Reznor 12, 20, LCSA-4 Series, 30, 50 Installation Commissioning Servicing & User Instructions

...

1610LCSA-4--EN

Gas-Fired, Balanced-Flue or

Power-Vented Unit Heater

LCSA-4

Installation, commissioning, servicing & user instructions

These appliances meet the following EC Directives

DIR 2009/142/EC: GAD

DIR 2004/108/EC: EMC

DIR 2006/95/EC: LVD

DIR 2006/42/EC MD

Applies to

Austria, Belarus, Bulgaria, China, Czech Republic, Croatia, Cyprus, Denmark, England, Estonia, Finland,

Germany, Greece, Hungary, Iceland, Latvia, Lithuania, Montenegro, New Zealand, Norway, Poland, Romania,

Russian Federation, Serbia, Slovakia, Slovenia, South Africa, Spain, Sweden, Turkey, Ukraine

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury, or death. All work must be carried out by appropriately qualified persons.

The manufacturer does not take any responsibility in the event of non-observance of the

regulations concerning the connection of the apparatus causing a dangerous operation of the

apparatus, possibly resulting in damage to the apparatus and/or environment in which the unit

is installed.

Please read this document carefully before commencing installation commissioning and/or

servicing.

Leave it with the user or attached to the appliance or gas service meter after installation.

Subject to modifications

1/25

TABLE OF CONTENTS

1.0 INTRODUCTION

1.1 Basic Information

1.2 Warranty

2.0 TECHNICAL DATA

2.1 Specifications

2.2 Dimensions

3.0 GENERAL REQUIREMENTS

3.1 Related Documents

3.2 Heater Location

3.3 Combustion Air Inlet Pipe and Flue Pipe

3.4 Air Supply

3.5 Air Distribution System

3.6 Electrical Supply

3.7 Gas Supply

4.0 INSTALLATION

4.1 Uncrating and Preparation

4.2 Suspending the Heater

4.3 Fitting the Combustion Air Inlet/Flue Pipe System

4.3.1 Fitting the Flue Pipe

4.3.2 Fitting the Combustion Air Socket Guard - Type B Installation

4.3.3 Fitting the Combustion Air Pipe - Type C Installation

4.4 Gas Connection

4.5 Electrical Connections

4.6 Room Thermostat Siting

5.0 AIR DISTRIBUTION

6.0 COMMISSIONING AND TESTING

6.1 Electrical Check

6.2 Gas Connection

6.3 Suspension and Support

6.4 Lighting the Heater

6.4.1 To Turn the Heater ON

6.4.2 To Turn the Heater OFF for Short Periods

6.4.3 To Turn the Heater OFF for Long Periods

6.5 Heater pipe work

6.6 Adjustments

6.7 Air Distribution System

6.8 Heater Controls

6.9 Handing Over

7.0 SERVICING INSTRUCTIONS

8.0 REMOVAL AND REPLACEMENT OF PARTS

8.1 Main Burner Removal

8.2 Main Burner Injectors

8.3 Ignition System

8.4 Operating Gas Valve

8.5 Limit Controls

8.6 Combustion Air Pressure Switch

8.7 Combustion Air Fan

9.0 FAULT FINDING

10.0 PARTS LIST

11.0 GAS CONVERSION

12.0 USERS INSTRUCTIONS

13.0 HEALTH & SAFETY STATEMENT

2/25

HAZARD INTENSITY LEVELS

DANGER

danger

WARNING

CAUTION

Failure to comply will result in

severe personal injury or

death and/or property

damage.

Failure to comply could result

in severe personal injury or

death and/or property damage

Failure to comply could result

in minor personal injury and/or

property damage.

INTRODUCTION

1

WARNING: The electrical isolator should

only be used in an emergency and should

not be used for closing down the main

burner, as it switches off the fan

prematurely and may damage the heat

exchanger, invalidating the warranty.

Attention :

This appliance is not intended for use by

persons (including children) with reduced

sensory or mental capacities, or lack of

experience and knowledge, unless they have

been given supervision or instruction

concerning use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure that

they do not play with the appliance.

1.1 Basic Information

The instructions in this manual apply to Model LCSA4 gas-fired/fan-assisted warm air heaters. These

models have an axial fan for air delivery. These

heaters are designed for overhead suspension and

are suitable for indoor installation only installed at an

operation ambient temperature between -15°C and

45°C. When installed as a type C12/C32 and where

the height above floor level is greater than 1.8

meters measured to the underside of the appliance

they may be used as a garage air heater. This

appliance must be installed in accordance with the

rules in force. Before installation, check that the

local distribution conditions, nature of gas and

pressure and adjustment of the appliance are

compatible.

A permanent electricity supply of 230 volts, 50 Hz,

single phase is required.

Heaters are approved for:

Type C

Type C

Type B

When the external control calls for heat, an

electronic control begins the ignition sequence to

provide for a safe start. About 30 seconds after the

call for heat, the fan will begin circulating warm air.

The electronic control will supervise the flame during

the entire heating cycle to ensure safe operation.

When the required room temperature is reached, the

main burner will shut down leaving the fan running to

cool down the heat exchanger. After approximately

45 seconds, the fan delay relay will turn off the fan.

- horizontal vent for balanced-flue heaters;

12

- vertical vent for balanced-flue heaters;

32

- vertical vent;

22

1.2 Warranty : Warranty is void if:

a) LCSA-4 heaters are installed in atmospheres containing flammable vapors or atmospheres

containing chlorinated or halogenated hydrocarbons or atmospheres containing any silicone,

aluminum oxide, etc., that adheres to spark ignition flame sensing probes.

b) The installation is not in accordance with these instructions.

c) Axial fan-type unit heater is connected to a duct system or fitted with a non-authorized air

distribution device.

3/25

2

TECHNICAL DATA

2.1 Specifications

Table 1a

LCSA-4 12 20 30 35 45 50 60 75 100 120 145

Gas category

Comb. Air & Flue, type B

Comb. Air & Flue, type C

(1)

(1)

Connection c ollars mm 80 100 100 130 130 130 130 130 130 130 130

Heat input Hs kW 13,33 26,42 31,63 43,95 54,38 61,08 73,25 87,85 114,87 144,81 165,47

Heat input Hi kW 12,00 23,80 28,50 39,60 49,00 55,00 66,00 79,15 103,50 130,40 149,00

Heat output kW 11,14 21,82 25,99 36,23 44,64 50, 77 60,92 73,13 94,50 119,32 137,39

Thermal Efficiency % 93,00 92,00 91,00 92,00 91,00 92,00 92,00 92,00 91,00 92,00 92,00

Gas c onsumption G20

Gas c onsumption G31

Gas cons um ption Lw (20mb ar)

Gas cons um ptio n Ls (13m bar)

Gas pipe connection

Real temperature rise

Air flow measured

(2)

(3)

(3)

m³/h 1,27 2,52 3,02 4,19 5,19 5,82 6,98 8, 38 10,95 13,80 15,77

kg/h NA 1,86 2,22 3,09 3,82 4,29 5,15 6,17 8,24 10,17 11,62

m³/h NA 3,07 3,68 5,11 6,32 7,10 NA 10,22 NA NA NA

(*)

m³/h NA 3,50 4,19 5,82 7,20 8,08 NA 11,63 NA NA NA

(*)

1/2"

K 30 31 33 33 313034 29 29 32 35

m³/h 1100 2000 2300 3200 4300 5000 5200 7300 8000 10800 11400

Nominal motor speed RPM 1381 1256 1333 1300 1310 928 1346 1344 935 872 875

Recommended mounting height

Horizontal t hrow

Sound Press ure

Sound Press ure

(5)

(6)

(7)

m2,5

m9,5

dB(A) 36

dB(A) 43

3 4 44455566

13 17 24 25 27 30 32 31 38 39

42 37 46 45 45 47 48 52 54 56

49 44 53 52 52 54 55 59 61 63

(4)

Elec trical service (protec tion IP20)

Total elec trical rating W 530

Weight kg 59

(*) : only fo r Polan d

(1) Gas A ppliance Class ific atio ns fo r Aprro ved Venting M ethods based o n CEN-repo rt CR1749:2001

(2) There is a difference between the gas co nnect io n diameter and the diamet er o f the supply line. Always use t he mo st adequate diam eter o f the supply

line to minimize the pressure dro p through the gas pipes - if necessary, reduce the diameter o f the supply line at the inlet o f the unit.

(3) Figure fo r iso therm al co nditions.

(4) Height f ro m flo or t o bo tto m surf ace of heater. These are recomm andatio ns o nly. Po sitio ning of unit heaters f o r proper perf ormance is applicat ion dependent.

Care sho uld be taken to avo id mount ing the heaters abo ve t hese reco mm endatio ns, unless downturn nozzle opt io ns are used, as significant stratification may

occur resulting in poo r floo r co verage and higher energy los ses thro ugh the ro of s tructure.

(5) Isot hermal co nditio ns at 20°C ambient air t emperature, discharge lo uvre zero def lectio n, v = 0,5 m/s. The air thro w will be influenced by the height o f t he

building, mounting height o f the unit, ambient temperature & adjustment o f t he louvres.

(6) Sound pressure level in dB(A) in free field co nditions , measured at 5 metres from the unit

(7) Sound pressure level in dB(A), measured at 5 m etres fro m the unit with A =160m² and Q=2

360 250 370 370 540 760 760 850 1730 1730

59 64 94 99 114 114 126 184 242 279

Table 1b : Gas categories

Country Gas category Country Gas category

Austria II2H3P Montenegro II2H3+

Belarus II2H3+ New Zealand II2H3+

Bulgaria I2H or I3P Norway II2H3 B/P

China II2H3+ Poland II2E3P

Czech republic II2H3+ Portugal II2H3+

Croatia II2H3P Romania II2H3 B/P

Cyprus II2H3+ Russian Federation I2H or I3P

Denmark II2H3 B/P Serbia II2H3+

England II2H3+ Slovakia II2H3+

Estonia II2H3+ Slovenia II2H3+

Finland II2H3 B/P South Africa II2H3+

Germany I2ELL Spain II2H3+

Greece II2H3+ Sweden II2H3 B/P

Hungary II2HS3P Turkey II2H3+

Iceland II2H3+ Ukraine I2H or I3P

Latvia II2H3+

Lithuania II2H3+

4/25

see table 1B

B22P

C12, C42, C62

3/4"

230/240V 1N ~ 50Hz

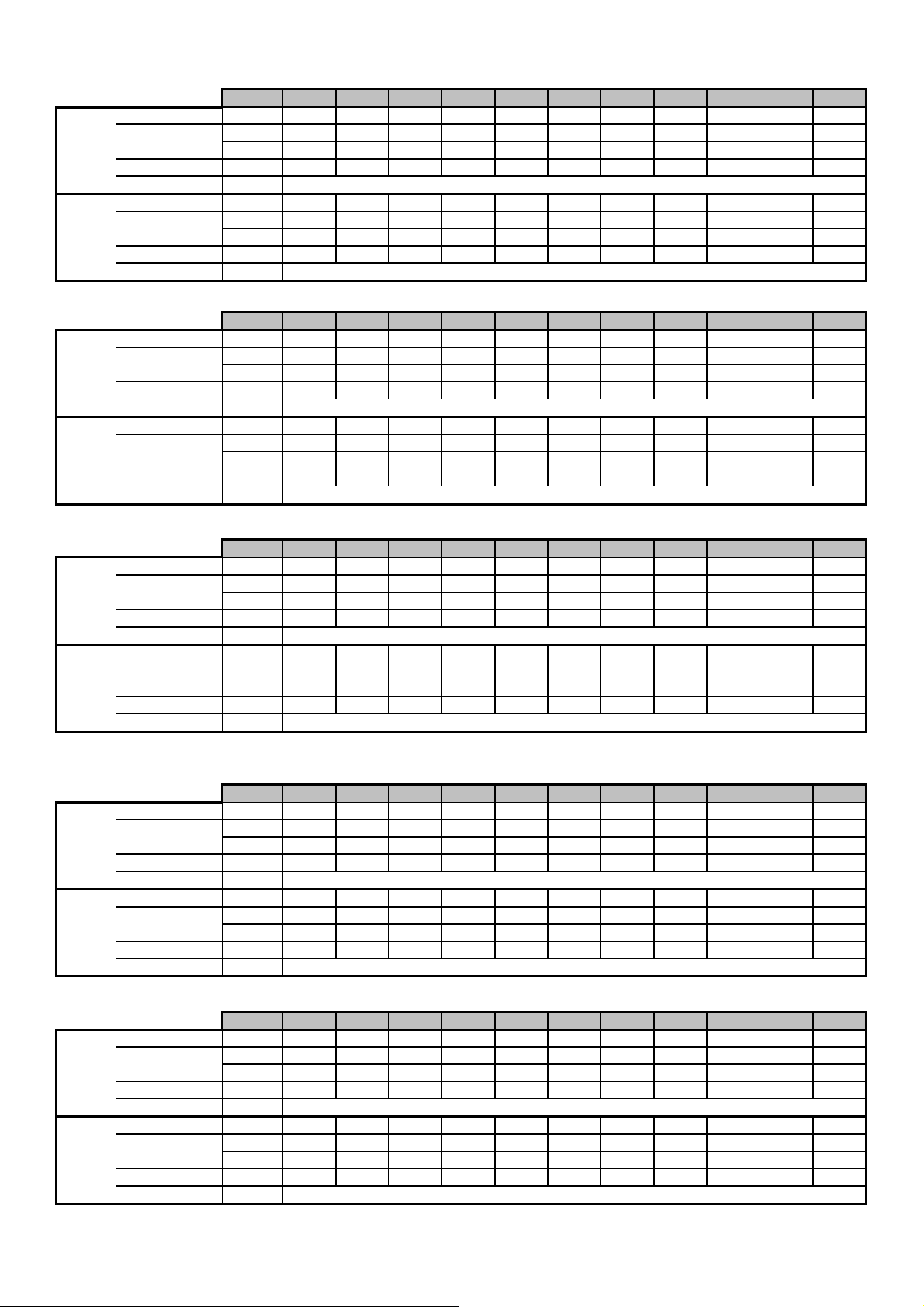

Table 2 :Injector size and burner pressures

Belarus, China, Croatia, Czech Republic, Cyprus, England, Estonia, Greece, Iceland, Latvia, Lithuania, Montenegro, New Zealand, Portugal, Serbia, Slovenia,

Slovakia, South Africa, Spain , Turkey, Poland

LCSA-4

Injector quantity 5 5 6 8 10 8 8 10 12 10 12

Injector size

G20

Burner pressure (1) mbar 8,10 8,00 7,25 7,10 6,90 9,20 8,50 8,30 7,50 9,20 9,00

Nat. Gas

Inlet pressure mbar

Injector quantity - 5 6 8 10 8 8 10 12 10 12

Injector size

G31

Burner pressure (1) mbar - 35,80 35,80 36,20 35,90 30,10 35,60 35,40 34,40 30,70 30,60

Prop. Gas

Inlet pressure mbar

Special poland

LCSA-4

Injector quantity - 5 6 8 10 8 - 10 - - -

Injector size

G27

Burner pressure (1) mbar - 8,30 8,20 8,35 8,25 11,40 - 9,25 - - -

Inlet pressure mbar

Injector quantity - 5 6 8 10 8 - 10 - - -

Injector size

G2,350

Burner pressure (1) mbar - 8,25 8,45 9,55

Inlet pressure mbar

Model1220303545506075100120145

mm 1,50 2,10 2,10 2,20 2,20 2,40 2,70 2,70 2,90 3,40 3,40

marking 150 210 210 220 220 240 270 270 290 340 340

20

mm - 1,15 1,15 1,15 1,15 1,40 1,45 1,45 1,50 1,95 1,90

marking - 115 115 115 115 140 145 145 150 195 190

37

Model1220303545506075100120145

mm - 2,40 2,40 2,40 2,40 2,60 - 3,00 - - -

marking - 240 240 240 240 260 - 300 - - -

20

mm - 2,60 2,60 2,50

marking - 260 260 250

2,60 3,40

260 340

8,40 6,00

13

-

3,90

-

390

-

5,25

---

---

---

Austria, Germany, Hungary, Russian Federation, Ukraine

LCSA-4

Injector quantity 5** 5 6 8 10 8 8 10 12 10 12

Injector size

G20

Burner pressure (1) mbar 8,10 8,00 7,25 7,10 6,90 9,20 8,50 8,30 7,50 9,20 9,00

Nat. Gas

Inlet pressure mbar

Injector quantity - 5 6 8 10 8 8 10 12 10 12

Injector size

G31

Burner pressure (1) mbar - 35,80 35,80 36,20 35,90 30,10 35,60 35,40 34,40 30,70 30,60

Prop. Gas

Inlet pressure mbar

(* ): Inlet pressure for Hungary = 25mbar

(**): no nat gas for Germany

Bulgaria, Denmark, Finland, Norway, Sweden

LCSA-4

Injector quantity 5 5 6 8 10 8 8 10 12 10 12

Injector size

G20

Burner pressure (1) mbar 8,10 8,00 7,25 7,10 6,90 9,20 8,50 8,30 7,50 9,20 9,00

Nat. Gas

Inlet pressure mbar

Injector quantity - 5 6 8 10 8 8 10 12 10 12

Injector size

G31

Burner pressure (1) mbar - 28,06 28,06 28,37 28,14 23,59 27,90 27,75 26,96 24,10 24,00

Prop. Gas

Inlet pressure mbar

Model1220303545506075100120145

mm 1,50 2,10 2,10 2,20 2,20 2,40 2,70 2,70 2,90 3,40 3,40

marking 150 210 210 220 220 240 270 270 290 340 340

mm - 1,15 1,15 1,15 1,15 1,40 1,45 1,45 1,50 1,95 1,90

marking - 115 115 115 115 140 145 145 150 195 190

Model1220303545506075100120145

mm 1,50 2,10 2,10 2,20 2,20 2,40 2,70 2,70 2,90 3,40 3,40

marking 150 210 210 220 220 240 270 270 290 340 340

mm - 1,15 1,15 1,15 1,15 1,40 1,45 1,45 1,50 1,95 1,90

marking - 115 115 115 115 140 145 145 150 195 190

20(*)

50

20

30

Romania

LCSA-4

Injector quantity 5 5 6 8 10 8 8 10 12 10 12

Injector size

G20

Burner pressure (1) mbar 8,10 8,00 7,25 7,10 6,90 9,20 8,50 8,30 7,50 9,20 9,00

Nat. Gas

Inlet pressure mbar

Injector quantity - 5 6 8 10 8 8 10 12 10 12

Injector size

G31

Burner pressure (1) mbar - 28,60 28,80 29,20 28,80 28,10 28,50 28,40 27,70 26,40 25,30

Prop. Gas

Inlet pressure mbar

(1) : with open service door

Model1220303545506075100120145

mm 1,50 2,10 2,10 2,20 2,20 2,40 2,70 2,70 2,90 3,40 3,40

marking 150 210 210 220 220 240 270 270 290 340 340

20

mm - 1,20 1,20 1,20 1,20 1,45 1,50 1,50 1,60 1,95 1,90

marking - 120 120 120 120 145 150 150 160 195 190

30

5/25

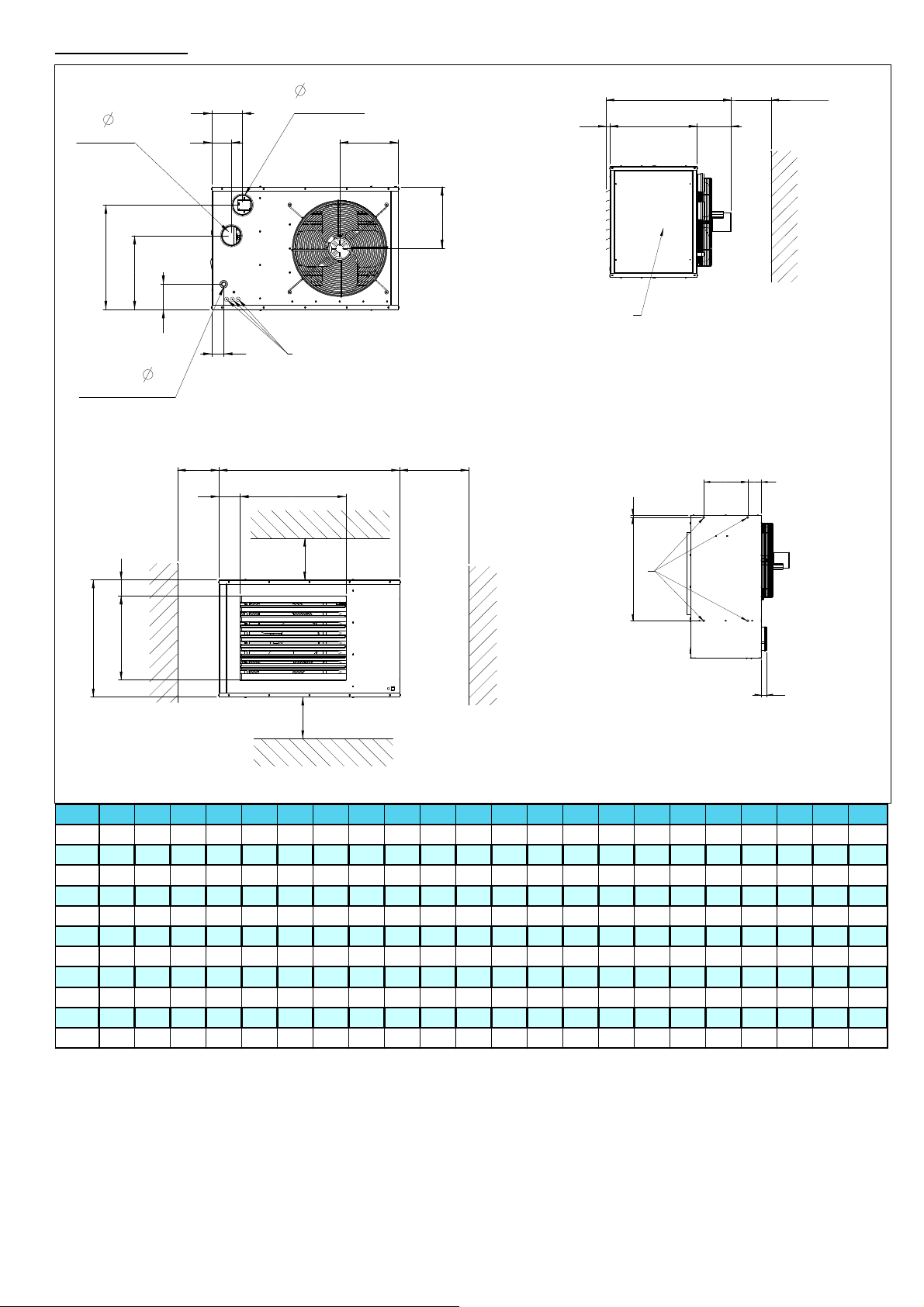

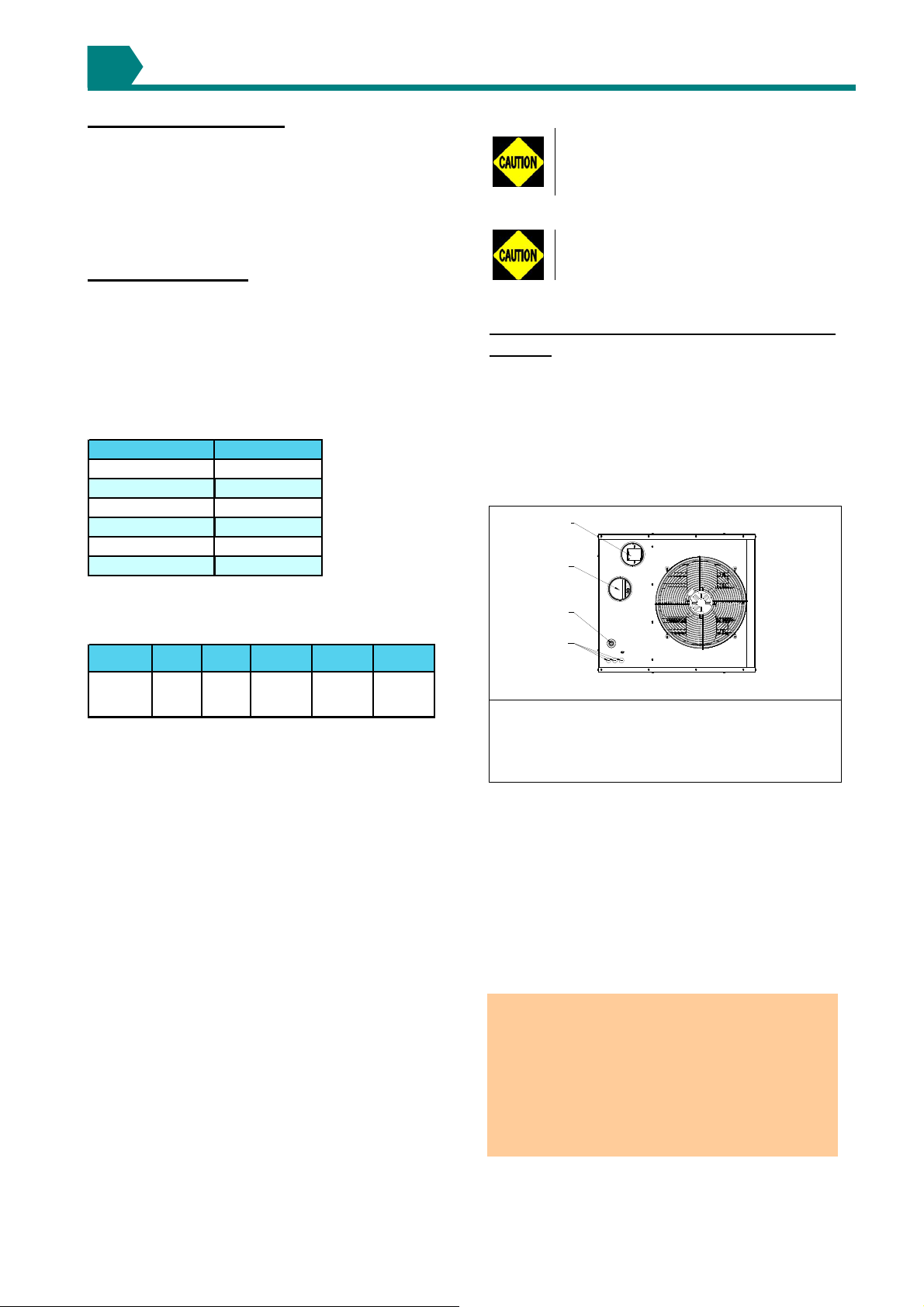

2.2 Dimensions

D

Flue Inlet

Q

P

N

W

Gas Connection

S

R

150

E

D

J

250 min

Flue Outlet

30

C

I

K

L

2

M

1

A

F

500 min

V

19

T

GH

150

3

U

B

51

150

LCSA-4 A B C D E F G H I J K L M N P Q R S T U V W

12 965 567 652 80 71 531 130 305 100 782 334 280 87 106 345 444 122 221 123 611 406 1/2"G

20 965 567 652 100 71 531 130 305 103 785 334 280 87 106 345 444 122 221 123 611 406 1/2"G

30 965 567 652 100 74 531 94 370 139 821 334 280 87 106 345 444 122 221 123 611 406 1/2"G

35 965 845 652 130 74 531 154 517 138 824 331 420 82 175 508 720 134 211 123 611 406 3/4"G

45 965 845 652 130 74 531 117 605 138 824 331 420 82 175 508 720 134 211 123 611 406 3/4"G

50 1298 845 652 130 151 759 154 517 156 838 409 425 82 175 508 720 135 212 123 942 406 3/4"G

60 1298 845 652 130 151 759 154 517 139 824 409 425 82 175 508 720 135 212 123 942 406 3/4"G

75 1298 845 652 130 151 759 117 605 139 824 409 425 82 175 508 720 135 212 123 942 406 3/4"G

100 1298 954 807 130 151 759 73 808 301 1022 479 477 82 180 608 833 212 212 123 942 550 3/4"G

120 1750 980 846 130 67 1100 164 602 177 1057 348 490 90 175 595 795 160 256 20 1365 770 3/4"G

145 1750 1150 846 130 67 1100 173 692 177 1057 348 570 90 177 736 936 160 256 20 1365 770 3/4"G

1 Electrical connections

2 Service panel

3 Suspension points (M10 female)

6/25

GENERAL REQUIREMENTS

3

3.1 Related documents

It is important that all gas appliances are installed in

accordance with the rules in force and by

appropriately qualified persons. Failure to install

appliances correctly could lead to prosecution. It is

in your own interest and that of safety to ensure

compliance with the law.

3.2 Heater location

The location chosen for the air heater must permit

the provision of a satisfactory flue system venting to

outdoor atmosphere and adequately ventilated to

provide for combustion air. The location must also

provide sufficient space to allow the heater to be

serviced.

Table 3

Minimum installation clearances (mm)

LCSA-4 mm

Top 150

Flue connector 150

Access panel 800

Non access side 150

Bottom 150

Rear* 450

* Measure rear clearance from the back of the motor

Table 4

Recommended mounting heights to underside (m)(*)

LCSA-4 12 20

Mounting

height

* Height from floor to bottom surface of heater. These are

recommendations only. Positioning of heaters depends on

application.

Air heaters should, where ever possible always be

installed to blow toward or along external wall

surfaces. Where two or more air heaters are

installed in the same room, a general scheme to

ensure continuous air circulation should be

maintained for best results.

Suspended heaters are most effective when located

as close to the occupancy zone as possible, this fact

should be born in mind when determining the

mounting heights to be used. Care should be

exercised to avoid directing warm air directly onto

the occupants. Partitions, columns, counters,

storage racking, etc. should be taken into account

when choosing the location so that an unobstructed

path for the air circulation can be maintained.

Where air heaters are located in the centre of the

space to be heated, the air should be discharged

toward outside walls. In large areas, they should be

located to discharge air along outside walls with

additional heaters provided to blow air into the

centre of the area.

In places where infiltration of cold is excessive, such

as entrance doors it is desirable to locate a heater

so that warm air is discharged directly toward the

source of cold air from a distance of 4,5 - 6,0m

2,53456

30→-50 60-→100 120→145

Air heaters should not be installed in

corrosive atmospheres, i.e. near plating

or degreasing plants or in areas where

there is a fire risk.

Do not locate the air heater where it may

be exposed to water spray, rain, etc.

3.3 Combustion air supply & flue

system

The air heater may be installed as a balanced flue

(Type C) heater requiring both a combustion air inlet

duct and a flue pipe or as a power vented (Type B)

heater, which requires only a flue pipe exhausting to

outdoors. All products of combustion must be flued

to outdoor atmosphere.

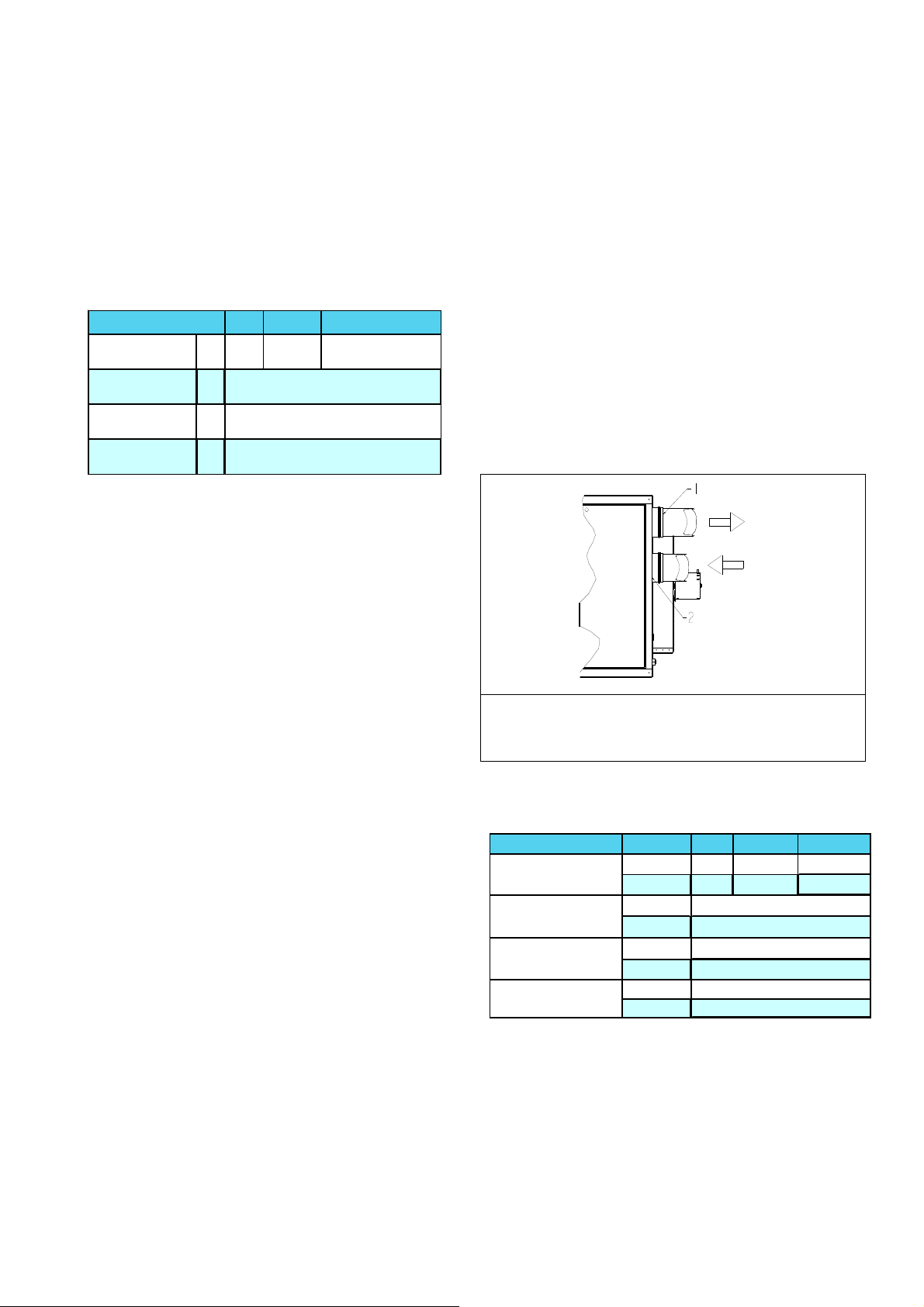

Figure 2a : Combustion air and flue pipe sockets

1

2

3

4

Legend :

1 Flue outlet socket

2 Combustion air inlet opening

3 Gas connection inlet with sealing ring

4 Electrical connections

Each heater installed as a type B appliance must be

fitted with an individual flue pipe and the combustion

air inlet opening must be provided with a protection

grill (ask your distributor for the appropriate

protection grill (IP20) (dia130 = PN 02 25094 ).

Each heater installed as a type C appliance must be

fitted with an individual combustion air/flue pipe

system. Only systems specified by the air heater

manufacturer may be used.

Common flue and combustion air systems must

not be used

IMPORTANT: The flue must be installed in

accordance with national and local regulations.

Failure to provide proper flueing could result in

death, serious injury and/or property damage.

The air heater must be installed with a flue to the

outside of the building. Safe operation of any

power vented gas apparatus requires a properly

operating flue system, correct provision for

combustion air, and regular maintenance and

inspection.

7/25

3.3.1 Flues for power vented installations

(Type B appliances)

If the air heater is to be installed as a type B

appliance, air for combustion will be taken from

within the space where the heater is installed.

Ensure that an adequate air supply for combustion

and ventilation is provided within the building in

accordance with the regulations & rules in force.

Table 5 shows flue pipe sizes and maximum pipe

lengths. The minimum flue length is 0.5 metres.

Table 5 Flue pipe diameters & maximum lengths

LCSA-4

Heater socket &

pipe dia

Maximum straight

length

Equivalent length m

of 45° elbow

Equivalent length

of 90° elbow

mm

m

m

20, 30

12 35->145

100 130

80

9

0.75

1.5

Single wall flue pipes are required. All joints must

be sealed to prevent products of combustion from

leaking into the building. An approved flue terminal

is required.

If the flue passes through a combustible element of

the building it must be enclosed by a sleeve of noncombustible material and separated from the sleeve

by at least a 25 mm air break. The temperature of

any combustible material near to the flue must not

exceed 65°C when the heater is in operation. The

flue must be at least 50 mm away from any

combustible material.

Single wall flue pipe exposed to cold air or run

through unheated areas must be insulated. Where

condensation is unavoidable, provision must be

made for the condensation to flow freely to a point

to which it can be released, i.e. a drain or gully. The

condensation drain from the flue must be

constructed from non-corrodible material not less

than 20 mm diameter. Copper or copper based

alloys must not be used for condensation drains.

3.3.2 Combustion air inlet pipe & flue pipe for

balanced flue installation (Type C appliances)

Balanced flue air heaters are designed to be fitted

with a combustion air inlet pipe that obtains outdoor

air and a flue pipe that exhausts flue products to

outdoors.

Air heaters if fitted with a power venter permitting

either a vertical or horizontal combustion air

inlet/flue pipe system. The heaters must be

installed with a concentric vertical or horizontal

flue/combustion air inlet. The heaters are only

approved for use when installed with the

appropriate approved concentric vent terminal.

See table 6.

Both the flue and combustion air pipes must be sealed.

Use gasket sealed seamless aluminium pipe or

equivalent.

The flue pipe must include a re-sealable test port to

allow good average sampling of the flue gas mixture

for testing, the port must be at least 450 mm away

from the air heater flue connection socket.

Follow any flue pipe manufacturers’ installation

instructions for making joints, including connections to

the air heater, for passing through a building element

and for support requirements. If more than one air

heater is being installed in the same place each heater

must have a separate flue system.

Where condensation is unavoidable, provision must

be made for the condensation to flow freely to a

point to which it can be released, i.e. a drain or

gully. The condensation drain from the flue must be

constructed from non-corrodible material not less

than 20 mm diameter. Copper or copper based

alloys must not be used for condensation drains.

Figure 2b :

Combustion air and flue pipe sockets, Type C

Legend :

1 Flue products flue outlet socket for flue pipe

2 Combustion air inlet opening

Table 6

Combustion air inlet & flue pipe requirements

LCSA-4 12 35 -> 145

Heater socket

& pipe dia

Max. straight

length

Equivalent length

of 45° elbow

Equivalent length

of 90° elbow

Concentric vertical vent or wall terminal : Mugro/Burfix dia 130

Concentric horizontal vent or roof terminal : Mugro/Burfix dia 130

Flue pipe 80 130

mm

Inlet pipe 80 130

Flue pipe

m

Inlet pipe

Flue pipe

m

Inlet pipe

Flue pipe

m

Inlet pipe

20, 30

100

100

9

9

0,75

0,75

1,5

1,5

8/25

Loading...

Loading...