Reznor AB225 Installation Manual

!

Y

C

N

E

E

V

N

G

O

A

C

C

U

S

T

O

M

CQS

E

Q

R

U

A

P

L

I

R

T

Y

O

D

U

C

T

P

R

O

C

E

S

R

G

S

E

N

T

P

U

-

T

R

A

T

S

M

Y

E

T

T

S

N

Y

S

A

R

R

A

W

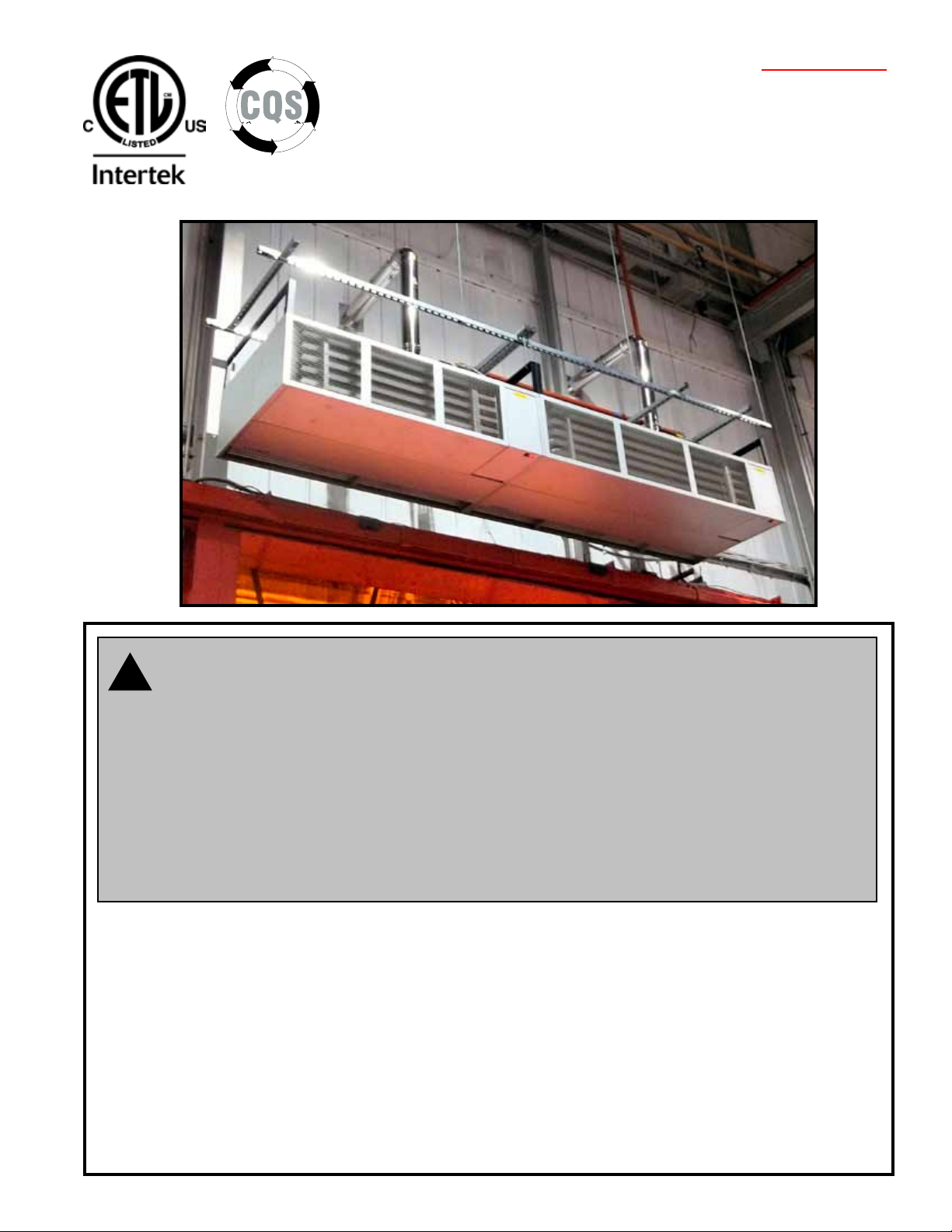

Installation, Operation & Spare Parts Manual for

Gas Fired Air Curtain

Obsoletes Form I-A C (1-16)

Form I-A C (2-16)

APPLIES TO:

Models AB 175 and AB 225

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death, or

property damage.

Be sure to read and understand the installation, operation, and service instructions in

this manual.

Improper installation, adjustment, alteration, service, or maintenance can cause

serious injury, death, or property damage.

— Do not store or use gasoline or other ammable vapors and liquids in the vicinity

of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier from a phone remote from the building. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the re department.

— Installation and service must be performed by a qualied installer, service agency,

or the gas supplier.

Form I-A C (2-16), Page 1

TABLE OF CONTENTS

1.0 General ................................................................. 2

1.1 Cautions and Warnings .................................... 2

1.2 General Information .......................................... 3

1.3 Warranty ........................................................... 3

1.4 Installation Codes ............................................. 3

2.0 Receiving, Uncrating and Preparing for Installation .. 3

3.0 Air Curtain Location ............................................ 4

4.0 Dimensions, Clearances & Features.................. 4

4.1 Dimensions ....................................................... 4

4.2 Combustible Clearances .................................. 5

4.3 Features ........................................................... 5

5.0 Position and Mounting ........................................ 6

5.1 Single Air Curtain .............................................. 6

5.2 Multiple Air Curtains ......................................... 6

5.3 Adjusting of Air Outlet Louvers ......................... 7

6.0 Mechanical ........................................................... 8

6.1 Gas Piping and Pressures ................................ 8

6.2 Venting ........................................................... 10

7.0 Electrical and Wiring ......................................... 13

7.1 Wiring ............................................................. 13

7.2 Typical Unit Wiring Diagram ........................... 13

7.3 Burner Controls .............................................. 14

8.0 Pre Startup Check, Adjustment, Startup & Shut-

down ..................................................................................14

8.1 Pre Startup Check .......................................... 14

8.2 Gas Connection Check .................................. 14

8.3 Gas Piping Check ........................................... 14

8.4 Gas Pressure Adjustment Procedure ............. 15

8.5 Vacuum Setting Check ................................... 16

8.6 Lighting Sequence .......................................... 16

8.7 Startup ............................................................ 16

8.8 Shutdown ....................................................... 16

9.0 Trouble Shooting ............................................... 17

10.0 Spare Parts ....................................................... 19

11.0 Service .............................................................. 20

INDEX ........................................................................ 22

INSTALLATION RECORD ........................................ 23

1.0 General

1.1 Cautions and

Warnings

Denitions of Hazard

Intensity Levels

used in this Manual

There are warning labels on the unit, on the front page and throughout this manual.

For your safety, comply with all warning during installation, operation and service of

this system. Denitions of the hazard intensity levels of the cautions, warnings and

dangers are shown below.

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in severe personal injury or

death and/or property damage.

2. WARNING: Failure to comply could result in severe personal injury

or death and/or property damage.

3. CAUTION: Failure to comply could result in minor personal injury

and/or property damage.

WARNING

Gas-red appliances are not designed for use in hazardous atmospheres containing

ammable vapors or combustible dust, in atmospheres containing chlorinated or

halogenated hydrocarbons, or in applications with airborne silicone substances.

WARNING

Should overheating occur, or the gas supply fail to shut off, shut off the manual gas valve

to the appliance before shutting off the electrical supply.

WARNING

Do not use this appliance if any part has been under water. Immediately call a qualied

service technician to inspect the appliance and replace any gas control that has been

under water.

Form I-A C (2-16), Page 2

1.2 General

Information

1.3 Warranty

This manual includes installation, operation and spare parts information. Before

beginning any procedure, carefully review the information, paying particular attention

to the warnings. If you do not have knowledge of local requirements, check with the

local agencies who might have requirements concerning the installation. Become

familiar with the requirements of your particular installation and make preparations for

necessary supplies, equipment and manpower.

These air curtains are ONLY for indoor applications designed to operate at an

ambient temperature range between 5°F (-15°C) to 86°F (30°C).

Never place or rest anything, especially ladders against the air curtain.

The installation instructions in this manual apply to Gas Fired Air Curtain Models

AB 175 and AB 225.

Refer to limited warranty information on the warranty form in the “Literature Bag”

shipped with this unit.

If an extended warranty form applies, keep the extended warranty information for

future reference and verication of warranty.

Warranty is void if:

a) The wiring is not in accordance with the diagram furnished with this unit.

b) The unit is installed without proper clearances to combustible materials

c) Unauthorized replacement parts are used.

1.4 Installation

Codes

California Warning

Label

Massachusetts

Requirements

2.0 Receiving,

Uncrating and

Preparing for

Installation

The units contained in this manual are design-certied to ANSI and CSA standards

by ETL. These models are approved for installation in the United States and in

Canada.

The units are approved for use with either natural gas or propane. The type of gas

for which the air curtain is equipped and the correct ring rate as shown on the rating

plate attached to the unit.

Electrical characteristics are shown on the unit rating plate.

These units must be installed in accordance with local building codes. In absence

of local codes in the United States, the unit must be installed in accordance with the

National Fuel Gas Code NAPA/ANSI Z223.1a (latest edition) or CAN/CSA-B149.1

and B149.2. (See Paragraph 1). These codes are available from CSA Information

Services 1-800-463-6727. Local authorities having jurisdiction should be consulted

before installation is made to verify local codes and procedure requirements.

If this system is being installed in the state of California, the installer MUST attach the

California warning label on the outside of the heat section access panel.

The California Warning label, P/N 196977, is shipped in the “Literature Bag”.

Select a dry, clean location on the heat section access panel and adhere the label.

If this system is being installed in the Commonwealth of Massachusetts, it must be

installed by a licensed plumber or licensed gas tter.

This unit was inspected and test operated at the factory prior to crating and was in

operating condition. If the unit was damaged in shipment, document the damage

with the transporting agency and contact your distributor. If you are an authorized

distributor, follow the FOB freight policy procedures.

Check the rating plate for the correct gas specications and the electrical

characteristics of the unit to insure that both utilities are compatible to with the gas

and electric services specic to the installation site.

Read this manual and become familiar with the installation requirements of your

particular unit. If you do not have knowledge of local requirements, check with the

gas company or other local agencies that may have requirements concerning this

installation.

Form I-A C (2-16), Page 3

3.0 Air Curtain

PLAN VIEW

Location

Check the supporting structure to be used to verify that it has sufcient load-carrying

capacity to support the weight of the air curtain assembly.

The air curtain assembly must be level and comply with the clearances as shown in

Figure 2.

CAUTION: Do not locate the air curtain where it may be exposed

to water spray, rain or dripping water.

4.0 Dimensions,

Clearances &

Features

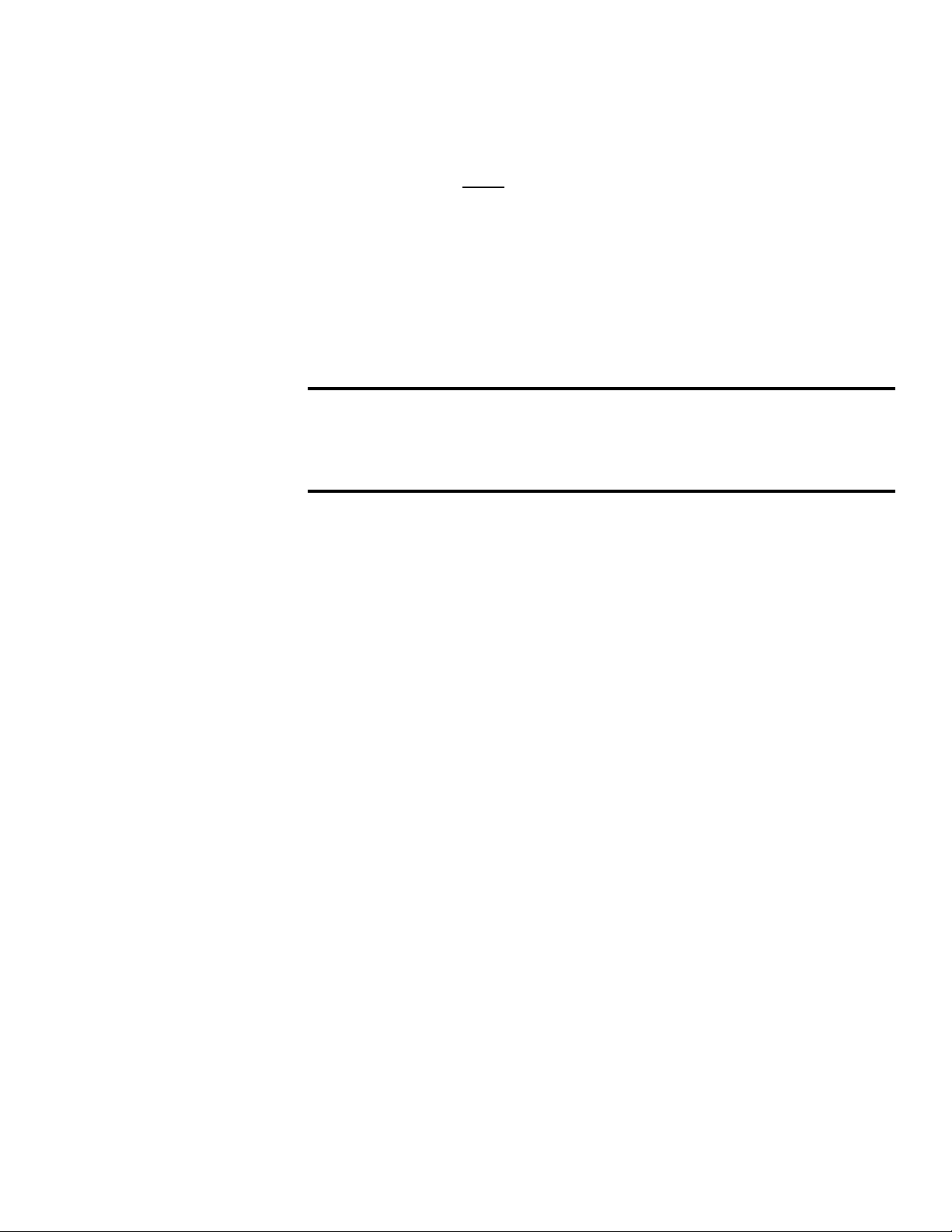

4.1 Dimensions

FIGURE 1 - Dimensions - inches/mm

Approximate Net Weight

Size 175 225

Weight - lbs

Weight - kg

408 507

185 230

F

E

Model

AB 175

AB 225

C

A

FRONT VIEW

RIGHT HAND VIEW

H

J

Gas Connection

B

G

K

Electrical Connection

L

Refer to Photo in Section

A

4.3 for actual features not

shown in PLAN VIEW

A

inch/mmB inch/mmC inch/mmD inch/mmE inch/mmF inch/mmG inch/mmH inch/mmJ inch/mmK inch/mmL inch/mm

68-7/8”

1750

88-9/16”

2250

37-3/8”

950

37-3/8”

950

18”

457

18”

457

27-9/16”

700

27-9/16”

700

32-5/16”

820

32-5/16”

820

4-7/8”

125

4-7/8”

125

67-5/16”

1710

87”

2210

45-1/4”

1149

45-1/4”

1149

14”

356

14”

356

3-5/16” 8414-5/8”

371

3-5/16” 8414-5/8”

371

D

Form I-A C (2-16), Page 4

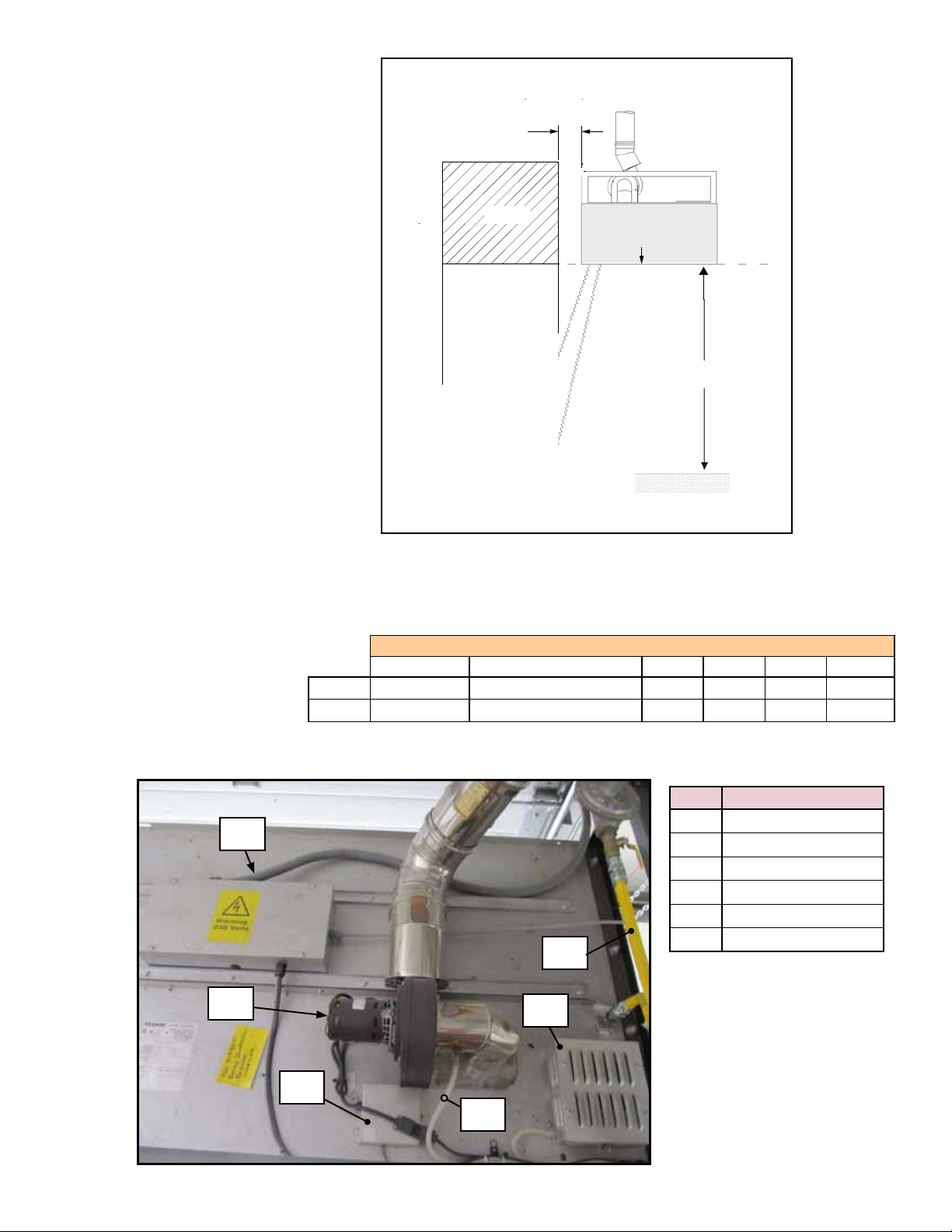

FIGURE 2 - Dimensional Clearances

Gap to be kept

to a minimum

4.2 Combustible

Clearances

Door

Outside

Bottom of air curtain

to be level with top

of door opening

6’- 0” (1.8m)

minimum

For safety and convenience, provide clearances as shown in the following table.

Clearance to combustibles is dened as the minimum distance from the heater to a

surface or object that is necessary to ensure that a surface temperature of 90°F above

the surrounding ambient temperature is not exceeded. Minimum clearances are also

listed on the heater rating plate.

Service Side Opposite Service Side Front Top Bottom Flue

Minimum Clearances to Combustibles - ALL Models

inches 18 6 3 18 36 6

mm 457 152 76 457 914 152

4.3 Features

No Feature

1 Main power cable

1

2 Gas supply line

3 Combustion air inlet

4 Limit control sensor

5 Vacuum line

6 Venter motor

2

6

3

4

5

Form I-A C (2-16), Page 5

5.0 Position and

Mounting

Determine the position of the air curtain with regard to clearances, venting, gas

supply connection, gas pressure, electrical supply connection and working height

consideration.

Air curtain units are supplied with mounting brackets pre-tted as either a single or

multiple units which can be bolted together for various door widths.

Refer to FIGURE 2 for minimum working height considerations.

5.1 Single Air

Curtain

5.2 Multiple Air

Curtains

Each single air curtain should be supported by cantilever brackets (not supplied) then

xed to the building structure by bolting directly using suitable support brackets or by

suspending from above using suitable steel work as shown in FIGURE 3 below.

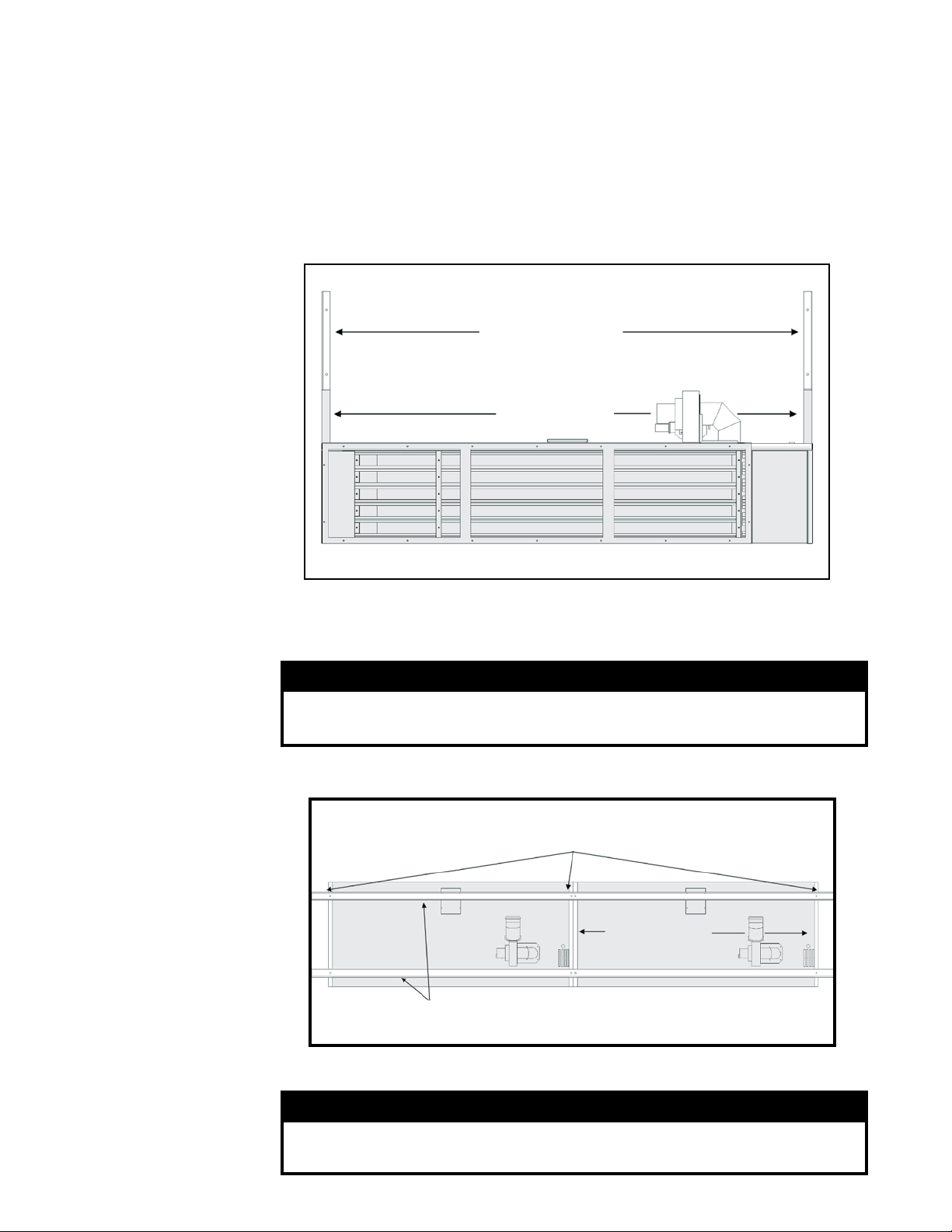

FIGURE 3 - Mounting of Single Air Curtain

Cantilever brackets

(not supplied)

Factory fitted mounting

brackets

FRONT VIEW

Multiple air curtains should be bolted together using 3 sets of 3/8-16 bolts, nuts and

washers tted through the existing holes in the factory provided mounting brackets

and then through the holes in the support channels (not supplied).

Form I-A C (2-16), Page 6

WARNING

Hardware must be positioned along the full length in the top of the

factory provided mounting brackets to insure proper load conditions.

The unit can now be directly attached to the building trusses by using suitable support

brackets or by suspending the unit from overhead steel work as shown in FIGURE 4.

FIGURE 4 - Mounting of Multiple Air Curtains

Support points

Air Curtain

Unit 1

Typical support channels (not supplied)

PLAN VIEW

If required, the support channels may be extend slightly past the ends of the air

curtains units to aid in fastening.

Factory fitted brackets

(supplied)

Air Curtain

Unit 2

WARNING

Mounting of Multiple Air Curtains may require larger support

channels to insure proper support of heavier loads.

5.3 Adjusting of Air

Outlet Louvers

To adjust the air outlet louvers:

• Loosening two hex head bolts at each end of the unit (total of four) as shown

below.

Button Head Socket

Cap Screws

Hex Head Bolts

• Loosen the two button head socket cap screws that lock the louvers in position.

(Note: two pair on Model AB 225 & one pair on Model AB 175) as shown.

• Now move the louvers to desired position and retighten all bolts / screws.

Form I-A C (2-16), Page 7

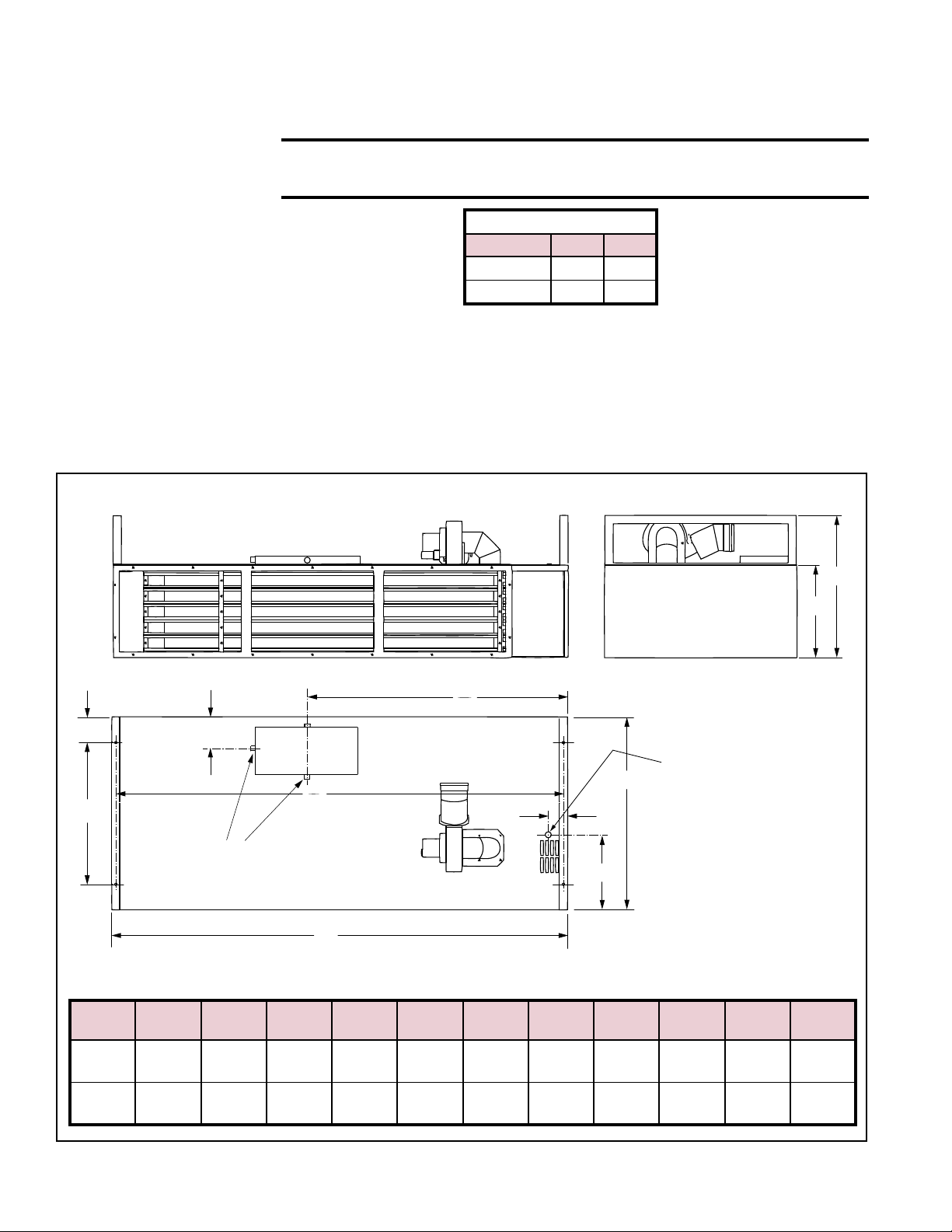

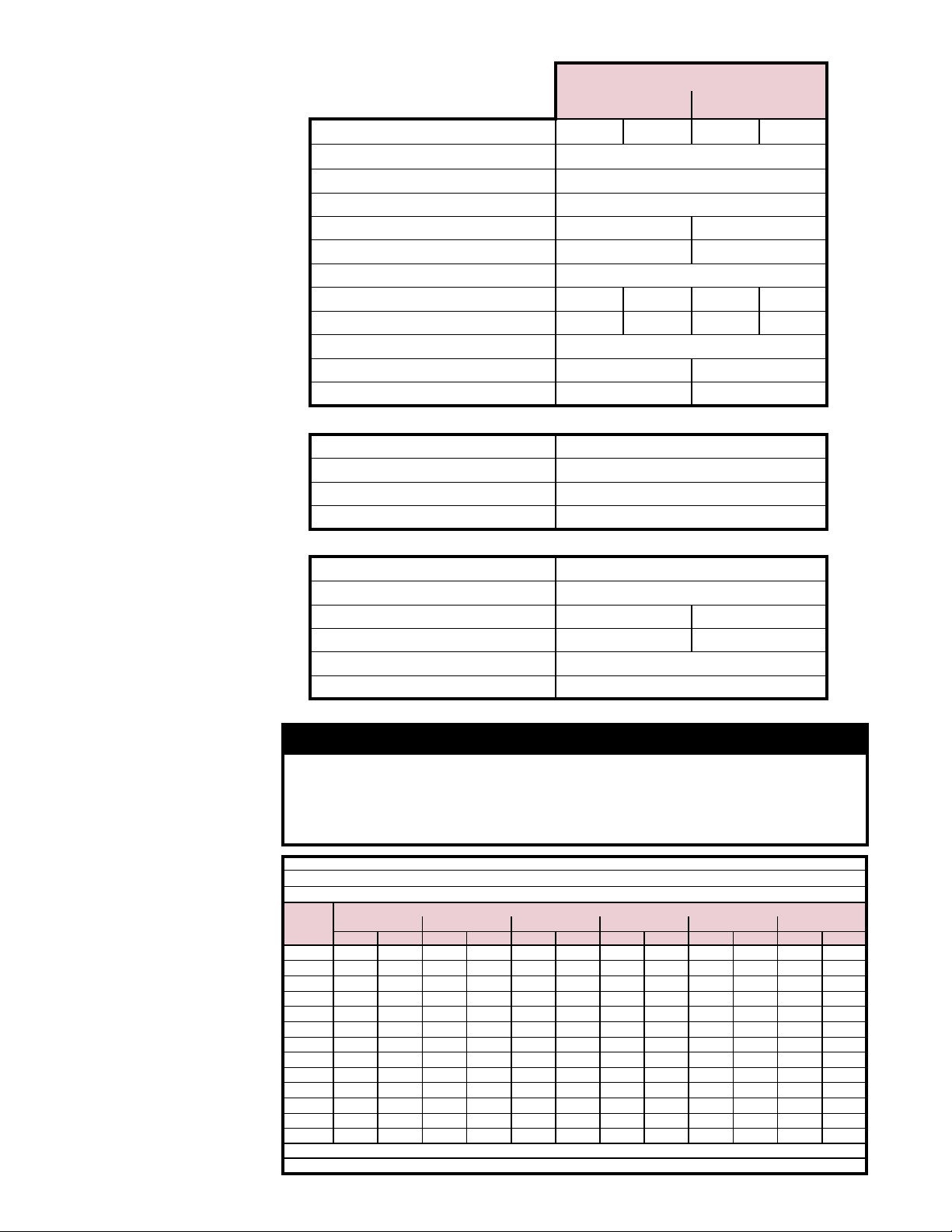

6.0 Mechanical

Models

Technical

Specications

Gas type

Gas connection

Max supply pressure (i.w.c.)

Min supply pressure (i.w.c.)

Gross heat input (BTU)

Gross heat output (BTU)

Number of orices

Orice size (mm)

Manifold pressure (i.w.c.)

Flue nominal diameter

Temperature rise (°C)

Temperature rise (°F)

Venter Fan

Voltage

RPM

Current

Capacitor

Air Distribution Fans

Type

Speeds

Number of fans

Maximum air volume (CFM)

Voltage

Power rating (per fan)

AB 225 AB 175

Natural Propane Natural Propane

1/2”NPT

14.0

5.0 / 12.0

225,000 175,000

180,000 140,000

5

3.3 1.85 2.9 #51 drill

3.5 10.0 3.5 10.0

6”

-5.0 / -2.8 -3.3 / -1.1

23 / 27 26 / 30

120 V / 60 Hz

3,400

1.7 A

10 mfd (370 Vac)

Direct Drive Centrifugal - 1/3 hp

2

4 3

6,170 4,320

230 V / 60 Hz

550 Watts

6.1 Gas Piping

and Pressures

Sizing a Gas

Supply Line

Form I-A C (2-16), Page 8

WARNING

This unit is equipped for a maximum gas supply pressure of 1/2

psi, 3.5 kPA or 14 inches water column. Supply pressure higher

than 1/2 psi requires installation of an additional lockup-type

service regulator external to the unit.

Capacity of Piping - Cubic Feet per Hour based on 0.3" i.w.c. Pressure Drop

Specic Gravity for Natural Gas -- 0.6 (Natural Gas -- 1000 BTU/Cubic Ft)

Specic Gravity for Propane Gas -- 1.6 (Propane Gas -- 2550 BTU/Cubic Ft)

Length

of

Pipe

20'

30'

40'

50'

60'

70'

80'

90'

100'

125'

150'

175'

200'

1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

Natural Propane Natural Propane Natural Propane Natural Propane Natural Propane Natural Propane

92 56 190 116 350 214 730 445 1100 671 2100 1281

73 45 152 93 285 174 590 360 890 543 1650 1007

63 38 130 79 245 149 500 305 760 464 1450 885

56 34 115 70 215 131 440 268 670 409 1270 775

50 31 105 64 195 119 400 244 610 372 1105 674

46 28 96 59 180 110 370 226 560 342 1050 641

43 26 90 55 170 104 350 214 530 323 990 604

40 24 84 51 160 98 320 195 490 299 930 567

38 23 79 48 150 92 305 186 460 281 870 531

34 21 72 44 130 79 275 168 410 250 780 476

31 19 64 39 120 73 250 153 380 232 710 433

28 17 59 36 110 67 225 137 350 214 650 397

26 16 55 34 100 61 210 128 320 195 610 372

Note: When sizing supply lines, consider possibilities of future expansion and increased requirements.

Refer to National Fuel Gas Code for additional information on line sizing.

Diameter of Pipe

Loading...

Loading...