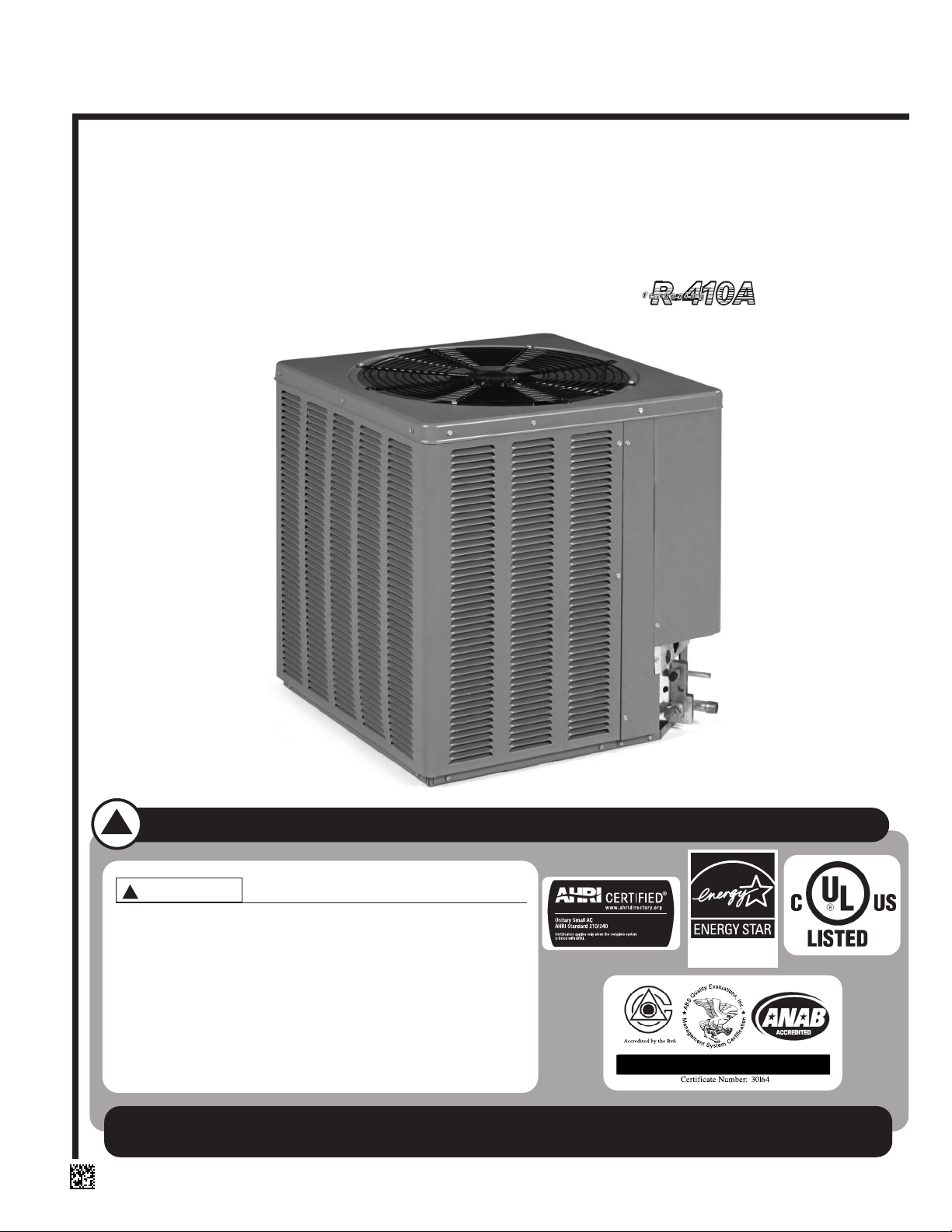

Page 1

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORTANT SAFETY INFORMATION!

!

DO NOT DESTROY THIS MANUAL

PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE BY A SERVICEMAN

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO

QUALIFIED, LICENSED SERVICE PERSONNEL FOR

PROPER INSTALLATION, ADJUSTMENT AND OPERATION

OF TH IS UN IT. READ THESE INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING INSTALLATION OR OPERATION.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT

IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR

MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRICAL

SHOCK, PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH.

WARNING

!

ISO 9001:2008

INSTALLATION INSTRUCTIONS

13 & 14.5 SEER SERIES

HEAT PUMPS

11⁄2 - 5 TONS FEATURING

NEW INDUSTRY STANDARD

R-410A REFRIGERANT R-410

(IN CERTAIN

MATCHED SYSTEMS)

SUPERSEDES 92-20522-75-08

92-20522-75-09

Page 2

TABLE OF CONTENTS

1.0 SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.0 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Checking Product Received. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

.3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2

2.4 Electrical and Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.0 LOCATING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Corrosive Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Heat Pump Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Operational Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 For Units With Space Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 Customer Satisfaction Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

.6 Unit Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3

3.7 Factory-Preferred Tie-Down Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.0 REFRIGERANT CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.0 REPLACEMENT UNITS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.0 INDOOR COIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.0 INTERCONNECTING TUBING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.1 Vapor & Liquid Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.2 Maximum Length of Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.3 Vertical Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.4 Tubing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.5 Tubing Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.6 Leak Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.0 DEMAND DEFROST CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.1 Defrost Initiation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.2 Defrost Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.3 Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.4 Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.5 Trouble Shooting Demand Defrost Operation . . . . . . . . . . . . . . . . . . . . . . . 16

8.6 High/Low Pressure Control Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.7 Enhanced Feature Defrost Control Diagnostic Codes. . . . . . . . . . . . . . . . . 17

9.0 START-UP – CHECKING AIRFLOW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

10.0 EVACUATION AND LEAK TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10.1 Evacuation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10.2 Final Leak Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

11.0 CHECKING REFRIGERANT CHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

11.1 Charging Units With R-410A Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

11.2 Measurement Device Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11.3 Charging By Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11.4 Gross Charging By Pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

11.5 Final Charge By Sub-Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

11.6 Finishing Up Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

12.0 ELECTRICAL WIRING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

12.1 Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

12.2 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

12.3 Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

13.0 FIELD INSTALLED ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

13.1 Compressor Crankcase Heat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

13.2 Low Ambient Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

13.3 High Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

13.4 Heat Pump Thermostat Warning Light Kit RXPX-D01. . . . . . . . . . . . . . . . . 25

14.0 SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

14.1 Single Pole Compressor Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

15.0 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

15.1 Electrical Checks Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

15.2 Cooling Mechanical Checks Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

15.3 Heating Mechanical Checks Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

15.4 Defrost Mechanical Checks Flow Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

15.5 General Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

15.6 Service Analyzer Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32-36

16.0 WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

16.1 Enhanced Defrost Control - PSC Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

16.2 Enhanced Defrost Control - ECM Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2

Page 3

1.0 SAFETY INFORMATION

WARNING

!

Disconnect all power to unit before starting maintenance. Failure to do so

can cause electrical shock resulting in severe personal injury or death.

WARNING

!

Turn off electric power at the fuse box or service panel before making any

electrical connections.

Also, the ground connection must be completed before making line voltage connections. Failure to do so can result in electrical shock, severe

personal injury or death.

WARNING

!

These instructions are intended as an aid to qualified licensed service

personnel for proper installation, adjustment and operation of this unit.

Read these instructions thoroughly before attempting installation or operation. Failure to follow these instructions may result in improper installation, adjustment, service or maintenance possibly resulting in fire, electrical shock, property damage, personal injury or death.

WARNING

!

The unit must be permanently grounded. Failure to do so can cause electrical shock resulting in severe personal injury or death.

WARNING

!

The manufacturer’s warranty does not cover any damage or defect to the

heat pump caused by the attachment or use of any components.

Accessories or devices (other than those authorized by the manufacturer) into, onto or in conjunction with the heat pump. You should be aware

that the use of unauthorized components, accessories or devices may

adversely affect the operation of the heat pump and may also endanger

life and property. The manufacturer disclaims any responsibility for such

loss or injury resulting from the use of such unauthorized components,

accessories or devices.

CAUTION

When coil is installed over a finished ceiling and/or living area, it is

recommended that a seconda ry sheet metal conden sa te p an be

constructed and installed under entire unit. Failure to do so can result

in property damage.

CAUTION

Single-pole contactors are used on all standard single-phase units up

through 5 tons. Caution must be exercised when servicing as only one leg

of the power supply is broken with the contactor.

3

Page 4

2.0 GENERAL

WARNING

!

The manufacturer’s warranty does not cover any damage or defect to the

heat pump caused by the attachment or use of any components.

ccessories or devices (other than those authorized by the manufactur-

A

er) into, onto or in conjunction with the heat pump. You should be aware

that the use of unauthorized components, accessories or devices may

adversely affect the operation of the heat pump and may also endanger

life and property. The manufacturer disclaims any responsibility for such

loss or injury resulting from the use of such unauthorized components,

accessories or devices.

2.1 CHECKING PRODUCT RECEIVED

Upon receiving unit, inspect it for any shipping damage. Claims for damage, either

apparent or concealed, should be filed immediately with the shipping company.

Check heat pump model number, electrical characteristics and accessories to

determine if they are correct. Check system components (evaporator coil, condensing unit, evaporator blower, etc.) to make sure they are properly matched.The information contained in this manual has been prepared to assist in the proper installation, operation and maintenance of the heat pump system. Improper installation, or

installation not made in accordance with these instructions, can result in unsatisfactory operation and/or dangerous conditions, and can cause the related warranty not

to apply.

Read this manual and any instructions packaged with separate equipment required

to make up the system prior to installation. Retain this manual for future reference.

To achieve optimum efficiency and capacity, the indoor cooling coils listed in the

heat pump specification sheet should be used.

MATCH ALL COMPONENTS:

• OUTDOOR UNIT

• INDOOR COIL/METERING DEVICE

• INDOOR AIR HANDLER/FURNACE

• REFRIGERANT LINES

2.2 APPLICATION

Before installing any heat pump equipment, a duct analysis of the structure and a

heat gain calculation must be made. A heat gain calculation begins by measuring all

external surfaces and openings that gain heat from the surrounding air and quantifying that heat gain. A heat gain calculation also calculates the extra heat load

caused by sunlight and by humidity removal.

There are several factors that the installers must consider:

• Outdoor unit location • Proper equipment evacuation

• System refrigerant charge • Indoor unit airflow

• Indoor unit blower speed • Supply and return air duct design and sizing

• System air balancing • Diffuser and return air grille location and sizing

4

Page 5

2.3 DIMENSIONS (SEE FIGURE 1)

L

H

SEE DETAIL A

w

A-00008

IGURE 1

F

DIMENSIONS

*

AIR DISCHARGE: ALLOW

60” [1524 mm] MINIMUM

CLEARANCE.

AIR INLETS

(LOUVERED PANELS) ALLOW 6”

[152.4 mm]

MINIMUM

CLEARANCE

SERVICE ACCESS

ALLOW 24” [609.6 mm]

CLEARANCE

2"

[50.8 mm]

BASERAIL*

*The 3, 31⁄2, 4 & 5 ton

models do not feature

a baserail.

DIMENSIONAL DATA

NOTE: GRILLE APPEARANCE

MAY VARY.

BASE PAN (BOTTOM VIEW)

DO NOT OBSTRUCT DRAIN HOLES

(SHADED).

13 SEER 18, 24 —

14.5 SEER

Height “H” (in.) [mm]

Length “L” (in.) [mm]

Width “W” (in.) [mm]

30 36

— 18, 24

—

261/4 [666.7] 261/4 [666.7] 261/4 [666.7]

5

/8 [600] 275/8 [701.6] 275/8 [701.6]

23

23

5

/8 [600]

5

/8 [701.6]

27

5

27

/8 [701.6]

30 36, 42, 48, 60

273/8 [695.3] 353/8 [898.5]

315/8 [803.2] 315/8 [803.2]

315/8 [803.2] 315/8 [803.2]

42, 48, 60

*NOTE: “H” dimension

includes baserails

and/or basepan.

5

Page 6

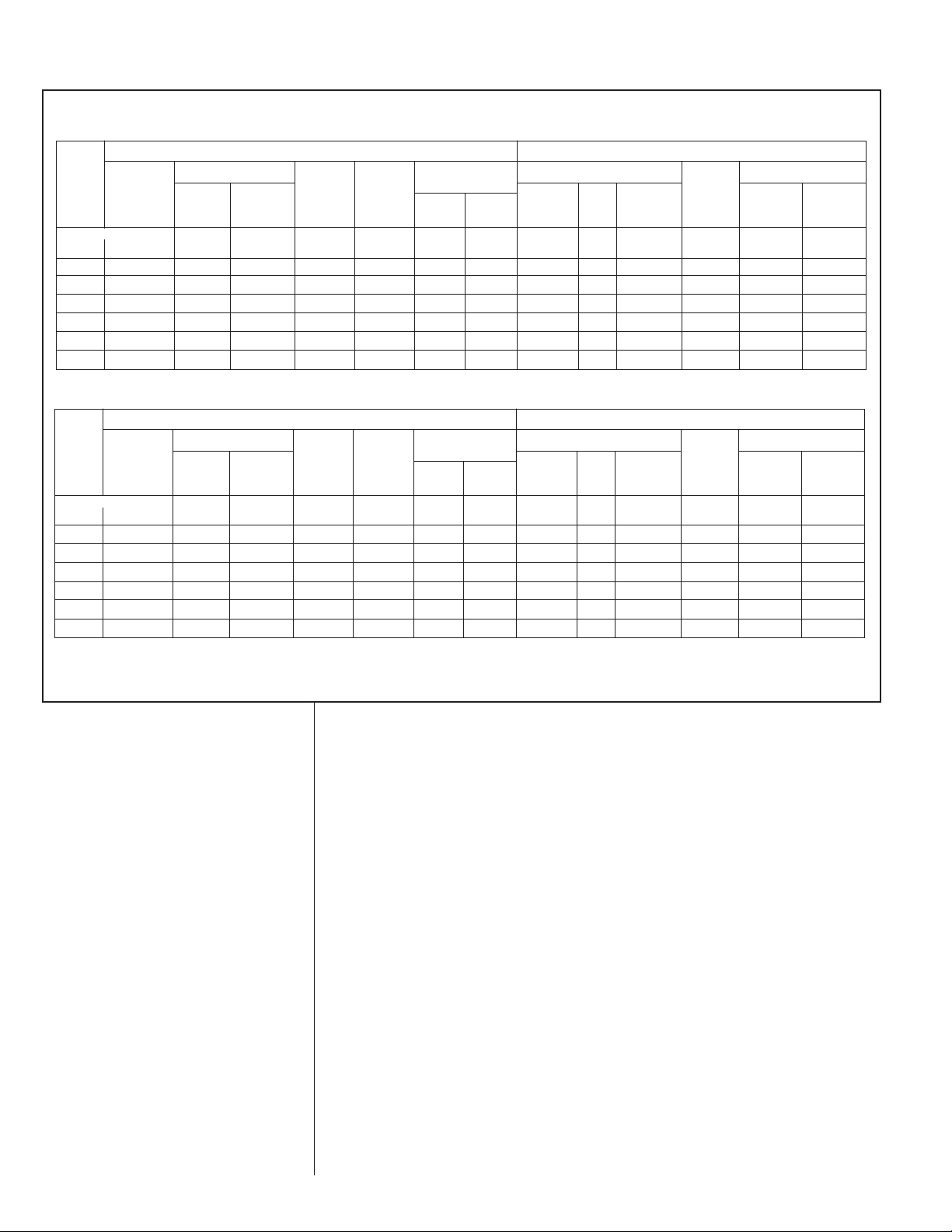

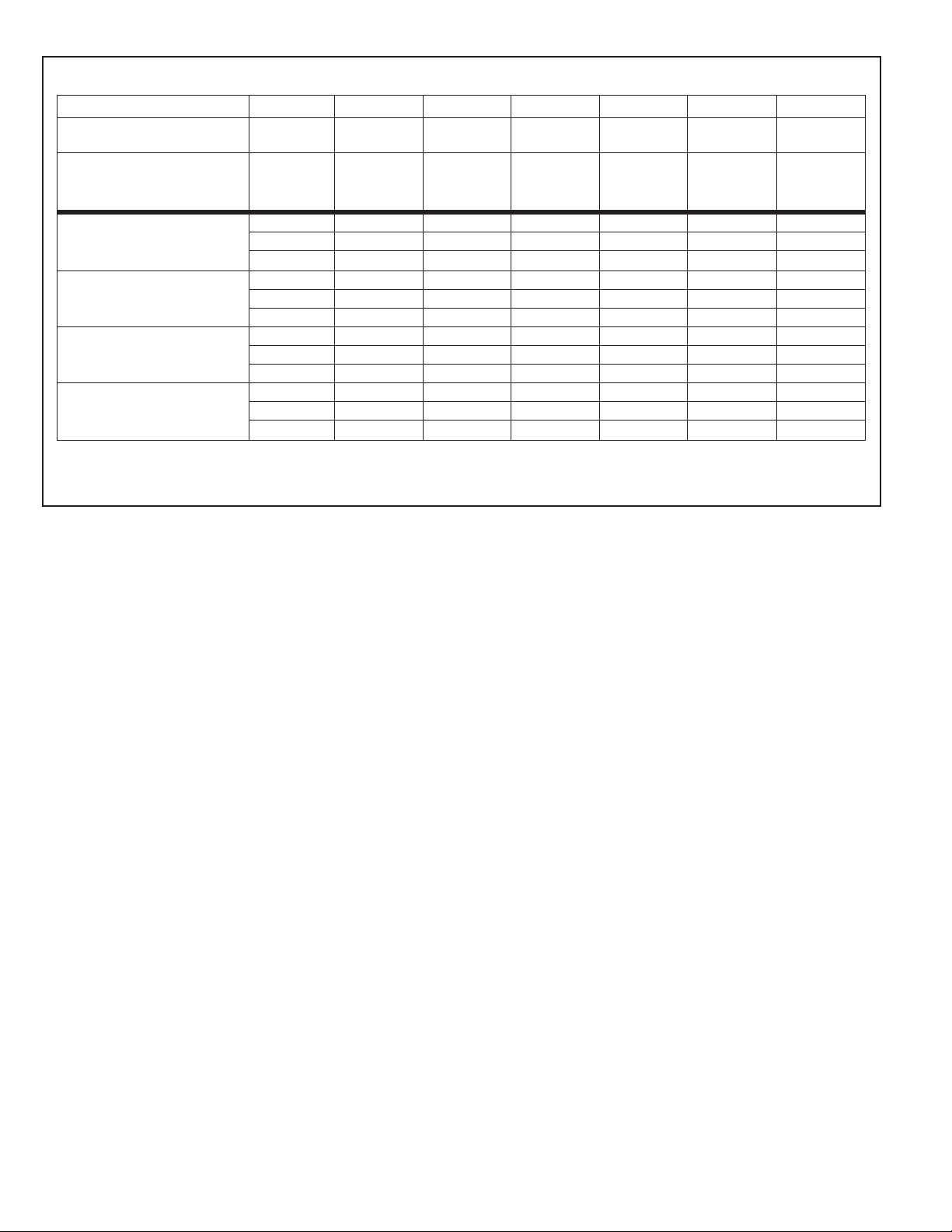

2.4 ELECTRICAL & PHYSICAL DATA (SEE TABLE 1)

TABLE 1

LECTRICAL AND PHYSICAL DATA – 13 SEER

E

LECTRICAL DATA PHYSICAL DATA

E

use or HACR

an Motor

odel

M

Number

Rev.7/29/2009

18 1-60-208-230 9/9 48 0.6 12/12 15/15 20/20 11.06 [1.03] 1 1700 [802] 91 [2580] 144 [65.3] 152 [68.9]

4 1-60-208-230 12.8/12.8 58.3 0.6 17/17 20/20 25/25 11.06 [1.03] 1 2370 [1118] 91 [2580] 130 [59] 138 [62.6]

2

0 1-60-208-230 14.1/14.1 73 0.8 19/19 25/25 30/30 13.72 [1.27] 1 2800 [1321] 101 [2863] 198 [89.8] 208 [94.3]

3

6 1-60-208-230 17/17 96.7 1.2 23/23 30/30 35/35 16.39 [1.52] 1 3575 [1687] 109 [3090] 215 [97.5] 227 [103]

3

2 1-60-208-230 21.8/21.8 112 1.2 29/29 35/35 50/50 21.85 [2.03] 1 3575 [1687] 150 [4252] 202 [91.6] 214 [97.1]

4

8 1-60-208-230 21.8/21.8 117 1.2 29/29 35/35 50/50 21.85 [2.03] 1 3575 [1687] 141 [3997] 205 [93] 217 [98.4]

4

60 1-60-208-230 26.3/26.3 134 1.2 35/35 45/45 60/60 21.85 [2.03] 1 3575 [1687] 228 [6464] 209 [94.8] 221 [100.2]

ELECTRICAL AND PHYSICAL DATA – 14.5 SEER

odel

M

Number

Rev. 7/29/2009

18 1-60-208/230 9/9 48 0.08 13/13 15/15 20/20 13.72 [1.27] 1 2590 [1222] 101.6 [2880] 154 [69.9] 164 [74.4]

24 1-60-208/230 12.8/12.8 58.3 0.08 17/17 25/25 25/25 13.72 [1.27] 1 2590 [1222] 100.8 [2858] 155 [70.3] 165 [74.8]

30 1-60-208/230 14.1/14.1 73 1.23 19/19 25/25 30/30 16.39 [1.52] 1 2595 [1225] 117.8 [3340] 118.5 [53.8] 181 [82.1]

36 1-60-208/230 16.7/16.7 79 1.3 23/23 30/30 35/35 21.85 [2.03] 1 3575 [1687] 136.5 [3870] 193 [87.5] 207 [93.9]

42 1-60-208/230 17.9/17.9 112 1.33 24/24 30/30 40/40 21.85 [2.03] 1 3575 [1687] 162.4 [4604] 193 [87.5] 208 [94.3]

48 1-60-208/230 21.8/21.8 117 2.8 31/31 40/40 50/50 21.85 [2.03] 2 3360 [1586] 258.4 [7326] 265 [120.2] 280 [127]

60 1-60-208/230 26.4/26.4 134 2.8 36/36 45/45 60/60 21.85 [2.03] 2 3360 [1586] 284 [8051] 265 [120.2] 280 [127]

NOTES:

➀ 20 Fins per inch [mm]

➁ Factory charged for 15 ft. [4.6 m] of line set

Phase

requency (Hz)

F

Voltage (Volts)

Phase

Frequency (Hz)

oltage (Volts)

V

ated Load

R

Amperes

RLA)

(

Rated Load

Amperes

RLA)

(

ocked Rotor

L

Amperes

LRA)

(

Locked Rotor

Amperes

LRA)

(

F

ull Load

F

Amperes

FLA)

(

LECTRICAL DATA PHYSICAL DATA

E

Fan Motor

ull Load

F

Amperes

FLA)

(

inimum

M

ircuit

C

Ampacity

mperes

A

Minimum

ircuit

C

Ampacity

mperes

A

F

Circuit Breaker

Minimum

mperes

A

Fuse or HACR

Circuit Breaker

inimum

M

Amperes

Maximum

mperes

A

aximum

M

Amperes

ace Area

F

Face Area

Sq. Ft.

Sq. Ft.

m

[

2

m

[

utdoor Coil WeightCompressor

O

No.

ows

R

2

]

utdoor Coil WeightCompressor

O

N

Rows

]

CFM

L/s]

[

o.

FM

C

[L/s]

efrig.

R

er

P

Circuit

z. [g]

O

Refrig.

er

P

Circuit

z. [g]

O

Net

bs. [kg]

L

et

N

Lbs. [kg]

Shipping

bs. [kg]

L

hipping

S

Lbs. [kg]

3.0 LOCATING UNIT

3.1 CORROSIVE ENVIRONMENT

The metal parts of this unit may be subject to rust or deterioration if exposed to a

corrosive environment. This oxidation could shorten the equipment’s useful life.

Corrosive elements include, but are not limited to, salt spray, fog or mist in seacoast

areas, sulphur or chlorine from lawn watering systems, and various chemical contaminants from industries such as paper mills and petroleum refineries.

If the unit is to be installed in an area where contaminants are likely to be a problem, special attention should be given to the equipment location and exposure.

• Avoid having lawn sprinkler heads spray directly on the unit cabinet.

• In coastal areas, locate the unit on the side of the building away from the waterfront.

• Shielding provided by a fence or shrubs may give some protection, but cannot

violate minimum airflow and service access clearances.

• Elevating the unit off its slab or base enough to allow air circulation will help

avoid holding water against the basepan.

Regular maintenance will reduce the build-up of contaminants and help to protect

the unit’s finish.

6

Page 7

!

WARNING

Disconnect all power to unit before starting maintenance. Failure to do so

can cause electrical shock resulting in severe personal injury or death.

• Frequent washing of the cabinet, fan blade and coil with fresh water will remove

most of the salt or other contaminants that build up on the unit.

Regular cleaning and waxing of the cabinet with an automobile polish will pro-

•

vide some protection.

• A liquid cleaner may be used several times a year to remove matter that will not

wash off with water.

Several different types of protective coil coatings are offered in some areas. These

coatings may provide some benefit, but the effectiveness of such coating materials

cannot be verified by the equipment manufacturer.

3.2 HEAT PUMP LOCATION

Consult local and national building codes and ordinances for special installation

requirements. Following location information will provide longer life and simplified

servicing of the outdoor heat pump.

NOTE: These units must be installed outdoors. No ductwork can be attached, or

other modifications made, to the discharge grille. Modifications will affect performance or operation.

3.3 OPERATIONAL ISSUES

• IMPORTANT: Locate the unit in a manner that will not prevent, impair or com-

promise the performance of other equipment horizontally installed in proximity

to the unit. Maintain all required minimum distances to gas and electric meters,

dryer vents, exhaust and inlet openings. In the absence of National Codes, or

manufacturers’ recommendations, local code recommendations and requirements will take presidence.

• Refrigerant piping and wiring should be properly sized and kept as short as

possible to avoid capacity losses and increased operating costs.

• Locate the unit where water run off will not create a problem with the equip-

ment. Position the unit away from the drip edge of the roof whenever possible.

Units are weatherized, but can be affected by the following:

o Water pouring into the unit from the junction of rooflines, without protective

guttering. Large volumes of water entering the heat pump while in operation

can impact fan blade or motor life, and coil damage may occur to a heat

pump if moisture cannot drain from the unit under freezing conditions.

o Freezing moisture, or sleeting conditions, can cause the cabinet to ice-over

prematurely and prevent heat pump operation, requiring backup heat, which

generally results in less economical operation.

• Closely follow clearance recommendations (See Figure 1).

o 24” [609.6 mm] to the service panel access

o 60” [1524 mm] above heat pump fan discharge (unit top) to prevent recircula-

tion

o 6” [152.4 mm] to heat pump coil grille air inlets (per heat pump).

IMPORTANT: Remove attached shipping strap. Failure to remove strap could result

in internal tubing stress. Plastic strap can be cut off from exterior of the unit and left

inside of unit. See page 30.

3.4 FOR UNITS WITH SPACE LIMITATIONS

In the event that a space limitation exists, we will permit the following clearances:

Single Unit Applications: Clearances below 6 inches [152.4 mm] will reduce unit

capacity and efficiency. Do not reduce the 60-inch [1524 mm] discharge, or the 24inch [609.6 mm] service clearances.

Multiple Unit Applications: When multiple heat pump grille sides are aligned, a 6inch [152.4 mm] per unit clearance is recommended, for a total of 12" [304.8 mm]

between two units. Two combined clearances below 12 inches [304.8 mm] will

reduce capacity and efficiency. Do not reduce the 60-inch [1524 mm] discharge, or

24-inch [609.6 mm] service, clearances.

7

Page 8

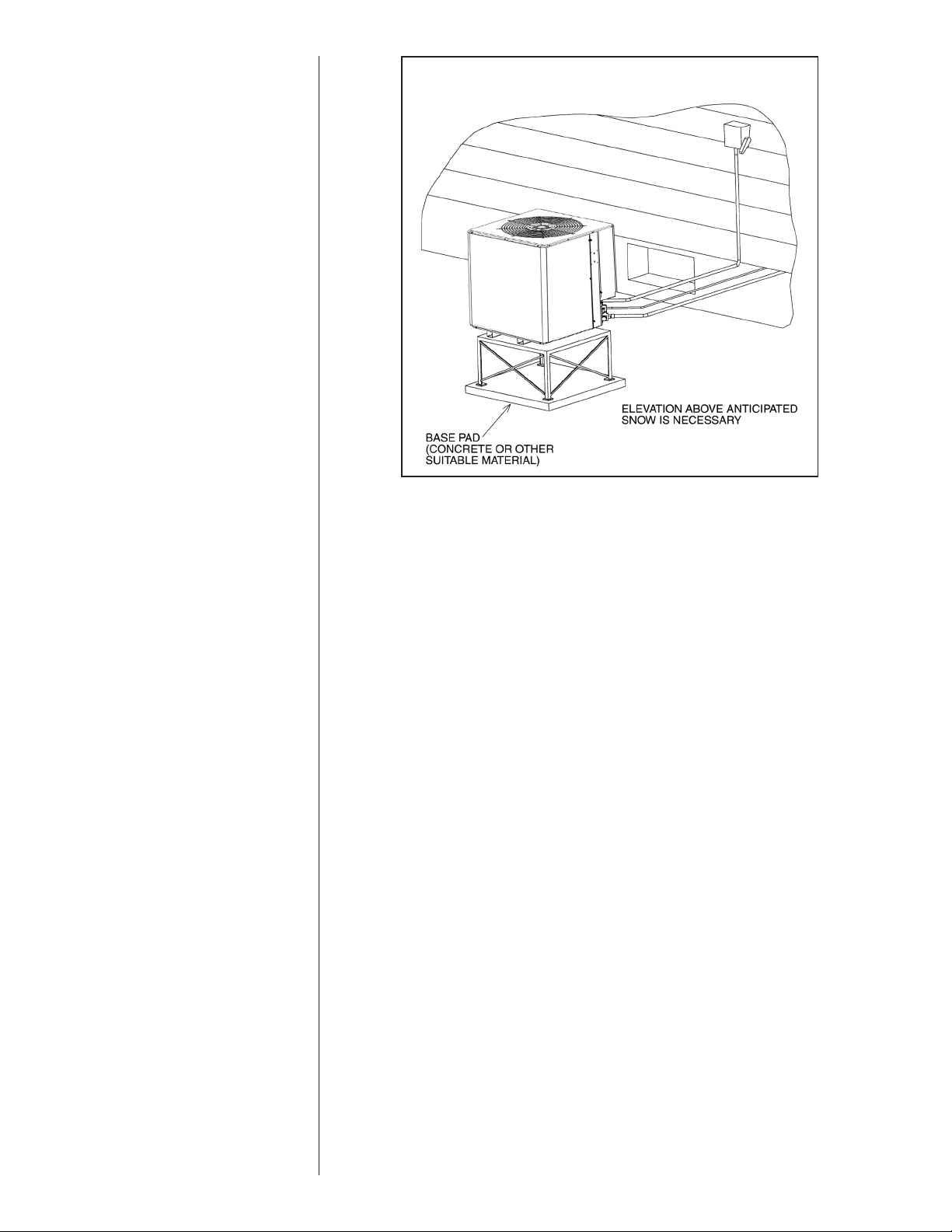

FIGURE 2

ECOMMENDED ELEVATED INSTALLATION

R

• Do not obstruct the bottom drain opening in the heat pump base pan. It is

essential to provide defrost condensate drainage to prevent possible refreezing

of the condensation. Provide a base pad for mounting the unit, which is slightly

pitched away from the structure. Route condensate off the base pad to an area

which will not become slippery and result in personal injury.

• Where snowfall is anticipated, the heat pump must be elevated above the base

pad to prevent ice buildup that may crush the tubing of the heat pump coil or

cause fin damage. Heat pump units should be mounted above the average

expected accumulated snowfall for the area.

3.5 CUSTOMER SATISFACTION ISSUES

• The heat pump should be located away from the living, sleeping and recreational spaces of the owner and those spaces on adjoining property.

• To prevent noise transmission, the mounting pad for the outdoor unit should

not be connected to the structure, and should be located sufficient distance

above grade to prevent ground water from entering the unit.

3.6 UNIT MOUNTING

If elevating the heat pump, either on a flat roof or on a slab, observe the

following guidelines.

• The base pan provided elevates the heat pump 2” [50.8 mm] above the base

pad.

• If elevating a unit on a flat roof, use 4” x 4” [101.6 mm x 101.6 mm] (or equivalent) stringers positioned to distribute unit weight evenly and prevent noise and

vibration (see Figure 2).

NOTE: Do not block drain openings shown in Figure 1.

• If unit must be elevated because of anticipated snow fall, secure unit and elevating stand such that unit and/or stand will not tip over or fall off. Keep in mind

that someone may try to climb on unit.

3.7 FACTORY-PREFERRED TIE-DOWN METHOD FOR OUTDOOR UNITS

IMPORTANT: The Manufacturers approved/recommended method is a guide to securing equipment for wind and seismic loads. Other methods might provide the same result,

but the Manufacturer’s method is the only one endorsed by the Manufacturer for securing equipment where wind or earthquake damage can occur. Additional information is

available in the PTS (Product Technical Support) section of the Manufacturer’s website

Rheemote.net and can be found as a listing under each outdoor model. If you do not

have access to this site, your Distributor can offer assistance.

8

Page 9

4.0 REFRIGERANT CONNECTIONS

All units are factory charged with Refrigerant 410A for 15 ft. [4.6 m] of line set. All

models are supplied with service valves. Keep tube ends sealed until connection is

to be made to prevent system contamination.

5.0 REPLACEMENT UNITS

To prevent failure of a new heat pump unit, the existing tubing system must be correctly sized and cleaned or replaced. Care must be exercised that the expansion

device is not plugged. For new and replacement units, a liquid line filter drier should

be installed and refrigerant tubing should be properly sized. Test the oil for acid. If

positive, a liquid line filter drier is mandatory.

6.0 INDOOR COIL

REFER TO INDOOR COIL MANUFACTURER’S INSTALLATION INSTRUCTIONS.

IMPORTANT: The manufacturer is not responsible for the performance and opera-

tion of a mismatched system, or for a match listed with another manufacturer’s coil.

6.1 LOCATION

Do not install the indoor coil in the return duct system of a gas or oil furnace.

Provide a service inlet to the coil for inspection and cleaning. Keep the coil pitched

toward the drain connection.

CAUTION

When coil is installed over a finished ceiling and/or living area, it is

recommended that a seconda ry sheet metal conden sa te p an be

constructed and installed under entire unit. Failure to do so can result

in property damage.

7.0 INTERCONNECTING TUBING

7.1 VAPOR AND LIQUID LINES

Keep all lines sealed until connection is made.

Make connections at the indoor coil first.

Refer to Line Size Information in Tables 2 and 3 for correct size and multipliers to be

used to determine capacity for various vapor line diameters and lengths of run. The

losses due to the lines being exposed to outdoor conditions are not included.

The factory refrigeration charge in the outdoor unit is sufficient for 15 feet [4.6 m] of

interconnecting lines. The factory refrigeration charge in the outdoor unit is sufficient

for the unit and 15 feet [4.6 m] of standard size interconnecting liquid and vapor

lines. For different lengths, adjust the charge as indicated below.

1/4” ± .3 oz. per foot [6.35 mm ± 8.5 g]

5/16” ± .4 oz. per foot [7.9 mm ± 11.3 g]

3/8” ± .6 oz. per foot [9.5 mm ± 17 g]

1/2” ± 1.2 oz. per foot [12.7 mm ± 34 g]

9

Page 10

7.2 MAXIMUM LENGTH OF LINES

The maximum length of interconnecting line is 150 feet [45.7 m]. Always use the

shortest length possible with a minimum number of bends. Additional compressor

oil is not required for any length up to 150 feet [45.7 m].

NOTE: Excessively long refrigerant lines cause loss of equipment capacity.

7.3 VERTICAL SEPARATION

eep the vertical separation to a minimum. Use the following guidelines when

K

installing the unit:

1. DO NOT exceed the vertical separations as indicated on Table 3.

2. It is recommended to use the smallest liquid line size permitted to minimize system charge which will maximize compressor reliability.

3. Table 3 may be used for sizing horizontal runs.

7.4 TUBING INSTALLATION

Observe the following when installing correctly sized type “L” refrigerant tubing

between the condensing unit and evaporator coil:

• If a portion of the liquid line passes through a hot area where liquid refrigerant

can be heated to form vapor, insulating the liquid line is required.

• Use clean, dehydrated, sealed refrigeration grade tubing.

• Always keep tubing sealed until tubing is in place and connections are to be

made.

• Blow out the liquid and vapor lines with dry nitrogen before connecting to the

outdoor unit and indoor coil. Any debris in the line set will end up plugging the

expansion device.

• As an added precaution it is recommended that a high quality, bi-directional filter drier is installed in the liquid line.

• Do not allow the vapor line and liquid line to be in contact with each other. This

causes an undesirable heat transfer resulting in capacity loss and increased

power consumption. The vapor line must be insulated.

• If tubing has been cut, make sure ends are deburred while holding in a position

to prevent chips from falling into tubing. Burrs such as those caused by tubing

cutters can affect performance dramatically, particularly on small liquid line

sizes.

• For best operation, keep tubing run as short as possible with a minimum number of elbows or bends.

• Locations where the tubing will be exposed to mechanical damage should be

avoided. If it is necessary to use such locations, the copper tubing should be

housed to prevent damage.

• If tubing is to be run underground, it must be run in a sealed watertight chase.

• Use care in routing tubing and do not kink or twist. Use a tubing bender on the

vapor line to prevent kinking.

• Route the tubing using temporary hangers, then straighten the tubing and

install permanent hangers. Line must be adequately supported.

• The vapor line must be insulated to prevent dripping (sweating) and prevent

performance losses. Armaflex and Rubatex are satisfactory insulations for this

purpose. Use 1/2” [12.7 mm] minimum insulation thickness, additional insulation may be required for long runs.

• Check Table 2 for the correct vapor line size. Check Table 3 for the correct liquid line size.

10

Page 11

7.5 TUBING CONNECTIONS

Indoor coils have only a holding charge of dry nitrogen. Keep all tube ends sealed

until connections are to be made.

• Use type “L” copper refrigeration tubing. Braze the connections with accepted

industry practices.

• Be certain both refrigerant shutoff valves at the outdoor unit are closed.

• Clean the inside of the fittings before brazing.

• Remove the cap and schrader core from service port to protect seals from heat

damage.

• Use an appropriate heatsink material around the copper stub and the service

valves before applying heat.

• IMPORTANT: Do not braze any fitting with the TEV sensing bulb attached.

• Braze the tubing between the outdoor unit and indoor coil. Flow dry nitrogen

into a service port and through the tubing while brazing.

• The service valves are not backseating valves. To open the valves, remove the

valve cap with an adjustable wrench. Insert a 3/16” [4.7 mm] or 5/16” [7.9 mm] hex

wrench into the stem. Back out counterclockwise.

• Replace the valve cap finger tight then tighten an additional 1/2 hex flat for a

metal-to-metal seal.

7.6 LEAK TESTING

• Pressurize line set and coil through service fittings with dry nitrogen to 150

PSIG [1034.2 kPa] maximum. Leak test all joints using liquid detergent. If a

leak is found, relieve pressure and repair.

11

Page 12

TABLE 2

SUCTION LINE LENGTH/SIZE VS CAPACITY MULTIPLIER (R-410A)

Unit Size

Suction Line Connection Size

Suction Line Run - Feet [m]

ptional

O

25’ [7.6] Standard

— Optional

Optional

50’ [15.24] Standard

— Optional

Optional

100’ [30.5] Standard

— Optional

Optional

150’ [45.7] Standard

— Optional

NOTES:

*Standard line size

Using suction line larger than shown in chart will result in poor oil return and is not recommended.

1 1/2 Ton 2 Ton 2 1/2 Ton 3 Ton 3 1/2 Ton 4 Ton 5 Ton

3/4”

[19] I.D.

5/8 [15.9] Opt.

3/4* [19] Std.

—

3/4”

[19] I.D.

5/8 [15.9] Opt.

3/4* [19] Std.

—

3/4”

[19] I.D.

5/8 [15.9] Opt.

3/4* [19] Std.

7/8 [22.2] Opt.

[19] I.D.

5/8 [15.9] Opt.

3/4* [19] Std.

7/8 [22.2] Opt.

1.00 1.00 1.00 1.00 1.00 1.00 1.00

1.00 1.00 1.00 1.00 1.00 1.00 1.00

——1.00 —— ——

0.98 0.98 0.96 0.98 0.99 0.99 0.99

0.99 0.99 0.98 0.99 0.99 0.99 0.99

——0.99 —— ——

0.95 0.95 0.94 0.96 0.96 0.96 0.97

0.96 0.96 0.96 0.97 0.98 0.98 0.98

——0.97 —— ——

0.92 0.92 0.91 0.94 0.94 0.95 0.94

0.93 0.94 0.93 0.95 0.96 0.96 0.97

——0.95 —— ——

3/4”

7/8”

[22.2] I.D.

3/4 [19] Opt.

7/8* [22.2] Opt.

—

7/8”

[22.2] I.D.

7/8 [22.2] Opt.

1 1/8* [28.6] Std.

—

7/8”

[22.2] I.D.

7/8 [22.2] Opt.

1 1/8* [28.6] Std.

—

12

Page 13

TABLE 3

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72]

1/4" [6.35] 25 [7.62] 50 [15.24] 75 [22.86] 77 [23.47] 62 [18.90] 46 [14.02]

5

/16" [7.93] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 119 [36.27] 115 [35.05]

3/8" [9.52]* 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [38.10] 131 [39.93]

1/4" [6.35] 25 [7.62] 50 [15.24] 35 [10.67] 9 [2.74] N/A N/A

5/16" [7.93] 25 [7.62] 50 [15.24] 75 [22.86] 87 [26.52] 80 [24.38] 74 [22.56]

3/8" [9.52]* 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 102 [31.09] 100 [30.48]

1/4" [6.35] 20 [6.10] N/A N/A N/A N/A N/A

5/16" [7.93] 25 [7.62] 39 [11.89] 29 [8.84] 20 [6.10] 10 [3.05] N/A

3/8" [9.52]* 25 [7.62] 50 [15.24] 48 [14.63] 45 [13.72] 41 [12.50] 38 [11.58]

5/16" [7.93] 25 [7.62] 28 [8.53] 14 [4.27] N/A N/A N/A

3/8" [9.52]* 25 [7.62] 45 [13.72] 41 [12.50] 36 [10.97] 31 [9.45] 27 [8.23]

1/2" [12.70] 25 [7.62] 50 [15.24] 52 [15.85] 51 [15.55] 50 [15.24] 49 [14.94]

5/16" [7.93] 25 [7.62] 50 [15.24] 40 [12.19] 22 [6.71] N/A N/A

3/8" [9.52]* 25 [7.62] 50 [15.24] 65 [19.81] 61 [18.59] 57 [17.37] 54 [16.46]

1/2" [12.70] 25 [7.62] 50 [15.24] 73 [22.25] 73 [22.25] 72 [21.95] 71 [21.64]

5/16" [7.93] N/A N/A N/A N/A N/A N/A

3/8" [9.52]* 15 [4.57] 10 [3.05] N/A N/A N/A N/A

1/2" [12.70] 19 [5.79] 18 [5.49] 17 [5.18] 16 [4.88] 15 [4.57] 14 [4.27]

3/8" [9.52]* 25 [7.62] 24 [7.32] 17 [5.18] 11 [3.35] N/A N/A

1/2" [12.70] 25 [7.62] 35 [10.67] 34 [10.36] 32 [9.75] 31 [9.45] 30 [9.14]

1/4" [6.35] 25 [7.62] 19 [5.79] N/A N/A N/A N/A

5/16" [7.93] 25 [7.62] 43 [13.11] 39 [11.89] 35 [10.67] 31 [9.45] 26 [7.93]

3/8" [9.52]* 25 [7.62] 48 [14.63] 47 [14.33] 46 [14.02] 44 [13.41] 43 [13.11]

1/4" [6.35] 25 [7.62] N/A N/A N/A N/A N/A

5/16" [7.93] 25 [7.62] 43 [13.11] 36 [10.97] 30 [9.14] 23 [7.01] 16 [4.88]

3/8" [9.52]* 25 [7.62] 50 [15.24] 49 [14.94] 47 [14.33] 45 [13.72] 42 [12.80]

1/4" [6.35] 18 [5.49] N/A N/A N/A N/A N/A

5/16" [7.93] 25 [7.62] 37 [11.28] 27 [8.23] 18 [5.49] N/A N/A

3/8" [9.52]* 25 [7.62] 49 [14.94] 46 [14.02] 43 [13.11] 39 [11.89] 36 [10.97]

5/16" [7.93] 25 [7.62] 33 [10.06] 19 [5.79] N/A N/A N/A

3/8" [9.52]* 25 [7.62] 50 [15.24] 46 [14.02] 41 [12.50] 36 [10.97] 32 [9.75]

1/2" [12.70] 25 [7.62] 50 [15.24] 57 [17.37] 56 [17.07] 55 [16.76] 54 [16.46]

5/16" [7.93] 25 [7.62] 50 [15.24] 33 [10.06] 16 [4.88] N/A N/A

3/8" [9.52]* 25 [7.62] 50 [15.24] 66 [20.12] 60 [18.29] 55 [16.76] 49 [14.94]

1/2" [12.70] 25 [7.62] 50 [15.24] 75 [22.86] 74 [22.56] 74 [22.56] 73 [22.25]

5/16" [7.93] 20 [6.10] N/A N/A N/A N/A N/A

3/8" [9.52]* 25 [7.62] 27 [8.23] 19 [5.79] 12 [3.66] N/A N/A

1/2" [12.70] 25 [7.62] 40 [12.19] 38 [11.58] 37 [11.28] 35 [10.67] 33 [10.06]

3/8" [9.52]* 25 [7.62] 37 [11.28] 25 [7.62] 13 [3.96] N/A N/A

1/2" [12.70] 25 [7.62] 50 [15.24] 54 [16.46] 51 [15.55] 49 [14.94] 46 [14.02]

Line Size

(Inch O.D.)

[mm]

Liquid Line Size

Outdoor unit Above or Below Indoor Coil

(Heat Pump Only)

To ta l Equivalent Length - Feet [m]

Maximum Vertical Separation - Feet [m]

3/8" [9.53]

2 1/2 Ton

3/8" [9.53]

R-410A

System

C

apacity

Model

Line Size

Connection

S

ize (Inch

I.D.) [mm]

!"#$%%&

1 1/2 Ton

3/8" [9.53]

2 Ton

3/8" [9.53]

5 Ton

3/8" [9.53]

3 Ton

3/8" [9.53]

3 1/2 Ton

3/8" [9.53]

4 Ton

3/8" [9.53]

1

1/2 Ton

3

/8" [9.53]

2 Ton

4 Ton

3/8" [9.53]

5 Ton

3/8" [9.53]

!'()#$%%&

2 1/2 Ton

3/8" [9.53]

3 Ton

3/8" [9.53]

3 1/2 Ton

3/8" [9.53]

LIQUID LINE SIZING (R-410A)

NOTES:

*Standard line size

N/A - Application not recommended.

13

Page 14

TABLE 4

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72]

5/8" [15.88]

3

/4" [19.05]*

7/8" [22.23]

5/8" [15.88]

3/4" [19.05]*

7/8" [22.23]

5/8" [15.88]

3/4" [19.05]*

7/8" [22.23]

5/8" [15.88]

3/4" [19.05]

7/8" [22.23]*

5/8" [15.88]

3/4" [19.05]

7/8" [22.23]*

5/8" [15.88]

3/4" [19.05]

7/8" [22.23]

3/4" [19.05]

7/8" [22.23]

1-1/8" [28.58]*

5/8" [15.88]

3/4" [19.05]*

7/8" [22.23]

5/8" [15.88]

3/4" [19.05]*

7/8" [22.23]

5/8" [15.88]

3/4" [19.05]*

7/8" [22.23]

5/8" [15.88]

3/4" [19.05]*

7/8" [22.23]

5/8" [15.88]

3/4" [19.05]

7/8" [22.23]*

5/8" [15.88]

3/4" [19.05]

7/8" [22.23]*

3/4" [19.05]

7/8" [22.23]*

1-1/8" [28.58]

SUCTION LINE SIZE - OUTDOOR UNIT ABOVE INDOOR COIL

R-410A

S

ystem

Capacity

Model

Line Size

C

onnection

Size (Inch

I.D.) [mm]

Line Size

(Inch O.D.)

[mm]

Suction Line Size

Outdoor Unit ABOVE Indoor Coil (Heat Pumps)

To ta l Equivalent Length - Feet [m]

2 Ton

Same as Liquid Line Size Table

NA

NA

1

1/2 Ton

Same as Liquid Line Size Table

N

A

NA

2 1/2 Ton

Same as Liquid Line Size Table

NA

Same as Liquid Line Size Table

Same as Liquid Line Size Table

3 Ton

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

3 1/2 Ton

7/8" [22.23]

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

!"#$%%&

1 1/2 Ton

Same as Liquid Line Size Table

NA

NA

!'()#$%%&

4 Ton

7/8" [22.23]

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

5 Ton

7/8" [22.23]

Same as Liquid Line Size Table

Same as Liquid Line Size Table

2 Ton

Same as Liquid Line Size Table

NA

NA

2 1/2 Ton

Same as Liquid Line Size Table

Same as Liquid Line Size Table

NA

3 Ton

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

3 1/2 Ton

7/8" [22.23]

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

4 Ton

7/8" [22.23]

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

5 Ton

7/8" [22.23]

Same as Liquid Line Size Table

Same as Liquid Line Size Table

NA

3

/4" [19.05]

3/4" [19.05]

3/4" [19.05]

3/4" [19.05]

3/4" [19.05]

3/4" [19.05]

3/4" [19.05]

3/4" [19.05]

UCTION LINE SIZING (R-410A)

S

NOTES:

*Standard line size

N/A - Application not recommended.

14

Page 15

TABLE 5

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72]

5/8" [15.88]

3

/4" [19.05]*

7/8" [22.23]

5/8" [15.88]

3/4" [19.05]*

7/8" [22.23]

5/8" [15.88]

3/4" [19.05]*

7/8" [22.23]

5/8" [15.88]

3/4" [19.05]

7/8" [22.23]*

5/8" [15.88]

3/4" [19.05]

7/8" [22.23]*

5/8" [15.88]

3/4" [19.05]

7/8" [22.23]

3/4" [19.05]

7/8" [22.23]

1-1/8" [28.58]*

5/8" [15.88]

3/4" [19.05]*

7/8" [22.23]

5/8" [15.88]

3/4" [19.05]*

7/8" [22.23]

5/8" [15.88]

3/4" [19.05]*

7/8" [22.23]

5/8" [15.88]

3/4" [19.05]*

7/8" [22.23]

5/8" [15.88]

3/4" [19.05]

7/8" [22.23]*

5/8" [15.88]

3/4" [19.05]

7/8" [22.23]*

3/4" [19.05]

7/8" [22.23]*

1-1/8" [28.58]

SUCTION LINE SIZE - OUTDOOR UNIT BELOW INDOOR COIL

R-410A

S

ystem

Capacity

Model

Line Size

C

onnection

Size (Inch

I.D.) [mm]

Line Size

(Inch O.D.)

[mm]

Suction Line Size

Outdoor Unit BELOW Indoor Coil (Heat Pumps)

To ta l Equivalent Length - Feet [m]

1

1/2 Ton

Same as Liquid Line Size Table

N

A

NA

NA

2 1/2 Ton

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

NA

2 Ton

Same as Liquid Line Size Table

Same as Liquid Line Size Table

NA

Same as Liquid Line Size Table

3 Ton

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

3 1/2 Ton

7/8" [22.23]

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

!"#$%%&

1 1/2 Ton

Same as Liquid Line Size Table

NA

NA

!'()#$%%&

4 Ton

7/8" [22.23]

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

5 Ton

7/8" [22.23]

Same as Liquid Line Size Table

Same as Liquid Line Size Table

2 Ton

Same as Liquid Line Size Table

Same as Liquid Line Size TableNANA

2 1/2 Ton

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

NA

3 Ton

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

3 1/2 Ton

7/8" [22.23]

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

4 Ton

7/8" [22.23]

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

5 Ton

7/8" [22.23]

Same as Liquid Line Size Table

Same as Liquid Line Size Table

Same as Liquid Line Size Table

NA

3

/4" [19.05]

3/4" [19.05]

3/4" [19.05]

3/4" [19.05]

3/4" [19.05]

3/4" [19.05]

3/4" [19.05]

3/4" [19.05]

UCTION LINE SIZING (R-410A)

S

NOTES:

*Standard line size

N/A - Application not recommended.

15

Page 16

8.0 DEMAND DEFROST CONTROL AND

8.0 HIGH/LOW PRESSURE CONTROLS

The demand defrost control is a printed circuit board assembly consisting of solid

state control devices with electro-mechanical outputs. The demand defrost control

monitors the outdoor ambient temperature, outdoor coil temperature, and the compressor run-time to determine when a defrost cycle is required.

Enhanced Feature Demand Defrost Control: Has high and low pressure control

inputs with unique pressure switch logic built into the microprocessor to provide

compressor and system protection without nuisance lock-outs. Cycles the compressor off for 5 seconds at the beginning and end of the defrost cycle to eliminate the

increased compressor noise caused by rapidly changing system pressures when

the reversing valve switches. See section 8.7 for diagnostic flash codes for the two

diagnostic LED’s provided on the control.

8.1 DEFROST INITIATION

A defrost will be initiated when the three conditions below are satisfied:

1) The outdoor coil temperature is below 35°F.

2) The compressor has operated for at least 34 minutes with the outdoor coil temperature below 35°F.

3) The measured difference between the ambient temperature and the outdoor

coil temperature exceeds a certain threshold.

Additionally, a defrost will be initiated if six hours of accumulated compressor run-time

has elapsed without a defrost with the outdoor coil temperature below 35°F.

8.2 DEFROST TERMINATION

Once a defrost is initiated, the defrost will continue until fourteen minutes has

elapsed or the coil temperature has reached the terminate temperature. The terminate temperature is factory set at 70°F, although the temperature can be changed

to 50°F, 60°F, 70°F or 80°F by relocating a jumper on the board.

8.3 TEMPERATURE SENSORS

The coil sensor is clipped to the top tube on the outdoor coil at the point feed by the

distribution tubes from the expansion device (short 3/8” dia. tube). The air sensor is

located on the defrost control board.

If the ambient sensor fails the defrost control will initiate a defrost every 34 minutes

with the coil temperature below 35°F.

If the coil sensor fails the defrost control will not initiate a defrost.

8.4 TEST MODE

The test mode is initiated by shorting the TEST pins. In this mode of operation, the

enable temperature is ignored and all timers are sped up by a factor of 240. To initiate a manual defrost, short the TEST pins. Remove the short when the system

switches to defrost mode. The defrost will terminate on time (14 minutes) or when

the termination temperature has been achieved. Short TEST pins again to terminate the defrost immediately.

8.5 TROUBLE SHOOTING DEMAND DEFROST OPERATION

Set the indoor thermostat select switch to heat and thermostat lever to a call for

heat.

Jumper the “test pins” to put the unit into defrost. If the unit goes into defrost and

comes back out of defrost, the indication is that the control is working properly.

If the unit did not go into defrost using the test pins, check to ensure that 24V is

being supplied to the control board. If 24V is present then replace the control.

16

Page 17

8.6 HIGH/LOW PRESSURE CONTROL MONITORING

Status of high and low pressure controls is monitored by the enhanced feature

demand defrost control and the following actions are taken.

High Pressure Control (optional) – Provides active protection in both cooling and

heating modes at all outdoor ambient temperatures. The high pressure control is an

automatic reset type and opens at approximately 610 psig and closes at approximately 420 psig. The compressor and fan motor will stop when the high pressure

control opens and will start again if the high side pressure drops to approximately

420 psig when the automatic reset high pressure control resets. If the high pressure

control opens 3 times within a particular call for heating or cooling operation, the

defrost control will lock out compressor and outdoor fan operation.

Low Pressure Control (standard) – Provides active protection in both heating and

cooling modes at all outdoor ambient temperatures. The low pressure control is an

automatic reset type and opens at approximately 15 psig and closes at approximately 40 psig. Operation is slightly different between cooling and heating modes.

Cooling Mode: The compressor and fan motor will stop when the low pressure

control opens and will start again when the low side pressure rises to approximately 40 psig when the low pressure control automatically resets. If the low

pressure switch opens 3 times within a particular call for cooling operation, the

defrost control will lock out compressor and outdoor fan operation.

Heating Mode: The compressor and fan motor will stop when the low pressure

control opens and will start again when the low side pressure rises to approximately 40 psig when the low pressure control automatically resets. If the low

pressure switch trips 3 times within 120 minutes of operation during a particular

call for heating operation, the defrost control will lock out compressor and outdoor fan operation. If the lock-out due to low pressure occurs at an outdoor

ambient temperature below 5°F, the defrost control will automatically exit the

lock-out mode when the outdoor ambient temperature rises to 5°F. This feature

is necessary since the low pressure control could possibly heave opened due to

the outdoor ambient being very low rather than an actual system fault.

Exiting Lock-Out Mode: To exit the lock-out mode, remove 24 volts to the defrost

control by removing power to indoor air-handler/furnace or by shorting the two

defrost control test pins together.

8.7 ENHANCED FEATURE DEFROST CONTROL DIAGNOSTIC CODES

LED 1 LED 2 Control Board Status

OFF OFF No Power

ON ON Coil Sensor Failure

OFF ON Ambient Sensor Failure

FLASH FLASH Normal

OFF FLASH Low Pressure Lockout (short test pins to reset)

FLASH OFF High Pressure Lockout (short test pins to reset)

ON FLASH Low Pressure Control Open

FLASH ON High Pressure Control Open

Alternate Flashing 5 Minute Time Delay

9.0 START-UP – CHECKING AIRFLOW

The air distribution system has the greatest effect on airflow. The duct system is

totally controlled by the contractor. For this reason, the contractor should use only

industry-recognized procedures. The correct air quantity is critical to air conditioning

systems. Proper operation, efficiency, compressor life, and humidity control depend

on the correct balance between indoor load and outdoor unit capacity. Excessive

indoor airflow increases the possibility of high humidity problems. Low indoor airflow

reduces total capacity and causes coil icing. Serious harm can be done to the compressor by low airflow, such as that caused by refrigerant flooding. Heat pump systems require a specified airflow. Each ton of cooling requires between 375 and 450

cubic feet of air per minute (CFM). See the manufacturer’s spec sheet for rated airflow for the system being installed. Duct design and construction should be carefully

done. System performance can be lowered dramatically through bad planning or

workmanship. Air supply diffusers must be selected and located carefully. They

must be sized and positioned to deliver treated air along the perimeter of the space.

If they are too small for their intended airflow, they become noisy. If they are not

located properly, they cause drafts. Return air grilles must be properly sized to carry

air back to the blower. If they are too small, they also cause noise. The installers

should balance the air distribution system to ensure proper quiet airflow to all rooms

in the home. This ensures a comfortable living space.

17

Page 18

Altitude

(feet)

SENSIBLE HEAT

CONSTANT

(SHC)

ALTITUDE

(FEET)

SENSIBLE HEAT

CONSTANT

(SHC)

Sea Level 1.08 6000 0.87

500 1.07 7000 0.84

1000 1.05 8000 0.81

2000 1.01 9000 0.78

3000 0.97 10000 0.75

4000 0.94 15000 0.61

5000 0.90 20000 0.50

These simple mathematical formulas can be used to determine the CFM in a residential or light commercial system. Electric resistance heaters can use:

olts x amps x 3.413

CFM =

Gas furnaces can use:

FM =

C

*Refer to furnace data plate for furnace output capacity. SHC = Sensible Heat

Constant (see table below), an air velocity meter or airflow hood can give a more

accurate reading of the system CFM. The measurement for temperature rise should

be performed at the indoor coil inlet and near the outlet, but out of direct line of sight

of the heater element or heat exchanger. For best results, measure air temperature

at multiple points and average the measurements to obtain coil inlet and outlet temperatures.

v

SHC x temp rise

Output Capacity in BTUH*

SHC x temp rise

10.0 EVACUATION AND LEAK TESTING

10.1 EVACUATION PROCEDURE

Evacuation is the most important part of the entire service procedure. The life and

efficiency of the equipment is dependent upon the thoroughness exercised by the

serviceman when evacuating air and moisture from the system.

Air or nitrogen in the system causes high condensing temperatures and pressure,

resulting in increased power input and non-verifiable performance.

Moisture chemically reacts with the refrigerant and oil to form corrosive hydrofluoric

acid. This attacks motor windings and parts, causing breakdown.

• After the system has been leak-checked and proven sealed, connect the vacuum

pump and evacuate system to 500 microns and hold 500 microns or less for at

least 15 minutes. The vacuum pump must be connected to both the high and low

18

sides of the system by connecting to the two pressure ports. Use the largest size

connections available since restrictive service connections may lead to false

readings because of pressure drop through the fittings.

• After adequate evacuation, open both service valves by removing both brass service valve caps with an adjustable wrench. Insert a 3/16” [5 mm] or 5/16” [8 mm]

hex wrench into the stem and turn counterclockwise until the wrench stops.

• At this time gauges must be connected to the access fitting on the liquid line

(small) service valve and the common suction port connected to the common suction line between the reversing valve and compressor to check and adjust charge.

IMPORTANT: Compressors (especially scroll type) should never be used to evacuate the air conditioning system because internal electrical arcing may result in a

damaged or failed compressor. Never run a scroll compressor while the system is in

a vacuum or compressor failure will occur.

10.2 FINAL LEAK TESTING

After the unit has been properly evacuated and service valves opened, a halogen

leak detector should be used to detect leaks in the system. All piping within the heat

pump, evaporator, and interconnecting tubing should be checked for leaks. If a leak

is detected, the refrigerant should be recovered before repairing the leak. The

Clean Air Act prohibits releasing refrigerant into the atmosphere.

Page 19

11.0 CHECKING REFRIGERANT CHARGE

WARNING

!

he top of the scroll compressor shell is hot. Touching the compressor

T

top may result in serious personal injury.

Charge for all systems should be checked against the Charging Chart inside the

access panel cover.

IMPORTANT:Use factory-approved charging method as outlined on the next 4

pages to ensure proper system charge.

NOTICE

!

The optimum refrigerant charge for any outdoor unit matched with a

CFL/CFM/H*L indoor coil/air handler is affected by the application.

Therefore, charging data has been developed to assist the field technician

in optimizing the charge for all mounting configurations (UF – Upflow, DF

– downflow, LH – Left Hand Discharge, and RH – Right Hand Discharge).

Refer to the charging chart inside the access panel cover on the unit and

choose the appropriate column for the specific application being installed

or serviced. New installations utilizing either a CFL/CFM indoor coil

installed on a gas furnace or an H*L air handler in the downflow or horizontal right hand discharge may require removal of refrigerant since the

factory charge could result in an overcharge condition.

11.1 CHARGING UNITS WITH R-410A REFRIGERANT

CAUTION

!

R-410A pressures are approximately 60% higher (1.6 times) than R-22

pressures. Use appropriate care when using this refrigerant. Failure to

exercise care may result in equipment damage or personal injury.

Charge for all systems should be checked against the Charging Chart inside the

access panel cover.

IMPORTANT:Do not operate the compressor without charge in the system.

Addition of R-410A will raise high-side pressures (liquid, and discharge).

NOTICE

!

System maintenance is to be performed by a qualified and certified technician.

The following method is used for charging systems in the cooling and heating

mode. All steps listed should be performed to insure proper charge has been set.

For measuring pressures, the service valve port on the liquid valve (small valve)

and the service port on the suction line between the reversing valve and compressor are to be used.

CONFIRM ID AIR FLOW & COILS ARE CLEAN

Confirm adequate Indoor supply air flow prior to starting the system. See the

Technical Specification sheet for rated air flow for each ID/OD unit match. Air

filter(s) and coils (indoor & outdoor) are to be clean and free of frost prior to starting

the system. Supply Air flow must be between 375 and 450 cfm per rated cooling ton

prior to adjusting system charge. If a humidification system is installed disengage it

from operating prior to charge adjustment. Refer to the “Checking Airflow” section of

this manual for further instruction.

19

Page 20

NOTICE

t

h

j y

!

Verify system components are matched according to the outdoor unit

Specification Sheet.

11.2 MEASUREMENT DEVICE SETUP

Step 1. With an R410A gauge set, attach the high pressure hose to the access

Step 2. Attach the low pressure hose to the common suction port connected to the

Step 3. Attach a temperature probe within 6” outside of the unit on the copper

fitting on the liquid line (small) service valve at the OD unit.

common suction line between the reversing valve and compressor.

liquid line (small line). For more accurate measurements clean the copper

line prior to measurement and use a calibrated clamp on temperature

probe or an insulated surface thermocouple.

11.3 CHARGING BY WEIGHT

NOTICE

!

ADJUST THE SYSTEM CHARGE BY WEIGHT FOR THE STRAIGHT

LENGTH OF THE REFRIGERANT LINE SET.

For a new installation, evacuation of interconnecting tubing and indoor coil is

adequate; otherwise, evacuate the entire system. Use the factory charge shown in

“Electrical and Physical Data” on page 6 of these instructions or on the unit data

plate. Note that the charge value includes charge required for 15 ft. [4.6 m] of

standard-size inter-connecting liquid line without a filter drier. Calculate actual

charge required with installed liquid line size and length using:

1/4” [6.4 mm] O.D. = .3 oz./ft. [8.5 g/.30 m]

5/16” [7.9 mm] O.D. = .4 oz./ft. [11.3 g/.30 m]

3/8” [9.5 mm] O.D. = .6 oz./ft. [17.0 g/.30 m]

1/2” [12.7 mm] O.D. = 1.2 oz./ft. [34.0 g/.30 m]

Add 6 oz. for field-installed filter drier.

With an accurate scale (+/– 1 oz. [28.3 g]) or volumetric charging device, adjust

charge difference between that shown on the unit data plate and that calculated for

the new system installation. If the entire system has been evacuated, add the total

calculated charge.

IMPORTANT: Charging by weight is not always accurate since the application can

affect the optimum refrigerant charge. Charging by weight is considered a starting

point ONLY. Always check the charge by using the charging chart and adjust as

necessary. CHARGING BY LIQUID SUB-COOLING MUST BE USED FOR FINAL

CHARGE ADJUSTMENT.

FIGURE 3

20

With thermostat in the “Off” position, turn the power on to the furnace or air handler

and the heat pump. Start the heat pump and the furnace or air handler with the

thermostat.

Page 21

11.4 GROSS CHARGING BY PRESSURES

Step 1. Following air flow verification and charge weigh in, run the unit for a

IMPORTANT: Indoor conditions as measured at the indoor coil must be within 2°F

of the following during gross charge (pressure) evaluation:

minimum of 15 minutes prior to noting pressures and temperature.

Cooling Mode: 80°F Dry Bulb

Heating Mode: 70°F Dry Bulb

NOTICE

!

If the Indoor temperature is above or below this range, run the system to

bring the temperature down or run the electric heat/furnace to bring the

temperature within this range. System pressure values provided in the

Charge Chart for outdoor dry bulbs corresponding to conditions outside

of ranges listed below, are provided as reference ONLY.

Step 2. Note the Outdoor Dry Bulb Temperature, ODDB°F = _______°F. Unit

Step 3. Locate and note the design pressures. The correct liquid and vapor

Step 4. If the measured liquid pressure is below the listed requirement for the given

charging is recommended under the following outdoor conditions ONLY:

Cooling Mode ONLY: 55°F outdoor dry bulb and above

Heating Mode ONLY: Between 40°F and 60°F outdoor dry bulb

pressures are found at the intersection of theInstalled system and the

outdoor ambient temperature on the Charging Chart located on the inside

of the control box cover of the outdoor unit.

Liquid Pressure: = ______psig; Vapor Pressure = ______psig

NOTICE

!

The refrigerant pressures provided are for gross charge check ONLY.

These pressure values are typical, but may vary due to application.

Evaporator (indoor coil in cooling mode / outdoor coil in heating mode)

load will cause pressures to deviate. Notice that all systems have unique

pressure curves. The variation in the slope and value is determined by the

component selection for that indoor/outdoor matched system. The

variation from system to system seen in the table is normal. The values

listed are for the applicable indoor coil match ONLY!

outdoor and indoor conditions, add charge. If the measured liquid pressure

is above the listed requirement for the given Outdoor and Indoor conditions

remove charge.

11.5 FINAL CHARGE BY SUB-COOLING

Step 1. After gross charging note the designed Sub-Cool value. The correct sub-

IMPORTANT: Indoor conditions as measured at the indoor coil are required to be

between 70°F and 80°F dry bulb for fine tune unit charge adjustment. Unit charging

is recommended under the following outdoor conditions ONLY:

cooling value is found at the intersection of the Installed system and the

outdoor ambient temperature on the Charging Chart located on the inside

of the control box cover of the outdoor unit.

SC° from Charging Chart = _________°F.

Cooling Mode ONLY: 55°F outdoor dry bulb and above

Heating Mode ONLY: Between 40°F and 60°F outdoor dry bulb

NOTICE

!

If the Indoor temperature is above or below the recommended range, run

the system to bring the temperature down or run the electric heat/furnace

to bring the temperature up. System sub-cooling values provided in the

Charge Chart for outdoor dry bulbs corresponding to conditions outside

of the above range, are provided as reference ONLY.

Step 2. Note the measured Liquid Pressure, Pliq = ______psig, as measured from

the liquid (small) service valve. Use the pressure temperature chart below

to note the corresponding saturation temperature for R410A at the

measured liquid pressure.

Liquid Saturation Temperature, SAT°F= _________°F.

21

Page 22

TABLE 6

S

ATURATION

TEMP

(Deg. F)

R

-410A

PSIG

S

ATURATION

TEMP

(Deg. F)

R

-410A

PSIG

S

ATURATION

TEMP

(Deg. F)

R

-410A

PSIG

S

ATURATION

TEMP

(Deg. F)

R

-410A

PSIG

-150 - -30 17.9 35 107.5 100 317.4

-140 - -25 22 40 118.5 105 340.6

-130 - -20 26.4 45 130.2 110 365.1

-

120 - -15 31.3 50 142.7 115 390.9

-110 - -10 36.5 55 156.0 120 418.0

-100 - -5 42.2 60 170.1 125 446.5

-

90 - 0 48.4 65 185.1 130 476.5

-80 - 5 55.1 70 201.0 135 508.0

-70 - 10 62.4 75 217.8 140 541.2

-60 0.4 15 70.2 80 235.6 145 576.0

-50 5.1 20 78.5 85 254.5 150 612.8

-40 10.9 25 87.5 90 274.3

-35 14.2 30 97.2 95 295.3

Step 3. Note the liquid line temperature, Liq° = __________°F, as measured from

Step 4. Subtract the liquid line temperature (Step 3) from the saturation

22

Step 5. Adjust Charge to obtain the specified sub-cooling value. If the measured

IMPORTANT: Excessive use of elbows in the refrigerant line set can produce

excessive pressure drop. Follow industry best practices for installation. Installation

and commissioning of this equipment is to be preformed by trained and qualified

HVAC professionals. For technical assistance contact your Distributor Service

Coordinator.

11.6 FINISHING UP INSTALLATION

• Disconnect pressure gauges from pressure ports; then replace the pressure port

• Replace the service valve caps finger-tight and then tighten with an open-end

• Replace control box cover and service panel and install screws to secure service

• Restore power to unit at disconnect if required.

• Configure indoor thermostat per the thermostat installation instructions and set

a temperature probe located within 6” outside of the unit on the copper

liquid line (small line). It is recommended to use a calibrated clamp on

temperature probe or an insulated surface thermocouple.

temperature (Step 2) to calculate Sub-Cooling. SAT°F______ - Liq°______

= SC°_______

sub-cool is below the listed requirement for the given outdoor and indoor

conditions, add charge. If the measured sub-cool is above the listed

requirement for the given outdoor and indoor conditions remove charge.

NOTICE

!

Systems should not be fine tune charged below 40°F outdoor dry bulb.

caps and tighten adequately to seal caps. Do not over tighten.

wrench adequately to seal caps. Do not over tighten.

panel.

thermostat to desired mode and temperature.

Page 23

12.0 ELECTRICAL WIRING

NOTE: Check all wiring to be sure connections are securely fastened, electrically

isolated from each other and that the unit is properly grounded.

WARNING

!

Turn off electric power at the fuse box or service panel before making any

electrical connections.

lso, the ground connection must be completed before making line volt-

A

ge connections. Failure to do so can result in electrical shock, severe

a

ersonal injury or death.

p

Field wiring must comply with the National Electric Code (C.E.C. in Canada) and

any applicable local code.

12.1 POWER WIRING

It is important that proper electrical power from a commercial utility is available at

the heat pump contactor. Voltage ranges for operation are shown in Table 7.

Install a branch circuit disconnect within sight of the unit and of adequate size to

handle the starting current (see Table 1).

Power wiring must be run in a rain-tight conduit. Conduit must be run through the

connector panel below the access cover (see Figure 1) and attached to the bottom

of the control box.

Connect power wiring to contactor located in outdoor heat pump electrical box. (See

wiring diagram attached to unit access panel.)

Check all electrical connections, including factory wiring within the unit and make

sure all connections are tight.

DO NOT connect aluminum field wire to the contactor terminals.

12.2 GROUNDING

A grounding lug is provided near the contactor for a ground wire.

!

The unit must be permanently grounded. Failure to do so can cause electrical shock resulting in severe personal injury or death.

TABLE 7

VOLTAGE RANGES (60 HZ)

Nameplate Voltage Maximum Load Design Conditions for

208/230 (1 Phase) 187 - 253

12.3 CONTROL WIRING

(See Figure 5)

If the low voltage control wiring is run in conduit with the power supply, Class I insulation is required. Class II insulation is required if run separate. Low voltage wiring

may be run through the insulated bushing provided in the 7/8” [22.2 mm] hole in the

base panel, up to and attached to the pigtails from the bottom of the control box.

Conduit can be run to the base panel if desired by removing the insulated bushing.

A thermostat and a 24 volt, 40 VA minimum transformer are required for the control

circuit of the condensing unit. The furnace or the air handler transformer may be

used if sufficient. See the wiring diagram for reference.

WARNING

Operating Voltage Range at Copeland

Compressors

23

Page 24

FIGURE 4

B

W2

G

Y

W1

B

ODD

C

R

Air Handler

Y

G

W2

E

H

eat Pump Thermostat

Heat Pump

Outdoor Unit

Y

B

C

R

R

D

C

Y

Field Installed

Line Voltage

-

WIRING INFORMATION

Factory Standard

-

W/BL

G/BK

Y

W/BK

G/Y

BR

BL

R

N

OTE: RED WIRE REQUIRED WITH RANCO DDL DEMAND DEFROST CONTROL.

ONTROL WIRING FOR AIR HANDLER

C

YPICAL THERMOSTAT:

T

EAT PUMP WITH

H

LECTRIC HEAT

E

NOTES:

1. Jumper “E” to “W2” to

transfer control of

supplemental heat to

1st stage when the

emergency heat switch

is on.

2. This wire turns on heat

for defrost, omit for most

economical operation.

3. Wire with colored tracing

stripe.

13.0 FIELD INSTALLED ACCESSORIES

13.1 COMPRESSOR CRANKCASE HEATER (CCH)

While scroll compressors usually do not require crankcase heaters, there are

instances when a heater should be added. Refrigerant migration during the off cycle

can result in a noisy start up. Add a crankcase heater to minimize refrigeration

migration, and to help eliminate any start up noise or bearing “wash out.”

TABLE 8

MAXIMUM SYSTEM CHARGE VALUES 13 & 14.5 SEER

Model Compressor Charge Limit Without

*These compressors come with factory installed crankcase heaters.

NOTE: Model sizes 48 and 60 have a factory installed crankcase heater.

Size Model Number Crankcase Heater

Model Compressor Charge Limit Without

Size Model Number Crankcase Heater

13 SEER Maximum Charge Values

18 ZP16K5E-PFV 9.6 lbs. [66.1 kPa]

18 H82J13BABCA *

24 ZP21K5E-PFV 9.6 lbs. [66.1 kPa]

30 ZP25K5E-PFV 9.6 lbs. [66.1 kPa]

30 H81J22BABCA *

36 ZP31K5E-PFV 9.6 lbs. [66.1 kPa]

36 HRH031U1LP6 9.6 lbs. [66.1 kPa]

42 ZP36K5E-PFV 12 lbs. [82.65 kPa]

42 HRH036U1LP6 9.6 lbs. [66.1 kPa]

48 ZP42K5E-PFV 12 lbs. [82.65 kPa]

60 ZP54K5E-PFV *

14.5 SEER Maximum Charge Values

18 ZP16K5E 9.6 lbs. [66.2 kPa]

24 ZP21K5E 9.6 lbs. [66.2 kPa]

30 ZP25K5E 9.6 lbs. [66.2 kPa]

36 ZP31K5E 9.6 lbs. [66.2 kPa]

42 ZP34K5E 12 lbs. [82.7 kPa]

24

Page 25

NOTE: The installation of a crankcase heater is recommended if the system charge

exceeds the values in Table 7.

All heaters are located on the lower half of the compressor shell. Its purpose is to

drive refrigerant from the compressor shell during long off cycles, thus preventing

damage to the compressor during start-up.

At initial start-up or after extended shutdown periods, make sure the heater is energized for at least 12 hours before the compressor is started. (Disconnect switch on

and wall thermostat off.)

13.2 LOW AMBIENT CONTROL (LAC) – COOLING MODE ONLY - RXAD-A08

This component senses compressor head pressure and shuts the heat pump fan off

when the head pressure drops to approximately 220 PSIG [1516.8 kPa]. This

allows the unit to build a sufficient head pressure at lower ambient in order to maintain system balance and obtain improved capacity. Low ambient control should be

used on all equipment operated below 70°F [21.1°C] ambient.

13.3 HIGH PRESSURE CONTROL (HPC)

This control keeps the compressor from operating in pressure ranges which can

cause damage to the compressor. This control is in the low voltage control circuit.

High pressure control (HPC) is a manual reset which opens near 610 PSIG [4205.8

kPa]. Do not reset arbitrarily without first determining what caused it to trip.

13.4 HEAT PUMP THERMOSTAT WARNING LIGHT KIT RXPX-D01

This component senses a compressor lock out and tells the thermostat service light

to come on. This will let the homeowner know that service is needed on the system.

NOTE: Warning light on thermostat will come on during a 5 minute compressor time

delay and for 5 seconds during defrost while the compressor is off. Homeowner

should only be concerned if light stays on for more than 5 minutes.

14.0 SERVICE

14.1 SINGLE-POLE COMPRESSOR CONTACTOR (CC)

CAUTION

Single-pole contactors are used on all standard single-phase units up

through 5 tons. Caution must be exercised when servicing as only one leg

of the power supply is broken with the contactor.

25

Page 26

15.0 TROUBLE SHOOTING

In diagnosing common faults in the heat pump system, develop a logical thought

pattern as used by experienced technicians. The charts which follow are not intended to be an answer to all problems but only to guide the technician’s thinking.

Through a series of yes and no answers, follow the logical path to a likely conclusion.

A novice technician should use these charts like a road map. Remember that the

hart should clarify a logical path to the problem’s solution.

c

15.1 ELECTRICAL CHECKS FLOW CHART

Repair and Recheck

YES NO for Cooling or Heating

Unit Running?

NO YES

Thermostat Problem? Go to

Mechanical Checks

Transformer Problem?

Repair and Recheck

Compressor Internal or Fuses Open

Compressor Winding Open Hot Gas Sensor

YES NO

Voltage on Compressor

Side of Contactor?

YES NO

Run Capacitor Voltage on Line

Side of Contactor?

Start Capacitor

NO YES

Potential Relay

Circuit Breakers Compressor Contactor

Overload Open Hi Pressure Cut-Out

YES

Compressor Winding

Unit Wiring and Grounded Compressor Time-Delay

Connections

26

Outdoor Fan Motor Unit Wiring and

Grounded Connections

Grounded Capacitor

Replace Fuses

or Reset Breakers

and Recheck System

Page 27

15.2 COOLING MECHANICAL CHECKS FLOW CHART

Unit Running?

Y

ES NO

Pressure problems? Checks Flow Chart

High Head Pressure Low Head Pressure Low Suction Pressure

Dirty Outdoor Coil Low on Charge Dirty Filters

Inoperative Outdoor Fan Open IPR Valve Dirty Indoor Coil

Overcharge Low Ambient Temperature Inadequate Indoor Air Flow

Recirculation of Inoperative Compressor Broken Indoor

Outdoor Air Valves Blower Belt

Non-condensibles Outdoor Check Valve Inoperative Indoor Blower

Closed

Higher than Ambient Low on Charge

Air Entering Outdoor Coil

Restricted Indoor Restricted Indoor

Wrong Outdoor Fan Rotation Metering Device Metering Device

Go to Electrical

Restricted Restriction in System

Filter Drier

Reversing Valve Indoor Air

Failure

Recirculation of

Wrong Indoor

Blower Rotation

Inadequate Ducts

Outdoor Check Valve Closed

Restricted Filter Drier

27

Page 28