Page 1

PROJECT NAME ______________________________________________________________________________

LOCATION __________________________________________________________________________________

ARCHITECT__________________________________________________________________________________

ENGINEER __________________________________________________________________________________

CONTRACTOR ______________________________________________________________________________

SUBMITTED BY ______________________________ DATE ________________________________________

UNIT SUMMARY

SUBMITTAL COVER SHEET

Quantity

Unit Designation

Model No.

Total Cooling

Sensible Cooling

Air Ent. Evaporator

Air Lvg. Evaporator

Heating Input

Heating Output

CFM/ESP

EER/SEER

Electrical

Minimum Ampacity

Min.-Max. Breaker

Net Unit Weight

Accessory

Catalog Form Number

ACCESSORIES: NOTES:

PRINTED IN U.S.A. 10-06 DC FORM NO. X11-1123 REV. 2

Supersedes Form No. X11-1123 Rev. 1

Page 2

SUBMITTAL SHEET FOR (-)ASL- JEC

2 thru 5 TON [7.03 thru 17.6 kW] ,

18 SEER HIGH EFFICIENCY CONDENSING UNITS

FORM NO. X33-1266 REV. 1

Supersedes Form No. X33-1266

JOB NAME LOCATION

CONTRACTOR ORDER NO.

ENGINEER

SUBMITTED FOR APPROVAL RECORD

DATE

UNIT MODEL NO.

COIL MODEL NO.

AIR HANDLER MODEL NO.

UNIT DATA

COOLING PERFORMANCE

EFFICIENCY ................................

_______

SEER

TOTAL CAPACITY*..................

_______

MBH [kW]

SENSIBLE CAPACITY*............

_______

MBH [kW]

OUTDOOR DESIGN TEMP. ....

_______

°F [°C] DB

TEMP. OF AIR ENTERING

EVAPORATOR COIL............

_______

°F [°C] DB

_______

°F [°C] WB

POWER INPUT REQUIREMENT ........

_______

kW

(*uses blower motor heat)

SUPPLY AIR BLOWER PERFORMANCE

TOTAL AIR SUPPLY ................

_______

CFM [L/s]

TOTAL RESISTANCE EXTERNAL

TO UNIT......................................

_______

IWG

BLOWER SPEED ..........................

_______

RPM

POWER OUTPUT REQUIREMENT ..

_______

BHP

MOTOR RATING ........................

_______

HP [W]

POWER INPUT REQUIREMENT ........

_______

kW

ELECTRICAL DATA

POWER SUPPLY......................

____________ Hz

TOTAL UNIT AMPACITY................

_______

AMPS

MINIMUM WIRE SIZE ....................

_______

AWG

MAXIMUM OVERCURRENT DEVICE

FUSES/HACR BREAKER ..........

_______

AMPS

CLEARANCES

ACCESS SIDE 24" [609.6 mm]

AIR INLETS 12" [304.8 mm]

ABOVE UNIT 60" [1524 mm]

Equipped with

Comfort Control2System

™

• Serial communication enabled

• Increased system reliability and efficiency

• 32+ on-board diagnostic and operating codes

•

Active Protection

™

homeowner “Call for Service” alert

• Exclusive Design with dual 7-segment led display

“Proper sizing and installation of equipment is critical to achieve optimal performance. Split system air conditioners and heat pumps must be matched with

appropriate coil components to meet ENERGY STAR criteria. Ask your Contractor for details or visit www.energystar.gov.”

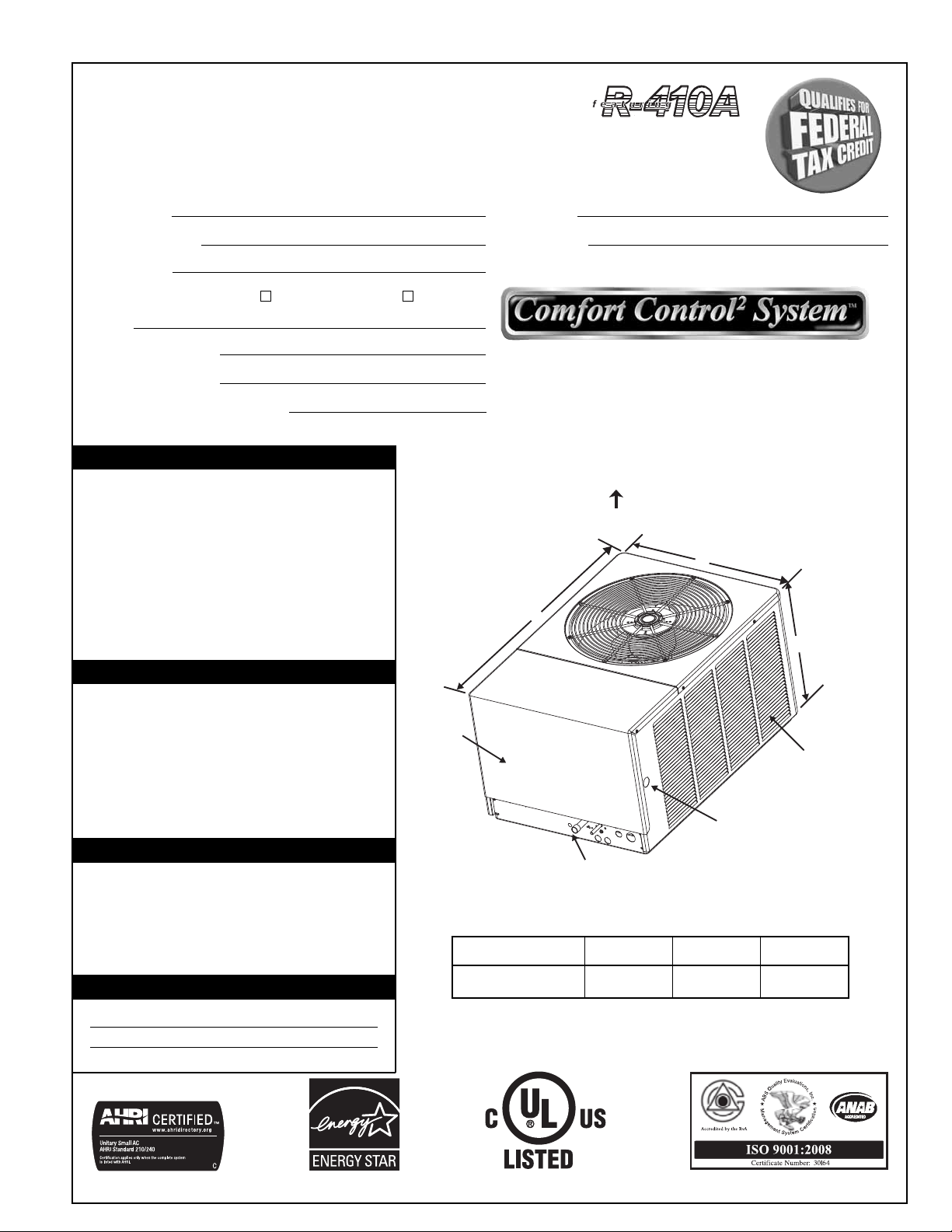

DIMENSIONS

Model Number

(-)ASL-

Height “H”

(Inches) [mm]

Length “L”

(Inches) [mm]

Width “W”

(Inches) [mm]

024JEC/036JEC/039JEC

048JEC/060JEC

33 [838]

443/8 [1127] 311/2 [800]

[ ] Designates Metric Conversions

ACCESS

PANE L

AIR DISCHARGE

ALLOW 60 [1524 mm] CLEARANCE

L

ALLOW 24 [610 mm]

ACCESS CLEARANCE

W

ALTERNATE HIGH VOLTAGE

CONNECTION (KNOCKOUT)

11

/32 [34 mm]

1

H

AIR INLETS

(LOUVERS)

ALLOW 6 [152 mm]

MIN. CLEARANCE

3 SIDES

Page 3

FEATURES FOR (-)ASL- JEC CONDENSING UNITS

2 thru 5 NOMINAL TON [7.03 thru 17.6 kW]

FIELD INSTALLED ACCESSORIES

SPECIAL NOTES ON EQUIPMENT:

The High Efficiency Two-Stage (-)ASL- JEC Con den sing Unit was designed with performance in mind.

These units offer comfort, energy conservation and

dependability for single, multi-family and light commercial applications. The Two-Stage (-)ASL- JEC Condensing Units are the result of an ongoing development

program for improved efficiencies. With system SEERʼs

as high as 19.5, and up to 14.30 EER, these units

continue a tradition of delivering high efficiency.

• Industryʼs lowest profile design: 33" maximum height

•The

Comfort Control2System™

provides over 32+

on-board diagnostics and fault history codes for

condensing units with single-phase compressors by

detecting system and electrical problems. The

integrated diagnostics with

Active Protection™

prevents compressor operation when potentially

harmful conditions are detected. Sends “Call for

Service” alert notification to the thermostat to alert

the homeowner of required service.

• Serial Communication Enhanced – When installed

with a Serial Communicating Air Handler

((-)HPL/(-)HPN-HM****JC) and user interface control

(-HC-TST501CMMS) Series 500 thermostat this unit

offers 4 or 2 wire installation, auto-configuration,

and diagnostic messaging with full communicating

capability.

• Legacy Enabled – Unit can be conventionally wired

using 24VAC with non-communicating air-handlers

or furnaces with non-communicating thermostat.

• Features a 10-year conditional unit replacement

warranty and 10-year parts warranty when properly

installed with the Manufacturerʼs air handler or the

Manufacturerʼs indoor coil with the Manufacturerʼs

gas furnace. See product warranty card for additional

information.

• Reliable Two-Stage operation for precise temperature

control with On-Demand dehumidification feature.

When matched with ECM gas furnace or air-handler,

the system adjusts airflow to help control humidity for

unsurpassed comfort in the cooling mode.

• All controls are accessible by removing one service

panel. Removable top grille provides access to the

condenser fan motor and condenser coil.

• Attractive, louvered wrap-around jacket protects the

coil from yard hazards and weather extremes. Top

grille is steel reinforced for extra strength. Cabinet is

powder painted for all-weather protection.

• For quiet operation and improved efficiency, models

feature an ECM two-speed condenser fan motor with

a 3-blade outdoor fan.

• All models meet or exceed a 1000-hour salt spray

test per ASTM B117 Standard Practice for Operating

Salt Spray Testing Apparatus.

[ ] Designates Metric Conversions

Before proceeding with installation, refer

to installation instructions packaged

with each model, as well as complying

with all Federal, State, Provincial, and

Local codes, regulations, and practices.

Rheem Sales Company, Inc.

P.O. Box 17010, Fort Smith, AR 72917

“In keeping with its policy of continuous progress and product improvement, Rheem reserves the right to make changes without notice.”

PRINTED IN U.S.A. 3-11 DC FORM NO. X33-1266 REV. 1

Supersedes Form No. X33-1266

Low Ambient Control (Model No. RXAD-A08) ..............................

Compressor Crankcase Heater ..................................................

Thermostat (See Specification Sheet for details) ..........................

Loading...

Loading...