Form CP-CAUA-GC (01-18)

Obsoletes CP-CAUA-GC (04-15)

Gas Conversion Kits and Instructions

Applies to: Model CAUA

General and Warnings

FOR YOUR SAFETY

— WHAT TO DO IF YOU

SMELL GAS

• Do not try to light any

appliance.

• Do not touch any

electrical switch; do not

use any phone in your

building.

• Leave the building

immediately.

• Immediately call your

gas supplier from a

phone remote from the

building. Follow the gas

supplier’s instructions.

• If you cannot reach your

gas supplier, call the

re department.

— Installation and service

must be performed by

a qualied installer,

service agency, or the

gas supplier.

DANGER:

The conversion kit is to be selected and installed by a qualied

service person in accordance with these instructions and

in compliance with all codes and requirements of authorities

having jurisdiction. Failure to follow instructions could result

in death, serious injury and/or property damage. The qualied

agency performing this work assumes responsibility for this

conversion.

In Canada, gas conversion shall be carried out in accordance with the

requirements of the Provincial Authorities having jurisdiction and in

accordance with the requirements of CSA-B149.1 and .2 installation

code.

WARNING

Improper installation, adjustment, alteration, service, or

maintenance can cause property damage, injury, or death.

Read the installation, operation, and maintenance instructions

thoroughly before installing or servicing this equipment.

FOR YOUR SAFETY: Do not store or use gasoline or other

ammable vapors and liquids in the vicinity of this or any

other appliance.

HAZARD INTENSITY LEVELS used in this manual.

1. DANGER: Failure to comply will result in severe personal injury or

death and/or property damage.

2. WARNING: Failure to comply could result in severe personal

injury or death and/or property damage.

3. CAUTION: Failure to comply could result in minor personal injury

and/or property damage.

DANGER:

The gas burner in this gas-red equipment is designed and equipped to provide safe, complete

combustion. However, if the installation does not permit the burner to receive the proper supply of

combustion air, complete combustion may not occur. The result is incomplete combustion which

produces carbon monoxide, a poisonous gas that can cause death.

DANGER

Safe operation of indirect-red gas burning equipment requires a properly operating vent system

which vents all ue products to the outside atmosphere. FAILURE TO PROVIDE PROPER VENTING

WILL RESULT IN A HEALTH HAZARD WHICH COULD CAUSE SERIOUS PERSONAL INJURY OR

DEATH.

If installed as a separated-combustion system, install either the horizontal or vertical combustion

air/vent system illustrated in the heater installation manual, using the concentric adapter supplied.

All installations must comply with the combustion air requirements in the installation codes and

instructions. Units installed in a conned space must be supplied with air for combustion and

ventilation as required by Code and in the heater installation manual. Combustion air at the burner

should be regulated only by manufacturer-provided equipment. NEVER RESTRICT OR OTHERWISE

ALTER THE SUPPLY OF COMBUSTION AIR TO ANY HEATER. MAINTAIN THE VENT SYSTEM IN

PROPERLY OPERATING CONDITION.

Form CP-CAUA-GC, P/N 170635R9, Page 1

Description and

Kit Selection

NOTE: When converting

a unit with a twostage valve (Option

AG2), check for valve

manufacturer. If the unit

has a two-stage WhiteRodgers valve, a new

two-stage gas valve is

required. See page 8 for

details.

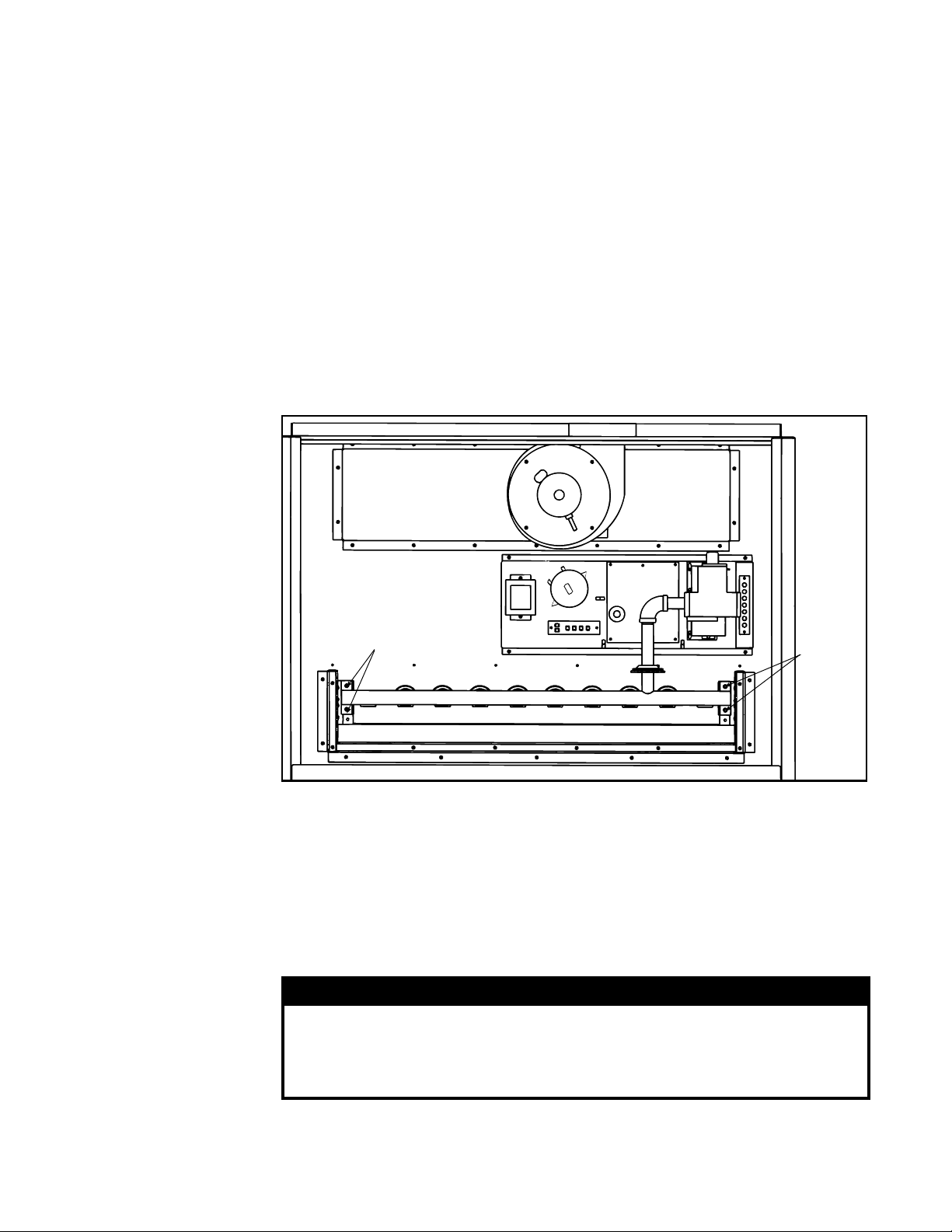

FIGURE 1 - View of

Model CAUA Control

Compartment with

Access Panel and

All Sections of

the Burner Cover

Removed

(Wires are not illustrated.)

The gas conversion kits in these instructions are for Model CAUA heaters equipped

with specic single-stage or two-stage valves (see NOTE left). The kits are for operation at sea level. See pages 5-6 for conversion kit application and components. See

page 7 for high altitude burner orices.

In order to verify which conversion kit is compatible to your heater, it is necessary to

know the type of valve that is on the heater. From the rating plate, copy the complete

Model of the heater. Also, copy the manufacturer's name and number found on the

gas valve.

IMPORTANT: Match the actual Model No. of the valve to the one listed for that kit.

If the actual Model No. is different from the one listed, contact your manufacturer

Representative to select and verify parts required for gas conversion.

Gas Conversion

1. Check kit contents to the parts list. (Parts lists are on pages 5-6.)

Instructions

2. Turn off the gas supply at a shutoff valve upstream of the combination gas valve

3. Install the Regulator Spring Kit

The manufacturer of the regulator spring kit and the gas valve

MUST be the same. Spring kits of different manufacturers are not

interchangeable, and each spring kit MUST be used only in the

Form CP-CAUA-GC, P/N 170635R9, Page 2

valve for which the kit is designated.

The conversion kits include two or three regulator spring kits -- one or two for a singlestage valve and one for a two-stage valve. Check the package carefully and choose

the regulator spring kit that corresponds with the valve on the heater. NOTE: The other

regulator spring kit(s) will not be used.

The kits listed in this manual are intended for use on units that will be operated at

sea level. Conversion of a unit using these kits will not alter the input rate. Refer to

the rating plate on the heater for input rate and other appropriate information.

and turn off the electrical supply. Open the control access panel.

WARNING

To install a regulator spring conversion kit, follow the valve manufacturer's

installation instructions that are included with the regulator spring kit. After a new

spring kit is installed, it is necessary to adjust the spring for the correct manifold

pressure. This adjustment can only be made after the heater is in operation.

Instructions are in Step No. 7.

4. Install Burner Orices

WARNING

Do not attempt to drill orices. Use factory-supplied orices only.

NOTES: Kits that apply to various sizes of heaters include the quantity of burner ori-

ces required for the largest size of heater. When converting the smaller sizes, there

will be extra burner orices which will not be used. Burner orices in these kits apply to

sea level operation only. For high altitude, see Burner Orice Chart, page 7.

1) Remove all burner cover sections. Depending on when the unit was

manufactured, there will be either two or three sections. If two, there will be

a right and a left section which extend over the front. If three, there will be a

right, a left, and a separate front section.

2) Disconnect the manifold from the valve.

3) Remove the screws that retain the manifold assembly. (See FIGURE 1.)

4) With the manifold assembly removed from the heater, unscrew all of the

existing orices and replace with the orices included in the conversion kit.

5. Re-Assemble the Heater

Reverse the procedure in Step 4 to re-assemble the heater.

Be certain that the manifold is positioned properly in relationship to the burner rack.

Attach the conversion disk to the heater near the gas valve.

6. Check for Gas Leaks

Use a commercial leak detecting uid or a rich soap and water solution. Leaks are

indicated by the presence of bubbles.

a) Turn on the gas shutoff valve upstream of the combination gas valve. Check for

gas leaks between the gas shutoff valve and the combination gas valve. If a leak

is detected, tighten the connection and recheck. When there are no leaks, turn the

manual shutoff valve off.

b) Turn on the electrical supply. Turn on the gas and follow the instructions on

the heater to relight the burner. Check all manifold connections for leaks. If a leak

cannot be stopped by tightening, turn off the gas and the electric, and replace the

part or parts until there are no leaks.

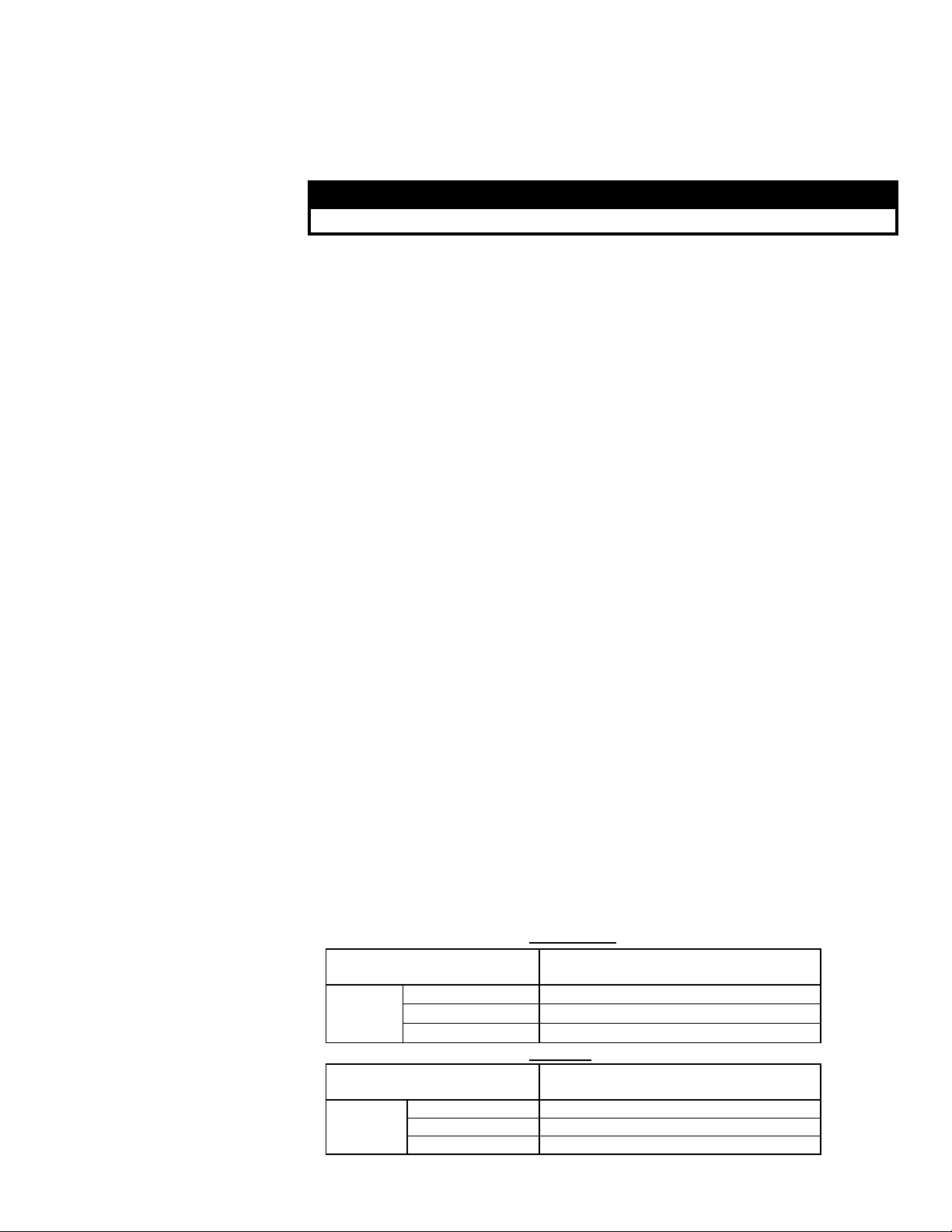

7. Measure the Manifold Pressure

Before attempting to measure or adjust the manifold gas pressure, be certain that

the inlet (supply) pressure is within the specied range (see pressure requirements

in tables below) for the gas being used both when the heater is in operation and

on standby. Incorrect inlet pressure could cause excessive manifold gas pressure

immediately or at some future time.

Follow these requirements and the instructions to measure and, if needed, adjust

the manifold gas pressure:

Pressure Requirements for Natural Gas

Inlet (Supply)Pressure

Manifold

Pressure

Pressure Requirements for Propane

Inlet (Supply) Pressure

Manifold

Pressure

Single stage 3.5" w.c.

2-stage high re 3.5" w.c.

2-stage low re 1.8" w.c.

Single Stage 10" w.c.

2-stage high re 10" w.c.

2-stage low re 5" w.c.

5" w.c. minimum (or as stated on the

rating plate); 14" w.c. maximum

11" w.c. minimum (or as stated on the

rating plate);14" w.c. maximum

Form CP-CAUA-GC, P/N 170635R9, Page 3

Loading...

Loading...