Page 1

HAZARD INTENSITY LEVELS

g

p

1. DANGER: Failure to comply will result in severe

personal injury or death and/or property damage.

2. WARNING: Failure to comply could result in severe

personal injury or death and/or property damage.

3. CAUTION: Failure to comply could result in minor

personal injury and/or property damage.

Optional Hanger Kits

Option Installation Form RZ-NA I-OPT-HK

(Version A.1)

Obsoletes Form I-OPT-HK Version A

APPLIES TO: Hanger Kit Options CK3,

CK7, CK8, CK9, CK10, CK19

Description/Application/Table of Contents

Description, parts listing, and illustrated instructions are provided for each hanger kit. These kits are designed

only for the models and applications described below. See the referenced heater installation manual for clear-

ances (top, sides, bottom, front, and rear), suspension dimensions, and weights. Suspension of the heater is the

responsibility of the installer.

Option

Kit

CK3

CK7

CK8

CK9

CK10

CK19

Description

Swivel Connections

for 1" Pipe for 4-pt

Suspension

4-pt Suspension

Conversion

Swivel Connections

for 2" pipe for 2-pt

Suspension

4-pt Suspension

Conversion Plus

Swivel Connections

Swivel Connectors

for 1" Pipe for 4-pt

Suspension

Alternate Sus

Points providing

nearly equal loading

at four points

ension

Use with

Models

(H)EEDU Duct

Furnace

F To add two hanger brackets for changing

UDAP; UDAS; F To adapt a unit with 2-pt suspension so

F To add two han

LDAP Packaged

Heaters; UDAP;

UDAS; UDBP;

UDBS; B; OH;

OB; RA; RAD;

and F with

optional 4-pt

suspension

B Suitable for units equipped with isolation

To adapt the duct furnace so that it may be

suspended from threaded 1" stationary

pipes.

from standard 2-pt suspension to 4-pt

suspension.

that it may also be suspended from two

threaded stationar

standard 2-pt suspension to 4-pt

suspension and adapt the unit so that it

may be suspended from four threaded 1"

stationary pipes.

To adapt a unit with 4-pt suspension so

that it may be suspended from four

threaded 1" stationary pipes.

vibration suspension and or seismic protectio n with lo nger than 10" rod hangers.

Option CK19 changes the suspension

points and suspension dimensions.

Application Page

y pipes.

er brackets to change from

Reference Heater Installation Manual

by Model

2 EEDU and HEEDU - Form RZ-NA I-

EEDU

2-3 F - Form RZ-NA I-F/B

3-4 UDAP and UDAS - Form RZ-NA I-

UDA

F - Form RZ-NA I-F/B

4 F - Form RZ-NA I-F/B

5-6 LDAP - Form RZ-NA I-LDAP

UDAP and UDAS - Form RZ-NA IUDA

UDBP and UDBS - Form RZ-NA IUDB

B and F - Form RZ-NA I-F/B

OH and OB - Form RZ-NA I-OH/OB

RA and RAD - Form RZ-NA IRA/RAD 140/235

RA and RAD - Form RZ-NA IRA/RAD 350/500

7-8 B - Form RZ-NA I-F/B

Other Ce iling Bracket for Unit Heaters - Option CK22 is available for small sizes of Models UDAP and UDAS.

Hanger See Supplemental Installation Form RZ-NA I-UD-CS.

Kits Infrared Models - Options CK11-CK18 are not included in this form. Options CK11-CK18 are hanging chain and

turnbuckle kits for tubular infrared heaters. For parts lists and instructions for hanger and turnbuckle kits, see Supplemental Installation Form RZ-NA I-VR-HK and/or RZ-NA I-VR/TRP/TR-TK. Hanging chain for infrared high intensity

heaters is Option UE1 or UE2. See Heater Installation Manual, Form RZ-NA I-RIH.

WARNING: The instructions in this sheet are written for adding new suspension points or

preparing a heater for suspension prior to installation. If your heater is installed, for your

safety, turn o the gas and the electric before adding or changing suspension. Follow the

instructions on the heater to restart. Check for proper operation.

Form I-OPT-HK (Version A.1), Mfg #98346 (Rev 4), Page 1

Page 2

Option Kits and Instructions

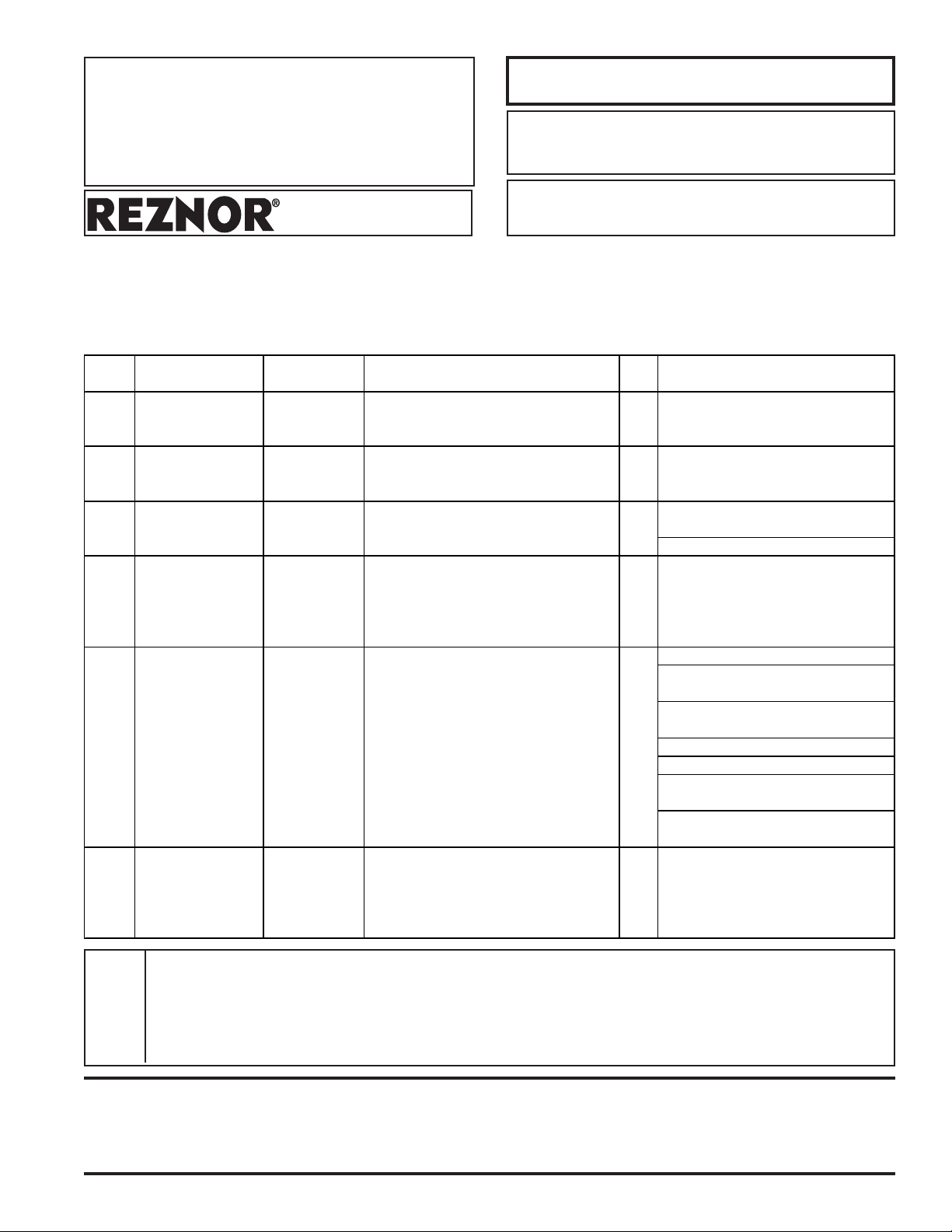

OPTION CK3 Swivel Connectors

for Model Series

EEDU

CAUTION: Check to be

sure that all swivels turn

freely.

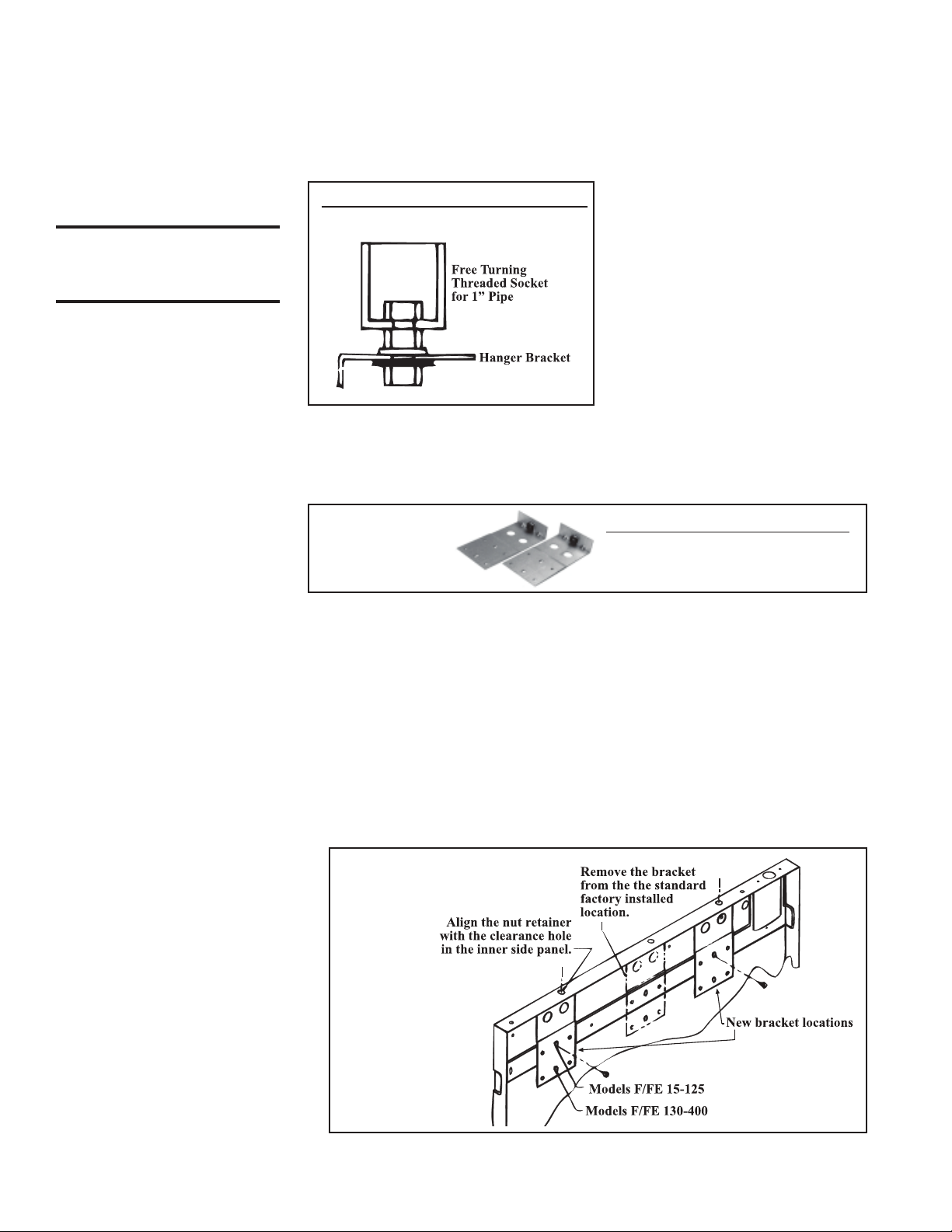

OPTION CK7 4-Point

Suspension for

Models F

This option is designed to add swivel connections to a Model (H)EEDU duct

furnace to suspend a single furnace from four 1" threaded stationary pipes.

Option CK3 (Package P/N 57959) includes:

Qty Description P/N

4 Swivel Connector Assy 9557

FIGURE 1

This option is designed to convert a Model F with standard 2-point suspension

to 4-point suspension.

Instructions

1. Remove lockwasher and nut

from swivel connector.

2. Put bolt down through hole in the

hanger bracket.

3. Attach securely with lockwasher

and nut.

4. Repeat on all hanger brackets.

Option CK7 (Package P/N 98508) includes:

FIGURE 2A

- Hanger Kit

Option CK7

Qty Description P/N

2 Hanger Bracket 96386

Assembly

(NOTE: Also applies to

obsolete Model FE.)

Installation Instructions for Option CK7

Tools Required - 5/16" Nut Driver

1. Remove the heater from the carton.

Remove the wooden crate bottom from the bottom of the heater.

Remove one of the heater outer side panels.

2. Remove the Factory-Installed Hanger Bracket Assembly

Remove the two screws that are holding the factory-installed hanger bracket

assembly to the heater. Re-insert the two screws (without the hanger bracket)

into the same holes in the heater inner side panel.

3. Determine the new locations for the two hanger bracket assemblies (one from

the kit and the one removed in Step 2). See FIGURE 2B.

FIGURE 2B - New

Bracket Locations

4. Install Hanger Bracket Assemblies - Remove the screw from the inner side

panel at one of the new locations. Position one of the hanger bracket assemblies

Form I-OPT-HK (Version A.1), Mfg #98346 (Rev 4), Page 2

Page 3

so that the nut retainer is aligned with the clearance hole in the top of the side

panel. Insert the screw removed from the side panel through the center slotted

hole in the hanger bracket. Adjust the bracket so that it is tight against the top of

the heater. Tighten screw securely.

Following the same procedure, attach the other hanger bracket assembly at

the second location. Replace the outer side panel.

5. Remove the outer side panel from the opposite side and repeat Steps 2-4 on that

side.

6. Installation of the 4-point suspension hanger kit is complete. Since the crate bot-

tom has been removed, protect the bottom of the heater with plywood or other

appropriate material. If the bottom is not supported, the bottom access panel

could be damaged.

Follow the instructions in the heater installation manual to complete the

installation of your heater.

OPTION CK8 2-Pt Suspension

with Swivel

Connectors Models UDAP,

UDAS, and F

(NOTE: Model F instructions

also apply to obsolete Model

FE.)

CAUTION: Check to be

sure that all swivels turn

freely.

The purpose of this option is to adapt a Model F heater with standard 2-point

suspension so that it can be suspended using two 1", threaded stationary pipes.

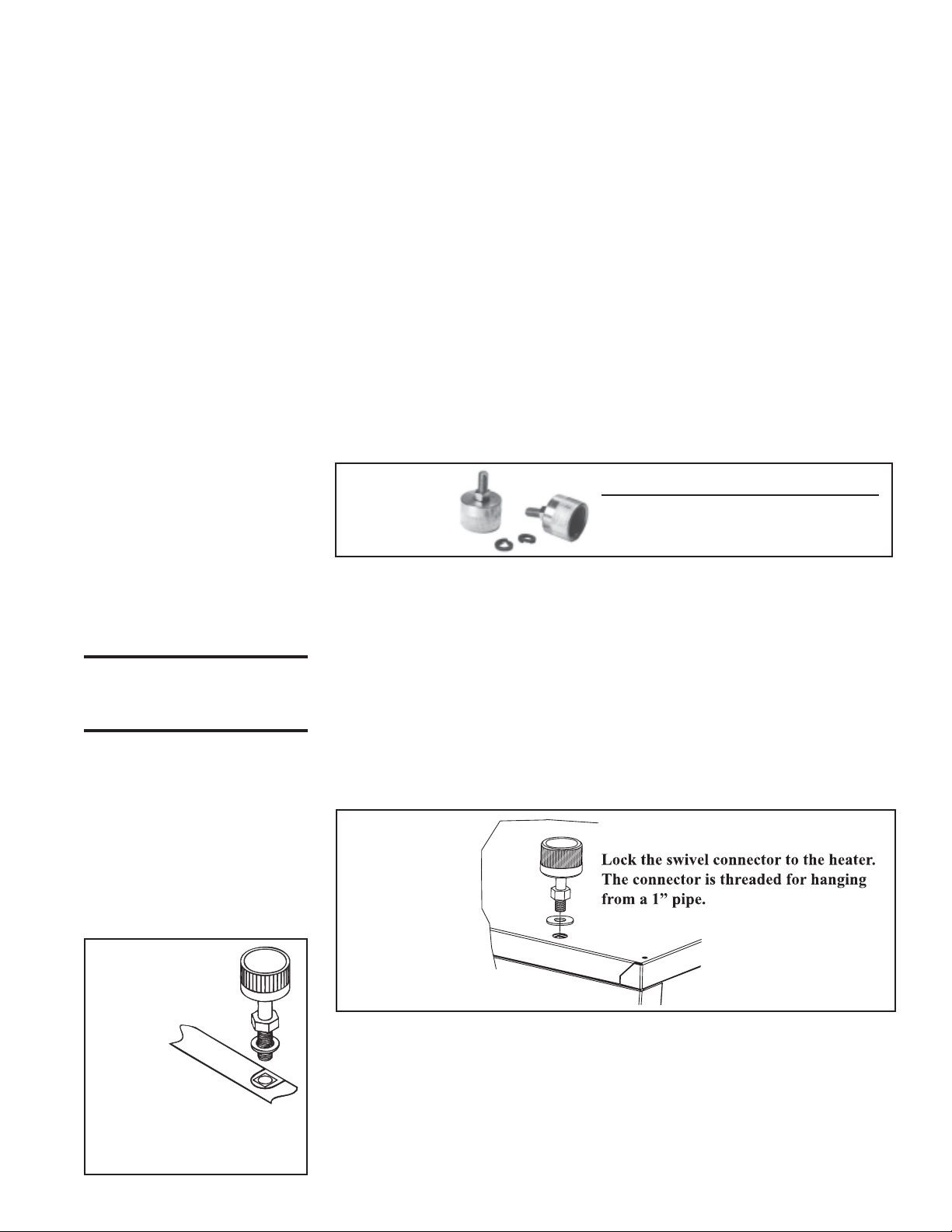

Option CK8 (Package P/N 98509) includes:

FIGURE 3A Hanger Kit,

Option CK8

Qty Description P/N

2 Swivel Connector Assy 17627

2 3/8" Lockwasher 5197

Installation Instructions for Option CK8

Tools Required - 9/16" Open-End Wrench

Models UDAP and UDAS (FIGURE 3B)

1. Locate the threaded suspension holes in the top of the heater cabinet that are

used for 2-pt suspension (center holes).

2. Place a lockwasher over each hole.

3. Screw the swivel hanger connector assembly into the heater's cage nut retainer.

(The lockwasher must be between the top panel and the swivel hanger connector assembly.) Tighten firmly.

NOTE: If installing a Model UDAS, be certain that the unused suspension holes on

the control side are plugged. Follow the heater installation instructions.

FIGURE 3B Model UDAP

or UDAS

FIGURE 3C

- Model F

Do NOT

capture

outer panel; it must be

removable for future

service.

Model F (FIGURES 3C & 3D)

1. Locate the two hanger bracket holes in the top of the heater cabinet.

2. Place a lockwasher over the hole, being careful not to catch the cutout portion of

the painted side panel. The outer panel must remain removable for future service. See FIGURE 3C.

3. Screw the swivel hanger connector assembly into the hanger bracket. (The

lockwasher must be between the inner heater side panel and the swivel hanger

connector assembly). Tighten firmly. See FIGURE 3D.

Form I-OPT-HK (Version A.1), Mfg #98346 (Rev 4), Page 3

Page 4

Hanger Option Kits and Instructions (cont'd)

OPTION CK8 2-Point

Suspension with

Swivel Connectors

-Models UDAP,

UDAS, and F

(cont'd)

OPTION CK9 4-Point

Suspension with

Swivel Connectors

- Models F only

(NOTE: Also applies to

obsolete Model FE)

FIGURE 3D - 2-Point

Suspension with Swivel

Connectors - Model F

Models UDAP, UDAS, and F

4. Repeat Steps 2 and 3 at the other suspension point.

5. Installation of the 2-point swivel connection kit is complete. Follow the instruc-

tions in the heater installation manual to complete installation of the heater.

This option is designed to convert a Model F with standard 2-point suspension

to 4-point suspension with swivel connectors.

Option CK9 (Package P/N 98510) includes:

Qty Description P/N

2 Hanger Bracket Assembly 98386

4 Swivel Connector Assembly 17627

4 3/8" Lockwasher 5197

CAUTION: Check to be

sure that all swivels turn

freely.

FIGURE 4A - Swivel 4-pt

Hanger Kit, Option CK9

Installation Instructions for Option CK9

Tools Required - 9/16" Open-End Wrench; 5/16" Nut Driver

1. Convert to 4-point Suspension - Refer to instructions for Option CK7 on

pages 2-3. Follow Steps 1 through 5 to convert the heater to 4-point suspension.

2. Install Swivel Connectors - Refer to instructions for Option CK8 on page 3.

Follow Model F Steps 1 through 3 to install the swivel connection. Attach a

swivel at each suspension point. See FIGURE 4B.

3. Installation of the 4-point suspension kit with swivel connections is complete.

Since the crate bottom has been removed, protect the bottom of the heater with

plywood or other appropriate material. If the bottom is not supported, the bottom

access panel could be damaged.

Follow the instructions in the heater installation manual to complete the installation of your heater.

FIGURE 4b - 4-Point Suspension

with Swivel Connectors - Model F

Form I-OPT-HK (Version A.1), Mfg #98346 (Rev 4), Page 4

Page 5

OPTION CK10 4-Point

Suspension with

Swivel Connectors

(Models LDAP;

UDAP, UDAS;

UDBP, UDBS; F, B;

OH, OB, RA, RAD See paragraph for

specific

applications)

(NOTE: Model F kits also

apply to obsolete Model FE.

Model B kits also apply to

obsolete Model BE.)

CAUTION: Check to be

sure that all swivels turn

freely.

This option is designed to add swivel connectors to a Model F unit heater that

is already equipped with optional 4-point suspension or to a Model LDAP,

UDAP, UDAS, UDBP, UDBS, B, OH, OB, RA or RAD heater that is standardly

equipped with 4-point suspension. The four swivel connections allow the heater

to be suspended from four 1", threaded stationary pipes.

Option CK10 (Package P/N 98511) Swivels for 3/8"

hanger rods/brackets includes:

Qty Description P/N

4 Swivel Connector Assy 17627

8 3/8" Lockwasher 5197

4 3/8" Hex Nuts 1438

FIGURE 5A - Swivel Hanger Kit,

P/N 98511, for 3/8" Hanger Brackets

Applications: All sizes of Models UDAP/UDAS ; all sizes of Models UDBP/

UDBS ; all sizes of Models F/B ; all sizes of Models OH/OB manufactured

prior to 10/94; and Models RA/RAD 110/140/235 manufactured prior to 10/

94.

Option CK10 (Package P/N 134477) Swivels for 1/2"

hanger rods/brackets includes:

Qty Description P/N

4 Swivel Connector Assy 134476

4 1/2" Lockwasher 45549

Installation

Instructions for

Option CK10

FIGURE 5B - Swivel Hanger Kit,

P/N 134477 for 1/2" Hanger Brackets

Applications: All sizes of Models OH/OB/RA/RAD manufactured beginning

10/94 (NOTE: Models RA/RAD 350 manufactured prior to 10/94 have 7/16"

hanger brackets. A swivel hanger kit is not available for RA/RAD 350 with

7/16" hanger brackets.)

Option CK10 (Package P/N 207938) Swivels for 1/2"

hanger rods/brackets includes:

Qty Description P/N

4 Swivel Connector Assy 207939

4 1/2" Lockwasher 45549

FIGURE 5C - Swivel Hanger Kit,

P/N 207938, for 1/2" Hanger Brackets

Applications: All sizes of Model LDAP .

Select the instructions for the unit being installed.

Models UDAS, UDAP, F, B - Follow the same instructions as for Option CK8,

pages 3-4. Repeat the process at all four hanger bracket locations. (NOTE: The

four nuts and four of the washers in the kit will not be used.)

(UDAS NOTE: Be sure that any unused suspension holes on the control side

are plugged; see heater installation instructions. )

Models UDBP, UDBS - The suspension points on the hanger bar on the top of

Model UDBP and UDBS heaters are not threaded. At each hole, place a

lockwasher, insert the swivel through the lockwasher and the hanger bar. Fas-

Form I-OPT-HK (Version A.1), Mfg #98346 (Rev 4), Page 5

Page 6

Option Kits and Instructions (cont'd)

Installation

Instructions for

Option CK10

(cont'd) -- Select

instructions that

apply to Model.

IMPORTANT: Be sure the

threaded swivel connectors

are locked to the hanger bar

as illustrated.

FIGURE 5D - Suspension

of a Model OH/OB/RA/

RAD with Optional

Swivel Connectors

(Option CK10) from 1"

threaded pipe

ten securely with a lockwasher and nut. See FIGURE 5C . Repeat the proce-

dure at each suspension point.

FIGURE 5C - Installing Swivel Connections on Model UDBP

and UDBS

Models OH, OB, RA, RAD - Four eld-

supplied 3/8" or 1/2" at washers are required.

1. Place a flat washer at the threaded

suspension point as illustrated in FIG-

URE 5D.

2. Put a lockwasher on the swivel assem-

bly and screw the swivel connector into

the suspension point. Tighten firmly.

3. Repeat the procedure at the other three

suspension points.

Installation of the four swivel connectors

is complete. Follow the instructions in the

heater installation manual to complete the

installation.

FIGURE 5E Suspension of a Model

LDAP with Optional

Swivel Connectors

(Option CK10) from

1" threaded pipe

"U"-shape

tting

Strut attached to

the top of the

heater

Form I-OPT-HK (Version A.1), Mfg #98346 (Rev 4), Page 6

Swivel

Assembly

Hex Nut

Lockwasher

Spring Nut

Model LDAP

1. Put a lockwasher on the swivel assem-

bly and screw the swivel connector into

the suspension point on the "U" fitting.

Tighten firmly.

2. Repeat the procedure at the other three

suspension points. Be sure the threaded

swivel connectors are locked to the

heater as illustrated.

Installation of the four swivel connectors

is complete. Follow the instructions in the

heater installation manual to complete the

installation.

Page 7

OPTION CK19 Alternative 4-Pt

Suspension Points

for Model B Blower

Units

(NOTE: Also applies to

obsolete Model BE.)

FIGURE 6B - Suspension

Dimensions for Model B Heater

with Hanger Kit Option CK19

This option is designed so that each suspension point carries a nearly equal

load. NOTE: Suspension point dimensions change; see FIGURE 6B.

Option CK19 (Package P/N 165742) includes:

N/PnoitpircseDytQ

1 Right Side Hanger Bar 162829

1 Left Side Hanger Bar 162830

4 HHD Tap Bolts 3/8-16NCX 1-1/2, #5 114350

8 3/8" Lockwasher 5197

FIGURE 6A - Hanger Kit for

Blower Model B, Option CK19

Size

25-50

75

100

125

165

200

250-300

400

A B

inches mm inches mm

11-7/8 302 9-1/8 232

13-7/8 352 11-1/8 283

15-7/8 403 13-1/8 333

21-5/8 549 18-7/8 479

18-5/8 473 15-7/8 403

21-5/8 549 18-7/8 479

27-1/8 689 24-3/8 619

35-3/8 899 32-5/8 829

Form I-OPT-HK (Version A.1), Mfg #98346 (Rev 4), Page 7

Page 8

OPTION CK19 Alternative 4-Pt

Suspension

Points for Model B

Blower Units

(cont'd)

Installation Instructions for Option CK19

Tools Required - 9/16" Open-End Wrench

1. Locate the four hanger bracket holes in the top of the heater cabinet (two on

each side).

2. On the side of the heater where the electrical supply connects, carefully place

two lockwashers over each hanger bracket hole. From the kit, select the hanger

bar with the wider flange and the cutout hole in the center. Position the hanger

bar along the top edge of the heater on top of the washers. (Two washers are

required between the heater and the hanger bar to allow for removal of the side

panel.). Attach the hanger bar with two of the bolts, securing them to the hanger

bracket weld nut. See FIGURE 6C.

3. Attach the left side hanger bar the same way using the remaining four washers

and two bolts.

4. The heater is ready for suspension from 3/8" threaded hanger rods. Use field-

supplied hardware to attach the hanger rods as illustrated in FIGURE 6D.

FIGURE 6C - Attach a

Hanger Bar along the Top

Edge on Each Side of the

Heater (bars extend out

over the blower)

View of hanger bar hardware with heater side panel removed

(for illustration only; do not remove side panel to install)

Sequence:

Bolt

Hanger Bar

2 Washers

Heater Top Panel

Hanger Bracket Nut (behind the heater side

panel; do not remove side panel)

Two washers (from the kit) are required between

the hanger bar and the heater to provide clearance

for removing the heater side panel for service.

FIGURE 6D - Use

threaded hanger

rods to suspend the

heater from the

hanger bar

suspension points

(hardware and

rods are eld

supplied)

REZNOR

Form I-OPT-HK (Version A.1), Mfg #98346 (Rev 4), Page 8

www.ReznorHVAC.com; (800) 695-1901

© 2014 Reznor LLC, All rights reserved. Printed in the U.S.A.

MANUFACTURER OF HEATING, COOLING, AND VENTILATING SYSTEMS

Trademark Note: Reznor

10/14 Form RZ-NA I-OPT-HK (Version A.1)

®

is registered in at least the United States.

Loading...

Loading...