Page 1

o^Tfp nrmr^rs)

REI/QX

' .

B225

IiILI„OF_CgNTEyTS page

1. GENERAL

1-1 Index of CO olayer controls 1/i

1*1* 1 General controls 1/1

1*1*2 Special controls 1/2

1*1*3 Rear panel connectors 1/3

2. t REMOVAL OF ASSEHBLIES

2.1 Removing the top cover 2/1

2*2 Removing tne side panels 2/1

2.3 Removing the individual circuit boards 2/1

2*4 Removing the player mechanism 2/1

2®5 Removing the display 2/2

2*6 Removing the po^er

2*7 Removing the drawer motor 2/1

2*8 Removing tne operating panel 2/3

Z«9 Removing the guide rods 2/3

t r

ansf or mator 2/2

3* CIRCUIT DESCRIPTIONS

3.1 SERVO 1 PC3 1.759.310 3/1

3.1®1 Stabilization of the supply voltages 3/1

3*1*2

Orawer position detector 3/1

3*1.3 Focus control loop 3/2

3*1*4

Oisc motor control loop 3/2

3.2 Microprocessor PC3 . 1.769.320 3/3

3.2*1 Microprocessor system 3/3

3^2*2

Drawer motor control 3/4

3*3 SERVO- 2 PCP 1.769*330 3/4

3.3^1 Radial control 3/4

3*3.2

Radial control circuit 3/4

3*3*3

Automatic gain control- {AGC-} circuit 3/5

3«3r-4 Offset control circuit. 3/5

3.3.5 Track detecting circuit 3/6

3*4 Preamplifier and laser PCB 1*769*100*35 3/6

3.4.1 Laser control 3/6

3*4^2

Focus and radial control signals 3/6

3«4*3 HF signal amplifier 3/6

3.5 Decoder PCh l-7o^.300 3/6

3*

t>

• 1 Digital signal processing

3»5«2 Digital sine-wave generator 3/7

3.

5. J

HFL and 0-J detector 3/7

3*o OAC TC3 1.769.23 3 3/7

3.t».l

digital filtering (oversampl ing) and 0/A conversion 3/7

3*6.2

Level adjustment and headphones amplifier 3/3

3/7

Page 2

mmmm

*• TEST POINTSt ADJUSTMENTS OH E225

4 i Test points on 622^ 4/1

4«-l»l Test points on SERVO I PCB 1«?69*310 4/1

4.1.2 Test points on SERVO 2 PCB 1.769.330 4/3

4.1.3 Test points on microprocessor PCB 1.769*320 4/4

4.1.4 Test points on decoder PCB 1.769.300 4/6

4.1.5 Test points on 0AC- PCB 1.769.260 4/8

4®2 Adjustments on CO player B225 4/9

4.2.1 Aids 4/9

4.2.2 Aligning the player mechanism? general 4/9

4*2®3

4.2.4 Adjusting the balance 4/9

4«Z*5 Adjusting the focus gain 4/10

4*2*6

4*»2#7

4.3 Measuring the audi.o data 4/11

4*3.1

A i 4s

4*3#2

4.3.3 Output level 4/11

4.3*4

4.3.5 Cross talk 4/12

4.3.6 Signal-to-noise ratio* linear 4/12

4.3.7 Signal-to-noise ratio? weighted - ' 4/12

4.3.3 Phase linearity 4/12

4.4 Listening test with reference CO 4/12

eel/ox

Adjusting the laser current 4/9

Checking the -tingle alignment 4/10

Adjusting the DC component of the focus signal 4/11

Harmonic distortion 4/11

Frequency response 4/11

B225

4/i1

5* DIAGRAMS

6. SPARE PARTS

7*

TECHNICAL APPENDIX

7.1 Technical data 7/1

7«Z

Dimensions 7/2"

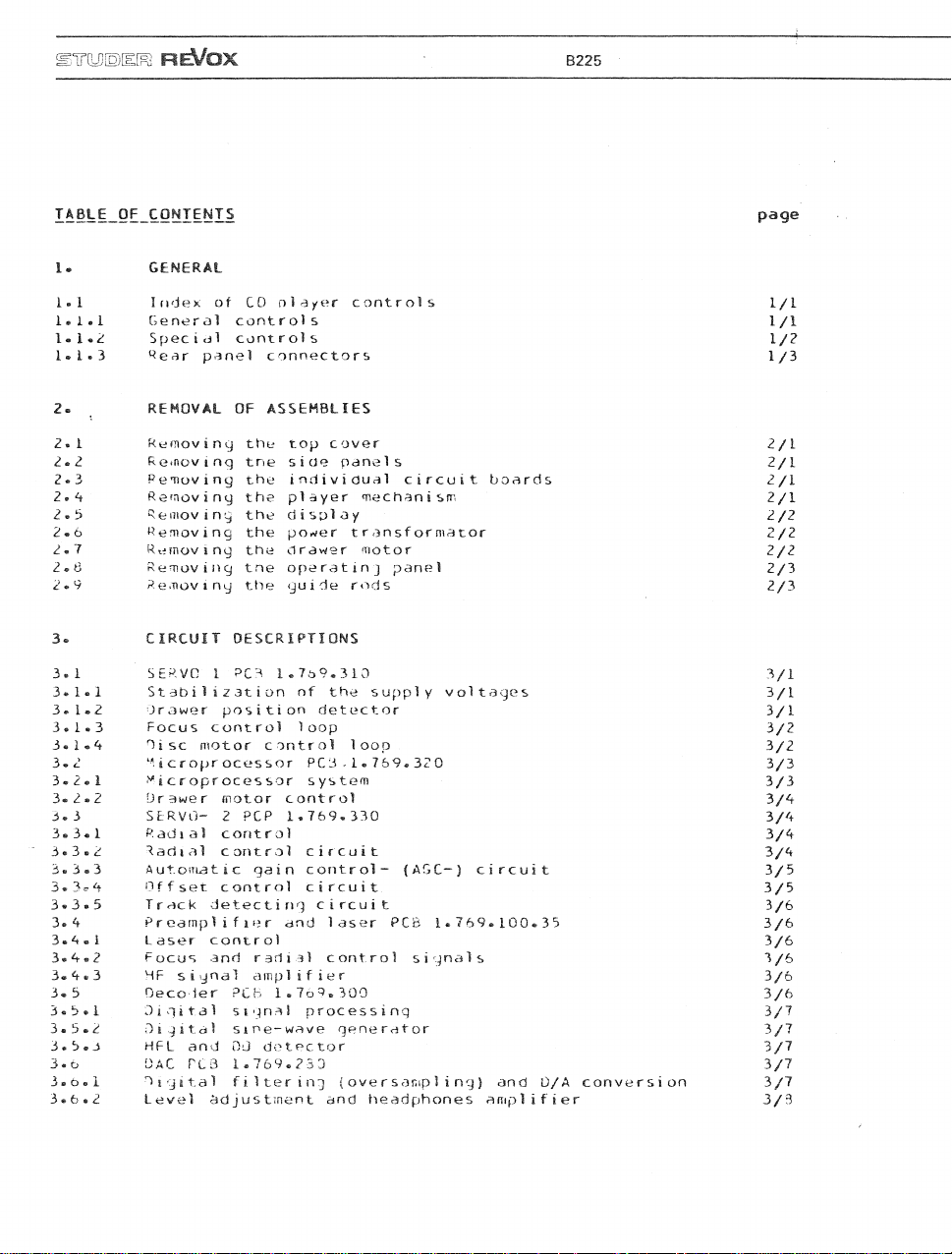

Page 3

R^/ax

B225

1.

1.1

1.1.1

1 Ij POWER *

[

2 j

LOAD

[

3 J

STOP *

[

4 J

PLAY/NEXT

H5"f REPEAT

[6j (CD drive)

[7j (Display)

[8j (keys 0-9)

GENERAL

Index of CD player controls

General controls

Key for switching the CD player ON and

OFF.

However, certain assemblies (such

as the IR receiver) remain always switched"

on (in so-called standby

The drawer with the player mechanism

[6j opens or closes when this key is

pressed.

Interrupts the player function. The

optical laser head is retracted to the

starting position and the program is

cancelled if the CD player was in program

mode.

The position in which the laser

pickup was operating before STOP was

pressed cannot be reproduced. If this

is desired, please refer to tJL (PAUSE)

key.

Play key with the following functions;

If pressed after LOAD [2j, the CD starts

to rotate, the content list is read, and

the disc is played starting at the first

selection

(TRACK) is accessed when this key is

pressed again.

If pressed after PROGRAM MODE [26 J has

been selected: play program mode is

activated.

The selection currf.r^ly being played

is repeated immediately when this key

is pressed. If the CD player is in STOP

mode,

disc will be played. If the CD player is

in program mode, the current program step

will be repeated.

Drawer module with CD player mechanism

and liquid-crystal display. The drawer

can be opened or closed with LOAD [2].

Multifunction LC display 'which provides

information on all operating modes of

the CD player and the content of the

loaded compact disc.

Digit keys for direct addressing of

a selection (TRACK) in conjunction with

PLAY/NEXT [4j, or for programming.

(TRACK).

the first selection of the compact

The next selection

mode).

The CD player can be switched on by pressing any of

the controls [ Ij through [8j of the upper row (except

REPEAT [5j and the digit key 0). The CD player starts

in the selected operating mode.

Page 4

mruim

REVOX

B225

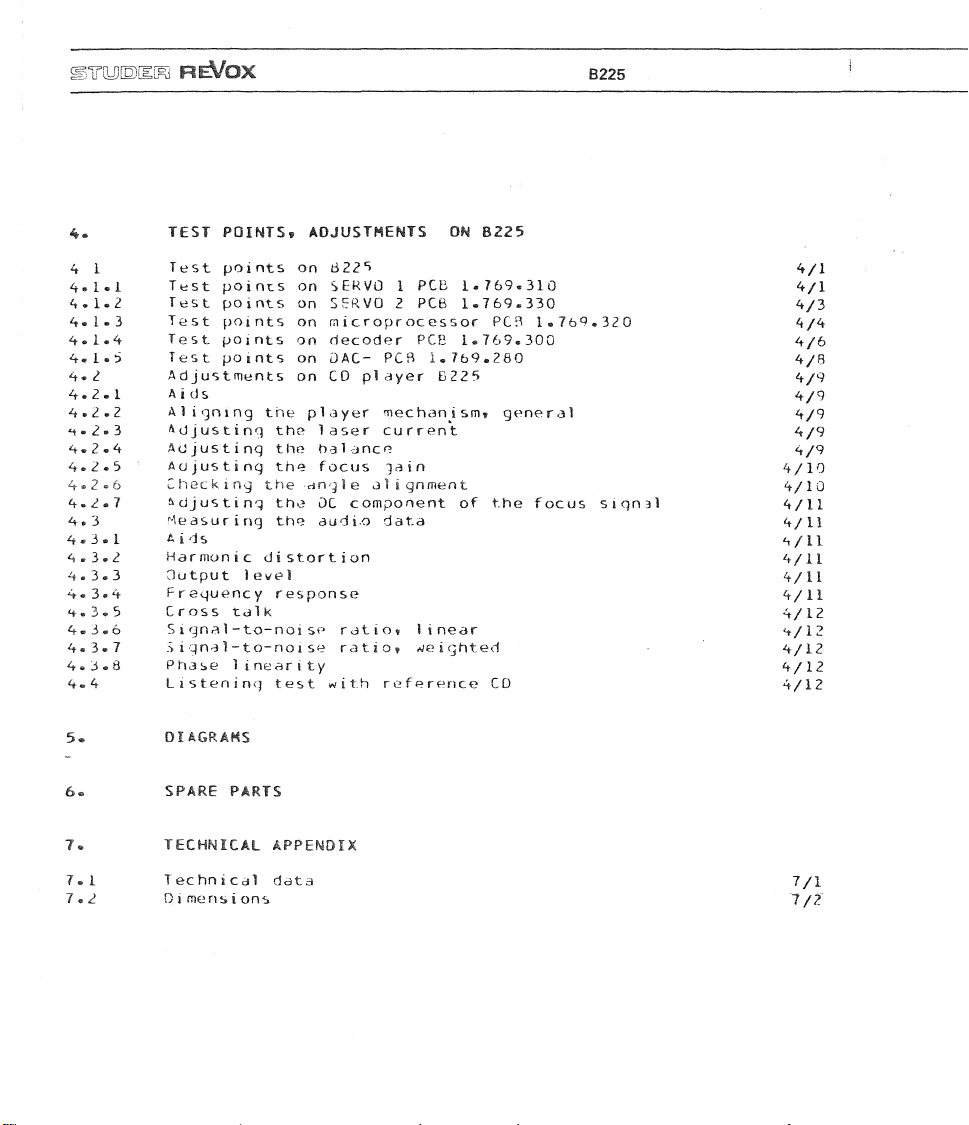

1.1.2

The controls

roughly divided into

for supplementary player functions,

controls.

A Controls

[9] PHONES

[10] VOLUME

[11j VOLUME

[12]

CAL

13] AUTOSTOP

[ 14j

Key •

[ 15 J

VA

[16]

« key

[17] DISPLAY

Special controls

in the

+

-

TONE

*

(pause ) *

lower front-panel section

two

for

Headphones jaGk socket

200

Increases

and

Decreases

and

This calibration button connects

1000

outputs

of a connected tape deck

accurately adjusted.

CAL TONE corresponds

output level. This maximum level

is system-dependent

be exceeded even

pulses.

Interrupts

at

or program step.

is automatically positioned

the beginning

The next selection

immediately when PAUSE

pressed. Upon conclusion

selection,

again

Repositions

location toward

Interrupts

at

Repositions

location toward

Switches over

The time elapsed since

of

in normal PLAY mode.

play time from

current selection

by pressing this

function groups: controls

supplementary player functions

to 600

the

the

Hz

the end of the

any

the

ohms.

the

level

level

calibration tone

so

to

time.

current selection

headphones level

of the

the

headphones level

of the

that

the

of the

the CD

PAUSE mode.

the

the

the

the

can be

and

programming

for

headphones

VARIABLE OUTPUT.

VARIABLE OUTPUT

the

by

playing sequence

current selection

The

is

player switches

pickup from

the end.

playing sequence

pickup from

the

display mode.

the

start

can be

key.

to the

recording level

can be

The 1000 Hz

to the

and

short peak

laser pickup

next selection.

started

start.

The

maximum

will

not

at

TA [15] is

of

this

any

any

the

start

is

displayed

total

to the

displayed

a

These functions

PROGRAMMING keys

18] LOOP

19]

[20]

[21]

[ 22] STORE

[ 23] MARK

[24] TRACK/TIME

+

-

IR

*

SENSOR

can

also

be

programmed.

Command key for repeating the CD

or the proqr^4«until STOP [3j is

pressed.

Forward "paging" in program mode.

Particularly useful for modifying

an existing program.

Same function as [19] but backward

paging.

Infrared receiver window

Memory load key to be pressed after

each program step entry. The next

program step is subsequently

displayed so that the corresponding

entries can be made.

Allows a start and a stop mark

to be set in programming mode while

a selection is being played. Any

CD location can thus be programmed.

Switches the display in programming

mode from selection (track) input

to time input (minutes and

seconds).

Page 5

mWU\n)MPd

R^OX

B225

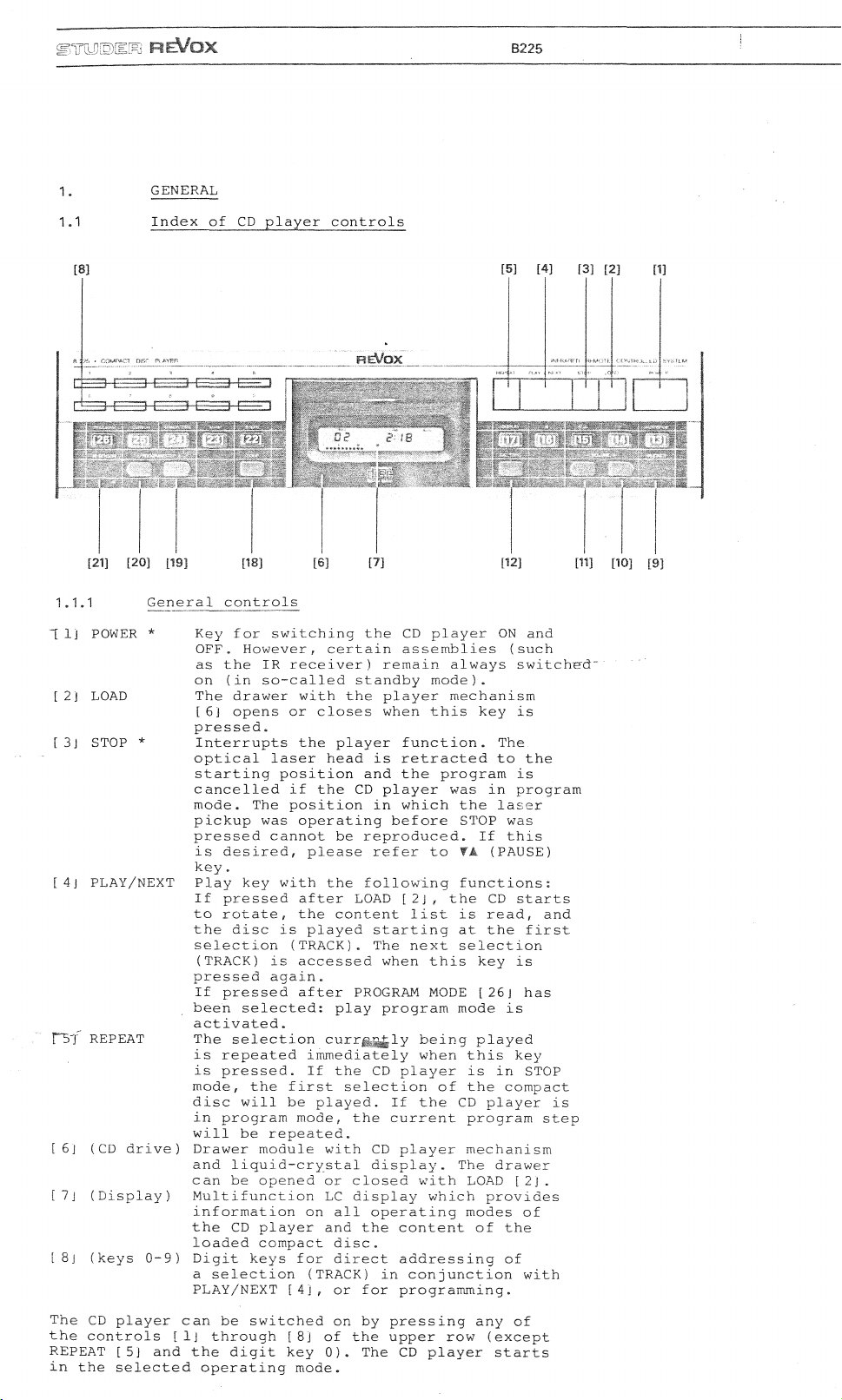

[25j CURSOR

[26 J

PROGRAM

Any position on the display can

be edited by approaching it with the

cursor.

TIME mode, the cursor must be

advanced with this key in order to

enter the seconds after the minutes.

Sets the program entry mode. If

PLAY/NEXT [4J is pressed after

the program entries have been

completed, the CD player starts in

PROGRAM mode,

If the CD player is to be started

in normal mode after the program

entries have been completed, press

the PROGRAM key

PLAY/NEXT [4].

NOTE; if the display is in

[ 26 J

again before

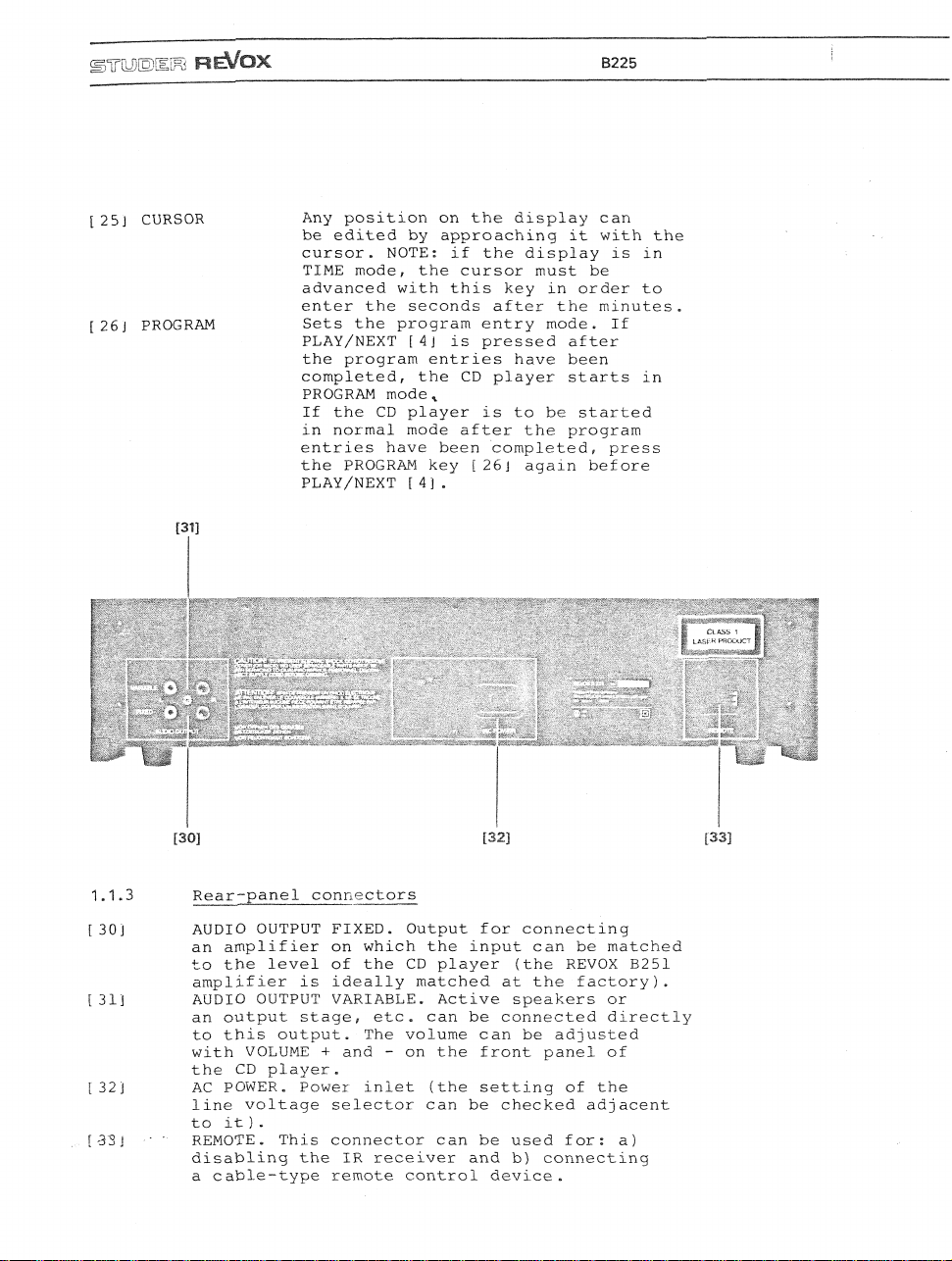

1.1.3 Rear-panel connectors

[30] AUDIO OUTPUT FIXED. Output for connecting

[31] AUDIO OUTPUT VARIABLE. Active speakers or

[32] AC POWER. Power inlet (the setting of the

..[33J

• "

an amplifier on which the input can be matched

to the level of the CD player (the REVOX B251

amplifier is ideally matched at the

an output stagef etc. can be connected directly

to this output. The volume can be adjusted

with VOLUME + and - on the front panel of

the CD player.

line voltage selector can be checked adjacent

to it ) .

REMOTE. This connector can be used for: a)

disabling the IR receiver and b) connecting

a cable-type remote control device.

factory).

Page 6

B^OX

B225

2 . REMOVAL OF ASSEMBLIES

Important:

Disconnect the CD player from the AC supply before

removing any parts of the housing.. For certain work

it is necessary to open or close the drawer module.

This can be done manually without damaging the unit.

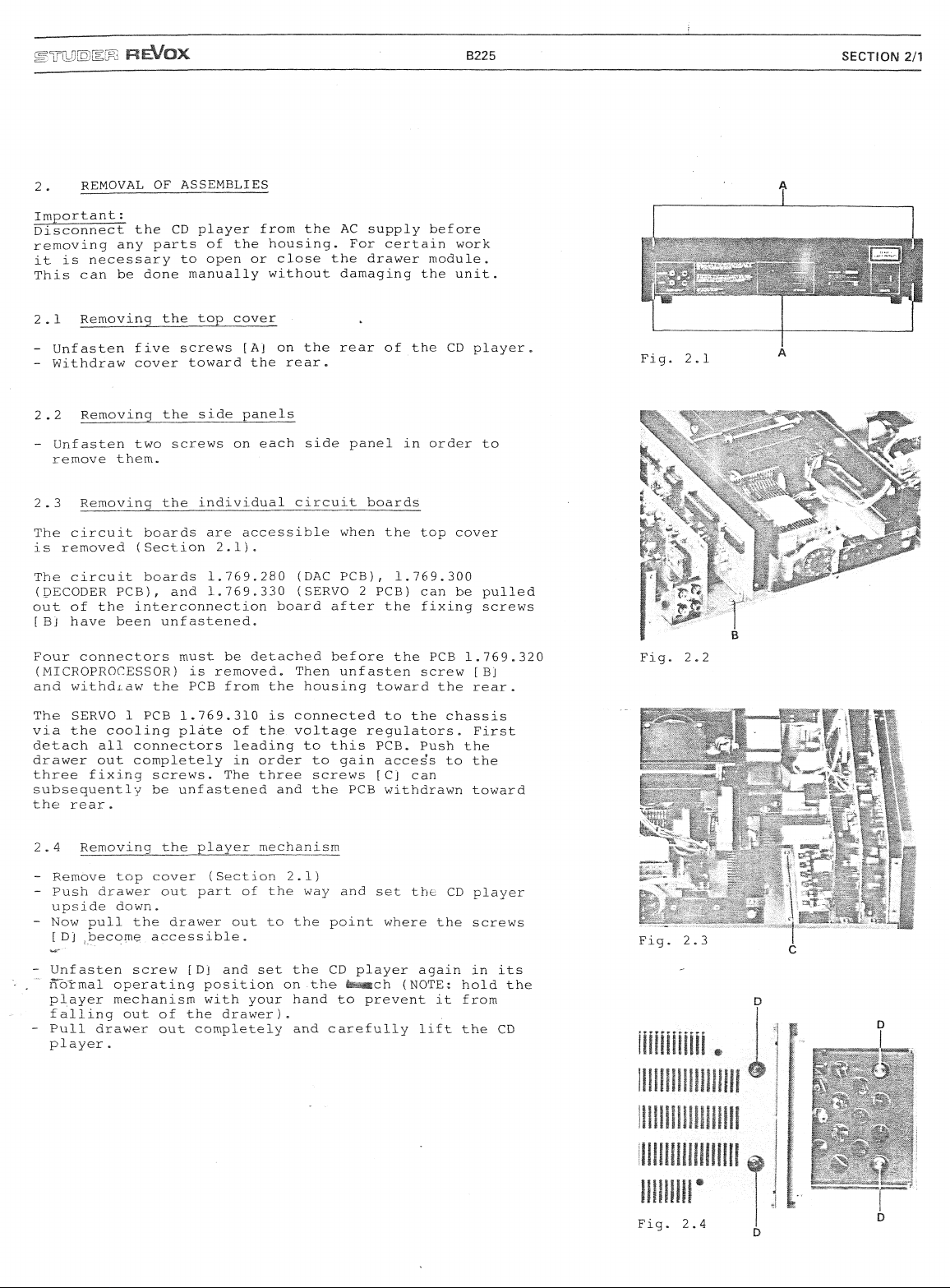

2.1 Removing the top cover

- Unfasten five screws [Aj on the rear of the CD player.

- Withdraw cover toward the rear.

2.2 Removing the side panels

- Unfasten two screws on each side panel in order to

remove them.

2

. 3

Removing the individual circuit boards

SECTION 2/1

The circuit boards are accessible when the top cover

is removed (Section 2.1).

The circuit boards 1.769.280 (DAC PCB), 1.769.300

(DECODER PCB), and 1.769.330 (SERVO 2 PCB) can be pulled

out of the interconnection board after the fixing screws

[ B] have been unfastened.

Four connectors must be detached before the PCB 1.769.320

(MICROPROCESSOR) is removed. Then unfasten screw [Bj

and withdraw the PCB from the housing toward the rear.

The SERVO 1 PCB 1.769.310 is connected to the chassis

via the cooling plate of the voltage regulators. First

detach all connectors leading to this PCB. Push the

drawer out completely in order to gain access to the

three fixing screws. The three screws [C] can

subsequently be unfastened and the PCB withdrawn toward

the rear

2

. 4

.

Removing the player mechanism.

- Remove top cover (Section 2.1)

- Push drawer out part of the way and set the CD player

upside down.

- Now pull the drawer out to the point where the screws

[ Dj ^become accessible.

- Unfasten screw [Dj and set the CD player again in its

- . ~ normal operating position on the

fc--^ch

(NOTE; hold the

player mechanism with your hand to prevent it from

falling out of the

drawer).

- Pull drawer out completely and carefully lift the CD

player.

Page 7

'umrnm ¥%EMOK

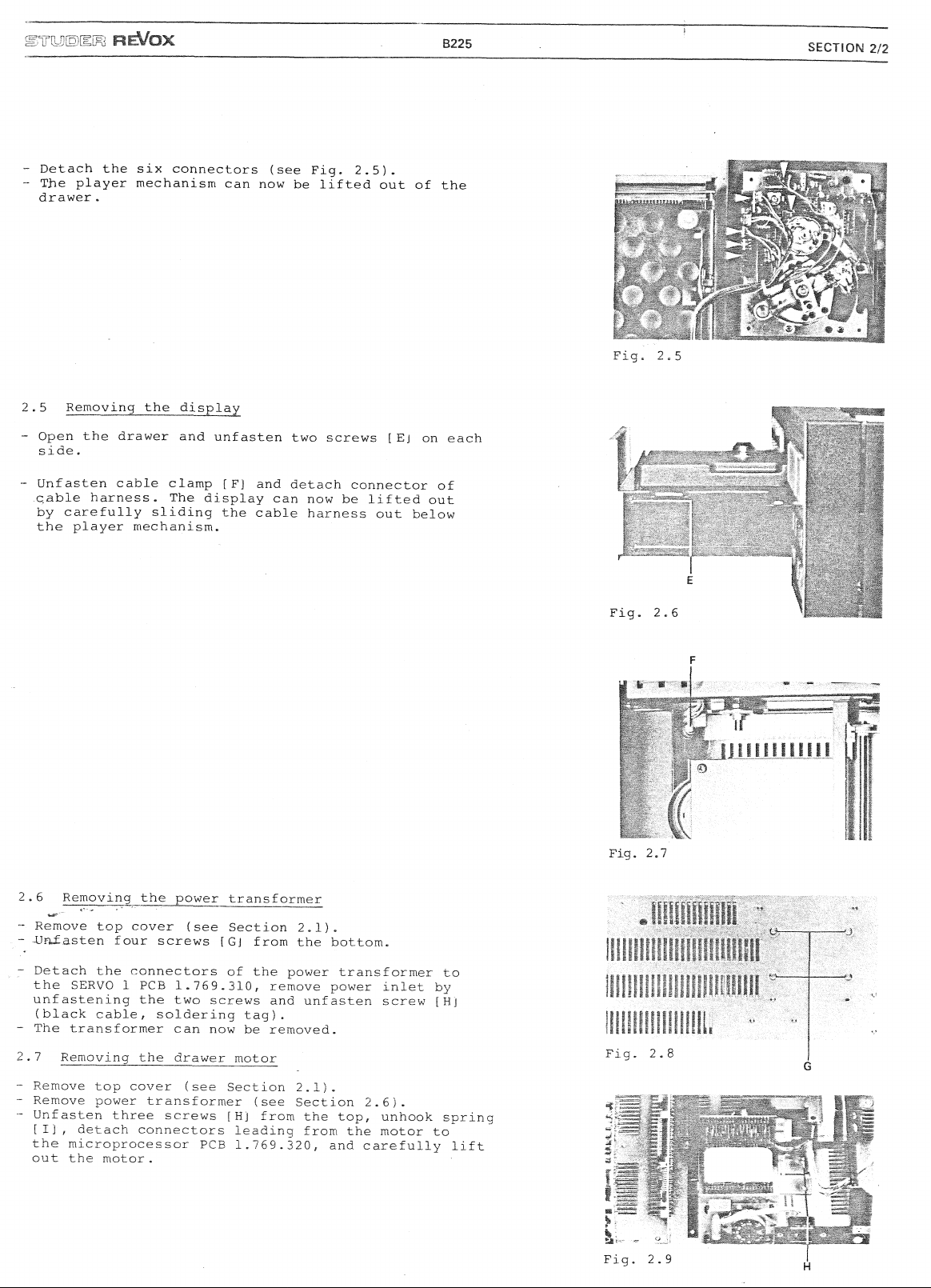

Detach the six connectors (see Fig. 2.5).

The player mechanism can now be lifted out of the

drawer»

2.5 Removing the display

B225

SECTION 2/2

- Open the drawer and unfasten two screws [ Ej

on each

side.

- Unfasten cable clamp [F] and detach connector of

cable harness. The display can now be lifted out

by carefully sliding the cable harness out below

the player mechanism.

2 •6

Removing the power transformer

- Remove top cover (see Section 2.1).

•

- JJniiasten four screws [Gj from the bottom.

- Detach the connectors of the power transformer to

the SERVO 1 PCB 1.769.310, remove power inlet by

unfastening the two screws and unfasten screw [Hj

(black cable, soldering tag).

- The transformer can now be removed.

2.7 Removing the drawer motor

- Remove top cover (see Section 2.1).

- Remove power transformer (see Section 2.6).

- Unfasten three screws [Hj from the top, unhook spring

[I],

detach connectors leading from the motor to

the microprocessor PCB 1.769.320, and carefully lift

out the motor.

Page 8

UJPEMKi KEl/OX

• .

B226

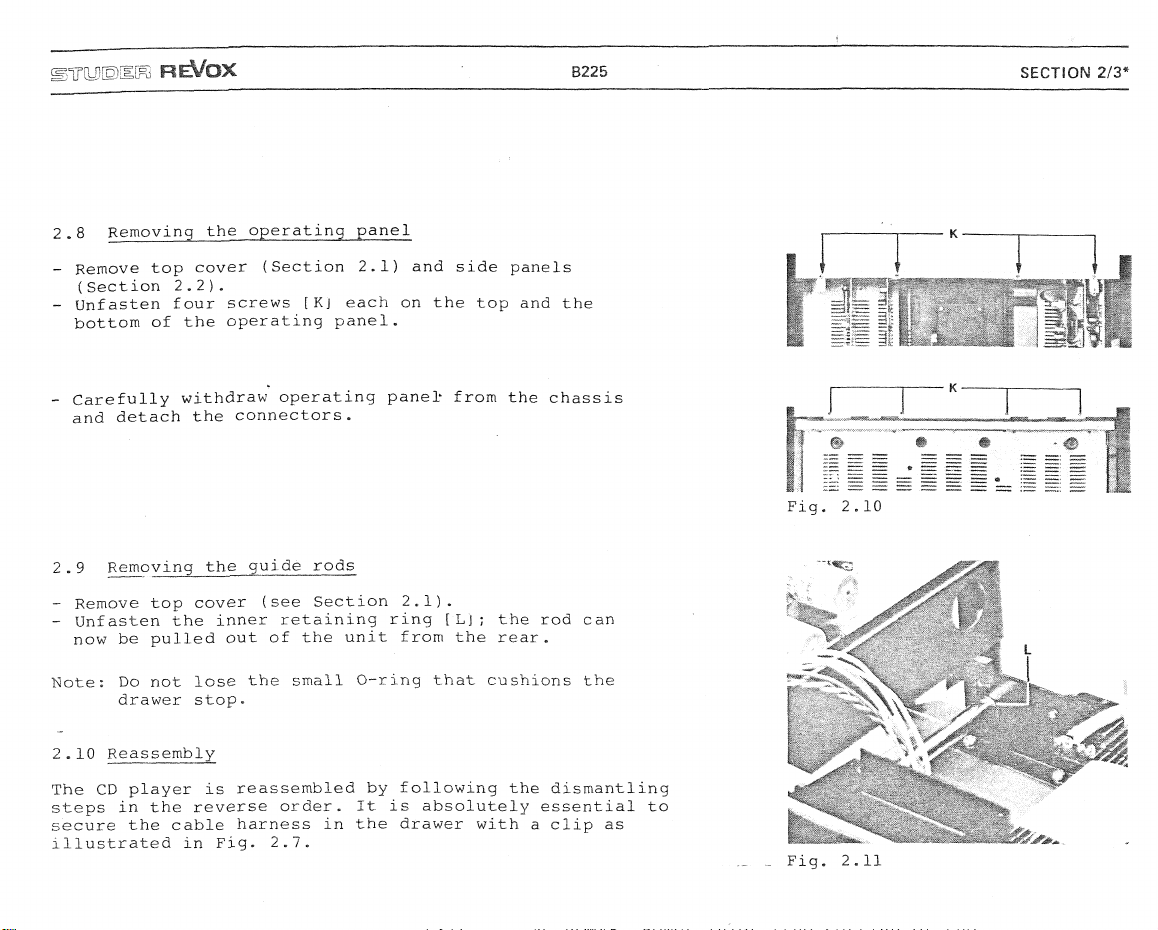

2.8 Removing the operating panel

- Remove top cover (Section 2.1) and side panels

(Section 2.2).

- Unfasten four screws [Kj each on the top and the

bottom of the operating panel.

Carefully withdraw operating panel' from the chassis

and detach the connectors.

2 -9

Removing the guide rods

- Remove top cover (see Section 2.1).

- Unfasten the inner retaining ring [Lj; the rod can

now be pulled out of the unit from the rear.

Note:

Do not lose the small O-ring that cushions the

drawer stop-

2.10 Reassembly

The CD player is reassembled by following the dismantling

steps in the reverse order. It is absolutely essential to

secure the cable harness in the drawer with a clip as

illustrated in Fig. 2.7.

Page 9

R^OX

3. CIRCUIT DESCRIPTIONS

B225

SECTION 3/1

3.1 SERVO 1 PCB

The following circuits are implemented on the SERVO 1

PCB;

- Stabilization of the supply voltages

- Drawer position detector

- Focus control loop

- Disc motor control loop

3.1.1 Stabilization of the supply voltages

All supply voltages are stabilized by voltage controllers

(IC 4 to IC 9,

The +5V supply (+5 V STBY) is always available. It

supplies the microprocessor system and the IR receiver

even when the CD player is switched off

The remaining supply voltages are switched on or off

by the microprocessor with the PS-OFF signal. When

the CD player is switched off, PS-OFF becomes "H" (+5 V)

and transistors Q9 and Q10 become conductive

(staturated),

to drop to a residual voltage of 1.3 V. The -7 V supply

is switched off through the circuit R38,

the -12 V supply via R52, R54, and Qll; and the -17 V

supply via R51,

supply voltages from becoming negative. The voltage

is doubled through diodes D15, D16, D17 and capacitors

C29,

C30# and taken to the voltage controller IC9 for

the -17 V supply. D18 protects the controller from

an excessive direct-axis component of the voltage.

1.769.310

LM317/LM337).

(standby).

causing the +5 V and +12 V supply voltages

R39? and Q8;

R53f and Q12. This prevents the positive

3.1.2 Drawer position detector

The two light barriers DLQ1 and DLQ2 (on PCB

1.769.310)

check whether the drawer is open or closed. The

corresponding signals indicate the following conditions:

Page 10

R^OX

B225

3.1.3 Focus control loop

The lens can be moved vertically and is designed similar

to the mechanical system of a speaker. The lens is

controlled magnetically. The coil is stationary and

the magnet moves. The focus error signal FOC-ERR is

first amplified (lead amplifier IC2a, R3, R12, R16,

R17,

C3, C4) and subsequently taken to the controlling

amplifier

R30,

lens

("lag"

amplifier Rl, R2, R5, Rll, R15, R29,

C2, C12, IC2b, Q6, Q7 and the impedance of the

coil).

In STOP mode, the control loop is interrupted

via Ql by the signal FOC-0 {= H) which means that no

unnecessary power is consumed by the output-amplifier

(Q6 and Ql).

SECTION 3/2

The start-up circuit (IC1, R6, R7 ) adjusts the focussing

to the reflective layer of the compact disc. The signals

FC-1 and FC-2 are alternatingiy switched to "H", causing

the lens to move alternatingiy up or down. Once the

correct focus has been found, the signal FOC-NEG briefly

drops to "L". The microprocessor then enables the focus

control loop

(FOC-0,

FC-1, and FC-2 -

"L"

)..

Up to 12,000

tracks per second are skipped in fast search mode.

Because the focussing lens readjusts for each track, a

whistling sound of approximately 12 kHz would develop as

is the case with a speaker. This whistling sound is

eliminated by R60, R61, C31, Q13 in the control loop.

This filter is only active in search mode.

3.1.4 Disc motor control loop

The data from the compact disc must be supplied as

steadily as possible to the digital signal processing

circuit.

depends on the position of the laser pick-up (constant

peripheral speed between 1.2 and 1.4 m/s).

If the laser pick-up reads in the middle of the CD,

the^speed is-much higher than near the edge. The speed

correction signal MCES is generated in the error

correction Ic"(SAA 7020 on PCB

The signal MCES is switched off or on via the signal

FOC-0 (R15, R16, IC3b on PCB

is first filtered via a 2nd order low pass (R22, R23,

R25r R26, R28, C10, Cll,

is formed by C9,R19, R21, R24, and R28, the

by IC3a, C6, C7 , R8 , Q2, and Q3.

As soon as the focal point has been found, the signal

FOC-0 changes to "LOW1' and the signal MCES is enabled.

A negative pulse via C5 is simultaneously triggered on

IC3a,

to rapidly accelerate the compact disc. The speed is

subsequently controlled by the MCES signal.

The speed with which these data (bits) arrive

1.769.300).

1.769.330).

IC3b).

pin 3, thereby fully driving transistor Q3 in order

The "lead network"

The signal

,r

lag network"

Page 11

WmrMM R^I/OX •

B225

•

SECTION

3/3

3.2 Microprocessor PCB

The microprocessor system and the drawer control are

implemented on the microprocessor PCB 1.769=320.

3.2.1 Microprocessor system

The master microprocessor (M-jiP, IC2 ) scans the keyboard

(POO to PG5, P10 to P14). The microprocessor system is

reset when the LOAD key is pressed. To enable

differentiation between a power failure and a LOAD

command, P15 of the master processor is also pulled to

"LfI in conjunction with a LOAD command. Capacitor C12

latches this condition until P15 is read. This

unconventional circuit arrangement offers the advantage

that a RESET command can be initiated at any time by

pressing the LOAD key in the event that the system

becomes blocked for any reason.

The commands from the IR receiver or the REMOTE socket

are read through the interrupt input of the master

processor . When a command arrives from the IR remote

control,

approximately one second, causing the LED in the IR

receiver window to turn on (command acknowledgment).

The signals

with drawer position information.

The signals CLK, DATA,

two LCD drivers PCE 2111 (on PCB

The gain of the headphones amplifier and the

VARIABLE OUTPUT is controlled by the signals CLK, DATA,

and DLEN-3 (on PCB

The slave microprocessor (S-]iP, IC4 ) processes the

subcode (supplementary information on the compact disk

such as track, time,

originate from PCB

Q-SYNC, SWCLK, Q-DATA, and

The-signals RC-0 and RC-0 switch the radial-control

loop on or off. When the radial control loop is switched

off (RC-0 = L), the laser pick-up can be repositioned

with the signals RCl, RC2, CUR-SUM, and CUR-DIR.

The track signal (TRK) is read through the interrupt

input of the slave processor. This signal changes to

"L"

direction in which the laser pick-up moves is reported

to the slave processor by the signal Tl. This signal

also changes to "L" as soon as the laser pick-up passes

over a track. It is also used in search mode for counting

the tracks. Because the counting speed of the

microprocessor is not high enough, only every other track

is counted in fast search mode (division by 2,

Any program entered through the keyboard Is stored

serially ,in.IC5 (serial RAM).

Both microprocessors are initialized by IC1 (reset chip

TL

7705).

via pin 7. A reset is also ' initialwai via Rl/ R8, and C8

when the LOAD key is pressed.

Commands from a cable-type remote control can be read

through the REMOTE socket (pin 2 and pin 3). These

commands are electrically isolated through the

optocoupier IC 12a. These signals are converted to

TTL signals by the comparator circuit (IC9a, R44, R45,

R48,

the infrared receiver, the voltage at pin 4 must be

higher than on pin 2 by +5 V. The +5 V STBY of the REMOTE

socket can be used for this purpose (interconnect pins 1

and 2, pins 4 and 5). The IR signal is thus short-

circuited via

the IR-REC signal is switched to "LOW" for

BRA^TOS3!

as soon as the laser pick-up passes over a track. The

The +5 V STBY supply is supervised by ICl

and R60). In order to disable the commands from

DLQ2,

1.769.320

and DRA-POS-F supply the processor

DLEN-1,

1.769.280).

etc.).

1.769.300

R41, R42, R43, R62, and IC9b.

and DLEN-2 control the

1.769.250).

The required signals

(IC13, SAA 7010, signals

P-BIT).

IC6b).

Page 12

57,

B225

and

C13,

r^;-:;:^,-

3.2.2 Drawer motor control

The drawer motor amplifier (IClOa, R52,53,56,

R58,

C14, Q8 and Q9) is controlled through the shift

register IC3 (pins 4 and 5). If the drawer movement

is blocked during the opening or closing operation,

the motor current rises and hence the voltage across

R64.

Signal Tl of the master processor consequently

changes'to "L" (circuit R40,54,55,59,63,

and

IClOb).

the direction of the drawer movement.

n^ox

Q6,^Q7,

In response the master processor reverses

SECTION 3/4

3.3

The SERVO 2 PCB

radial control and the IR receiver.

3.3.1 Radial control

A moving arm allows the laser pick-up to follow the

track horizontally. This arm basically functions like

a moving coil instrument.

The radial-control circuit can be subdivided into four

blocks:

- Radial control circuit

- AGC circuit

- Offset control circuit

- Track detection circuit

3.-3.2

The value of the radial-error signal can be computed

as follows^ RE= kd (II +12+13 +14) - k (II + 12).

The value of k is determined by the AGC circuit, and

d by the offset control circuit.

RAD-ERR2 =11+12

RAD-ERR1 =13+14

The signals RAD-ERR1 and RAD-ERR2 are summed via the

circuit IC9b, R58/59/61/62/63 and Q6. The sum flows as a

current through R63 and Q6. The error signal RAD-ERR 2 is

converted via R55 and R57 to a current that flows through

R54 and transistor E of IC8. The factor k is formed by

transistors A and B as well as C and D

formed by Q5 and transistor F

The signal RAD-ERR 2 x k (=k [II + 12]) on pin 10 of IC9c

appears on pin 9 of IC9c; the signal [RAD-ERR1 +

RAD-ERR2J kd (= kd [11 + 12 + 13 + 14j) appears on pin 10

of IC9c. The difference signal (RE), developed in IC9c,

appears on Pin 8 (RE = kd [II + 12 + 13 + 14 j - K[I1 +

K2j ). The "lag" network of the radial control is

implemented by R66, R67, R68, C15, and IC9d, the "lead"

network by R69, R7

IC5 through the protective diodes D5 and D6. The signal

is^taken through switch B (IC5) to pin 2 of IC2 which

together with Q2, Q3; R6, R7", R8, RT1, and C5 constitutes

the_output stage for the radial-control signal RAD-MOT+/

-RAD-MOT-.

disabled (Signal

forward and reverse mode. The laser pick-up can be

positioned during this phase with the signals RC-1, RC-2,

CUR-DIR, and CUR-SUM.

SERVO-2 PCB

Radial-control circuit

RT1 protects the

1.769.330

1.769.330

0,

RC-o).

contains the circuits for

and C16. The signal is conducted to

coil;-

This occurs in search, pause,

(IC8).

(IC8),

ThJBMwontrol can be

factor d is

Page 13

KEI/OX

B225

3.3.3 Automatic gain control (AGC) circuit

The bandwidth of the radial-control circuit is stabilized

by this circuit. A 650 Hz sine-wave signal is generated

in the circuit IClOc, IClld, C22,

R86,

R87? R90, and R91. As the gain increases or

C23# C24, C25,

R85

r

decreases the phase relation of the supplied signal

becomes also larger or smaller with respect to the

returning signal* The two signals are compared in the

phase detector (ICll) and a new signal is developed.

The latter is proportional to the phage and also to the

gain.

This signal controls the factor k. The gain is laid,

out for a" phase shift between the signals -of -.135° The

650 Hz.sine-wave signal is therefore fed into the control

loop at pin 13 of IC9d through a 45° phase shifter (R84,

C21).

The phase shift is 90° at the input of the phase

detector. The 650 Hz sine-wave signal is eliminated from

the control circuit through a bandpass (IClOd,

R83,

C19, C20) and converted in IClla to a square-wave

signal.

This square-wave signal is input to the phase

R82

r

comparator (ICllc, pin 8). The phase reference is

supplied by pin 9 of ICllc.

3.3.4 Offset control circuit

The asymmetry of the reflected laser beam is corrected

by this circuit to ensure that the laser beam is kept

exactly on the center of the track. The difference

between minimum and maximum reflection is the greatest

(presence of pit = minimum reflection, between pits

= maximum reflection) when the laser beam follows exactly

the center of the track.

SECTION 3/5

Through the 650 Hz sine-wave signal the moving arm

oscillates with an amplitude of 0.05 jim.

If the laser beam is on the track center, all half-waves

of the filtered out signal are folded to the same

(positive) side. If the laser beam is to the right of the

track center, the signal is in~phase with the 650 Hz

oscillations of the moving arm, or antiphase if the beam

is on the left of the track center.

The voltage across R63 is proportional to the reflected

light intensity

through IC6a,

(11 + 12 + I3 + I4).

R30f R31r and

The voltage is amplified

R64# and the 650 Hz component

is filtered out in a bandpass (R32, R33, R34, R35, R37,

Cll,

C12, and

IC7b).

The filtered signal is inverted

through lC7ar R36, and R38. The former and the

noninverted signal are taken to switch C of IC5. The

output of this switch (IC5, pin 4) is integrated through

IC7d and C.30 and determines the factor d (Q5 and

transistor' F of IC8). The status of switch C (IC5)

is controlled by the 650 Hz signal in the control loop

. -vara-the bandpass

R42f R43r R44 , R45, C13, C14 , D4,

" and IC7c.

Page 14

WT^ZJ'jLTi R^OX

B225

3 . 3.5 Track detection circuit

The tracks which are skimmed over by the laser pick-up

are read through the interrupt input of the slave

processor

(TRK-SIG).

This signal is generated from the

signal available at IC6, pin 1 (proportional to

[

I1 +

I2

is

+ I3 + I4J

,!L,!

when no error location is detected on the CD.

),

the DO and the HFL signal. The signal DO

The HFL signal is "H" when the HF signal is large enough.

The TRK signal is only "L" when the HE signal is too

small.

location is detected on the CD

For each skipped track, HFL is "L" if no error

(DO="L").

The radial-error

signal RE (IC9c, pin 8) informs whether the laser scanner

is positioned to the left or the right of the track. The

signal required for this purpose (RAD-POS) is generated

via IC3c, R12, R19, and R20 from the radial-error signal.

3.4 Preamplifier and laser PCB 1.769.100.35

This board comprises the following circuits:

- Laser control

- Signals for focus and radial control

- HF signal amplifier

SECTION 3/8

3.4.1 Laser control

The laser diode is supplied via Q4. The intensity of

the laser light can be checked through the "monitor

photo diode" and adjusted with the trimmer potentiometer

R8CT.

The signal LAS-OFF (from PCB

1.769.310

/ IC1) switches

the laser on or off. If the intensity of the laser

becomes too small, the current flowing through the

monitor photodiode decreases correspondingly. The voltage

across R84 also drops. The output of.opamp IC3a

consequently becomes more positive and Q4 more

conductive. The intensity of the laser is adjusted by

discharging some of the current through the monitor

photodiode via R80 and R81.

3.4.2 Focus and radial-control signals

The following signals are generated by this circuit;

- FOC-ERR

- RAD-ERR1

- RAD-ERR2

The currents of the four photodiodes (Al to A4) are

amplified in IC1. The corresponding error signals are

developed by the subsequent network. The focus error

signal is proportional to (11+14) -

(12+13).

13 + 14

constitutes the•RAD-ERRl signal, II + 12 the RAD-ERR2

signal.

The gain of the focus control loop can be

-^djiis/ted with R58, the balance with R41 (not included in

'all

versions).

" '3-4.3 HF signal amplifier

The circuit comprising transistors Ql through Ql constitutes the signal amplifier with bandpass characteristic.

Low-frequency (e.g. control signals of the servos)

and high-frequency disturbance signals are consequently

filtered out.

3.5 Decoder PCB

1.769.300

The decoder PCB contains the following circuits:

- Digital signal processing

- Digital sine-wave generator

- HF£ and DO detector

Page 15

mnruiDjiMM HEMOX B225 SECTION 3/7

3.5.1 Digital signal processing

The HF signal is converted in IC13 (SAA 7010} into

diqital siqnals and split into audio and information

data (subcode, for the slave

signal is also regenerated in JC13. The audio data

are brought into the correct time slot pattern. Corrupted

audio data are not recognized in 1C12 and corrected

if necessary. Should the errors be incorrigible, the

missing sample values are replaced in. IC10 (SAA 7000)

through interpolation. Should this also be infeasible,

the HF signal is slowly muted (soft

of the CD motor is controlled by the signal MCES (IC1,

pin

4 )

.

3.5.2 Digital sine-wave generator

The PROM (IC4) contains a value table for the sine-wave

signal which represents the maximum possible level

of a CD.

The circuit consists of IC5 through IC9 with IC5 and

IC6 supplying the addresses for the PROM. Parallel/serial

data conversion is performed in IC3. The change-over

between audio data from the CD and the 1 kHz sine-wave

signal is controlled by IC1.

3•5•3

HFL and DO detector

The HF signal is fed into the inverting differential

amplifier Ql and Q2 through C6 and R2. The output signals

are DC-decoupled via C8 and C9 respectively and tied

to DC ground via D2 and D3. D4 and D5 or D6 and D7

respectively constitute a full-wave rectifier each

through which the capacitors C10 or Cll are charged.

With a normal HF signal the DO signal is "LSi and the

HFL signal is "H". If the HF signal drops to approximately 70% of the normal value, the HFL signal also

changes to

!,Lt!

.

Only when the HF signal drops to

approximately 10% of - the normal value does the DO signal

change to "H".

To prevent the output signals of IC11 from being

influenced too strongly by minor contaminations (e.g.

fingerprints) on the CD, transistor Q3 has been added to

the output. When the RF level is at nominal value, pin 7

of IC11 is

"Hl! .

Q3 becomes conductive and the circuit

with Cll receives a smaller time constant. With level

fluctuations caused by minor contaminations, the levels

of the two input capacitors fluctuate in parallel, but

neither the DO nor the HFL signal are affected.

processor).

muting).

The CLOCK

The speed

3.6 DAC PCS

Tfee"

following'circuits are implemented on this PCB:

1.769.280

.

- Digital filtering (oversampling) and digital/analog

- •conversion

- Level adjustment and headphones" aTifffiifier

3.6.1 Digital filtering (oversampling) and D/A conversion

IC1 (SAA 7030) contains two identical filters for both

channels. These filters feature 3 sections:

~ Oversampling section

- Transversal digital filter

- Noise shaper

After each scanning cycle, the new sample values are

inserted by interpolation into the 16-bit information

arriving from the decoder. The scanning rate thus becomes

4 times greater (4 x 44.1 kHz = 176.4 kHz). The spectral

lines above 20 kHz up to 176.4 kHz - 20 kHz are filtered

out by the transversal filter. The sample values are

truncated to 14

bits.

The noise shaper subsequently

delays the truncation error by the scan duration and

negatively added to the next sample value. The

guantisizing noise caused by truncation is thereby

largely shifted toward the frequency range above 20 kHz.

The digital signal is converted in IC101 or IC201

(TDA 1540) to an analog signal. In order to filter out

the residual frequency component at n (176.4 kHz

+; 20 kHz), a low pass of the third order (Bessel filter)

has been added to the converter output.

Page 16

r'r:;T*5^

The preemphasis is corrected with the circuit illustratec

in Fig. 3.13. The subcode on the CD specifies whether

the selection was recorded with or without preemphasis.

The characteristic of the corresponding filter can

be adjusted with the PREEM signal.

3.6.2 Level adjustment and headphones amplifier

The volume is controlled by a DUAL D/A converter

(AD7528).

corresponding input (IC103a, pin 2 = left-hand channel

/ IC 203bf pin 6 = right-hand

feedback resistances of both opamps remain unchanged

which means that the level can only be attenuated with

this circuit. The dual D/A converter is controlled by a

CMOS shift register through the signals DLEN-3, DATA, and

CLK. The circuit illustrated in Fig. 3.14 constitutes the

output amplifier for the headphones socket and also

the VARIABLE OUTPUT* The signal is also attenuated for

this purpose through a voltage divider so that the signal

is the same (2 V RMS) at both outputs (FIXED and

VARIABLE).

to prevent power-on switching clicks. When power is

applied., the relay is selected by the

KILL signal (which rises to +5 V after approximately

1 to 2

through-connected when the supply voltages are stable.

R^QX

It serves as an attenuator before the

channel).

The signal is taken through relay Kl in order

seconds).

As a result, the outputs are only

The negative-

B225

SECTION 3/8*

Page 17

REI/OX

4.

TEST POINTS, ADJUSTMENTS ON

4 m i

Test points on B225

B2 2 5

4.1.1 Test points on SERVO 1 PCB 1.769.310

B225

SECTION 4/1

Page 18

'lDj[j

If no CO is mounted when PLAY is selected* the signals on TP26

an

CJ

2 7 become ^l?V in four intervals of approximately one second

each • "

R^OX

B225

SECTION 4/2

(*) In PLAY- mode* the signal pattern of these test points depends

on the wobble of the mounted compact disc*

Page 19

w^rumi

4.1.2 Test points on SERVO 2 PCB 1.769.330

R^OX

B225

SECTION 4/3

Page 20

h FtEMOX

B225

SECTION

4/4

when signals

•4.3V occur

4.13 Test points on MICmPRGCESSQR PCB 1.769.320,

are

on

received froni

TP52«

the IR-

remote control t pulses

of

Page 21

R^OX

6225

SECTION

4/5

Page 22

^T'^\£:WM REl/OX

B225

'

SECTION 4/6

Test with reference CD part No. 46241

Black dots

are

located

on

track 17

of

the disc surface* The

following should be measured v^hen this track is played:

Page 23

WUMEM

FIEMQX

B225

SECTION

4/7

Page 24

L

^£=.1^

FIEMQK

B225

SECTION 4/8

4.1.5 Test points on DAC PCB

1,769.280

The internal calibration must be switched on for the

following measurements;

Page 25

=

c^.

4 m2 Adjustments on CD player B225

Note:

Cleanliness

and ensures that

can enter into the

KEI/OX

in

the work area

no

contaminants

CD

mechanism.

is of

or

B225

outmost importance

metal particles

SECTION 4/9

If any work

it

is

(refer

Before putting the

on

essential

to

last page

printed circuit boards

to

observe the ESE recommendations

of

contents).

CD

player into operation ensure

is

necessary,

that the transport screws have been unfastened.

The

CD

bearings which should not

player mechanism

If the drawer must

to perform certain measurements

•rear light barrier must

responds

disc must

as if

be

the drawer were closed) and the compact

secured with a removed adhesive magnet.

The optical system

is

equipped with self-lubricating

be

lubricated.

be

open and a disc mounted

be

of

the laser can

or

adjustments,

interrupted (the detector

be

in

order

the

cleaned with

an air brush.

Coil Ll on the decoder PCB

aligned by IC13 (SAA7010) and consequently requires

no adjustment*

4.2.1 Aids

-

DC

voltmeter

1.769.300

is automatically

- Cathode ray oscilloscope

- Reference CD, frequency response, part No. 46240

- Reference CD, drop

- Mirror

No.

- Set

CD

for adjusting the optical system, part

46242

of

service PCBs and cables, part No. 46230

outs,

part No. 46241

- ESE work location kit, part No. 46200

4.2.2 Aligning

player mechanism, general

- Remove top cover.

- Connect

CD

player

to AC

supply and open the drawer

by pressing the LOAD key.

- Cover rear light barrier.

- Mount reference disc 5 (part No. 46241) and secure

it with a removed adhesive magnet.

- Selection

work.

LOOP.-command

1 of

It

is, therefore^ advantageous

the

CD is to be

in

programming mode.

played for all alignment

to

enter

the

"4T2". 3 Adjusting the laser current

- Switch

and reinsert

- Connect

- Adjust the voltage

CD

player off, remove SERVO 2 PCB

it

DC

via the service PCB (part No.

voltmeter

to

to

500

R63

mV

on

SERVO 2 PCB.

+50

1.769.330

mV

with the trimmer

46230).

potentiometer RS0 (on player mechanism 1.769.100.35).

Adjustments should only

be

made

if

the measured voltage

is outside the specified tolerance range.

CAUTION:

Voltages above 550

mV

shorten the life

of

the laser

pick-up.

- Switch

4.2.4 Adjusting the balance (if trimmer

CD

player off and reinstall SERVO 2 PCB.

is

present)

- Set potentiometer R41 (on player mechanism

1.769.100.35)

to

its center position.

Page 26

REMGX

B225

4.2.5 Adjusting the focus gain

-- Switch CD player off, remove SERVO 1 PCB 1.76 9.310

and reinsert it via the service PCB.

- Connect AF generator to the X input of an oscilloscope

and via an R-C-R element (according to Fig. 4.12)

to pin 6 of IC2 (on

1.769.310),

(f=600 Hz +5 Hz,

U=250 to 300 mV RMS).

- With trimmer potentiometer R58 (on player mechanism

PCB 1.769.100.35), align for minimum amplitude A

of the Lissajous figure.

SECTION 4/10

, 2 .

6 Checking the angle alignment

t

Place the mirror on the focussing unit and mount

the optical system alignment disc (secure with adhesive

magnet) .

Place the player mechanism below? a light source that

produces a linear, straight shadow.

Bring the-laser scanner arm to its center position

and rotate the CD player in such a way that the arm

stands parallel to the line below? the light source

(refer to Fig.

4.13).

When the reflection on the glass disc and in the

mirror is viewed as illustrated in Fig. 4.13. The

distance between the two lines should not exceed 2.5 mm.

Position the CD player in such a way that the shadow

forms a 90° angle to the scanner arm (see Fig.

4.14).

The distance between the two lines (reflections)

should not exceed 2.5 mm.

Page 27

^-yiLr^Ju

The angle alignment must be corrected if the deviation

is too large:

- Unfasten screw [A] until the support plate [ B]

be shifted.

- The support plate can now be shifted according to

Fig*

is correct.

- The angle alignment must be rechecked after the

foregoing adjustments have been made.

4.2.7 Adjusting the DC component of the focus signal

- Connect DC voltmeter to Rl (SERVO 1 PCB 1.76

The following adjustment is only necessary if the DC

deviation exceeds

is not possible.

- Adjust the axial set screw of the disc motor in such

a way that 0 V +_50 mV is measured.

- If the motor is replaced, perform the adjustments

according to 4.2.6 and 4.2*7*

4.3 Measuring the audio data

R^OX

4.5. Retighten the screw [A] when the position

+JL4 0

mV. Replace the motor if alignment

B225

can

9.310).

SECTION 4/11

4.3.1 Aids

-_ Reference CD, part No. 46240

- Automatic distortion meter (e.g. Tektronix AA 501;

the RESPONSE button must be in the RMS position for

all measurements)

- Measuring filter (for distortion measurement)

~ Frequency counter

- Oscilloscope

4.3.2 Harmonic distortion

- Measuring arrangement according to Fig. 4.16

- Adjust for maximum level with VOLUME + key

- Mount reference disc (part No.

4 for measuring the left-hand channel and track 8

for measuring the right-hand channel.

- The harmonic distortion should be less than 0.006%.

4.3.3 Output level

- Press CAL TONE button and adjust for maximum level

with VOLUME + key.

- The level of the FIXED and VARIABLE outputs should

be 2 V RMS +10%. The balance between channels should be

better than 0.2 dB.

4^,3 . 4 -Frequency response

- Adjust for maximum level with VOLUME + key.

"'-—The calibration tone (1 kHz) serves as the 0 dB

reference.

- Play tracks 4 and 8 (CD part No. 46240) and measure

the outputs FIXED and VARIABLE. The frequency response

shoul-d be within +0 to -X3.6 dB.

46240).

Play track

Page 28

?rr-S-£:JL\Fi FI&/OX B225 ! SECTION 4/12*

4.3.5 Cross talk

- Adjust for maximum level with VOLUME + key,

- Reference = CAL TONE 1000 Hz)

- Measure both outputs across a 30 kHz low-pass:

Play track 8 for measuring cross talk R -> L

Play track 4 for measuring cross talk L -> R

- The cross talk attenuation should be at least 90 dB.

4.3.6 Signal-to-noise ratio, linear

- Maximum volume, reference = CAL TONE 1000 Hz.

- Play track 18 and measure the outputs FIXED and

VARIABLE via a 30 kHz low-pass.

- The measured value should be higher than -96 dB,

4.3.7 Signal-to-noise ratio, weighted

- Maximum volume, reference = CAL TONE 1000 Hz.

- Play track 18 and measure the outputs FIXED and

VARIABLE via an A filter.

- The measured value should be higher than 100 dB,

4.3.8 Phase linearity

- Connect oscilloscope to one of the outputs.

- Play track 20 and visually assess the square-wave

signals at 100 Hz, 400 Hz, 1002 Hz, and 5512 Hz.

The curve should be shaped symmetrically (see

Fig.

4.17).

, .

4.4 Listening test with reference CD (part No. 4 6241)

The reference CD simulates the following errors for

checking the error correction system:

- Information gaps with a length of 400 to 900 pm (tracks

5 through 9)

- Black dots from 300 to 800 micrometers

(tracks 1*1 through track 17)

- Simulated fingerprint (tracks 18 and 19)

The simulated defects should not cause any drop-outs

(reproduction

can for example be caused by the following errors:

- IC13 (SAA 7010,

with PLL defect.

- HFL an DO detector defective.

gaps).

If drop-outs become audible, this

demodulator),

clock regeneration

Page 29

Loading...

Loading...