PCD / AEB

PACKAGED FURNACES

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

(Suitable for Operation with up to 100% Fresh Air)

READ MANUAL CAREFULY BEFORE INSTALLING

OR OPERATING THE FURNACE

SAVE THESE INSTRUCTIONS FOR REFERENCE

FOR YOUR SAFETY FOR YOUR SAFETY

If you smell gas follow these

instructions,

The use and storage of gasoline or other

flammable vapors and liquids in open

1) Open windows. containers in the vicinity of this appliance

2) Do not touch electrical switches. is hazardous.

3) Extinguish any open flame.

4) Call the gas supplier immediately.

MODEL: SERIAL NUMBER:

JOB: DATE OF INSTALLATION:

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH. PLEASE READ THE

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTION

THOROUGHLY.

*THIS UNIT IS TO BE SERVICED BY QUALIFIED PERSONNEL*

**DO NOT TAMPER WITH THE UNIT OR CONTROLS**

INSTALLER’S RESPONSIBILITY

Installer please note: This equipment has been test fired and inspected. It has been shipped free from defects from

our factory. However, during shipment and installation, problems such as loose wires, leaks or loose fasteners

may occur. It is the installer’s responsibility to inspect and correct any problems that may be found.

INSTALLER/SERVICE CONTRACTOR

NAME:

ADDRESS:

TELEPHONE:

CONTACT:

RECEIVING AND WAREHOUSING

Inspect the unit upon arrival for any shipping damage. If any part is missing or damaged, notify the carrier at once.

1

FRONT

If the unit cannot be installed immediately, store it and its accessories in a clean and dry place.

HANDLING AND SUSPENSION

Do not handle the unit by attaching hooks, jacks or chains to the unit casing or any other component. Spreader bars

are recommended when making single point lifts.

Horizontal indoor units may be handled and suspended using the lugs on the base frame.

Horizontal rooftop units are provided with base frame lugs.

Vertical upflow units (including AC model) and vertical down flow models are provided with eye bolts to ease

handling.

For all models, the heating and blower sections are shipped separately. (see Fig. 1 for exploded view). Assemble

the sections by aligning the pre-drilled flanges and securing the assembly with the fasteners provided. Use gasketing

material to prevent infiltration at the joints.

Optional sections such as mixing boxes are shipped separately. A list of these, along with any other unit components

that have been shipped separately from the unit, is included at the end of this manual.

GENERAL INSTALLATION NOTES:

This unit must be installed in accordance with the current standard CAN/CSA/1-B149.1 or CAN/CSA/1-B149.2.

Installation codes for gas burning appliances and equipment, and/or the applicable provincial regulations for the

class, which should be carefully followed in all cases. Authorities having jurisdiction should be consulted before

installations are made.

USA Units: Installation must be made in accordance with local codes, or in absence of local codes, with ANSI

Standard Z223.1-1992 (N.F.P.A. No 54) “National Fuel Gas Code”, or the latest edition of. All ANSI and NFPA

Standards referred to in these installation instructions are the ones that were applicable at the time the design of this

appliance was certified. The ANSI Standards are available from the American Gas Association, 1515 Wilson

Boulevard, Arlington, Virginia 22209. The NFPA Standards are available from the National Fire Protection

Association, Batterymarch Park, Quincy, Massachusetts 02269. The heaters are designed for use in airplane hangers

when installed in accordance with ANSI/NFPA No. 409 and in public garages when installed in accordance with the

NFPA No. 88A and NFPA No. 88B.

CLEARANCES

MODEL

CONFIGURATION CLEARANCES TO COMBUSTIBLE

CONSTRUCTION ( in inches)

TOP

FLUE BACK SIDES FLOOR

C Horizontal Suspended 6 36 18 36 6 *

D Vertical Upflow Floor set 6 36 18 36 6 C

R Vertical Down flow Floor set 0 36 18 36 6 NC**

M Horizontal Floor set 6 36 18 36 6 NC**

AC Vertical Upflow High Velocity Floor set 6 36 18 36 6 C

Notes: *Three inch bottom clearance.

** May be installed on combustible floor when mounted on 4-inch steel base channels. Floor clearance is

measured from bottom of unit casing.

2

For service, it is advisable to maintain a minimum 24-inch clearance on the side opposite the controls and 42-inch

clearance on the control side. If this unit is to be operated within a confined space or within a building of unusually

tight construction, air for combustion and ventilation must be obtained from outdoors or other spaces freely

communicating with the outdoors. At least one square inch of free area per 1000 Btuh of total input rating of all

appliances within the space provided up to 400,000 Btuh. Refer to CAN/CSA/1-B149.1 natural gas, or

CAN/CSA/1- B149.2 and B139, propane gas and B139 for air supply requirements of appliances heating input

exceeding 400,000 Btuh. For USA units refer to ASSI Z223.1 section 1.3.4.2 and 1.3.4.3 for combustion air

requirements.

Ducts connected to the furnace shall have removable access panels on both the upstream and downstream sides of

the furnace. These openings shall be accessible when the furnace is installed and shall be sized to allow the

observation of smoke or reflected light inside the casing to indicate the presence of leaks in the heat exchanger. The

covers for the openings shall be attached in such a manner as to prevent leaks.

The furnace must not be operated in the presence of chlorinated vapors. When such vapors mix with the products of

combustion, highly corrosive compounds result which will cause the premature failure of the heat exchanger and

other components, voiding the warranty.

CONNECTING THE FLUE

In making flue connections to the unit, observe the following general recommendations. In addition, these

connections must conform to the requirements of current CAN/CSA/B149.1 natural gas and CAN/CSA/ B149.2 and

be in accordance with provincial and local authorities who have jurisdiction. For USA units, all venting installations

shall be in accordance with the latest edition of Part 7, “Venting of Equipment”, of the National Fuel Gas Code,

ANSI Z223.1-1992 (or the latest edition), or applicable provisions of local building codes.

*See Fig. II and Fig. III for C vent system.

*Some jurisdiction may require a positive pressure vent system.

*The flue must be securely attached to the unit with tight joints.

*The pipe from the unit to the flue should rise at least ¼ inch per foot.

*The flue must not be sized to have a cross-sectional area less than that of the flue collar at the

unit. See Fig. II and Fig. III.

*Other appliances must not be connected so as to vent through the flue of this unit.

*Do not use 90-degree tees or elbows greater than 45 degrees.

*Do not support the weight of the stack on the flue connection of the heating section.

*Minimize connecting pipe length and the number of bends by locating the unit as close to the flue pipe as

possible.

*Maintain clearances between the flue pipe and combustible materials that are acceptable to the federal,

provincial and local authorities having jurisdiction.

*Unit must be connected to a flue having sufficient draft to ensure proper operation of the unit.

3

1) FOR POWER VENTED UNITS: The flue draft should be adjusted at the damper of the induced

draft fan when the unit is operating on high fire. The overfire draft measured with a manometer at the

test port in the relief door should be minus 0.01 to minus 0.50 in W.C. as specified on the rating plate

of the unit.

2) FOR GRAVITY VENTED UNITS: The flue draft should be adjusted at the damper of the burner fan

when the unit is operating at high fire. The overfire draft measured with a manometer at the test port in

the relief door should be positive 0.01 to positive 1.0 in W.C. as specified on the rating plate.

ELECTRICAL CONNECTIONS

NOTE: This unit has been examined and tested for compliance with CSA C22.2 No. 0 and CSA C22.2 No. 3.

All electrical work must conform to the requirements of the current CSA standard C22.1 Canadian Electric Code

Part 1 and local ordinances.

Control voltage is as indicated on the rating plate.

Follow the wiring diagram supplied with the unit. This type of unit is available with a variety of fuel control

schemes. Please ensure that you are using the correct wiring diagram for installation or trouble shooting.

If a space thermostat is used with the furnace, locate the thermostat so that cold drafts and hot discharge air streams

do not affect its performance. Do not mount the thermostat on the casing on the unit, as it will be affected by

radiated and conducted heat. Refer to the instructions furnished with the thermostat for further details.

If any of the original wire as supplied with the unit must be replaced, it must be replaced with type TEW 105 degrees

or its equivalent except where noted.

Temperature controllers, limit controllers, remote selector switches, door switches or any other auxiliary electrical

items must be connected to the terminals provided and shown on the wiring diagram.

For units shipped in two sections, electrical connections between sections are to be made by installer in the field.

Field wiring to be done by the installer is denoted by dotted lines on the wiring diagram. Solid lines on the wiring

diagram indicate factory wiring by the manufacturer.

NOTE: Because bolts and set screws may become loose during unit shipment, such fasteners should be tightened

upon installation.

WARNING: Fire or explosion hazard can cause property damage, severe injury, or death. Check for gas

leaks with rich soap and water solution any time work is done on a gas line. Never use an open

flame to detect gas leaks.

GAS PIPING

All gas piping should be in accordance with CAN/CSA/1-B149 and the regulations of local authorities having

jurisdiction. Emergency manual shut down valve should be provided upstream of piping to unit and should be

labeled for quick identification. Color coding of gas piping is also recommended.

Carefully check the unit rating plate for fuel type and supply pressure.

*Locate the high pressure regulator, if required, at least five feet from the unit.

*Gas lines must not be located in such a way as to hinder access to the unit

4

*A tee shall be installed in the supply line at the same elevation as the gas inlet connection. The tee must be

equipped with a nipple and pipe cap to serve as a condensate collector.

*Test for tightness of gas connections after installation.

GAS VENT

High gas pressure regulator (if required), low pressure regulator, pilot pressure regulator, gas pressure switch (if

supplied), and normally open vent valve (if supplied) must be vented outside of building for an indoor unit. (Check

with authorities having jurisdiction).

GENERAL OPERATING INSTRUCTIONS

WARNING: Fire or explosion hazard can cause property damage, severe injury, or death. Check for gas

leaks with rich soap and water solution any time work is done on a gas line. Never use an open

flame to detect gas leaks.

GAS-FIRED UNITS

Refer to the rating plate for fuel input and supply pressures.

DO NOT ATTEMPT TO START THE BURNER IF THE UNIT IS FULL OF VAPOR OR GAS, OR IF THE

COMBUSTION IS VERY HOT.

DO NOT USE THIS UNIT TO BURN GARBAGE OR PAPER.

DO NOT LEAVE COMBUSTIBLE MATERIALS NEAR THE UNIT.

SHUT OFF THE MANUAL FUEL SUPPLY VALVE IF THE BURNER IS SHUT DOWN FOR AN EXTENDED

PERIOD OF TIME.

ENSURE CLEAN-OUT DOORS ARE IN PLACE BEFORE STARTING THE BURNER.

DO NOT START THE BURNER UNLESS THE BLOWER ACCESS DOORS ARE SECURELY IN PLACE.

START-UP PROCEDURES

WARNING: Fire or explosion hazard can cause property damage, severe injury, or death. Check for gas

leaks with rich soap and water solution any time work is done on a gas line. Never use an open

flame to detect gas leaks.

PRECAUTIONS

1. Ensure the main disconnect switch is in the “off” position.

2. Ensure the burner on-off switch is in the “off” position.

3. Check all electrical connections and tighten if necessary.

4. Check main fans (by rotating fan shaft by hand), bearing set screws, exhauster wheel, and pulley set screws.

5

5. Lubricate (if necessary) the burner, induced draft fan and main fan motors. The specifications on

the motors for grease and oil shall be adhered to.

6. Check heater outlets and exhauster, or induced draft discharge for obstructions.

7. Check fan-limit control. Setting should be as follows:

MODEL CONFIGURATION MAIN AUXILIARY

LIMIT FAN* LIMIT FAN*

C Horizontal Suspended 240 120 NA NA

D Vertical Upflow Floor set 180 80 NA NA

R Vertical Down flow Floor set 180 80 165 100

M Horizontal Floor set 240 120 NA NA

AC Vertical Upflow Floor set 180 80 NA NA

*Fan “ON” settings, set differential for Fan “OFF” 15-20 degrees below fan setting.

8. Ensure that the flue is in place and providing proper overfire draft as noted in previous section on

“Connecting the Flue”.

9. The induced draft proving switch (power vented units only) is factory set and must not be tampered with. This

switch will not allow unit operation if overfire draft is outside of the acceptable operating range.

10. Check all fuse blocks to determine that all fusing is installed.

11. Set the operating controls (eg. thermostat, remote panel switches) so as to allow heating

operation of the unit.

12. Reset the primary flame safeguard by pushing the reset button or lever.

13. Reset motor starter by pushing the reset button, if so equipped.

14. Check building system gas supply and be sure all lines are purged of air.

15. Check building system gas supply pressure.

CAUTION - GAS UNITS

At maximum input the gas pressure must fall within the range specified on the unit rating plate.

Optional high and low gas pressure switches (if supplied) must be reset.

16. Check all piping for tightness and correct any signs of leaks.

WARNING: Fire or explosion hazard can cause property damage, severe injury, or death. Check for gas

leaks with rich soap and water solution any time work is done on a gas line. Never use an open

flame to detect gas leaks.

START-UP

1. Refer to factory test report for correct settings that are to be checked on the unit.

2. Check the supply fan motor thermal overload setting against the rating plate figure.

3. Ensure burner on-off switch is “off”. (On heating units using a fan plenum switch, jumper the fan switch).

4. Put the main disconnect switch in the “on” position, thus activating the supply fan. Check for correct direction

of rotation.

5. Check supply fan motor load against rating plate figure. If actual figure is significantly different than the rating

plate value, take corrective actions with respect to duct work and accessories external to the unit

6

6. The thermal overloads must be left set appropriate to the motor performance after all adjustments have been

made.

7. Repeat steps 2 through 6 for the induced draft fan motor (power vented units only).

8. Remove jumper from fan switch if installed in step 4 above.

9. Ensure all manual fuel valves are open.

10. Turn on-off switch on burner to “on” position.

11. Check direction of rotation of burner fan.

12. Set thermostat to temperature desired.

13. After a prepurge period the pilot will light and main burner will energize. Check for good clean flame and

smooth light-off conditions.

14. Check unit performance as described on the factory test report. (Include items such as stack temperature, CO-2

level, flame signals, etc.). Readings obtained in the field should not deviate significantly from those obtained at

the factory.

SHUT DOWN

EMERGENCY SHUT DOWN

1. Set disconnect switch to “off” position.

2. Close the manual main fuel valve.

3. Set the burner on-off switch to “off” position.

SERVICE SHUT DOWN

1. Set the burner toggle switch to “off” position.

2. Close the manual main fuel valve.

3. Set the operating controls (eg. thermostat, remote panel switches) so as to prevent heating operation.

TROUBLE SHOOTING GUIDE

WARNING: Fire or explosion hazard can cause property damage, severe injury, or death. Check for gas

leaks with rich soap and water solution any time work is done on a gas line. Never use an open

flame to detect gas leaks.

7

The equipment has been electrically and fire tested prior to shipment. However, during transit, misadjustment of

controls and loose wires could develop. Do not assume a control is defective until it and its associated wiring is

checked.

This equipment has may items supplied to us by outside vendors. This manual is accompanied by information sheets

on most of these items which should be referred to for detailed service information.

The following is an obvious list of items that could cause field problems; however, it does not cover all problems

encountered and is meant to be used as a guide only.

1. EXHAUSTER* AND/OR BURNER MOTORS FAIL TO RUN. CONTROL RELAY DOES NOT

FUNCTION.

A) Blown fuses. Main disconnect open.

B) Control relay off on flame failure. Push reset button on control.

C) Thermostat or duct stat not calling for start-up. Defective control.

D) Loose wire or low voltage.

E) Motor overcurrent protector tripped in open position or defective.

F) Controls in limit circuit defective or tripped in open position.

G) Control transformer defective.

2. EXHAUSTER* AND/OR BURNER MOTORS RUN, NO IGNITION OR MAIN FLAME. PRIMARY RELAY

WILL NOT INDICATE FLAME FAILURE.

A) Exhauster* and/or burner motors running backwards.

B) Misadjusted draft.

C) Misadjusted or defective exhauster draft switch*.

D) Main safety gas valve proof of closure switch and/or low fire proving switch (on modulating burners only)

not made.

E) High or low gas pressure switch tripped.

3. EXHAUSTER* AND/OR BURNER MOTORS RUN, NO IGNITION OR MAIN FLAME. PRIMARY

RELAY LOCKS OUT ON FLAME FAILURE.

A) Fuel valve manually closed.

B) Ignition transformer or pilot defective. Defective or improperly gapped ignition electrodes. Cracked

porcelain.

C) Broken or loose wire in fuel circuit.

D) Gas nozzles obstructed or plugged.

E) Gas pilot valve defective. Main fuel valve defective.

F) Insufficient fuel at supply. Air in system.

4. BURNER SHORT CYCLES.

A) High limit switch misadjusted or defective.

B) Draft switch* misadjusted or defective.

C) Various ductstats defective or settings improper.

5. EXHAUSTER* AND/OR BURNER MOTORS RUN, IGNITION AND MAIN FLAME. MAIN FAN MOTOR

FAILS TO OPERATE.

A) Automatic fan switch not set properly or defective.

B) Blown fan fuses.

C) Motor overcurrent protector tripped open or defective.

8

6. UNABLE TO ADJUST FIRE TO BURN CLEANLY.

A) Insufficient exhauster* draft.

B) Insufficient or too much fuel at supply.

C) Incorrect adjustment of air shutters at burner.

D) Insufficient combustion air available.

E) Burner blower wheel running backwards.

7. INSUFFICIENT HEAT BEING DISCHARGED INTO AREA.

A) Main fan blowers running backwards.

B) High limit switch setting too low or defective.

C) Burner locked in low fire position.

D) Ductstat setting improper or defective.

E) Field mounted thermostat and/or ductstats improperly wired.

*APPLIES TO POWER VENTED UNIT ONLY.

MAINTENANCE

Regular maintenance is necessary to ensure the efficient operation and long life of this unit. This maintenance should be

performed by, or supervised by, qualified service personnel. A maintenance schedule should be prepared for the unit

based on its application and location.

RECOMMENDED MONTHLY MAINTENANCE

1. Check for loose connections in the wiring.

2. Check the voltage at the unit while it is in operation.

3. Check motor amperage draws against rating plate values.

4. Inspect all contactors to ensure that they are clean and making good contact.

5. Check all fittings, valves and lines for leaks.

6. Check the burner; clean and adjust if necessary.

7. Check the flame sensor; clean if necessary.

8. Check the fuel supply pressure to the unit.

9. On gas fired units, check the manifold pressure.

10. Clean or replace air filters if necessary. Replace filters only with type equivalent to those supplied with the unit

by the factory.

11. Check all damper, linkages and damper actuators; adjust and tighten as required.

12. Check all belts; adjust or replace as necessary.

13. Check operation of all safety controls.

RECOMMENDED YEARLY MAINTENANCE

1. Perform the monthly maintenance recommended.

2. Inspect blower wheels and housing; clean if necessary.

3. Inspect all set screws on blower wheels and pulleys to ensure that they are secured to their respective shafts.

4. Check ignition spark and adjust gap if necessary.

5. Inspect and clean ignition electrodes.

6. Check flame supervisor relay.

7. Inspect all operating and safety controls; clean and replace if necessary.

8. Inspect the header box and secondary tubes through the access panels provided. Check for carbon deposits,

soot, scale, or rust; clean as required. Check condition of flue pipe.

9. Clean the primary combustion chamber.

10. Clean the burner.

NOTE: Refer to manufacturer literature provided for maintenance requirements of optional equipment.

9

BEARING INSTALLATION AND MAINTENANCE

NOTE: To prevent premature failure – please ensure greasing instructions below are applied. As well,

tighten bearing set screws, collars, and wheel lugs every four to six months.

ENGINEERING – BALL & ROLLER BEARINGS LUBRICATION

For bearings that are equipped with hydraulic grease fitting threaded into the housing for ease of lubrication, the

proper amount of lubricant in the bearing is important. Both excessive and inadequate lubrication may cause failure.

The bearings should be re-lubricated while they are rotating (if it is safe to do so); the grease should be pumped in

slowly until a slight bead forms around the seals. The bead in addition to acting as an indicator of adequate relubrication provides additional protection against the entry of foreign matter and helps flush out contaminates in the

bearing.

By the time the slight bead is formed, it will be noticed that the bearing temperature will rise. It is not uncommon for

the temperature to rise as much as 30 degrees Fahrenheit after re-lubrication. If necessary to re-lubricate while the

bearing is idle, refer to the recommended re-lubrication grease chart tables on the following page for various sizes of

the bearings.

Lubricant-Standard Bearings:

All bearing units are pre-lubricated at the factory with lithium soap grease which is compatible with multi-purpose

grease readily available from local suppliers. The lubricant selected for factory lubrication uses a highly refined

mineral oil with a high viscosity index, thickened with lithium soap to conform to NLGI grade 2 consistency. A

suitable additive package is added to protect the highly polished rolling contact surfaces from corrosion and

oxidation of the lubricant. The lubricant is satisfactory for an operating temperature range of –30 F to +250 F.

Select standard industrial grade greases that conform to the following specification for optimum bearing

performance:

General Duty Ball & Roller;

58-75 SUS @ 210 F

450-750 SUS @ 100 F

Premium Duty Ball & Roller;

68-75 SUS @ 210 F

600-750 SUS @ 100 F

Heavy Duty Roller Bearing;

82 SUS @ 210 F

886 SUS @ 100 F

NOTE: For heavy loaded roller bearing applications, grease with EP additives is often recommended for optimum

performance.

10

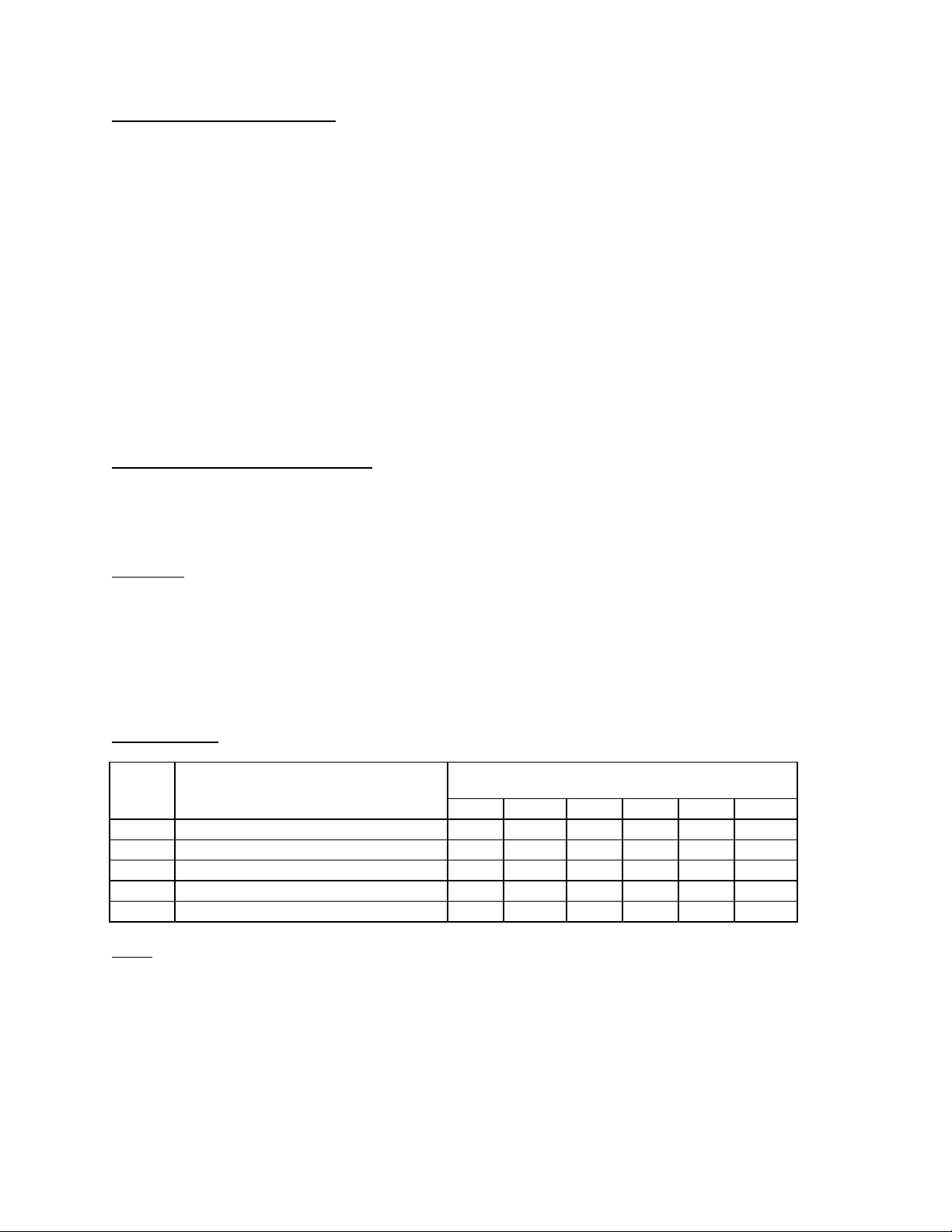

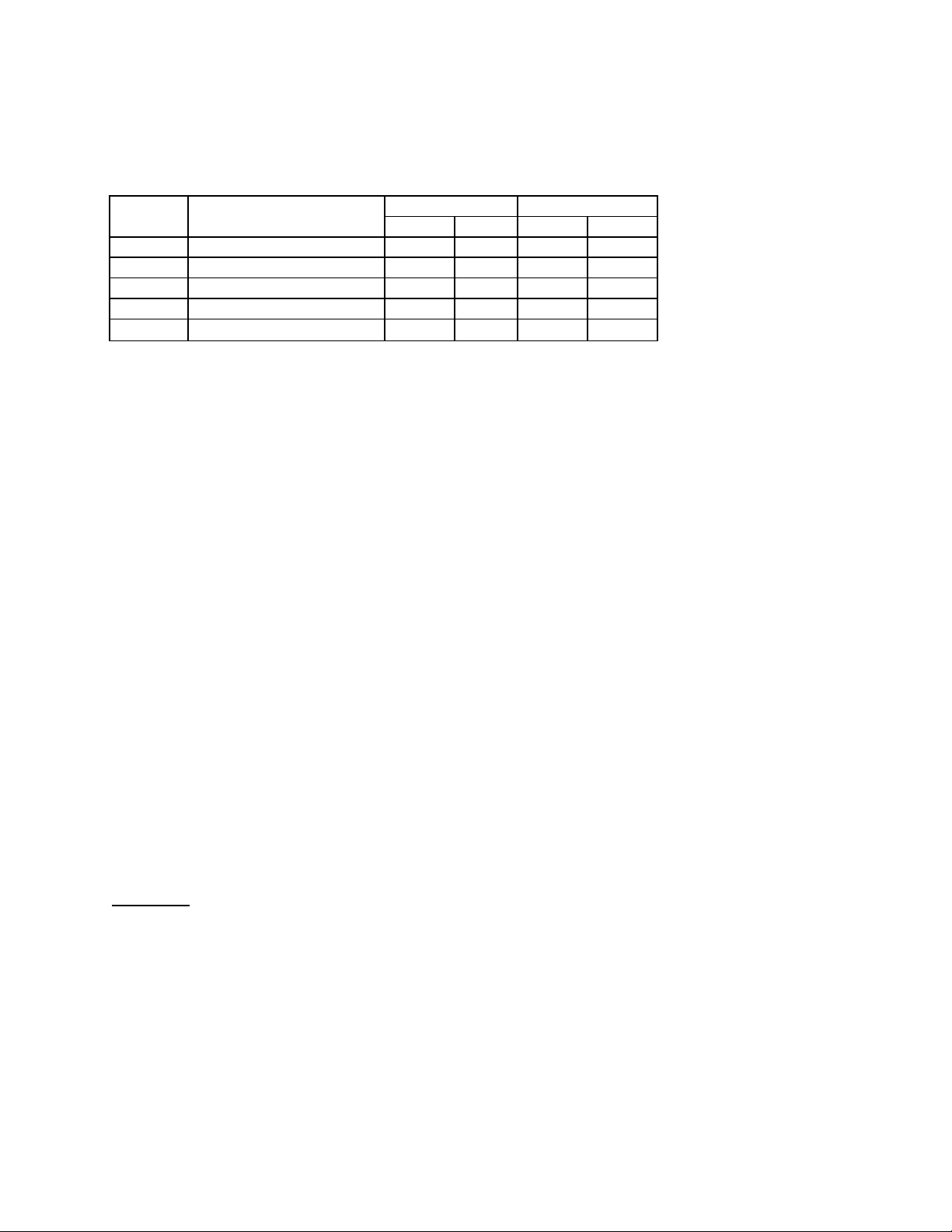

Table 1. Recommended Lubrication

Ball Bearings Roller Bearings

Shaft Size

(inches)

Grease Charge

(ounces)

Shaft Size

(inches)

Grease Charge

(ounces)

1/4 to 3/16 0.03 1-3/16 to 1-1/4 0.1

1/2 to 3/4 0.1 1-3/8 to 1-7/16 0.22

1-1/4 to 1-1/2 0.15 1-1/2 to 1-11/16 0.32

1-11/16 to 1-15/16 0.2 1-3/4 to 2 0.5

2 to 2-7/16 0.3 2 to 2-3/16 0.55

2-1/2 to 2-15/16 0.5 2-1/4 to 2-1/2 0.65

3 to 3-7/16 0.85 2-11/16 to 3 0.85

3-1/2 to 4 1.5 3-3/16 to 3-1/2 1.25

- - 3-15/16 to 4 2.5

- - 4-7/16 to 4-1/2 3.1

Frequency of re-lubrication depends upon operating conditions. The bearing operating temperature is the best index

for determining a re-lubrication schedule. The following chart gives the frequency of re-lubrication based upon

continuous operation for various operating temperatures and can be used as a satisfactory guide for determining

when bearings should be re-lubricated.

Table 2. Lubrication Frequency

Speed Temperature Cleanliness Greasing Interval

100 RPM Up to 120 F Clean 5 months

500 RPM Up to 130 F Clean 2 months

1000 RPM Up to 210 F Clean 2 weeks

1500 RPM Over 150 F Clean Weekly

Any speed Up to 150 F Dirty 1 week to 1 month

Any speed Over 150 F Dirty Daily to 1 week

Any speed Any temperature Very dirty Daily to 1 week

Any speed Any temperature Extreme conditions Daily to 1 week

11

SPA

N L

E

NGT

H

X

FORCE

DEFLECTION 1/64”

PER INCH OF SPAN

TENSIONING V-BELT DRIVES

1. Ideal tension is the lowest tension at which the belt will not slip under peak load conditions.

2. Check tension frequently during the first 24-48 hours of operation.

3. Over-tensioning shortens the belt and bearing life.

4. Keep belts free from foreign material that may cause slip.

5. Make V-drive inspection on a periodic basis. Tension when slipping. Never apply belt dressing as this will

damage the belt and cause early failure.

Check and tighten belt tension. The following procedure is recommended for tightening belts:

a) Measure span “X” shown in Figure A.

b) At the center of span length “X”, apply a force perpendicular to the span and large enough to deflect belt

1/64” for each inch of span length. Example- the required deflection for a 40” span would be 40/64” or

5/8”.

c) Compare the force applied with the values given in Table III. If force is between the minimum and

maximum range shown, the drive tension should be satisfactory. A force below the minimum value

indicates an under tightened belt and force that exceeds the maximum value indicates an over tightened belt.

FIGURE A

12

TABLE III

BELT CROSS MOTOR PULLEY DEFLECTION FORCE

SECTION PITCH DIAMETER MINIMUM MAXIMUM

(Marked on Belt)

3.0” - 3.6” 2.62lbs. 3.25lbs.

A 3.8” - 4.8” 3.0lbs. 4.0lbs.

5.0” - 7.0’ 3.25lbs. 5.0lbs.

3.4” - 4.2” 3.0lbs. 5.0lbs.

B 4.4” - 5.6’ 4.0lbs. 5.87lbs.

5.8” - 8.6” 5.25lbs. 7.87lbs.

GIDM INDUSTRIAL HEATER - WARRANTY

I.C.E. MFG. LTD. WARRANTS THAT IT WILL SUPPLY TO OR REPAIR FOR THE PURCHASER OF THIS

PACKAGE UNIT HEATER THE HEAT EXCHANGER FREE OF CHARGE F.O.B. FACTORY IF SAID HEAT

EXCHANGER WEARS OUT OR FAILS UNDER NORMAL USE AND SERVICE DUE TO A DEFECT IN

MATERIAL AND/OR WORKMANSHIP DURING FIVE (5) YEARS FROM DATE OF SHIPMENT FROM THE

FACTORY PROVIDED AN ALL STAINLESS HEAT EXCHANGER IS PROVIDED. COMBINATION

STAINLESS STEEL WITH MILD STEEL SECONDARY HEAT EXCHANGERS ARE WARRANTED FOR

ONE (1) YEAR.

ALL MECHANICAL COMPONENTS, MOTORS, BLOWERS, VALVES, AND CONTROLS ARE COVERED

BY A ONE (1) YEAR LIMITED WARRANTY.

THIS WARRANTY DOES NOT INCLUDE ANY FREIGHT, LABOUR, OR SALES TAXES THAT MAY BE

INCURRED BY THE PURCHASERS AND IS SUBJECT TO THE FOLLOWING CONDITIONS.

1) THE UNIT SHALL BE INSTALLED BY A QUALIFIED HEATING CONTRACTOR IN ACCORDANCE

WITH PROVISIONS OF THE SERVICE MANUAL.

2) THE UNIT SHALL HAVE BEEN INSTALLED IN ACCORDANCE WITH ALL PROVINCIAL AND

LOCAL CODES.

3) THE UNIT SHALL HAVE BEEN SUBJECT TO ONLY NORMAL USE IN SERVICE AND SHALL NOT

HAVE BEEN MISUSED, NEGLECTED, ALTERED OR OTHERWISE DAMAGED.

4) THE UNIT SHALL HAVE BEEN OPERATED WITHIN ITS PUBLISHED CAPACITY AND WITH THE

PRESCRIBED FUEL.

5) ALL AUTOMATIC CONTROLS SHALL HAVE BEEN OPERATIVE AT ALL TIMES.

6) THE UNIT HAS NOT BEEN ALLOWED TO EXCEED its PROPER TEMPERATURE LIMITS DUE TO

CONTROL MALFUNCTION OR INADEQUATE AIR CIRCULATION.

7) THERE IS NO EVIDENCE OF TAMPERING OR DELIBERATE DESTRUCTION.

8) THE UNIT HEATER HAS NOT BEEN SUBJECT TO AIR FOR COMBUSTION CONTAMINATED WITH

FLUORIDES, DRY CLEANING FLUID VAPORS HAIRDRESSING FLUID VAPORS, (OR ANY VAPORS

FOUND TO HAVE ADVERSE EFFECT ON METALS).

NO REPRESENTATIVE OF ICE MFG. LTD., OR ANY OF ITS DISTRIBUTORS OR DEALERS, IS

AUTHORIZED TO ASSUME FOR ICE MFG. LTD. ANY OTHER OBLIGATIONS OR LIABILTY IN

CONNECTION WITH THIS PRODUCT, NOR ALTER THE TERMS OF THIS WARRANTY IN ANY WAY.

THIS WARRANTY IS LIMITED TO THE EXPRESS PROVISIONS CONTAINED HEREIN AND DOES NOT

EXTEND TO LIABILITY FOR LABOUR COSTS INCURRED IN REPLACING DEFECTIVE PARTS.

AUTHORIZATION TO RETURN ANY ALLEGED DEFECTIVE PARTS MUST BE OBTAINED FROM THE

FACTORY BEFORE THE PART IS TRANSPORTED AND THE TRANSPORTATION CHARGES FOR ANY

ALLEGED DEFECTIVE PARTS SHALL BE PREPAID BY THE OWNER. ICE MFG. LTD. WILL NOT

ACCEPT CHARGES FOR PARTS PURCHASED UNLESS THE CONDITIONS OF THIS WARRANTY HAVE

BEEN SATISFIED.

THE EXPRESS WARRANTIES HEREIN CONTAINED ARE IN LIEU OF ANY OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING THE WARRANTY OF MERCHANTABILITY AND OF FITNESS

FOR ANY PARTICULAR PURPOSE. ICE MFG. LTD. SHALL NOT BE LIABLE FOR DAMAGES,

INCLUDING SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF, OR IN

CONNECTION WITH THE PERFORMANCE OF THE GIDM SERIES UNIT HEATER OR its USE BY THE

OWNER. ICE MFG. LTD. LIABILITY IS LIMITED EXCLUSIVELY TO REPAIR AND OR REPLACEMENT

OF THE DEFECTIVE PART. PARTS CAN BE OBTAINED FROM ICE MFG. LTD. WINNIPEG, MANITOBA

ON THE BASIS THAT CREDIT WILL BE ISSUED IF DEFECTIVE PARTS RETURNED QUALIFY FOR

REPLACEMENT PURSUANT TO THE TERMS AND CONDITIONS OF THIS WARRANTY.

13

ECONOMITE 400-33 & F400-33 GAS BURNERS

INITIAL START UP AND ADJUSTMENT

CAUTION: Only qualified service personnel should attempt initial start-up.

1. Study these instructions, the wiring diagrams and flame safeguard instructions. Locate and identify all of the

burner components.

2. Have on hand: CO and CO2 tester stack thermometer, 0” to 30” W.C. gas pressure gauge, U-Tube manometer

and DC volt meter.

3. Make the proper setting on all limit controls and set the operating control to call for heat.

4. Check the piping for leaks. A quick way to do this is to turn off main shut-off valve “A” and pilot valve “B”,

then turn on the gas pressure to the gas supply line and observe the meter test dial. There should be no

movement of the dial hand for at least five minutes on a half foot dial (proportionally longer on larger dials).

All other gas appliances must, of course, be completely shut off during this test. If a leak is detected it should be

located with a soap suds test and corrected. If air or inert gas (do not use oxygen) under pressure is used for

leak detection, do not subject the main and pilot valves or regulators to pressure readings exceeding ½ PSI

(disconnect piping to prevent damage during high pressure leak testing).

5. Purge the gas supply line up to the main and pilot manual valves. Do not purge into the combustion chamber.

6. Make sure that the main and pilot manual gas valves are closed and that the burner line switch is off.

7. The pilot gas pressure regulator is set for 3 ½” W.C. outlet pressure which is suitable for natural gas and average

draft conditions. If propane gas is to be used, adjust the regulator to its minimum outlet pressure setting.

8. Firmly push in the flame safeguard manual reset button “C” and the Model F400 motor manual overload reset.

9. Check that the blower motor rotates freely.

10. Turn line switch on momentarily and check for proper blower wheel rotation.

11. Open pilot manual valve “B”.

12. Trial for pilot ignition. Turn switch to winter operation. If power vented, burner will be powered when air

switch contacts close. Flame safeguard is powered; motor relay 3K pulls in. As motor reaches operating speed,

the blower interlock switch “makes” to initiate a 30 second prepurge period. After prepurge, the load relay 1K

pulls in to energize the pilot solenoid and ignition transformer and the pilot should light.

13. If the pilot fails to light during the 15 second trial, it is probably due to air in the pilot line. Wait one minute and

push flame safeguard reset button to restart, (400 motor will continue to run during the safety lockout. F400

motor will stop approximately 15 seconds after solenoid valve closes).

14. Observe the pilot flame. If it is weak, screw in the pilot regulator adjustment. If it is excessively rich and large

or floating from the pilot tip, back off the regulator adjustment. Set the pilot to a stable blue flame which burns

firmly within the pilot tip. Check flame current with a DC volt meter. It should show a steady 15-17 volts

(Fireye) or 3-5 VDC (Honeywell). Operate air shutter throughout range to check pilot stability. Adjust pilot

regulator slowly to obtain highest reading possible, try several relights.

15. Set the shutter to match the intended input, i.e. full open for maximum, closed for minimum or partially open

for mid-range.

16. Slowly open main manual valve until the main flame ignites. Continue to open valve, adjusting air shutter if

necessary, if the manual valve is fully opened before input is reached, screw in regulator adjustment. Set

regulator to desired manifold pressure, marked on the rating plate.

NOTE: Do not screw the adjusting nut in past the point where no further increase in manifold pressure is noted.

If the specified pressure cannot be reached, check for proper inlet pressure at the inlet of the main manual valve

with the burner running.

17. Readjust the main air shutter to provide a quiet soft flame-blue at the burner nozzle with well defined orange tips

for natural gas or with well defined yellow tips for propane.

18. The primary air adjustment which affects the flame length has been set wide open for average conditions.

Decrease the primary air if a longer, softer flame is desired.

19. Cycle the burner on and off several times to check its operation.

20. Check the operation of the limit and operating controls.

21. Check the flue gas temperature ahead of the diverter. It should be above 300°F. Excessive flue temperatures

will result in low efficiencies. Low flue temperatures may cause excessive condensation. Reset gas input if

necessary to adjust stack temperature, (on/off operation only).

22. Make the final setting of the air shutter by checking the flue gases with an “Orsat” or other similar combustion

testing instrument. There should be no carbon monoxide and the carbon dioxide content should be within limits

prescribed by the local gas company. Make sure that the main air shutter is locked securely in place.

23. Recheck pilot to make sure that its operation has not deteriorated because of main shutter adjustment. If

necessary, readjust pressure regulator.

14

24. Modulation operation: see wiring diagram and modulating instruction sheets supplied with this unit for correct

set up.

25. If linkage between Butterfly valve and Burner (gravity unit only) and Venter fan if power vented needs to be

adjusted from factory setting, (see below).

GIDM LINKAGE SET-UP WITH POWER VENTS

1. Install a manometer on suction at test port in pop-up door.

a) Ensure there is a negative pressure at that point on low fire through to high fire.

- .50 To - 75” W.C. low fire and -.01 to -.10 on high fire.

2. To increase exhaust move drive rod toward damper pin (decrease the distance between drive rod and center pin).

3. To increase combustion air move drive rod towards center pin (decrease the distance between drive rod and

center pin).

4. To ensure a negative pressure throughout full modulation range, you may have to speed up exhaust and or burner

damper to match gas flow to the burner.

Move drive rod closer to the drive pin on the butterfly valve, (this will reduce the movement of the burner

damper).

5. Adjust low and high fire on the stop screws on the butterfly valve.

NOTE: The motor is allowed to over run with the spring linkage set the travel on the Penn Johnson motor to ensure

it does not go too far or damage to the motor could occur.

MINIMUM EQUIPMENT TO START-UP AND SET-UP GIDM GAS BURNER

1. CO and CO2 tester.

2. Stack thermometer.

3. 0” to 10” W.C. gas pressure gauge or magnehelic 0” to 10” W.C.

4. U-tube manometer or -5” to +5” magnehelic gauge.

5. DC volt meter.

15

ECONOMITE 400-33 & F400-33 GAS BURNERS

4904-45

Quadrant-Air Shutter Adjustment

5253-10

PVC tubing—7/16”I.D. x 2” long

PART # DESCRPTION PART # DESCRIPTION

3981-001 4” Diameter Stainless Sleeve 5253-01 Pilot assembly with insulators, rods, temflex and

baffle.

4905-15 Air shutter-Internal 5234-40 Flame rod Gland Nut

4917-00 Main Orifice Holder 5234-50 Flame rod assembly.

4918-11 Orifice Elbow (1” NPT) 5249-01 Pilot air baffle.

4919-60 Blower Wheel with centrifugal actuator and Disc 5249-32 Spark rod assembly.

4919-90 Centrifugal Actuator Disc 5250-00 Pilot tip with cone less insulators, rods, temflex

and baffle.

4927-509 1/6 HP motor 120/1/60 [G.E. 5KH35FN123X 5272-00 Blower inlet grille.

(note 1/3 HP substitute), 5KH33DG655Y,

5KH33DN171Y; Dayton 6K149; Marathon 5939-01 Flame rod wire--5” through 9” burner tube.

48S34D191A, 48S34D203; Universal Electric

HH1E001N; Century X-173668-XX] 8433-06 Pilot spud (.021)—PROPANE (3N4-021,

Y90AA-5232).

4922-90 Primary Air Shutter Kit

8433-10 Pilot spud (.032)—NATURAL (2-15M1-032,

4924-10 Inlet Side Plate Y90AA-5232).

4944-02 Main Spud 25/64” (.390) minimum capacity-- 8437-419 1/6HP totally enclosed motor 115/1/60 (Century

NATURAL—drill 7/16” (.437) for 400/540 MBH X-176797-XX) special and Canadian burners

range and omit for 540/700 range only. Not interchangeable with drip proof motor

4921-50.

4944-03 Main Spud #21 Drill(.390) minimum capacity--

PROPANE—drill for desired capacity per manual 8447-11 Ignition transformer 120/1/60 primary, 6000 volts

secondary (Webster 612-6A020, 612-6A044;

4944-10 Main Spud Extension France 3RABVR-19; Jefferson #638-181).

4946-00 Motor Spacer (4 required) 8450-21 Orifice holder sealing gasket.

4959-05 External Pilot Air Tube Kit 8451-06 Spark rod insulator sleeve.

5201-00 ½” sq. pass thru for 1/4” tube fitting (gas line) 8484-72 Heyco strain relief (SR-4K-1)--Flame rod wire.

5201-10 ½” sq. pass thru for 5/16” tube fitting (air line) 8484-75 Heyco strain relief (SR-11-2)--Spark rod wire.

5202-08 Pilot Spud #55 (.052) drill [was #54(.055)]-- 8484-78 Heyco snap bushing (B-8875-750).

NATURAL AND PROPANE

8502-05 Spark cable--15” burner tube.

5211-51 Motor, wheel and side plate assembly 120/1/60

8502-06 Spark cable--5” through 9” burner tube.

5225-263 Blower housing and burner tube assembly--9”

8423-16 Blower interlock switch (MICRO BZ-2RQ174-A2).

WARNING: Explosion hazard. Can cause serious injury or death. This device can malfunction if it gets wet. Never try to use a device

that has been wet - replace it.

DECODING CENTURY MOTOR NUMBERS. Single digit prefix denotes manufacturer’s location. Double digit suffix denotes

manufacturer’s mechanical code.

16

GP TYPE C FORCED DRAFT BURNER C-6.2 TO C-12.9

INITIAL START UP

1. Make sure burner power switch is off and manual main and pilot valves are closed.

2. Make proper settings on limit controls.

3. Have on hand CO and CO2 tester, stock thermometer, 0” to 30”W.C. gas pressure gauge, u- tube manometer and

D.C. volt meter.

4. Turn on burner power switch momentarily to check blower rotation.

5. Check gas tightness of main and pilot safety shut off valves (if used) by connecting a pressure gauge to the

pressure tap located between the safety shut-off valve and the test firing valve. When the test firing valves are

closed and the manual shut-off valves are opened, no pressure rise should show on the pressure gauge.

6. The air damper has been factory set approximately during test firing if need to adjust see linkage set up sheet

provided with unit. Turn on the burner switch, while the main and pilot gas firing valves are closed. After the

prepurge the ignition transformer and solenoid valves will be energized. Observe the ignition spark for proper

location and firmness. After the trial for ignition time, the ignition transformer and solenoid valve are

deenergized and the burner will lock out.

7. Open the pilot test firing valve and turn on the burner switch, while the manual main shut-off valve stays closed.

After the prepurge, the ignition transformer and the pilot solenoid valve are energized. Observe the pilot flame

and if necessary, adjust the pilot pressure regulator to obtain a stable flame with the highest steady flame signal.

For flame signal readings, see attached flame safeguard manual. With the main manual shut-off valve still closed,

the flame safeguard will lock out after approximately 10 seconds, only with high/low and modulating burners

which use an interrupted pilot. Repeat the ignition cycle a few times to ensure a fast ignition and stable pilot

flame.

8. Open the main manual shut-off valve and set the high/low limit switch and the modulating controller so that after

establishing a main flame, the burner will travel to high fire. Start the burner. In high fire, check the manifold

pressure with the required pressure for the firing rate, (see suggested inspection list) and if necessary, adjust

pressure regulator. Readjust the air damper if fire looks to lean or too rich.

9. Take a gas meter reading and readjust manifold gas pressure if necessary. Take a CO2 or O2 and a CO reading.

CO2 should be between 8-1/2 and 9-1/2 % and O2 should not be more than 5%, both with a maximum CO reading

of .04%. Readjust air damper accordingly.

10. With high/low and modulating burners, mark the high air damper position and set the high/low limit control or

modulating control so that the burner travels to low position. Visually adjust the input adjuster on the main gas

shut-off valve actuator if low fire is too rich or too lean. Take gas meter reading and readjust the input adjuster

according to the required low fire input, but not less than indicated in the specifications table. In order to keep

the high fire setting unchanged when adjusting the low fire air damper position, drive the burner to high fire,

change the positioning of the linkage as indicated in “Low Fire Adjustment”, drive the burner back to low fire

and check the CO2 or O2 readings. Repeat this procedure until a satisfactory setting is obtained.

11. Make sure all linkage connections are tight and check the readings in high and low fire again.

11a. The motor is allowed to over run with the spring linkage. Set the travel on the Johnson motor to ensure it does

not go too far, or damage to the motor could occur.

12. Reset controller and limits to their desired settings.

WARNING

DO NOT ADJUST FLAME VISIBLY. INSTRUMENTS ARE THE ONLY SAFE AND

RELIABLE MEANS TO DETERMINE THE PROPER ADJUSTMENTS.

17

BURNER SAFETY CHECK

1. Start and stop burner several times to ensure proper operation.

2. Check operation of combustion safeguard control by simulating a flame failure, making certain the burner locks

out on safety within the proper time.

3. Check operation of the air flow switch, making certain fuel valve closes when the air flow diaphragm switch

opens.

4. Bypass discharge controller and check to ensure high limit will shut down burner on temperature increase. If

changed reset as per factory setting.

5. Reset operating control to desired temperature. Permit burner to run until it is shut off by the operating control.

Adjust operating control, if necessary, until it causes burner to stop and start within desired range.

6. With the burner running, check hi and low gas pressure switch if on manifold. The burner should shut off

immediately.

7. Conduct minimum, pilot turn down test, reduce gas pressure to pilot with manual shut off cock to the point pilot

flame is extinguished or fails to prove. Increase gas flow slightly. Main flame must be ignited with this pilot

flame.

8. The following readings should be taken and record after final adjustments have been made.

a) Burner input (CFH gas).

b) Percent CO2 or O2.

c) CO indication.

d) Stack temperature.

e) Firebox pressure.

f) Fuel pressure (in W.C.-gas) (main and pilot).

g) Voltage to burner.

9. Give instruction to owner (operator).

WARNING: SHOULD OVERHEATING OCCUR

1. Shut off the manual gas control (s) to the burner.

2. Do not shut off the control switch to the pump or blower.

18

Loading...

Loading...