDED THAT AN AUXILIARY DRAIN PAN BE INSTALLED UNDER THIS FURNACE AND ANY INSTALLED

EVAPORATOR COIL THAT IS LOCATED IN ANY AREA OF

A STRUCTURE WHERE DAMAGE TO THE BUILDING OR

BUILDING CONTENTS MAY OCCUR AS A RESULT OF AN

OVERFLOW OF THE A/C COIL DRAIN PAN.

!

WARNING

DO NOT INSTALL THIS FURNACE IN A MOBILE HOME!!

THIS FURNACE IS NOT APPROVED FOR INSTALLATION

IN A MOBILE HOME. DOING SO COULD CAUSE FIRE,

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

!

WARNING

INSTALL THIS FURNACE ONLY IN A LOCATION AND POSITION AS SPECIFIED IN THE LOCATION REQUIREMENTS AND CONSIDERATIONS SECTION OF THESE

INSTRUCTIONS.

!

WARNING

IMPROPER INSTALLATION CAN RESULT IN UNSATISFACTORY OPERATION AND/OR DANGEROUS CONDITIONS

AND ARE NOT COVERED BY THE MANUFACTURER’S

WARRANTY.

!

WARNING

DO NOT BYPASS, JUMPER, OR REMOVE ANY SAFETY

SWITCH FROM THE FURNACE CONTROL CIRCUIT. IF A

SAFETY SWITCH CAUSES THE FURNACE TO SHUT

DOWN OR OPERATE INTERMITTENTLY, IT IS AN INDICATION OF A POTENTIAL SAFETY HAZARD THAT MUST BE

ADDRESSED BY A QUALIFIED TECHNICIAN, SERVICE

AGENCY OR THE GAS SUPPLIER. DO NOT RESET

SAFETY CONTROLS WITHOUT CORRECTIVE ACTION

AND/OR VERIFICATION OF PROPER SAFE OPERATION

BY A QUALIFIED INSTALLER, SERVICE AGENCY OR THE

GAS SUPPLIER.

REPLACE ANY SAFETY CONTROL COMPONENT ONLY

WITH IDENTICAL OEM REPLACEMENT PARTS. WHEN A

NEW SAFETY SWITCH IS INSTALLED, IT MUST BE

TESTED FOR A MINIMUM OF 15 MINUTES WITH THE

FURNACE OPERATING AT MAXIMUM INPUT RATE AND

WITH BOTH BLOWER AND BURNER DOOR INSTALLED.

IF THE FURNACE IS INSTALLED IN A CLOSET, THE

CLOSET DOOR MUST ALSO BE CLOSED FOR THIS

TEST. REPEAT THE TEST AT THE MINIMUM INPUT RATE

IF THE FURNACE IS A MULTI-STAGE FURNACE.

!

WARNING

USE ONLY WITH THE TYPE OF GAS APPROVED FOR

THIS FURNACE. REFER T O THE FURNACE RATING

PLATE.

!

WARNING

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME.

USE A COMMERCIALLY AVAILABLE SOAP SOLUTION

MADE SPECIFICALLY FOR THE DETECTION OF LEAKS

TO CHECK ALL CONNECTIONS, AS SPECIFIED IN GAS

SUPPLY AND PIPING SECTION OF THESE INSTRUCTIONS.

!

WARNING

COMBUSTION PRODUCTS MUST BE DISCHARGED OUTDOORS. CONNECT THIS FURNACE TO AN APPROVED

VENT SYSTEM ONLY, AS SPECIFIED IN THE VENT PIPE

INSTALLATION SECTION OF THESE INSTRUCTIONS.

!

WARNING

WHEN A FURNACE IS INSTALLED SO THAT SUPPLY

DUCTS CARRY AIR CIRCULATED BY THE FURNACE TO

AREAS OUTSIDE THE SPACE CONTAINING THE FURNACE, THE RETURN AIR SHALL ALSO BE HANDLED BY

DUCT(S) SEALED TO THE FURNACE CASING AND TERMINATING OUTSIDE THE SPACE CONTAINING THE FURNACE.

!

WARNING

WHENEVER THE FACTORY RETURN-AIR CONNECTION

IS NOT USED IT MUST BE SEALED. A SOLID METAL

BASE PLATE MUST BE INSTALLED AND SEALED. FACTORY BASE PLATES ARE AVAILABLE AS ACCESSORY

ITEMS. (PART NUMBERS ARE LISTED IN THE SPEC

SHEET FOR THE FURNACE.) FAILURE TO INSTALL AND

SEAL THE BASE PLATE AND RETURN AIR DUCT CONNECTIONS MAY ALLOW CARBON MONOXIDE AND

OTHER CONTAMINANTS TO BE DRAWN INTO THE CONDITIONED AIR SPACE AND DISTRIBUTED THROUGHOUT

THE HEATED SPACE.

!

WARNING

DO NOT OPERATE THE SYSTEM WITHOUT FILTERS. A

PORTION OF THE DUST ENTRAINED IN THE AIR MAY

TEMPORARILY LODGE IN THE AIR DUCT RUNS AND AT

THE SUPPLY REGISTERS. ANY CIRCULATED DUST PARTICLES WILL BE HEATED AND CHARRED BY CONTACT

WITH THE FURNACE HEAT EXCHANGER. THIS SOOTY

RESIDUE WILL SOIL CEILINGS, WALLS, DRAPES, CARPETS AND OTHER HOUSEHOLD ARTICLES. SOOT DAMAGE MAY ALSO RESULT WITH, OR WITHOUT, FILTERS IN

PLACE, WHEN CERTAIN TYPES OF CANDLES ARE

BURNED, OR CANDLEWICKS ARE LEFT UNTRIMMED.

6

!

WARNING

COMBUSTION AND VENTILATION AIR MUST BE PROVIDED TO THE FURNACE AS REQUIRED BY THE NATIONAL FUEL-GAS CODE (U.S.) AND CSA B149.1

(CANADA) AND THE COMBUSTION AND VENTILATION

AIR SECTION OF THESE INSTRUCTIONS.

Page 7

7

SAFETY

Safety Information

IMPORTANT INFORMATION ABOUT

EFFICIENCY AND INDOOR AIR

QUALITY

Central cooling and heating equipment is only as efficient as the

duct system that carries the cooled or heated air. To maintain efficiency, comfort and good indoor air quality, it is important to have

the proper balance between the air being supplied to each room

and the air returning to the cooling and heating equipment.

Proper balance and sealing of the duct system improves the efficiency of the heating and air conditioning system and improves

the indoor air quality of the home by reducing the amount of airborne pollutants that enter homes from spaces where the ductwork and / or equipment is located. The manufacturer and the

U.S. Environmental Protection Agency’s Energy Star Program

recommend that central duct systems be checked by a qualified

contractor for proper balance and sealing.

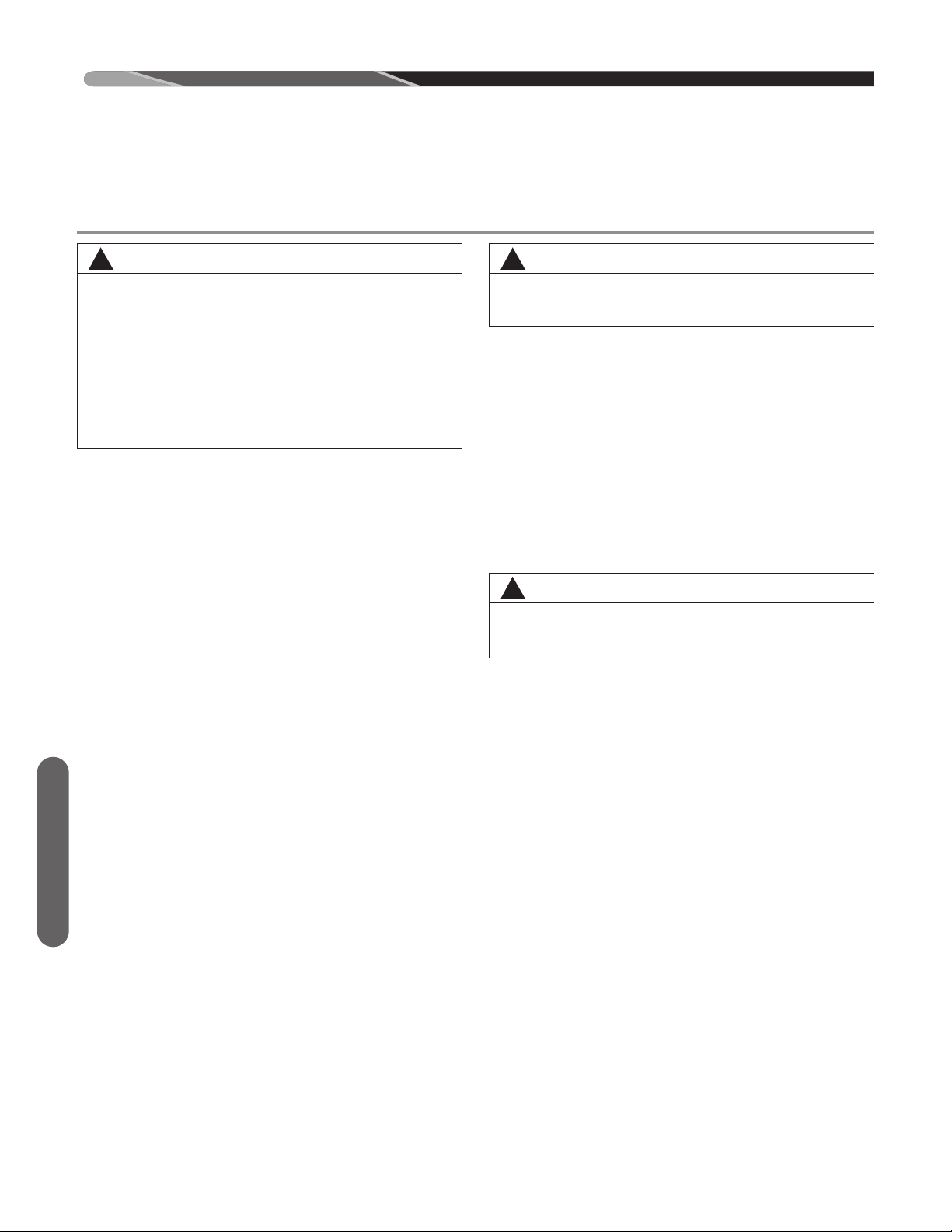

FIGURE 2

MIGRATION OF DANGEROUS SUBSTANCES, FUMES, AND ODORS INTO

LIVING SPACES

Adapted from

Residential Duct Diagnostics and Repair

, with permission of Air Conditioning

Contractors of America (ACCA).

!

WARNING

DUCT LEAKS CAN CREATE AN UNBALANCED SYSTEM

AND DRAW POLLUTANTS SUCH AS DIRT, DUST, FUMES

AND ODORS INTO THE HOME CAUSING PROPERTY

DAMAGE. FUMES AND ODORS FROM TOXIC, VOLATILE

OR FLAMMABLE CHEMICALS, AS WELL AS AUTOMOBILE EXHAUST AND CARBON MONOXIDE (CO), CAN BE

DRAWN INTO THE LIVING SPACE THROUGH LEAKING

DUCTS AND UNBALANCED DUCT SYSTEMS CAUSING

PERSONAL INJURY OR DEATH (SEE FIGURE 2).

• IF AIR-MOVING EQUIPMENT OR DUCTWORK IS LOCATED IN GARAGES OR OFF-GARAGE STORAGE

AREAS - ALL JOINTS, SEAMS, AND OPENINGS IN THE

EQUIPMENT AND DUCT MUST BE SEALED TO LIMIT

THE MIGRATION OF TOXIC FUMES AND ODORS INCLUDING CARBON MONOXIDE FROM MIGRATING

INTO THE LIVING SPACE.

• IF AIR-MOVING EQUIPMENT OR DUCTWORK IS LOCATED IN SPACES CONTAINING FUEL BURNING APPLIANCES SUCH AS WATER HEATERS OR BOILERS ALL JOINTS, SEAMS, AND OPENINGS IN THE EQUIPMENT AND DUCT MUST ALSO BE SEALED TO PREVENT DEPRESSURIZATION OF THE SPACE AND

POSSIBLE MIGRATION OF COMBUSTION BYPRODUCTS INCLUDING CARBON MONOXIDE INTO THE LIVING SPACE.

!

WARNING

BLOWER AND BURNERS MUST NEVER BE OPERATED

WITHOUT THE BLOWER DOOR IN PLACE. THIS IS TO

PREVENT DRAWING GAS FUMES (WHICH COULD CONTAIN HAZARDOUS CARBON MONOXIDE) INTO THE

HOME THAT COULD RESULT IN PERSONAL INJURY OR

DEATH.

!

WARNING

ALWAYS INSTALL THE FURNACE TO OPERATE WITHIN

THE FURNACE’S INTENDED TEMPERATURE-RISE

RANGE WITH A DUCT SYSTEM WHICH HAS AN EXTERNAL STATIC PRESSURE WITHIN THE ALLOWABLE

RANGE, AS SPECIFIED IN THE DUCTING SECTION OF

THESE INSTRUCTIONS. SEE ALSO FURNACE RATING

PLATE.

THE FURNACE MAY BE USED FOR HEATING OF BUILDINGS OR STRUCTURES UNDER CONSTRUCTION.

INSTALLATION MUST COMPLY WITH ALL INSTALLATION

INSTRUCTIONS INCLUDING:

PROPER VENT INSTALLA TION;

FURNACE OPERATING UNDER THERMOSTAT

CONTROL;

RETURN AIR DUCT SEALED TO THE FURNACE;

AIR FILTERS IN PLACE;

SET FURNACE INPUT RATE AND TEMPERATURE

RISE PER RATING PLATE MARKINGS;

MEANS FOR PROVIDING OUTDOOR AIR RE-

QUIRED FOR COMBUSTION;

RETURN AIR TEMPERATURE MAINTAINED BE-

TWEEN 55°F (13°C) AND 80°F (27°C); AND

CLEAN FURNACE, DUCT WORK AND COMPO-

NENTS UPON SUBSTANTIAL COMPLETION OF

THE CONSTRUCTION PROCESS, AND VERIFY

THAT THE FURNACE OPERATING CONDITIONS

INCLUDING IGNITION, INPUT RATE, TEMPERATURE RISE AND VENTING, ACCORDING TO THE

INSTRUCTIONS AND CODES.

Page 8

8

1. IMPORTANT: If using a cooling evaporator coil with this fur-

nace, be sure the air passes over the heat exchanger before

passing over the cooling coil. The cooled air passing over the

warm ambient air inside the heat exchanger tubes can cause

condensation inside the tubes resulting in corrosion and eventual failure. An auxiliary drain pan should extend under any

evaporator coil installed with the furnace.

If there are manual dampers, they must be equipped to prevent

heating or cooling operation unless the damper is in the full heat

or cool position.

2. NOTE: This furnace is shipped with heat exchanger support

brackets installed under the back of the heat exchanger. These

may be removed before installation, but it is not required.

3. IMPORTANT:

This furnace is not approved or recommended

for installation on its back, with access doors facing upwards.

4. This furnace is suitable for installation in buildings constructed

on-site. This heating unit should be centralized with respect to

the heat distribution system as much as practicable.

5. NOTE: These furnaces are approved for installation in attics,

as well as alcoves, utility rooms, closets and crawlspaces.

6. IMPORTANT:

Support this unit when installed. For attic or cra wl

space installation, horizontal furnaces may be installed on combustible wood flooring or by using support brackets. See Figure

3.

7. IMPORTANT:

If installing in a utility room, be sure the door is

wide enough to:

a. allow the largest part of the furnace to pass; or

b. allow any other appliance (such as a water heater) to pass.

SITE SELECTION

1. Select a site in the building near the center of the proposed, or existing, duct system.

2. Give consideration to the vent system piping when selecting the furnace location. Be sure the venting system

can get from the furnace to the termination with minimal

length and elbows.

3. Locate the furnace near the existing gas piping. Or, if

running a new gas line, locate the furnace to minimize

the length and elbows in the gas piping. See Figure 3.

4. Locate the furnace to maintain proper clearance to

combustibles as shown in following Figure 4.

CLEARANCE – ACCESSIBILITY

The design of forced air furnaces with input ratings as

listed in the tables under Figure 4 are to combustible materials shown in inches.

See name/rating plate and clearance label for specific

model number and clearance information.

Service clearance of at least 24 inches (30 cm) is recommended in front of all furnaces.

NOTE: Use recommended 24” (30 cm) clearance if accessibility clearances are greater than fire protection clearances.

ACCESSIBILITY CLEARANCES, WHERE GREATER, MUST

TAKE PRECEDENCE OVER FIRE PROTECTION CLEARANCES.

GENERAL INFORMATION

LOCATION REQUIREMENTS

Location

!

WARNING

WHEN THIS FURNACE IS INSTALLED IN A RESIDENTIAL

GARAGE, IT MUST BE INSTALLED SO THE BURNERS

AND IGNITION SOURCE ARE LOCATED NO LESS THAN

18 INCHES [450MM] ABOVE THE FLOOR. THIS IS TO PREVENT THE RISK OF IGNITING FLAMMABLE VAPORS

WHICH MAY BE PRESENT IN A GARAGE. ALSO, THE FURNACE MUST BE LOCATED OR PROTECTED TO AVOID

PHYSICAL DAMAGE BY VEHICLES. FAILURE TO FOLLOW

THESE WARNINGS CAN CAUSE A FIRE OR EXPLOSION,

RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY

OR DEATH.

!

WARNING

THIS FURNACE IS NO T APPROVED OR RECOMMENDED

FOR INSTALLATION ON ITS BACK, WITH ACCESS DOORS

F ACING UPWARDS.

!

WARNING

DO NOT LIFT THE UNIT BY THE HEAT EXCHANGER

TUBES. DOING SO CAN D AMAGE THE HEAT EXCHANGER ASSEMBLY.

Page 9

9

Location

GENERAL INFORMATION (cont.)

LOCATION REQUIREMENTS

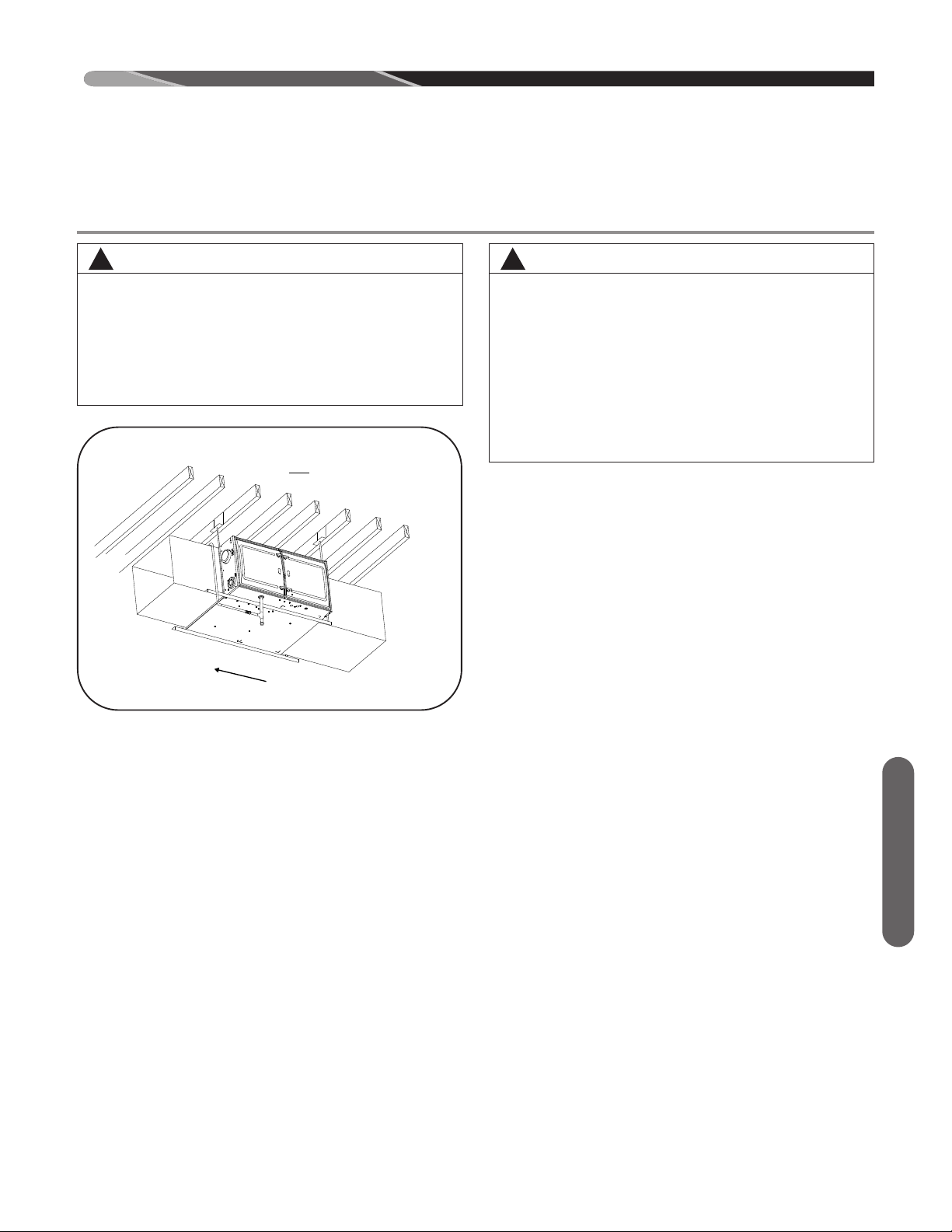

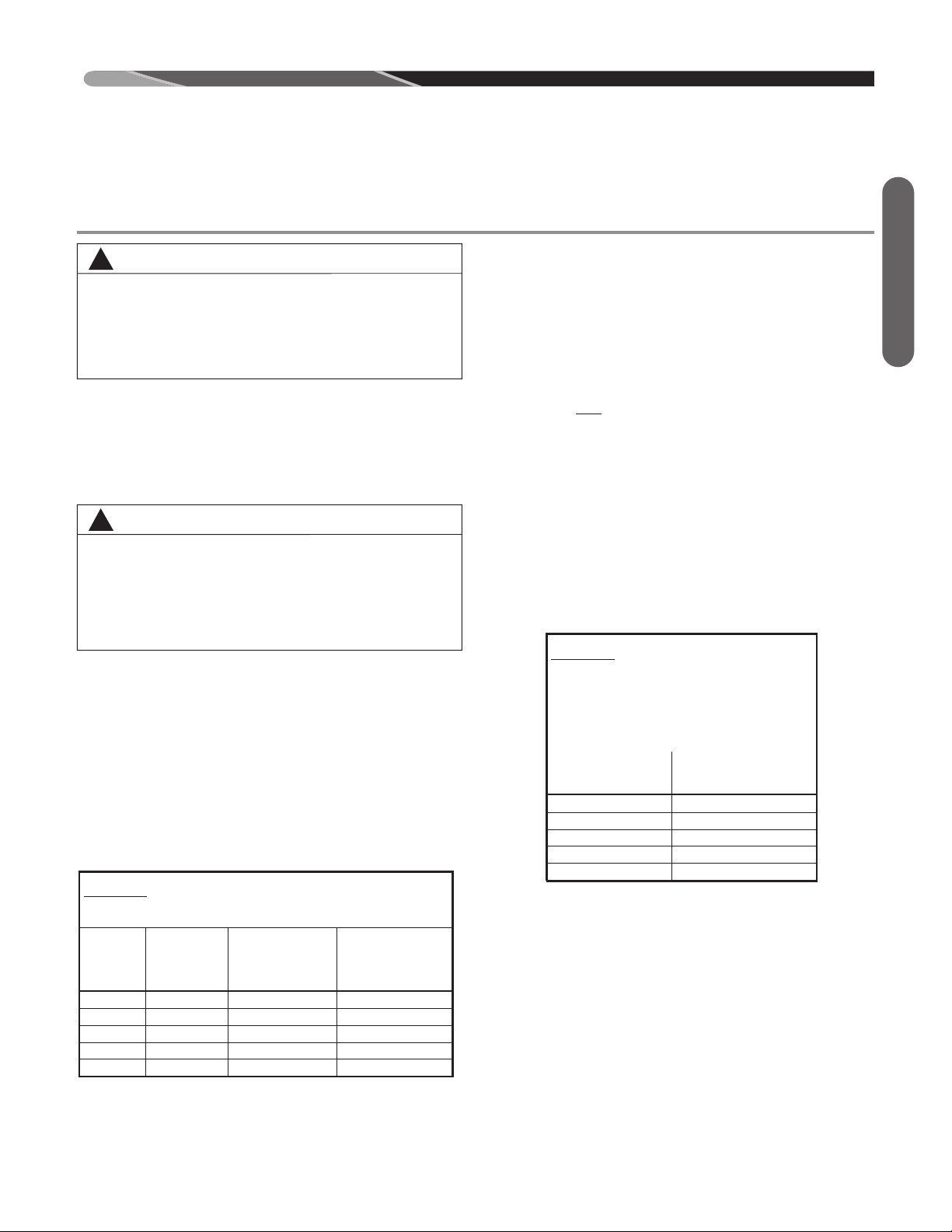

ST-A1220-03

FIGURE 3

!

WARNING

COMBUSTIBLE MATERIAL MUST NOT BE PLACED ON

OR AGAINST THE FURNACE JACKET. THE AREA

AROUND THE FURNACE MUST BE KEPT CLEAR AND

FREE OF ALL COMBUSTIBLE MATERIALS INCLUDING

GASOLINE AND OTHER FLAMMABLE VAPORS AND LIQUIDS. PLACEMENT OF COMBUSTIBLE MATERIALS ON,

AGAINST OR AROUND THE FURNACE JACKET CAN

CAUSE AN EXPLOSION OR FIRE RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH. THE

HOMEOWNER SHOULD BE CAUTIONED THAT THE FURNACE AREA MUST NOT BE USED AS A BROOM CLOSET

OR FOR ANY OTHER STORAGE PURPOSES.

!

WARNING

UPFLOW AND HORIZONTAL FURNACES ARE DESIGNCERTIFIED FOR INSTALLATION ON COMBUSTIBLE

FLOORS. NO TE, HOWEVER, THAT FURNACES MUST NOT

BE INSTALLED DIRECTLY ON CARPETING, TILE OR

OTHER COMBUSTIBLE MATERIAL OTHER THAN WOOD

FLOORING. INSTALLATION ON A COMBUSTIBLE MATERIAL CAN RESULT IN FIRE, CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

NOTE:

HORIZONTAL LEFT ORIENTATION DEPICTED IN ILLUSTRATION.

HORIZONTAL RIGHT ORIENTATION IS SIMILAR IN INSTALLATION.

AIR FLOW

Page 10

10

BOTTOM

TOP

LEFT SIDE FRONT RIGHT SIDE

GAS

CONNECTION

ELECTRICAL CONNECTION

LINE VOLTAGE

ELECTRICAL CONNECTION

LOW VOLTAGE

OPTIONAL

GAS CONNECTION

OPTIONAL LOW

VOLTAGE WIRING

OPTIONAL LINE VOLTAGE

WIRING

A

I

R

F

L

O

W

RETURN

AIR

SUPPLY

AIR

HOT

MODEL A B C D E F RIGHT SIDE BACK TOP FRONT VENT

5 14 13 27/32 10 5/8 ༃ 11 1/2 1 7/8 0 4༄ 01 36༅ 85 lbs.

7 17 1/2 16 11/32 12 3/8 ༃ 15 2 1/2 0 3༄ 01 36༅ 105 lbs.

10 21 19 27/32 14 1/8 ༃ 18 1/2 2 1/2 0 0 0 1 3 6༅ 120 lbs.

12 24 1/2 23 11/32 15 7/8 ༃ 22 2 1/2 0 0 0 1 3 6༅ 140 lbs.

15 24 1/2 23 11/32 15 7/8 ༃ 22 2 1/2 0 0 0 1 3 6༅ 150 lbs.

༃MAY REQUIRE 3" TO 4" OR 3" TO 5" ADAPTER.

4" ADAPTER INCLUDED WITH (-)801P UNITS.

༄MAY BE 0" WITH TYPE B VENT.

༅MAY BE 1" WITH TYPE B VENT.

LEFT SIDE

REDUCED CLEARANCE (IN.)

SHIP

WGTS.

FIGURE 4

UPFLOW/HORIZONTAL DIMENSIONS

Location

REDUCED CLEARANCE (IN.)

Input A B C D E F

Left Right

Back Top Front Vent

Ship.

Side Side Wgts.

050 14 12

27

/32 10

5

/8 ➀ 11

1

/2 1

7

/8 0 4➁ 0 1 3 6➂ 85 lbs.

070 17

1

/2 16

11

/32 12

3

/8 ➀ 15 2

1

/2 0 3➁ 0 1 3 6➂ 105 lbs.

100 21 19

27

/32 14

1

/8 ➀ 18

1

/2 2

1

/2 0 0 0 1 3 6➂ 120 lbs.

120 24

1

/2 23

11

/32 15

7

/8 ➀ 22 2

1

/2 0 0 0 1 3 6➂ 140 lbs.

150 24

1

/2 23

11

/32 15

7

/8 ➀ 22 2

1

/2 0 0 0 1 3 6➂ 150 lbs.

CLEARANCE TO COMBUSTIBLE MATERIAL (INCHES)

UPFLOW/HORIZONTAL MODELS

➀ May require 3” to 4” or 3” to 5” adapter.

4” adapter optional.

➁ May be 0” with type B vent.

➂ May be 1” with type B vent.

*See furnace speck sheet for availability.

ST-A1220-04

Page 11

11

Proper air flow is required for the correct operation of this

furnace. Restricted air flow can cause erratic operation and

can damage the heat exchanger. The duct system must

carry the correct amount of air for heating and cooling if

summer air conditioning is used.

IMPORTANT: When using outside air, design and adjust

the system to maintain a return air temperature ABOVE

55° F during the heating season.

NOTE: Return air grilles and warm air registers must not

be obstructed or closed.

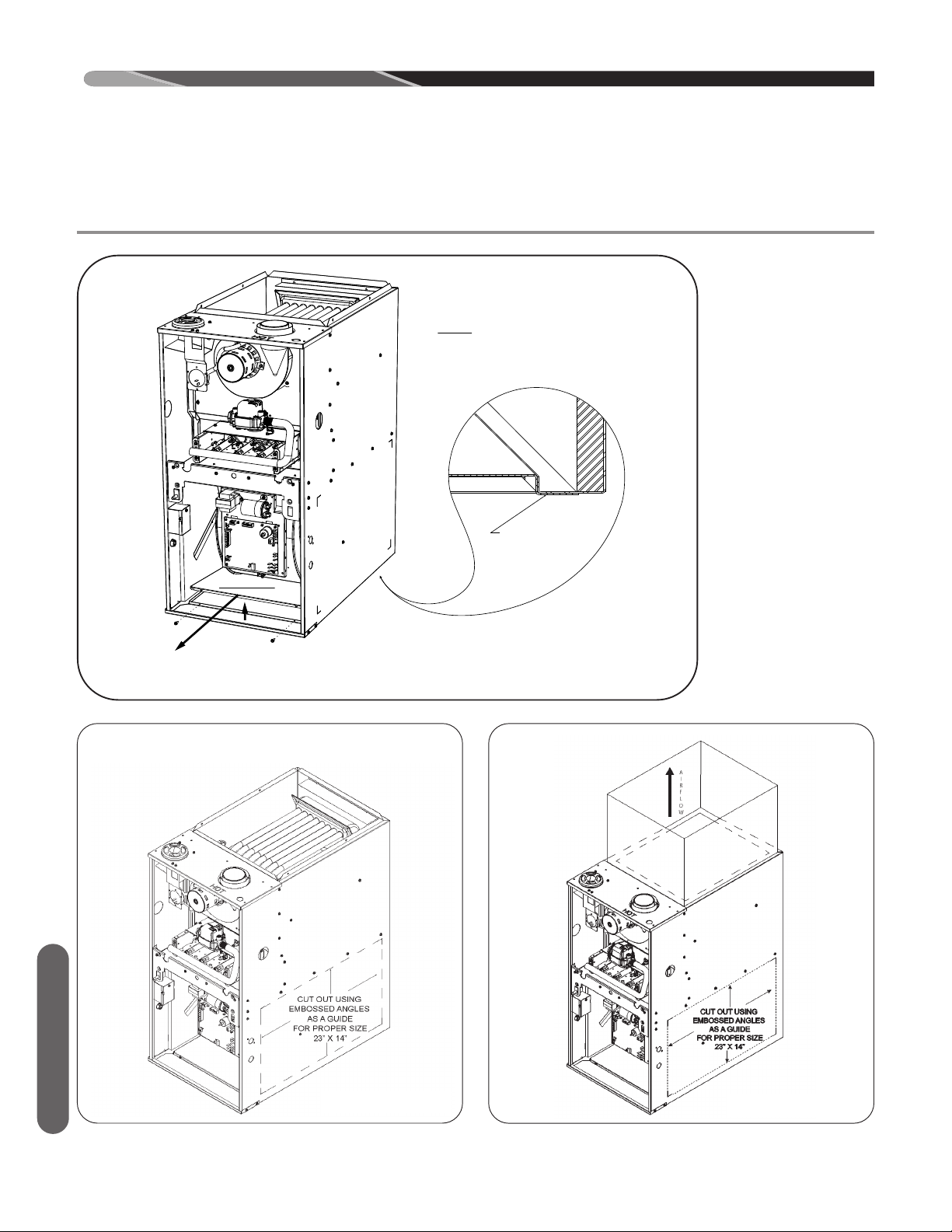

UPFLO W INSTALLATIONS

1. Position the unit to minimize long runs of duct or runs

of duct with many turns and elbows.

2. For side return: Cut an opening in the side. The opening should be cut the full width and height of the

knockouts on the unit. See Figure 6.

3. If summer air conditioning is desired, position the indoor coil on the supply-air side of the unit. Ensure that

no air can bypass the coil.

4. Connect the furnace to the supply air plenum. See Figure 7.

5. Connect the return air ducting to the return-air opening

at the bottom and/or side of the unit. Make the connections air-tight to prevent the migration of toxic fumes

and odors including carbon monoxide from migrating

into the living space.

6. If a filter is installed near the furnace, be sure to have

adequate space for installation and removal of the unit

filter.

7. NOTE: Where the maximum airflow is 1800 CFM or

more, BOTH sides or the bottom must be used for the

return air. Do not take return air from the back of the

unit.

NOTE: DO NOT take return air from furnace rooms,

garages or cold areas. Avoid return air from utility rooms,

kitchens, laundry rooms and bathrooms.

DUCTING

Ducting

!

WARNING

BLOWER AND BURNERS MUST NEVER BE OPERATED

WITHOUT THE BLOWER DOOR IN PLACE. THIS IS TO

PREVENT DRAWING GAS FUMES (WHICH COULD CONTAIN HAZARDOUS CARBON MONOXIDE) INTO THE

HOME THAT COULD RESULT IN PERSONAL INJURY OR

DEATH.

!

WARNING

THE SOLID METAL BASE (SHIPPED WITH THE 801P

FURNACE) PLATE MUST BE INSTALLED IN THE

FURNACE BOTTOM WHEN USING SIDE AIR RETURN. FAILURE TO INSTALL A BASE PLATE COULD

CAUSE THE PRODUCTS OF COMBUSTION TO CIRCULATE INTO THE LIVING SP ACE AND CREATE

POTENTIAL LY HAZARDOUS CONDITIONS, INCLUDING CARBON MONOXIDE POISONING OR DEATH.

FOR BOTTOM RETURN, A SOLID METAL BASE PAN

MUST NOT BE INSTALLED. SEE FIGURE 5.

!

WARNING

SOME HEATING AIRFLOW VALUES MAY BE

HIGHER THAN THOSE REQUIRED FOR COOLING.

BE SURE TO SIZE DUCT FOR THE MAXIMUM POSSIBLE AIRFLOW VALUE.

SIZE AIRFLOW DISTRIBUTION SYSTEM TO ACCEPTABLE INDUSTRY STANDARDS AND METHODS. TOTAL STATIC PRESSURE DROP OF THE AIR

DISTRIBUTION SYSTEM SHOULD NOT EXCEED .8

INCHES W.C. THIS WILL INCLUDE ANY AIR CONDITIONER COIL, AIR FILTRATION SYSTEM, ZONING

SYSTEM, DUCTWORK, ETC. REFER TO ADDED

EQUIPMENT TECHNICAL INFORMATION TO OBTAIN

PRESSURE DROP INFORMATION WHEN EQUIPMENT IS OPERATING AT RECOMMENDED HEATING OR COOLING CFMS.

Page 12

12

Ducting

DUCTING

FIGURE 5

FIGURE 6

FIGURE 7

ST-A1220-10

ST-A1220-11

ST-A1220-08

LIFT UP, PULL OUT

NOTE:

SOLID BASE PLATE PROVIDED WITH (-)801P

MODELS ONLY.

WHEN SOLID BASE PLATE IS USED . TAPE

AROUND BOTTOM FLANGES OF CABINET

BEFORE THE UNIT IS INSTALLED.

SOLID BASE FLANGE

FITS UNDER

CABINET BOTTOM

1. REMOVE 2 SCREWS, LIFT BASE UP, SLIDE FORWARD TO REMOVE.

2. INSTALLATION IS REVERSE OF REMOVAL.

** VERIFY REAR FLANGE IS SEALED PROPERLY AS SHOWN IN DETAIL.

ST-A1220-10-X0

Page 13

13

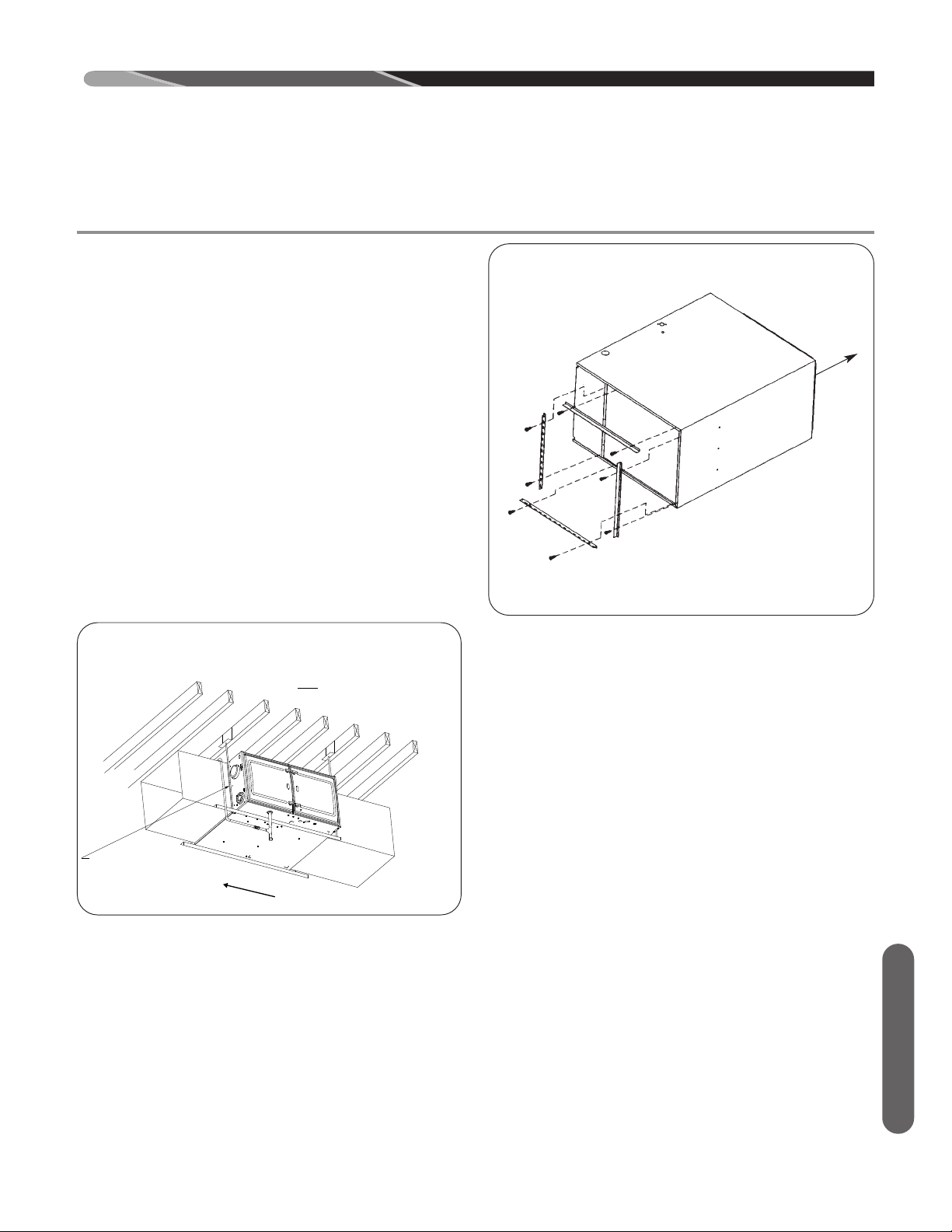

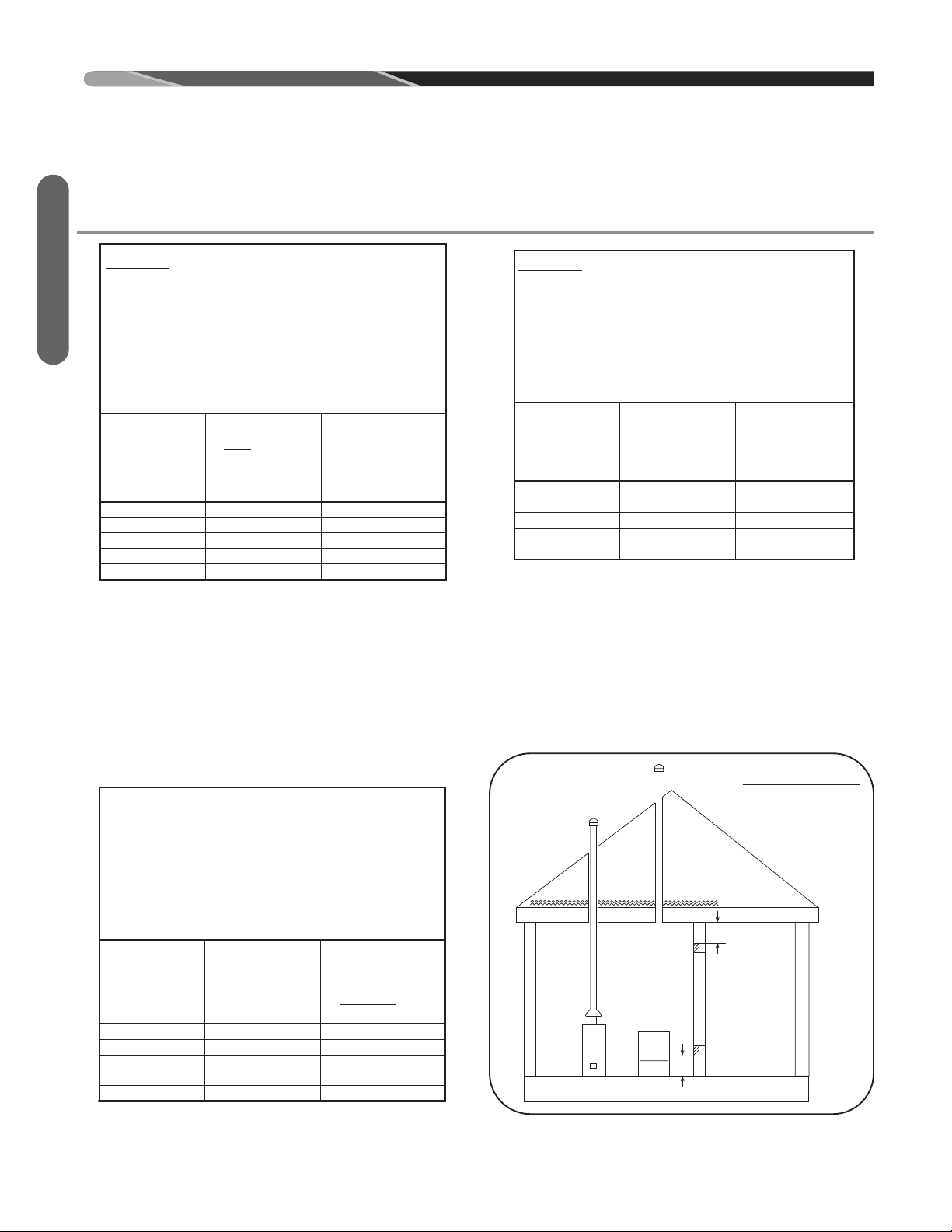

HORIZONTAL UNITS

1.Position the unit to minimize long runs of duct or runs of

duct with many turns and elbows.

2.Unit can be mounted left or right side airflow configuration.

3.Position the unit on adequate supports or by using support brackets (see Figure 8) and connect supply plenum.

4.If summer air conditioning is desired, position the indoor

coil on the supply air side of the unit. Insure that no air

can bypass this coil.

5.Secure the four angle brackets (shipped with (-)801P

units) to the return air opening. See Figure 9. Connect

the return air ducting to the return air opening at the top

of the unit. Make the connection air tight to prevent entraining combustion gases from an adjacent fuel-burning

appliance.

NOTE: Do not block furnace access with support rods.

Maintain clearances recommended in Figure 8. Allow

enough space for proper service maintenance or replacement of the heat exchanger and blower assembly.

DUCTING

FOUR ANGLE BRACKETS, SHIPPED WITH (-)801P UNITS, CAN BE

INSTALLED HORIZONTALLY. THESE BRACKETS MAY BE USED TO

SECURE THE RETURN AIR DUCT TO A HORIZONTAL UNIT.

RETURN

AIRFLOW

REAR VIEW

FIGURE 9

HORIZONTAL RETURN AIR DUCT

(LEFT-HAND AIRFLOW POSITION SHOWN)

NOTE:

HORIZONTAL LEFT ORIENTATION DEPICTED IN ILLUSTRATION.

HORIZONTAL RIGHT ORIENTATION IS SIMILAR IN INSTALLATION.

AIR FLOW

NOTE:

DO NOT BLOCK FURNACE ACCESS WITH

SUPPORT RODS, ALLOW SPACE FOR

PROPER SERVICE MAINTIENCE OR

REPLACEMENT OF THE HEAT EXCHANGER

AND BLOWER ASSEMBLY .

FIGURE 8

HORIZONTAL FURNACE INSTALLED W/SUPPORT BRACKETS

ST-A1220-03

Ducting

Page 14

14

Combustion Air

COMBUSTION AND VENTILATION AIR

1. IMPORTANT:

Air for combustion and ventilation must not

come from a corrosive atmosphere. Any failure due to corrosive elements in the atmosphere is excluded from warranty

coverage.

2. Combustion air must be free of acid forming chemicals; such

as sulphur, fluorine and chlorine. These elements are found in

aerosol sprays, detergents, bleaches, cleaning solvents, air

fresheners, paint and varnish removers, refrigerants and many

other commercial and household products. Vapors from these

products when burned in a gas flame form acid compounds.

The acid compounds increase the dew point temperature of

the flue products and are highly corrosive after they condense.

3. The following types of installation may require OUTDOOR AIR

for combustion, due to chemical exposures:

• Commercial buildings

• Buildings with indoor pools

• Furnaces installed in laundry rooms

• Furnaces in hobby or craft rooms

• Furnaces installed near chemical storage areas.

4. If combustion air is exposed to the following substances (but

not limited to the following), it should not be used and the furnace may require outdoor air for combustion.

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine-based swimming pool chemicals

• Water softening chemicals

• De-icing salts or chemicals

• Carbon tetrachloride

• Halogen type refrigerants

• Cleaning solvents (such as perchloroethylene)

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid

• Cements and glues

• Antistatic fabric softeners for clothes dryers

• Masonry curing and acid washing materials

Combustion air requirements are determined by whether the furnace is in an open (unconfined) area or in a confined space such

as a closet or small room.

When the furnace is installed in the same space with other gas appliances, such as a water heater, be sure there is an adequate

supply of combustion and ventilation air for the furnace and the

other appliances. Do not delete or reduce the combustion air supply required by the other gas appliances in this space. See Z223.1,

National Fuel Gas Code (NFPA 54). An unconfined space must

have at least 50 cubic feet (volume) for each 1,000 BTUH of the

total input of all appliances in the space. If the open space containing the appliances is in a building with tight construction (contemporary construction), outside air may still be required for the

appliances to burn and vent properly. Outside air openings should

be sized the same as for a confined space.

IMPORTANT: ONLY THE CURRENT VENT INSTRUCTIONS

APPLY. All gas furnaces cannot be common-vented.

OVERTEMPERATURE SAFETY

SWITCHES

Furnaces are equipped with safety switches in the burner compartment to protect against over-temperature conditions caused

by inadequate combustion air supply. The switches are located

in the burner compartment. If a switch is tripped it must be manually reset after clearing the fault condition which caused it to

open.

IMPORTANT:

This is not a direct vent furnace. Review venting

instructions before installing.

!

WARNING

THIS FURNACE AND ANY OTHER FUEL-BURNING APPLIANCE MUST BE PROVIDED WITH ENOUGH FRESH AIR

FOR PROPER COMBUSTION AND VENTILATION OF THE

FLUE GASES. MOST HOMES WILL REQUIRE THAT OUTSIDE AIR BE SUPPLIED INTO THE FURNACE AREA. FAILURE TO DO SO CAN CAUSE DEATH FROM CARBON

MONOXIDE POISONING.

!

WARNING

ADEQUATE FACILITIES FOR PROVIDING AIR FOR COMBUSTION AND VENTILATION MUST BE PROVIDED IN ACCORDANCE WITH SECTION 5.3, AIR FOR COMBUSTION

AND VENTILATION, OF THE NATIONAL FUEL GAS CODE,

ANSI, Z223.1 LATEST EDITION OR APPLICABLE PROVISIONS FOR THE LOCAL BUILDING CODES, AND NOT

OBSTRUCTED SO AS TO PREVENT THE FLOW OF AIR TO

THE FURNACE.

COMBUSTION AIR REQUIREMENTS

!

WARNING

ALL FURNACE INSTALLATIONS MUST COMPLY WITH

THE NATIONAL FUEL GAS CODE AND LOCAL CODES TO

PROVIDE ADEQUATE COMBUSTION AND VENTILATION

AIR FOR THE FURNACE. FAILURE TO DO SO CAN CREATE HAZARDOUS CONDITIONS RESULTING IN PROPERTY DAMAGE, BODILY INJURY OR DEATH FROM

SMOKE, FIRE OR CARBON MONOXIDE.

!

WARNING

DO NOT BYPASS, JUMPER, OR REMOVE ANY SAFETY

SWITCH FROM THE FURNACE CONTROL CIRCUIT. IF A

SAFETY SWITCH CAUSES THE FURNACE TO SHUT

DOWN OR OPERATE INTERMITTENTLY, IT IS AN INDICATION OF A POTENTIAL SAFETY HAZARD THAT MUST BE

ADDRESSED BY A QUALIFIED TECHNICIAN, SERVICE

AGENCY OR THE GAS SUPPLIER. DO NOT RESET

SAFETY CONTROLS WITHOUT CORRECTIVE ACTION

AND/OR VERIFICATION OF PROPER SAFE OPERATION

BY A QUALIFIED INSTALLER, SERVICE AGENCY OR THE

GAS SUPPLIER.

REPLACE ANY SAFETY CONTROL COMPONENT WITH

IDENTICAL OEM REPLACEMENT PARTS ONLY.

Page 15

15

COMBUSTION AND VENTILATION AIR (cont.)

For improved indoor air quality, added safety and product performance we recommend direct vent type installations. If non-direct type vent system is used, the requirements for combustion

air must be provided as identified in the National Fuel Gas Code.

Combustion air requirements are determined by whether the furnace is in an open (unconfined) area or in a confined space such

as a closet or small room.

FURNACE LOCATED IN AN UNCONFINED SPACE

USING INDOOR AIR FOR COMBUSTION:

An unconfined space must have at least 50 cubic feet for each

1,000 BTUH of total input for all appliances in the space. Table 1

below specifies minimum space requirements and a few examples of the room sizes required for different inputs. The sizes are

based on 8-foot ceilings.

If the open space containing the furnace is in a building with tight

construction, outside air may still be required for the furnace to

operate and vent properly. Outside air openings should be sized

the same as for a confined space.

FURNACE LOCATED IN A CONFINED

SPACE

A confined space is defined as any space for a given furnace input

rating which is smaller than that which is specified in Table 1 as

minimum for an “unconfined” space. If the space is less than that

specified in this table, the space is defined as

“confined”.

If the space is small enough to be designated as “confined”, it

must have openings into the space which are located in accordance with the requirements set forth in the following subsections

A and B. Size connected to the heated area or to the outside, and

by the input of ALL appliances in the space.

If the confined space is within a building with tight construction,

combustion air must be taken from outdoors or from an area

freely communicating with the outdoors.

A. USING INDOOR AIR FOR COMBUSTION:

IMPORTANT: Air should not be taken from a heated space

with a fireplace, exhaust fan or other device that may produce negative pressure.

If combustion air is taken from the heated area, the openings

must each have at least 100 square inches of free area.

Each opening must have at least one square inch of free

area for each 1,000 BTUH of total input in the space. Table 2

shows some typical examples of openings required for combustion air openings required for a confined space.

B. USING OUTDOOR AIR FOR COMBUSTION:

IMPORTANT: Do not take air from an attic space that is

equipped with power ventilation.

The confined space must communicate with the outdoors in

accordance with Methods 1 or 2 below. The minimum dimension of air openings shall not be less than 3 inches. Where

ducts are used, they shall be of the same cross-sectional

area as the free area of the openings to which they connect.

METHOD 1:

Two permanent openings, one located within 12 inches of the

top and one located within 12 inches of the bottom of the enclosure, shall be provided. The openings shall communicate

directly, or by ducts, with the outdoors or spaces (crawl or

attic) that freely communicate with the outdoors.

Combustion Air

COMBUSTION AIR REQUIREMENTS: CONFINED AND

UNCONFINED SPACES

!

WARNING

ALL FURNACE INSTALLATIONS MUST COMPLY WITH

THE NATIONAL FUEL GAS CODE, NFPA 54 AND LOCAL

CODES TO PROVIDE ADEQUATE COMBUSTION AND

VENTILATION AIR FOR THE FURNACE. FAILURE TO DO

SO CAN RESULT IN EXPLOSION, FIRE, PROPERTY DAMAGE, CARBON MONOXIDE POISONING, PERSONAL INJURY OR DEATH.

!

WARNING

READ AND FOLLOW THE GENERAL VENTING REQUIREMENTS AND GUIDELINES OF THIS MANUAL FOR ADDI-

TIONAL VENTING REQUIREMENTS PERTAINING TO ALL

FURNACE INSTALLATIONS (INCLUDING DIRECT AND

NON-DIRECT VENTING). FAILURE TO FOLLOW ALL INSTRUCTIONS IN THIS MANUAL CAN RESULT IN EQUIPMENT FAILURE, EQUIPMENT DAMAGE, PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

150,000 7,500 940 32 x 30

TABLE 1: MINIMUM SPACE REQUIREMENTS

FOR UNCONFINED SPACE, NON-DIRECT VENT

150,000 150

TABLE 2: MINIMUM FREE AREA

OPENING REQUIRED FOR A

FURNACE LOCATED IN A

CONFINED SPACE USING

INDOOR AIR FOR COMBUSTION.

TABLE 7: MINIMUM SPACE REQUIREMENTS

FOR UNCONFINED SPACE, NON-DIRECT VENT*

Input

(BTUH)

50,000 2,500 313 16 x 20

75,000 3,750 470 24 x 20

100,000 5,000 625 32 x 20

125,000 6,300 790 36 x 30

Minimum

Space

(Cubic Ft)

Minimum Area

with 8

Ceilings (sq )

Typical Room

Size w/ 8'

Ceilings ( x )

TABLE 8: MINIMUM FREE AREA

OPENING REQUIRED FOR A

FURNACE LOCATED IN A

CONFINED SPACE USING

INDOOR AIR FOR COMBUSTION.

Input (BTUH)

50,000 100

75,000 100

100,000 100

125,000 130

Free Area for Each

Opening (sq inches)

Page 16

A. Where directly communicating with the outdoors through an

opening or where communicating to the outdoors through

vertical ducts as shown in Figure 11, each opening shall

have a minimum free area of 1 square inch for each 4,000

BTUH of total appliance input rating of all equipment in the

enclosure. Table 3 specifies the minimum area for

each of the 2 combustion air openings and minimum round

duct diameter for direct openings and vertical ducting only.

B. Where communicating with the outdoors through horizontal ducts, each opening shall have a minimum free area of 1

square inch for each 2,000 BTUH of total appliance input rating of all equipment in the enclosure (see Figure 12). Table 4

specifies the minimum area for each of the 2 combustion air

openings and minimum round duct diameter for horizontal

ducting only.

METHOD 2:

One permanent opening located within 12 inches of the top of

the enclosure, shall be permitted where the equipment has

clearances of at least 1 inch from the sides and back and 6

inches from the front of the appliance. The opening shall directly communicate with the outdoors or communicate

through a vertical or horizontal duct to the outdoors or spaces

(crawl or attic) that freely communicate with the outdoors,

and shall have a minimum of:

150,000 38 8

TABLE 3: MINIMUM FREE AREA REQUIRED

FOR EACH OPENING (WHEN TWO OPENINGS

ARE USED) WITH A FURNACE:

1. LOCATED IN A CONFINED SPACE

2. USING OUTDOOR AIR FOR COMBUSTION

3. COMMUNICATING DIRECTLY TO THE

3. OUTSIDE THROUGH AN OPENING OR

3. THROUGH A VERTICAL DUCT.

16

Combustion Air

COMBUSTION AND VENTILATION AIR (cont.)

150,000 75 10

TABLE 4: MINIMUM FREE AREA REQUIRED

FOR EACH OPENING (WHEN TWO OPENINGS

ARE USED) WITH A FURNACE:

1. LOCATED IN A CONFINED SPACE

2. USING OUTDOOR AIR FOR COMBUSTION

3. COMMUNICATING DIRECTLY TO THE

3. OUTSIDE THROUGH A HORIZONTAL DUCT.

150,000 75 10

TABLE 5: MINIMUM FREE AREA REQUIRED

FOR EACH OPENING (WHEN TWO OPENINGS

ARE USED) WITH A FURNACE:

1. LOCATED IN A CONFINED SPACE

2. USING OUTDOOR AIR FOR COMBUSTION

3. COMMUNICATING DIRECTLY TO THE

3. OUTSIDE THROUGH A HORIZONTAL DUCT.

COMBUSTION AIR REQUIREMENTS: CONFINED AND

UNCONFINED SPACES

GAS

WATER

HEATER

FURNACE

12”

MAX

12”

MAX

NOTE:

EACH OPENING SHALL

HAVE A FREE AREA OF

NOT LESS THAN ONE

SQUARE INCH PER

1,000 BTU PER HOUR OF

THE TOTAL INPUT

RATING OF ALL

EQUIPMENT IN THE

ENCLOSURE, BUT NOT

LESS THAN 100

SQUARE INCHES.

ST-A1227-01

FIGURE 10

NON-DIRECT VENT

AIR FROM

HEATED

SPACE

VENT PENETRATIONS

FOR NON DIRECT VENT FURNACES

AIR FROM HEATED SPACE

TABLE 9 : MINIMUM FREE AREA REQUIRED

FOR EACH OPENING (WHEN TWO OPENINGS

ARE USED) WITH A FURNACE:

1. LOCATED IN A CONFINED SPACE

2. USING OUTDOOR AIR FOR COMBUSTION

3. COMMUNICATING DIRECTLY TO THE

OUTSIDE THROUGH AN OPENING OR

T H R O U G H A V E R T I C A L V E N T D U C T . *

Total Input for

ALL Gas

Appliances

(BTUH)

50,000 13 5

75,000 19 5

100,000 25 6

125,000 32 8

TABLE 1 0: MINIMUM FREE AREA REQUIRED

FOR EACH OPENING (WHEN TWO OPENINGS

ARE USED) WITH A FURNACE:

1. LOCATED IN A CONFINED SPACE

2. USING OUTDOOR AIR FOR COMBUSTION

3. COMMUNICATING DIRECTLY TO THE

OUTSIDE THROUGH A H ORIZONTAL DUCT.

Total Input for

ALL Gas

Appliances

(BTUH)

50,000 25 6

75,000 38 8

100,000 50 8

125,000 63 10

Free Area for

Each Opening

w h e n 2 S e p a r a t e

Openings are

used (sq inches)

Free Area for

Each Opening

when 2 Separate

Openings are

used (sq inches)

R o u n d P i p e D u c t

Diameter ( Vercal

Duct Only) (inches)

Round Pipe Duct

Diameter

(Horizontal Duct

Only) (inches)

TABLE 1 1: MINIMUM FREE AREA REQUIRED

FOR AN OPENING (WHEN O N E OPENING IS

USED) WITH A FURNACE:

1. LOCATED IN A CONFINED SPACE

2. USING OUTDOOR AIR FOR COMBUSTION

3. COMMUNICATING DIRECTLY TO THE

OUTSIDE.

Total Input for

ALL Gas

Appliances

(BTUH)

50,000 25 6

75,000 38 8

100,000 50 8

125,000 63 10

*

Free Area for an

Opening when 1

Opening is used

(sq inches)

Round Pipe Duct

Diameter (inches)

Page 17

17

COMBUSTION AND VENTILATION AIR (cont.)

A. 1 Square inch for each 3,000 BTUH of the total input rat-

ing of all equipment located in the enclosure

and

B. Not less than the sum of the areas of all vent connectors

in the confined space.

If the unit is installed where there is an exhaust fan, sufficient

ventilation must be provided to prevent the exhaust fan from creating negative pressure.

AIR INTAKE PIPE CONNECTION

A double-elbow may be installed to top inlet air opening,

BUT IS NOT REQUIRED.This will help to prevent accidental

blockage of the intake opening. Reference Figure 13 for

proper elbow diameter.

NOTE: Inlet is specifically designed to prevent material from

being pulled into furnace. If elbows are not used, the intake opening must be kept clean and free of debris.

ATTACH OPTIONAL DOUBLE ELBOW TO TOP INLET AIR

OPENING TO PREVENT ACCIDENTAL BLOCKAGE OF

INTAKE OPENING. THIS IS NOT A REQUIREMENT. (SEE

PREVIOUS PAGE.) SINGLE ELBOW IS ALLOWED BUT

MAY NOT PREVENT DEBRIS FROM BEING DROPPED

INTO THE FURNACE.

GROUND OR

SHELF SURFACE

6" MIN.

6" MININUM

CLEARANCE

PVC

DOUBLE

ELBOW

#8 SCREWS

METAL FLUE

PIPE ONLY

EXHAUST

#8 SCREWS

FIGURE 13

COMBUSTION AIR FITTING – NON-ATTIC COMBUSTION AIR PULL

Combustion Air

GAS

WATER

HEATER

FURNACE

OPTIONAL 1 SQ. INCH PER 4000 BTUH INLET AIR

GABLE

VENT

VENTILATED

ATTIC GABLE OR

SOFFIT VENTS

OUTLET AIR

IN ATTIC

MUST BE

ABOVE

INSULATION

1 SQ. INCH PER

4000 BTUH INLET AIR

12” MAX

1 SQ. INCH PER

4000 BTUH

OUTLET AIR

GAS

WATER

HEATER

FURNACE

12”

MAX

INLET AIR 1 SQ. INCH

PER 2000 BTUH

OUTLET AIR 1 SQ. INCH

PER 2000 BTUH

OUTLET AIR

1 SQ. INCH PER

4000 BTUH

INLET AIR

1 SQ. INCH PER

4000 BTUH

ST-A1227-03

ST-A1227-02

FIGURE 11

NON-DIRECT VENT

AIR FROM ATTIC

OR CRAWL

SPACE

FIGURE 12

NON-DIRECT VENT

OUTSIDE AIR

USING A

HORIZONTAL

DUCT

COMBUSTION AIR REQUIREMENTS: CONFINED AND

UNCONFINED SPACES

VENT PENETRATIONS

FOR NON DIRECT VENT FURNACES

AIR FROM ATTIC/CRAWL SPACE

VENT PENETRATIONS

FOR NON DIRECT VENT FURNACES

AIR FROM ATTIC/CRAWL SPACE

Page 18

Combustion Air

18

COMBUSTION AND VENTILATION AIR (cont.)

It is also acceptable to run the condensate drain (or refrigerant) line access over the air intake hole as long as a 1" minimum clearance is maintained.

Combustion air openings must not be restricted in any manner.

IMPORTANT: When indoor combustion air is used, the inlet air

opening at the furnace must be protected from accidental blockage.

IMPORTANT:

If the furnace is in a location with an exhaust fan,

there must be sufficient ventilation to prevent the exhaust fan

from creating a negative pressure in the room.

Combustion air openings must NOT BE RESTRICTED in any

manner.

CONSULT LOCAL CODES FOR SPECIAL REQUIREMENTS.

B: Method 3

For the optimum in quiet operation, attic air may be brought di-

rectly to the furnace.

IMPORTANT: In applications using Method 3 for combustion air,

the attic must be ventilated by gable or soffit vents.

COMBUSTION AIR FROM ATTIC

If attic combustion air is used, the inlet air opening at the furnace

must be protected from accidental blockage. Install a 90° elbow

pointing horizontally at the top of inlet air pipe. See Figure 14

(maximum of 2, 45° or 90° elbows, allowed).

NOTE: Maximum length of pipe that may be used for combustion

air is 10 feet with two elbows. Lengths of more than 10 feet can

result in nuisance pressure switch trips.

!

CAUTION

COMBUSTION AIR INTAKES CANNOT BE TERMINATED

OUTSIDE. DOING SO CAN CAUSE IMPROPER OPERATION OF THE FURNACE.

INCLUDING

HORIZONTAL DIRECTION

ATTACH A 90° ELBOW TO TOP INLET AIR

OPENING TO PREVENT ACCIDENTAL BLOCKAGE

OF INTAKE OPENING.

CAUTION

!

PVC

ELBOW

#8 SCREWS

#8 SCREW

METAL FLUE PIPE ONLY

10 FT. MAX.

12" MIN. FROM

TOP OF INSULATION

6" MINIMUM

CLEARANCE

PVC

COUPLER

EXHAUST

ATTIC SPACE

INDOOR SPACE

INSULATION

USE OF SHEET METAL

AIR INTAKE PIPE INSTEAD

OF PVC MAY RESULT IN

NOISE ISSUES.

FIGURE 14

COMBUSTION AIR FITTING – OPTIONAL ATTIC COMBUSTION AIR PULL

Page 19

19

COMBUSTION AND VENTILATION AIR (cont.)

GENERAL INFORMATION

The furnace must be vented in accordance with these instructions,

National Fuel Gas Code, ANSI Z223.1 and requirements or codes

of the local utility or other authority having jurisdiction.

DRAFT INDUCER

FURNACE CATEGORY INFORMATION

This furnace is shipped as a Category I type induced draft furnace. A Category I furnace operates with a nonpositive vent pressure and has a vent gas temperature at least 140°F above the

dew point of the vent gases. A Category I type may be a draft

hood equipped furnace or have a fan assisted combustion system (induced draft). The inducer is used to pull flue products

through the combustion chamber and as they leave the furnace,

most of the energy has been dissipated. The buoyant effect of the

flue gases provides venting to the outdoors.

During the off cycle, the inducer is off and there is very little flow

through the vent, cooling the vent. During the on cycle there is no

dilution airflow, as with a draft hood type furnace. Although the

vent heats up rapidly without dilution air, the flue products contain

more water vapor, which results in a higher dew point temperature. It is most important that you follow the guidelines in these

instructions to prevent the possible formation of condensation in

the venting system.

As a Category I furnace it may be vented vertically with type B-1

vent pipe and also may be common vented, as described in

these instructions.

IMPORTANT APPLICATION NOTES

When the furnace is used as a replacement, the existing vent

system should be inspected to assure that there are no obstructions, blockage, or any signs of corrosion and is properly sized for

use with this furnace.

NOTE: When the vent table permits more than one diameter of

pipe for a connector or vent, the smallest permitted diameter

must be used.

Vent pipe may be type “B-1,” either rigid or suitable flexible construction that carries a U.L. listing.

Common venting is allowed with vertical B-1 vent systems, and

lined masonry chimneys. Follow the National Fuel Gas Code

ANSI Z223.1 or proper installation practices.

NOTE: Follow combustion air instructions as outlined in this manual.

Single wall vent connectors to “B-1 vent or masonry chimneys”

may be used under the guidelines of the National Fuel Gas Code

ANSI Z223.1.

The entire length of the vent connector shall be readily accessible for inspection, cleaning and replacement.

“B-1” VERTICAL VENTING

NOTE: Refer to the National Fuel Gas Code, ANSI Z223.1.

Type “B-1” vents must be installed in accordance with the terms

of their listings and the vent manufacturer’s instructions.

“B-1” vents must be supported and spaced in accordance with

their listings and the manufacturer’s instructions. All vents must

be supported to maintain their minimum clearances from combustible material.

*NOTE: All furnaces have a 3” vent connection as shipped from the factory. A 3” to 4”, 3” to 5”, or 4” to 5” vent transition may be required when

vertically vented or common vented with metal vent pipes. THE VENT

TRANSITION CONNECTION MUST BE MADE AT THE FURNACE

VENT EXIT. It must originate with an adapter if required, at the furnace

flue collar and terminate either in a listed cap or roof assembly. When

common venting, the vent connector size may differ from the above diameters depending on application. See National Fuel Gas Code ANSI

Z223.1 or latest edition tables.

!

WARNING

DEVICES ATTA CHED TO THE FLUE OR VENT FOR THE

PURPOSE OF REDUCING HEAT LOSS UP THE CHIMNEY

HAVE NOT BEEN TESTED AND HAVE NOT BEEN INCLUDED IN THE DESIGN CERTIFICATION OF THIS FURNACE. WE, THE MANUFACTURER, CANNOT AND WILL

NOT BE RESPONSIBLE FOR INJURY OR DAMAGE

CAUSED BY THE USE OF SUCH UNTESTED AND/OR UNCERTIFIED DEVICES, ACCESSORIES OR COMPONENTS.

!

WARNING

VENT PIPE ATTACHING HOLES MUST BE PREDRILLED

IN THE DRAFT INDUCER COLLAR TO PREVENT DAMAGING THE INDUCER. DRILL 1/8” DIAMETER HOLES

THROUGH THE VENT PIPE AND COLLAR AND USE #8

SCREWS TO ATTACH. SEE FIGURE 16. FAILURE TO FOLLOW THIS WARNING CAN CAUSE RECIRCULATION OF

FLUE PRODUCTS CAUSING CARBON MONOXIDE POISONING RESULTING IN PERSONAL INJURY OR DEATH.

VENTING

VERTICAL VENTING

Categorized

Furnace Vent

Input Size Recommended

(See NFGC)

50K 3”

75K *4”

100K *4”

125K *5”

150K *5”

Combustion Air

Page 20

20

Combustion Air

COMBUSTION AND VENTILATION AIR (cont.)

VERTICAL VENT SYSTEMS:

1. A gas vent shall terminate above the roof surface with a listed

cap or listed roof assembly. Gas vents 12 inches in size or

smaller with listed caps shall be permitted to be terminated in

accordance with Figure 15, provided they are at least 8 feet

from a vertical wall or similar obstruction. All other gas vents

shall terminate not less than 2 feet above the highest point

where they pass through the roof and at least 2 feet higher

than any portion of a building within 10 feet.

2. A type B-1 gas vent shall terminate at least 5 feet in vertical

height above the highest connected equipment draft hood or

flue collar.

3. Must rise

1

/4” per foot away from the furnace on horizontal runs

and be supported with straps or hangers so it has no sags or

dips. Supports at 4 foot intervals and at all elbows are recommended.

4. The vent connector must be mechanically fastened to the outlet collar of the furnace with at least (2) sheet metal screws except vent connectors that are B-1 material. These shall be

assembled in accordance with the manufacturer’s instructions.

See Figures 16 and 17.

5. Any angle greater than 45 degrees from the vertical is considered horizontal. The total horizontal distance of a vent plus the

horizontal vent connector serving draft-hood equipped appliances shall not be greater than 75 percent of the vertical

height of the vent.

Single appliance venting of a fan assisted furnace into a tile-lined

masonry chimney is prohibited. The chimney must be lined with

either Type B vent or with a listed, single wall, metal lining system. Reference National Fuel Gas Code, ANSI Z223.1. See Figure 18 for typical B-1 vent chase.

NOTE:A chimney adapter is available as an accessory (see accessory section of this manual). Follow manufacturer’s instructions.

SPECIAL VENT SYSTEMS (SVS)

IMPORTANT:

It is THE FURNACE MANUFACTURER’s position

now that new

installations of any HTPV pipe used in a category

III

vent application, including Selkirk’s Selvent™ IIHTPV prod-

uct, should cease immediately.

!

WARNING

DO NOT CONNECT THIS FURNACE TO A CHIMNEY USED

TO VENT A SOLID FUEL APPLIANCE (WOOD OR COAL).

VENTING WITH A SOLID FUEL APPLIANCE CAN LEAD TO

IMPROPER FUNCTIONING OF THE UNIT, AND DUE TO

SOOTING, THE POSSIBILITY OF FIRE RESULTING IN

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

A0991-01

FIGURE 16

ATTACHING TO DRAFT INDUCER COLLAR

-

FIGURE 15

TYPICAL VENTING WITH “B-1” VENT

ST-A1220-24

LISTED CAP

LISTED GAS VENT

MINIMUM ALLOWABLE HEIGHT

FROM ROOF TO DISCHARGE OPENING

X

12

ROOF PITCH = X/12

ROOF PITCH “H” (MIN.) FT.

FLAT TO 6/12 1.0

OVER 6/12 TO 7/12 1.25

OVER 7/12 TO 8/12 1.5

OVER 8/12 TO 9/12 2.0

OVER 9/12 TO 10/12 2.5

OVER 10/12 TO 11/12 3.25

OVER 11/12 TO 12/12 4.0

OVER 12/12 TO 14/12 5.0

OVER 14/12 TO 16/12 6.0

OVER 16/12 TO 18/12 7.0

ST-A1220-24

OVER 18/12 TO 20/12 7.5

OVER 20/12 TO 21/12 8.0

Page 21

21

COMBUSTION AND VENTILATION AIR (cont.)

FIGURE 17

FIGURE 18

DEDICATED VENTING THROUGH

CHIMNEY WITH “B-1” VENT

ST-A1220-09

Combustion Air

1. STANDARD 3” FLUE CONNECTION.

FRESH AIR INLET

2. 4” ADAPTER - OPTIONAL

SEE NATI ONAL FUEL GAS CODE FOR SIZING OPTIONS

1.

2.

ST-A1220-09-01

Page 22

22

COMBUSTION AND VENTILATION AIR (cont.)

PO WER VENT SYSTEMS

When vertical venting is not possible, the only acceptable method

for horizontal venting is with the use of Tjernlund model GPAK1TR or Field Controls models SWG-4R power venter. Type B

vent pipe and fittings must be used. Common venting is not permitted

All application and installation instructions supplied with the

power venter must be followed.

Please address all questions regarding power venter installation,

agency listings and furnace model compatibility to:

Tjernlund Products, Inc.

(800) 255-4208 or (612) 426-2993

Field Controls L.L.C.

(800) 742-8368 or (919) 522-0214

EXISTING VENT SYSTEMS

IMPORTANT RETROFIT

VENTING INSTRUCTIONS

If this furnace is a replacement installation, ALWAYS INSPECT

the existing vent system to be sure there are no obstructions,

blockages, or signs of corrosion.

When the existing furnace is removed from a venting system

serving other appliances, the venting is likely to be too large to

properly vent the remaining attached appliances.

The following steps shall be followed with each appliance that remains connected to the common venting system, while the other

appliances that remain connected to the common venting systems are not in operation.

NOTE: When the vent table permits more than one diameter

of pipe for a connector or vent, the smallest permitted diameter must be used.1. Seal any unused openings in the common venting system.

NOTE: Ensure existing venting system complies with latest addi-

tion of National Fuel Gas Code ANSI Z223.1 and all local

codes/regulations.

1. Visually inspect the venting system for proper size and horizontal pitch and determine that there is no blockage, restriction, leakage, corrosion or other deficiencies which could

cause an unsafe condition.

2. Insofar as is practical, close all building doors, windows and all

doors between the space where the appliances remaining connected to the common venting system are located. Turn on

clothes dryers and any appliance not connected to the common venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate a summer exhaust fan. Close fireplace dampers.

3. Follow the lighting instructions. Place the appliance being inspected into operation. Adjust the thermostat so the appliance

will operate continuously.

4. Test for spillage at the draft hood relief opening after 5 minutes

of main burner operation. Use the flame of a match or candle,

or smoke from a cigarette, cigar, or pipe.

5. After it has been determined that each appliance that remains

connected to the common venting system properly vents

(when tested as outlined above) return doors, windows, exhaust fans, fireplace dampers and any other gas-burning appliance to their previous conditions of use.

6. If improper venting is observed during any of the above tests,

the common venting system must be resized. Refer to National

Fuel Gas Code, ANSI Z223.1.

Combustion Air

Page 23

23

Gas Supply

IMPORTANT SAFETY INFORMATION

NATURAL GAS AND PROPANE

(LIQUEFIED PETROLEUM GAS / LPG)

SAFETY

GAS SUPPLY

GAS SUPPLY

GAS SUPPLY AND PIPING

!

WARNING

• FURNACES USING PROPANE GAS ARE DIFFERENT FROM NATURAL GAS MODELS. A NATURAL

GAS HEATER WILL NO T FUNCTION SAFELY ON

PROPANE AND VICE VERSA. CONVERSIONS OF

HEATER GAS TYPE SHOULD ONLY BE MADE BY

QUALIFIED INSTALLERS USING FACTORY SUPPLIED COMPONENTS. THE FURNACE SHOULD

ONLY USE THE FUEL TYPE IN ACCORDANCE

WITH LISTING ON RATING PLATE. ANY OTHER

FUEL USAGE WILL RESULT IN DEATH OR SERIOUS PERSONAL INJURY FROM FIRE AND/OR EXPLOSION.

• BOTH NATURAL GAS AND PROPANE HA VE AN

ODORANT ADDED TO AID IN DETECTING A GAS

LEAK. SOME PEOPLE MAY NOT PHYSICALLY BE

ABLE TO SMELL OR RECOGNIZE THIS ODORANT.

IF YOU ARE UNSURE OR UNFAMILIAR WITH THE

SMELL OF NATURAL GAS OR PROP ANE, ASK

YO UR LOCAL GAS SUPPLIER. OTHER CONDITIONS, SUCH AS “ODORANT F ADE,” WHICH

CAUSES THE ODORANT T O DIMINISH IN INTENSITY, CAN ALSO HIDE, CAMOUFLAGE, OR OTHERWISE MAKE DETECTING A GAS LEAK BY

SMELL MORE DIFFICULT.

• UL OR CSA RECOGNIZED FUEL GAS DETECTORS

ARE RECOMMENDED IN ALL ENCLOSED

PROPANE AND NA TURAL GAS APPLICATIONS

WHEREIN THERE IS A POTENTIAL FOR AN EXPLOSIVE MIXTURE OF FUEL GAS TO ACCUMULATE.

FUEL DETECTOR INSTALLA TION SHOULD BE IN

ACCORD ANCE WITH THE DETECTOR MANUFACTURER’S RECOMMENDATIONS AND/OR LOCAL

LAWS, RULES, REGULATIONS, OR CUSTOMS.

• BEFORE ATTEMPTING TO LIGHT THE FURNACE,

MAKE SURE TO LOOK AND SMELL FOR GAS

LEAKS. USE A SOAPY SOLUTION TO CHECK ALL

GAS FITTINGS AND CONNECTIONS.

BUBBLING AT A CONNECTION INDICATES A LEAK

THAT MUST BE CORRECTED. WHEN SMELLING TO

DETECT A GAS LEAK, BE SURE TO ALSO SNIFF

NEAR THE FLOOR. PROPANE GAS IS HEAVIER

THAN AIR AND TENDS TO COLLECT AT LOWER

LEVELS MAKING IT MORE DIFFICULT TO SMELL AT

NOSE LEVEL. NATURAL GAS IS LIGHTER THAN AIR

AND WILL RISE, POSSIBLY ACCUMULATING IN

HIGHER PORTIONS OF THE STRUCTURE.

• IF A GAS LEAK IS PRESENT OR SUSPECTED:

- DO NOT ATTEMPT TO FIND THE CAUSE Y OURSELF.

- NEVER

USE AN OPEN FLAME TO TEST FOR GAS

LEAKS. THE GAS CAN IGNITE RESULTING IN

DEATH, PERSONAL INJURY, OR PROPERTY

DAMAGE.

-DO NOTTRY TO LIGHT ANY APPLIANCE.

-DO NOTTOUCH AND ELECTRICAL SWITCH.

-DO NOTUSE ANY PHONE IN YOUR BUILDING.

- LEAVE THE BUILDING IMMEDIATELY AND CALL

THE GAS SUPPLIER FROM A NEIGHBOR’S

PHONE. FOLLOW THE GAS SUPPLIER’S INTR UCTIONS.

- IF YOU CANNOT REACH YOUR GAS SUPPLIER,

CALL THE FIRE DEPARTMENT.

- DO NOT RETURN TO THE BUILDING UNTIL AUTHORIZED BY THE GAS SUPPLIER OR FIRE DEPARTMENT.

• SHOULD OVERHEATING OCCUR OR THE GAS

SUPPLY F AIL TO SHUT OFF, TURN OFF THE MANUAL GAS CONTROL VALVE TO THE FURNACE.

• CONSULT WITH THE LOCAL BUILDING DEPARTMENT AND FUEL GAS SUPPLIER BEFORE INST ALLING THE HEA TER:

- THE INSTALLATION AND PURGING OF GAS PIPING MUST CONFORM TO LOCAL CODES, UTILITY COMPANY REQUIREMENTS, AND THE

LATEST EDITION OF NATIONAL FUEL GAS

CODE (NFGC) - ANSI Z223.1/NFPA 54.

- LP FURNACES SHOULD NOT BE INSTALLED

BELOW GRADE (IN A B ASEMENT FOR EXAMPLE) IF SUCH INSTALLATION IS PROHIBITED BY

FEDERAL, STATE, PRO VINCIAL, AND/OR LOCAL

LAWS, RULES, REGULATIONS, OR CUSTOMS.

- INSTALLATION OF A GAS PRESSURE REGULATOR MAY BE REQUIRED IN THE GAS SUPPLY

LINE. THE REGULATOR SHOULD NOT EXCEED

THE MAXIMUM SUPPLY PRESSURE LISTED ON

THE FURNACE RATING PLATE. DO NOT USE AN

INDUSTRIAL-TYPE GAS REGULATOR.

- FOLLOW ALL LOCAL CODES AND SECTION 8.3

OF NFGC WITH REGARD TO PURGING OF GAS

PIPING TO ENSURE THA T THE AIR AND/OR FUEL

GAS IN THE GAS PIPING IS PROPERLY VENTED

TO A LOCATION WHERE AN EXPLOSIVE MIXTURE CANNOT A CCUMULATE.

(Continued on next column)

Page 24

24

Gas Supply

GAS SUPPLY

IMPORTANT:

Any additions, changes or conversions required for

the furnace to satisfactorily meet the application should be made

by a qualified installer, service agency or the gas supplier, using

factory-specified or approved parts.

IMPORTANT:

Connect this furnace only to gas supplied by a

commercial utility or commercial fuel provider.

IMPORTANT:

A U.L. or CSA recognized fuel gas and CO detector(s) are recommended in all applications, and their installation

should be in accordance with the detector manufacturer’s recommendations and/or local laws, rules, regulations or customs.

Install the gas piping according to all local codes, state codes and

regulations of the utility company, whichever holds jurisdiction.

If possible, run a separate gas supply line directly from the meter

to the furnace. Consult the local gas company for the location of

the manual main shut-off valve.The gas line and manual gas

valve must be adequate in size to prevent undue pressure

drop and never smaller than the pipe size to the combination

gas valve on the furnace. Refer to Table 6 for the recom mended

pipe size for natural gas and Table 7 for LP gas pipe sizes.

IMPORTANT:

It is permissible to run flexible gas connector inside

the unit to a piece of black pipe. If local codes allow the use of a

flexible gas appliance connector, always use a new listed connector. Do not use a connector which has previously serviced another

gas appliance. Massachusetts law limits flexible gas connectors to

a maximum of 36”.

Install a ground joint union outside the cabinet and within 3

feet to easily remove the control v alve assembly. Install a

manual shut-off valve in the gas line outside the furnace casing. The valve should be readily accessible to turn the gas supply

on or off. Install a drip leg in the gas supply line as close to the furnace as possible. Always use a pipe compound resistant to the

action of liquefied petroleum gases on all threaded connections.

IMPORTANT:

When making gas pipe connections, use a back-up

wrench to prevent any twisting of the control assembly and gas

valve. Do not overtighten the connection.

Any strains on the gas valve can change the position of the gas

orifices in the burners. This can cause erratic furnace operation.

IMPORTANT:

ENSURE that the furnace gas control valve not be

subjected to high gas line supply pressures.

DISCONNECT the furnace and its individual shut-off valve from

the gas supply piping during any pressure testing that exceeds

1/2 PSIG (3.48 kPa).

GAS PIPE INSTALLATION

GAS VALVE

MANIFOLD

MANIFOLD

FLAME SENSOR

FLAME SENSOR

BURNERS

BURNERS

DIRECT SPARK

IGNITOR

DIRECT

SPARK

IGNITOR

MANUAL GAS VALVE

(IN CLOSED POSITION)

UNION

DUCT

UNION

DRIP LEG

DRIP LEG

4 TO 5 FEET

ABOVE FLOOR

REQ'D BY SOME

UTILITIES

4 TO 5 FEET

ABOVE FLOOR

REQ'D BY SOME

UTILITIES

UPFLOW

HORIZONTAL

GAS VALVE

FIGURE 19

GAS PIPING INSTALLATION

MANUAL GAS VALVE

(IN CLOSED

POSITION)

GAS PIPING

!

WARNING

THIS FURNACE IS EQUIPPED AT THE FACTORY

FOR USE ON NATURAL GAS ONLY. CONVERSION

TO LP GAS REQUIRES A SPECIAL KIT IS AVAILABLE AT THE DISTRIBUTOR. FAILURE TO USE THE

PROPER CONVERSION KIT CAN CAUSE FIRE,

CARBON MONOXIDE POISONING, EXPLOSION,

PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH. SEE THE CONVERSION KIT INDEX SUPPLIED WITH THE FURNACE. THIS INDEX IDENTIFIES THE PROPER LP GAS CONVERSION KIT

REQUIRED FOR EACH PARTICULAR FURNACE.

Page 25

25

GAS SUPPLY (cont.)

IMPORTANT: ENSURE that the furnace gas valve is not to be

subjected to high gas line supply pressures.

DISCONNECT the furnace and its individual manual gas stop

from the gas supply piping during any pressure testing that ex-

ceeds 1/2 PSIG. (3.48 kPa).

Natural gas supply pressure must be 5" to 10.5" w.c. LP gas

supply pressure must be 11" to 13" w.c.

This pressure must

be maintained with all other gas-fired appliances in operation.

The minimum gas supply pressure to the gas valve for proper furnace input adjustments is 5" w.c. for natural gas, however 6" to 7"

is recommended. The minimum gas supply pressure is 11" w.c.

for LP gas.

GAS V AL VE

This furnace has a 24-volt gas valve. It has ports for measuring

supply and manifold gas pressure. The valve body contains a

pressure regulator to maintain proper manifold gas pressure.

A control switch is on the valve body. It can be set to only the

“ON” or “OFF” positions. The gas valve is a slow-opening valve.

See Figure 20.

When energized, it takes 2 to 3 seconds to fully open.

GAS PRESSURE

!

CAUTION

ELEVATIONS ABOVE 2000 FT. REQUIRE THAT THE

FURNACE INPUT RATING BE ADJUSTED AND THAT

THE SIZE OF THE BURNER ORIFICES BE RECALCULATED BASED ON ELEVATION AND GAS HEATING VALUE. THE BURNER ORIFICES MAY (OR MAY

NOT) NEED TO BE CHANGED. SEE THE SECTION

TITLED “HIGH ALTITUDE INSTALLATIONS” OF THIS

BOOK FOR INSTRUCTIONS.

FIGURE 20

TYPICAL GAS VALVE (HONEYWELL)

REGULATOR CAP

!

WARNING

NEVER PURGE A GAS LINE INTO THE COMBUSTION CHAMBER. NEVER USE MATCHES, FLAME

OR ANY IGNITION SOURCE FOR CHECKING LEAKAGE. FAILURE TO ADHERE TO THIS WARNING CAN

CAUSE A FIRE OR EXPLOSION RESULTING IN

PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH.

TO CHECK FOR GAS LEAKAGE, USE AN APPRO VED CHLORIDE-FREE SOAP AND WATER SOLUTION, OR OTHER APPROVED METHOD.

T ABLE 6

NATURAL GAS PIPE CAPACITY TABLE (CU. FT./HR.)

Capacity of gas pipe of different diameters and lengths in cu. ft. per hr. with pressure drop of 0.3 in. and specific

gravity of 0.60 (natural gas).

Nominal Length of Pipe, Feet

Iron Pipe

Size, Inches 10 20 30 40 50 60 70 80

1/2 132 92 73 63 56 50 46 43

3/4 278 190 152 130 115 105 96 90

1 520 350 285 245 215 195 180 170

1-1/4 1,050 730 590 500 440 400 370 350

1-1/2 1,600 1,100 890 760 670 610 560 530