Page 1

User Manual

EN

TIGA FX MANUAL WHEELCHAIR

IssUE 14 - 2015

Page 2

User Manual | Thank you

Thank you

for buying RGK…

We hope the product and service you have received has met your expectations. Please

take time to read the instructions contained within, to familiarise yourself with your

new RGK chair and to ensure you get maximum performance and longevity from it.

Russel Simms,

Commercial Director

WARNING!

Do not operate this equipment without rst reading and understanding this manual.

If you are unable to understand the warnings and instructions, contact a healthcare

professional (doctor / therapist) before attempting to use this equipment - otherwise

injury or damage may result.

As the manufacturer, RGK Wheelchairs declares

that the lightweight wheelchairs conform to the

93/42/EEC / 2001/47/EEC guideline.

Please contact RGK or your local authorised RGK dealer if you

have any questions regarding the use, maintenance or safety

of your wheelchair.

RGK Wheelchairs, Units 8a/b/c , Ring Road, Zone 2 ,

Burntwood Business Park, Burntwood, Staordshire, WS7 3JQ,

United Kingdom

info@rgklife.com

User Manual

Issue No: 14 | 2015

02

Page 3

User Manual | Contents

Contents

03 User Manual Contents

04 Special Notes

05 Safety Summary

07 Product Description

09 Production Identication

10 Handling Of Wheelchairs

10 Tilting

Tilting Unattended

12 Reaching, leaning & bending forward

13 Transferring

14 Lengthening and shorting the wheel base

14 Manoeuvring your wheelchair

15 Safety Inspection Checklist

16 Troubleshooting / Maintenance

Troubleshooting Guide Mechanical

Maintenance Safety Precautions

17 Suggested Maintenance Procedures

18 Procedure 1

Backrest Adjustments

Adjusting/Replacing Back Upholstery

19 Procedure 2

Seat Cushion / Sling Replacement

Seat Upholstery Replacement

20 Procedure 3

Removing & Fitting Rear Wheels

21 Procedure 4

Adjusting The Quick-Release Axle

22 Procedure 5

Replacing Hand Rims;

Tyres & Inner Tubes

23 Procedure 6

Adjusting and Replacing The Camber Bar

24 Procedure 7

Replacing Front Fork Assembly

& Castors Wheels

25 Procedure 8

Wheel Locks

Adjusting / Replacing Wheel Locks

26 Procedure 9

Footrest

Standard Footrest Adjustment / Replacement

Installing / Adjusting Optional Angle Adjustable

Footrest

27 Procedure 10

Folding and Unfolding the backrest and front

tube section

28 Procedure 11

Adjusting Height Adjustable Stroller Handles:

Fold Down Pushing Handles and Screw In

Pushing Handles

29 Procedure 12

Adjust the Anti-Tipper

30 Procedure 13

Side Guards

31 Procedure 14

Straps

32 Technical

33 Warranty

User Manual

Issue No: 14 | 2015

03

Page 4

User Manual | Special Notes

Special Notes

The manual must be read thoroughly to avoid damage when handling

and using your RGK Wheelchair.

Denitions of words used in this manual

Wheelchair Selection

DANGER

Advice to the user of a Potential Risk of serious

injury or death if the advice is not followed.

WARNING

Advice to the user of a Potential Risk of

injury if the advice is not followed.

As a manufacturer of wheelchairs, RGK endeavours

to supply a wide variety of wheelchairs to meet many

needs of the end user. However, nal selection of the

type of wheelchair to be used by an individual rests

solely with the user and his/her health care professional

capable of making such a selection.

DO NOT use the footplate as a platform when getting in

or out of the wheelchair.

Always wear your seat restraint, if recommended.

CAUTION

Advice to user that Potential Damage to

equipment may occur if the advice is

not followed.

NOTE:

General advice or best practice

The wheelchair shown and described in this user guide

may not correspond in every detail exactly to your own

model and accessories.

However, all instructions are completely relevant,

regardless of additions that you may have added at the

time of order

The expected life of your RGK wheelchair is 5 years

of normal use by a single user. The expected life of

your wheelchair is above all dependent on the user’s

disability and the maintenance of the wheelchair.

Dierent users may experience both a shorter and a

longer service life for their wheelchair than those stated

above.

Please DO NOT use or t any third party components

to the wheelchair unless they are ocially approved by

RGK Wheelchairs Ltd.

NOTE:

The information contained in this document

is subject to change without notice.

User Manual

Issue No: 14 | 2015

04

Page 5

User Manual | Safety Summary

Safety Summary

WARNING

Transportation

Wheelchair tie-down restraints and seat restraints.

RGK recommends that wheelchair users not

be transported in vehicles of any kind while in

wheelchairs. It is RGK’s position that users of

wheelchairs should be transferred into appropriate

seating in vehicles for transportation and use be

made of the restraints made available by the auto

industry.

RGK cannot and does not recommend any

wheelchair transportation systems.

As regards restraints-seat belts, it is the obligation

of the dealer, therapists and other health care

professionals to determine if a seating restraint

is required to ensure the safe operation of this

equipment by the user.

Serious injury can occur in the event of a fall from a

wheelchair.

DO NOT use the footplate as a platform when getting

in or out of the wheelchair.

Safety Summary

Never exceed the maximum load of 125KG this

includes any additional items carried or attached on the

wheelchair. If you exceed the maximum load, this can

lead to permanent damage to your RGK wheelchair or

you may fall, tip over, lose control which may lead to

serious injury to either yourself or third parties.

Environment

WARNING

Any products left in extreme hot or cold

climates could result in hot/cold surfaces

which could result in personal injury

WARNING

Do not expose the product or any of its accessories

to any form of excessive heat or naked ame.

Finger Traps

WARNING

This product has moving parts and

therefore could trap the user’s ngers.

Use extreme caution when moving.

“Safety and Handling” of the wheelchair requires the close attention of the wheelchair user as well as the assistant. This

manual points out the most common procedures and techniques involved in the safe operation and maintenance of the

wheelchair. It is important to practice and master these safe techniques until you are comfortable in manoeuvring around

the frequently encountered architectural barriers.

Use this information only as a “basic” guide. The techniques that are discussed on the following pages have been used

successfully by many.

Individual wheelchair users often develop skills to deal with daily living activities that may dier from those described

in this manual. RGK recognises and encourages each individual to try what works best for him/her in overcoming

architectural obstacles that they may encounter. Techniques in this manual are a starting point for the new wheelchair user

and assistant with “safety” as the most important consideration for all.

User Manual

Issue No: 14 | 2015

05

Page 6

User Manual | Safety Summary

Safety Summary

Weight Training

RGK DOES NOT recommend the use of its wheelchairs

as a weight training apparatus. RGK products have NOT

been designed or tested as a seat for any kind of weight

training. If occupant uses said wheelchair as a weight

training apparatus, RGK shall NOT be liable for bodily

injury and the warranty will be voided immediately.

Stability and Balance

To assure stability and proper operation of your

wheelchair, you must at all times maintain proper

balance. Your wheelchair has been designed to remain

upright and stable during normal daily activities as long

as you do not move beyond the centre of gravity.

Virtually all activities which involve movement in the

chair have an eect on the centre of gravity.

Fig 1

WARNING

The position of the footrest, camber tube, height,

as well as the tautness of the back upholstery are

directly related to the chairs stability. Any change

to one or any combination of the three may cause

the chair to decrease in stability. Use EXTREME

caution when using a new seating position for the

rst time.

Castors pointing forward

Make sure the castors are pointing in the forward

position whenever you lean forward. This can be

achieved by advancing the chair and then reversing it

in a straight line. See Fig 1.

Coping with the irritation of everyday obstacles can

be alleviated somewhat by learning how to manage

your wheelchair. Keep in mind your centre of gravity to

maintain stability and balance.

User Manual

Issue No: 14 | 2015

06

Page 7

User Manual | Product Description

RGK TIGA FX Manual

Propelled Wheelchair

Product Description

The TIGA fx is a manually propelled wheelchair which

is suitable for a wide range of users whose mobility has

been reduced or removed by a disability or chronic

illness. The TIGA fx is hand built from aerospace grade

aluminium. Two frame design options are available,

either an open frame or a closed frame design,

delivering a lightweight and versatile wheelchair. The

design incorporates an aluminium frame, with either

an integrated aluminium camber bar and footrest

suited to the more experienced users looking for the

lightest option, or can be prescribed with an adjustable

aluminium camber bar and adjustable height footrest,

scissor or push to lock brakes, adjustable tension seat

sling, backrest and calf strap all as standard, with further

options available.

The design accommodates a wide range of disabilities

for all ages of user up to a maximum user weight of

125kg.

Suitability is dependent upon the degree and nature of

disability and must be determined through a thorough

client risk assessment carried out by a qualied medical

professional or RGK personnel. This wheelchair is

suitable for a means of transfer from one location to

another where physical mobility is impaired or reduced

and is not designed for any other purpose.

Consideration must be given at point of prescription

to required usage with regard to the capabilities of the

user and the environment and terrain on which the

product will be used.

The TIGA fx, manufactured by RGK Wheelchairs Ltd, is

CE marked as a Class 1 Medical Device and complies

with the Essential Requirements of the Medical Device

Directive 93/42/EEC.

By denition all wheelchairs are marketed as a medical

device where a “medical device”* means an instrument,

apparatus, appliance, material or other article, whether

used alone or in combination, together with any

software necessary for its proper application, which-

(a) is intended by the manufacturer to be used for

human beings for the purpose of-

(i) diagnosis, prevention, monitoring, treatment or

alleviation of disease,

(ii) diagnosis, monitoring, treatment, alleviation of or

compensation for an injury or handicap,

(iii) investigation, replacement or modication of the

anatomy or of a physiological process, or

(iv) control of conception; and

(b) does not achieve its principal intended action

in or on the human body by pharmacological,

immunological or metabolic means, even if it is assisted

in its function by such means.

* denition taken from the Medical Devices Directive

93/42/EEC

User Manual

Issue No: 14 | 2015

07

Page 8

User Manual | Product Description

RGK TIGA FX Manual

Propelled Wheelchair

A Backrest

B Brakes

C Rear Wheel

D Front Castor

E Front Castor Forks

F Footplate

G Footplate cover

H Camber Bar

I Frame

J Under Seat Brace Bar

K Cushion & Cover

L Sideguard

M Q-Lock release lever

A

L

K

J

B

I

H

G

F

User Manual

Issue No: 14 | 2015

C

E

D

08

Page 9

User Manual | Identification / Serial Number

Identification / Serial Number –

Bespoke to you

The serial number of your bespoke product is located on either the under seat

cross brace bar (J Product Description) or camber bar (H Product Description) or inside the backrest upholstery (A).

Please provide the following information whenever you have to order replacement parts.

Serial Number

Name

Dealer

RGK Chair Label Information

A Model

B Chair Serial Number

C Month Manufactured

D Year Manufactured

A

TIGA FX FXA001 1/2013

00 44 (1) 543 67 00 77

info@rgklife.com

MAX USER WEIGHT 125KG

F G H

B C D E

E Manufacturer Address

F Manufacturer Contact Number

G Manufacturer Email Address

H Maximum User Weight

RGK Wheelchairs Ltd

Unit 8 b/c Ring Rd, Zone 2

Burntwood Ind Est

Burntwood, Staffs

England WS7 3JQ

User Manual

Issue No: 14 | 2015

09

Page 10

User Manual | Handling of Wheelchairs

Safety Handling

of your Wheelchair

WARNING

A note to wheelchair assistants

DO NOT attempt to lift the wheelchair by any

removable (detachable) parts.

Lifting by means of any removable (detachable)

parts of a wheelchair may result in injury to you the

assistants and damage your wheelchair.

Tilting

When tilting the wheelchair, an assistant should

grasp the back of the chair on a non-removable

(non-detachable) part. Inform the chair occupant

before tilting the chair and remind him/her to lean

back.

Be sure the occupant’s feet and hands are clear of all

wheels. Apply a continuous motion until the balance

point is achieved.

NOTE – Wheelchair Assistants

When assistance to the wheelchair user is required,

remember to use good body mechanics. Keep your

back straight and bend your knees whenever tilting

the wheelchair or traversing kerbs, or any other

impediments

At this point, the assistant will feel a dierence in

the weight distribution. Turn the chair in the desired

direction if necessary. Slowly lower the chair in one

continuous movement. See Fig 2.

DO NOT let the chair drop the last few inches

to the ground. This could result in injury to

the occupant.

Fig 2

CAUTION

User Manual

Issue No: 14 | 2015

DO NOT tilt the chair without assistance. After

mastering the techniques of tilting the chair, use this

procedure to tackle kerbs, short stairs, etc.

10

Page 11

User Manual | Handling of Wheelchairs

Method 1

The assistant should tilt the chair until the front castors

clear the kerb. Roll the chair forward and lower the front

castors to the pavement. Push the chair forward until

the rear wheels roll up and over the kerb. See Fig 3 and

Fig 4.

Fig 3

Fig 4

Method 2

The assistant should stand on the pavement and turn

the chair so that the rear wheels are against the kerb.

The chair should be tilted back to the balance point

and, in one continuous movement, the rear wheels

should be pulled up and over the kerb. See g 5.

DO NOT return the front castors to the ground

until the chair back has been pulled backward

far enough to clear the edge of the kerb. Unless

the assistant has exceptional upper body

strength, it is recommended that two assistants

be utilised when choosing Method 2.

Fig 5

WARNING

DO NOT attempt to lift a wheelchair by lifting

on any removable (detachable) parts. Lifting

by means of any removable (detachable)

parts of a wheelchair may result in injury to

the user or damage to the wheelchair.

WARNING

Extreme caution is advised when it is necessary to

move an occupied wheelchair up or down the stairs.

RGK recommends using two assistants and making

thorough preparations. Make sure to use ONLY

secure, non-detachable parts for hand-hold supports.

User Manual

Issue No: 14 | 2015

11

Page 12

User Manual | Handling of Wheelchairs

Reaching, Leaning and Bending – Forward

When reaching for any objects either in front, to

the side or behind your wheelchair make sure that

you do not lean too far out of your wheelchair,

as this will change your centre of gravity, and

there is a risk of tipping or losing your balance.

DANGER

DO NOT use an escalator to move a

wheelchair between oors as this could

cause serious personal injury or property

damage.

Transferring to and from other seats

CAUTION

The hanging of additional loads such as a

laptop bag or back pack on your backrest can

aect the rearward stability of your chair. This

can cause your wheelchair to lift at the front

and the chair to tip backwards, potentially

causing injury or property damage.

WARNING

BEFORE attempting to transfer in or out of the

wheelchair, every precaution should be taken to

reduce the gap distance. Turn both castors toward

the object you are transferring onto. See Fig 9. Also be

certain the wheel locks are engaged to help prevent

the wheels from moving.

Fig 9

CAUTION!

User Manual

Issue No: 14 | 2015

When transferring, position yourself as far back

as possible in the seat. This will prevent damaged

upholstery and the possibility of the chair tipping

forward.

WARNING

Do not stand on footplate during transfer.

12

Page 13

User Manual | Handling of Wheelchairs

Transferring to and from other seats

WARNING

RGK does NOT recommend that your wheelchair

be transported up or down stairways with you in

it.

WARNING

Fig 10

DO NOT attempt to lift the wheelchair by any

removable (detachable) parts. Lifting by means of

any removable (detachable) parts of a wheelchair

may result in injury to you the assistants and

damage your wheelchair.

NOTE

Wheelchair Assistants

When assistance to the wheelchair user is required,

remember to use good body mechanics. Keep your

back straight and bend your knees whenever titling

the wheelchair or traversing kerbs, or any other

impediments.

NOTE

This activity may be performed independently

provided you have adequate mobility and upper

body strength. Position the chair as close as possible

along side the seat to which you are transferring, with

the front castors pointing toward it, engage wheel

locks. Shift body weight into seat with transfer.

During independent transfer, little or no seat platform

will be beneath you. Use a transfer board if at all

possible.

Castors pointing forward

WARNING

DO NOT attempt to reach objects if you have to move

forward in the seat or pick them up from the oor by

reaching down between your knees.

WARNING

The position of the footrest, camber tube and rear

seat height, as well as the tautness of the back

upholstery are directly related to the chairs stability.

Any change to one or any combination of the four

may cause the chair to decrease in stability. Use

EXTREME caution when using a new seating position

for the rst time.

Many activities require the wheelchair owner to reach,

bend and transfer in and out of the wheelchair. These

movements will cause a change to the normal balance,

the centre of gravity, and the weight distribution

of the wheelchair. To determine and establish your

particular safety limits, practice bending, reaching and

transferring activities in several combinations in the

presence of a qualied health professional BEFORE

attempting active use of the wheelchair.

User Manual

Issue No: 14 | 2015

Proper positioning is essential for your safety. When

reaching, leaning, bending or bending forward, it is

important to use the front castors as a tool to maintain

stability and balance. See Fig 10.

13

Page 14

User Manual | Handling of Wheelchairs

WARNING

Any change in axle position can aect your centre of gravity and stability.

Lengthening and shortening the wheelbase

Lengthening the wheelbase will increase the stability

and maintain standard manoeuvrability of the chair.

Shortening the wheelbase will increase the

manoeuvrability and distribute additional weight onto

the rear wheels.

To lengthen the wheelbase move Camber Bar toward

the rear of the frame. See Fig 11.

To shorten the Wheelbase move the Camber Bar

toward the front of the frame. See Fig 11.

Fig 10

Fig 11

A B

Remember to lean your upper body further forward

when going up slopes and steps. See Fig 12.

Fig 11

Fig 1 2

Remember to lean your upper body further back

when going down slopes and steps. See Fig 13.

Fig 12

Fig 13

A = Rearward / Lengthen B = Forward / Shorten

Manoeuvring your RGK wheelchair

WARNING

BEFORE attempting to manoeuvre your new

wheelchair it is important to practice and master

these techniques until you are comfortable and

competent.

WARNING

During operation, handrims can get hot when

being used to slow down. Extra caution is to be

used when going downhill.

WARNING

Manoeuvring across a slope may

aect the stability of the wheelchair.

Use extreme caution on slopes.

Never try to climb or descend a slope diagonally.

See gure 14.

Fig 13

Fig 14

User Manual

Issue No: 14 | 2015

14

Page 15

User Manual | Safety Inspection Checklist

Safety Inspection

Checklist

NOTE: Regular cleaning will reveal loose or worn parts and enhance the smooth operation or your wheelchair. To operate properly

and safely, your wheelchair must be cared for just like any other vehicle. Routine maintenance will extend the life and eciency of

your wheelchair. Initial adjustments should be made to suit your personal body structure and preference. Thereafter follow these

maintenance procedures.

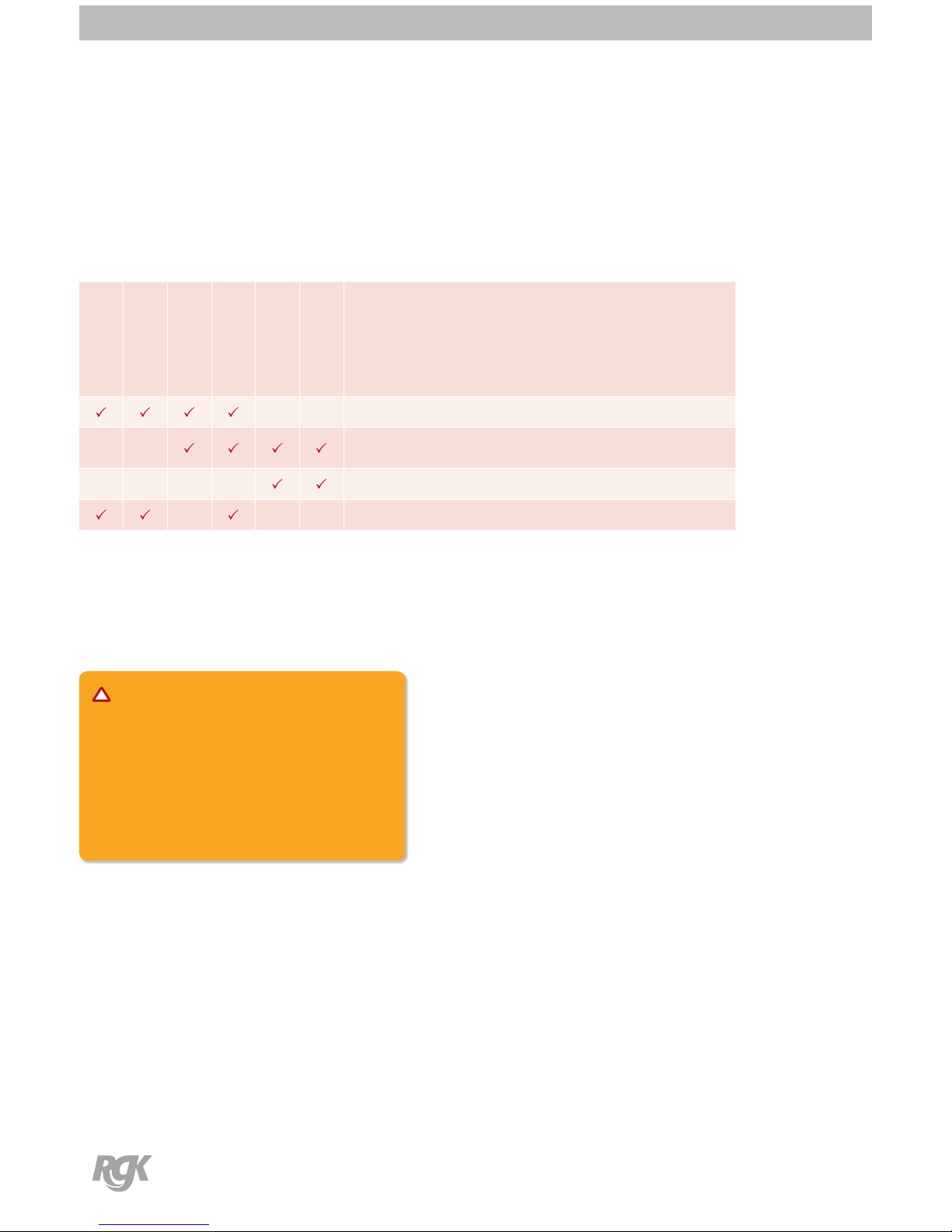

Item

Initially

Inspect /

Adjust

Weekly

Inspect /

Adjust

Monthly

Inspect /

Adjust

Yearly

General

• Wheelchair rolls straight (no excessive drag or pull to one side).

• Frame - Inspect frame for cracks and damage

• Fasteners - Inspect all fasteners are secured

Wheel Locks

• Do not interfere with tyres when rolling

• Pivot points free of wear and looseness

• Wheel locks easy to engage

Seat and Back Upholstery

• Inspect for rips or sagging.

• Inspect fastening aps to ensure they securely latch

Rear Wheels

• Adjustable Axle Position Camber Bar is securely tightened.

• Quick/Quad release axles lock properly

• No excessive side movement or binding when lifted and spun.

Handrims

• Inspect for signs of rough edges or peeling.

Spokes

• Inspect for bent or broken spokes.

• All spokes uniformly tight.

Front Castor

• Inspect wheel/fork assembly for proper tension by spinning castor;

caster should come to gradual stop.

• Loosen / tighten locknut if wheel wobbles noticeably or binds to a stop.

• Wheel bearings are clean and free of moisture.

CAUTION: As with any vehicle, the wheels and tyres should be checked

periodically for cracks and wear, and should be replaced when necessary.

Tyres

• Inspect for at spots and wear

• If pneumatic tyres check for proper ination.

CAUTION: As with any vehicle, the wheels and tyres should be checked

periodically for cracks and wear, and should be replaced when necessary.

Cleaning

User Manual

Issue No: 14 | 2015

15

Page 16

User Manual | Troubleshooting Guide Mechanical

Troubleshooting Guide

Mechanical

Chair veers right

Chair veers left

Sluggish turn or

performance

Castor utters

Squeaks

and rattles

WARNING

After making adjustments, always make sure

that parts are properly tightened BEFORE using

the wheelchair.

DO NOT over-tighten hardware attaching to the

frame. This could cause damage to the frame

tubing.

Solutions

Loose-ness

in chair

Check tyres for correct and equal pressure

Check for loose castor stem nuts

Check all xtures are secure and tight.

Check spokes and nipples for tension

Check that both castors contact the ground at the same time

User Manual

Issue No: 14 | 2015

16

Page 17

User Manual | Troubleshooting Guide Mechanical

Maintenance

Suggested Maintenance Procedures

1. Before using your RGK Wheelchair, make sure all

nuts and bolts are tight. Check all parts for damage

or wear and replace. Check all parts for proper

adjustment.

2. Keep quick / quad-release axles free of dirt to

ensure positive locking and proper operation. Refer

to adjusting the quick-release axle or adjusting the

quad-release axle in Procedure 3 of this manual.

3. Clean and polish Quick-Release Axles once a

month – DO NOT OIL.

WARNING

Do not use the wheelchair unless it has the proper

tyre pressure (P.S.I). DO NOT over inate the tyres.

Failure to follow these suggestions may cause the

tyre to explode and cause bodily harm.

4. Recommended tyre pressure is listed on the side

wall of the tyre.

5. The wheels and tyres should be checked

periodically for cracks and wear, and should be

replaced when necessary at your authorised

dealer.

6. Regularly check for loose spokes in the rear wheels.

If loose, have them adjusted at your authorised

dealer.

7. Periodically check handrims to ensure they are

secured to the rear wheels. Refer to handrim

replacement in procedure 5 of this manual.

8. Periodically adjust wheel locks in correlation to tyre

wear. Refer to adjusting wheel locks in procedure 8

of this manual.

9. Periodically check castor wheel bearings to make

sure they are clean and free from moisture. Refer to

replacing your front castor wheels in procedure 7

of this manual.

10. Check upholstery for sagging, rips or tears. Adjust

or replace as necessary

11. The seat upholstery is secured by means of Velcro

straps around the frame. The upholstery can easily

be removed from the frame by loosening the

straps under the seat. Refer to placing your seat

upholstery see procedure 2 of this manual.

12. The backrest upholstery is removed by loosening

the cover, detaching the centre pad and wings,

Refer to adjusting / replacing your upholstery see

procedure 1.

13. Wipe down the seat and backrest upholstery with

a clean damp cloth. It is important to keep the

wheelchair clean, both for your own comfort and

longevity of the chair. Clean the frame with a nonabrasive cleaning agent.

User Manual

Issue No: 14 | 2015

NOTE

It is recommended to clean and disinfect the frame

and upholstery frequently.

Store wheelchair in a cool, dry place out of direct

sunlight and in original packaging.

WARNING

Do not reuse single use fasteners. Contact your

authorised dealer for more information.

17

Page 18

User Manual | Procedure 1

Procedure 1

This Procedure includes the following:

Adjusting / Replacing the Back Upholstery

The backrest upholstery is individually adjustable by

adjusting either the Velcro straps or Velcro securing

wings located under the centre pad.

Adjusting / replacing the back upholstery

To remove back upholstery, remove cushion, release

backrest tail from seat sling, release side securing straps

and lift upholstery squarely o.

To re-t reverse above procedure. See Fig 15.

Fig 15

Side Securing Straps

Backrest Tail

Seat Sling

To adjust tension, pull centre pad up from the rear (side

with RGK logo) Re-position side wings to increase/

decrease tension and securely re-t centre pad. See Fig

16.

With strap adjustable backrest upholstery use straps to

decrease/increase tension (not illustrated).

Fig 15

Fig 16

L/H Side Wing

R/H Side Wing

WARNING

The position of the footrest, camber tube and rear

seat height, as well as the tautness of the back

upholstery are directly related to the chairs stability.

Any change to one or any combination of the four

may cause the chair to decrease in stability. Use

EXTREME caution when using a new seating position

for the rst time.

CAUTION

Velcro used on upholstery may cause property

damage if contacted closely.

User Manual

Issue No: 14 | 2015

Centre Pad

18

Page 19

User Manual | Procedure 2

Procedure 2

This Procedure includes the following:

Replacing the Seat Upholstery

Seat Upholstery Replacement

1. Remove the seat cushion and back upholstery

tail from the seat sling. See Fig 17.

2. Remove rear wheels from chair.

Fig 17

Side Securing Straps

3. Unlatch the fastening aps that secure the seat

upholstery to the chair frame. See Fig 18.

4. Remove the existing seat upholstery,

by peeling apart the velcro straps.

5. Install the NEW seat upholstery making

sure the fastening aps hang over the

right and left sides of the chair frame.

6. Place the front fastening aps in front of the

cross frame bar and securely latch together.

7. Securely latch the remaining

fastening aps together.

8. Ret rear wheels. See procedure 3

9. Reinstall the back upholstery and seat cushion

onto the chair. Refer to adjusting the back

upholstery in procedure 1 of this manual.

Fig 16

Fig 18

Backrest Tail

Seat Sling

Fastening Flap

User Manual

Issue No: 14 | 2015

19

Page 20

User Manual | Procedure 3

Procedure 3

This Procedure includes the following:

Removing rear wheels and attaching them to and from your wheelchair.

The wheels can, therefore, be installed or removed without using tools.

Removing rear wheels and attaching them to

and from your wheelchair.

1. Push in the detent/RGK button of the quickrelease axle. Pull both axle and wheel away

from your wheelchair. See Fig 19.

2. Repeat STEP 1 for the opposite wheel

3. To reinstall the rear wheels onto your

wheelchair. Push in the detent/RGK button

of the quick-release axle and insert quick

release axle into the camber bar. Pushing both

axle and wheel towards your wheelchair

Fig 19

WARNING

Changing the size of your rear wheels can

aect the performance of the wheelchair. Please

contact RGK Wheelchairs Ltd,

numbers located on the back of this manual before

changing rear wheel size.

NOTE

Pull on the rear wheels to make sure the detent pin

/ RGK cap of the quick release axle are fully released

before operating the wheelchair.

WARNING

Any adjustments to your quick release pins – then

YOU must ensure your wheels lock on both sides of

your wheelchair.

When attaching the rear wheels, always check that

they are securely mounted. Pull on the rear wheels

to make sure the detent pin/RGK cap of the quick

release axle are fully released before operating the

wheelchair.

User Manual

Issue No: 14 | 2015

You should NOT be able to pull the rear

wheel o.

20

Page 21

User Manual | Procedure 4

Procedure 4

This Procedure includes the following:

Adjusting the Quick-Release Axle

Adjusting the Quick-Release Axle

1. Remove rear wheel and quick-release axle from the

chair.

2. Remove quick release axle from the wheel by

depressing detent pin/RGK button in the quickrelease axle and slide axle through the wheel hub.

See Fig 20.

4. Release detent pin/RGK button ensuring that the

locking pins are fully released. Increase or decrease

end play by adjusting the locknut on the end of the

quick-release axle. See Fig 20.

5. Reinstall rear wheel onto the chair.

NOTE

Please note the quick release axle is removable and

can be adjusted in length.

Fig 20

B

A

A = Lengthen B = Shorten

WARNING

Any adjustments to your quick release pins – then

YOU must ensure your wheels lock on both sides of

your wheelchair.

When attaching the rear wheels, always check that

they are securely mounted. Pull on the rear wheels

to make sure the detent pin / RGK cap of the quick

release axle are fully released before operating the

wheelchair.

User Manual

Issue No: 14 | 2015

You should NOT be able to pull the rear wheel o.

21

Page 22

User Manual | Procedure 5

Procedure 5

This procedure includes the following:

Replacing the Hand Rim; Repairing/Replacing rear wheel, tyre/tube;

WARNING

If a handrim should become damaged it could lead

to injury, and should be replaced.

Handrim replacement

1. Remove the rear wheel from the chair by

depressing the detent/RGK button.

2. Remove all air from the tube by pressing down on

the pin in the centre of the valve stem

3. While carefully holding the tyre, tube and rim strip

to one side, hold the allen head screws and remove

the locknuts that secure the handrim to the rear

wheel.

4. Remove the existing handrim.

5. Install the NEW handrim by reversing the above

procedures.

6. Inate the tyre to the correct psi rating on the

sidewall of the tyre.

7. Reinstall rear wheel to the chair.

8. Repeat the procedure for the opposite rear wheel if

necessary.

NOTE

It is not necessary to remove tyre and tube when

replacing hand rim on either Spider or X-Core

Wheels.

Repairing / replacing rear wheel, tyre & tube

1. Remove the rear wheel from the chair..

2. Remove all air from the tube by pressing down on

the pin in the centre of the valve stem.

3. Unscrew the valve securing ring (Presta valves only).

Using tyre levers, remove outside tyre bead from

wheel rim, unscrew valve securing ring (Presta valves

only) remove tube. Remove tyre from rim. Reverse

procedure to t tyre/tube.

4. Inate the tyre to the correct psi rating on the side

wall of the tyre.

5. Reinstall rear wheel to the chair.

6. Repeat the procedure for the opposite rear wheel if

necessary.

NOTE:

If replacing the rear wheels or tyres with a dierent

size than what was originally on the chair please note

this will raise or lower the rear of the chair and may

have an adverse eect on your balance.

Please contact your dealer or mobility advisor for

additional advice.

WARNING

Tyre MUST be deated before any disassembly

procedures are performed.

WARNING

DO NOT inflate tyre until it is completely assembled.

User Manual

Issue No: 14 | 2015

WARNING

Make sure the detent/RGK button of the quick

release axle is fully released BEFORE operating the

wheelchair.

22

Page 23

User Manual | Procedure 6

Procedure 6

This procedure includes the following:

Adjusting or Replacing your camber bar

Adjusting / replacing the camber bar

This procedure applies to two dierent camber bar

types, both requiring a 5mm allen key.

WARNING

Tyre MUST be deated before any disassembly

procedures are performed.

Fig 19 Fig 20

1. Remove the rear wheels from the chair.

(As procedure 3)

2. Loosen ONLY the allen head screws that secure

the adjustable camber bar to the chair frame.

NOTE:

Ensure the allen head screws are loose enough to

allow the adjustable camber bar to move freely along

the chair frame to avoid scratching the chair frame.

3. Move the adjustable axle position camber bar

forward or back along the chair frame to adjust.

Lengthening the wheelbase will increase the

stability and maintain standard manoeuvrability of

the chair. Shortening the wheelbase will increase

the manoeuvrability and distribute additional

weight onto the rear wheels.

4. Measure both attaching points of the adjustable

axle position camber bar from both back posts to

ensure the adjustable camber bar is positioned at a

90° angle to the chair frame.

5. Securely tighten the allen head screws that secure

the adjustable camber bar to the chair frame.

6. Reinstall the rear wheels onto the chair.

7. Move the chair before using to make sure there is

no excessive drag to either side.

NOTE:

If drag to either side occurs, repeat the above

procedures until the chair rolls correctly.

WARNING

DO NOT inate tyre until it is

completely assembled.

WARNING

Make sure the detent pin of the quick/quad

release axle is fully released BEFORE operating the

wheelchair.

WARNING

The position of the footrest, camber bar,

as well as the tautness of the back upholstery, are

directly related to the chairs stability.

Any change to one or any combination of the

three may cause the chair to decrease in stability.

Use EXTREME caution when using a new seating

position for the rst time.

Fig 21

D

A

A = Rearward / Lengthen

B = Forward / Shorten

C

B

User Manual

Issue No: 14 | 2015

23

Page 24

User Manual | Procedure 7

Procedure 7

This procedure includes the following:

Replacing the Front Castor Fork assembly and Castor Wheels

Replacing Fork Assembly

1. Remove cap Fig 22.

2. Remove the bolt and locknut that secure the front

fork assembly.

3. Remove the front castor fork assembly using 19mm

socket spanner downwards through the castor

housing noting any washer sequence.

4. Install the NEW front castor fork and reverse steps 2 1 to ret.

5. Repeat the procedure for the opposite front castor if

necessary.

NOTE:

Bearings must be tted by an authorised dealer.

Failure to do so will result in invalid warranty on

the parts.

Replacing Front Castor Wheels

1. Using two 4mm Allen keys, remove 1 of the 2 screws

that locate the castor axle.

2. Remove the castor axle by sliding it out. Remove the

castor wheel and spacers from the castor fork.

3. Install the NEW castor wheel, castor axle and

spacers to the castor fork, by reversing STEPS 1 & 2.

CAUTION:

RGK DO NOT recommend replacing the front

castor forks or castor wheels with a dierent size

other than what was originally supplied on the

chair.

By changing to a dierent size castor fork or castor

wheel will have an adverse eect on the running of

the chair and the end users balance.

User Manual

Issue No: 14 | 2015

24

Page 25

User Manual | Procedure 8

Procedure 8

This procedure includes the following:

Adjusting / Replacing Wheel Locks

NOTE:

Before adjusting or replacing any style of wheel

lock ensure that the tyres are inated to the

recommended pressure as indicated on the tyre.

Wheel Locks - Adjustment / Replacement

1. To replace push/pull wheel lock: See Fig 23.

Fig 23

Loosen the two allen head screws in the clamp/

plate which secure the wheel lock to the frame.

Slide wheel lock out of clamp/plate. Fit new wheel

lock by reversing procedure.

2. To replace under seat scissor lock: Use same

procedure as push/pull lock. See Fig 24.

3. Adjustment - All wheel lock styles:

4 The wheel lock tyre pressure bar should embed by

5-7mm into the (pneumatic) tyre when engaged.

Adjust to give satisfactory locking of the chair

wheels.

WARNING

After any adjustments, repair or service and before

use, make sure all attaching hardware is tightened

securely – otherwise injury or damaged may result.

WARNING

If wheel locks do not hold occupied wheelchair in

place please adjust as above, or contact your dealer –

otherwise injury or damages may occur.

Fig 24

WARNING

The wheel locks are designed to work when your

wheelchair is static. Wheel locks should not be

applied during use and tyre pressure should be as

indicated on the tyre.

User Manual

Issue No: 14 | 2015

25

Page 26

User Manual | Procedure 9

Procedure 9

This Procedure includes the following:

Adjusting the footrest height / angle, and replacing the footrest.

Adjusting / replacing the footrest

1. Loosen the two allen head screws that secure the

footrest to the chair frame. (Located at the rear of

the frame see Fig 25)

2. Remove footrest – ensuring the footrest is removed

with equal pressure.

3. Remove existing and install NEW footrest.

4. Position the NEW / existing footrest to a determined

height.

5. Tighten the two allen head screws “A”

that secure the footrest to the chair frame. See

Fig 25.

Fig 25

Footrest height adjustement

A

Angle adjusting the footrest platform

1. To adjust the angle on your angle adjustable

footrest. Loosen two button head allen screws “A”

(see g 26) on top of foot platform.

2. Rotate until desired angle is achieved.

3 Securely tighten two button head allen screws.

Fig 26

WARNING

The footrest assembly MUST be at least 40mm above

the ground/oor to avoid hitting protruding objects

when using this wheelchair.

Angle adjust footrest assembly

WARNING

The position of the footrest, camber tube and rear

seat height, as well as the tautness of the back

upholstery are directly related to the chairs stability.

Any change to one or any combination of the four

may cause the chair to decrease in stability. Use

EXTREME caution when using a new seating position

for the rst time.

User Manual

Issue No: 14 | 2015

WARNING

Do not stand on the footrest/footplate! Even if the

user is sitting in the chair, there is still a risk of tipping

over and injury.

WARNING

When transferring, do not stand on the footboard,

there is a risk of tipping over and injury.

26

Page 27

User Manual | Procedure 10

Procedure 10

This Procedure includes the following:

Folding & unfolding the backrest, Folding & unfolding the front tube section.

WARNING

Your folding back and folding front tube section

MUST be locked securely in place before using your

wheelchair.

Folding your backrest

1) To fold the backrest, rotate the locking collar,

ensuring the grooves line up. See Fig 27.

2) Depress both levers down, (Fig 28) this allows the

backrest to move forward and fold away. See Fig 29.

Folding the front section

1) Remove rear wheels.

2) Rotate the locking collar’s ensuring the groves line

up. See Fig 27.

3) Depress both Q lock levers down, this allows the

front folding tube section to fold under the chair.

Locking the backrest

1) Hold either side oft he backrest and pull the

backrest back into an upright position, ensuring both

sides click into position.

Fig 27

Fig 28

Fig 29

2) Once clicked into position, rotate the collars.

Ensuring the groves are NO longer aligned. See Fig

30.

Locking the front folding section

1) Pull the front section forward allowing the Q lock

levers to click into position.

2) Once the Q lock leavers have clicked into position,

rotate the collars. Ensuring the groves are NO

longer aligned. See Fig 30.

NOTE:

The wheelchair shown and described in this user

guide may not correspond in every detail exactly.

User Manual

Issue No: 14 | 2015

Fig 30

CAUTION

This product contains moving parts.

Beware of nger trapping.

27

Page 28

User Manual | Procedure 11

Procedure 11

This Procedure includes the following:

Height adjustable pushing handles, Fold-down push handles.

WARNING

DO NOT attempt to lift the wheelchair by any

removable (detachable) parts.

This includes Height adjustable pushing handles,

Fold-down push handles & Screw

in Push handles

Lifting by means of any removable (detachable)

parts of a wheelchair may result in injury to you the

assistants and damage your wheelchair.

Height adjustable push handles

1. To operate this style of pushing handle open the

mini quick release leaver as indicated (Fig 31). By

opening the quick release lever allows the stroller

handle to be adjusted in height.

2. Once the desired height is achieved then close the

mini lever.

3. If the lever becomes loose, then the nut on the mini

release lever requires tightening. (The nut on the

mini release lever determines on how tightly the

clamp is applied)

Flip-down push handles

To fold down your pushing handles, depress the button

(2) when required again, simply lift back into position

and lock. See Fig 32.

Fig 32

Button Release

Screw in Pushing Handles

These are screwed into position by turning the handle

clock wise, and anti clockwise to remove.

See Fig. 33.

Fig 33

Fig 31

User Manual

Issue No: 14 | 2015

28

Page 29

User Manual | Procedure 12

Procedure 12

This Procedure includes the following:

Adjusting the Anti-Tipper.

Adjusting the Anti-tipper

1. Press in the release buttons that secures the antitipper wheel to the anti-tipper bar.

2. Adjust the height of the anti-tipper wheels to

between 25mm and 50mm of the ground.

3. Repeat steps 1 – 2 for the opposite anti-tipper.

WARNING

RGK strongly recommends ordering the anti-tips

as an additional safeguard for the wheelchair user.

NOTE:

Anti-tippers MUST be fully engaged. Ensure the

release button of the anti-tipper fully protrudes out

of the hole in the anti-tipper socket.

Ensure both anti-tippers are adjusted to the

same height.

Fig 34

Fig 35

NOTE:

Only rotate anti-tipper 180˚. Do not rotate 360˚

User Manual

Issue No: 14 | 2015

29

Page 30

User Manual | Procedure 13

Procedure 13

This Procedure includes the following:

Folding sideguards

Folding Sideguards (All Materials)

During the folding down process of the TIGA fx, the

sideguards can be pushed down to fold at against

the chair seat once the cushion has been removed.

See Fig. 36

Fig 36

User Manual

Issue No: 14 | 2015

30

Page 31

User Manual | Procedure 14

Procedure 14

This procedure include the following:

Strapping:

Location of the strapping

The strap can positioned either, under the

wheelchair and passing up between the side guards

(if tted) and fastened across the lap or pelvis. Other

option is passing around the back and inserted in

between the insides of the centre pad as per Fig 38.

This style of strap is a positioning strap only.

Fig 38

WARNING

It is not designed for use as a safety device to

withstanding high stress loads such as auto safety

belts.

With regards to chest positioning straps – it is the

obligation of the therapists and other healthcare

professionals to determine if a chest strap/harness

is required.

User Manual

Issue No: 14 | 2015

31

Page 32

User Manual | Technical Data

Technical Data

From Max

Overall Width 250 cm 460 cm

Overall Seat Height 300 cm 600 cm

Overall Frame Length 400 cm 800 cm

Weight in Kg 8Kg -

User Weight - 125Kg

Torque

Backrest Pivot Plate 10

Wheel Lock 10

Camber Bar 10

Footrest Adjustment Height 10

All other items 10

NM

Please note

RGK Wheelchairs Ltd are bespoke and

individually made for you, therefore your

wheelchair may fall below or over the above

mentioned sizes

Recycling/Disposal

Prior to the wheelchair being re-used, it must be

carefully prepared. All surfaces which come into

contact with the user must be cleaned down and

treated with a disinfection spray.

In the following section, there is a description of the

materials used on our wheelchairs.

Aluminum:

Armrest, Footrest, Hand Rims, Anti-Tippers, Frame,

Footplate covers

Steel:

Anti-tippers, Frame Wheels, Fixings, Wheel Locks,

Footplate covers

Castor forks, Wheels, side guards,

Fixing points, Quick release axle pins, Footrest,

User Manual

Issue No: 14 | 2015

Titanium:

Side guards Anti-Tippers, Frame, Footrest

Plastic:

covers, Arm pads

Packing:

cardboard

Upholstery:

(There may be a charge imposed).

Castor Forks, Quick release axle, Fixings,

Handles, Tube stoppers, Castors, Footplate

Plastic bags made from polyethylene,

Woven polyester Cotton Leather

Disposal or recycling should be carried

out by a disposal company or at a public

disposal point. You could also return your

wheelchair to your dealer for disposal

32

Page 33

User Manual | Notes

Warranty

Product Grouping

TIGA

Warranty

This warranty is extended only to the named

purchaser/user of the product. This warranty gives

you specic legal rights and you may also have

other legal rights. RGK warrants the main frame to

be free from defects in materials and workmanship

for a period of 5 years of the original purchaser/user

from the date of purchase from RGK Wheelchairs

Ltd or a dealer with a copy of the invoice required

for coverage under this warranty.

All Integrated/welded components parts included,

but limited to:

• Integrated/welded camber bars

• Integrated/welded side guards

• Integrated/welded footrest

• Integrated pushing handles

Are supplied with a 5 year warranty.

All component parts including, but not limited to:

• camber tubes • folding backrest

• pushing handles • castor forks

• anti-tippers • sideguards & armrests

• wheel components • upholstery and strapping

• wheel locks are supplied with 12 month warranty.

All component parts including, but not limited to:

• bushings and bearings

• tyres and inner tubes

• Adjustable height footrest, if 3rd party devices

are tted. i.e. Free Wheel

• push handle grips, foam parts and plastic/rubber

coated parts are supplied without warranty.

All components parts included, but not limited to:

• Other 3rd part supplied equipment, either

powered assist, propulsion systems, specialist

cushions will be referred back to the

manufactures warranty period.

Expectation

If within the stated warranty period and such

product shall be proven to be defective, such

product shall be repaired or replaced at RGK’s option

and cost. This warranty does not include any third

party labour or shipping charges incurred in the

repair or replacement of any such product. RGK’S

sole obligation and your exclusive remedy under

this warranty shall be limited to such repair or

replacement.

Contact

For warranty service, please contact the dealer

from whom you purchased your RGK product.

In the event you do not receive satisfactory

warranty service, please contact RGK directly by

the methods shown below. Provide the dealer’s

name, address and the date of purchase, indicate

nature of the defect and, if the product is serialized,

indicate the serial number. Do not return products

to our factory without our prior consent.

Limitations and Exclusions

The foregoing warranty shall not apply to serial

numbered products if the serial number has

been removed or defaced, products subjected

to negligence, accident, improper operation,

maintenance or storage, commercial or institutional

use, products modied without RGK’s express written

consent, including, but not limited to:

• modication through the use of unauthorized

parts or attachments

• products damaged by reason of repairs made to

any component without the specic consent of

RGK

• a product damaged by circumstances beyond

RGK’s control (such evaluation will be solely

determined by RGK)

• problems arising from normal wear

• failure to adhere to the product use instructions

• the use of any approved power assist or propulsion

systems(eg. Handcycles) shall reduce the warranty

period for the main frame to 24 months

• the use of additional 3rd party equipment ie Free

Wheel attachment, unless incorporated at design

and build stage.

Summary

The foregoing warranty is exclusive and in lieu of

all other express warranties. Implied warranties,

if any, including the implied warranties of the

merchantability and tness for a particular purpose,

shall not extend beyond the duration of the

expressed warranty provided herein and the remedy

for violations of any implied warranty shall be limited

to repair of the defective frame pursuant to the terms

contained herein. RGK shall not be liable for any

consequential or incidental damages whatsoever.

Please remember to complete your

Warranty Card and return it. Thank You.

Prière de bien vouloir renseigner le formulaire

de garantie. Merci.

Si prega ricordarsi di completare il questionario

per le gararisia. Grazie.

Bitte vergessen sie auch nicht, den

Garantie-Fregebogen auszufüllen.

Vielen Dank.

No se olvide de rellenar su cuestionario

de garantía. Gracias.

RGK Wheelchairs Ltd

Units 8b/c, Ring Road, Zone 2, Burntwood Business

Park, Burntwood, Staordshire, WS7 3JQ, England

Tel: +44 (0)1543 670077 Fax: +44 (0)1543 670088

E-mail: info@rgk-wheelchairs.co.uk

Please make a reference of your chair model and serial number (found on sticker on your camber bar) and quote this whenever

calling the oce regarding your chair. For example if you would like to order replacement parts; we will be able to nd out the

ones you have and also alternatives that t your chair.

Chair Model: Serial No:

User Manual

Issue No: 14 | 2015

33

Page 34

Customer Service: 1.905.660.2459 / 1.800.263.3390

or visit www.SunriseMedical.ca

Loading...

Loading...