Reznor BE Option Installation Manual

Duct Flange, Option CD9

g

g

C E R T I F I E D

Description and

Application

Kit Components

FIGURE 1 - Duct Flange for

Models UDBP and UDBS

Top & Side/Bottom

& Side (2)

FIGURE 2 - Duct Flange for

Models B and BE

Top and Bottom

Pieces (2)

Sides

(2)

Installation Form RZ-NA I-OPT-DF

Obsoletes Form 434/436-DF

®

The duct flange option is designed for connecting the heater to warm air ductwork.

This option applies to blower type unit heater Models UDBP, UDBS, B, and BE.

See duct connection dimensions for each model on page 2. Check the components

against the appropriate table below.

Model UDBP and UDBS 30, 45 60, 75 100, 125

Option Pkg P/N 202909 202910 202911 202912 202913 202914

Components (qty in parenthesis):

Duct Flange Section (Side

& Top / Side & Bo tto m)

Sheetmetal Screws, #10 x

1/2"

Model B and BE 25, 50 75 100 125 130 165 200 250, 300 400

Option Pkg P/N 101194 101195 101501 135591 101196 101197 101198 101199 101200

Components (Qty in parenthesis):

Flange Top and

Bottom

Duct Flange Sides

Screws, #10 x

1/2" lon

Screws, #10 x

3/8" lon

(2)

101155

(2)

101163

(6)

11813

(4)

96426

APPLIES TO: Models UDBP, UDBS,

201750

(16)

11813

(2)

101156

(2)

101163

(6)

11813

(4)

96426

(2)

201751

11813

(2)

101157

(2)

101163

(6)

11813

(4)

96426

(2)

(14)

(2)

101159

(2)

101163

(6)

11813

(4)

96426

(2)

201752

(16)

11813

(2)

101157

(2)

101164

(6)

11813

(6)

96426

150, 175,

200

(2) 201813

(18) 11813

(2)

101158

(2)

101164

(6)

11813

(6)

96426

225, 250

(2)

201814

(18)

11813

(2)

101159

(2)

101164

(6)

11813

(6)

96426

B, and BE

300, 350,

400

(2) 201815

(18) 11813

(2)

101160

101164

11813

96426

101161

(2)

101164

(6)

11813

(6)

96426

(2)

(2)

(8)

(6)

WARNING: Improper installation, adjustment, alteration, service, or maintenance can cause

property damage, injury or death. Read the installation, operation, and maintenance instructions

thoroughly before installing or servicing this equipment.

Installation

Instructions

Installation should be done by a qualified agency in accordance with these instructions and in compliance with all codes and requirements of authorities having

jurisdiction.

Follow the instructions for the heater model being serviced.

1. If the heater is installed, turn off the gas and the electric power. Allow time

for the louvers to cool before beginning installation of the duct flange.

2. Remove the Horizontal Louvers

Models UDBP and UDBS - Louvers are removed individually. Push toward

the spring, releasing the louver. Remove all louvers.

Models B and BE - Louvers and frame are removed as an assembly. Remove

the screws that attach the louver frame sides to the inner side panels of the

heater. Remove the louver assembly. Save the screws; discard the assembly.

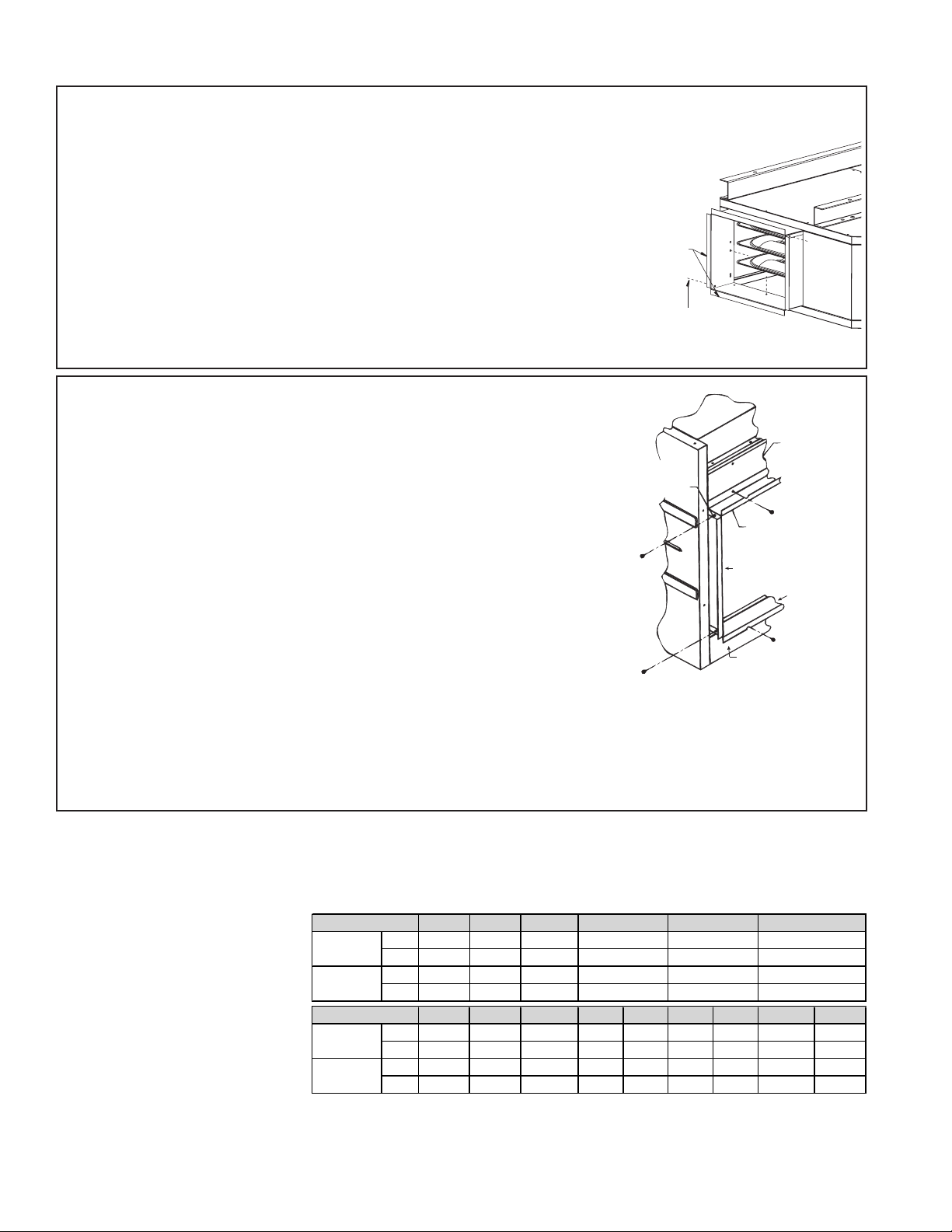

3. Install the Duct Flange

Models UDBP and UDBS - See FIGURE 3.

Models B and BE - See FIGURE 4

Form RZ-NA I-OPT-DF, P/N 101192 (Rev 2), page 1

Top Front

Panel

Duct Flange

Top

Duct

Flange

Bottom

Outer

Tab

Bottom Front Panel

(remove screws to

attach duct flange)

Duct Flange Side

Installation Instructions (cont’d)

FIGURE 3 - Installing Duct Flange on Model UDBP or UDBS

Attach Sections - In the discharge opening, position one L-shaped section on

the left side and across the top. Line up the vertical section with the holes in

Model UDBP

or UDBS

cabinet; attach with sheetmetal screws. Using the clearance holes in the duct

flange as a guide, drill 1/8” holes across the top of the heater cabinet opening.

Attach with sheetmetal screws.

Position the second duct flange section so that the top corner is inside the already

installed section and the bottom corner on the outside. Attach up the side using

(2) Duct

Flange

L-Shaped

Sections

the holes in the cabinet. Using the clearance holes in the duct flange as a guide,

drill 1/8” holes across the bottom of the heater cabinet opening. Attach with

sheetmetal screws.

At the two corners where the sections meet, attach sections with a sheetmetal

Sheetmetal

Screws

screw; insert screws with points to inside of duct flange.

FIGURE 4 - Installing Duct Flange on Models B and BE

Attach Sides (Duct flange sides are interchangeable; there is no right or left piece.)

- Position a side piece in the heater opening with the duct flange toward the outside;

match two holes with the holes from the louver assembly that was removed in Step

2. Using the screws removed from louver assembly, attach the duct flange side at

the two holes. Repeat to attach the other side.

Additional screws are required on each side. On Sizes 25-125, two additional screws

are required; on Sizes 130-400, three additional screws are required per side. Drill

3/32" diameter holes in both inner side panels of the heater.

Use the 3/8" long screws to finish attaching the duct flange sides. (Since the duct

flange sides are interchangeable, there will be one hole at each end that is not used.)

Attach Duct Flange Top and Bottom (see illustration)

Top: 1) Position the duct flange top with the outer tabs down over the outside of

the side pieces.

2) Using the holes in the heater top front panel, attach the duct flange top.

3) Insert the corner screws in the top and the sides with the screw ends to the inside of the duct flange.

Bottom: 1) Remove and save the screws from the bottom front panel of the heater.

2) Position the duct flange bottom with the tabs over the sides.

3) Attach, re-inserting the screws removed from the front of the heater.

4) Insert the corner screws (with points to the inside), attaching the bottom and sides of the duct flange.

Model B

or BE

Ductwork

Ductwork should be fitted over

the vertical flange and fastened

to the top, bottom and sides with

sheetmetal screws. Seal joints

with duct tape to prevent air leaks.

Properly sized ductwork based on

CFM and static pressure is required for a good heating installation. All supply ducts should be

equipped with dampers so that air

delivery may be balanced.

Form RZ-NA I-OPT-DF, P/N 101192 (Rev 2), page 2

4. When the duct flange and ductwork is complete, turn on the electric power

and the gas. Follow the instructions on the lighting instruction plate to relight

the heater. Check for proper operation.

Duct Connection Dimensions - including 3/4" (19mm) duct flange

UDBP and UDBS

Width

Height

B and BE

Width

Height

inch es

mm

inch es

mm

inch es

mm

inch es

mm

30, 45 60, 75 100, 125

15-5/16 15-5/16 15-5/16

389 389 389

11-1/2 14-1/2 22-1/2

292 368 572

25, 50 75 100 125 130 165 200 250, 300 400

12-1/4 14-1/4 16-1/4 22 16-1/4 19 22 27-1/2 35-3/4

311 362 413 559 413 483 559 699 908

17-3/8 17-3/8 17-3/8 17-3/8 23-7/8 25-3/8 25-3/8 25-3/8 25-3/8

441 441 441 441 606 606 606 606 606

150, 175, 200

24-1/2

622

17-1/2

445

225, 250

24-1/2

622

23-1/2

597

300, 350, 400

24-1/2

622

31-1/2

800

(800) 695-1901; www.ReznorOnLine.com

©2014 Reznor, LLC. All rights reserved. Printed in the U.S.A.

MANUFACTURER OF HEATING, COOLING, AND VENTILATING SYSTEMS

Trademark Note: Reznor® and TCORE

0514 Form I-OPT-DF (Version 0.1)

2

®

are registered in at least the United States.

Loading...

Loading...