Page 1

�

Form CP-F/B-IGN (Version B)

Obsoletes Form CP-F/B-IGN (Version A)

Ignition Conversion Kit Instructions

Apples to: Models F and B

Ignition Conversion Kits to Convert Models F and B with Standing Pilot to

Spark-Ignited, Intermittent Safety Pilot System With or Without Lockout

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury, or death. Read the installation instructions thoroughly

before installing this equipment.

Description/

Application

IMPORTANT

NOTE: These

are not gas

conversion

kits, ignition

conversion only.

NOTE: A unit with a

vent damper (Option

AV7) requires P/N

257010, an ignition

controller for

intermittent spark

pilot with lockout

The ignition conversion kits in this form are for Model F and Model B unit heaters equipped

with standing pilot and single stage gas valve. Before beginning conversion, determine

that your kit is compatible with your heater. Spark-ignited, intermittent safety pilot systems

without lockout are not available with propane gas; propane gas requires 100% lockout.

IGNITION CONVERSION KIT SELECTION CHART for Models F and B

Kits to convert from standing pilot to spark-

ignited, intermittent recycling safety pilot

Model Gas Type Kit P/N Model Gas Type Kit P/N

F/B 25-165

F/B 200-250 100526 F/B 200-250 100529

F 300-400; B 300 100527 F 300-400; B 300 100530

B 400 102348 B 400 102349

(without lockout)

100525 F/B 25-165

Natural

See pages 7-8 for a parts

listing of each kit.

Kits to convert from standing pilot to

spark-ignited, intermittent safety

with 100% lockout

100528

Natural

F/B 25-200

F 250-400; B 250-300 100532

B 400 102350

Propane

100531

(Option AH3)

WARNING: This ignition conversion kit is to be installed by a qualied agency in

accordance with these instructions and in compliance with all codes and requirements

of authorities having jurisdiction. Failure to follow instructions could result in death,

serious injury, and or property damage. The qualied agency performing this work

assumes responsibility for this installation.

Instructions for

Installing Ignition

Conversion Kit

1. Turn off the gas supply at a shutoff valve upstream of the combination valve and turn

off the electrical supply.

2. Change Combination Valve

Disconnect the main gas line, the wires and the pilot tubing from the valve and remove the

valve. Install the valve provided with the kit being sure that the gas ow through the valve

is in the proper direction and that the valve is in an allowable orientation. Follow the valve

manufacturer’s instructions and, if applicable, the replacement valve kit instructions for

details on installing the valve.

Reconnect the main gas line. Do not reconnect the pilot tubing or wires at this time.

WARNING: The operating valve is the primary safety shutoff.

The gas supply line must be free of dirt or scale before connecting the unit to ensure positive closure.

3. Install the Ignition Controller (See FIGURE 1 for location.)

Attach the ignition controller mounting bracket to the rear of the heater using the holes in

the cabinet and the #10x3/8” screws in the kit. Position the ignition controller on the bracket

with the wire terminals across the bottom. Use the #8x5/8” screws to attach the ignition

controller to the bracket.

Form CP-F/B-IGN, P/N100550 (Rev 3), Page 1

Page 2

Instructions

(cont’d)

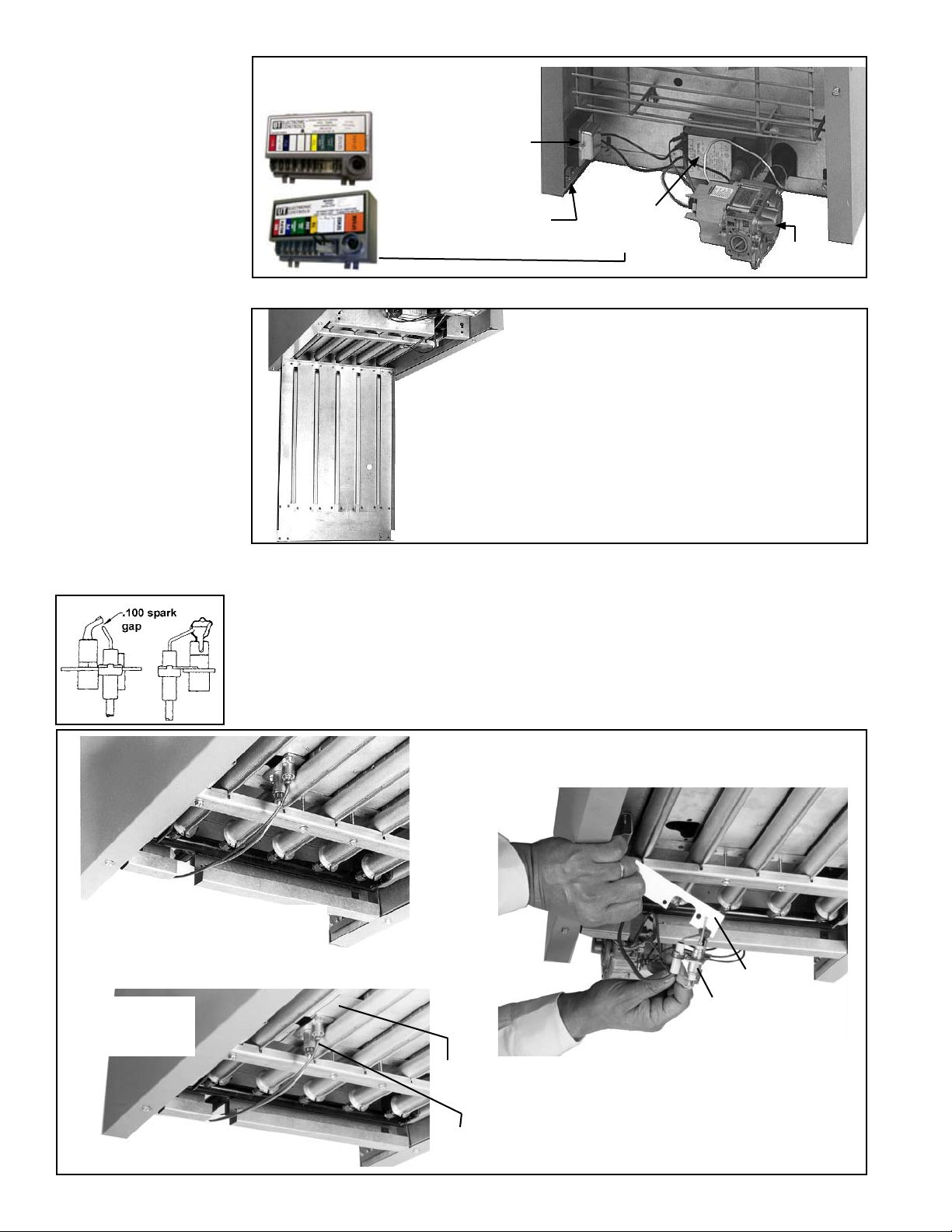

Replacement Controller, either

P/N 257009 or 257010

FIGURE 1 - Ignition

Control Location

FIGURE 2 - Bottom

Access Panel Open

FIGURE 3 - Pilot

Spark Gap

Transformer

Ignition

Terminal Strip

4. Change Pilot

Remove the two screws located at the rear bottom of the

heater that retain the bottom access panel. Allow the bottom panel to hinge down from the front.

The bottom of the pilot is now visible (See FIGURE 4A,

below.) Remove the screws holding the match-lit pilot

and remove the pilot assembly.

The match-lit pilot consisted of the pilot with hood and the ame-sensing thermocouple.

The new spark pilot assembly has a hooded pilot, a ame sensor rod, and an ignitor. Before

installing the pilot, verify the correct spark gap between the pilot hood and the ignitor. See

FIGURE 3. The spark gap must be maintained at .100”. The spark gap is set by the manufacturer and should be correct, but it is wise to recheck before installation. If adjustment is

required, hold the ceramic base with a pair of pliers while adjusting the rod.

Install the spark pilot assembly being sure that the pilot burner is extended toward the

burner tube. Be sure to include the pilot shield that is used only with the spark pilot assembly. (See FIGURES 4A, 4B, and 4C.)

Controller

location

Valve

FIGURE 4A - (1) Remove the

match-lit pilot assembly.

FIGURE 4C (3) Spark Pilot

Installed

Form CP-F/B-IGN, Page 2

FIGURE 4B - (2) Install the pilot shield and spark pilot

assembly with pilot burner extending toward the

burner tube.

Pilot

Shield

Pilot

Burner

Pilot Shield

Pilot Assembly with Flame Probe

Page 3

CAUTION:

Control, P/N

257010, with

lockout is

required with

a vent damper.

The controller

has a safety

feature that

once it is used

with a vent

damper, it

will no longer

operate a unit

without a vent

damper.

Attach one end of the ame sensor wire (150°C red silicone wire) to the ame probe on

the pilot assembly. Attach the other end of the ame sensor wire to Terminal “SENSE” on

the ignition controller. Attach the free end of the high tension spark wire (wire attached to

the ignitor on the pilot assembly) to the spike (“SPARK”) terminal on the ignition controller.

Push the wire rmly so that the spike is fully inserted and the wire secure.

Connect the pilot tubing to the gas valve. Position the tubing, high tension wire and ame

sensor wire in a location where they will not interfere with gas or air entering the burner or

be pinched by the bottom panel. Do not wrap the high tension wire and the ame sensor

wire together. The tubing and the wires may be routed through the opening for the manifold

pipe.

5. Wiring (Follow the appropriate new wiring diagram label in the kit.)

Remove the outer left heater side panel (left when facing the rear of the heater), revealing

the wiring.

Using the wires on the heater and the new wire assemblies in the kit, make the connections according to the instructions below and the new wiring diagram label in the kit.

(a) Replace transformer – Models with standard 115 volt supply require a transformer

change when converting to spark ignition. Models with optional 208, 230 or 460 supply voltage do not require a transformer change. If your unit requires a transformer

change, disconnect the wires from the transformer and remove the transformer from

the heater. (See FIGURE 1.) To install the new transformer, through the “large” hole in

the side panel for mounting the transformer, slide the Tinnerman clips over the transformer screw holes. Insert the new transformer in the mounting hole and fasten with

the 1-3/4” long screws included in the kit. Reconnect the brown wire from the terminal

strip and the line voltage yellow and black wires. Do not reconnect the blue wire.

(b) ECO (Energy Cutoff) Wiring – The ECO wiring on a unit with a standard pilot is

routed through the rear of the heater. When the unit is converted to spark, the ECO

wiring must be re-routed through the side panel. Follow these instructions to re-route

and reconnect the ECO wires (Refer to Wiring Diagram on page 6):

(1) On the rear of the heater (fan panel), remove the Heyco device (strain relief bush-

ing) that holds the two red wires going through the fan panel. (These wires were

disconnected from the gas valve in Step 2.)

(2) On the side of the heater, remove the small fan/limit control access panel (See

FIGURE 5). Reach through the access hole and pull both red wires completely

through the fan panel into the heater where the ECO is located. One of these

wires will be used on the converted heater, but the other must be replaced with

the longer red wire in the conversion kit. Carefully disconnect one of the wires

from the ECO control and discard that wire. The red ECO wire in the kit has two

different terminals. Connect the end with the straight insulated terminal to the

ECO control.

(3) Remove the Heyco device (See FIGURE 5) from the inner side panel. Add the two

red ECO wires to the fan and limit wires that are already there. Using pliers, rein-

FIGURE 5 - Outer

Side Panel Removed

Showing Access to

ECO Wiring through

the Fan/Limit

Control Access

Panel (panel is

removed)

Add the ECO wires

to the Heyco device

holding the fan and

Limit

Control

Fan

Control

limit wires.

ECO Device

FIGURE 6 - Rear View of

a Model F showing ECO

Wire Conguration after

Conversion

Fan

Control

Form CP-F/B-IGN, P/N100550 (Rev 3), Page 3

ECO

Device

Limit

Control

Page 4

Instructions

(cont’d)

(b) ECO (Energy Cutoff) Wiring (cont’d)

stall the Heyco device. Check to be sure that none of the wires (ECO, fan or limit)

come in contact with the heat exchanger tubes.

(4) Connect the red ECO wire with the 90° insulated terminal to the transformer. If

a new transformer was not installed, disconnect the blue wire to make this connection. If a new transformer was installed, make the connection on the 24V side

where the blue wire had been connected to the old transformer.

(5) At the terminal strip (See FIGURE 1), disconnect and discard the blue wire. At the

same place on the terminal strip, connect the other red ECO wire.

(6) Re-attach the small fan and limit control access panel.

(c) Combination Gas Valve – Connect the blue, black, and brown wires from the igni-

tion control. Attach the blue wire either to the P, TH-TR or PV terminal, depending on

the gas valve model. Attach the black wire to either M, TH or MV terminal. Attach the

brown wire to the terminal marked either C, TR or PV-MV (See Diagram, page 6).

6. Change the Lighting Instruction Plate and the Wiring Diagram on Heater

Lighting Instruction Plate – The new lighting instruction plate is self-adhesive and can be

placed over the original lighting instruction plate. Make sure the surface of the old instruction plate is clean and dry. Remove the backing and adhere the new lighting instruction

plate so that it covers the original standing pilot instruction plate.

Wiring Diagram – The new wiring diagram is also self-adhesive and is made to cover the

original diagram on the heater.

If the heater is a Model F; a Model B with a direct drive blower motor; a Model B with a beltdriven blower with a motor without a contactor; or a Model B with a belt driven blower with

a motor with a contactor, select the diagram that matches the heater. Remove the backing

and adhere it over the diagram on the heater.

If the heater is a Model B with a belt-driven blower with a motor with a starter, contact your

Reznor Representative, providing the complete model number, the serial number, and the

number of the wiring diagram originally supplied on the heater. When the custom wiring

diagram arrives, verify that it matches, remove the backing, and adhere it over the wiring

diagram on the heater.

FIGURE 7 - Proper

Flame Adjustment

Form CP-F/B-IGN, Page 4

7. Check the main gas line for leaks using a commercial leak detecting uid or a rich

soap and water solution. Leaks are indicated by the presence of bubbles.

WARNING: All components of gas supply must be leak tested

prior to placing equipment in service. NEVER TEST FOR LEAKS

WITH AN OPEN FLAME. Failure to comply could result in severe

personal injury, property damage or death.

Turn on the electric and the gas. Relight, following the instructions on the new lighting

instruction plate.

WARNING: In the event of improper ignition, wait at least ve

minutes before attempting to relight heater.

Check all gas connections including the pilot connections for leaks, If a leak cannot be

stopped by tightening, replace the part.

Observe the pilot ame through the pilot lighting hole. The ame should extend ½ to 1” past

the ame sensing device (FIGURE 7).

To adjust the pilot ame, remove the pilot adjustment cover screw from the combination

valve. Turn the inner adjustment screw clockwise to decrease or counterclockwise to

increase the pilot ame. Replace the cover screw after adjustment to prevent gas leakage.

8. Adjust Manifold Pressure

Depending on how the unit was originally equipped, the correct pressure adjustment may

depend on the area of the country in terms of elevation. Check the elevation listed on the

rating plate.

Page 5

If the rating plate indicates 0-2000 ft, and the installation is located at 0-2000 ft, follow

a)

the instructions to check the manifold pressure to be sure that it is 3.5 inches w.c. for

natural gas or 10.0 inches w.c. for propane.

If the rating plate indicates a higher elevation the elevation adjustment was made at the

b)

factory by an orice change. Follow the instructions to check the manifold pressure to be

sure that it is 3.5 inches w.c. for natural gas or 10.0 inches w.c. for propane.

If the rating place indicates 0-2000 ft and the actual elevation is higher, determine the

c)

correct manifold pressure for the elevation and follow the instructions to set the valve

outlet pressure.

Manifold Pressure Settings by Elevation

Elevation Ranges Natural Gas Propane

Feet Meters (inches W.C.)

0- 2000 1-610 3.5 10.0

2001-3000 911-915 2.8 7.7

3001-4000 916-1220 2.5 7.1

4001-5000 1221-1525 2.3 6.4

5001-6000 1526-1830 2.1 5.8

6001-7000 1831-2135 1.9 5.2

7001-8000 2136-2440 1.7 4.6

8001-9000 2441-2745 1.5 4.1

Instructions:

With the manual valve positioned to prevent ow to the main burners, connect a

1)

manometer to the 1/8” pipe outlet pressure tap in the valve. Use a water column

manometer that is readable to the nearest tenth of an inch. NOTE: A manometer (uid-

lled gauge) is recommended rather than a spring type gauge due to the difculty of

maintaining calibration of a spring type gauge.

Remove the cap from the pressure adjusting screw and adjust the manifold pressure

2)

to the pressure determined to be correct for the installation. Cycle the main burners

once or twice to properly seat the adjustment spring in the valve.

WARNING: Manifold gas pressure must never exceed 3.5” w.c.

for natural gas or 10” w.c. for propane gas.

Measure the manifold pressure. If further adjustment is necessary, correct pressure setting

3)

by turning the regulator screw IN (clockwise) to increase pressure. Turn regulator screw

OUT (counterclockwise) to decrease pressure. When the pressure is correct, remove the

manometer and replace the cap. Check for leaks at the pressure tap tting.

CAUTION: DO NOT bottom out the gas valve regulator adjustment screw. This can result in unregulated manifold pressure

causing excess overre and heat exchanger failure.

With the heater operating, determine that the inlet pressure to the heater is between 5 and

3)

14 inches w.c. for natural gas or between 11 and 14 inches w.c. for propane gas. Take this

reading as close as possible to the heater. (Most heaters are equipped with gas valves

that have an inlet pressure tap.) If the inlet pressure is not within the specied range the

inlet pressure must be corrected and the manifold pressure re-checked.

If the gas valve has been adjusted for operation above 2000 ft, nd the high altitude

4)

manifold pressure label in the kit. Using a permanent marker, ll-in the pressure setting

and adhere the label to the heater in a conspicuous location close to the gas valve.

9. Check for reliable and safe operation by operating the heater for several complete

cycles. CHECK FOR PROPER OPERATION OF ALL SAFETY FEATURES.

WARNING: Wait at least ve minutes before attempting to relight

heater in the event of pilot outage or improper ignition.

10. Replace the side panel and close the bottom access panel. Restore the heater to

normal operation. If a thermostat with a heat anticipator is used, it should be reset to

approximately .8 amperes.

Form CP-F/B-IGN, P/N100550 (Rev 3), Page 5

Page 6

L1

(HOT)

R

24V

LINE VOLT

BR

GROUND TERMINAL

(TERMINAL STRIP)

L2

(COM)

BR

R

SET ANT. AT 0.8 AMPS

SINGLE STAGE THERMOSTAT

W1

R

W1

Y Y

LIMIT

CONTROL

Y

BR

R

BK

FIELD WIRING

TERMINAL STRIP

FACTORY WIRING

- TURN ON MAIN AND PILOT MANUAL GAS VALVES.

- TURN ON POWER TO UNIT.

- SET THERMOSTAT AT DESIRED SETTING.

- THERMOSTAT CALLS FOR HEAT FIRING UNIT AT FULL RATE AFTER PILOT

PROVING SEQUENCE.

BR

BLOCKED VENT

MANUAL RESET

SWITCH

Y

- FAN CONTROL SENSES HEAT EXCHANGER TEMPERATURE, ENERGIZING THE

FAN OR BLOWER MOTOR.

CONTROL

TRANSFORMER

UNIT WIRING

FIELD WIRING

WIRE CONNECTOR

CRIMP TERMINAL

R

ENERGY CUT-OFF

(PRIOR TO AUGUST 1999)

*

USED ON UNITS PRODUCED

AFTER APRIL 1991

*

- FOR CONTINUOUS FAN OPERATION SET S/W SWITCH AT "ON" POSITION.

REDUNDANT GAS VALVE

ALTERNATE W.R. OR ROBERTSHAW

BL

P

BK

BR

MAIN

PILOT

M

C

PV

PILOT

MV

PV-MV

MAIN

REDUNDANT GAS VALVE

HONEYWELL

BL

BK

IGNITION

CONTROLLER

PROBE

GRD

SPARK

FLAME SENSING

24V

MV/PV

GND BURNER

24V GND

MV

SENSE

TH

PV

G

UNIT CHASSIS

GROUND

OPTIONAL VENT DAMPER

FIELD INSTALLED

BR

RR

ON 115/460V. UNITS THE CONTROL TRANSFORMER IS A SINGLE VOLTAGE PRIMARY.

- ON 208/230V. UNITS THE CONTROL TRANSFORMER HAS A DUAL VOLTAGE PRIMARY.

TO PREVENT VOLTAGE DROP BEYOND FIVE PERCENT OF SUPPLY LINE VOLTAGE.

- LINE AND BLOWER MOTOR BRANCH CIRCUIT WIRE SIZE SHOULD BE OF A SIZE

A TEMPERATURE RATING OF AT LEAST 105 DEGREES C., EXCEPT FOR ENERGY

MUST BE REPLACED, IT MUST BE REPLACED WITH WIRING MATERIAL HAVING

- CAUTION: IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE APPLIANCE

- DOTTED WIRING AND THE FOLLOWING CONTROLS ARE SUPPLIED AND INSTALLED

- THE FOLLOWING CONTROLS ARE SUPPLIED AS OPTIONAL EQUIPMENT:

- THE FOLLOWING CONTROLS ARE SUPPLIED BY REZNOR FOR FIELD INSTALLATION:

FOR 115/460V. UNITS USE BLACK AND YELLOW LEADS.

FOR 208V. UNITS USE BLACK AND RED LEADS (CAP YELLOW).

FOR 230V. UNITS USE BLACK AND YELLOW LEADS (CAP RED).

THERMOSTAT

CUTOFF OR SENSOR LEAD WIRE WHICH MUST BE 150 DEGREES C.

- USE #18 GA. WIRE FOR 24 VOLT CONTROL WIRING ON UNIT.

BY OTHERS: NONE

CONTROL SWITCH

NOTES

USE DUAL ELEMENTS TIME DELAY FUSES AND SIZE ACCORDING TO 1.25

TIMES THE MAXIMUM TOTAL INPUT AMPS.

- WHEN PROVIDING OR REPLACING FUSES IN THE FUSIBLE DISCONNECT SWITCH

- DISCONNECT SWITCH IS FIELD FURNISHED OR AVAILABLE FROM FACTORY AS AN OPTION.

- IF THE FLAME IS EXTINGUISHED DURING MAIN BURNER OPERATION,

THE SAFETY SWITCH CLOSES THE MAIN VALVE AND RECYCLES THE

SPARK GAP.

ON UNITS EQUIPPED WITH LOCKOUT CONTROL, IF PILOT IS NOT

ESTABLISHED WITHIN 120 SECONDS. THE UNIT LOCKS OUT FOR ONE

HOUR, UNLESS IT IS RESET BY INTERRUPTING POWER TO

THE CONTROL CIRCUIT. (SEE LIGHTING INSTRUCTIONS)

CONTROLLER FOR OPTIONAL VENT DAMPER

(APPLIES ONLY TO CONTROLLER WITH LOCKOUT)

NEW WIRE PROVIDED WITH THE IGNITION

LINE VOLTAGE ON HEATER

WHITE - W

PURPLE - PR

BLUE - BL

GREEN - G

YELLOW - Y

ORANGE - O

RED - R

BROWN - BR

BLACK - BK

WIRING CODE

OPERATING SEQUENCE

NOTE: Minimum flame proving

signal strength is 0.2 microamps.

Typical Wiring Diagram - Intermittent Spark Pilot

with or without Lockout, Single-Stage Heating

Field and Replacement Wiring Notes

1. Dotted wiring supplied by others.

2. Thermostat supplied as optional equipment.

3. Use 14 gauge wire for line wiring to unit.

4. Use 18 gauge wire for control wiring on unit.

5. Line and blower or fan control branch circuit wire sizes should be of a size to

prevent voltage drops beyond 5% of supply line voltage.

FIELD CONTROL WIRING

Length and Gauge

Total Wire

Length

Distance from

Unit to Control

Recommended

Wire Gauge

150’ (46M) 75’ (23M) 18 gauge

250’ (76M) 125’ (38M) 16 gauge

350’ (107M) 175’ (53M) 14 gauge

Form CP-F/B-IGN, Page 6

Page 7

Parts Lists - Ignition Conversion Kits for Models F and B

NOTE: These kits are ignition conversion kits only; NOT gas conversion kits.

WARNING: These kits are for Reznor Models F and B only. Do not use them on any

other products.

SECTION 1 - Kits to convert natural gas units from standing pilot to spark-ignited, intermittent safety pilot

without lockout, Option AH2 (not applicable to propane units – propane requires pilot with lockout).

Ignition Conversion Kit P/N 100525

Applies to: Model F 25-165, Natural Gas; Model B 25-165, Natural Gas

Qty P/N Description

1 96307 Gas Valve, 1/2”, M/H #VR8204-M1000 (Single stage)

1 257474 Ignition Controller Assy including:

1 257009 Ignition Control Non-Lockout, UTEC 1003-638A

1 133108 Black Wire Assy (I.C. “MV”)

1 98215 Brown Wire Assy (I.C. “MV/PV”)

1 98214 Blue Wire Assy (I.C. “PV”)

1 257074 Green Wire Assy (I.C. “GND BURNER”)

1 98215 Brown Wire Assy I.C. “24V GND”)

1 257014 Red Wire Assy (I.C.”SENSE”)

1 122655 Yellow Wire Assembly (I.C. “TH”)

1 173307 Black Wire Assembly (I.C. “TH”)

1 97204 Pilot Shield

1 97534 Pilot Assy, Johnson #Q9OFF-1

1 98044 Red Wire Assy (ECO to Transformer) 18 ga. x 20”, 150°C w/2 Terminals

1 257012 Controller Bracket

2 64246 #10 x 3/8” lg Screws (to attach bracket to heater)

4 195638 #8 x 3/8” lg Screws (to attach control to bracket)

1 102708 Transformer, 35 VA, Basler #BE141640-RAK

2 103152 Screws, #6 x 1-3/4” lg (for mounting transformer)

2 111233 Clips, Tinnerman #C6310-6Z-4 (for transformer screws)

1 96101 Lighting Instruction Plate

1 100550 Instruction Sheet CP-F/B-IGN

Wiring Diagrams (select the one that matches the heater):

1 258173 For Model F 25-65

1 258174 For Model B 25-100 w/direct drive motor & B 50-165 w/belt drive motor (no contactor)

1 258175 For Model B 75-165 with belt drive motor with contactor

1 Special Consult factory for Wiring Diagram for Model B with a starter.

Ignition Conversion Kit P/N 100526

Applies to: Model F 200-250, Natural Gas; Model B 200-250, Natural Gas

Qty P/N Description

1 121599 Gas Valve, 1/2”, M/H #VR8304M2816 (single stage)

1 257474 Ignition Controller Assy including:

1 257009 Ignition Control Non-Lockout, UTEC 1003-638A

1 133108 Black Wire Assy (I.C. “MV”)

1 98215 Brown Wire Assy (I.C. “MV/PV”)

1 98214 Blue Wire Assy (I.C. “PV”)

1 257074 Green Wire Assy (I.C. “GND BURNER”)

1 98215 Brown Wire Assy I.C. “24V GND”)

1 257014 Red Wire Assy (I.C.”SENSE”)

1 122655 Yellow Wire Assembly (I.C. “TH”)

1 173307 Black Wire Assembly (I.C. “TH”)

1 97204 Pilot Shield

1 97534 Pilot Assy, Johnson #Q9OFF-1

1 98044 Red Wire Assy (ECO to Transformer) 18 ga. x 20”, 150°C w/2 Terminals

1 257012 Controller Bracket

2 64246 #10 x 3/8” lg Screws (to attach bracket to heater)

4 195638 #8 x 3/8” lg Screws (to attach control to bracket)

1 102708 Transformer, 35 VA, Basler #BE141640-RAK

2 103152 Screws, #6 x 1-3/4” lg (for mounting transformer)

2 111233 Clips, Tinnerman #C6310-6Z-4 (for transformer screws)

1 96101 Lighting Instruction Plate

1 100550 Instruction Sheet CP-F/B-IGN

Wiring Diagrams (select the one that matches the heater):

1 258173 For Model F 25-65

1 258174 For Model B 25-100 w/direct drive motor & B 50-165 w/belt drive motor (no contactor)

1 258175 For Model B 75-165 with belt drive motor with contactor

1 Special Consult factory for Wiring Diagram for Model B with a starter.

SECTION 2 - Kits to convert

natural gas units from

standing pilot to sparkignited, intermittent safety

pilot with lockout, Option

AH3.

The loose yellow wire is not used in this

application. .

The loose yellow wire is not used in this application.

Ignition Conversion Kit P/N 100528

Applies to: Model F 25-165, Natural Gas; Model B 25-165, Natural Gas

Qty P/N Description Qty P/N Description

1 96307 Gas Valve, 1/2”, M/H #VR8204-M1000 (single stage) 1 257012 Controller Bracket

1 257475 Ignition Controller Assy including: 2 64246 #10 x 3/8” lg Screws (to attach bracket to heater)

1 257010 Ignition Control w/100% Lockout, UTEC 1003-514 3 195638 #8 x 3/8” lg Screws (to attach control to bracket)

1 133108 Black Wire Assy (I.C. “MV”) 1 102708 Transformer, 35 VA, Basler #BE141640-RAK

1 98215 Brown Wire Assy (I.C. “MV/PV”) 2 103152 Screws, #6 x 1-3/4” lg (for mounting transformer)

1 98214 Blue Wire Assy (I.C. “PV”) 2 111233 Clips, Tinnerman #C6310-6Z-4 (for transformer screws)

1 257074 Green Wire Assy (I.C. “GND Burner”) 1 96101 Lighting Instruction Plate

1 98215 Brown Wire Assy I.C. “24V GND”) 1 100550 Instruction Sheet CP-F/B-IGN

1 173303 Red Wire Assy (I.C. “24V”) Wiring Diagrams (select the one that matches the heater):

1 257014 Red Wire Assy (I.C.”Sense”) 1 258173 For Model F 25-65

1 122655 Yellow Wire Assy (I.C. “TH”)

1 173307 Black Wire Assembly (I.C. “TH”)

1 97204 Pilot Shield 1 258175 For Model B 75-165 with belt drive motor with contactor

1 97534 Pilot Assy, Johnson #Q9OFF-1

1 98044

Red Wire Assy (ECO to Transformer) 18 ga. x 20”, 150°C

w/2 Terminals

Ignition Conversion Kit P/N 102348

Applies to: Model B 400, Natural Gas

Qty P/N Description

1 222037

1 257474 Ignition Controller Assy including:

1 257009 Ignition Control Non-Lockout, UTEC 1003-638A

1 133108 Black Wire Assy (I.C. “MV”)

1 98215 Brown Wire Assy (I.C. “MV/PV”)

1 98214 Blue Wire Assy (I.C. “PV”)

1 257074 Green Wire Assy (I.C. “GND BURNER”)

1 98215 Brown Wire Assy I.C. “24V GND”)

1 257014 Red Wire Assy (I.C.”SENSE”)

1 122655 Yellow Wire Assembly (I.C. “TH”)

1 173307 Black Wire Assembly (I.C. “TH”)

1 97204 Pilot Shield

1 97534 Pilot Assy, Johnson #Q9OFF-1

1 98044 Red Wire Assy (ECO to Transformer) 18 ga. x 20”, 150°C w/2 Terminals

1 257012 Controller Bracket

2 64246 #10 x 3/8” lg Screws (to attach bracket to heater)

4 195638 #8 x 3/8” lg Screws (to attach control to bracket)

1 96101 Lighting Instruction Plate

1 100550 Instruction Sheet CP-F/B-IGN

1 258175 For Model B 400 with belt drive motor with contactor

1 Special Consult factory for Wiring Diagram for Model B 400 with a starter.

Ignition Conversion Kit P/N 100527

Applies to: Model F 300-400, Natural Gas; Model B 300, Natural Gas

Qty P/N Description

1 222037

1 257474 Ignition Controller Assy including:

1 257009 Ignition Control Non-Lockout, UTEC 1003-638A

1 133108 Black Wire Assy (I.C. “MV”)

1 98215 Brown Wire Assy (I.C. “MV/PV”)

1 98214 Blue Wire Assy (I.C. “PV”)

1 257074 Green Wire Assy (I.C. “GND BURNER”)

1 98215 Brown Wire Assy I.C. “24V GND”)

1 257014 Red Wire Assy (I.C.”SENSE”)

1 122655 Yellow Wire Assembly (I.C. “TH”)

1 173307 Black Wire Assembly (I.C. “TH”)

1 97204 Pilot Shield

1 97534 Pilot Assy, Johnson #Q9OFF-1

1 98044 Red Wire Assy (ECO to Transformer) 18 ga. x 20”, 150°C w/2 Terminals

1 257012 Controller Bracket

2 64246 #10 x 3/8” lg Screws (to attach bracket to heater)

4 195638 #8 x 3/8” lg Screws (to attach control to bracket)

1 102708 Transformer, 35 VA, Basler #BE141640-RAK

2 103152 Screws, #6 x 1-3/4” lg (for mounting transformer)

2 111233 Clips, Tinnerman #C6310-6Z-4 (for transformer screws)

1 96101 Lighting Instruction Plate

1 100550 Instruction Sheet CP-F/B-IGN

Wiring Diagrams (select the one that matches the heater):

1 258173 For Model F 30-400

1 258174 For Model B 25-100 w/direct drive motor &l B 50-165 w/belt drive motor (no contactor)

1 258175 For Model B 300 with belt drive motor with contactor

1 Special Consult factory for Wiring Diagram for Model B with a starter.

Replacement Valve Kit including P/N 221525 Valve, W/R #36H32-441; Compression Nut,

P/N 97572; and Instruction Sheet, P/N 222038

The loose yellow wire is not used in this application.

Replacement Valve Kit including P/N 221525 Valve, W/R #36H32-441; Compression Nut,

P/N 97572; and Instruction Sheet, P/N 222038

The loose yellow wire is not used in this application.

The loose yellow wire is not

used in this application.

1 258174

1 Special Consult factory for Wiring Diagram for Model B with a

For Model B 25-100 w/direct drive motor & B 50-165 w/belt

drive motor (no contactor)

starter .

Form CP-F/B-IGN, P/N100550 (Rev 3), Page 7

Page 8

SECTION 2 - Kits to convert natural gas units from

standing pilot to spark-ignited, intermittent safety

pilot with lockout, Option AH3 (cont’d).

Ignition Conversion Kit P/N 100529

Applies to: Model F 200-250, Natural Gas; Model B 200-250, Natural Gas

Qty P/N Description

1 121599 Gas Valve, 1/2”, M/H #VR8304M2816 (single stage)

1 257475 Ignition Controller Assy including:

1 257010 Ignition Control w/100% Lockout, UTEC 1003-514

1 133108 Black Wire Assy (I.C. “MV”)

1 98215 Brown Wire Assy (I.C. “MV/PV”)

1 98214 Blue Wire Assy (I.C. “PV”)

1 257074 Green Wire Assy (I.C. “GND BURNER”)

1 98215 Brown Wire Assy I.C. “24V GND”)

1 173303 Red Wire Assy (I.C. “24V”)

1 257014 Red Wire Assy (I.C.”SENSE”)

1 122655 Yellow Wire Assy (I.C. “TH”)

1 173307 Black Wire Assy (I.C. “TH”)

1 97204 Pilot Shield

1 97534 Pilot Assy, Johnson #Q9OFF-1

1 98044 Red Wire Assy (ECO to Transformer) 18 ga. x 20”, 150°C w/2 Terminals

1 257012 Controller Bracket

2 64246 #10 x 3/8” lg Screws (to attach bracket to heater)

4 195638 #8 x 3/8” lg Screws (to attach control to bracket)

1 102708 Transformer, 35 VA, Basler #BE141640-RAK

2 103152 Screws, #6 x 1-3/4” lg (for mounting transformer)

2 111233 Clips, Tinnerman #C6310-6Z-4 (for transformer screws)

1 96101 Lighting Instruction Plate

1 100550 Instruction Sheet CP-F/B-IGN

Wiring Diagrams (select the one that matches the heater):

1 258173 For Model F 200-250

1 258174 For Model B 200-250 w/direct drive motor &l B 50-165 w/belt drive motor (no contactor)

1 258175 For Model B 200-250 with belt drive motor with contactor

1 Special Consult factory for Wiring Diagram fFor Model B with a starter.

Ignition Conversion Kit P/N 100530

Applies to: Model F 300-400, Natural Gas; Model B 300, Natural Gas

Qty P/N Description

1 222037

1 257475 Ignition Controller Assy including:

1 257010 Ignition Control w/100% Lockout, UTEC 1003-514

1 133108 Black Wire Assy (I.C. “MV”)

1 98215 Brown Wire Assy (I.C. “MV/PV”)

1 98214 Blue Wire Assy (I.C. “PV”)

1 257074 Green Wire Assy (I.C. “GND BURNER”)

1 98215 Brown Wire Assy I.C. “24V GND”)

1 173303 Red Wire Assy (I.C. “24V”)

1 257014 Red Wire Assy (I.C.”SENSE”)

1 122655 Yellow Wire Assy (I.C. “TH”)

1 173307 Black Wire Assy (I.C. “TH”)

1 97204 Pilot Shield

1 97534 Pilot Assy, Johnson #Q9OFF-1

1 98044 Red Wire Assy (ECO to Transformer) 18 ga. x 20”, 150°C w/2 Terminals

1 257012 Controller Bracket

2 64246 #10 x 3/8” lg Screws (to attach bracket to heater)

4 195638 #8 x 3/8” lg Screws (to attach control to bracket)

1 102708 Transformer, 35 VA, Basler #BE141640-RAK

2 103152 Screws, #6 x 1-3/4” lg (for mounting transformer)

2 111233 Clips, Tinnerman #C6310-6Z-4 (for transformer screws)

1 96101 Lighting Instruction Plate

1 100550 Instruction Sheet CP-F/B-IGN

Wiring Diagrams (select the one that matches the heater):

1 258173 For Model F 300-400

1 258175 For Model B 300 with belt drive motor with contactor

1 Special Consult factory for Wiring Diagram for Model B with a starter.

Ignition Conversion Kit P/N 102349

Applies to: Model B 400, Natural Gas

Qty P/N Description

1 222037

1 257475 Ignition Controller Assy including:

1 257010 Ignition Control w/100% Lockout, UTEC 1003-514

1 133108 Black Wire Assy (I.C. “MV”)

1 98215 Brown Wire Assy (I.C. “MV/PV”)

1 98214 Blue Wire Assy (I.C. “PV”)

1 257074 Green Wire Assy (I.C. “GND BURNER”)

1 98215 Brown Wire Assy I.C. “24V GND”)

1 173303 Red Wire Assy (I.C. “24V”)

1 257014 Red Wire Assy (I.C.”SENSE”)

1 122655 Yellow Wire Assy (I.C. “TH”)

1 173307 Black Wire Assy (I.C. “TH”)

1 97204 Pilot Shield

1 97534 Pilot Assy, Johnson #Q9OFF-1

1 98044 Red Wire Assy (ECO to Transformer) 18 ga. x 20”, 150°C w/2 Terminals

1 257012 Controller Bracket

2 64246 #10 x 3/8” lg Screws (to attach bracket to heater)

4 195638 #8 x 3/8” lg Screws (to attach control to bracket)

1 96101 Lighting Instruction Plate

1 100550 Instruction Sheet CP-F/B-IGN

1 Special Consult factory for Wiring Diagram for Model B with a starter.

Replacement Valve Kit including P/N 221525 Valve, W/R #36H32-441;

Compression Nut, P/N 97572; and Instruction Sheet, P/N 222038

Replacement Valve Kit including P/N 221525 Valve, W/R #36H32-441;

Compression Nut, P/N 97572; and Instruction Sheet, P/N 222038

258175 For Model B 400 with belt drive motor with contactor

The loose yellow wire is not used in this application.

The loose yellow wire is not used in this application.

The loose yellow wire is not used in this

application.

SECTION 3 - Ignition Conversion Kits to convert propane gas units from standing pilot to spark-ignited, intermittent pilot safety system with lockout, Option AH3.

Ignition Conversion Kit P/N 100531

Applies to: Model F 25-200, Propane; Model B 25-200, Propane

Qty P/N Description

1 96310 Gas Valve, 1/2”, M/H #VR8204-M1018 (single stage)

1 257475 Ignition Controller Assy including:

1 257010 Ignition Control w/100% Lockout, UTEC 1003-514

1 133108 Black Wire Assy (I.C. “MV”)

1 98215 Brown Wire Assy (I.C. “MV/PV”)

1 98214 Blue Wire Assy (I.C. “PV”)

1 257074 Green Wire Assy (I.C. “GND BURNER”)

1 98215 Brown Wire Assy I.C. “24V GND”)

1 173303 Red Wire Assy (I.C. “24V”)

1 257014 Red Wire Assy (I.C.”SENSE”)

1 122655 Yellow Wire Assy (I.C. “TH”)

1 173307 Black Wire Assy (I.C. “TH”)

1 97204 Pilot Shield

1 97535 Pilot Assy, Johnson #Q9OFF-2

1 98044 Red Wire Assy (ECO to Transformer) 18 ga. x 20”, 150°C w/2 Terminals

1 257012 Controller Bracket

2 64246 #10 x 3/8” lg Screws (to attach bracket to heater)

4 195638 #8 x 3/8” lg Screws (to attach control to bracket)

1 102708 Transformer, 35 VA, Basler #BE141640-RAK

2 103152 Screws, #6 x 1-3/4” lg (for mounting transformer)

2 111233 Clips, Tinnerman #C6310-6Z-4 (for transformer screws)

1 96101 Lighting Instruction Plate

1 100550 Instruction Sheet CP-F/B-IGN

Wiring Diagrams (select the one that matches the heater):

1 258173 For Model F 25-200

1 258174 For Model B 25-200 w/direct drive motor and B 50-165 w/belt drive motor (no contactor)

1 258175 For Model B 75-200 with belt drive motor with contactor

1 Special Consult factory for Wiring Diagram for Model B with a starter.

Ignition Conversion Kit P/N 100532

Applies to: Model F 250-400, Propane; Model B 250-300, Propane

Qty P/N Description

1 221634

1 257475 Ignition Controller Assy including:

1 257010 Ignition Control w/100% Lockout, UTEC 1003-514

1 133108 Black Wire Assy (I.C. “MV”)

1 98215 Brown Wire Assy (I.C. “MV/PV”)

1 98214 Blue Wire Assy (I.C. “PV”)

1 257074 Green Wire Assy (I.C. “GND BURNER”)

1 98215 Brown Wire Assy I.C. “24V GND”)

1 173303 Red Wire Assy (I.C. “24V”)

1 257014 Red Wire Assy (I.C.”SENSE”)

1 122655 Yellow Wire Assy (I.C. “TH”)

1

1 97204 Pilot Shield

1 97535 Pilot Assy, Johnson #Q9OFF-2

1 98044 Red Wire Assy (ECO to Transformer) 18 ga. x 20”, 150°C w/2 Terminals

1 257012 Controller Bracket

2 64246 #10 x 3/8” lg Screws (to attach bracket to heater)

4 195638 #8 x 3/8” lg Screws (to attach control to bracket)

1 102708 Transformer, 35 VA, Basler #BE141640-RAK

2 103152 Screws, #6 x 1-3/4” lg (for mounting transformer)

2 111233 Clips, Tinnerman #C6310-6Z-4 (for transformer screws)

1 96101 Lighting Instruction Plate

1 100550 Instruction Sheet CP-F/B-IGN

Wiring Diagrams (select the one that matches the heater):

1 258173 For Model F 250-400

1 258174 For Model B 250 with belt drive motor (no contactor)

1 258175 For Model B 250-300 with belt drive motor with contactor

1 Special Consult factory for Wiring Diagram for Model B with a starter.

Ignition Conversion Kit P/N 102350

Applies to: Model B 400, Propane

Qty P/N Description

1 221634

1 257475 Ignition Controller Assy including:

1 257010 Ignition Control w/100% Lockout, UTEC 1003-514

1 133108 Black Wire Assy (I.C. “MV”)

1 98215 Brown Wire Assy (I.C. “MV/PV”)

1 98214 Blue Wire Assy (I.C. “PV”)

1 257074 Green Wire Assy (I.C. “GND BURNERr”)

1 98215 Brown Wire Assy I.C. “24V GND”)

1 173303 Red Wire Assy (I.C. “24V”)

1 257014 Red Wire Assy (I.C.”SENSE”)

1 122655 Yellow Wire Assy (I.C. “TH”)

1

1 97204 Pilot Shield

1 97535 Pilot Assy, Johnson #Q9OFF-2

1 98044 Red Wire Assy (ECO to Transformer) 18 ga. x 20”, 150°C w/2 Terminals

1 257012 Controller Bracket

2 64246 #10 x 3/8” lg Screws (to attach bracket to heater)

4 195638 #8 x 3/8” lg Screws (to attach control to bracket)

1 96101 Lighting Instruction Plate

1 100550 Instruction Sheet CP-F/B-IGN

1 258175 For Model B 400 with belt drive motor with contactor

1 Special Consult factory for Wiring Diagram for Model B 400 with a starter.

Replacement Valve Kit including P/N 221526 Valve, W/R #36H32-4422; Compression Nut,

P/N 97572; 1/2x3/4 Hex Bushing, P/N 37385; and Instruction Sheet, P/N 222039

173307 Black Wire Assy (I.C. “TH”)

Replacement Valve Kit including P/N 221526 Valve, W/R #36H32-442; Compression Nut,

P/N 97572; 1/2x3/4 Hex Bushing, P/N 37385; and Instruction Sheet, P/N 222039

173307 Black Wire Assy (I.C. “TH”)

The loose yellow wire is not used in this application.

The loose yellow wire is not used in this application.

The loose yellow wire is not used in this application.

Form CP-F/B-IGN, Page 8

©2009 Thomas & Betts Corporation, All rights reserved.

Trademark Note: Reznor® is registered in the United States and other countries.

03/09 Form CP-F/B-IGN (Version B)

Loading...

Loading...