Rheem 13PJL Installation Manual

INSTALLATION INSTRUCTIONS

WARNING

13 & 14 SEER SERIES

CUBE HEAT PUMPS

11⁄2 - 5 TONS FEATURING

EARTH-FRIENDLY R-410A REFRIGERANT R-410

▲WARNING

These instructions are intended as an aid to qualified licensed

service personnel for proper installation, adjustment and

operation of this unit. Read these instructions thoroughly

before attempting installation or operation. Failure to follow

these instructions may result in improper installation, adjustment, service or maintenance possibly resulting in fire, electrical shock, property damage, personal injury or death.

NOTE: Appearance of unit may vary.

!

92-20522-57-03

SUPERSEDES 92-20522-57-02

TABLE OF CONTENTS

1.0 SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.0 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Checking Product Received. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Electrical and Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.0 LOCATING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Corrosive Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Heat Pump Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Operational Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 For Units With Space Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 Customer Satisfaction Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.6 Unit Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.7 Factory-Preferred Tie-Down Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.0 REFRIGERANT CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.0 REPLACEMENT UNITS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.0 INDOOR COIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.0 INTERCONNECTING TUBING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.1 Vapor & Liquid Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.2 Maximum Length of Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.3 Vertical Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.4 Tubing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.5 Tubing Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.6 Leak Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.0 DEMAND DEFROST CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.1 Defrost Initiation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.2 Defrost Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.3 Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.4 Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.5 Demand Defrost Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8.6 Trouble Shooting Demand Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

9.0 EVACUATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

10.0 START UP & PERFORMANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

11.0 CHECKING AIRFLOW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

12.0 CHECKING REFRIGERANT CHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

12.1 Charging By Liquid Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

12.2 Charging By Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

12.3 Final Leak Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

13.0 ELECTRICAL WIRING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

13.1 Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

13.2 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

13.3 Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

14.0 FIELD INSTALLED ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

14.1 Compressor Crankcase Heat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

14.2 Low Ambient Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

14.3 High Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

15.0 SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

15.1 Single Pole Compressor Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

16.0 TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

16.1 Electrical Checks Flow Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

16.2 Cooling Mechanical Checks Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

16.3 Heating Mechanical Checks Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

16.4 Defrost Mechanical Checks Flow Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

16.5 Subcooling Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

16.6 General Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

16.7 Service Analyzer Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

17.0 WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2

1.0 SAFETY INFORMATION

WARNING

!

Disconnect all power to unit before starting maintenance. Failure to do so

can cause electrical shock resulting in severe personal injury or death.

WARNING

!

Turn off electric power at the fuse box or service panel before making any

electrical connections.

Also, the ground connection must be completed before making line voltage connections. Failure to do so can result in electrical shock, severe

personal injury or death.

WARNING

!

These instructions are intended as an aid to qualified licensed service

personnel for proper installation, adjustment and operation of this unit.

Read these instructions thoroughly before attempting installation or operation. Failure to follow these instructions may result in improper installation, adjustment, service or maintenance possibly resulting in fire, electrical shock, property damage, personal injury or death.

WARNING

!

The unit must be permanently grounded. Failure to do so can cause electrical shock resulting in severe personal injury or death.

WARNING

!

The manufacturer’s warranty does not cover any damage or defect to the

heat pump caused by the attachment or use of any components.

Accessories or devices (other than those authorized by the manufacturer) into, onto or in conjunction with the heat pump. You should be aware

that the use of unauthorized components, accessories or devices may

adversely affect the operation of the heat pump and may also endanger

life and property. The manufacturer disclaims any responsibility for such

loss or injury resulting from the use of such unauthorized components,

accessories or devices.

CAUTION

When coil is installed over a finished ceiling and/or living area, it is

recommended that a secondary sheet metal condensate pan be

constructed and installed under entire unit. Failure to do so can result

in property damage.

CAUTION

Single-pole contactors are used on all standard single-phase units up

through 5 tons. Caution must be exercised when servicing as only one leg

of the power supply is broken with the contactor.

3

2.0 GENERAL

WARNING

!

The manufacturer’s warranty does not cover any damage or defect to the

heat pump caused by the attachment or use of any components.

Accessories or devices (other than those authorized by the manufacturer) into, onto or in conjunction with the heat pump. You should be aware

that the use of unauthorized components, accessories or devices may

adversely affect the operation of the heat pump and may also endanger

life and property. The manufacturer disclaims any responsibility for such

loss or injury resulting from the use of such unauthorized components,

accessories or devices.

2.1 CHECKING PRODUCT RECEIVED

Upon receiving unit, inspect it for any shipping damage. Claims for damage, either

apparent or concealed, should be filed immediately with the shipping company.

Check heat pump model number, electrical characteristics and accessories to

determine if they are correct. Check system components (evaporator coil, condensing unit, evaporator blower, etc.) to make sure they are properly matched.The information contained in this manual has been prepared to assist in the proper installation, operation and maintenance of the heat pump system. Improper installation, or

installation not made in accordance with these instructions, can result in unsatisfactory operation and/or dangerous conditions, and can cause the related warranty not

to apply.

Read this manual and any instructions packaged with separate equipment required

to make up the system prior to installation. Retain this manual for future reference.

To achieve optimum efficiency and capacity, the indoor cooling coils listed in the

heat pump specification sheet should be used.

MATCH ALL COMPONENTS:

• OUTDOOR UNIT

• INDOOR COIL/METERING DEVICE

• INDOOR AIR HANDLER/FURNACE

• REFRIGERANT LINES

2.2 APPLICATION

Before installing any heat pump equipment, a duct analysis of the structure and a

heat gain calculation must be made. A heat gain calculation begins by measuring all

external surfaces and openings that gain heat from the surrounding air and quantifying that heat gain. A heat gain calculation also calculates the extra heat load

caused by sunlight and by humidity removal.

There are several factors that the installers must consider:

• Outdoor unit location • Proper equipment evacuation

• System refrigerant charge • Indoor unit airflow

• Indoor unit blower speed • Supply and return air duct design and sizing

• System air balancing • Diffuser and return air grille location and sizing

4

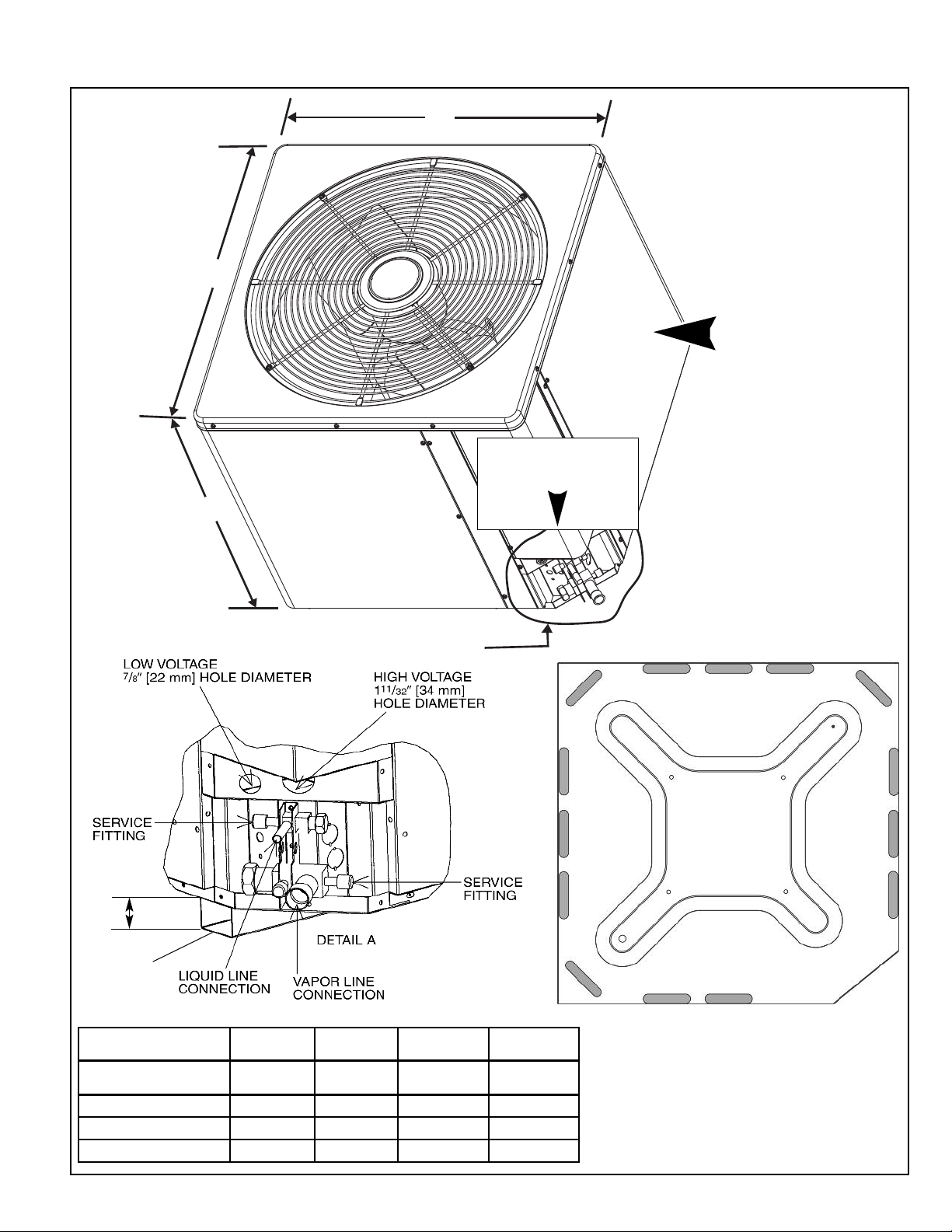

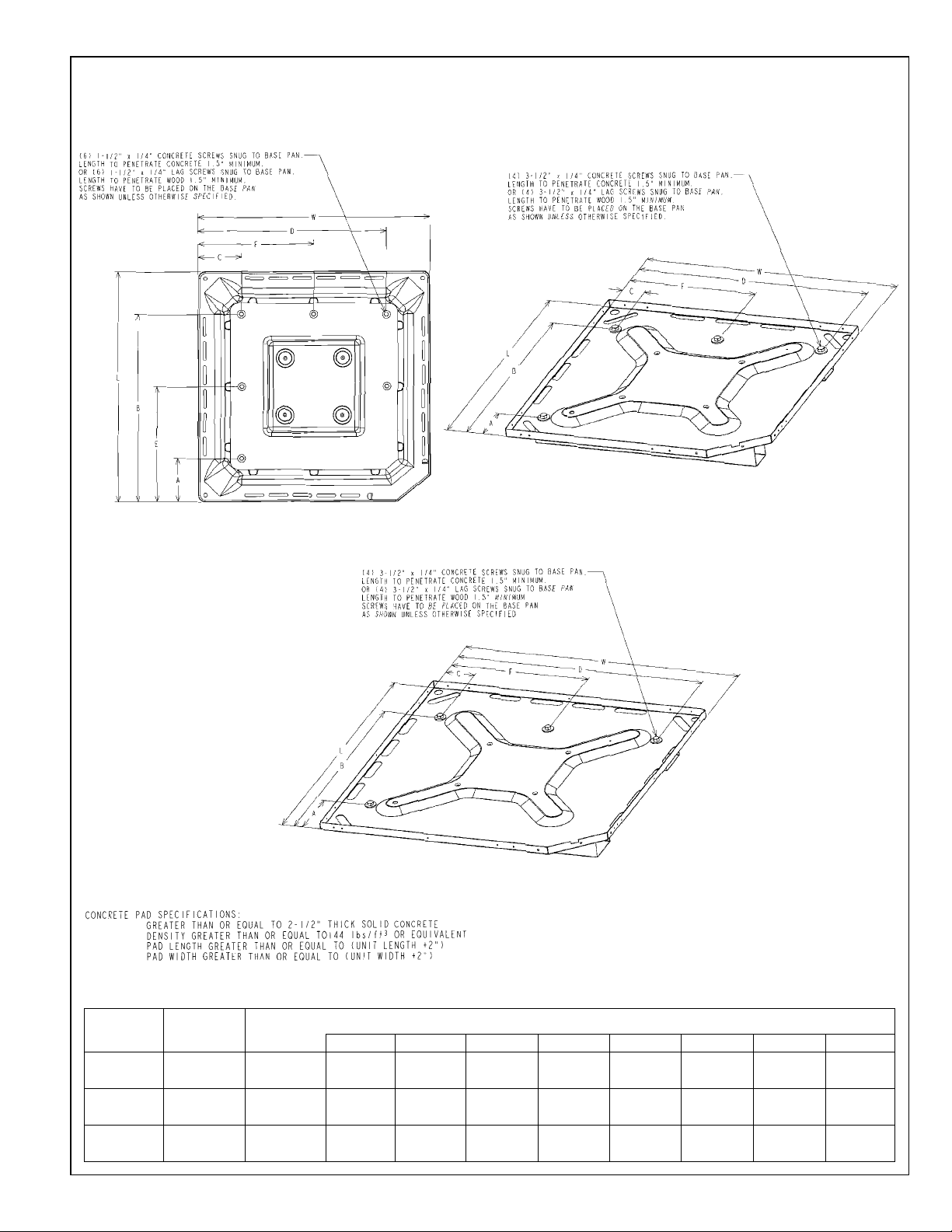

2.3 DIMENSIONS (SEE FIGURE 1)

L

H

SEE DETAIL A

w

A-00008

FIGURE 1

DIMENSIONS

AIR DISCHARGE: ALLOW

60” [1524 mm] MINIMUM

CLEARANCE.

AIR INLETS

(LOUVERED PANELS) ALLOW 6”

[152.4 mm]

MINIMUM

CLEARANCE

SERVICE ACCESS

ALLOW 24” [609.6 mm]

CLEARANCE

2"

[50.8 mm]

BASERAIL*

*The 3, 31⁄2, 4 & 5 ton

models do not feature

a baserail.

DIMENSIONAL DATA

13 SEER

Cooling Capacity

14 SEER

Cooling Capacity

Height “H” (in.) [mm]

Length “L” (in.) [mm]

Width “W” (in.) [mm]

18, 24

18, 24

261/4 [666.7]

235/8 [600]

235/8 [600]

30

30

261/4 [666.7] 273/8 [695.3] 353/8 [898.5]

275/8 [701.6] 315/8 [803.2] 315/8 [803.2]

275/8 [701.6]

36

36

315/8 [803.2]

42, 48, 60

42, 48, 60

315/8 [803.2]

NOTE: GRILLE APPEARANCE

MAY VARY.

BASE PAN (BOTTOM VIEW)

DO NOT OBSTRUCT DRAIN HOLES

(SHADED).

5

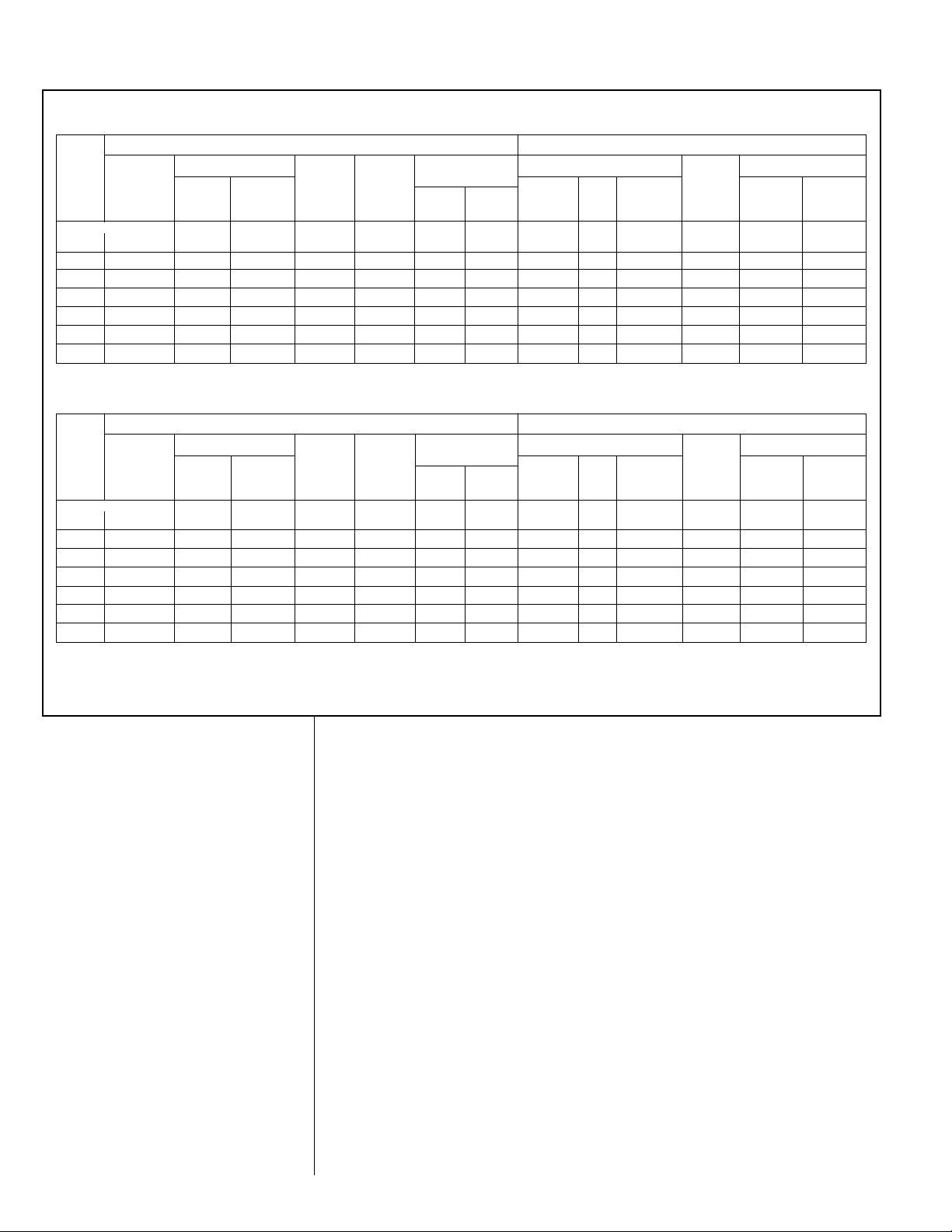

2.4 ELECTRICAL & PHYSICAL DATA (SEE TABLE 1)

TABLE 1

ELECTRICAL AND PHYSICAL DATA – 13 SEER

ELECTRICAL DATA PHYSICAL DATA

Model

Number

Rev.1/10/2008

18 1-60-208-230 9/9 48 0.6 12/12 15/15 20/20 11.06 [1.03] 1 1700 [802] 91 [2580] 144 [65.3] 152 [68.9]

24 1-60-208-230 12.8/12.8 58.3 0.6 17/17 20/20 25/25 11.06 [1.03] 1 2370 [1118] 91 [2580] 130 [59] 138 [62.6]

30 1-60-208-230 14.1/14.1 73 0.8 19/19 25/25 30/30 13.72 [1.27] 1 2800 [1321] 101 [2863] 198 [89.8] 208 [94.3]

36 1-60-208-230 17/17 96.7 1.2 23/23 30/30 35/35 16.39 [1.52] 1 3575 [1687] 109 [3090] 215 [97.5] 227 [103]

42 1-60-208-230 21.8/21.8 112 1.2 29/29 35/35 50/50 21.85 [2.03] 1 3575 [1687] 150 [4252] 202 [91.6] 214 [97.1]

48 1-60-208-230 21.8/21.8 117 1.2 29/29 35/35 50/50 21.85 [2.03] 1 3575 [1687] 141 [3997] 205 [93] 217 [98.4]

60 1-60-208-230 26.3/26.3 134 1.2 35/35 45/45 60/60 21.85 [2.03] 1 3575 [1687] 228 [6464] 209 [94.8] 221 [100.2]

ELECTRICAL AND PHYSICAL DATA – 14 SEER

Model

Number

Rev.1/10/2008

18 1-60-208-230 9/9 48 0.6 12/12 15/15 20/20 11.06 [1.03] 1 1700 [802] 91 [2580] 144 [65.3] 152 [68.9]

24 1-60-208-230 12.8/12.8 58.3 0.6 17/17 20/20 25/25 11.06 [1.03] 1 2370 [1118] 91 [2580] 130 [59] 138 [62.6]

30 1-60-208-230 14.1/14.1 73 0.8 19/19 25/25 30/30 13.72 [1.27] 1 2800 [1321] 101 [2863] 180 [81.6] 190 [86.2]

36 1-60-208-230 17/17 96.7 1.2 23/23 30/30 35/35 16.39 [1.52] 1 3575 [1687] 109 [3090] 215 [97.5] 227 [103]

42 1-60-208-230 17.9/17.9 112 1.2 24/24 30/30 40/40 21.85 [2.03] 1 3575 [1687] 150 [4252] 202 [91.6] 214 [97.1]

48 1-60-208-230 21.8/21.8 117 1.2 29/29 35/35 50/50 21.85 [2.03] 1 3575 [1687] 141 [3997] 205 [93] 217 [98.4]

60 1-60-208-230 26.4/26.4 150 1.2 35/35 45/45 60/60 21.85 [2.03] 2 3360 [1586] 259 [7343] 277 [125.6] 289 [131.1]

Phase

Frequency (Hz)

Voltage (Volts)

Phase

Frequency (Hz)

Voltage (Volts)

Rated Load

Amperes

(RLA)

Rated Load

Amperes

(RLA)

Locked Rotor

Amperes

(LRA)

Locked Rotor

Amperes

(LRA)

Fan Motor

Full Load

Amperes

(FLA)

ELECTRICAL DATA PHYSICAL DATA

Fan Motor

Full Load

Amperes

(FLA)

Minimum

Circuit

Ampacity

Amperes

Minimum

Circuit

Ampacity

Amperes

Fuse or HACR

Circuit Breaker

Minimum

Amperes

Fuse or HACR

Circuit Breaker

Minimum

Amperes

Maximum

Amperes

Maximum

Amperes

Face Area

Sq. Ft.

2

] ➀

[m

Face Area

Sq. Ft.

2

] ➀

[m

Outdoor Coil WeightCompressor

No.

Rows

Outdoor Coil WeightCompressor

No.

Rows

CFM

[L/s]

CFM

[L/s]

Refrig.

Per

Circuit

Oz. [g]

Refrig.

Per

Circuit

Oz. [g]

Net

Lbs. [kg]

Net

Lbs. [kg]

Shipping

Lbs. [kg]

Shipping

Lbs. [kg]

NOTES:

➀ 20 Fins per inch [mm]

➁ Factory charged for 15 ft. [4.6 m] of line set

3.0 LOCATING UNIT

3.1 CORROSIVE ENVIRONMENT

The metal parts of this unit may be subject to rust or deterioration if exposed to a

corrosive environment. This oxidation could shorten the equipment’s useful life.

Corrosive elements include, but are not limited to, salt spray, fog or mist in seacoast

areas, sulphur or chlorine from lawn watering systems, and various chemical contaminants from industries such as paper mills and petroleum refineries.

If the unit is to be installed in an area where contaminants are likely to be a problem, special attention should be given to the equipment location and exposure.

• Avoid having lawn sprinkler heads spray directly on the unit cabinet.

• In coastal areas, locate the unit on the side of the building away from the waterfront.

• Shielding provided by a fence or shrubs may give some protection, but cannot

violate minimum airflow and service access clearances.

• Elevating the unit off its slab or base enough to allow air circulation will help

avoid holding water against the basepan.

Regular maintenance will reduce the build-up of contaminants and help to protect

the unit’s finish.

6

!

WARNING

Disconnect all power to unit before starting maintenance. Failure to do so

can cause electrical shock resulting in severe personal injury or death.

• Frequent washing of the cabinet, fan blade and coil with fresh water will remove

most of the salt or other contaminants that build up on the unit.

• Regular cleaning and waxing of the cabinet with an automobile polish will pro-

vide some protection.

• A liquid cleaner may be used several times a year to remove matter that will not

wash off with water.

Several different types of protective coil coatings are offered in some areas. These

coatings may provide some benefit, but the effectiveness of such coating materials

cannot be verified by the equipment manufacturer.

3.2 HEAT PUMP LOCATION

Consult local and national building codes and ordinances for special installation

requirements. Following location information will provide longer life and simplified

servicing of the outdoor heat pump.

NOTE: These units must be installed outdoors. No ductwork can be attached, or

other modifications made, to the discharge grille. Modifications will affect performance or operation.

3.3 OPERATIONAL ISSUES

• IMPORTANT: Locate the unit in a manner that will not prevent, impair or com-

promise the performance of other equipment horizontally installed in proximity

to the unit. Maintain all required minimum distances to gas and electric meters,

dryer vents, exhaust and inlet openings. In the absence of National Codes, or

manufacturers’ recommendations, local code recommendations and requirements will take presidence.

• Refrigerant piping and wiring should be properly sized and kept as short as

possible to avoid capacity losses and increased operating costs.

• Locate the unit where water run off will not create a problem with the equip-

ment. Position the unit away from the drip edge of the roof whenever possible.

Units are weatherized, but can be affected by the following:

o Water pouring into the unit from the junction of rooflines, without protective

guttering. Large volumes of water entering the heat pump while in operation

can impact fan blade or motor life, and coil damage may occur to a heat

pump if moisture cannot drain from the unit under freezing conditions.

o Freezing moisture, or sleeting conditions, can cause the cabinet to ice-over

prematurely and prevent heat pump operation, requiring backup heat, which

generally results in less economical operation.

• Closely follow clearance recommendations (See Figure 1).

o 24” [609.6 mm] to the service panel access

o 60” [1524 mm] above heat pump fan discharge (unit top) to prevent recircula-

tion

o 6” [152.4 mm] to heat pump coil grille air inlets (per heat pump).

3.4 FOR UNITS WITH SPACE LIMITATIONS

In the event that a space limitation exists, we will permit the following clearances:

Single Unit Applications: Clearances below 6 inches [152.4 mm] will reduce unit

capacity and efficiency. Do not reduce the 60-inch [1524 mm] discharge, or the 24inch [609.6 mm] service clearances.

Multiple Unit Applications: When multiple heat pump grille sides are aligned, a 6inch [152.4 mm] per unit clearance is recommended, for a total of 12" [304.8 mm]

between two units. Two combined clearances below 12 inches [304.8 mm] will

reduce capacity and efficiency. Do not reduce the 60-inch [1524 mm] discharge, or

24-inch [609.6 mm] service, clearances.

7

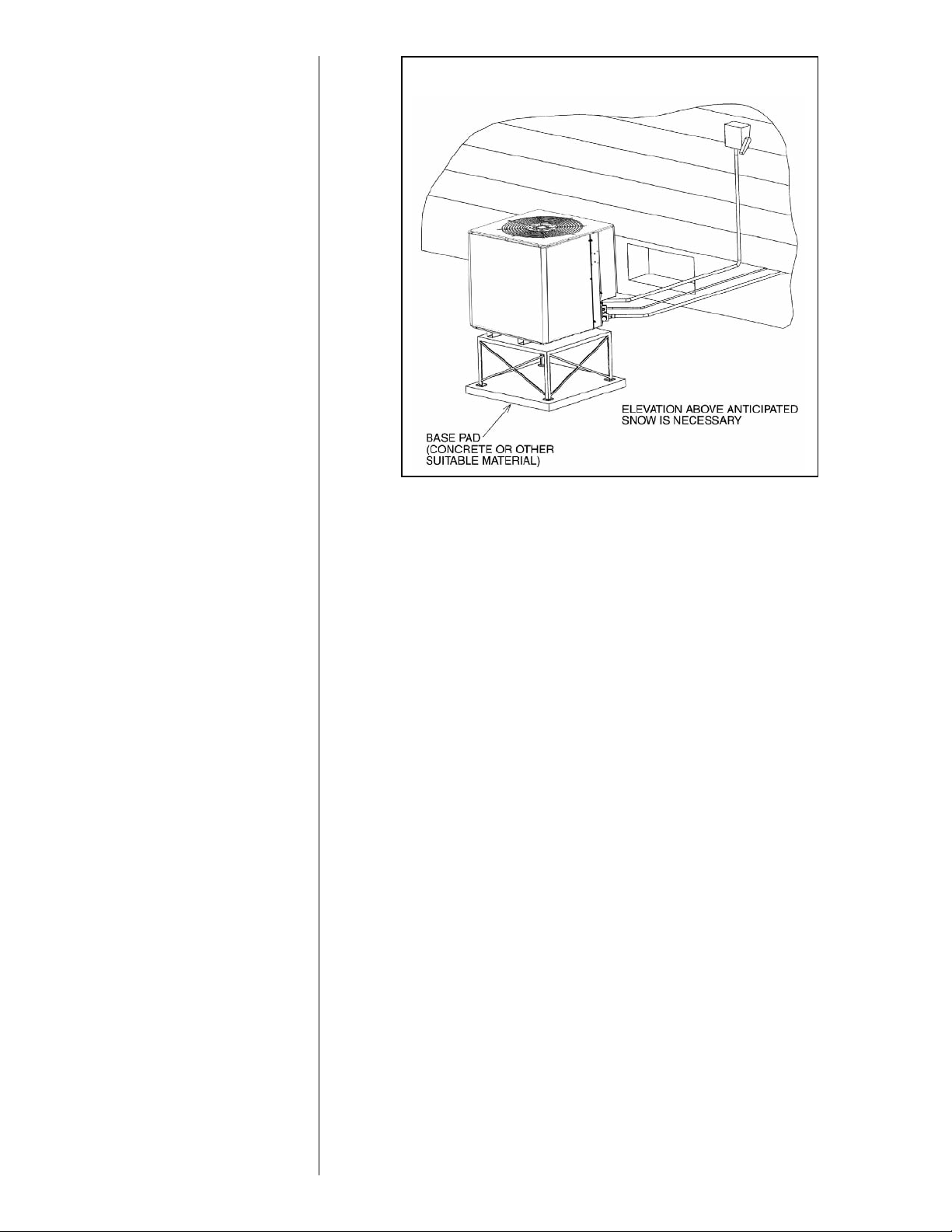

FIGURE 2

RECOMMENDED ELEVATED INSTALLATION

• Do not obstruct the bottom drain opening in the heat pump base pan. It is

essential to provide defrost condensate drainage to prevent possible refreezing

of the condensation. Provide a base pad for mounting the unit, which is slightly

pitched away from the structure. Route condensate off the base pad to an area

which will not become slippery and result in personal injury.

• Where snowfall is anticipated, the heat pump must be elevated above the base

pad to prevent ice buildup that may crush the tubing of the heat pump coil or

cause fin damage. Heat pump units should be mounted above the average

expected accumulated snowfall for the area.

3.5 CUSTOMER SATISFACTION ISSUES

• The heat pump should be located away from the living, sleeping and recreational spaces of the owner and those spaces on adjoining property.

• To prevent noise transmission, the mounting pad for the outdoor unit should

not be connected to the structure, and should be located sufficient distance

above grade to prevent ground water from entering the unit.

3.6 UNIT MOUNTING

If elevating the heat pump, either on a flat roof or on a slab, observe the

following guidelines.

• The base pan provided elevates the heat pump 2” [50.8 mm] above the base

pad.

• If elevating a unit on a flat roof, use 4” x 4” [101.6 mm x 101.6 mm] (or equivalent) stringers positioned to distribute unit weight evenly and prevent noise and

vibration (see Figure 2).

NOTE: Do not block drain openings shown in Figure 1.

• If unit must be elevated because of anticipated snow fall, secure unit and elevating stand such that unit and/or stand will not tip over or fall off. Keep in mind

that someone may try to climb on unit.

3.7 FACTORY-PREFERRED TIE-DOWN METHOD

INSTRUCTIONS:

IMPORTANT: These instructions are intended as a guide to securing equipment for windload ratings of “120 MPH sustained wind load” and “3-second, 150 MPH gust.” While this

procedure is not mandatory,the Manufacturerdoes recommend that equipment be properly secured in areas where high wind damage may occur.

STEP 1: Beforeinstalling,clear pad of any dirt or debris.

IMPORTANT: The pad must be constructed of industry-approved materials, and

must be thick enough to accommodate the concrete fastener.

8

FIGURE 3

TIE-DOWN KIT ASSEMBLY

VIEW B

VIEW C

NOTE:

13 SEER

MODELS

18/24

30

36/42/48/60

14 SEER

MODELS

18/24

30

36/42/48/60

TIE DOWN

ASSEMBLY

VIEW

C

D

B

VIEW D

TIE DOWN ASSEMBLY DIMENSIONS

LWABCDEF

23.63”

[600]

27.63”

[701.8]

31.63”

[803.4]

23.63”

[600]

27.63”

[701.8]

31.63”

[803.4]

3.5”

[88.9]

5”

[127]

5.63”

[143]

18.63”

[473.2]

21.13”

[536.7]

24.5”

[622.3]

1.94”

[49.7]

2.75”

[69.8]

5.63”

[143]

20.19”

[512.8]

23.38”

[593.8]

24.5”

[622.3]

CENTER LINE

OF UNIT

CENTER LINE

OF UNIT

CENTER LINE

OF UNIT

CENTER LINE

OF UNIT

CENTER LINE

OF UNIT

CENTER LINE

OF UNIT

9

STEP 2: Centerbasepan on pad, ensuringit is level.

STEP 3: Removeunit top panel by removing screws around the perimeter of top panel.

STEP 4: Drill 4 or 6 holes (1/4” [6.35 mm] diameter) in the unit basepan only

STEP 5: Selectand obtainappropriate concrete or lag screwsand flat washers per figure3.

STEP 6: Drill pilot holes in pad through the basepanclearance holes drilled in Step 4,

STEP 7: Drive concrete screws or lag screws through

STEP 8: Re-connect fan motor wire leads to contactor per the unit wiring diagram and

STEP 9: Finish unit installation per Sections 4 - 14 in this manual.

Disconnect fan motor leads from contactor and lay top panel aside taking care

not to damage the fan.

per figure 3.

1

ensuring that the holes are at least

tener being used. Use the concrete screw or lag screw manufacturer’s recommended hole diameter for the pilot holes.

unit base-pan and into the pad. Use flat washers under the head of the screws.

Snug screws to basepan.

NOTE: Do not over-tightenthe concrete or lag screws. Doing so can weaken or strip

the fastener and cause it to break or pull out.

lower unit top onto the unit. Take care to place the fan motor wire conduit in the

slot in the top of the control box as the top is lowered onto the unit. Re-install

screws that attach unit top to the unit.

⁄4” [6.35 mm] deeper than the concrete fas-

1

⁄4” [6.35 mm] clearance holes in

4.0 REFRIGERANT CONNECTIONS

All units are factory charged with Refrigerant 410A for 15 ft. [4.6 m] of line set. All

models are supplied with service valves. Keep tube ends sealed until connection is

to be made to prevent system contamination.

5.0 REPLACEMENT UNITS

To prevent failure of a new heat pump unit, the existing tubing system must be correctly sized and cleaned or replaced. Care must be exercised that the expansion

device is not plugged. For new and replacement units, a liquid line filter drier should

be installed and refrigerant tubing should be properly sized. Test the oil for acid. If

positive, a liquid line filter drier is mandatory.

6.0 INDOOR COIL

REFER TO INDOOR COIL MANUFACTURER’S INSTALLATION INSTRUCTIONS.

IMPORTANT: The manufacturer is not responsible for the performance and opera-

tion of a mismatched system, or for a match listed with another manufacturer’s coil.

6.1 LOCATION

Do not install the indoor coil in the return duct system of a gas or oil furnace.

Provide a service inlet to the coil for inspection and cleaning. Keep the coil pitched

toward the drain connection.

CAUTION

When coil is installed over a finished ceiling and/or living area, it is

recommended that a secondary sheet metal condensate pan be

constructed and installed under entire unit. Failure to do so can result

in property damage.

10

Loading...

Loading...