Reznor B Option Installation Manual

®

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in severe personal

injury or death and/or property damage.

2. WARNING: Failure to comply could result in severe personal injury or death and/or property damage.

3. CAUTION: Failure to comply could result in minor personal

injury and/or property damage.

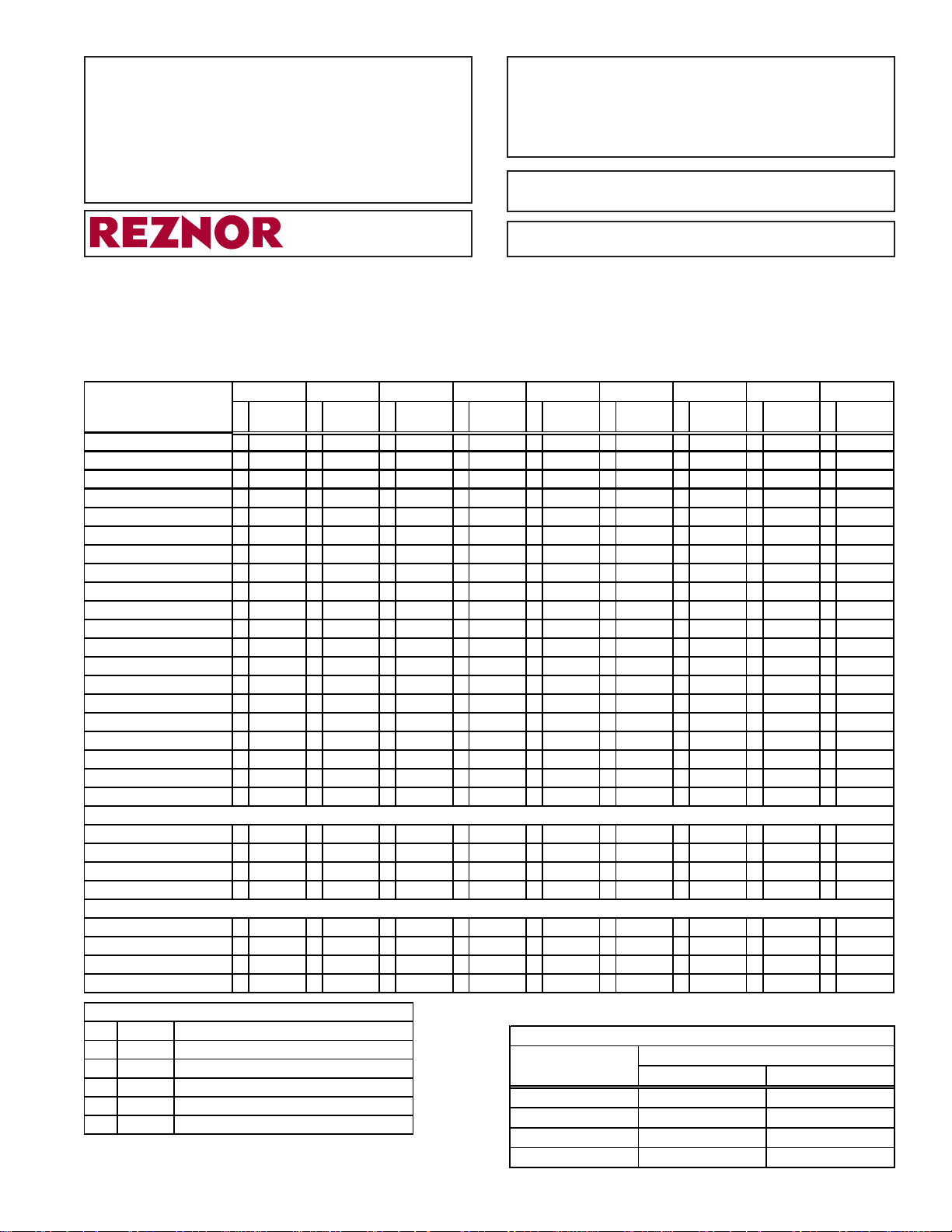

OPTIONS CW1, CW2, CW3

BLOWER/FILTER CABINET

INST ALLATION FORM RZ-NA I-B-BF

Obsoletes Form RGM 434/436-BF-A

APPLIES TO: Model B

Option Description

Application NOTE: Cabinet

also fits no longer manufactured

Reznor Model BE.

The blower/filter cabinet option is designed for field assembly and must be installed on the heater prior

to heater installation. Option CW1 includes filter racks that are adaptable for 1" or 2" filters but does not

include the filters. Option CW2 includes 1" permanent aluminium filters. Option CW3 incudes 2"

permanent filters.

Check the parts in the option package with the following list. SAVE THE CARDBOARD PACKING

INSERTS; they will be used for supports during installation.

The option 25-50 75 100 125 130 165 200 250-300 400

package includes:

Option CW1- Pkg P/N

Option CW2- Pkg P/N

Option CW3- Pkg P/N

Top and Bottom Panels

Top Right & Btm Left

Top Left and Btm Right

Stiffening Channel

Stiffening Angle

Right Side Hanger Bar

Left Side Hanger Bar

Fron t Leg s

Top Filler Panel Assy

Bttm Filler Panel Assy

Rear Legs

Door Panels

Door Stops

Cen ter Fltr Brk t Assy

Filter Angle

Filter Brack et

Parts Bag (see below)

Permanent Aluminum Filters in O ption Package CW2 only

16" x 20" x 1" -- -- -- -- -- -- -- 2 101607 -20" x 20" x 1" 1 101608 1 101608 1 101608 1 101608 -- -- -- 2 101608 -16" x 25" x 1" -- -- -- -- 1 101609 1 101609 1 101609 -- 2 101609

20" x 25" x 1" -- -- -- -- 1 101610 1 101610 1 101610 -- 2 101610

Permanent Aluminum Filters in O ption Package CW3 only

16" x 20" x 2" -- -- -- -- -- -- -- 2 101620 -20" x 20" x 2" 1 101621 1 101621 1 101621 1 101621 -- -- -- 2 101621 -16" x 25" x 2" -- -- -- -- 1 101622 1 101622 1 101622 -- 2 101622

20" x 25" x 2" -- -- -- -- 1 101623 1 101623 1 101623 -- 2 101623

Qty

P/N

101543 101544 101545 140836 101546 101547 101548 101549 101550

101628 101629 101630 140884 101631 101632 101633 101634 101635

101636 101637 101638 140885 101639 101640 101641 101642 101643

2 99707 2 99707 2 99707 2 140841 2 100642 2 100642 2 100642 -- --

-- -- -- -- -- -- -- 2 101582 2 101584

-- -- -- -- -- -- -- 2 101583 2 101585

-- -- -- -- -- -- -- 2 101551 2 101551

-- -- -- -- -- -- -- 2 101601 2 101601

1 101578 1 101578 1 101578 1 101578 1 101580 1 101580 1 101580 1 101580 1 101580

1 101579 1 101579 1 101579 1 101579 1 101581 1 101581 1 101581 1 101581 1 101581

2 99761 2 99762 2 99763 2 137404 2 100634 2 100635 2 100636 2 100637 2 100638

1 101562 1 101563 1 101564 1 140838 1 101565 1 101566 1 101567 1 101568 1 101569

1 101570 1 101571 1 101572 1 140840 1 101573 1 101574 1 101575 1 101576 1 101577

2 99708 2 99708 2 99708 2 99708 2 100639 2 100639 2 100639 2 100640 2 100641

2 99712 2 99712 2 99712 2 99712 2 100646 2 100646 2 100646 2 100646 2 100646

2 99711 2 99711 2 99711 2 99711 2 100645 2 100645 2 100645 2 100645 2 100645

-- -- -- -- 1 101624 1 101624 1 101624 1 101625 1 101626

2 99710 2 99710 2 99710 2 99710 4 101591 4 101591 4 101591 4 101592 4 101593

2 99709 2 99709 2 99709 2 99709 2 101595 2 101595 2 101595 2 101596 2 101597

1 101600 1 101600 1 101600 1 101600 1 101600 1 101600 1 101600 1 101600 1 101600

Qty

P/N

Qty

P/N

Qty

P/N

Qty

P/N

Qty

P/N

Qty

P/N

Qty

P/N

Qty

P/N

Parts Bag (P/N 101600) includes:

Qty P/N Description

118 11813 #10 x 1/2" lg Sheet Metal Screws

14 16246 #1/4 - 20 x 3/4" lg Hex Head Cap Screws

6 7328 #1/4 - 20 Hex Nuts (Keps)

1 101599 Foam Rubber Gasket (1/8"x3/4"x20"lg)

4 82177 Plastic Plug, Niagara Plastics #412-2

Duct Opening Dimensions

Dimensions of Cabinet Opening for Return Air Duct

Heater Duct Opening (inches)

Size Width Height

25-125 14-3/4 15-7/8

130-200 20-1/2 23-7/8

250-300 26 23-7/8

400 34-1/4 23-7/8

Form I-B-BF, P/N 99714 (Rev 2), Page 1

WARNING: Improper installation, adjustment, alteration, service, or maintenance can cause property

damage, injury or death. Read the installation, operation, and maintenance instructions thoroughly

before installing or servicing this equipment.

INSTALLATION INSTRUCTIONS

Installation should be done by a qualified agency in accordance with the

instructions on this sheet and in compliance with all codes and requirements of authorities having jurisdiction.

Tools Required: Ratchet or preferably cordless screwdriver with 5/16"

socket and 3/8" socket (or 3/8" wrench); 7/16" wrench

1. Preparation

All holes are punched at the factory. Use #1/4-20 x 3/4" long machine

screws where specified in the instructions. Otherwise, use the #10 x 1/2"

long sheetmetal screws.

Except for the crate bottom, remove the shipping crate from the heater.

Leave the heater attached to the crate bottom.

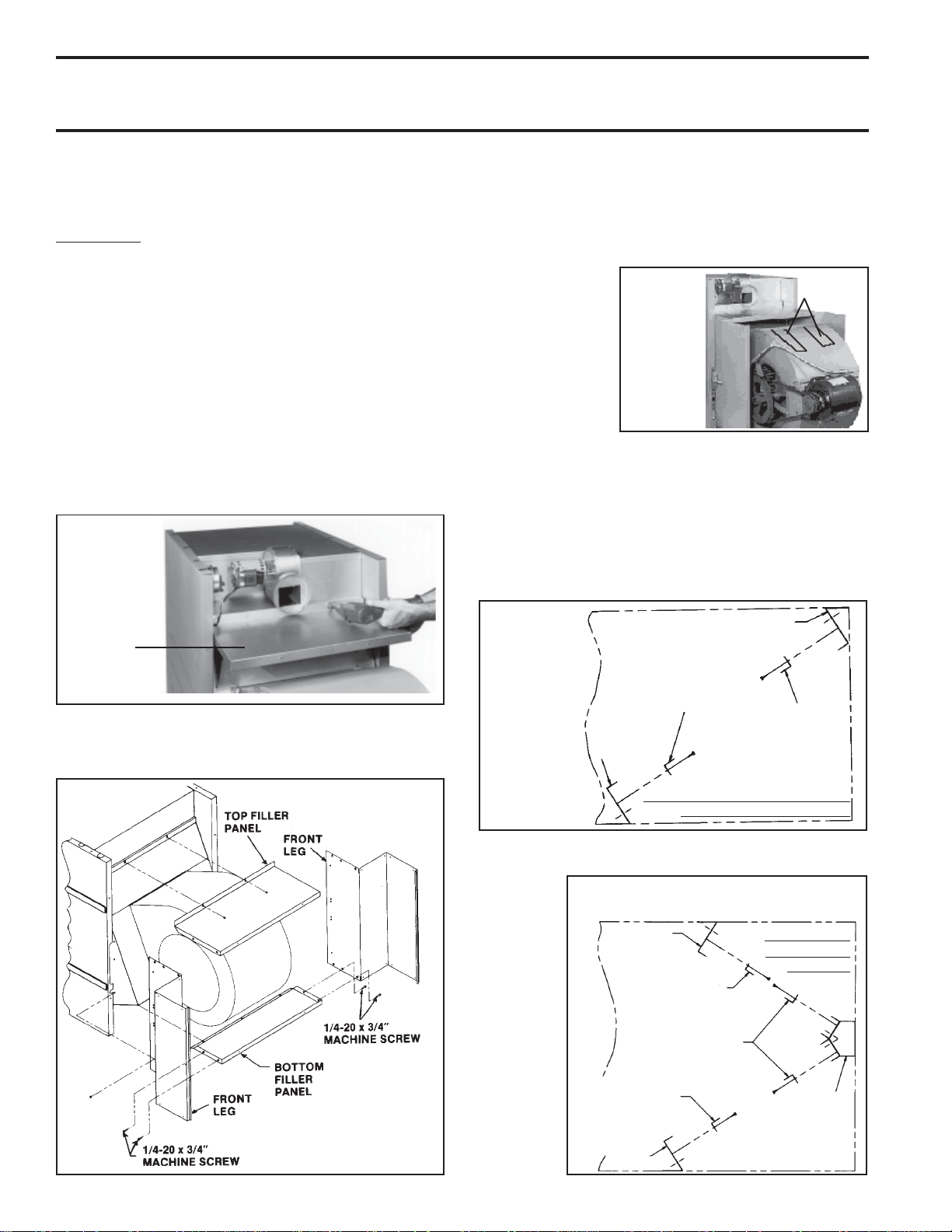

2. Install Top & Bottom Filler Panels on Heater

(Filler panels are the two unpainted pieces that "fill-in" the space between the heater and the blower cabinet.)

Install Top Filler Panel (See FIGURES 1 and 2) - Remove the screws

from the top back of the heater and re-insert them attaching the top filler

panel (use slotted holes). Position top filler panel with the rear flange

going down.

FIGURE 1 Install Top

Filler Panel

Top

Filler

Panel

Install Bottom Filler Panel (See FIGURE 2) - Locate the holes in the

bottom of the blower adapter back. Using these holes, install the bottom

filler panel with the rear flange up.

3. Install Cabinet Front Legs on Heater (See

FIGURE 2)

Slide the edge of one of the legs (legs are interchangeable) in next to the

inner side panel of the heater. Fasten the leg to the heater back panel using

the 1/2" long sheetmetal screws. Using the 3/4" long machine screws,

attach the leg to the bottom filler panel. Attach the other front leg.

4. Gasket Strips

(See FIGURE 3)

Cut the self-adhesive gasket strip into two10-inch

pieces. Attach one of the

strips to each side of the

top of the blower housing

(parallel with the sides).

FIGURE 3

- Adhere

Gasket

Strips to

Top

Surface of

the Blower

Gasket

Strips

Housing

5. Assemble

Filter Channels

The filter channels are created by assembling the filter brackets and the

"L" shaped filter angles. The filter brackets are designed to be used with

either 1" or 2" filters. If using 1" filters, attach the filter angles to create

a 1" channel on the filter brackets. If using 2" filters, attach the filter

angles to create a 2" filter channel. Follow the instructions in the illustrations.

Sizes 25-125 (See FIGURE 4) - Attach one angle to the top filter bracket

and one angle to the bottom filter bracket.

FIGURE 4 Assembly

Instructions

for Filter

Brackets and

Angles for

Sizes 25-125

Note: Illustration

also shows the

configuration of

the installed filter

channels. Assemble

brackets and angles

only in Step 5.

Filter Angle - for

1" filters, use top

hole; for 2" filters,

use bottom hole

Bottom

Filter

Bracket

Filter Channel Configuration (side

view of blower/filter cabinet)

Top Filter

Bracket

Filter Angle - for

1" filters, use

bottom hole; for

2" filters, use top

hole

FIGURE 2 - Attach Filler

Form I-B-BF, P/N 99714 (Rev 2), Page 2

Panels and Blower

Cabinet Front Legs

Sizes 130-400 (See FIGURE 5) - Package includes four angles. Attach

one angle to the top filter bracket and one angle to the bottom filter

bracket. If using 1" filters,

attach the two

angles to the

center filter

bracket. If using 2" filters,

these two filter

angles are not

used.

(Note in

FIGURE 4

also applies

to Sizes 130-

400.)

FIGURE 5 - Assembly Instructions for Filter

Brackets and Angles for Sizes 130-400

Top Filter

Bracket

Filter Angle - for

1" fltrs, use btm

hole; for 2"fltrs,

use top hole

Two Angles (Used

with 1" fltrs only)

Filter Angle - for

1" fltrs, use top

hole; for 2"fltrs,

use btm hole

Btm Fltr

Bracket

Filter Channel

Configuration

(side view)

Center Filter

Bracket Assembly

(attach angles

when using 1"

filters)

Loading...

Loading...