RF Hunter HF FOG130 Installation Manual

INFORMATION ENCLOSED:

HF 080, HF 130 & HF 165

•

Specifications

•

Assembly & Operating Instructions

•

Parts List

•

Service Instructions

ECCO ONE

•

Specifications

•

Assembly & Operating Instructions

•

Parts List

•

Service Instructions

MINI MAX III

•

Specifications

•

Assembly & Operating Instructions

•

Parts List

FOG 065 & FOG 130

•

Specifications

•

Assembly & Operating Instructions

•

Parts List

•

Service Instructions

Important Information

Filter Powder Instructions

Limited Warranty

Important Safety Instructions

Fryer Puck Information

2011 List Pricing

2011 Filtrator Price List

2011 ECCO ONE Price List

2011 MINI MAX Price List

2011 FOG Price List

2011 Standard Stock Items with Pricing

ITEM # _______________

R.F. HUNTER CO., INC. FILTRATOR (Electric)

FILTRATOR (Electric)

R.F. Hunter Co., Inc. has been designing, selling and servicing

commercial quality filtrators for over 65 years. We offer a full

range of models and sizes to accommodate

65 lb. to 130 lbs. and F.O.G. units at 65 lbs. and 130 lbs. plus

filters, Filtrator compound and replacement parts.

MODEL # HF 80, HF 130 & HF 165

Description

All FILTRATOR filters are completely

self contained - cart, container and power

unit combined into one compact portable

unit. The container, container cover, cart,

power unit housing, base, and “T” handle

are stainless steel. All other exterior

surfaces are nickel-plated steel. Pumps

are specially machined to handle high

temperature edible oils. The specially

fabricated 48” hose is designed for the

same purpose with embedded wire

reinforcement. The unit is equipped with

a ½ H.P. heavy-duty motor. The 15 ½ x

15 ½ square screen can be used with either

a cloth filter for heavy sediment

conditions or a paper envelope for light

sediment conditions.

Electrical Specifications

110-115 VAC, ½ H.P., 60 HZ, 8.8-7.4

AMP, 1.0 SF. Equipped with oil proof

lead wire cord and molded 3 prong

grounding plug. Thermal and torque

overload protection also provided.

Standard Accessories

2 Filter Cloths Bags (FB03) or

50 Filter Paper Envelopes (FE09)

25 Ind. Packets of Filter Powder (FP22D)

Pre Filter Assembly for HF 80 (FA09)

Pre Filter Assembly for HF 130/165

(FA10)

Optional Accessories

Extension Cord

113 Crosby Road, Suite. #9, Dover, NH 03820-4370

Tel: (603) 742-9565 Fax: (603) 742-9608 (800) 332-9565

Email: sales@rfhunter.com Visit our website at: www.rfhunter.com

HF SERIES ELEC FRONT 1-11

ITEM # _______________

SPECIALISTS IN KITCHEN ECONOMY SINCE 1945

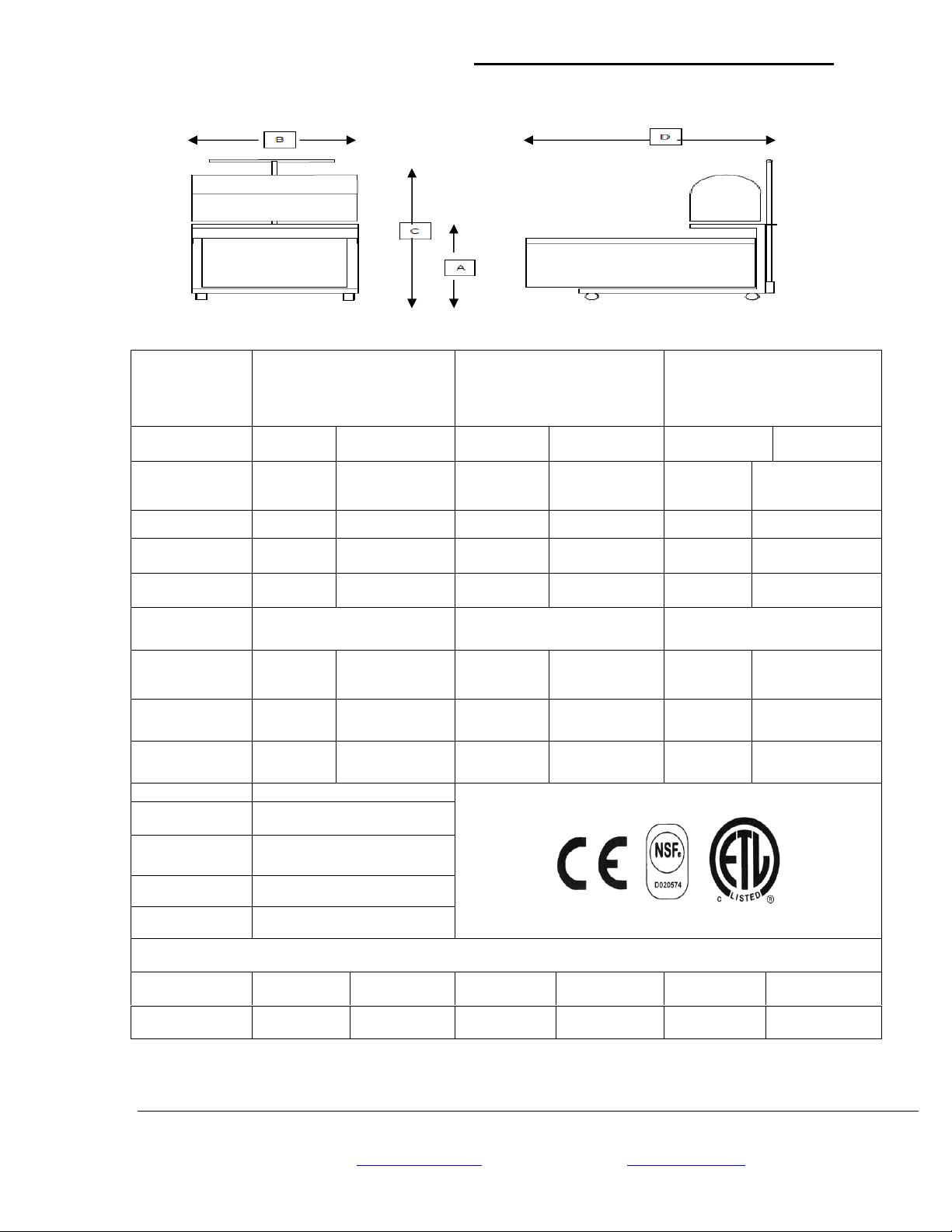

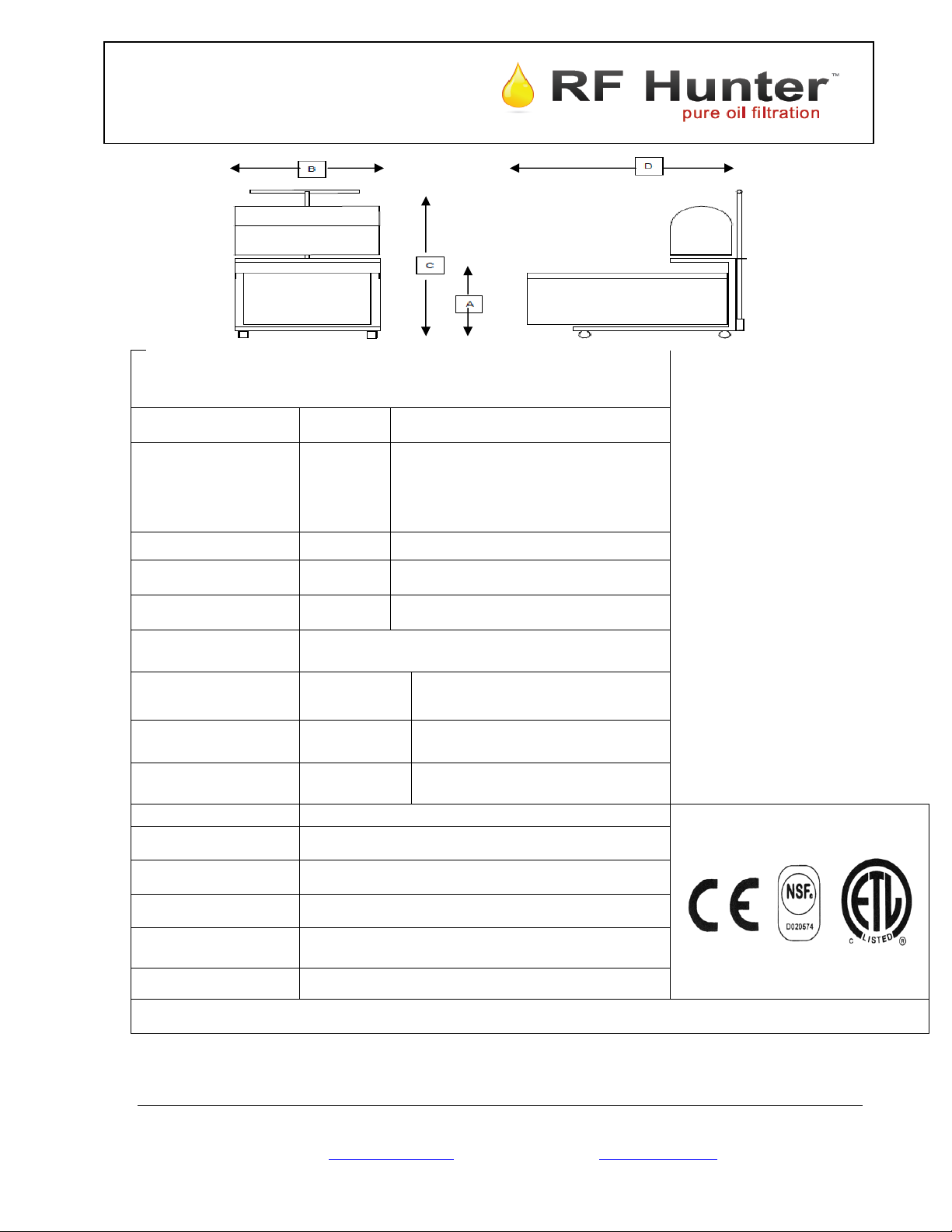

MODEL #: HF SERIES

R.F. HUNTER CO., INC.

HF 80 (ELECTRIC)

DIMENSION

A

B 16.375” 41,59 cm 19.375” 49,21 cm 19.375” 49,21 cm

C 27” 68,58` cm 27” 68,58 cm 31.75” 80,61 cm

D 26.50” 66,25 cm 30.5” 77,47 cm 30.50” 77,47 cm

Filter Media Cloth Bag or Paper Envelope Cloth Bag or Paper Envelope Cloth Bag or Paper Envelope

Container

Capacity

Shipping

Weight

Shipping Cube*

Electrical (ALL MODELS)

Volts 110-115

112 lbs 50,89 Kgs 122 lbs 55,42 Kgs 127 lbs 57,68 Kgs

12.5 cu.

MODEL

HF 130 (ELECTRIC)

US METRIC US METRIC

11.75” 29.85 cm 11.75” 29,85 cm 15.25” 38,74 cm

80 lbs. 36,3 litres 130 lbs 58,9 litres 165 lbs. 74,8 litres

Ft.

,35 cu. Meters 12.5 cu. Ft. , 35 cu. Meters 12.5 cu. ft. ,35 cu. meters

MODEL

MODEL

HF 165 (ELECTRIC)

US METRIC

Amps 8.8-7.4

Phase 1

HZ 60

* If shipped common carrier. Shipment via UPS in two boxes :

Power Unit 2.6 cu. Ft. ,07 cu. meters 2.6 cu. Ft. .07 cu. meters 2.6 cu. Ft. ,07 cu. meters

Container Body 5.1 cu. Ft. ,18 cu. meters 8.3 cu. Ft ,14 cu. Meters 8.3 cu. Ft. ,14 cu meters

R.F. HUNTER CO., INC. FILTRATOR - ELECTRIC

113 Crosby Road, Ste. #9, Dover NH 03820-4370

Tel: (603) 742-9565 Fax: (603) 742-9608 (800) 332-9565

Email: sales@rfhunter.com Visit our website at: www.rfhunter.com

HF SPEC BACK E 1-11

HF

ELEC AOI

1-11

H F S E R I E S

A s s e m b l y & O p e r at i n g I n s t r u c t i o n s

Before attaching hoses to the power unit, make sure the motor is operative by plugging it into an electrical outlet and

turning on the switch. If the motor does not run, turn it off immediately and refer to the “SERVICE INSTRUCTIONS”

sheet for information. Please read the important safety instruction sheet before operating.

ASSEMBLY INSTRUCTIONS

Slide container into cart with square end to the rear of cart. Place power unit on

top of the cart with the ‘SUCTION” side (see arrow on label on top of power unit)

facing toward the container.

Filter Screen Assembly – Place filter cloth bag or paper envelope over the screen

so that the hole of the cloth bag or the paper envelope allows the threaded stem of

the filter screen to poke through. Fold cloth bag or paper envelope over the top of

the screen and place clamp over the screen to hold filter in place. Attach filter

screen stem to screen and place the filter screen assembly in the container. The

clamped end of the filter screen should be toward the rear end of the container.

Attach union nut to “SUCTION” side of the power unit. Tighten union nut by

hand only.

Once the filter screen assembly is in place, slide the container cover over the

container. The four slots of the cover should face toward the front end of the

container. The half round piece of the cover is assembled by placing the tabs

through the slotted holes.

Attach discharge hose and nozzle to “DISCHARGE” side of the power unit and

hand tighten the union nut. (Never use wrench to tighten).

Slide the “T” handle into the handle holder on the cart. Insert retaining pin

through both sides of the “T” handle holder bracket.

ASSEMBLY OF YOUR PRE FILTER

CAREFULLY place the long rod support through the top opening of the PRE

FILTER material.

Place the support rod on the container rim with the round portion of the filter

facing the rounded end of the container.

Place the flap of the PRE filter over the edge of the container. This will secure the

filter in place.

Your HF Series is now assembled & ready to operate using the operating

instructions below

OPERATION WITH YOUR PRE FILTER

Drain the oil from the fryer through the Pre filter into the container. The sediment will

become trapped allowing the oil to pass through. Once the filtering is completed and

the oil is returned to the fryer, remove the filter to your cleaning area. CAREFULLY

lift the Pre filter from the container. Allow any residual oil to drain from the Pre filter.

Once the oil has drained, dump the sediment into your waste receptacle. Wash, rinse

and dry the Peek filter and return it to its position on the container.

OPERATING INSTRUCTIONS

CAUTION: Oil/shortening will cause parts to become hot. Use care when handling to

avoid injury.

Open the door of the fryer and roll the HF SERIES up to the fryer so that the front end

of the container is under the drain valve. Plug power unit into an electrical outlet.

You are now ready to begin draining your frypot and filtering your oil/shortening.

With oil/shortening at approximately 300°F, turn off fryer and take out the

crumb screen. Sprinkle one cup (8 oz. By volume) of FILTER POWDER

into the oil/shortening per 35-40 lbs. of oil. Mix the powder into the

oil/shortening. Lift the round half piece on the cover to an upright position

to allow oil to drain into the container. When properly positioned, the

rounded cover acts as a splashguard. Open the fryer drain valve to allow

oil/shortening to drain into the HF SERIES container. Turn on the power

unit. Caution: Make sure nozzle points toward the bottom of the fryer.

Oil/shortening will be recirculated into the fryer, and by directing the

nozzle, sediment can be washed out of the frypot. When the sediment has

been completely washed out from the fryer, turn power unit off. Close

fryer drain valve, and turn on power unit. The filtered oil/shortening is

now being pumped back into the fryer.

When the oil/shortening is returned completely to the fryer, turn off the power

unit, unplug and remove the HF SERIES. Replace crumb screen and turn

on the fryer. The fryer is now ready to use.

CARE & CLEANING OF HF SERIES

CAUTION: Be sure parts have cooled before handling/cleaning.

Remove the HF SERIES to your cleaning area. Remove cover from the

container and disconnect the filter screen assembly. Turn power unit 90° so that

the discharge and suction side of the power unit overhang the shelf of the cart.

Disconnect the discharge hose/nozzle from the power unit. Allow oil/shortening

to drain from the discharge hose into the container. Put hose aside. Tip power

unit so that the discharge side of the power unit faces down toward the container

to allow the oil/shortening to drain from the pump. Return power unit to its

proper position on the shelf of the cart.

DRAINING THE PUMP IS EXTREMELY IMPORTANT

If the pump is not drained, hardened oil/shortening may prevent the pump from

rotating when the power is supplied to the motor.

While holding the screen assembly over the container, shake the screen to

remove sediment from the cloth bag or paper envelope. Remove stem from

screen and then remove cloth bag or paper envelope from the screen. Clean the

screen stem assembly, container, cover, discharge hose/nozzle by washing,

rinsing and thoroughly drying each part. The screen can be separated by holding

the screen upside down and gently tapping the threaded stem on a hard surface.

The cloth filter bag can be reused once it has been washed. The power unit

housing, cart and outside parts of the container can also be cleaned using a

stainless steel cleaner/polish.

NOTE: DO NOT RUN WATER THROUGH PUMP.

After the HF SERIES has been cleaned, reassemble the various components,

replace the cloth filter bag or paper envelope on the screen. Attach the screen

stem to the power unit as well as the nozzle/DHA. Replace the pre filter on the

container and the unit is ready for the next filter cycle.

113 Crosby Road, Ste. #9, Dover, NH 03820-4370

Tel: (603) 742-9565 Fax: (603) 742-9608 (800) 332-9565

Email: sales@rfhunter.com Visit our website at: www.rfhunter.com

HF05048

HF03PB

HF11

HF04A

HF28

HF27

HF26

HF091

HF SERIES

P

arts List

(Electric)

HF2515

HF18EXT

HF09

*HF02

HF92

*HF04

FA09

HF91CL

HF03P

FA10

HF12

*HF01

HF18EXT

HF13

See enlarged view of FILTRATOR™ Power Unit (HF13) on reverse side.

113 Crosby Road, Ste. #9, Dover NH 03820-4370

Tel: (603) 742-9565 Fax: (603) 742-9608 (800) 332-9565

Email: judy@rfhunter.com Visit our website at: www.rfhunter.com

HFPLFRONT 9-10

* HF01 CONTAINER

HF091 UNION NUT ASSEMBLY

HF21 MOTOR/PUMP

HF21C CLOSED COUPLING PUMP & MOTOR

HF20

HF16WP

HF18D

HF21C

HF22

HF23 HF16G

HF14

HF19

HF17

HF155

HF SERIES PARTS LIST

HF18EXT

Stainless steel construction rectangular with one rounded end.

All containers have corners.

For Models:

80 (24”L x 16”W x 8.5”D)

130 (28”L x 19”W x 8.5”D)

165 (28”L x 19”W x 12”D)

* HF02 CART

Stainless steel frame with four 2” diameter casters mounted

underneath. For Models:

80 (18 ¼ ”L x 16 ¼”W x 11 ½””D)

130 (19 ¾” L x 19 ¼”W x 11 ½”D)

165 (19 ¾”L x 19 ¼”W x 15 ¼”D)

HF03P CASTER

2” diameter wheel located under cart.

HF03PB CASTER WITH LOCK

2” diameter. Wheel with lock located under cart.

* HF04 CONTAINER COVER

Two piece stainless steel, round with knob and rectangular

with slot. For Models:

80 ( 16 ¼” x 24 ¼”)

130 (19 ¼” x 28”)

165 (19 ¼” x 32”)

HF04A CONTAINER COVER KNOB

Black, round attaches to ½ round piece of container cover.

HF05048 DISCHARGE HOSE

½” diameter., 48” length, wire reinforced hose with 2 hose

nipples and ferrules.

HF06048 DISCHARGE HOSE ASSEMBLY

½” wire reinforced hose with 2 hose ferrules and 2 hose

nipples and union nut assembly. 48” long.

HF07 STREET ELBOW

½” 90° street elbow attached to hose nipple and/or screen

stem piping. Part of union nut assembly.

HF08 BALL END

Screws onto ½” street elbow and attaches union nut to the

pump nipple socket. Part of Union Nut Assembly (HF091)

HF09 UNION NUT

Octagonal shaped with 2 molded yellow handles, inside

thread. Attaches screen stem assembly and discharge hose

assembly to pump nipple sockets of power unit. Part of

HF091-Union Nut Assembly.

Consists of HF07, HF08 & HF09. Attaches discharge hose

and stem assemblies to pump nipple sockets.

HF1106 48” DHA WITH NOZZLE

Consists of HF06048 & HF11.

HF11 DISCHARGE NOZZLE

Nickel plated pipe with black handle. Attaches to

discharge hose assembly.

HF12 DISCHARGE NOZZLE HANDLE

Black, phenolic, to fit discharge nozzle.

HF13 POWER UNIT

Stainless Steel Construction “Mailbox” shape, includes

motor/pump combination, housing., base, housing handle,

rocker switch, rocker switch guard, lead wire, pump

nipples/sockets, grommets & base.

HF14 POWER UNIT HOUSING

Stainless steel “Mailbox” cover. Includes housing handle,

grommets, switch, switch guard & lead wire.

HF155 POWER UNIT HOUSING HANDLE

Located on top of Power Unit Housing

(5” center to center).

HF16WP2 POWER UNIT SWITCH (Rocker)

Black phenolic rocker on/off switch.

HF16G POWER UNIT SWITCH GUARD

HF17 GROMMET

Black rubber piece located on each side of power unit

housing.

HF18D LEAD WIRE ( 6 inches in length)

3 wire electrical cord.

HF18EXT EXTENSION CORD

Lead wire extension cord.

HF19 PUMP NIPPLE

½” x 4” nickel plated piping, screws into pump through

power unit housing.

HF20 PUMP NIPPLE SOCKET

Attaches to pump nipple. Union nut screws onto socket to

attach discharge hose or stem assembly to power unit.

HF20C PUMP NIPPLE SOCKET ASSEMBLY

Consists of HF19 & HF20.

113 Crosby Road, Ste. #9, Dover NH 03820-4370

Tel: (603) 742-9565 Fax: (603) 742-9608 (800) 332-9565

Email: judy@rfhunter.com Visit our website at: www.rfhunter.com

One piece, closed coupling motor/pump combination. For pre

2001 Power Unit Models.

WITH CAPACITOR

One piece, closed coupling motor/pump combination. For

power units sold after 2001.

HF22 POWER UNIT BASE

Stainless steel rectangular piece with base feet and plastic

cover for reset button access.

HF23 BASE FEET

Located on bottom of the power unit base.

* HF24 SCREEN STEM ASSEMBLY

Includes rectangular 2 piece screen (HF2515), screen stem

nut (HF26), stem piping (HF27), union nut assembly

(HF091) & clamp (HF28).

80 & 130 (1/2” x 13 ¼”)

165 (1/2” x 171/2 ”)

HF2515 FILTER SCREEN

2 piece nickel plated filter screen 15 ½” x 15 ½”. Used

with filter paper envelope (FE09) or square cloth filter bag

(FB03).

HF26 SCREEN STEM NUT

Cone shaped nut attached to piping. Screws onto threads

of square screen.

* HF27 SCREEN STEM PIPING

One piece ½” diameter nickel plated piping, bent in one

location. For Models:

80 & 130 (1/2” x 13 ¼”)

165 (1/2” x 17”)

HF28 CLAMP

Stainless steel construction used to hold paper envelope on

filter screen.

HF91CL “T” HANDLE ASSEMBLY

HF92 HANDLE GRIP FOR “T”

HANDLES

HF93 RETAINING PIN

For “t” handle not shown.

FA09 PRE FILTER ASSEMBLY FOR HF80

FA10 PRE FILTER ASSEMBLY FOR HF130/165

HFPLBACK 1-11

SERVICE INSTRUCTIONS

ELECTRIC

These s e r v i c e i ns t r u c tions a r e i n t e n d e d a s a gui de t o c o r r e c t ce r t ai n

proble m s t h a t m a y be enc o un t e re d. If y o u h a v e any que s ti o n s , pl e a se c al l

the S e r v i c e De pa rt m e nt a t 1- 80 0 -3 3 2 - 9 56 5 .

CAUTION: ALWAYS UNPLUG UNIT BEFORE WORKING ON ELECTRICAL ITEMS.

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

1. Motor does not work

A) Loose or Broken Wire 1. Loose Wire – reattach wire to proper

B) Reset Button not Positioned Correctly 2. Remove clear plastic plug from the

terminal on switch or motor.

Broken Wire – replace with a new

one rated the same as the original.

bottom of the power unit base, reach

in and push in red button on the

motor until a “click” is heard.

Replace plastic plug before

resuming operation. For older

models it is necessary to remove the

housing to reach the reset button.

C) Defective Switch 3. Replace Switch

D) Defective Motor

E) Hardened oil/shortening in pump 5. Remove pump, disassemble and,

NOTE: To replace any component inside the Power Unit other than the fuse requires the removal of the Power Unit Housing Cover.

4. Replace Motor

using a clean cloth, remove

hardened oil/shortening from gears

and inside of pump. Reassemble

pump and insure gear shaft rotates

freely before attaching pump to

motor. Reset red button on motor.

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

1. Lack of Suction or Discharge

Action

A) Hardened oil/shortening in pump

B) Hardened oil/shortening in hose

C) Loose Fittings 8. Check tightness of fittings at screen,

C) Overused Filter Cloth Bag or Filter

Paper Envelope

D) Cracked and/or Swollen Hose

6. See 5 above.

7. Place hose near heat source to

loosen hardened oil/shortening.

Place drip pan under hose to contain

oil.

stem, ball end, union nut and pump

nipple socket.

9. Replace Cloth Filter Bag or Filter

Paper Envelope.

10. Replace Hose

113 Crosby Road, Ste. #9, Dover, NH 03820-4370

Tel: (603) 742-9565 Fax: (603) 742-9608 (800) 332-9565

E-mail:

sales@rfhunter.com

Visit our website at

www.rfhunter.com

HFSI ELEC 9-10

ITEM # _______________

R.F. HUNTER CO., INC. ECCO ONE (Electric)

ECCO ONE (Electric)

R.F. Hunter Co., Inc. has been designing, selling and

servicing commercial quality filtrators for over 65 years.

We offer a full range of models and sizes to accommodate

65 lb. to 165 lbs. and FOG units at 65 lbs. and 130 lbs. plus

filters, filter powder and replacement parts.

MODEL # ECCO ONE

Description

The ECCO ONE is a 65 lb. capacity filter

designed to be used with drain type fryers.

The compact design allows for ease of

operation and storage. All metal parts are

either stainless or nickel plated steel

which provides years of carefree use. The

hose, motor and pump are specially

constructed to handle the high

temperature edible oils. The two piece

container cover provides protection to the

operator during operation. The front part

lifts to form a splashguard and the rear

portion prevents objects from falling into

the container.

Electrical Specifications

110-115 VAC, ½ H.P., 60 HZ, 8.8-7.4

AMP, 1.0 SF. Equipped with heavy duty

switch, oil proof lead wire cord and

molded 3 prong grounding plug. Thermal

and torque overload protection also

provided. Heavy-duty ½ H.P. Motor.

Standard Accessories

50 Filter Paper Envelopes (FE02)

25 Ind. Packets of Filter Powder (FP22D)

Pre Filter Assembly (FA11)

Optional Accessories

Extension Cord (HF18EXT)

113 Crosby Road, Suite. #9, Dover, NH 03820-4370

Tel: (603) 742-9565 Fax: (603) 742-9608 (800) 332-9565

Email: sales@rfhunter.com Visit our website at: www.rfhunter.com

ECCO SPEC FRONT E USA 1-11

ITEM

#______________

MODEL#: ECCO ONE ELECTRIC

SPECIFICATIONS

DIMENSION

A

US METRIC

12.00” 30,48 cm

B 17.75” 45,09 cm

C 27” 68,58 cm

D 22.00” 55,88 cm

Filter Media Cloth Bag or Paper Envelope

Container Capacity 65 lbs. 29,5 litres

Shipping Weight 107 lbs 48,62 Kgs

Shipping Cube* 12.5 cu. Ft. ,35 cu. Meters

Electrical

Volts 110-115

Amps 8.8-7.4

Phase Single

HZ 60

Plug Configuration NEMA 5-15P

R.F. HUNTER CO., INC. ECCO ONE ELECTRIC

* If shipped common carrier. Shipment via UPS in two boxes of 2.6 cu. Ft. (,07 cu meters) and 6.2 cu. Ft. (,18 cu meters)

113 Crosby Road, Ste. #9, Dover NH 03820-4370

Tel: (603) 742-9565 Fax: (603) 742-9608 (800) 332-9565

Email: sales@rfhunter.com Visit our website at: www.rfhunter.com

ECCO SPEC BACK E USA 1-11

Loading...

Loading...