LM35 AND LM45 LAMINATORS

FROM SERIAL NO A670945 (LM45)

FROM SERIAL NO A671035 (LM35)

ILLUSTRATED PARTS LISTS

AND

SERVICE INSTRUCTIONS

Compiled by David Bird Issue No 4

Approved by Paul Aries (Technical Manager) Date 01/07/02

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

1

TABLE OF CONTENTS

ILLUSTRATED PARTS MANUAL

LM35 AND LM45 LAMINATORS

Preface Page 2

Illustrations and Parts Lists with

Recommended Spares Pages 3 – 8

Mouldings Page 3 – 4

Head Page 5 – 6

Electrics Page 7 – 8

Service Manual Page 9 – 15

Section 1 Page 9

Section 2 Page 9

Section 3 Page 9

Section 4 Page 10

Section 5 Page 11

Section 6 Page 11

Section 7 Page 11

Section 8 Page 12

Section 9 Page 12

Section 10 Page 13

Section 11 Page 14

Section 12 Page 14

Section 13 Page 15

Section 14 Page 15

Specifications Page 16

Wiring Diagrams Page 17 – 18

LM35 Page 17

LM45 Page 18

Amendment Record Page 19

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

2

PREFACE

This manual provides the instructions for the replacement of all the components that may become worn

or damaged. Details of replacement parts and ordering information are given in associated illustrated

parts list. For operating instructions see OI-477-07-96 and laminator carrier instructions see OI-521-0797 for both LM35 and LM45.

Illustrated Parts Lists

For each machine, these give full details of the replacement part numbers with supporting diagrams to

show the location of the components.

Service Instructions

For each machine, these give the recommended servicing procedure with supporting pictorial diagrams

for added clarity

WARNING

1. Check the machine RATING PLATE DETAILS are compatible with the electrical mains supply.

2. Disconnect the electrical mains supply before removing any covers.

3. The machine MUST have a sound Electrical Earth connection.

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

3

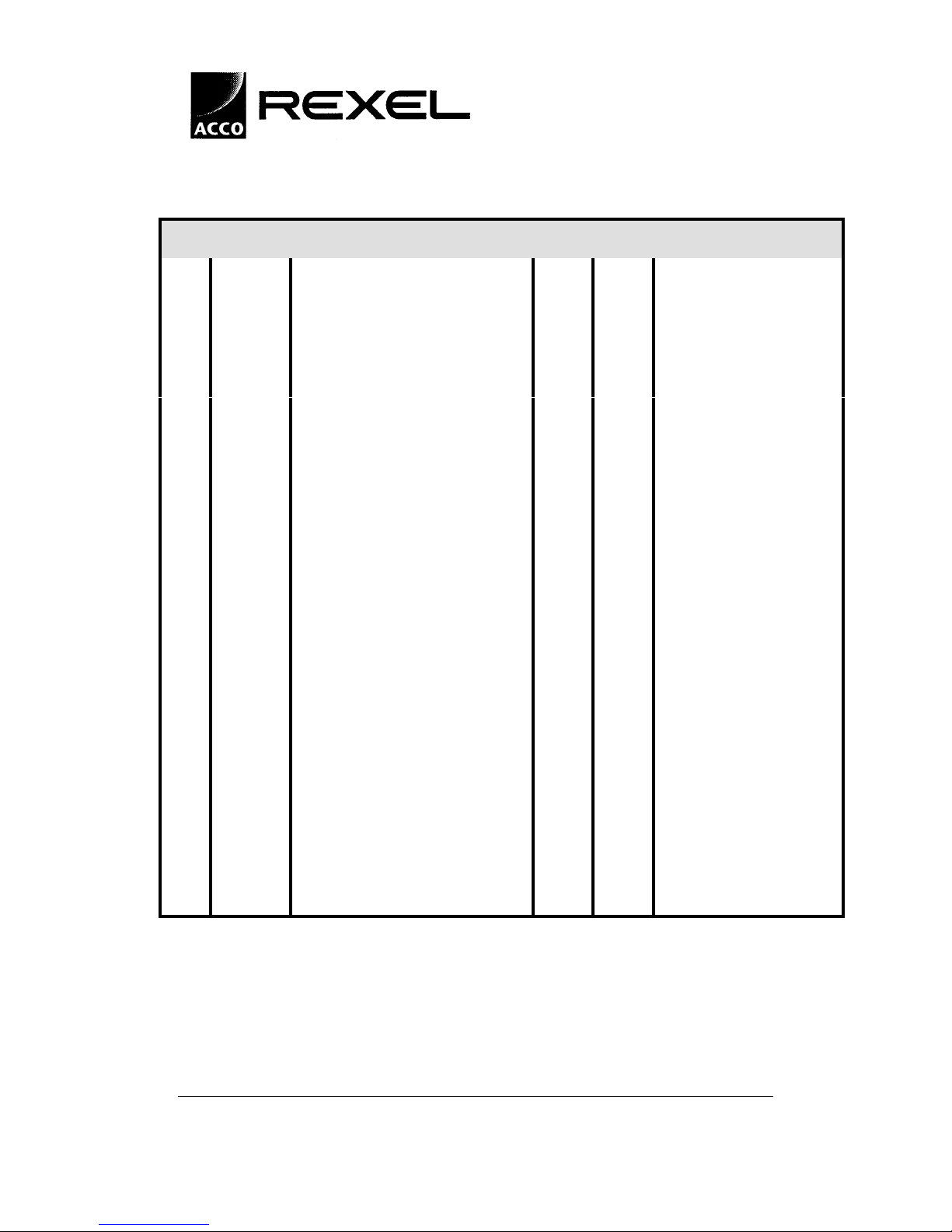

MOULDINGS

NO PART DESCRIPTION 35 45 COMMENT

1 D50543 Top Ellipse Rexel 1 1

2 D50539 Bottom Ellipse 1 1 Made from D50501

3 D50502 Entry Moulding 1 1

4 D50555 Entry Moulding With Printing 1 1

5 D50504 Main Front Shelf 1 1

6 D50505 Main Lid 1 1

7 D50506 Paper Support 1 1

8 D50507 Keypad Cover 1 1

9 D50508 Pcb Cover Plate 1 1

10 D000332 Keypad Decal - 1

11 D000349 LM35 Model No. Decal 1 - NOT SHOWN

11 D000350 LM45 Model No. Decal - 1 NOT SHOWN

12 SL18-294 Rubber Feet 4 4

13 SCR714 M4 X 12 Plasform Pan Head Screw 4 4

14 SCR713 M3 X 8 Plasform Pan Head Screw 2 3

15 D50589 Lcd Cover 1 18 D50578 Fixing Bracket - 1

19 D50579 Paper Deflector Blade - 1

21 PLN31 Plain Washer - 1

22 A50594 MAIN LID COMPLETE 1 1 COMPRISES 6, 7

24 D000185 Service Call Decal 1 1

25 RPLM35 Rating Decal 1 - NOT SHOWN

25 RPLM45 Rating Decal - 1

27 D000368 Carrier Warning Decal 1 - NOT SHOWN.

A50575 MAIN LID ASSEMBLY 1 1 COMPRISES 5, 6, 7, 8

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

4

MOULDINGS

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

5

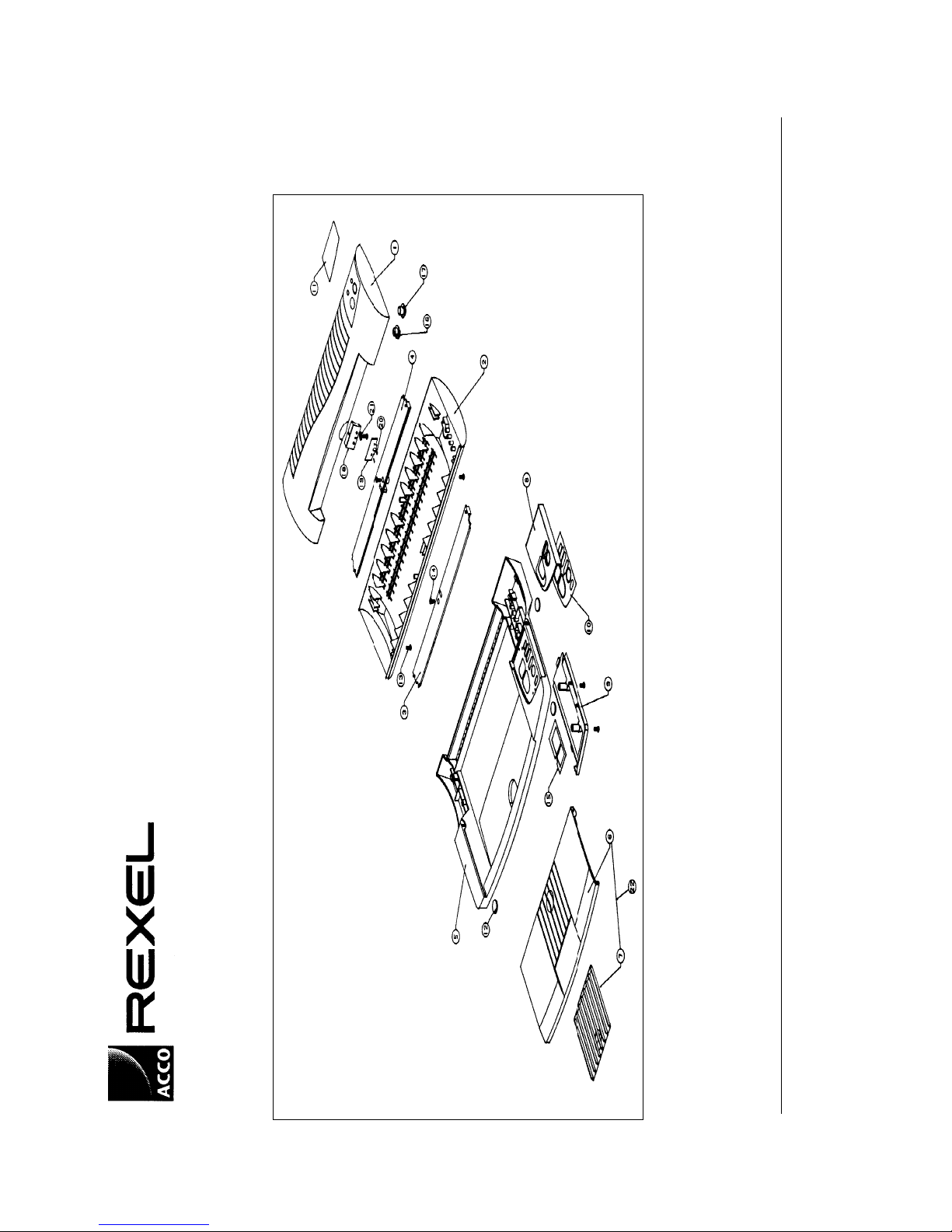

HEADS

NO PART DESCRIPTION 35 45 COMMENT

1 A50607 Driven Roller Shaft Assembly 3 2

2 BR 27 Ball Bearing 8 8

3 D50599 Roller Gear 4 4

4 TRU 66 10mm Circlip 4 4

5 Insulating Blanket 2 2

5A A50620 LM35/45 Heater Assembly 1 1

Comprises 5-9, 21,22, plus electrics 15-19,

22-25

6 Heater Compression Spring 8 8

7 Heater Backing Plate 2 2

8 Bottom Heater Extrusion 1 1

9 Top Heater Extrusion 1 1

10 D50598 Sideframe 2 2

11 D50601 Side Frame Pin 4 4

12 D50514 Idler Gear 1 1

13 D50515 Idler Gear Pin 1 1

14 TRU 91 8mm Push On Fastener 1 1

15 D50612 Extension Spring (Front) 4 4

16 D50600 Extension Spring (Rear) 4 4

18 D50597 Lever Arm 4 4

19 A50615 Driven Roller Assembly (Steel) - 1

20 A50605 Drive Roller Shaft Assembly 1 20 A50617 Drive Roller Shaft Assembly - 1

21 Pressure Bar Support Clip 3 3

22 Blanket Retaining Clips 5mm 12 12

23 D50591 Top Backing Plate (2mm) - -

Not used on LM35, replaced with Pressure

Bar

24 D50608 Pressure Bar 1 1

25 TRU 85 Grip Washer - 2

A50622 SPARES HEAD ASSEMBLY 1 -

Comprises 1 - 18, 20, 22, 25 plus Electrics

15 - 17, 23, 24 + earth

A50623 SPARES HEAD ASSEMBLY - 1

Comprises 1 - 25 plus Electrics 15 - 17, 23,

24+ earth

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

6

HEAD

10

1

2

3

4

5

6

7

8

9

1112

13

14

15

16

17

18

1

45

25, 35

19

20

21

22

23

24

25

22

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

7

ELECTRICS

NO PART DESCRIPTION 35 45 COMMENT

1 D50535 Switch Blanking Plate 1 1

2 D50511 Keypad 1 2 D50519 Keypad - 1

3 A50620 LM35/45 Heater Assembly 1 1 NOT SHOWN comprising

15-19, 22-25 plus heads 5-

9, 21,22.

4 SL17-508 Control Pcb 1 4 SL17-309 Control Pcb - 1

5 SL20-267 Motor 1 5 SL20-268 Motor - 1

6 SL4-102 Cordset 1 1 UK ONLY

7 PLN31 M3 Plain Flat Standard Washer 2 2

8 NM14 Nyloc Nut M3 X 0.5 2 2

9 SL18-310 Nylon Spacers 2 2

10 SCM115 M3 X 20 C’sunk P/Pan Drive Screw 2 2

11 SL13-87 Crimp Terminal Housing 2-Way 1 1

12 SL13-90 Crimp Terminal Housing 4-Way 1 13 SL13-91 Crimp Terminal Housing 3-Way - 1 NOT SHOWN

14 SL13-88 Crimp Terminal Housing 2-way - 1 NOT SHOWN

15 M3 Plain Washer Brass 3 3

16 M3 X 12 C’sunk Slot Head Brass 2 2

17 M3 Full Nut Brass 3 3

18 M3 Shakeproof Washer Ext 2 2

19 Wiring Assembly 1 1

20 NOT USED

21 SCR713 M3 X 8 Self Tap Screw 2 2

22 Butt Connector 2 2

23 Top Heater Element (With Fuse) 1 1

24 Bottom Heater Element (with fuse) 1 1

25 Thermistor Assembly 1 1 NOT SHOWN

26 NOT USED

27 D50581 Microswitch Actuator Arm - 1

28 D50525 Microswitch Assembly - 1 NOT SHOWN

30 SL13-86 Crimp Terminal - 2 NOT SHOWN

31 SL13-85 Crimp Terminal 2 2 NOT SHOWN

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

8

ELECTRICS

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

9

SECTION 1

Removal and Replacement of Top Cover

1 Ensure that the mains cable is disconnected from the supply.

2 Remove the two fixing screws from the rear of the machine.

3 Slide top cover forward to unclip it from the front fixings.

4 Remove metal switch blanking plate from inside the top cover.

5 Replace the top cover with the new one and reverse above

procedures to secure the new top cover in place. Replace switch

blanking plate.

SECTION 2

Removal and Replacement of Entry/Exit Mouldings

1 Remove top cover as explained in Section 1.

2 There are two screws, one securing each entry moulding to the

bottom ellipse -remove these.

3 To replace entry mouldings, slide into position and secure with

screws. [LM45] -- ensure microswitch actuator is positioned in its

slot in the front moulding before fixing down.

4 Replace top cover. (Section 1).

SECTION 3

To Remove and Replace the Head

1 Invert the machine and remove two screws which hold in place

both the PCB and its cover.

2 Release three push fit connectors from the PCB (1 x 2 way--

thermistor, 1 x 2 way mains and 1 x 4 way heater/motor (LM35),

1 x 3 way heater and 1 x 2 way motor (LM45)) and put aside the

pushbutton actuators.

3 Remove top cover (Section 1).

4 Remove entry mouldings (Section 2).

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

10

5 Lift the head out of the bottom moulding, extricating wires

released from the PCB through the hole in the moulding.

Remember the earth lead remains attached to the head at this

stage.

6 Cut the incoming mains’ earth wire (green/yellow) to the ‘head

side’ of the existing crimp type butt connector.

7 Remove the head away from the case and place it flat on the

worksurface in a clean environment.

8 Replace the unit in reverse sequence--join severed earth lead with

a new crimp butt connector, relocate wires to PCB via hole in

moulding [NB. it will be found easier to undo the two screws fixing

the lower ellipse to the front shelf when pushing the wires through

to the PCB compartment].

9 Refit keypad membrane, PCB and cover.

10 Re-fit top cover.

SECTION 4

Removal and Replacement of the Motor

1 Remove the head as described in Sections 3 or 4.

2 Locate and unfasten two M3 screws, with Nyloc nuts, holding the

motor to the side frame. Note the position of the spacers.

3 Remove two motor wires from the four way connector (LM35) and

the two way connector (LM45) by depressing the exposed metal

pin with a sharp object, such as a small screwdriver.

4 To replace the motor, first locate the drive peg in the slot in the

roller shaft end (NB ONLY turn the roller shaft to align, NOT the

gearbox spindle, as this will destroy the motor unit) .

5 Refit and tighten motor fasteners, with spacers between the

sideframe and motor. Do not overtighten the nuts as this will

deform the plastic spacers.

6 Re-fit two motor wires (with appropriate crimp ends) to the 4 way

connector.

7 Replace head unit and top cover as described previously (refer

sections 3, 2 & 1).

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

11

SECTION 5

Removal and Replacement of Gears

1 Remove head unit from casing as explained in Section 1, 2 & 3.

2 Remove circlips of gears needing to be replaced (note, there is no

groove for the clips), and take off the gears.

3 Fit new gear(s), raised boss towards the centre of the machine,

and secure with circlip(s). [NB it can be tricky to re-mesh the

gears whenever the rollers have turned relative to one another,

and the springs are in tension -- one way is to release one spring].

4 Replace head into its case (Sections 3, 2 & 1).

SECTION 6

Removal and Replacement of Tension Springs and Lever Arms

1 Remove head unit and place on the working surface.

2 Remove/replace tension springs as required [NB. rear springs are

stronger than those at the front].

3 Remove lever arms by removing the push fixings on pressure bar,

and slide bar out so that lever arms are removeable.

4 Replace lever arms and springs as required.

5 Replace the head into its casing.

SECTION 7

To Replace Rollers and Roller Bearings

DISASSEMBLY

1 Carry out all procedures necessary to remove the head away from

the casing (Sections 1, 2 & 3).

2 Remove the four gears from the ends of the roller shafts, as

described in section 5.

3 Remove lever arm springs (not necessary to remove lever arms),

the pressure bar, but from ‘motor-end’ only, generally as described

in section 6 above.

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

12

4 Pull sideframes apart to release the rollers, with their bearings, as

well as the heater assemblies.

RE-ASSEMBLY

1 Replace rollers and/or ball bearings as necessary. Fit re-used

bearings to new rollers or vice versa

2 One recommended method of re-assembly, is firstly to fit rollers

with bearings to ‘gear-end’ side frame, and provide support to the

sub-assembly by re-fitting pressure bar, lever arms and springs.

Leave off the gears at this stage.

3 Stand the unit vertically and place heater assemblies into position

between the rollers, flat sides facing.

4 Carefully feed the ‘motor-end’ side frame onto its roller shaft and

heater assembly ends including pressure bar.

5 Fit lever arm springs, then replace gears and circlips (refer

sections 5 & 6).

6 Replace head and cover as described above, sections 3, 2 & 1.

SECTION 8

To Remove and Replace Heater Assemblies--All Models.

1 It is felt that due to the work involved in removing and replacing

the heater assemblies, it is more economic to replace the head

unit as a whole – see section 3.

SECTION 9

Removal and Replacement of Sideframes

1 Remove top cover, head, (refer sections 1, 2, 3 or 4).

LEFT HAND SIDEFRAME

1 Remove the gears (Section 5).

2 Remove ‘gear-end’ springs and lever arms (Section 6).

3 Remove the push on fastener and hence the idler gear.

4 Slide sideframe off roller spindles/bearings and replace with new

part.

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

13

5 To reassemble, fit frame back on to rollers/bearings, paying

particular attention to locating the heater assemblies properly

(refer section 7).

6 Fit and connect up lever arms and springs, replace idler gear and

thermal fuse.

7 Fit head and top cover (sections 3, 2 and 1).

RIGHT HAND SIDEFRAME

1 Remove the motor as described in section 4 (no need to extract

motor wires from PCB connector).

2 Remove ‘motor end’ springs and lever arms (Section 6).

3 Remove top heater earth connection from its stud.

4 Remove the wire to the lower heater from the PCB connector.

5 Cut link wire between the heaters.

6 Slide sideframe off roller spindles/bearings and extract wires

through hole in lower part of the frame.

7 Replace side frame and re-assemble the head, generally as

described in section 7, RE-ASSEMBLY, 1 to 5.

8 Route wires through hole in side frame, or over the top as

described in section 9, and re-join the heater link wires using a

suitable butt connector.

9 Refit motor (Section 4).

10 Replace head and top cover (Sections 3, 2 & 1).

SECTION 10

Removal and Replacement of Front Shelf Moulding

1 Remove top cover/PCB, and head (Sections 1, 2 & 3).

2 Remove keypad membrane and plastic LCD cover.

3 Remove the two top to bottom ‘ellipse’ fixing screws.

4 Unclip top cover (ellipse) from base by sliding it forward and out.

Reassemble in reverse sequence.

5 Re-assemble in reverse sequence.

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

14

SECTION 11

Removal and Replacement of Main Lid

1 Unclip main lid from front shelf by pushing in firmly.from the

sides, slightly deflecting the middle of the lid.

2 Replace the lid by aligning its hinge pegs with holes in the front

shelf and pushing into place.

SECTION 12

Removal and Replacement of Paper Support

1 Open up the paper support tray.

2 Firmly grasp the support and depress it in the middle to enable

release of the hinge pegs from their locations in the main lid

3 Replace paper support.

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

15

SECTION 13

Replacement of Keypad Cover -- LM45 only

NB

THE KEYPAD COVER ON THE LM35 IS FIXED INTO POSITION

AND SHOULD NOT BE REMOVED.

1 The keypad cover is secured to the front shelf by two side

fixing/hinge pegs which clip into two holes.

2 To free the cover, slightly pull its outer edges apart.

3 Replace the keypad cover.

SECTION 14

Replacement of Keypad Membrane

1 Remove PCB with its cover (Section 3 pt 1). Do not disconnect any

wires.

2 Replace the keypad membrane.

3 Ensure LCD cover is in position when reassembling.

4 Re-place PCB with cover.

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

16

SPECIFICATIONS

LM35/LM45

Power Supply

220/240v 50HZ

Height mm

113.4

Width mm

483

Depth mm

324.2

Weight kg

6Kg

Motor Power W

0.42W (LM35)

4W (LM45)

Pouch size (max)

A3

Feed Rate

0.5m/min (LM35)

0.5m/min to 1.0/min (LM45)

Maximum Pouch Thickness

500 micron

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

17

LM 35 – WIRING

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

18

LM45 – WIRING

ILLUSTRATED PARTS MANUAL

LM35, LM45 LAMINATORS

Rexel Business Machines, Westbank, Droitwich Spa, Worcestershire. WR9 9AP England

Tel: +44 (0) 1905 771555 Fax: +44 (0) 1905 823374

19

AMENDMENT RECORD SHEET

ISSUE NO DECRIPTION

CARO No

1 Original -

2-3 Not recorded

4 PCB and Heater Assemblies now being

supplied from a single source resulting in

changed work procedures affecting servicing

procedures.

456

Loading...

Loading...