Page 1

1610LCSA-4--EN

Gas-Fired, Balanced-Flue or

Power-Vented Unit Heater

LCSA-4

Installation, commissioning, servicing & user instructions

These appliances meet the following EC Directives

DIR 2009/142/EC: GAD

DIR 2004/108/EC: EMC

DIR 2006/95/EC: LVD

DIR 2006/42/EC MD

Applies to

Austria, Belarus, Bulgaria, China, Czech Republic, Croatia, Cyprus, Denmark, England, Estonia, Finland,

Germany, Greece, Hungary, Iceland, Latvia, Lithuania, Montenegro, New Zealand, Norway, Poland, Romania,

Russian Federation, Serbia, Slovakia, Slovenia, South Africa, Spain, Sweden, Turkey, Ukraine

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury, or death. All work must be carried out by appropriately qualified persons.

The manufacturer does not take any responsibility in the event of non-observance of the

regulations concerning the connection of the apparatus causing a dangerous operation of the

apparatus, possibly resulting in damage to the apparatus and/or environment in which the unit

is installed.

Please read this document carefully before commencing installation commissioning and/or

servicing.

Leave it with the user or attached to the appliance or gas service meter after installation.

Subject to modifications

1/25

Page 2

TABLE OF CONTENTS

1.0 INTRODUCTION

1.1 Basic Information

1.2 Warranty

2.0 TECHNICAL DATA

2.1 Specifications

2.2 Dimensions

3.0 GENERAL REQUIREMENTS

3.1 Related Documents

3.2 Heater Location

3.3 Combustion Air Inlet Pipe and Flue Pipe

3.4 Air Supply

3.5 Air Distribution System

3.6 Electrical Supply

3.7 Gas Supply

4.0 INSTALLATION

4.1 Uncrating and Preparation

4.2 Suspending the Heater

4.3 Fitting the Combustion Air Inlet/Flue Pipe System

4.3.1 Fitting the Flue Pipe

4.3.2 Fitting the Combustion Air Socket Guard - Type B Installation

4.3.3 Fitting the Combustion Air Pipe - Type C Installation

4.4 Gas Connection

4.5 Electrical Connections

4.6 Room Thermostat Siting

5.0 AIR DISTRIBUTION

6.0 COMMISSIONING AND TESTING

6.1 Electrical Check

6.2 Gas Connection

6.3 Suspension and Support

6.4 Lighting the Heater

6.4.1 To Turn the Heater ON

6.4.2 To Turn the Heater OFF for Short Periods

6.4.3 To Turn the Heater OFF for Long Periods

6.5 Heater pipe work

6.6 Adjustments

6.7 Air Distribution System

6.8 Heater Controls

6.9 Handing Over

7.0 SERVICING INSTRUCTIONS

8.0 REMOVAL AND REPLACEMENT OF PARTS

8.1 Main Burner Removal

8.2 Main Burner Injectors

8.3 Ignition System

8.4 Operating Gas Valve

8.5 Limit Controls

8.6 Combustion Air Pressure Switch

8.7 Combustion Air Fan

9.0 FAULT FINDING

10.0 PARTS LIST

11.0 GAS CONVERSION

12.0 USERS INSTRUCTIONS

13.0 HEALTH & SAFETY STATEMENT

2/25

Page 3

HAZARD INTENSITY LEVELS

DANGER

danger

WARNING

CAUTION

Failure to comply will result in

severe personal injury or

death and/or property

damage.

Failure to comply could result

in severe personal injury or

death and/or property damage

Failure to comply could result

in minor personal injury and/or

property damage.

INTRODUCTION

1

WARNING: The electrical isolator should

only be used in an emergency and should

not be used for closing down the main

burner, as it switches off the fan

prematurely and may damage the heat

exchanger, invalidating the warranty.

Attention :

This appliance is not intended for use by

persons (including children) with reduced

sensory or mental capacities, or lack of

experience and knowledge, unless they have

been given supervision or instruction

concerning use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure that

they do not play with the appliance.

1.1 Basic Information

The instructions in this manual apply to Model LCSA4 gas-fired/fan-assisted warm air heaters. These

models have an axial fan for air delivery. These

heaters are designed for overhead suspension and

are suitable for indoor installation only installed at an

operation ambient temperature between -15°C and

45°C. When installed as a type C12/C32 and where

the height above floor level is greater than 1.8

meters measured to the underside of the appliance

they may be used as a garage air heater. This

appliance must be installed in accordance with the

rules in force. Before installation, check that the

local distribution conditions, nature of gas and

pressure and adjustment of the appliance are

compatible.

A permanent electricity supply of 230 volts, 50 Hz,

single phase is required.

Heaters are approved for:

Type C

Type C

Type B

When the external control calls for heat, an

electronic control begins the ignition sequence to

provide for a safe start. About 30 seconds after the

call for heat, the fan will begin circulating warm air.

The electronic control will supervise the flame during

the entire heating cycle to ensure safe operation.

When the required room temperature is reached, the

main burner will shut down leaving the fan running to

cool down the heat exchanger. After approximately

45 seconds, the fan delay relay will turn off the fan.

- horizontal vent for balanced-flue heaters;

12

- vertical vent for balanced-flue heaters;

32

- vertical vent;

22

1.2 Warranty : Warranty is void if:

a) LCSA-4 heaters are installed in atmospheres containing flammable vapors or atmospheres

containing chlorinated or halogenated hydrocarbons or atmospheres containing any silicone,

aluminum oxide, etc., that adheres to spark ignition flame sensing probes.

b) The installation is not in accordance with these instructions.

c) Axial fan-type unit heater is connected to a duct system or fitted with a non-authorized air

distribution device.

3/25

Page 4

2

TECHNICAL DATA

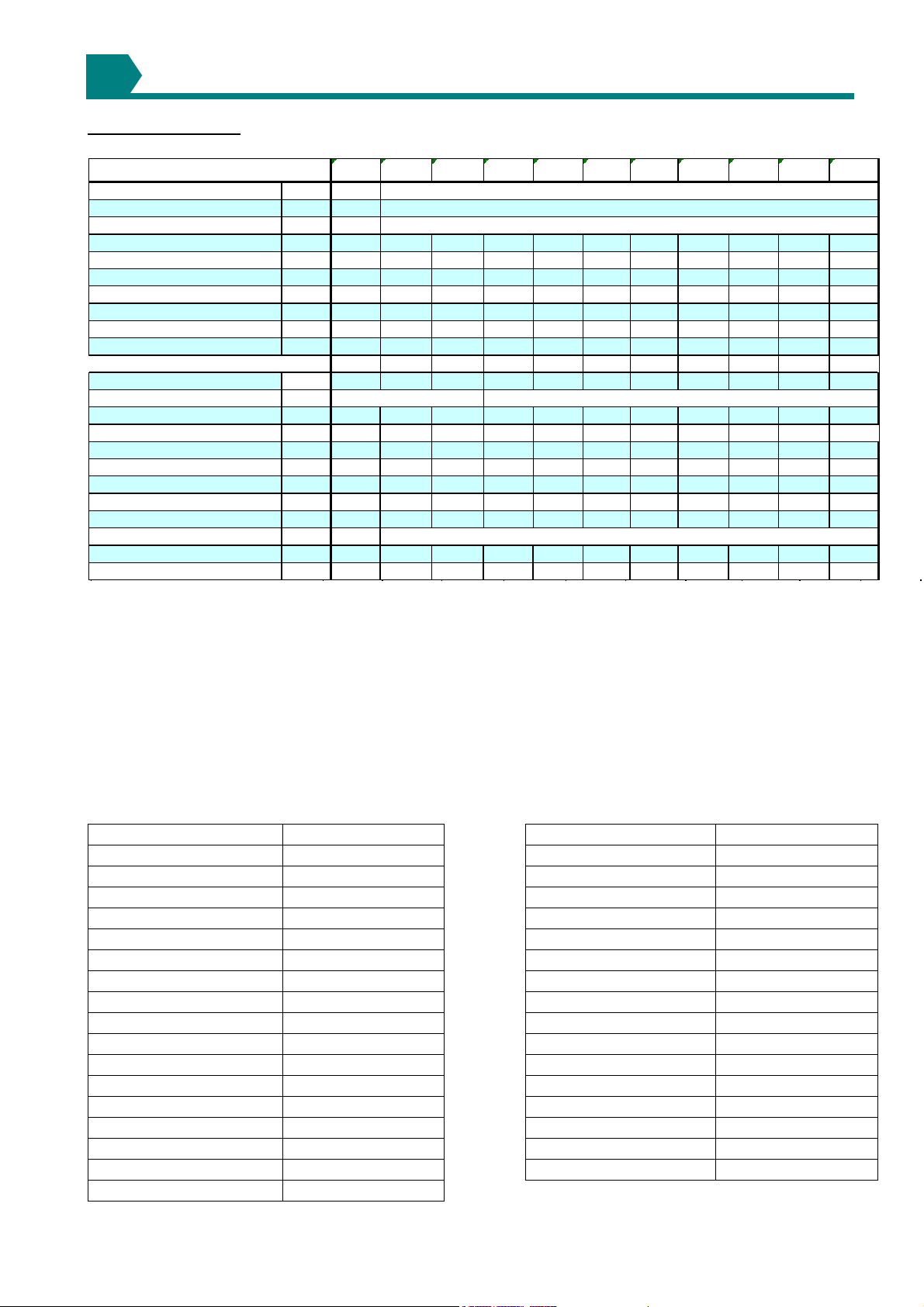

2.1 Specifications

Table 1a

LCSA-4 12 20 30 35 45 50 60 75 100 120 145

Gas category

Comb. Air & Flue, type B

Comb. Air & Flue, type C

(1)

(1)

Connection c ollars mm 80 100 100 130 130 130 130 130 130 130 130

Heat input Hs kW 13,33 26,42 31,63 43,95 54,38 61,08 73,25 87,85 114,87 144,81 165,47

Heat input Hi kW 12,00 23,80 28,50 39,60 49,00 55,00 66,00 79,15 103,50 130,40 149,00

Heat output kW 11,14 21,82 25,99 36,23 44,64 50, 77 60,92 73,13 94,50 119,32 137,39

Thermal Efficiency % 93,00 92,00 91,00 92,00 91,00 92,00 92,00 92,00 91,00 92,00 92,00

Gas c onsumption G20

Gas c onsumption G31

Gas cons um ption Lw (20mb ar)

Gas cons um ptio n Ls (13m bar)

Gas pipe connection

Real temperature rise

Air flow measured

(2)

(3)

(3)

m³/h 1,27 2,52 3,02 4,19 5,19 5,82 6,98 8, 38 10,95 13,80 15,77

kg/h NA 1,86 2,22 3,09 3,82 4,29 5,15 6,17 8,24 10,17 11,62

m³/h NA 3,07 3,68 5,11 6,32 7,10 NA 10,22 NA NA NA

(*)

m³/h NA 3,50 4,19 5,82 7,20 8,08 NA 11,63 NA NA NA

(*)

1/2"

K 30 31 33 33 313034 29 29 32 35

m³/h 1100 2000 2300 3200 4300 5000 5200 7300 8000 10800 11400

Nominal motor speed RPM 1381 1256 1333 1300 1310 928 1346 1344 935 872 875

Recommended mounting height

Horizontal t hrow

Sound Press ure

Sound Press ure

(5)

(6)

(7)

m2,5

m9,5

dB(A) 36

dB(A) 43

3 4 44455566

13 17 24 25 27 30 32 31 38 39

42 37 46 45 45 47 48 52 54 56

49 44 53 52 52 54 55 59 61 63

(4)

Elec trical service (protec tion IP20)

Total elec trical rating W 530

Weight kg 59

(*) : only fo r Polan d

(1) Gas A ppliance Class ific atio ns fo r Aprro ved Venting M ethods based o n CEN-repo rt CR1749:2001

(2) There is a difference between the gas co nnect io n diameter and the diamet er o f the supply line. Always use t he mo st adequate diam eter o f the supply

line to minimize the pressure dro p through the gas pipes - if necessary, reduce the diameter o f the supply line at the inlet o f the unit.

(3) Figure fo r iso therm al co nditions.

(4) Height f ro m flo or t o bo tto m surf ace of heater. These are recomm andatio ns o nly. Po sitio ning of unit heaters f o r proper perf ormance is applicat ion dependent.

Care sho uld be taken to avo id mount ing the heaters abo ve t hese reco mm endatio ns, unless downturn nozzle opt io ns are used, as significant stratification may

occur resulting in poo r floo r co verage and higher energy los ses thro ugh the ro of s tructure.

(5) Isot hermal co nditio ns at 20°C ambient air t emperature, discharge lo uvre zero def lectio n, v = 0,5 m/s. The air thro w will be influenced by the height o f t he

building, mounting height o f the unit, ambient temperature & adjustment o f t he louvres.

(6) Sound pressure level in dB(A) in free field co nditions , measured at 5 metres from the unit

(7) Sound pressure level in dB(A), measured at 5 m etres fro m the unit with A =160m² and Q=2

360 250 370 370 540 760 760 850 1730 1730

59 64 94 99 114 114 126 184 242 279

Table 1b : Gas categories

Country Gas category Country Gas category

Austria II2H3P Montenegro II2H3+

Belarus II2H3+ New Zealand II2H3+

Bulgaria I2H or I3P Norway II2H3 B/P

China II2H3+ Poland II2E3P

Czech republic II2H3+ Portugal II2H3+

Croatia II2H3P Romania II2H3 B/P

Cyprus II2H3+ Russian Federation I2H or I3P

Denmark II2H3 B/P Serbia II2H3+

England II2H3+ Slovakia II2H3+

Estonia II2H3+ Slovenia II2H3+

Finland II2H3 B/P South Africa II2H3+

Germany I2ELL Spain II2H3+

Greece II2H3+ Sweden II2H3 B/P

Hungary II2HS3P Turkey II2H3+

Iceland II2H3+ Ukraine I2H or I3P

Latvia II2H3+

Lithuania II2H3+

4/25

see table 1B

B22P

C12, C42, C62

3/4"

230/240V 1N ~ 50Hz

Page 5

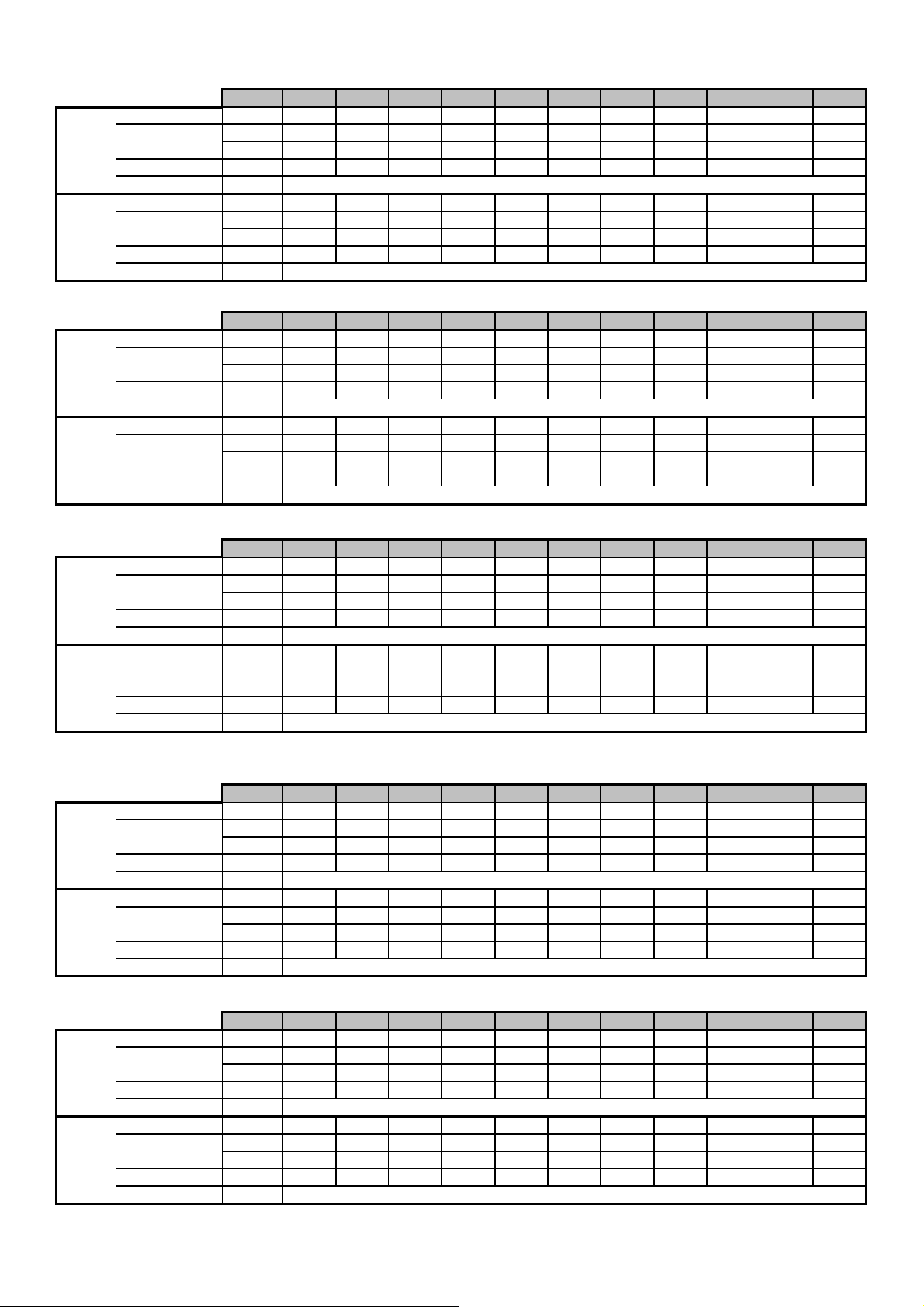

Table 2 :Injector size and burner pressures

Belarus, China, Croatia, Czech Republic, Cyprus, England, Estonia, Greece, Iceland, Latvia, Lithuania, Montenegro, New Zealand, Portugal, Serbia, Slovenia,

Slovakia, South Africa, Spain , Turkey, Poland

LCSA-4

Injector quantity 5 5 6 8 10 8 8 10 12 10 12

Injector size

G20

Burner pressure (1) mbar 8,10 8,00 7,25 7,10 6,90 9,20 8,50 8,30 7,50 9,20 9,00

Nat. Gas

Inlet pressure mbar

Injector quantity - 5 6 8 10 8 8 10 12 10 12

Injector size

G31

Burner pressure (1) mbar - 35,80 35,80 36,20 35,90 30,10 35,60 35,40 34,40 30,70 30,60

Prop. Gas

Inlet pressure mbar

Special poland

LCSA-4

Injector quantity - 5 6 8 10 8 - 10 - - -

Injector size

G27

Burner pressure (1) mbar - 8,30 8,20 8,35 8,25 11,40 - 9,25 - - -

Inlet pressure mbar

Injector quantity - 5 6 8 10 8 - 10 - - -

Injector size

G2,350

Burner pressure (1) mbar - 8,25 8,45 9,55

Inlet pressure mbar

Model1220303545506075100120145

mm 1,50 2,10 2,10 2,20 2,20 2,40 2,70 2,70 2,90 3,40 3,40

marking 150 210 210 220 220 240 270 270 290 340 340

20

mm - 1,15 1,15 1,15 1,15 1,40 1,45 1,45 1,50 1,95 1,90

marking - 115 115 115 115 140 145 145 150 195 190

37

Model1220303545506075100120145

mm - 2,40 2,40 2,40 2,40 2,60 - 3,00 - - -

marking - 240 240 240 240 260 - 300 - - -

20

mm - 2,60 2,60 2,50

marking - 260 260 250

2,60 3,40

260 340

8,40 6,00

13

-

3,90

-

390

-

5,25

---

---

---

Austria, Germany, Hungary, Russian Federation, Ukraine

LCSA-4

Injector quantity 5** 5 6 8 10 8 8 10 12 10 12

Injector size

G20

Burner pressure (1) mbar 8,10 8,00 7,25 7,10 6,90 9,20 8,50 8,30 7,50 9,20 9,00

Nat. Gas

Inlet pressure mbar

Injector quantity - 5 6 8 10 8 8 10 12 10 12

Injector size

G31

Burner pressure (1) mbar - 35,80 35,80 36,20 35,90 30,10 35,60 35,40 34,40 30,70 30,60

Prop. Gas

Inlet pressure mbar

(* ): Inlet pressure for Hungary = 25mbar

(**): no nat gas for Germany

Bulgaria, Denmark, Finland, Norway, Sweden

LCSA-4

Injector quantity 5 5 6 8 10 8 8 10 12 10 12

Injector size

G20

Burner pressure (1) mbar 8,10 8,00 7,25 7,10 6,90 9,20 8,50 8,30 7,50 9,20 9,00

Nat. Gas

Inlet pressure mbar

Injector quantity - 5 6 8 10 8 8 10 12 10 12

Injector size

G31

Burner pressure (1) mbar - 28,06 28,06 28,37 28,14 23,59 27,90 27,75 26,96 24,10 24,00

Prop. Gas

Inlet pressure mbar

Model1220303545506075100120145

mm 1,50 2,10 2,10 2,20 2,20 2,40 2,70 2,70 2,90 3,40 3,40

marking 150 210 210 220 220 240 270 270 290 340 340

mm - 1,15 1,15 1,15 1,15 1,40 1,45 1,45 1,50 1,95 1,90

marking - 115 115 115 115 140 145 145 150 195 190

Model1220303545506075100120145

mm 1,50 2,10 2,10 2,20 2,20 2,40 2,70 2,70 2,90 3,40 3,40

marking 150 210 210 220 220 240 270 270 290 340 340

mm - 1,15 1,15 1,15 1,15 1,40 1,45 1,45 1,50 1,95 1,90

marking - 115 115 115 115 140 145 145 150 195 190

20(*)

50

20

30

Romania

LCSA-4

Injector quantity 5 5 6 8 10 8 8 10 12 10 12

Injector size

G20

Burner pressure (1) mbar 8,10 8,00 7,25 7,10 6,90 9,20 8,50 8,30 7,50 9,20 9,00

Nat. Gas

Inlet pressure mbar

Injector quantity - 5 6 8 10 8 8 10 12 10 12

Injector size

G31

Burner pressure (1) mbar - 28,60 28,80 29,20 28,80 28,10 28,50 28,40 27,70 26,40 25,30

Prop. Gas

Inlet pressure mbar

(1) : with open service door

Model1220303545506075100120145

mm 1,50 2,10 2,10 2,20 2,20 2,40 2,70 2,70 2,90 3,40 3,40

marking 150 210 210 220 220 240 270 270 290 340 340

20

mm - 1,20 1,20 1,20 1,20 1,45 1,50 1,50 1,60 1,95 1,90

marking - 120 120 120 120 145 150 150 160 195 190

30

5/25

Page 6

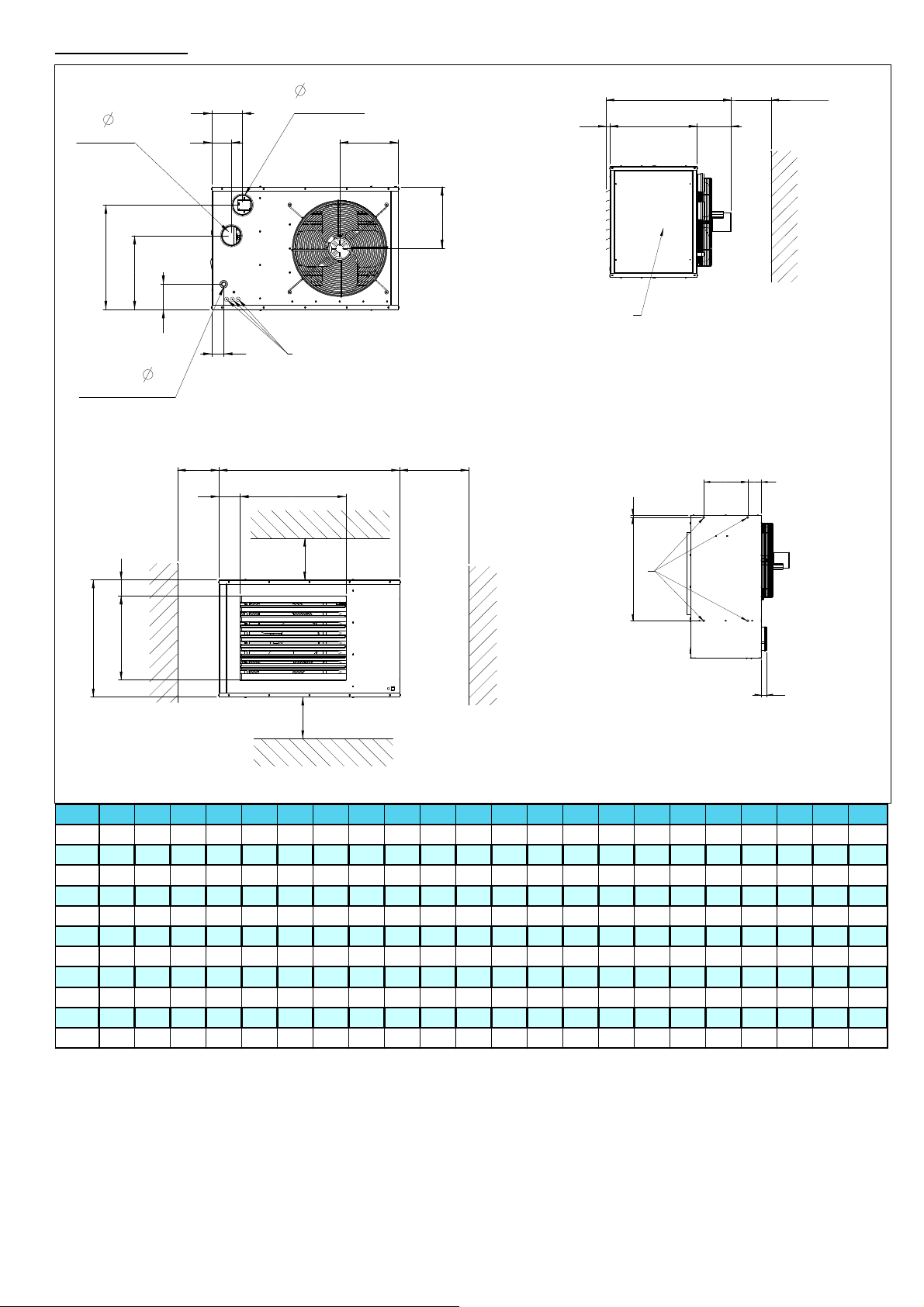

2.2 Dimensions

D

Flue Inlet

Q

P

N

W

Gas Connection

S

R

150

E

D

J

250 min

Flue Outlet

30

C

I

K

L

2

M

1

A

F

500 min

V

19

T

GH

150

3

U

B

51

150

LCSA-4 A B C D E F G H I J K L M N P Q R S T U V W

12 965 567 652 80 71 531 130 305 100 782 334 280 87 106 345 444 122 221 123 611 406 1/2"G

20 965 567 652 100 71 531 130 305 103 785 334 280 87 106 345 444 122 221 123 611 406 1/2"G

30 965 567 652 100 74 531 94 370 139 821 334 280 87 106 345 444 122 221 123 611 406 1/2"G

35 965 845 652 130 74 531 154 517 138 824 331 420 82 175 508 720 134 211 123 611 406 3/4"G

45 965 845 652 130 74 531 117 605 138 824 331 420 82 175 508 720 134 211 123 611 406 3/4"G

50 1298 845 652 130 151 759 154 517 156 838 409 425 82 175 508 720 135 212 123 942 406 3/4"G

60 1298 845 652 130 151 759 154 517 139 824 409 425 82 175 508 720 135 212 123 942 406 3/4"G

75 1298 845 652 130 151 759 117 605 139 824 409 425 82 175 508 720 135 212 123 942 406 3/4"G

100 1298 954 807 130 151 759 73 808 301 1022 479 477 82 180 608 833 212 212 123 942 550 3/4"G

120 1750 980 846 130 67 1100 164 602 177 1057 348 490 90 175 595 795 160 256 20 1365 770 3/4"G

145 1750 1150 846 130 67 1100 173 692 177 1057 348 570 90 177 736 936 160 256 20 1365 770 3/4"G

1 Electrical connections

2 Service panel

3 Suspension points (M10 female)

6/25

Page 7

GENERAL REQUIREMENTS

3

3.1 Related documents

It is important that all gas appliances are installed in

accordance with the rules in force and by

appropriately qualified persons. Failure to install

appliances correctly could lead to prosecution. It is

in your own interest and that of safety to ensure

compliance with the law.

3.2 Heater location

The location chosen for the air heater must permit

the provision of a satisfactory flue system venting to

outdoor atmosphere and adequately ventilated to

provide for combustion air. The location must also

provide sufficient space to allow the heater to be

serviced.

Table 3

Minimum installation clearances (mm)

LCSA-4 mm

Top 150

Flue connector 150

Access panel 800

Non access side 150

Bottom 150

Rear* 450

* Measure rear clearance from the back of the motor

Table 4

Recommended mounting heights to underside (m)(*)

LCSA-4 12 20

Mounting

height

* Height from floor to bottom surface of heater. These are

recommendations only. Positioning of heaters depends on

application.

Air heaters should, where ever possible always be

installed to blow toward or along external wall

surfaces. Where two or more air heaters are

installed in the same room, a general scheme to

ensure continuous air circulation should be

maintained for best results.

Suspended heaters are most effective when located

as close to the occupancy zone as possible, this fact

should be born in mind when determining the

mounting heights to be used. Care should be

exercised to avoid directing warm air directly onto

the occupants. Partitions, columns, counters,

storage racking, etc. should be taken into account

when choosing the location so that an unobstructed

path for the air circulation can be maintained.

Where air heaters are located in the centre of the

space to be heated, the air should be discharged

toward outside walls. In large areas, they should be

located to discharge air along outside walls with

additional heaters provided to blow air into the

centre of the area.

In places where infiltration of cold is excessive, such

as entrance doors it is desirable to locate a heater

so that warm air is discharged directly toward the

source of cold air from a distance of 4,5 - 6,0m

2,53456

30→-50 60-→100 120→145

Air heaters should not be installed in

corrosive atmospheres, i.e. near plating

or degreasing plants or in areas where

there is a fire risk.

Do not locate the air heater where it may

be exposed to water spray, rain, etc.

3.3 Combustion air supply & flue

system

The air heater may be installed as a balanced flue

(Type C) heater requiring both a combustion air inlet

duct and a flue pipe or as a power vented (Type B)

heater, which requires only a flue pipe exhausting to

outdoors. All products of combustion must be flued

to outdoor atmosphere.

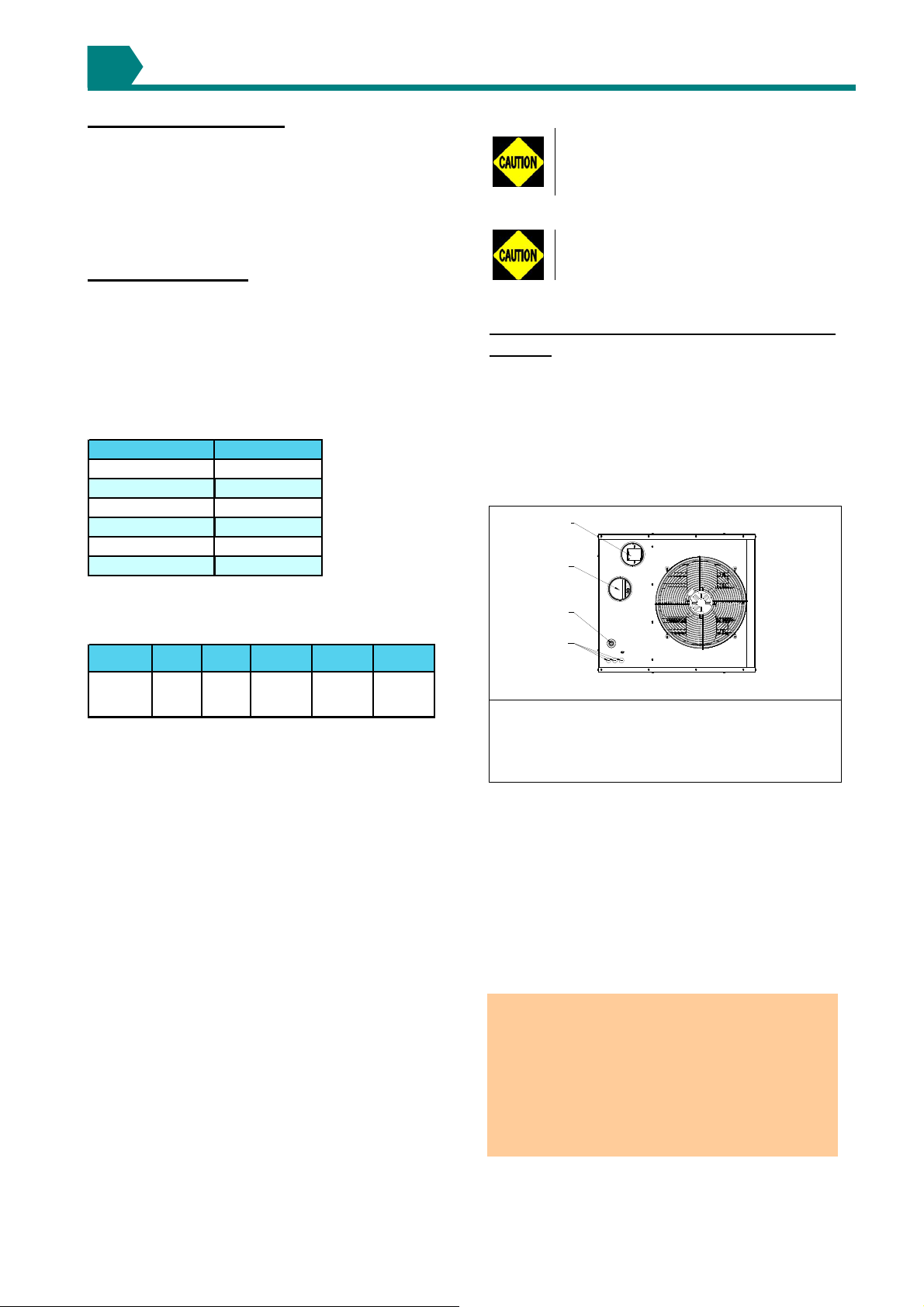

Figure 2a : Combustion air and flue pipe sockets

1

2

3

4

Legend :

1 Flue outlet socket

2 Combustion air inlet opening

3 Gas connection inlet with sealing ring

4 Electrical connections

Each heater installed as a type B appliance must be

fitted with an individual flue pipe and the combustion

air inlet opening must be provided with a protection

grill (ask your distributor for the appropriate

protection grill (IP20) (dia130 = PN 02 25094 ).

Each heater installed as a type C appliance must be

fitted with an individual combustion air/flue pipe

system. Only systems specified by the air heater

manufacturer may be used.

Common flue and combustion air systems must

not be used

IMPORTANT: The flue must be installed in

accordance with national and local regulations.

Failure to provide proper flueing could result in

death, serious injury and/or property damage.

The air heater must be installed with a flue to the

outside of the building. Safe operation of any

power vented gas apparatus requires a properly

operating flue system, correct provision for

combustion air, and regular maintenance and

inspection.

7/25

Page 8

3.3.1 Flues for power vented installations

(Type B appliances)

If the air heater is to be installed as a type B

appliance, air for combustion will be taken from

within the space where the heater is installed.

Ensure that an adequate air supply for combustion

and ventilation is provided within the building in

accordance with the regulations & rules in force.

Table 5 shows flue pipe sizes and maximum pipe

lengths. The minimum flue length is 0.5 metres.

Table 5 Flue pipe diameters & maximum lengths

LCSA-4

Heater socket &

pipe dia

Maximum straight

length

Equivalent length m

of 45° elbow

Equivalent length

of 90° elbow

mm

m

m

20, 30

12 35->145

100 130

80

9

0.75

1.5

Single wall flue pipes are required. All joints must

be sealed to prevent products of combustion from

leaking into the building. An approved flue terminal

is required.

If the flue passes through a combustible element of

the building it must be enclosed by a sleeve of noncombustible material and separated from the sleeve

by at least a 25 mm air break. The temperature of

any combustible material near to the flue must not

exceed 65°C when the heater is in operation. The

flue must be at least 50 mm away from any

combustible material.

Single wall flue pipe exposed to cold air or run

through unheated areas must be insulated. Where

condensation is unavoidable, provision must be

made for the condensation to flow freely to a point

to which it can be released, i.e. a drain or gully. The

condensation drain from the flue must be

constructed from non-corrodible material not less

than 20 mm diameter. Copper or copper based

alloys must not be used for condensation drains.

3.3.2 Combustion air inlet pipe & flue pipe for

balanced flue installation (Type C appliances)

Balanced flue air heaters are designed to be fitted

with a combustion air inlet pipe that obtains outdoor

air and a flue pipe that exhausts flue products to

outdoors.

Air heaters if fitted with a power venter permitting

either a vertical or horizontal combustion air

inlet/flue pipe system. The heaters must be

installed with a concentric vertical or horizontal

flue/combustion air inlet. The heaters are only

approved for use when installed with the

appropriate approved concentric vent terminal.

See table 6.

Both the flue and combustion air pipes must be sealed.

Use gasket sealed seamless aluminium pipe or

equivalent.

The flue pipe must include a re-sealable test port to

allow good average sampling of the flue gas mixture

for testing, the port must be at least 450 mm away

from the air heater flue connection socket.

Follow any flue pipe manufacturers’ installation

instructions for making joints, including connections to

the air heater, for passing through a building element

and for support requirements. If more than one air

heater is being installed in the same place each heater

must have a separate flue system.

Where condensation is unavoidable, provision must

be made for the condensation to flow freely to a

point to which it can be released, i.e. a drain or

gully. The condensation drain from the flue must be

constructed from non-corrodible material not less

than 20 mm diameter. Copper or copper based

alloys must not be used for condensation drains.

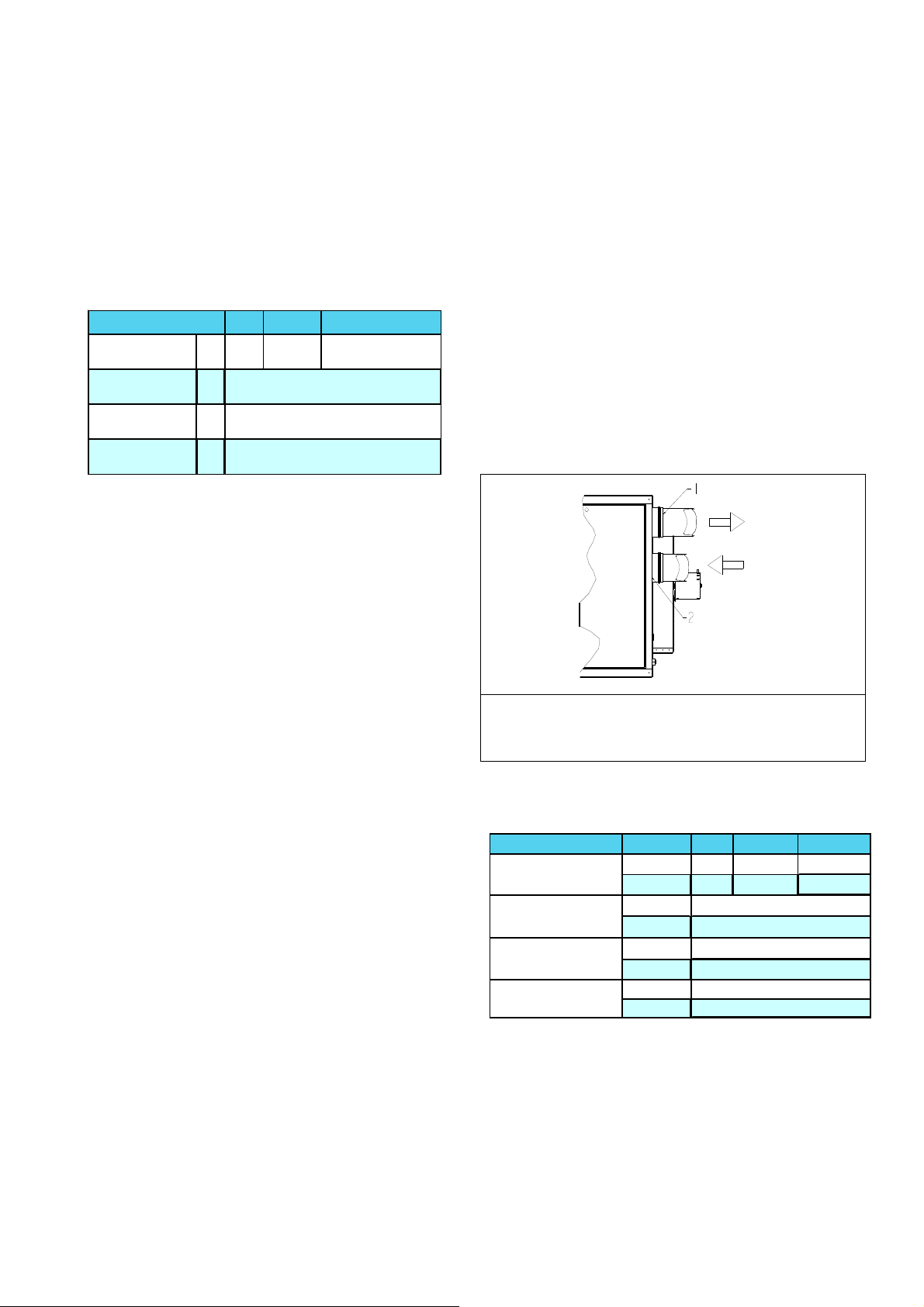

Figure 2b :

Combustion air and flue pipe sockets, Type C

Legend :

1 Flue products flue outlet socket for flue pipe

2 Combustion air inlet opening

Table 6

Combustion air inlet & flue pipe requirements

LCSA-4 12 35 -> 145

Heater socket

& pipe dia

Max. straight

length

Equivalent length

of 45° elbow

Equivalent length

of 90° elbow

Concentric vertical vent or wall terminal : Mugro/Burfix dia 130

Concentric horizontal vent or roof terminal : Mugro/Burfix dia 130

Flue pipe 80 130

mm

Inlet pipe 80 130

Flue pipe

m

Inlet pipe

Flue pipe

m

Inlet pipe

Flue pipe

m

Inlet pipe

20, 30

100

100

9

9

0,75

0,75

1,5

1,5

8/25

Page 9

3.4 Air supply

It is important to ensure that there is an adequate

air supply at all times for both combustion and

heating requirements. Modern constructions involve

the greater use of insulation, improved vapour

barriers, and weather proofing. This practice means

that buildings are sealed much tighter than in the

past.

The combustion air supply for a power vented gas

fired air heater (Type B installation) can be affected

by lack of air supply. Natural infiltration may not be

adequate. Use of extract fans aggravates this

situation. It is important to ensure that there is an

adequate air supply at all times. Reliance on doors

and windows is not allowed. Always ensure that an

adequate inlet for fresh air for combustion is

provided sized to suit the total installation of any

combustion apparatus.

Fit an access guard to the combustion air inlet on

the back of the heater and take appropriate action to

ensure that it remains unblocked. See figure 2c.

WARNING: This model air heater is

installed as a type B application and is

designed to take air for combustion from

the space in which it is installed. Do not

restrict the combustion air intake.

Figure 2c :

Combustion air and flue pipe sockets, Type B

Legend :

1 combustion products flue outlet socket

2 combustion air inlet opening

3 Protection grill (option) (PN 02 25094)

3.5 Air distribution

Follow recommended practice for building air

distribution.

The following notes are of particular importance:

"Where free blowing air heaters are installed it must be

taken into account that heated air is buoyant when it

leaves the appliance, therefore, air patterns within the

space being heated will modify the air throw pattern

achieved.

In building having low heat loss where single heaters

are required to cover a large floor area and in buildings

with high ceiling heights, air re-circulation fans e.g.

Maximizors may be fitted to ensure even heat

distribution and minimize stratification. Care should be

taken to avoid impeding air flow with storage racking,

partitions, etc."

3.6 Electrical supply

Wiring external to the air heater must be carried out

in accordance with the rules if force and by

appropriately qualified persons.

A constant 230 Volt 50 Hertz single phase fused

electricity supply with neutral link is required. All

heaters and controls must be earthed. A lockable

isolator with contact separation of at least 3.0 mm

on all poles should be installed adjacent to the

appliance and within reach of any person working on

the heater.

When a number of heaters are to be connected as

part of a single installation each heater must be

provided with a separate isolator.

The electrical connection to the air heater is at the

back of the appliance. The final connection must be

made in the terminals provided in the control

compartment. Follow the wiring diagram provided

with the air heater.

Electrical supply cable conductor size should be 1.5

mm. Fit the cord grip supplied with the heater. The

length of conductors between the cord grip and the

terminals must be such that in the event that the

cable becomes taut the line conductors do so before

the earth conductor.

3.7 Gas supply

LCSA-4 air heaters are designed to operate on

either natural gas (G20) or propane gas (G31).

Refer to the specifications in section 2 of this

document and to the data plate for details of supply

pressures.

The gas meter and gas service must be checked by

the supply undertaking to ensure that they are

adequate to deal with the total load of all gas fired

apparatus installed.

9/25

Page 10

INSTALLATION

4

4.1 Unpacking and preparation

Prior to dispatch, the air heater was operated and

tested at the factory. If the heater has incurred any

damage in shipment, file a report claim within 2

working days from receipt.

Check the shipping label and data plate to ensure

the specification of gas and electrical supplies are

compatible. Read this document and become

familiar with the installation requirements and the

appliance before commencing installation.

4.2 Suspending the air heater

Before installing the appliance, check to ensure that

the supporting structure is adequate to carry the

weight of the appliance and its ancillaries i.e. flue

system.

Table 7 Approximate Net weights (kg)

LCSA-4

Weight 59 64 94 99 114 126 184 242 279

When the heater is lifted for suspension, support the

bottom of the heater with plywood or other

appropriately placed material. If the bottom is not

supported, damage could occur.

The heater is supplied with four point suspension.

All points must be used. Two threaded nut retainers

are provided on each side of the top of the heater.

See dimensions in section 2.2 and figure 3.

Figure 3 Suspension detail

Be sure that the threaded hanger rods are locked to the

heater as illustrated. Recommended maximum hanger

rod length is 1.8m.

12

30 35 45

20

Add a nut to lock the

M10x1.5 hanger rod to

the heater

50

75 100 120 145

60

IMPORTANT:

Suspend the heater from the threaded nut retainers. Do

not suspend from the heater cabinet panels.

Do not place or add additional weight to the suspended

air heater. See hazard levels, page 2.

The heater must be installed in a level plane to ensure

proper operation.

4.3 Fitting the Combustion air inlet/Flue

system

Flue pipe runs may be horizontal or vertical and

terminate either through the wall or roof. See table 5

for maximum pipe length for an appliance installed

as type B or table 6 for maximum lengths and

approved supplied concentric terminals for a heater

installed as a type C appliance.

All pipe runs must be independently supported so

that the heater does not carry any of the weight of

the flue system.

4.3.1 Fitting the flue pipe

The flue pipe socket is located on the back of the air

heater.

Flue pipes must be sealed. Use seamless,

aluminium pipe or equivalent. Follow pipe

manufacturer's instructions (see figures 4 & 5).

Table 8 Flue pipe socket size (dia mm)

LCSA-4

Socket

12 20,30 35 -> 145

80 100 130

4.3.2 Installing a guard on the combustion air

inlet pipe for power vent (Type B installations)

The combustion air inlet socket is located at the

back of the heater. When installed as a type B

appliance, protect the inlet by fitting an access

guard on the socket. Do not block this socket as it

supplies combustion air for the burner (see

figure 4).

4.3.3 Fitting the combustion air inlet pipe for

balanced flue (Type C installations)

The combustion air pipe attaches directly to the inlet

socket at the back of the heater. Air inlet pipes must

be sealed. Use seamless aluminium or equivalent.

Follow the pipe manufacturer's installation

instructions. See typical installations in figure 5.

Table 9 Air inlet socket size (dia mm)

LCSA-4

Socket

12 20,30 35 -> 145

80 100 130

10/25

Page 11

Figure 4

4.4 Gas connection

Connection to a gas network may only be carried out

by appropriately qualified persons. The gas

installation must comply with the rules in force using

materials appropriate for gas installation.

To facilitate servicing, the air heater must be fitted

with an approved gas service tap and union fitting or

union tap adjacent to the appliance.

The inlet gas supply line must be installed so as to

permit the access door to be opened and to allow

removal of the slide out burner assembly.

Air heaters suspended by flexible suspension

materials or drop rods must be connected to the gas

supply using an approved flexible connector.

Sufficient slack must be provided in the connection

to allow for movement of the appliance. Use a

flexible connector of suitable size to reduce the

pressure drop and the possibility of gas flow noise.

Do not use the appliance gas supply to

balance or support any part of the

appliance

Figure 6

Legend :

1 Gas tube inlet sealing ring

2 Inlet gas pipe

3 Union fitting

4 Gas service tap

5 Gas pipe

.

Figure 5

4.5 Electrical connections

The electrical installation may only be carried out by

appropriately qualified persons observing the rules

in force.

All electrical connections should be made in the

heater control compartment (refer to figure 9).

Screw type terminals are provided. Connections

should be in accordance with the terminal markings

and the wiring diagram affixed to the air heater or

included with this document.

danger

ATTENTION : Failure in electrical wiring can

bring real damage to components of this

appliance. Please follow very carefully the

wiring diagram supplied with this air heater.

The minimum external controls required for the air

heater are a room thermostat. It is essential the

main input line and neutral to terminals L and N

remains live at all times even when the appliance

is switched off this is to ensure correct

operation of the unit.

An indicator light and burner reset button are fitted

inside the appliance. To add a remote reset button,

make connections to the terminals in the electric

box as indicated on the wiring diagram.

IMPORTANT:

If the reset button requires activating for any reason the

cause should be identified before resetting. After

resetting stay with the appliance for long enough to

ensure that lock-out does not reoccur (suggest 5

minutes).

Fix all electric cables and installer’s wiring to the control

panel and ensure they do not touch the combustion

collector box.

THIS APPLIANCE MUST BE EARTHED!

11/25

Page 12

4.6 Room thermostat location

Do not attempt to control more than 1 air heater

from a room thermostat or control panel unless a

properly wired relay is fitted. Follow instructions

supplied with such panels.

The location of the room thermostat is important. It

should not be fitted on an outside wall. Avoid

location in draughty areas or where it may be

influenced by heat

AIR DISTRIBUTION

5

sources e.g. the sun, process plant, etc. The

thermostat or temperature sensor should be

mounted on a vibration free surface and mounted

about 1,5 meters above floor level. Follow the

thermostat manufacturers fitting instructions. The

thermostat must be suitable for switching 230 volts.

LCSA-4 air heaters are fitted with adjustable

horizontal louvers over the range 0 - 45 degrees

from the horizontal so as to be able to direct the

airflow downwards.

COMMISIONING & TESTING

6

The commissioning and testing may only be carried

out by appropriately qualified persons.

This section should be read and fully understood

before commencing commissioning and testing.

6.1 Electrical check

After completion of the installation and before

switching on the electrical supply to the appliance, a

preliminary check must be carried out by a qualified

electrician. The following must be checked:

* Ensure that all cables & installer’s wiring are

fixed to the gas pipe & that they do not touch

the combustion collector box

* Check that all wiring is connected in

accordance with the appliance circuit diagram;

* Ascertain that the correct fuse value and cable

size has been provided;

* Check to ensure that the appliance is earthed

by conducting an earth continuity test. Connect

a test meter, one lead to the appliance earth

terminal and the other to the mains incoming

earth point at the electrical isolator. A

resistance reading of 1,0 ohm or less must be

indicated. If a higher reading is obtained, check

all cable connections to ensure adequate

security and cleanliness. If problem still exists ,

it may be necessary to consult the electricity

supply undertaking;

* Carry out a polarity test. Connect one lead of a

suitable AC voltmeter to earth and connect the

DO NOT ADJUST THE LOUVRES BEYOND THEIR

STOPS.

other lead to the live supply terminal (L) at the

air heater. Switch ON the power to the air

heater and check for correct voltage.

The same result should be obtained by

connecting the test leads between live and

neutral.

Connect the voltmeter test leads to N and E. A

reading of 0V should be obtained. If these

tests do not conform to the above, there is a

fault which must be rectified before proceeding

further with the commissioning;

* Check that a suitable thermostat or control

panel has been fitted;

* Ensure that an electrical isolator with two pole

separation with a minimum air break between

poles of 3,0 mm has been fitted adjacent to the

air heater.

6.2 Gas connection

Only persons formally qualified to work on gas

fired apparatus may carry out commissioning

and testing.

The whole of the gas service installation including

the

meter must be inspected, tested for soundness and

purged in accordance with appropriate requirements

by a qualified person.

Never use a flame for checking gas

soundness.

12/25

Page 13

6.3 Suspension and support

Check to ensure that the air heater is adequately

suspended or supported and that no other parts have

been fitted that are not independently supported and

secured. For safe and correct operation, check the

heater is level in both planes.

6.4 Lighting the air heater

LCSA-4 air heaters are all fitted with automatic spark

ignition systems. When adequate airflow for

combustion is proven by an air proving control and a

pre-purge period has elapsed, the integral ignitor and

multi-functional gas control operate. The ignition

spark ignites the gas creating the burner flame which

is detected by a flame rod sensor. If a burner flame is

not detected, the ignition controller proceeds to lockout and requires manually resetting. Lock-out is

indicated by the red warning light on the air heater.

Note : If the first reset is not successful, wait 15

seconds before attempting reset.

6.4.1 To turn the air heater "ON"

The following checks should be carried out before

attempting to light the air heater.

* Ensure that the gas supply to the air heater is

turned ON;

* Ensure that the electrical supply to the air heater

is switched ON;

* If fitted ensure that a time switch is set to an ON

period

* Set room thermostat to call for heat. e.g. to above

room ambient temperature. The burner will now

light.

The burners can be seen through the viewing port.

* Adjust the room thermostat to the required

operating comfort temperature. The air heater will

now start automatically when heat is called for by

the room thermostat.

Note : If the air heater will not start on initial start-up,

the ignition controller may be in lock-out position and

require resetting. This may occur especially if the

appliance has been on stand-by for a prolonged

period.

6.4.2 To turn the air heater "OFF" for short

periods

Adjust the room thermostat to its lowest setting or

'OFF'. The fan will continue to run to cool the heater

and then switch OFF automatically.

6.4.3 To turn the air heater "OFF" for long

periods

Adjust the room thermostat to OFF or its lowest

setting. When the fan has stopped, turn OFF the gas

supply and then switch OFF the electricity supply to

the air heater.

6.5 Air heater gas pipe work

The soundness of the air heater pipe work has been

checked prior to leaving the factory. However during

installation, connections may have been loosened.

Check the soundness of the appliance pipe work

using a soapy solution. If any leaks are found they

must be rectified immediately.

Never use a flame for checking gas

soundness.

6.6 Adjustments

6.6.1 Burner gas pressure adjustment

The gas pressure is set for the required heat input

before the appliance leaves the factory. Provided

the gas supply to the air heater is in accordance

with the supply pressure described on the appliance

data plate the operating pressure will not require

adjustment. To check the pressure, the following

procedure should be carried out:

* Ascertain from section 1 of this document and

the appliance data plate the correct operating

gas pressure for the air heater;

* Turn the room thermostat control to its lowest

setting;

* Remove the screw from the burner pressure test

point of the multi-functional control valve.

Connect a manometer to the test point( see

figure 7);

* Adjust the room thermostat to call for heat e.g.

above room ambient temperature;

* Observe the burner gas pressure on the

manometer and compare to the required

pressure;

* If necessary, adjust the burner gas pressure

(only for natural gas). Remove the cover screw.

Turn the regulator screw anti-clockwise to

decrease pressure or clockwise to increase

pressure (see figure 7);

* Set room thermostat to lowest setting to turn the

burners OFF. Replace the test point screw (if

removed) and with the main burner alight, test

for gas soundness using a soapy solution.

Reset temperature control/room thermostat to

comfort operating level.

13/25

Page 14

Figure 7 : Honeywell gas valve

Legend :

1 Gas valve HONEYWELL VR4601AB

2 Inlet pressure gas test point

3 Burner pressure gas test point

4 Burner pressure regulator cover

5 Burner pressure regulator

6 Electrical connection 230V

6.7 Air distribution system

Adjust the air outlet discharge louvres to provide a

satisfactory spread of the warm air. Direct the air

towards the floor avoiding blowing directly on people

who may be in the vicinity of the appliance.

If louvre adjustment is carried out whilst

the appliance is hot wear gloves to avoid

being burnt.

6.8 Air heater controls and operation

Check air heater operation after all adjustments have

been carried out. Set the temperature control above

ambient temperature.

LCSA-4 air heaters are fitted with a pressure

sensitive, combustion air safety control that monitors

the combustion airflow.

The control operates with the settings given in table

10 (settings are for sea level installations)

When the combustion air safety control closes,

verifying airflow, the gas control valve will open and

the burner will light. When insufficient airflow, the

burner will extinguish until the airflow returns to the

acceptable level.

Wait approximately 30 seconds after the burner has

lit, the time delay relay will activate the thermal fan

control which will energize the fan motor. Continue to

operate the air heater for several minutes to ensure

correct operation.

Turn room thermostat to its lowest setting. The main

burners should extinguish while the fan continues to

run to cool the air heater. The fan delay relay will

normally be de-energized and stop the fan motor in

approximately 45 seconds.

Table 10 Combustion air pressure control settings

Normal

LCSA-4

12

20 >163 135

30

35 >200 155

45/50 >183 155

60 >240 175

75 >290 185

100 >250 210

120 >250 238

145 >250 238

at 2x1m pipe with terminal

equilibrium

warm (Pascal)

>131

>170 130

Set point 'off'

(Pascal)

119

6.9 Handing over

Upon satisfactory completion of commissioning and

testing, hand the instructions to the user or their

representative.

Advise the appropriate person how to safely use and

operate the air heater and describe the use of

appropriate external controls. Ensure that the

person understands how to start the heater and how

to turn it OFF.

Suggest that the instructions are placed close to the

air heater for future reference. In the absence of an

appropriate location fix them to the gas service

meter. Ensure they are not placed where they may

restrict the airflow from the heater or where they

may catch fire from a hot surface.

Advise the person who is resuming responsibility

that for continued safe operation the air heater

should be serviced at least once a year.

14/25

Page 15

SERVICING INSTRUCTIONS

7

IMPORTANT:

Only appropriately qualified persons may carry out

servicing and fault finding on this gas fired equipment.

Before commencing service ensure that both the gas and

the electricity are turned and switched "OFF" and that the

air heater has cooled down. Inadvertent substitution or

replacement of components similar to those specified or

replacement in a manner contrary to the method herein

described could constitute a hazard and lead to

prosecution.

When cleaning air heaters, wearing of eye

protection and a dust face mask is

recommended.

LCSA-4 air heaters will operate with a minimum of

maintenance. To ensure long life and satisfactory

and safe performance, an air heater that is operated

under normal conditions should be inspected and

cleaned at the start of each heating season. If the

air heater is operated in an area where unusual

amounts of dust, etc are present in the air, more

frequent servicing is recommended.

When any service is completed, be sure that

components are reassembled correctly to ensure

that no unsafe condition exists.

Upon completion of the service carry out the

commissioning instructions outlined in section 6 of

this document.

WARNING: Excessive dirt build-up on the

inside of the burner ports could cause

unburnt gas to spill out of the back of the

burner tube causing a fire or explosion.

To prevent this occurring, clean all of the

burner ports at least annually.

Service procedure

The following procedures should be carried out at

least annually:

1. Remove the burner assembly as in section 8.1.

Clean thoroughly, (cleaning the burners requires

an emery cloth, wire brush and a cleaning cloth stubborn deposits on burners are best cleaned

using "acetone" as a solvent).

* Check the condition of the ignitor and clean to

remove all deposits. Check the spark gap (3,0

mm).

* Check the sensor - clean as necessary.

* Remove any soot deposits from the burner with

a wire brush. Clean the ports with a degreaser

or acetone. A vacuum cleaner or compressed

air may assist in this cleaning operation. Wipe

the

inside of the burner tube clean (cleaning

thoroughly with a degreaser as recommended

will retard future build-up of dirt). Inspect the

burner for any damage or deterioration. If the

burner is damaged or corroded, replace it.

2. The heat exchanger should remain clean unless

a problem has developed due to poor

combustion. Examine the heat exchanger tubes

internally and externally for any sign of

deterioration. The outside of the tubular heat

exchanger can be cleaned from the front of the

heater with an air jet and/or a flexible brush.

Remove any dust and grease deposits.

The inner surfaces of the heat exchanger can be

reached for cleaning with the burner and

combustion air fan (venter) assemblies removed.

Clean with a flue brush or a heavy wire to which

wire wool has been attached.

Brush inside each heat exchanger tube until all

foreign material has been removed. The use of a

flashlight is necessary to carry out this

operation.

3. Clean the axial fan blades, fan guard, and fan

motor to remove all external dirt . Check the

security of the fan on the motor.

Note: Fan motors are lubricated for life

and do not require lubricating.

4. Remove any dirt and/or grease that may have

accumulated on the venter fan motor and its

housing. NOTE: The combustion air fan motors

are lubricated for life and do not require oiling or

greasing.

5. The gas multi-functional control valve requires

no field maintenance except cleaning of its

exterior and checking the condition of the wire

connections. Instructions for testing pressure are

given in section 6.6.

6. Check the flue/combustion air system for

soundness. Reseal/replace any parts that are

not sound.

7. Check all wiring connections. Check wiring for

any signs of damage. Replace any suspect

wiring with an equivalent specification.

8. Check operation of thermal fan control and

control relay.

9. When service is complete carry out full

commissioning procedure as per section 6 of this

document

.

15/25

Page 16

Removal & replacement of parts

8

LCSA-4 air heaters must only be fitted with

authorized replacement parts. These heaters must

use certificated spare parts to comply with

legislation.

8.1 Main burner removal

Instructions for burner removal (see figure 8):

1. Turn OFF the gas supply to the air heater.

2. Switch OFF the electricity supply to the air

heater.

3. Open the access door.

4. Disconnect the union in the gas supply outside of

the appliance.

5. Remove gas supply pipe from multi-functional

gas control valve.

6. At the burner rack assembly, remove the nuts

that secure the burner manifold to the burner

rack. Lift the burner rack/manifold assembly

upward and pull the assembly out of the air

heater.

Instructions for re-assembly:

1. Reverse the procedure for removal making sure

that all parts are installed correctly. Check that

all components are secure.

2 When lighting, always follow the lighting

instructions on the air heater.

Figure 9 View of the Control Compartment

1

12

Remember!

After any service work has been carried out, the air

heater must be fully commissioned. See section 6

of this document

Figure 8 (for clarity, the heater cabinet & other parts

are not illustrated)

9

8

11

13

1 Burner

2 LC3 limit controls

3 Burner operating lamp H6

10

2

4 Reset switch S3

5 Spark igniter ER

6 Control panel

7 Gas valve V1

8 Fan motor M1

9 Venter motor M3

10 Fan control relay KFC

11 LC1 limit control

12 Flame sensor IS

7

13 Reset LC3

14 Fuse F3.1

3

4

5

6

14

16/25

Page 17

8.2 Burner injectors

1. Carry out steps 1 to 6 of section 8.1.

2. Unscrew the main burner injectors.

3. Re-fit new injectors.

4. Re-assemble in reverse order.

8.3 Ignition system

To access the ignition system, follow steps 1 to 3 in

section 8.1.

Ignitor- refer to figure 9 and locate the ignitor (on

the side of the burner rack). Disconnect the wire,

remove the screw and the ignitor. Clean with an

emery cloth.

Note: Spark gap must be maintained to 3.0 mm (see

figure 10a)

Re-fit the ignitor as per figure 10b.

Due to high voltage on the spark wire and

electrode, do not touch when energized.

See hazard levels.

Flame sensor -

flame sensor. Disconnect the wire, remove the

screw and the flame sensor. Clean with an emery

cloth.

Ignition controller -

circuit monitors the operation of the burner including

ignition. Do not attempt to dismantle the ignition

controller. Each heating season ignition cables

should be checked for insulation deterioration and

good connections.

Proper operation of the direct spark ignition

system requires a minimum flame current of 1,0

μA when measured with a micro-ammeter.

Fig. 10a - Ignitor assembly

Fig. 10b : Fitting the ignitor

For further information and checkout procedure of

the direct spark ignition system, refer to the

manufacturers control operating instructions a copy

of which is supplied with the air heater.

Refer to figure 9 and locate the

The enclosed integrated

8.4 Multi-functional gas control valve

1. Ensure gas supply to the air heater is turned

OFF.

2. After the air circulation fan has stopped, switch

OFF the electricity supply to the air heater.

3. Mark for future identification and disconnect the

wires connected to the valve.

4. Disconnect the gas service union between the

control valve and the gas service tap. Remove

the gas control valve.

5. Re-fit a replacement valve making all of the

required connections.

6 Carry out complete commissioning procedure

prior to placing the appliance back into service

as outlined in section 6.0

The gas control operating valve is the

prime safety shut-off.

All gas supply lines must be free of dirt,

scale, etc. before connecting to the air

heater thus ensuring positive closure of

the control valve.

8.5 Thermal overheat (limit) controls

If it is determined that the thermal overheat control

needs replacing, use only authorized replacements

that are designed for this appliance.

To gain access to the control, open the controls

compartment access door. Refer to figure 9 for

control locations. The control near the top of the air

heater is a disc type control. Both controls are

capillary types with a capillary tube that extends into

the heat exchanger area. To remove the controls,

disconnect the wires leading to them, remove the

fixing screws and lift clear of the inner casing panel.

Note: The capillary control is fitted to a bracket.

With the bracket removed from the air heater,

remove the control from the bracket.

When replacing a capillary control be careful not to

damage the capillary tube by kinking. Make bends

with a generous radius (approx 25 mm).

8.6 Combustion air control/switch

If it is determined that the air differential pressure

switch needs replacing, use only authorized

replacements that are designed for the air heater

being serviced. These switches are calibrated to

operate at the designed combustion air flow duty for

each appliance size in the product range.

8.7 Combustion air fan (venter)

1. Ensure gas supply to the air heater is turned

OFF

2. After the air circulation fan has stopped, switch

OFF the electricity supply to the air heater.

3. To gain access to the fan open the hinged

controls compartment access door. refer to

figure 9 for location

4. Mark for future identification and disconnect the

wires connecting the fan motor at the terminals

on the main wiring junction.

5. Remove combustion air fan and clean as

necessary using a wire brush and solvent to

remove sticky residues.

6. Re-assemble and check for free rotation before

proceeding to test the appliance.

Note : the combustion air fan motor is lubricated for

life. DO NOT OIL or GREASE.

17/25

Page 18

9

FAULT FINDING

Fault finding may only be carried out by appropriately qualified persons

9.1 Main fault finding chart - Lock-out indicator light is "OFF", but air heater will not

operate

Is the thermostat above

room temperature and if

Is t here conti nui ty between

terminal s 9 &10

no yes

yes

used is the time

clock"ON"

yes

Is power venti ng operat ing?

no

Reset limit control

no

Set thermostat above room

temperat ure & if used make

certain the time clock is ON

Check electronic

igniti on control

Is there a restriction i n the

flue pipe or inlet grill

yes no yes

Correct fault

Is the pressure tubing

connected & in sound

condition?

no yes

Is t he wheel di rty

yes

Does the power venter

operate?

no

Is there 230V between

L&N?

Is there 230V between

1 & N ?

yes

Is there 230V between

11 & 12 ?

no

Is there conti nuity between

no

9 & 10 ?

yes

yes

no

no

yes

Determine what caused the

limit to trip

Place i nto normal operat ion

Check the mains

Check the ti me/tempeature

control

Check venter motor

Replace pressure swit ch

Clean the venter wheel

Connect or repl ace tubi ng

Check pressure switch

18/25

Page 19

9.2 Ignition Controller Lockout indicator Light Repeatedly Comes "ON"

Is polarity of mains

correct?

no

Correct polarity

yes

Does the inlet gas

correct the gas supply

pressure

Check spark gap and

ceramic & check

spark wire &

connector

no yes

pressure agree with the

data badge

no no

Is a spark visible ?

Wait 15" and press

reset button

During 5" trial for ignition is

a flame visible in ths view

port?

check

electronic

ignition

control

check multi

functional

gas valve

During 5" trial for ignition

no

is a spark visible?

Spark visible, still no

yes

Is there 220 to 240V

between terminals

Check electronic

yes

flame

13 & N

no

ignition control

yes

Check flame signal using

micro amp meter. Is signal

greater than 1,0 micro

Amps?

no

Remove corrosion

& scale from flame

sensing rod & clean

ceramic insulation

Check flame signal. Is it

greater than 1,0 micro

Amps?

Check electronic

yes

ignition control

yes

Place in normal

operation

19/25

Page 20

9.3 Limit Control Fault Finding Chart (limit control trips)

Note LCSA-4 air heaters are equipped with 2 limits (a recycling limit and a manual reset limit). During normal operation, neither limit should

trip even if the main electric supply is interrupted during operation. In the event of motor failure, the recycling limit will trip opening the gas

valve.

Adjust thermostat

temp. setting above

ambient to energize fan

& gas solenoid valve

Does the fan

motor operate?

yes no

no

Replace

the motor

yes

Is there 220-240V at

terminals N and 4?

yes

yes

Remove the

restricition

Check for excessive

main burner pressure

Has any non-factory authorized air distribution

device been placed on the heater? Is there excessive

static pressure in the ductwork? Did the motor overload

Does the fan control

energize the fan motor

in less than 75"?

yes

9.4 Fan Fault Finding Chart

Consult fan

fault finding

trip?

no

no

Consult fan

fault finding

yes

Does the limit trip

before the fan is

energized?

no

Place system in normal

operation

Adjust thermostat

temperature

setting above ambient to

energize the fan and the

fan solenoid valve

no

Replace the

fan start relay

Is there 220-240V

at terminals N & 4?

Replace fan

Does the fan

no yes

operate ?

yes

motor

20/25

Place the system

in normal operation

Page 21

PARTS LISTING

10

LCSA-4 Part number

Delta P switch S3: 12 30 60617 238 238Pa out 250Pa in

Delta P switch S3: 20/30 30 60617 175 175Pa out 203Pa in

Delta P switch S3: 35/45 30 60621 155

Delta P switch S3: 50 30 60617 200 200Pa out 210Pa in

Delta P switch S3: 60 / 75 / 100 30 60617 175 175Pa out 203Pa in

Delta P switch S3: 120/145 30 60617 185 185Pa out 203Pa in

Overheat control device LC1 (not 120/145) 03 24959 04 90°C out 85° C in

Overheat control device LC3 (all, exc 100, 120 & 145) 03 24959 03 110° C out reset

Overheat control device LC3 (100) 03 24959 96° C out reset

Overheat control device LC3 (120/145) 03 24959 03 110° C out reset

Overheat control device LC3 (120/145) 03 24958 86° C out reset

Venter motor (all exc 120/145) 11 43426 04

Venter motor 120/145 20 25749

Gas valve one stage 35/45/60/75/100 03 25136

Gas valve one stage 12/20/30 03 25141

Gas valve one stage 120/145 03 25144

Burner relay E 03 25324

Ignition electrode ER 03 400US 42

Ignition electrode ER (120/145) 05 25186

Flame sensor electrode IS 03 401US 195292

ERP fan 12 01 27003

ERP fan 20 01 27006

ERP fan 30 01 27021

ERP fan 35/45 01 27010 01

ERP fan 50 01 27011 01

ERP fan 60/75 01 26063

ERP fan 100 01 27014 02

ERP fan 120/145 (2x) 01 26063

GAS CONVERSION

11

1627Pa out 1767Pa in

Settings

11.1 LCSA-4 air heaters are designed to

operate on natural, propane or butane

gas and will be supplied fitted for the gas

type ordered. In the event of site

conversion to a different gas type it is

necessary to convert the gas burner and

burner controls.

11.2 Affix new data plate and gas type oversticker.

11.3 Upon completion of conversion recommission the air heater in accordance

with section 6 of this document.

11.4 Changes to carry out:

Natural gas: use Honeywell VR4601AB

(PN 03 25136) - set pressure regulator as

per Table 2A

propane: use Honeywell VR4601B

(PN 03 25136B) or VR4601AB + blocking

plate

To adapt gas injectors and gas inlet pressures,

we refer to table 2A/2B.

21/25

Page 22

12

USER INSTRUCTIONS

Operating:

How the air heater works:

Gas is burned by an atmospheric burner which fires

into a heat exchanger. The gas burner is controlled

by a double gas valve via an electronic burner

control, which is actuated automatically via external

controls i.e. a room thermostat and/or a time switch.

The burner is ignited by a spark igniter. When the

burner fires and warms the heat exchanger, the heat

is sensed by a thermally actuated fan control which

switches on the fan when the air temperature has

reached its preset operating level.

At the end of a heating cycle the burner is switched

off, the air circulation fan will continue to run until

the air heater has cooled to a safe condition.

Thereafter the fan will remain off until the next cycle

is initiated.

Safety:

1. Flame failure is detected by the ionization probe

which is the sensor and will immediately result in

gas valve shut down.

2. Safety against overheating is assured by two

overheat controls. The first is an automatic

recycle control which protects against low air

flow i.e. clogged air ways, fan failure etc. The

second, which is set to a higher level than the

first one, is a control which locks out and

switches off the burner in the event of gross

overheating for any reason. Manual intervention

is necessary to reset this control device.

Resetting of the automatic burner control may

also be required.

3. The location of the air heater should be

maintained at normal atmospheric pressure.

Changes to the building after air heater

installation, should have regard to the heating

installation, i.e. structural changes causing

excessive draughts from doors, windows etc.

Other air handlers and installation of air

extraction equipment which may cause a

negative pressure environment, can seriously

affect the operation of this type of air heater,

especially if combustion air supply is not ducted.

To light the heater:

1. Turn on the gas supply to the air heater.

2. Switch on the electricity supply to the air heater.

3. Ensure time switch (if fitted) is set to an 'ON'

cycle.

4. Adjust control/room thermostat to desired

temperature.

5. Air heater will light automatically when the room

thermostat calls for heat after about 30 sec.

6. If the appliance does not light:

a) check that the burner control does not require

resetting. An indicator light glows at the inside

panel of the appliance and on a remote control if

fitted. Reset by pushing reset/button inside the

appliance or the remote control.

b) check if thermal overheat control requires

resetting

7 If the thermal overheat control requires resetting

and doing so restarts the air heater, wait until

the appliance warms to thermal equilibrium, to

ensure the overheat control does not lock out

again. If it does and the temperature near the

heater is less than 30°C, then switch off the

appliance and call for service. If the temperature

is over 30°C, take appropriate action to reduce

the ambient temperature near the air heater.

Air circulation:

1. The space heating process is for air to be

circulated through the appliance whereby it gains

heat from a heat exchanger. The air is directly

discharged into the space to be heated. The air

is eventually re-circulated. Therefore it is very

important that an unobstructed path for the

circulation of the air will be maintained. This is

particularly important if the air heater has been

installed to blow through the wall between two

rooms.

2. Sometimes the air circulation fan of the

appliance is connected to a remote over-ride

switch. This enables air to be used for circulation

purposes when the air heater is not used for

heating purposes e.g. in summer.

To use this feature:

a) switch ON electricity

b) switch ON manual override switch, this may

be fitted as a feature on a remote composite

control.

Maintenance:

1. Maintenance and service must only be carried

out by appropriately qualified persons e.g.

"Corgi" registered undertakings.

2. It is in your interest to ensure proper service and

maintenance is carried out at a regular basis.

Periods between services are dependent upon

the local environment where the heater is

installed. All gas appliances should be serviced

at least once a year.

3. In case of any damage to the appliance, it must

be shut down completely and checked by an

appropriately qualified person.

4. In the event of difficulties in resolving any of

these matters, please do not hesitate to contact

the manufacturer or their official distributor.

NEVER SWITCH OFF ELECTRICTY SUPPLY TO THE AIR

HEATER WITHOUT FIRST CLOSING THE GAS

ISOLATING TAP

22/25

Page 23

HEALTH & SAFETY STATEMENT

13

13.1 General

Under the Consumer Protection Act 1987 and

Section 6 of the Health and Safety at Work Act 1974

we hereby provide the following information on

substances hazardous to health.

Product range reference LCSA-4 air heaters.

13.2 Cautionary note

During first firing some smoking may occur, this is

due to the burning off of protective/lubricating oils

used during appliance production. Most of this will

have been removed during the production testing

process. It is a wise precaution to ensure that

adequate ventilation is provided during the initial

firing and throughout the commissioning period, this

is particularly important if the discharge air is to blow

into a confined space. This smoking does not

constitute a poison hazard.

13.3 Declaration

LCSA heaters contain no asbestos; copper is not

employed in gas carrying components; solder which

has a melting point below 450°C is not used; paints

for corrosion protection and decoration are heat

cured and contain no lead.

The above appliances meet the Electrical Safety

requirements of EN60 335 Pt 1 1988.

13.6 Thermostat.

Material: Illuminating Kerosene.

Description: Sealed phial contains a small quantity in

liquid form.

Recognition: Colorless liquid, paraffin oil/petroleum

hydrocarbon odor.

Characteristics: Non-corrosive, flammable with no

poisonous reference-CH poison Class 3

Precautions: Avoid handling. This product can irritate

and defat the skin. Prolonged contact may cause

dermatitis. Avoid breathing vapor. Avoid eye contact.

Do not ingest.

First Aid: Skin. Wash thoroughly with soap and water.

Eyes. Rinse immediately with copious amounts of

clean water.

Ingestion: Seek medical advice.

NOTE: If skin irritation persists seek medical advice.

13.7 Electrolytic Capacitor

Two types are used by random selection:

Recognition: 1. Plastic enclosure 2. Aluminium

enclosure

Material: Contained liquid electrolyte

Known hazards: Electric shock possible if charged.

Precautions: Discharge to ground/earth. Do not

incinerate.

First Aid: Treat for electric shock if affected.

13.4 Miscellaneous

Small quantities of adhesives and sealants used in

the product are dried and cured and present no

known hazard.

13.5 Insulation and Seals.

Material: Alumino - silicon fiber - crane glass

Description: Tapes

Known hazards: Some people can suffer reddening

and itching of the skin. Fiber entry into the eyes will

cause foreign body irritation. Inhalation will cause

irritation to the respiratory tract.

Precautions: Wear protective gloves when handling.

People with a history of skin complaints may be

susceptible to irritation.

Dust levels are only likely when the material is

abraded.

In general normal handling and use for this purpose

will not present discomfort. Follow good hygiene

practices, wash hands before consuming food or

using the toilet.

First Aid: Medical attention must be sought following

eye contact or prolonged reddening of the skin.

23/25

Page 24

CERTIFICATE

EC DECLARATION OF CONFORMITY OF MACHINERY

(Annex II 1 A of EC Machinery Directive 2006/42/EC)

Nortek Global HVAC Belgium nv

J&M Sabbestraat 130/A000

B-8930 Menen, Belgium

Hereby declares that the following gas-fired unit heaters:

LCSA-4

Types 12, 20, 30, 35, 45, 50, 60, 75, 100, 120, 145

Complies with the requirements of the above mentioned machinery directive

Complies with the requirements of further directives, namely

GAD 2009/142/EC - EMC 2004/108/EC – LVD 2006/95/EC

the following harmonized standards have been applied:

EN 1020: Non-domestic gas-fired forced convection air heaters for space heating not

exceeding a net heat input of 300 kW, incorporating a fan to assist transportation of

combustion air and/or combustion products.

The following notified body

Technigas

Chaussée de Vilvorde 156

BE 1120 Brussels

Has been involved with regarding to the

EC type examination number E1058/5521

Menen, 01.10.2016

J. Dubus

Engineering Team Leader

24/25

Page 25

NORTEK GLOBAL HVAC (UK) LTD

Park Farm Road

Folkestone

United Kingdom

Tel.

01303 259 250

www.reznor.eu

Registered in England N° 1390934. Registered office: 10 Norwich Street, London, EC4A 18D

Nortek Global HVAC is a registered trademark of the Nortek Global HVAC Limited. Because of continuous product innovation. Nortek Global HVAC

reserves the right to change product specification without due notice.

Kent

25/25

Loading...

Loading...