1800MHz - 1900MHz ADJUSTABLE BANDWIDTH

OFF-AIR REPEATERS

OR1-SBHP1-1800

OR2-SBHP1-1800

OR1-SBHP1-1900

OR2-SBHP1-1900

Doc. code 91 080 0701F - Rel. 04

TECHNICAL HANDBOOK

Radio Frequency Systems

Kabelkamp 20

30179 Hannover, Germany

Tel.: +49 511 676 2731

Fax: +49 511 676 2515

E-mail: sales.europe@rfsworld.com

INDEX

1) SAFETY RULES................................................................................................................................... 1

2) STANDARDS........................................................................................................................................ 2

2.1) MANUFACTURE LABELS

2.2) SYMBOLS

3) GENERAL DESCRIPTION................................................................................................................... 3

3.1) EXAMPLE: USE IN TUNNELS

3.2) OPERATING PRINCIPLE - 1800MHz - 1900MHz ADJUSTABLE BAND OFF-AIR REPEATERS

3.3) ATTACHED DOCUMENTS

4) INSTALLATION AND POWER-UP PROCEDURES............................................................................ 4

4.1) INSTALLATION

A - INITIAL CHECK

B - POSITIONING THE REPEATER

C - POWER SUPPLY SOURCE CONNECTIONS AND ALARMS CONNECTIONS

D.C. POWERED EQUIPMENT

AC POWERED EQUIPMENT (ALTERNATE CURRENT)

4.2) POWER-UP

4.3) ROUTINE MAINTENANCE

1800MHz – 1900MHZ Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

INDEX

1

1

1) SAFETY RULES

1.1 Introduction

The equipment described in this technical handbook has been designed and tested in conformity of

international safety standards IEC215 / EN60215 and IEC950 / EN60950; the equipment has to be used

under the responsibility of specialised personnel only. In accordance with IEC215 / EN60215, adjustment,

maintenance and repair of the exposed equipment shall be carried out only by qualified personnel, who are

aware of the hazards involved. The minimum qualifications are established in the standard.

Final installation of the systems must fulfil the EMF emission levels, as requested by regulations in force

(recommendation n. 1999/519/EC).

WARNING: Installation Notes

Modular equipment, intended to be housed insidea rack cabinet, must be installed within a protected

access area only.

This area must be opportunely protected by security system that will exclude the entry, even if accidental, to

not authorized and trained personnel. Alternatively, the cabinet, in which the equipment is housed, must be

closed on all sides, to allow the access to internal parts to authorized personnel only

1.2 AC Power supply

When working on the equipment always make sure that the equipment is not connected to the mains

supply.

Before power up always make sure that the equipment is connected to earth by using the equipment

grounding bolt.

If it is necessary to fit an AC power supply plug to power cable, the User must observe the following colour

codes: LIVE terminal to BROWN lead NEUTRAL terminal to BLUE lead EARTH terminal to GREEN/YELLOW

lead The User must also ensure that the protective earth wire would be the last to break, should the cable be

subject to excessive strain.

1.3 Safety precautions

For the correct and safe use of the equipment it is essential that both operation personnel and services

personnel follow generally accepted safety procedures (see IEC Publications 215: "Safety measures for

radio transmitting equipment" and 61010-1: "Safety requirements for electrical equipment for measureme nt,

control, and laboratory use") in addition to the safety precautions specified in this technical handbook.

Specific warnings and caution statements, where applicable, can be found throu ghout this technical

handbook. Warning and caution statements and/or symbols are ma rked on the equipment where is

necessary. (see also ANNEX n°1).

As far as the equipment safety devices are concerned please remind that: -periodic functional check shall be

carried out on protective devices; -functional check shall be carried out on protective devices, when they

have operated under fault conditions; -safety devices shall not be altered or disconnected except for

replacement; -safety circuit shall not be modified.

SAFETI RULES ENG

1.4 Caution and warning statements

Caution

destruction of equipment or other property. Warning of danger

requires correct procedures or practices in order to avoid personal injury.

It's used to indicate the correct operation and maintenance, in order to prevent damage or

Used to indicate the potential hazard that

1.5 Impaired safety protection

Whenever it is likely that safe operation is impaired, the apparatus must be in-operative and secured against

unintended operation. The appropriate servicing staff authority must be informed.

For instance, the safety is likely to be impaired if the equipment fails to perform the prescribed

measurements, or shows visible damages.

1.6 Electrostatic sensitive devices

In case of electrostatic sensitive devices ( for instance all ICs and many other semicondu ctor devices belong

to this class) it is essential to use a right protection to reduce the risk of personal injury. Careless handling,

during repair, may imply life danger. When repairing, make sure that you are connected with the same

potential as the ground of the equipment by means of the right devices, i.e. a GIRDLE (a wrist wrap with

resistance) and a WINDING CORD to be connected to the girdle and to the relevant socket placed on the

equipment.

You must also keep components and tools at this potential.

1.7 Electrolytic Capacitors

Non-solid electrolytic capacitors must not contain chemicals, which may be regarded as hazardous, if

incorrectly handled. Caution is necessary, should the outer case be fractured.

1.8 Electric shock

In case of electric shock it is recommended not to touch the person before breaking the circuit by means of

the power supply switch; should it be not possible to break the circuit power supply it would be advisable to

try to rescue the person by means of some insulating materials: e.g. a wood stick, a nylon cord or a suitable

service made of plastics, etc.

NEVER TOUCH ELECTROCUTED PEOPLE WITH YOUR HAND AS LONG AS THEIR BODIES ARE

SUBJECTED TO VOLTAGE, OTHERWISE YOU TOO WOULD GET ELECTOCUTED.

Call the doctor and then immediately perform the artificial respiration as described here belo w:

SAFETI RULES ENG

Lay the patient on his back with his arms parallel to his body; if the patient lies on an

inclined plane, please make sure that his stomach be slightly lower than his breast.

Open the patient's mouth and check if there are foreign bodies. Kneel down near the

patient at the same level as his head's, put one of your hands under his head and the

other one under his neck. Lift the patient's neck and let his head fall backwards the

most possible.

Shift your hand from the patient's neck to his chin; put your thumb between his chin

and his mouth, your forefinger along his jawbone, keep your other fingers tight. By

doing these operations start the self-oxygenation by means of deep breathings in

standing open-mouthed. With your thumb between the patient's chin and his mouth,

keep the patient's lips closed and blow into his nasal cavities.

During these operations see if the patient's breast rises. If it is not so, his nose may be

obstructed; in this case, by levering on his chin with your hand, open the patient's

mouth, put your lips on and blow into his oral cavity. Look at the patient's breast and

see if it rises. One can use this second method instead of the first one also if the

patient's nose is not obstructed, provided that his nose be occluded by squeezing his

nostrils with your hand after shifting it from his head. The patient's head must be kept

bent backwards the most possible.

Start with ten fast and deep expirations, then go on at the rhythm of twelve/fifteen expirations per minute.

Continue as long as the patient has recovered consciousness, or a doctor has ascertained his death.

1.9 Burns

As far as burns are concerned: Don't try to take off clothes from the burnt

parts; Pour some cold water on body burnt areas and ask immediately for a

doctor; Don't apply ointments or oily tinctures.

SAFETI RULES ENG

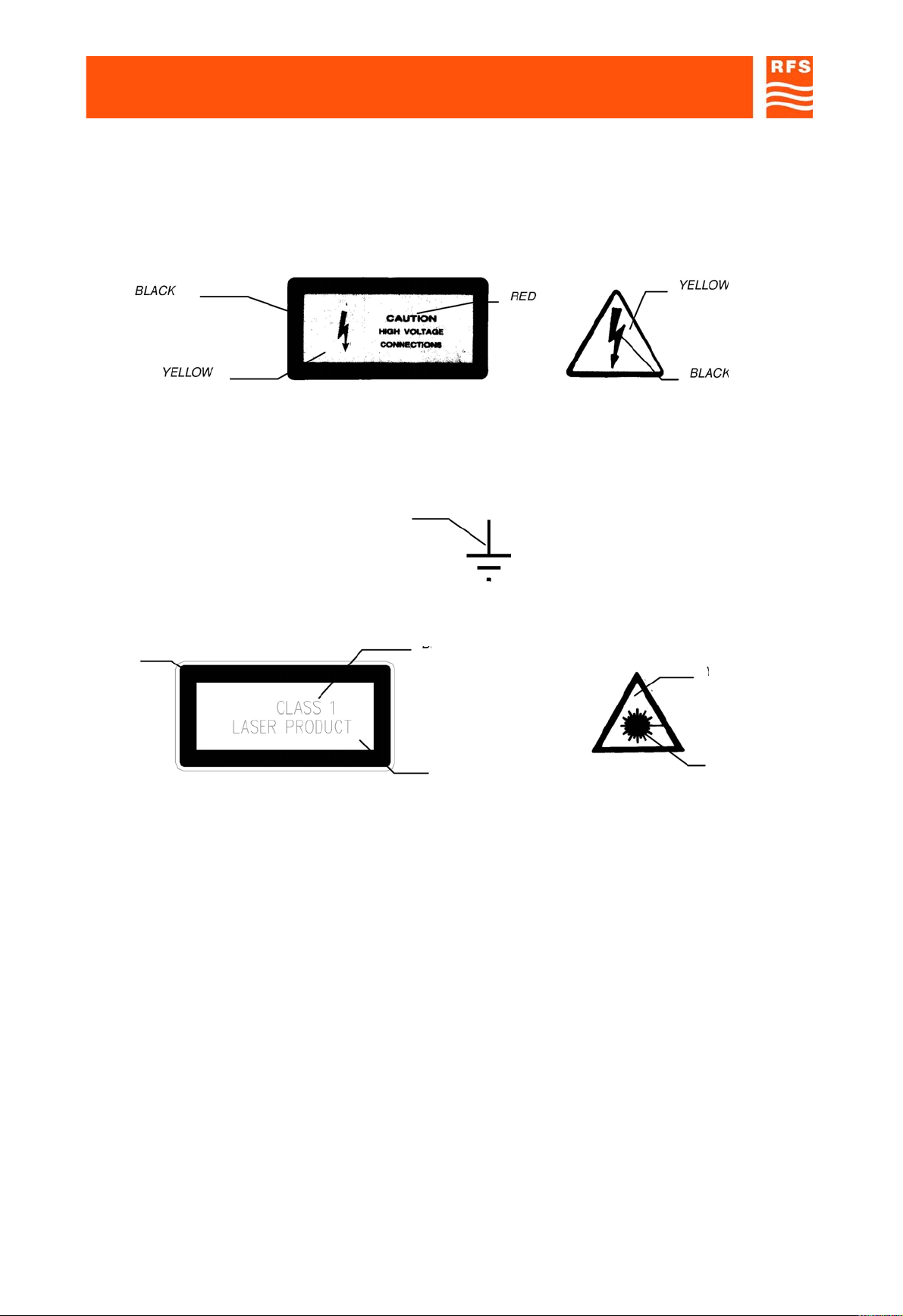

ANNEX 1 When the equipment or the modules are equipped with the labels as shown here below, it is essential to

observe the warnings contained

-LIVE VOLTAGE POINT

-PROTECTIVE EARTHING TERMINAL

BLACK

-CLASS 1 LASER PRODUCT

YELLOW

BLA

CK

BLACK

EXPLANATORY LABEL (affixed to the WARNING LABEL (affixed to the CLASS 1 product side)

CLASS 1 product front)

Products which are of CLASS 1 as defined in the IEC EN 60825-1, fourth edition “Safety of laser

products -Part 1: Equipment classification, requirements and user's guide”. Even if the product is of

CLASS 1, please observe the following safety procedures, prescribed in the cited norm:

• do not observe directly the laser beam,

• do not use observation optics (lens, microscopes, telescopes, etc.),

• do not expose eyes directly.

YELLO

W

BLACK

SAFETI RULES ENG

-DEVICES SENSITIVE TO THE ELECTROSTATICS

WARNING: Please observe the due precautions in handling devices which are sensitive to the

electrostatics.

-NON-SOLID ELECTROLYPTIC CAPACITORS MAY CONTAIN CHEMICALS TO BE REGARDED AS

HAZARDOUS, IF INCORRECTLY HANDLED.

WARNING

THE MAXIMUM CAUTION IS REQUIRED IF THE OUTER CASE IS FRACTURED

SAFETI RULES ENG

2

2) STANDARDS

2.1. MANUFACTURE LABELS

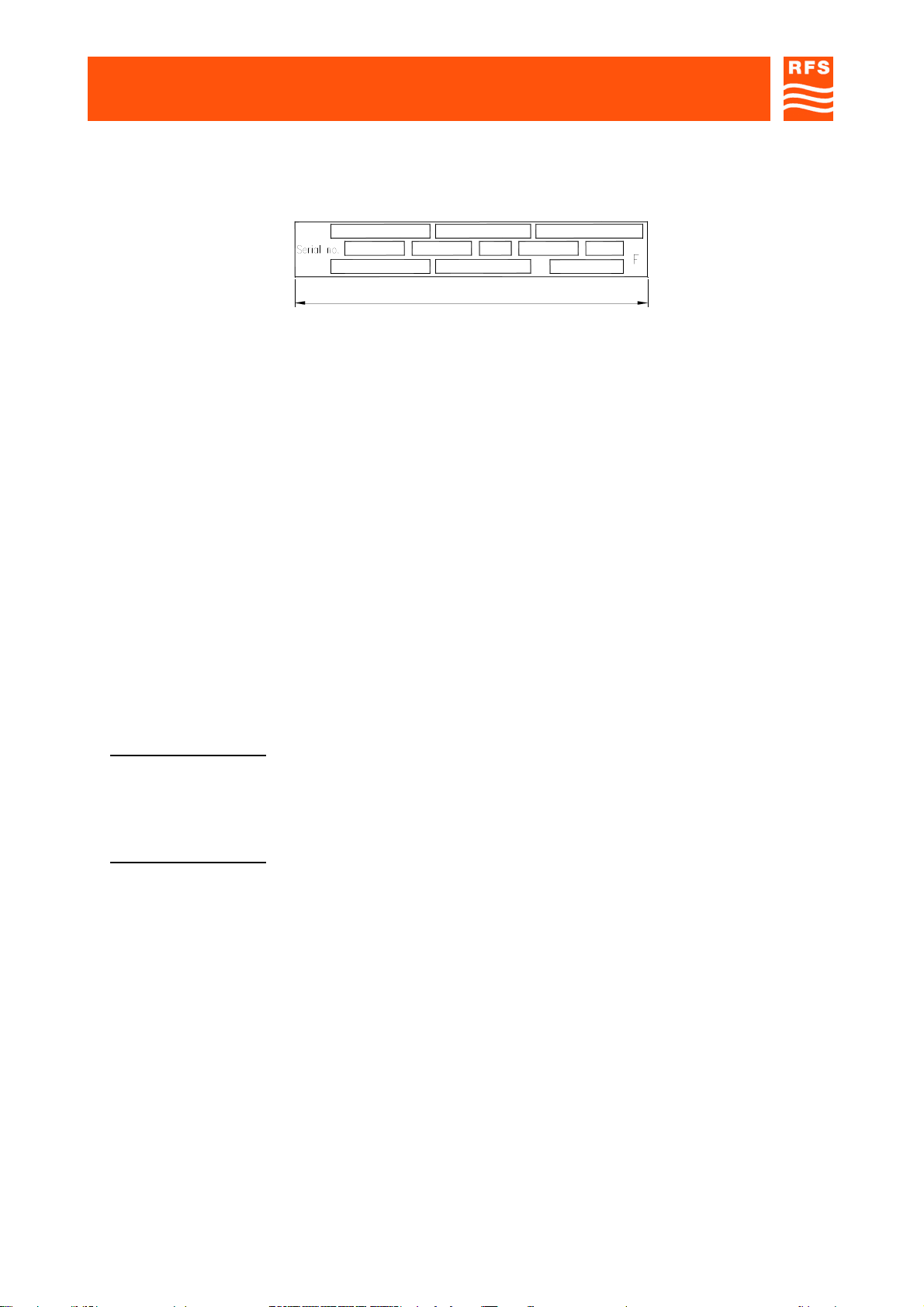

2.1.1 BAR CODE LABEL

Fig. 1

Label fields (ref. Fig.1):

a) Serial number: this field contains the serial number (made up of a 7-digit sequential group) of the

module or equipment.

b) F (final test tracing out): this field contains an F letter that has been barred to certify that the item has

been successfully tested in the factory Final Test Dept.

c) Customer order reference.

d) Equipment acronym or manufacture part number.

e) ICS (Item Change Status): this field contains the item ICS, made up of 2 digits, starting from 01, of the

manufacture part number or equipment.

Fig.2 shows an example of bar code label applied:

Fig. 2

On equipment other labels may be present, as integration of what reported in bar code label (fig.1);

see following pages.

STANDARDS Page 1

2.1.2 MANUFACTURE LABELS FOR RACK CABINETS AND EQUIPMENT

(1)

(4)

(9)

(2)

(5) (6)

(10)

90mm

(7)

(3)

(8)

(11)

Fig. 3

Label fields (ref. Fig.3):

(1) SYSTEM (it will be filled in only if the rack cabinet or the equipment belong to a system):

this field contains the system acronym.

(2) EQUIPMENT:

This field contains the acronym of the rack cabinet or equipment.

(3) MANUFACTURE PART NUMBER:

This field contains the manufacture part number either of the rack cabinet or the equipment.

(4) SERIAL NUMBER:

This field contains the serial number (made up of a 5-digit sequential group) of the rack cabinet or

equipment.

The serial number of each item comes from the manufacture orders print-out (for domestic and foreign

markets).

(5) QIF (Quality Identification Factor):

FACTORY USE ONLY

(6) ICS (Item Change Status):

This field contains the item ICS, made up of 2 digits, of the rack cabinet or equipment.

(7) ORIGIN CODE:

FACTORY USE ONLY

(8) MANUFACTURE YEAR AND WEEK:

This field contains the manufacture year and week of the rack cabinet or equipment (4 digits, the first two

of which indicate the year, while the last two digits indicate the relevant week) e.g. 9515: 15th week of

1995.

STANDARDS Page 3

(9) SUPPLY VOLTAGE (from MAINS and/or from DC SOURCE)

(10) ABSORBED CURRENT

(11) MAINS FREQUENCY

F (final test tracing out):

This field contains an F letter that has been barred to certify that the item has been successfully tested in

the factory Final Test Dept.

Fig.4 shows an example of manufacture label as applied to a RACK CABINET or to an EQUIPMENT.

58822 A0122

230Vac/48Vdc

00021 01

0.5Aac/0.89Adc

50/60 Hz

Fig. 4

(•) System acronym (if any)

For instance, you will find the manufacture label placed:

- on the upper left corner of the rack cabinet frame;

- on the rear side (or on the external right side) of the equipment rack.

9515

STANDARDS Page 4

2.1.3 MANUFACTURE LABELS FOR RACKS AND PLUG-IN, OR WIRING TYPE, MODULES

(1)

(4)

(2)

(5) (6) (8)

(3)

(7)

Fig. 5

Label fields (ref. Fig.5):

(1) SYSTEM (it will be filled in only if the rack or the module to be label belong to a system):

this field contains the system acronym.

(2) EQUIPMENT:

This field contains the acronym of the rack, or module.

(3) MANUFACTURE PART NUMBER:

This field contains the manufacture part number of the rack or module.

(4) SERIAL NUMBER:

This field contains the serial number (made up of a 5-digit sequential group) of the rack or module.

The serial number of each item comes from the manufacture orders print-out (for domestic and foreign

markets).

(5) QIF (Quality Identification Factor)

FACTORY USE ONLY

(6) ICS (Item Change Status):

This field contains the item ICS, made up of 2 digits, of the rack or module.

(7) ORIGIN CODE:

FACTORY USE ONLY

(8) MANUFACTURE YEAR AND WEEK:

This field contains the manufacture year and week of the rack or module (4 digits, the first two of which

indicate the year, while the last two digits indicate the relevant week) e.g. 9515: 15th week of 1995.

STANDARDS Page 5

F (final test tracing out):

This field contains an F letter that has been barred to certify that the item (rack or module) has been

successfully tested in the factory Final Test Dept.

Fig.6 shows an example of manufacture label as applied to a RACK or PLUG-IN, or WIRING TYPE

MODULES.

58822 A012200021 01 9515

Fig. 6

(•) System acronym (if any)

For instance, you will find the manufacture label placed:

- on the topside of the plug-in module, right or left;

- on the topside of the wiring-type module.

2.1.4 SUB-MODULES MANUFACTURE LABEL

F

Fig. 7

Label fields (ref. Fig.7):

(3) MANUFACTURE PART NUMBER:

This field contains the sub-module manufacture part number.

(5) QIF (Quality Identification Factor)

FACTORY USE ONLY

(6) ICS (Item Change Status):

This field contains the item ICS, made up of 2 digits, of the sub-module.

(7) ORIGIN CODE:

FACTORY USE ONLY

STANDARDS Page 6

(8) MANUFACTURE YEAR AND WEEK:

This field contains the manufacture year and week of the submodule (4 digits, the first two of which

indicate the year, while the last two digits indicate the relevant week) e.g. 9542: 42nd week of 1995.

F (final test tracing out):

This field contains an F letter that has been barred to certify that the item (sub-module) has been

successfully tested in the factory Final Test Dept.

Fig. 8 shows an example of manufacture label as applied to a SUB-MODULE.

00081.01 B0111

Fig. 8

You will find the manufacture label placed on the sub-module top, left, or right side.

F

STANDARDS Page 7

2.2) SYMBOLS

EQUIPMENT FRONT SYMBOLS

SYMBOLS DESCRIPTION SYMBOLS DESCRIPTION SYMBOLS DESCRIPTION

Earth connection Impulsive command Band-stop filter

Ground Fuse Low-pass filter

Chassis ground Thermal breaker High-pass filter

AC Failure Modulator,

demodulator

DC Overtemperature Stereo

Pulse current Output monitoring

signal

Battery / accumulator Input monitoring

signal

Positive connector

P

Negative connector

P

OFF

L.O.

Direct power

monitoring socket

Reflected power

monitoring socket

Local oscillator

monitoring socket

ON Gating as opening

criterion

STAND-BY Gating as closing

criterion

Balance

Amplifier

Adjustable gain

amplifier

Loudspeaker

connection

Audio connection

Headphone

connection

Stereo headphone

ON push-button Channel / band filter Star connection

STANDARDS Page 8

EQUIPMENT FRONT SYMBOLS

f

5MHz

SYMBOLS DESCRIPTION SYMBOLS DESCRIPTION SYMBOLS DESCRIPTION

Delta connection Receiving antenna Dual sound

High voltage Linearization

Start push-button Limiter upper

threshold

Local, manual

command

Automatic Adjusting

OFF / inhibited

(function)

ON / active

(function)

Stand-by

(function)

Output connector

Input connector

Limiter lower

threshold

Max adjusting

Min adjusting

Adjusting

Frequency adjusting

Xtal adjusting

Clock display

(operation time

counter)

Fan, blower Amplitude tuning

Antenna Band tuning

Transmission antenna Mono

STANDARDS Page 9

Freq. tuning

BLOCK DIAGRAM SYMBOLS

dB

THERMAL

SYMBOLS DESCRIPTION SYMBOLS DESCRIPTION SYMBOLS DESCRIPTION

Linear variability 2-way switch NAND general symbol

Automatic adjustment Voltage control

NOT general symbol

electromagnetic relay

Combiner general

Transformer Preemphasis

sign

2-way power divider Rectifier general

Deenphasis

symbol

2-way power

combiner

=

DC/DC converter Delay line general

symbol

=

3-way power divider Bridge rectifier Coaxial type time

delay limiter

4-way power divider

REG

3dB Hybrid Zener regulator

Voltage regulator Resistive attenuator

Pad

LIM.

WHITE

White limiter

Constant current bias

Fixed phase shifter

device

BIAS

Positive peak clipper Sinusoidal oscillator

SWITCH

Thermal switch

Negative peak clipper Ex-OR Band-pass filter

Circulator OR general symbol Band-stop filter

Isolator NOR general symbol Low-pass filter

Switch AND general symbol High-pass filter

STANDARDS Page 10

BLOCK DIAGRAM SYMBOLS

SYMBOLS DESCRIPTION SYMBOLS DESCRIPTION SYMBOLS DESCRIPTION

f

f/n

Divider by n DC amplifier Optical amplifier

f/n

FI

OL

RF FI

OL

f

Multiplier by n Differential

f

comparator

Mixer general symbol Phase comparator

Up-converter from IF

to RF

RF

Down-converter from

RF to IF

P. SYNC

CLAMP

Voltage / frequency

V

converter

Detector amplifier

Lamped to the

syncrhronizing signal

peak

Schmitt’s trigger

Directional coupler Amplitude linearity

precorrector

Double directional

coupler

Amplitude limiter

without distortion

Directional coupler

Equalizer general sign

with double detector

Detector

A

Amplitude equalizer

Peak detector Phase equalizer

3

X

X

To rise to cubical

power

Amplifier general

T

RF

symbol

Multistage amplifier

RF

Propagation time

equalizer

Laser diode electricaloptical transmitter

Optical-electrical

receiver

STANDARDS Page 11

3

μ

p

μ

3) GENERAL DESCRIPTION

Mobile phone systems have increasingly been spreading in these last years.

Besides providing reliable and good quality connections, telecommunication system services should cover

as widest territory as possible.

It is well-known that connections to users’ terminals are obtained on air by means of steady stations named

radio bases, located through the whole territory so as to obtain a continuous covering through cells one next

to another.

That allows a great number of users to enter the system using few channels.

It is important to maintain the continuity of radio-electrical coverage (and consequently, of service within

each cell) in order to guarantee an acceptable level of communication.

BTS Tri-cellular

FIGURE 1 – SUBDIVISION OF THE TERRITORY IN CELLS

Off-Air Repeaters are proposed as a valid and economical solution to optimize the cell coverage of the

territory and irradiate shadow area as an alternative to solutions requiring dedicated Radio-Bases (Figure 2).

MicroBTS solution Repeater solution

2Mbit radio connection

The repeater costs are 50% lower

BTS

than with the solution

BTS

Shadow Zone

BTS

Shadow Zone

BTS

Re

eater

Source

FIGURE 2 – RADIO-ELECTRICAL PROBLEMS IN CELL NETWORK COVERAGE

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

CHAPTER 3

3.1

Off-Air Repeaters on one side receive the signals from the radio base station, amplify them and re-transmit

them in the direction of the shadow area (down-link path). On the other side Off-Air Repeaters receive the

signals from the mobiles (MS), amplify them and re- transmit them to the base station (up-link path).

When a single Off-Air Repeater does not provide satisfactory coverage, the repeater can be used along with

other equipment. Different solutions are provided: cascade systems, based on Bi-Directional Amplifiers, and

optical fibre solutions, based on Remote Units.

3.1) EXAMPLE: USE IN TUNNELS

The Off-Air Repeater interfaces directly with the BTS of the provider of the services to be extended, and can

be used along with other equipment distributed inside the tunnels. Such equipment can be divided into two

types, according to the radio-coverage system used:

- Bi-directional amplifiers, for cascade systems.

- Remote Units, for optical systems.

The following are a few examples of general projects for radio-elec tric coverage in tunnels.

• Tunnels with a length of less than 300 meters.

In this case, one single Off-Air Repeater is sufficient. It is located at the entrance to the tunnel, equipped

with an antenna which irradiates in the direction of the shadow zone (Figure 3).

DO

W

N

L

I

N

U

K

P

L

I

N

K

OFF-AIR

REPEATER

DOWN

UP

Power Supply

(230Vac)

48Vdc Power Supply

and external signals

DOWN

UP

FIGURE 3

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

3.2

CHAPTER 3

• Tunnels with a length in the 300-meter to 600-meter range.

Also in this case, one single Off-Air Repeater is sufficient. The repeater is located at the entrance to the

tunnel and equipped with a leaky cable. This cable can be combined with a directional antenna to

irradiate a portion of the area in front of the tunnel exit (Figure 4).

DO

W

N

L

I

N

U

K

P

L

I

N

K

OFF-AIR

REPEATER

DOWN

UP

Power Supply

(230Vac)

48Vdc Power Supply

and external signals

DOWN

UP

FIGURE 4

• Tunnels with a length of more than 600 meters.

The signal can be enhanced in two ways:

a) By an Off-Air Repeater at the entrance to the tunnel, connected to a cascade of bi-directional

amplifiers inside the tunnel which re-generate the signal with amplification steps at a distance of

250mt. ÷ 400mt. from one another (Figure 5).

D

O

WN

L

I

N

U

P

K

L

I

N

K

OFF-AIR

REPEATER

DOWN

RF

UP

DC

POWER

SUPPLY

BF

BF

DC

RF

RF-DC-BF

Bias-T

DOWN

UP

RF-DC-BF

BI-DIRECTIONAL

AMPLIFIER

RF-DC-BF

BI-DIRECTIONAL

AMPLIFICATION STEP

RF-DC-BF

RF-DC-BF

AMPLIFIER

FIGURE 5

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

CHAPTER 3

3.3

b) By an Off-Air Repeater connected to master unit and optical remote units with amplification steps of

no more than 1200mt. each. The optical fiber system extends the signal through an antenna or a

passive distribution system (Figure 6).

D

OW

N

L

I

N

K

U

P

L

I

N

K

OFF-AIR

REPEATER

DOWN

RF

UP

Power Supply

(230Vac)

DOWN

UP

48Vdc Power

Supply and external

signals

MASTER

UNIT

REMOTE

UNIT

FIGURE 6

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

3.4

CHAPTER 3

3.2) OPERATING PRINCIPLE – 1800/1900MHz ADJUSTABLE BANDWIDTH OFF-AIR REPEATERS

The repeaters described in this handbook have been developed to permit cell coverage as set forth by the

DCS (Digital Cellular System) standard for cell phones operating on the 1800MHz band or by the PCS

(Personal Communications Service) standard for cell phones operating on the 1900MHz band. The DC

powered repeater can be power-fed by a 48Vdc power supply source only. The AC powered repeater can be

power-fed from MAINS (230Vac) or from a 48Vdc power supply source or both from MAINS and from a

48Vdc source. The presence of both power supply voltages guarantees the continuity of the coverage

service even in case of failure of one source. The commutation is handled automatically by the repeater.

Off-Air Repeaters are bi-directional amplifiers. The signal to be extended follows two distinct paths: the uplink path, from the mobiles to the radio base station, and the down-link path, from the radio base station

towards the mobiles.

Figure 7 provides a block-diagram of the 1800/1900MHz adjustable band Off-Air Repeater.

NETWORK

RS232

G

MANAGEMENT

MODEM

5.5Vdc

UNIT

5.5Vdc

10.5Vdc

DC/DC

CONVERTER

48Vdc

IN

48Vdc

230Vac

LF

AC/DC

CONVERTER

IN

MANAGEMENT BUS

E1

LNA UP

dB

5.5Vdc

HPA

DOWN

10.5Vdc

B2

DOWN

MS

UP

A2

BTS

DOWN

UP

ALC

5.5Vdc

LNA DOWN

C1 D1

dB

B1

10.5Vdc

5.5Vdc

HPA UP

E2

A1

5.5Vdc

10.5Vdc

BAND SELECTIVE 1

DOWN LINK

UP LINK

5.5Vdc

D2

BAND SELECTIVE 2

DOWN LINK

UP LINK

ALC

10.5Vdc

5.5Vdc

C2

FIGURE 7 – 1800/1900MHz OFF-AIR REPEATERS BLOCK-DIAGRAM

In down-link the RF signal from the donor antenna is filtered and pre-amplified by a low-noise amplifier (LNA,

ref. C1).

The selection of the band of frequencies to be extended is handled by two band-selective modules, ref. D1

and ref. D2, which make the band-pass and frequency center programmable entities.

The band of frequencies to be extended can be managed by the user by means of the management system.

The signal is then amplified by the High power amplifier (ref. E1) filtered by the MS side duplexer, ref.

B2,and transmitted by an antenna or a passive distribution system.

A VSWR detector is equipped.

The up-link path is identical to the down-link path described above.

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

3.5

CHAPTER 3

The 48Vdc powered repeater is equipped with a DC/DC converter, ref. F.

The A.C. powered repeater is equipped also with an AC/DC converter, ref. L.

The management module, ref. G, makes it possible to manage the repeater in remote mode via a built-in

modem, or in local mode through the RS232 connector, available on the management module.

The repeater management is performed by means of the Operation and Maintenance Terminal software,

both in local mode and in remote mode (ref. Chap. 4).

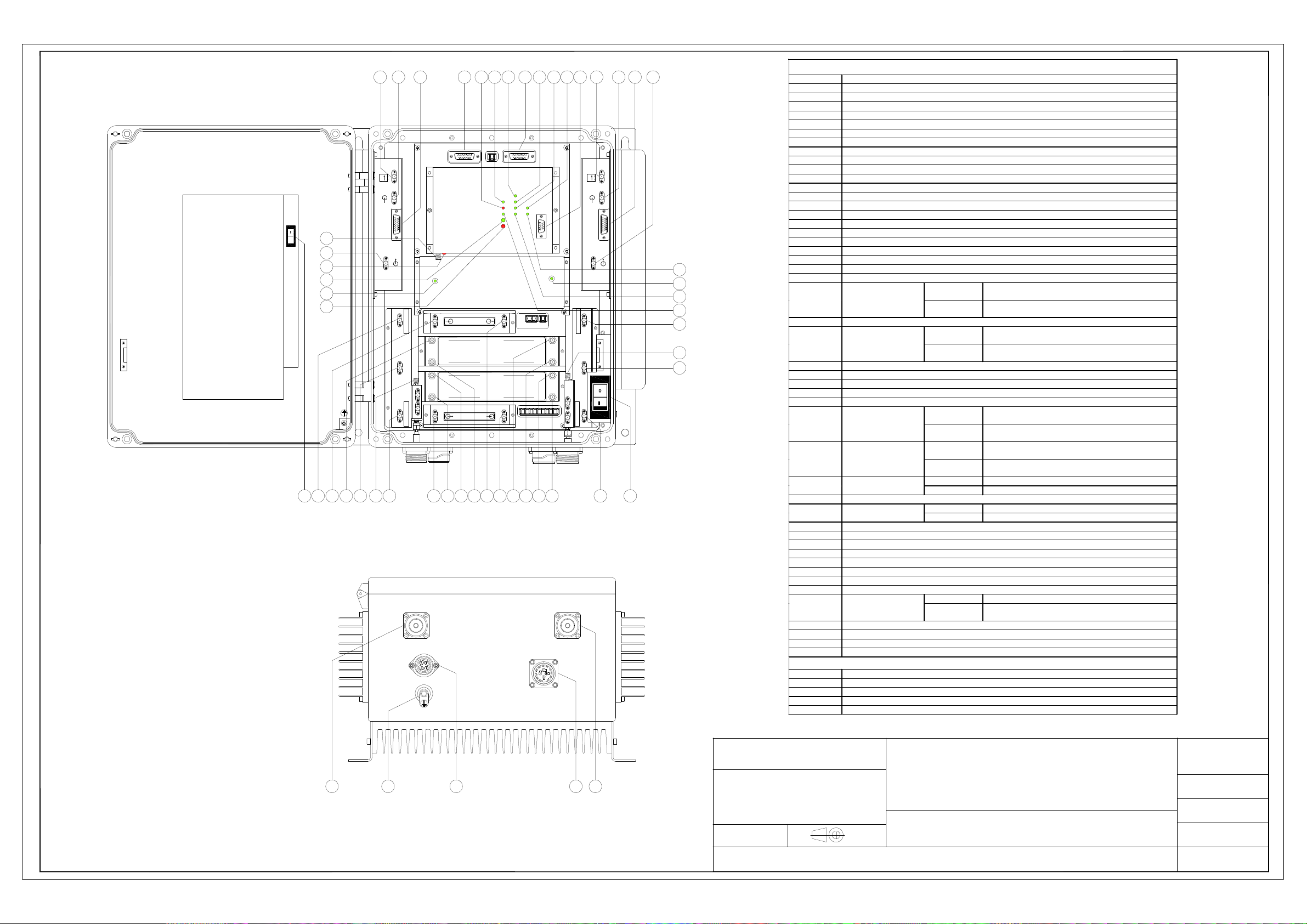

3.3) ATTACHED DOCUMENTS

TECHNICAL CHARACTERISTICS

1800MHz 48Vdc/230Vac ADJUSTABLE BAND OFF-AIR REPEATERS

ILL DCS OFF-AIR REPEATERS (ILLUSTRATIVE DRAWINGS)

Sheet 1, equipment composition and backplane access points map

Sheet 2, modules access points map and external access points m ap

TECHNICAL CHARACTERISTICS

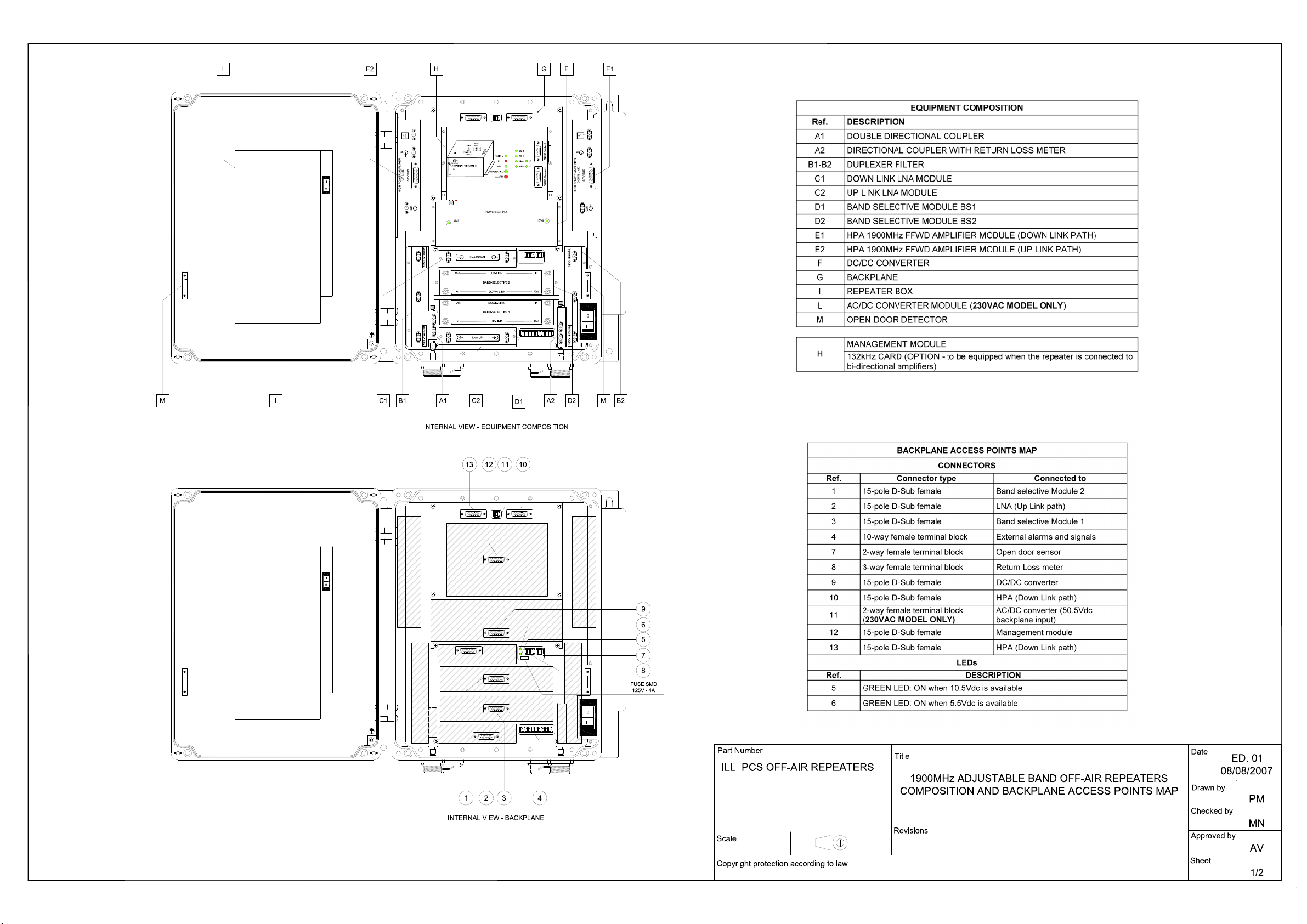

1900MHz 48Vdc/230Vac ADJUSTABLE BAND OFF-AIR REPEATERS

ILL PCS OFF-AIR REPEATERS (ILLUSTRATIVE DRAWINGS)

Sheet 1, equipment composition and backplane access points map

Sheet 2, modules access points map and external access points m ap

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

CHAPTER 3

3.6

ANNEX 1

TECHNICAL CHARACTERISTICS

1800MHz 48Vdc/230Vac ADJUSTABLE BAND OFF-AIR REPEATERS

TECHNICAL CHARACTERISTICS

Up Link operating frequency band

Down Link operating frequency band

Number of amplified bands

1800MHz OFF-AIR

REPEATER

48Vdc MODEL

1710 ÷ 1785MHz

1805 ÷ 1880MHz

1800MHz OFF-AIR

REPEATER

230Vac MODEL

1

Programmable Bandwidth / steps From 1MHz to 16.5MHz / 10kHz step adjustable

Output Power 28dBm (2 carriers)

3rd Order Intercept Point (OIP3) 57dBm

Output Power at 1dB compression point

36dBm

Noise Figure @ max. gain 8dB

Gain / Step

50 ÷ 80dB / 1dB step

Ripple into operating band ± 2dB

Total processing delay

6μs

Return Loss 14dB

ALC threshold (default value)

Spurious emissions and intermodulation products

< -36dBm (in the frequency band 9kHz ÷ 1GHz)

< -30dBm (in the frequency band 1GHz ÷ 12.75GHz)

3dB over nominal output power

(this value can be changed on site)

Local Control Interface RS232

Remote Control Interface PSTN – GSM/DCS modem

Power Supply

-72 ÷ -36Vdc

-72 ÷ -36Vdc

85÷265Vac (50-60Hz)

Power Consumption 110W @ 48Vdc 140VA @ 230Vac

MTBF 50 000 hours

Operating Temperature (*) -20°C up to +55°C

Degree of protection provided by enclosure IP65

RF connectors 7/16 female

Dimensions (h-w-d)

(max. volume - heat sinks included)

423x395x230mm

Weight 23Kg

All values are typical at 25°C unless otherwise specified

(*) Degraded performances from +50°C to +55°C

1800MHz-1900MHz ADJUSTABLE BAND Annex TECHNICAL CHARACTERISTICS

OFF-AIR REPEATERS

1

HPA - UP LINK - communicates with management

HPA - UP LINK - does not communicate with

HPA - DOWN LINK - communicates with

HPA - DOWN LINK - does not communicate with

LNA - DOWN LINK - communicates with

LNA - DOWN - does not communicate with

LNA - UP LINK - communicates with management

LNA - UP LINK - does not communicate with

45 44 43 42 40 39 33 32 30

41 35

37

38

34 3136

Ref. DESCRIPTION

1 DUPLEXER - BTS side - Up Link path SMA connector

2 LNA - Down Link - input

3 Band Selective 2 Up-Link path output

4 DUPLEXER - BTS side - input/output SMA connector

5 Directional coupler - BTS side - SMA (f) input/output connector

6 DUPLEXER - BTS side - SMA Down Link connector

9 LNA - Up Link path - output

10 Band Selective 1 Up Link Input

11 Band Selective 1 Down Link Output

MODULES ACCESS POINTS MAP

P

IN

UP LINK

46

0

SPV BUS

HIGH POWER AMPLIFIER

OPERATING

132KHz

ALARM

BS 2

BS 1

RL

U LNA

+5V

D

U

HPA D

RS232

P

IN

SPV BUS

DOWN LINK

HIGH POWER AMPLIFIER

47

48

49

OUT

5V5

POWER SUPPLY

10V5

50

51

1710-1785MHz

1805-1880MHz

57

1

5

4 6 9 10 14 15

LNA DOWN

Out

Out

In

UP-LINK

BAND-SELECTIVE 2

DOWN-LINK

DOWN-LINK

BAND-SELECTIVE 1

UP-LINK

LNA UP

In

OutIn

In

Out

1805-1880MHz

1710-1785MHz

OUT

29

28

27

26

25

24

23

2111 16 18172 13

223 12

INTERNAL VIEW - MODULES ACCESS POINTS

12 Band Selective 2 Down Link Input

13 LNA - Down Link path - output

14 LNA - Up Link path - input

15 Band Selective 2 Up Link path input

16 Band Selective 2 Down Link path output

17 Band Selective 1 Down Link path Input

18 Band Selective 1 Up Link path output

21 DUPLEXER - MS side - Up Link path SMA connector

22 48Vdc ONLY circuit breaker

23 DUPLEXER - MS side - input/output SMA connector

24 Directional coupler - MS side - SMA (f) input/output connector

25 DUPLEXER - MS side - Down Link path SMA connector

26 GREEN LED: +5Vdc available

27

GREEN / RED LED

HPA UP

GREEN

RED

unit

management unit

28 GREEN LED: +10.5V available

29

GREEN / RED LED

HPA DOWN

GREEN

RED

management unit

management unit

30 HPA Down Link output

31 Sub-D 15-pole management link between Down Link HPA and management unit

32 HPA Down Link input

33 HPA Down Link monitoring SMA connector

34 Sub-D 9-poles RS232 connector

35

36

37

GREEN / RED LED

LNA DOWN

GREEN / RED LED

LNA UP

GREEN / RED LED

Band Selective 1

GREEN

RED

GREEN

RED

GREEN BS1 communicates with management unit

RED BS1 does not communicate with management unit

management unit

management unit

unit

management unit

38 Sub-D 15-pole management link between Down Link HPA and management unit

39

GREEN / RED LED

Band Selective 2

GREEN BS2 communicates with management unit

RED BS2 does not communicate with management unit

40 GREEN LED 132kHz: 132kHz (line amplifier management carrier) correctly operating

41 RED LED: Return Loss alarm

42 Sub-D 15-pole management link between Up Link HPA and management unit

43 Sub-D 15-pole management link between Up Link HPA and management unit

44 HPA Up Link input

45 HPA Up Link monitoring SMA connector

46 GSM modem RF output

47 HPA Up Link output

48

RED LED: modem

operation

RED ON Trying to connect to network

BLINKING

RED

Modem correctly operating

49 GREEN LED: equipment correctly operating

50 GREEN LED: 5.5V available

51 RED LED: equipment fault

57 (*) AC voltage ONLY circuit breaker

EXTERNAL ACCESS POINTS MAP

52 BTS side 7/16 RF connector

53 Equipment Grounding

54 (*) AC voltage input (230Vac)

55 48Vdc input / external alarms Connector

56 MS side 7/16 RF connector

(*) 230VAC MODEL ONLY

Part Number

ILL DCS OFF-AIR REPEATERS

Title

1800MHz ADJUSTABLE BAND OFF-AIR REPEATERS

MODULES ACCESS POINTS MAP AND EXTERNAL

52

53 54

BOTTOM VIEW - REPEATER CASE CLOSED

EXTERNAL ACCESS POINTS

55 56

Scale

Copyright protection according to law

Revisions

ACCESS POINTS MAP

ED. 01-1

29/09/2006

Date

31/01/2007

Drawn by

Checked by

Approved by

Sheet

ED. 02

CG

MN

AV

2/2

ANNEX 2

TECHNICAL CHARACTERISTICS

1900MHz 48Vdc/230Vac ADJUSTABLE BAND OFF-AIR REPEATERS

TECHNICAL CHARACTERISTICS

Up Link operating frequency band

Down Link operating frequency band

Number of amplified bands

1900MHz OFF-AIR

REPEATER

48Vdc MODEL

1850 ÷ 1910MHz

1930 ÷ 1990MHz

1900MHz OFF-AIR

REPEATER

230Vac MODEL

1

Programmable Bandwidth / steps From 1MHz to 16.5MHz / 10kHz step adjustable

31dBm (1 carrier)

Output Power (GSM/TDMA)

28dBm (2 carriers)

25dBm (4 carriers)

26dBm (1 carrier)

Output Power (CDMA)

23dBm (2 carriers)

20dBm (4 carriers)

3rd Order Intercept Point (OIP3) 57dBm

Output Power at 1dB compression point

36dBm

Noise Figure @ max. gain 8dB

Gain / Step

50 ÷ 80dB / 1dB step

Ripple into operating band ± 2dB

Total processing delay

6μs

Return Loss 14dB

ALC threshold (default value)

Spurious emissions and intermodulation products

< -13dBm (in the frequency band 9kHz ÷ 1GHz)

< -13dBm (in the frequency band 1GHz ÷ 12.75GHz)

3dB over nominal output power

(this value can be changed on site)

Local Control Interface RS232

Remote Control Interface

Power Supply

PSTN – GSM (850, 900, 1800, 1900)

or CDMA (850, 1900) modem

-72 ÷ -36Vdc

-72 ÷ -36Vdc

85÷265Vac (50-60Hz)

Power Consumption 110W @ 48Vdc 140VA @ 230Vac

MTBF 50 000 hours

Operating Temperature (*) -20°C up to +55°C

Degree of protection provided by enclosure IP65

RF connectors 7/16 female

Dimensions (h-w-d)

(max. volume - heat sinks included)

423x395x230mm

Weight 23Kg

All values are typical at 25°C unless otherwise specified

(*) Degraded performances from +50°C to +55°C

1800MHz-1900MHz ADJUSTABLE BAND Annex TECHNICAL CHARACTERISTICS

OFF-AIR REPEATERS

2

4

4) INSTALLATION AND POWER-UP PROCEDURES

Ref.: ILL DCS OFF-AIR REPEATERS / ILL PCS OFF-AIR REPEATERS

WARNING:

Before installing the equipment, carefully read the safety norms herewith attached.

A correct repeater installation and setting procedure requires a good knowledge and experience in

installing telecommunication equipment. These activities should be performed by skilled personnel

only. Remember that if the equipment is not installed correctly, it may:

- put the donor BTS temporary out of service,

- be damaged by excessively high input or output signal levels.

4.1) INSTALLATION

1. INITIAL CHECK

Make sure that the supply is complete and/or that the material has not been damaged during transport.

The list of the materials that make up the equipment is described in the relative PACKING LIST.

Should any parts be missing, or should some be damaged, kindly inform the Sales Dept. of RFS

immediately, in order to facilitate replacing and/or repairing the parts involved.

WARNING:

Before installing the equipment, always make sure that the repeater is not powered up:

- Check that both ON/OFF switches located inside the alternate current powered repeater are

in the OFF position (AC voltage circuit breaker, ref. 59 and 48Vdc circuit breaker, ref. 22

FIGURE 1a).

- Check that the ON/OFF switch (48Vdc circuit breaker, ref. 22, FIGURE 1b) located inside the

direct current powered repeater is in the OFF position.

The LEDs inside the repeater must be turned off.

P

IN

UP LINK

0

SPV BUS

HIGH POWER AMPLIFIER

AC voltage

circuit breaker

ref. 59

a) 230Vac MODEL

INTERNAL VIEW

OUT

1710-1785MHz1805-1880MHz

BS 2

132KHz

BS 1

RL

ULNA

+5V

U

HPA D

OPERATING

ALARM

POWER SUPPLY

5V5 10V5

LNA DOWN

Out

UP-LINK

BAND-SELECTIVE 2

In

DOWN-LINK

Out

DOWN-LINK

BAND-SELECTIVE 1

In

UP-LINK

LNA UP

48Vdc circuit

breaker

ref. 22

P

IN

D

SPV BUS

DOWN LINK

HIGH POWER AMPLIFIER

OUT

In

Out

In

Out

1710-1785MHz 1805-1880MHz

P

IN

UP LINK

SPV BUS

HIGH POWER AMPLIFIER

OUT

5V5 10V5

1710-1785MHz1805-1880MHz

Out

In

Out

In

LNA DOWN

LNA UP

OPERATING

POWER SUPPLY

UP-LINK

BAND-SELECTIVE 2

DOWN-LINK

DOWN-LINK

BAND-SELECTIVE 1

UP-LINK

132KHz

ALARM

BS 2

BS 1

RL

ULNA

+5V

U

HPA D

48Vdc circuit

breaker

ref. 22

P

IN

D

SPV BUS

DOWN LINK

HIGH POWER AMPLIFIER

OUT

In

Out

In

Out

1710-1785MHz 1805-1880MHz

b) 48Vdc MODEL

INTERNAL VIEW

FIGURE 1 – EQUIPMENT POWER SWITCHES

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

CHAPTER 4

4.1

2. POSITIONING THE REPEATER

The Off-Air Repeater is housed inside a case which provides high-degree environmental protection (IP65).

Therefore it is suitable for outdoor wall mount installation. It can also be installed inside specific cabinets

equipped with UPS units.

Fix the Off-Air Repeater in vertical position on the wall, or on the vertical guides present inside the cabinet:

• Lift the equipment and fix its position with four M8 bolts, which are to be inserted in the pre-cut slots

(ref. A, FIGURE 2).

• After checking the correct positioning of the equipment, fully tighten the bolts.

334.00 mm (13.15 in.)

A A

366.00 mm (14.41 in.)

AA

FIGURE 2 - POSITION OF THE HOLES IN THE SUPPORT BRACKETS FOR THE EQUIPMENT

3. POWER SUPPLY SOURCE CONNECTIONS AND ALARMS CONNECTIONS

• Before carrying out any other electrical connection connect the rack to the station ground, using the

ground bolt on the bottom of the repeater (ref. 53, FIGURE 3).

• Make sure that the power supply source provides the prescribed nominal voltage.

If so, connect the equipment to the power supply source, as described below.

MS side

RF connector

ref. 56

BTS side

RF connector

ref. 52

MS side

RF connector

ref. 56

BTS side

RF connector

ref. 52

Equipment

Grounding

ref. 53

AC voltage input

from MAINS

a) 230Vac MODEL

BOTTOM VIEW

ref. 54

48Vdc input and

external alarms

Connector

ref. 55

Equipment

Grounding

ref. 53

b) 48Vdc MODEL

BOTTOM VIEW

48Vdc input and

external alarms

Connector

ref. 55

FIGURE 3 – EXTERNAL CONNECTORS

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

CHAPTER 4

4.2

• D.C. POWERED EQUIPMENT

- Connect the 15-pole (f) connector on the bottom of the repeater (ref. 55, FIGURE 3) to the 48Vdc/Alarm

cable (supplied with the equipment).

The cable permits D.C power supply (48Vdc) to the equipment. It also makes available the remote

signals detailed into Table 1.

- Connect the cable to the power supply source (48Vdc) and connect the external signals.

PLEASE NOTE:

The 48Vdc power supply cable (also including the external alarms), provided standard with the

equipment, must never be longer than 3 meters in length (connectors included).

48Vdc POWER SUPPLY AND EXTERNAL ALARMS CONNECTOR

WIRES COLOR OF 48VDC

PIN TYPE OF SIGNAL

POWER SUPPLY AND

EXTERNAL ALARMS

CABLE

0 0Vdc RED

1 0Vdc RED

2 - 48Vdc BLACK

3

48Vdc

POWER SUPPLY

- 48Vdc BLACK

4 EXTERNAL ALARM 3 GRAY

5 EXTERNAL ALARM 4 BROWN

6 EXTERNAL ALARM 2 ORANGE

7 EXTERNAL ALARM 1 PINK

EXTERNAL ALARMS

8 GROUND - GND GREEN

9

+5Vdc EXT. ALM.

COMMON

WHITE

10 NOT CONNECTED

11 BLUE

12

SPV CARRIER FOR BDAs

(IF ANY)

132kHz

VIOLET

13 NOT CONNECTED

14 NOT CONNECTED

TABLE 1 – 48Vdc POWER SUPPLY AND REMOTE SIGNALS CONNECTOR PIN-OUT

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

CHAPTER 4

4.3

• AC POWERED EQUIPMENT (ALTERNATE CURRENT)

- Connect the 230Vac power cable to the connector located on the bottom of the repeater (ref. 54,

FIGURE 3). The connector pin assignments is detailed in Table 2.

230Vac POWER SUPPLY CONNECTOR

PIN CABLE 230VAC POWER SUPPLY

CABLE COLOR

1 LINE BROWN

2 NEUTRAL BLUE

3 GROUND (GND) YELLOW / GREEN

4 NOT CONNECTED

TABLE 2 – 230Vac POWER SUPPLY CONNECTOR PIN-OUT

- Connect the other end of the cable to the power supply source (230Vac).

- Also connect the 48Vdc power and alarms cable, provided standard, to the 15-pin connector located on

the bottom of the equipment (ref. 55, FIGURE 3).

The cable makes remote signals available. The connector pin-out is detailed into table 1.

The cable can also be connected to a 48Vdc power supply, to feed the equipment with a D.C. voltage.

PLEASE NOTE:

The 48Vdc power supply cable (also including the external alarms), provided standard with the

equipment, must never be longer than 3 meters in length (connectors included).

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

CHAPTER 4

4.4

4.2) POWER-UP

Warning: before power up, make sure that the isolation between the donor antenna and the

service antenna is at least 15dB greater than the repeater gain.

1. Connect the cable from the donor antenna to a spectrum analyzer and check input signal presence and

level. After measurement disconnect the spectrum analyzer.

2. Switch on the equipment by means of the switches placed inside the repeater (FIGURE 1a and b).

3. Check the LEDs status on the management module: FIGURE 4 and Table 3 show LEDs status on the

management module under normal operating conditions.

11S

132KHz

RL

+5V

OPERATING

ALARM

1S 2S 4S3S 5S

U

U

BS 2

BS 1

HPA D

6S10S 9S 8S 7S

DLNA

FIGURE 4 – MANAGEMENT MODULE: LEDS STATUS - CORRECT POWER UP

REF. STATUS MEANING

LED 1S OFF

LED 2S ON

Equipment correctly operating

LED 3S ON Management module: +5Vdc available

LED 4S ON, GREEN

LED 5S ON, GREEN

LED 6S ON, GREEN

LED 7S ON, GREEN

LED 8S ON, GREEN

LED 9S ON, GREEN

HPA (High Power Amplifier) - UP LINK -

communicates with management module

HPA (High Power Amplifier) - DOWN LINK -

communicates with management module

LNA (Low Noise Amplifier) - DOWN LINK -

communicates with management module

BS1 communicates with management module

BS2 communicates with management module

LNA (Low Noise Amplifier) - UP LINK - communicates

with management module

LED 10S ON, GREEN 132kHz correctly operating

LED 11S OFF

NO Return Loss alarm

TABLE 3 - MANAGEMENT MODULE: LEDS STATUS - CORRECT POWER UP

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

CHAPTER 4

4.5

4. Check that the green LED on the 230Vac power supply module (when equipped) is ON (ref. 60, ILL

DCS OFF-AIR REPEATERS, sheet 2).

5. Check LEDs status on the 48Vdc power supply module: FIGURE 5 and Table 4 show LEDs status on

the power supply module (DC/DC converter) under normal operating conditions.

POWER SUPPLY

5V5 10V5

1A 2A

FIGURE 5 – DC/DC CONVERTER: LEDS STATUS - CORRECT POWER UP

REF. STATUS MEANING

LED 1A ON 5.5Vdc from DC/DC converter available

LED 2A ON 10.5Vdc from DC/DC converter available

TABLE 4 - DC/DC CONVERTER: LEDS STATUS - CORRECT POWER UP

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

CHAPTER 4

4.6

6. WIRELESS MODEMS

a. Models equipped with CDMA modem

data communication between repeater (via built-in CDMA modem) and management workstation

(PC where OMT/OMC management softw ares have been previously installed) via PSTN and/or

CDMA modem, must be established in CSD (CIRCUIT-SWITCHED DATA) mode only. All other

modalities are not allowed.

As CDMA modems don’t use SIMs, the network’s parameters have to be set manually by using the

HyperTerminal. Please contact your local Operator, communicating modem’s ESN (check the sticker at the

top of the management module), to get the needed parameters. Most common parameters are:

Typical CDMA Network Parameters

Acronyms Full name

MSL

MDN

MTN

Master Subsidy

Lockcode

Mobile Data Number Provided by the Operator Modem phone number

Mobile Telephone

Number

Network's setting /

Terminal's setting

Provided by the Operator Modem lock / unlock code -

Provided by the Operator Modem phone number

Description Notes

MDN & MTN are

synonyms

MDN & MTN are

synonyms

MNC

MCC

ESN

MIN

IMSI

(Home) SID

(Home) NID

PRI

PRL

PCA

PCB

SCA

SCB

A-key

Mobile Network Code Provided by the Operator

Mobile Country Code Provided by the Operator

Electronic Serial Number

Mobile Identification

Number

International Mobile

Subscription Identity

System ID Provided by the Operator

Network ID Provided by the Operator

Product Release

Instruction

Preferred Roaming List Provided by the Operator List of NIDs/SIDs -

Primary Channel A Provided by the Operator RF primary channel -

Primary Channel B Provided by the Operator RF primary channel Secondary Channel A Provided by the Operator RF secondary channel Secondary Channel B Provided by the Operator RF secondary channel -

Autenthification key Provided by the Operator Key for the autenthification

Proprietary of the modem

(factory setting)

Provided by the Operator Subscriber's account number -

Provided by the Operator International modem ID

Provided by the Operator Carrier information -

2 digit number that represents a

sub-network in the IMSI

Predefined number that

represents a Country in the IMSI

Modem internal proprietary ID

(factory setting)

ID of the sub-network where

modem can operate

ID of the sub-network where

modem can operate

-

-

It can be found into the

sticker at the top of the

management module

IMSI = MCC + MNC +

MIN

SID & NID are synonyms

SID & NID are synonyms

Built-in modem's one is

random

Note: not all parameters could be needed

In normal operating conditions the jumper must remain connected (if removed, the remote management will

be avoided). It can be temporary removed to set the Operator’s parameters into the built-in modem by using

the RS232 modem port. The same serial cable used for local management, can be used to set the modem.

Once the modem setting is complete, reconnect the jumper to the normal operating position

.

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

4.7

CHAPTER 4

The following procedure explains how to set the modem’s parameters.

Please note: AT commands, contained between the inverted commas, must be strictly typed as it follows.

1) Switch-off the repeater

2) Remove the jumper at RS232 (modem) connector

3) Connect the serial cable (supplied with repeater) with your laptop and RS232 (modem) connector

4) Switch-on the repeater and wait for the complete auto-diagnostic test

5) Run HyperTerminal software on your laptop (if you’re using Microsoft XP, run HyperTerminal from

start/programs/accessories/communication/HyperTerminal)

6) Type the connection’s name (e.g. repeater’s modem) and press OK

7) Chose the right PC’s serial port (COM) and press OK

8) Set the bit-rate at “9600” baud

9) Set the number of bits at “8”

10) Set the parity at “no parity”

11) Set the bit stop at “1”

12) Set the flow control at “no flow control”

13) Press OK

14) Type “AT” and press ENTER (modem should reply with “OK”)

15) Type “AT+E1” and press ENTER (modem should reply with “OK”)

16) Type “AT+CGSN” and press ENTER to display the ESN number (if needed)

17) Type “AT+WSPC=1,000000” and press ENTER to get access to CDMA AT commands

18) Type “AT+WMDN=xxx” where xxx is the MDN number (10 to 15 digits) and press ENTER

If needed, to get current MDN number, type “AT+WMDN?” and press ENTER

19) Type “AT+WIMI=xxx” where xxx is the IMSI number (15 digits) and press ENTER

If needed, to get current IMSI number, type “AT+WIMI? and press ENTER

20) Type “AT+WSID=, xxx, yyy” where xxx is the SID number (1 up to 5 digits / 0 up to 32767) and yyy

is the NID number (1 up to 5 digits / 0 up to 65535 – if not provided, set 65535

) and press ENTER

If needed, to get current IMSI number, type “AT+WIMI? and press ENTER

With the this command you’ve set SID & NID number in first memory location. Up to 20 (0 up to 19)

locations are supported. To set other SIDs & NIDs, please use the following sintax:

Type “AT+WSID=zz, xxx, yyy” where zz is the location (up to 2 digits / 1 up to 19) where these SIDs

& NIDs have to be stored, xxx is the SID number (1 up to 5 digits / 0 up to 32767) and yyy is the NID

number (1 up to 5 digits / 0 up to 65535 – if not provided, set 65535

) and press ENTER

Please note: to set both SID & NID at 0 in location 2, type “AT+WSID=2”

21) Type “AT+WPCC=xxx,yyy” where xxx is primary channel “a” (up to 4 digits / 0 up to 2047) and yyy

is primary channel “b” (up to 4 digits / 0 up to 2047) and press ENTER

If needed, to get current primary channels, type “AT+WPCC? and press ENTER

22) Type “AT+WSCC=xxx,yyy” where xxx is secondary channel “a” (up to 4 digits / 0 up to 2047) and

yyy is secondary channel “b” (up to 4 digits / 0 up to 2047) and press ENTER

If needed, to get current secondary channels, type “AT+WSCC? and press ENTER

23) Type “AT+WCMT=1” and press ENTER to store these settings into the modem. The modem will be

automatically re-start with new settings. Please wait for 10-20 seconds prior to type other commands

24) Type “AT” and press ENTER (modem should reply with “OK”)

25) Type “AT+E1” and press ENTER (modem should reply with “OK”)

26) Type “AT+CICB=0” and press ENTER to allow CSD data connections

27) Close the HyperTerminal

28) Remove the serial cable

29) Switch-off the equipment

30) Reconnect the existing jumper cable with RS232 (modem)

Please note: not all the above mentioned parameters could be necessary. For any problem, please contact

our local subsidiary.

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

CHAPTER 4

4.8

b. Models equipped with GSM modem

How to install/remove the SIM card from the built-in modem

• Open the repeater.

• Check that the switches inside the repeater are set to 0 - OFF (FIGURE 1a and b).

• Insert the SIM enabled to data transmission in not transparent mode 9600BPS (FIGURE 6)

FIGURE 6 – DETAIL OF THE SIM INSERTION

• Close the Management Module

• Switch on the equipment (AC voltage circuit breaker, ref. 57, 48Vdc circuit breaker, ref. 22, FIGURE

1a-b).

• Close the repeater.

7. INSTALL THE OPERATION AND MAINTENANCE SOFTWARE OMT REPEATER

Install on your PC the Operation and Maintenance Terminal software to set and manage the equipment

(please refer to the software User’s manual). The repeater can be managed in remote mode via a builtin modem, or in local mode.

8. START OMT Repeater IN LOCAL MODE

In LOCAL mode the notebook is connected to the repeater via RS232 serial cable.

- Open the repeater door (by unscrewing four screws located on the equipment front door).

Connect your notebook to the management module (connector RS232, ref. 34, FIGURE 7) using the provided

serial cable (null-modem type).

RS232

Modem

ref. 58

P

IN

UP LINK

SPV BUS

HIGH POWER AMPLIFIER

OUT

OPERATING

POWER SUPPLY

5V5 10V5

RS232

Link

ref. 59

BS 2

132KHz

BS 1

RL

ULNA

D

+5V

U

HPA D

ALARM

RS232 (Repeater) RS232 (Modem)

RS232

Repeater

ref. 34

P

IN

SPV BUS

DOWN LINK

HIGH POWER AMPLIFIER

OUT

LNA DOWN

Out

BAND-SELECTIVE 2

Out

BAND-SELECTIVE 1

In

LNA UP

UP-LINK

DOWN-LINK

DOWN-LINK

UP-LINK

In

OutIn

In

Out

FIGURE 7 – RS232 CONNECTORS

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

CHAPTER 4

4.9

- The connector RS232 (ref. 58,FIGURE 7) and the connector RS232 (ref. 59, FIGURE 7) are

connected with a cable (only in models equipped with CDMA modem).

- Switch on your notebook and start Windows.

- To Run the program select the related folder in the Windows ‘Start’ menu and click.

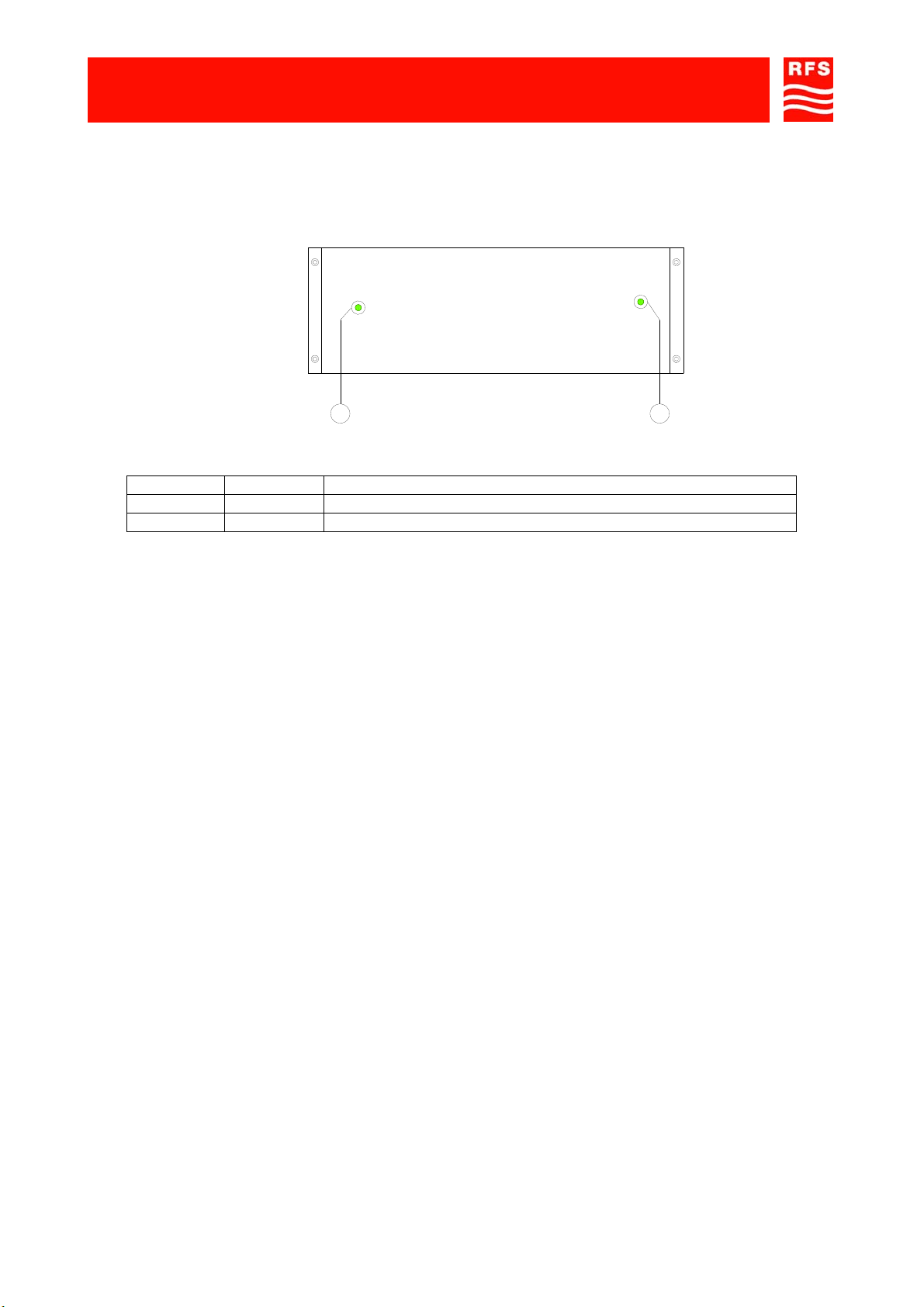

- The ‘Login panel’ is displayed (FIGURE 8).

- Select read/write user.

PLEASE NOTE It’s not requested to insert the password the first opening of the program. It’s recommended

to change the password to avoid undesired accesses to the program (to change the password, please refer

to the Operation and Maintenance Terminal Software User’s manual).

- Click ‘Ok’ to start the software.

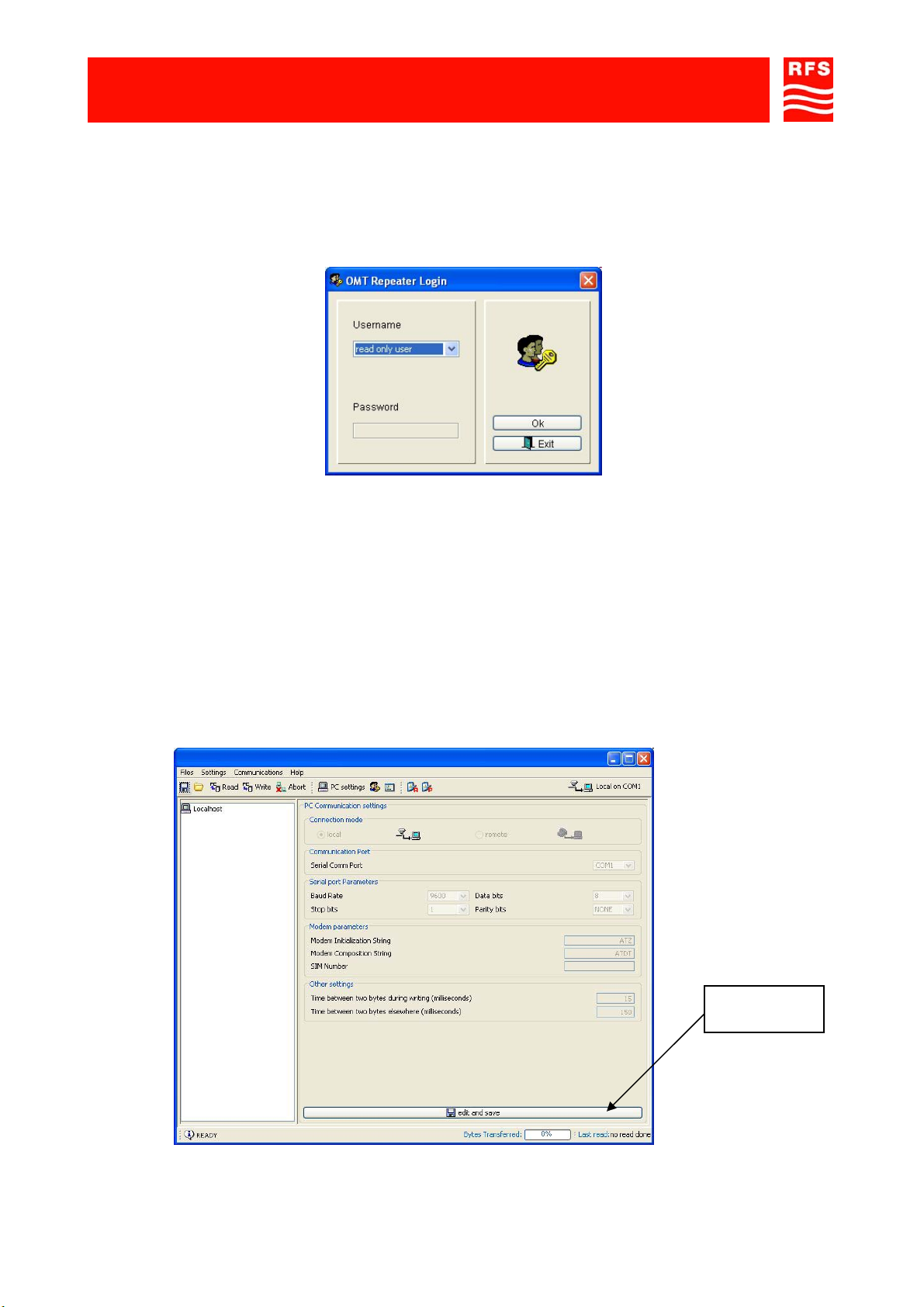

The window ‘Communication settings’ is displayed: check that local ‘Connection mode’ is selected.

If remote Connection mode is selected it is possible to change the Connection mode as follows:

- select the ‘Edit and save’ button in the lower part of the panel to enable changes;

- select local Connection mode;

- press the ‘Edit and save’ button again to confirm.

FIGURE 8 – LOGIN PANEL

Edit and save

button

FIGURE 9 – ‘COMMUNICATION SETTINGS’ PANEL

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

CHAPTER 4

4.10

9. SET THE REPEATER GAIN, FREQUENCY CENTER AND BANDWIDTH

- Select the menu entry ‘Read’ in the ‘Device’ menu, or click the ‘

Read’ button, to read the

equipment configuration and status.

The software main window is displayed.

By means of the software set the repeater gain as described below.

NOTE

How to modify parameters:

- Click on the ‘edit and save’ button, in the lower part of the window, to enable changes to the repeater

parameters.

- Click again on the ‘edit and save’ button to save changes.

- The menu entry ‘Write’, in the ‘Device’ menu, makes it possible to apply changes to the repeater. A

password is required: default password is blank. To change the password please refer to the

software User’s manual.

a) In the tree structure of the repeater system (FIGURE 9) select the repeater (double click on

‘Repeater’): on the right side of the window, the configuration and status panels of the repeater

will be shown (Description, Spectrum, Parameters, Alarms, Communications, Advanced).

b) In the description panel, the user should select ( FIGURE

10) if the system is TDMA or CDMA.

This selection allows to load the right values of RF power transmitted by the HPAs (only for

1900MHz repeaters)

.

FIGURE 10 – Selection TDMA / CDMA

c) In the ‘Spectrum’ panel (FIGURE 11)set both ‘UL-attenuation’ and ‘DL-attenuation’ to 30 (dB) -

maximum attenuation, i.e. minimum gain.

d) Connect the cable from the donor antenna to the BTS connector on the bottom of the repeater

(ref. 52, FIGURE 3).

e) Connect the MS connector on the bottom of the repeater (ref. 56, FIGURE 3) to a spectrum

analyzer.

f) In the Spectrum panel, set the Up-link frequency center and bandwidth.

In the same panel set the repeater gain (UL-Up-link- attenuation, DL-Down-link- attenuation).

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

CHAPTER 4

4.11

PLEASE NOTE:

should it be necessary to set an attenuation greater than 15dB it is strongly recommended to

connect a fixed attenuator between donor antenna and the repeater BTS side port to avoid

BTS desensitisation due to excessive radiated up-link noise.

g) Check via the spectrum analyzer that the output signal level (MS side) is correct.

When the output signal level is correct, disconnect the spectrum analyzer.

FIGURE 11 – ‘SPECTRUM’ PANEL

If the repeater is used in stand-alone configuration, connect the cable from the service antenna to

the MS connector on the bottom of the repeater (ref. 56, FIGURE 3).

If the repeater is the head station of an optical fiber system, refer to the OPTICAL FIBER COVERAGE

SOLUTIONS technical handbook to install and set Master Unit and Remote Units.

If the repeater is part of a cascade system, refer to the IN-LINE AMPLIFIERS technical handbook to

install and set in-line amplifiers.

During operation the equipment can be managed, both in LOCAL and in REMOTE mode, via the software.

In REMOTE mode the equipment is managed via a modem link. On the repeater side the modem is

installed within the equipment management module.

If installing /removing the SIM card from the built-in modem is necessary, please refer to the following

procedure 6b (HOW TO INSTALL/REMOVE THE SIM CARD FROM THE BUILT-IN MODEM).

For details regarding the software, please refer to the software User’s manual.

4.3) ROUTINE MAINTENANCE

This equipment does not require any ORDINARY MAINTENANCE (or preventive maintenance) servicing.

1800MHz-1900MHz Off-Air Repeaters (OR Series) Page 91 080 0701F – Rel.04

CHAPTER 4

4.12

ABBREVIATIONS AND ACRONYMS

AC Alternating Current

ALC Automatic Level Control

BDA Bi-Directional Amplifier

BTS Base Transceiver Station

DC Direct Current

DCS Digital Cellular System

EGSM Enhanced Global System for Mobile Communications

EMC Electro-Magnetic Compatibility

FET Field-Effect Transistor

GSM Global System for Mobile Communications

GSM-R GSM - Railway

HPA High Power Amplifier

IF Intermediate Frequency

IP3 Third order Intercept Point

LNA Low Noise Amplifier

MMIC Monolithic Microwave Integrated Circuit

MS Mobile Station

MTBF Mean Time Between Failures

MU Master Unit

NF Noise Figure

OMC Operation and Maintenance Center

OMT Operation and Maintenance Terminal

PC Personal Computer

PEP Peak Envelope Power

PLL Phase-Locked Loop

PSTN Public Switched Telephone Network

RAM Random Access Memory

RF Radio Frequency

RL Return Loss

RU Remote Unit

SAW Surface Acoustic Wave

SIM Subscriber Identity Module

SPV Supervision

TTL Transistor, Transistor, Logic

UMTS Universal Mobile Telecommunications System

UPS Uninterruptible Power Supply

VCO Voltage Controlled Oscillator

ABBREVIATIONS AND ACRONYMS

Loading...

Loading...