Page 1

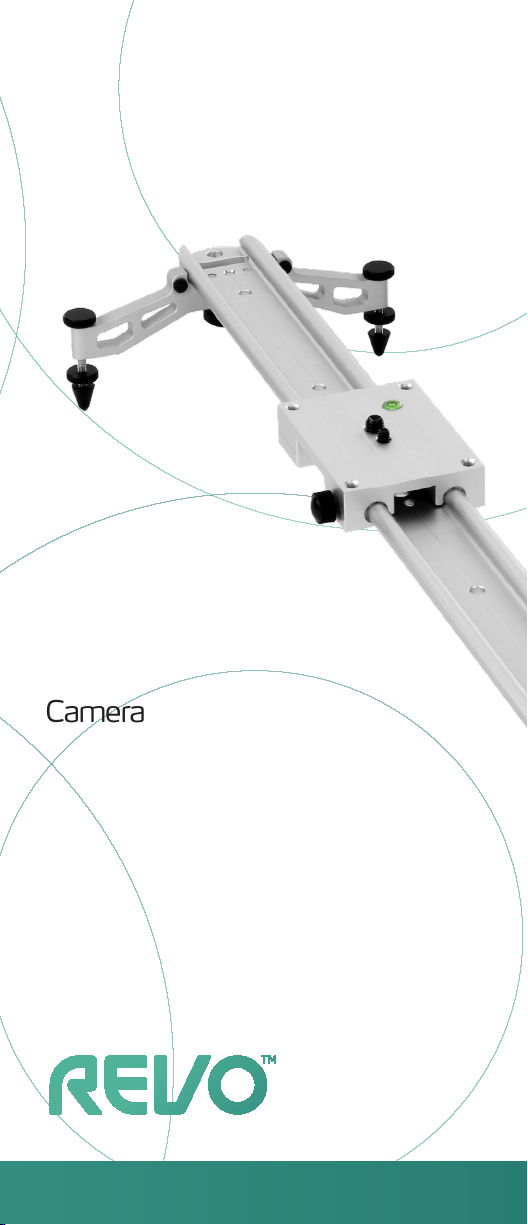

RS-600AF

RS-850AF

RS-1200AF

Camera

Track Slider

With Adjustable Feet

Page 2

Congratulations on your purchase of the Revo

Camera Track Slider.

Revo’s camera track slider is a sturdy, portable, and

lightweight mini dolly that adds production value to any

video shoot. It provides the ability to get quick, smooth

short-run dolly shots and a variety of tracking shots without

having to carry a full dolly system and track.

The heavy-duty aluminum construction with

precision-engineered rails provide smooth and quiet

panning for the entire length of the rails and ensure

effortless motion for a rig of up to 21 pounds. Individually

adjustable feet and an integrated bull’s-eye bubble level

make leveling the rail easy and ensure that it won’t wobble

if placed on a slightly uneven surface. Threaded mounts

(3/8” and 1/4”-20) on the mounting plate assure

compatibility with most cameras or tripod heads.

The camera track slider is easily assembled without tools.

One or two sets of threaded 1/4”-20 and 3/8” holes on the

rail provide the option of mounting the slider on top of a

single tripod (RS-600AF), or between two tripods

(RS-850AF and RS-1200AF).

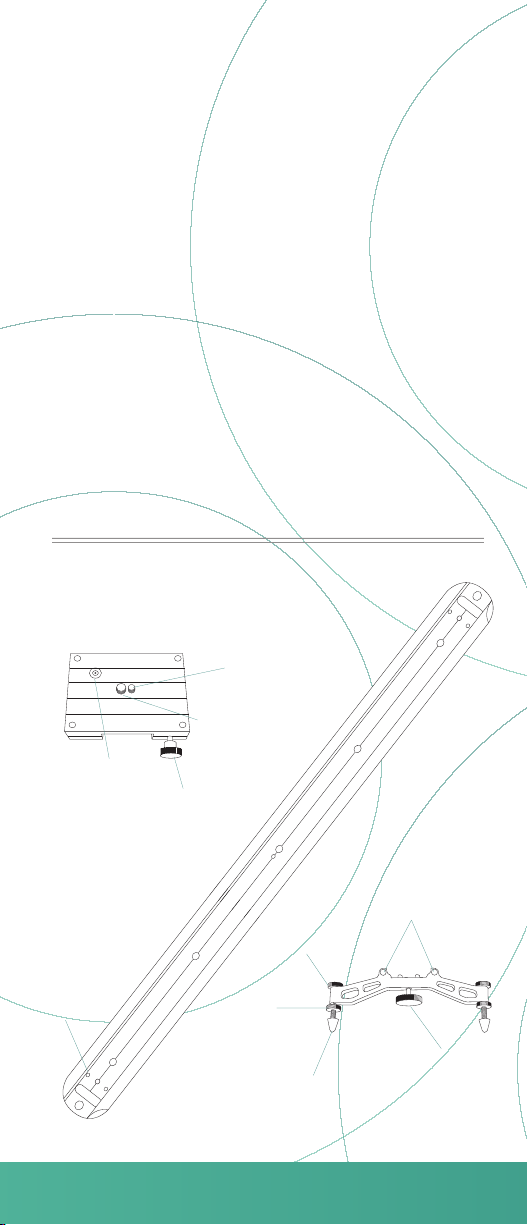

Components

Camera mount platform

Camera sliding rail

Bubble

level

1/4”-20

threaded

holes (for

adjustable

feet)

1/4”-20 mounting

screw

3/8” mounting

screw

Tension

control knob

Locking

nut

Height

adjustment

knob

Leg with

adjustable

feet

2× Adjustable feet

Rubber

pads

Thumb

screw

Page 3

Instructions

Attaching a camera or tripod head to the camera

mount

Remove the camera mount from the sliding rail by

1

sliding the camera mount off of the rail. This may

require removing either of the adjustable feet.

Unscrew the mounting screw that will not be used

2

from the camera mount and set it aside.

Use the 3/8” or 1/4”-20 mounting screw to attach a

3

camera or tripod head to the mounting plate.

1/4”-20 screw3/8” screw

Note: the mounting screw may need to be tightened with

an Allen key (not included.)

Attaching the legs and adjusting the feet

Align the two posts on the leg with the guide holes on

1

the rail. Make sure the rubber pads on the frame are

facing in toward the center of the rail.

Rubber Pads

Tighten the thumb screw until tight and the leg is

2

secure.

Once one leg has been attached, slide the camera

3

mounting plate with the tripod head/camera onto the

rail.

Attach the second leg.

4

Refer to the bubble level on the camera mounting

5

plate to determine if it is level. Also check to see if the

assembled track slider wobbles.

Loosen the locking nuts on all of the feet.

6

Page 4

Adjust the height of each foot until the bubble in the

7

bubble level is within the bull’s-eye, or until all feet rest

uniformly on the surface without wobbling.

B

A

Tighten the locking nuts by tightening them against

8

the frame of the leg.

Tripod attachment

The rail has 3/8” and 1/4”-20 threaded holes for attaching

to one or two tripods.

The RS-600AF is designed to be attached to a single

tripod, and the threaded holes are located in the center of

the rail.

The RS-850AF and the RS-1200AF are designed to

attach to two tripods, and the threaded holes are located

at either end of the rail.

To attach the rail to one or two tripods, do the following:

Remove one of the adjustable feet and the camera

1

mounting plate from the rail.

(RS-600AF) Screw the threaded mount of the tripod

2

into the threaded hole of the rail.

(RS-850AF and RS-1200AF) After attaching one end

3

of the rail to the first tripod, slide the camera mounting

plate onto the rail from the other end, and then attach

the second tripod to the other side of the rail.

Reattach the feet so that feet are in place at both ends

4

of the rail and prevent the camera from sliding off.

Page 5

Adjusting the tension of the camera mounting

plate

To adjust the tension, do the following:

To add tension, turn the tension control knob

1

clockwise.

For less tension, turn the tension control knob counter

2

clockwise.

Specifications

RS-600AF

Load capacity: 21 lbs. (1 0 kg)

Dimensions: 3.5˝ × 2.75˝ × 23.6˝ (9 × 7 × 60 cm)

Weight: 1.86 lbs. (847 g)

Height adjustment: 0.5˝ (1 cm)

RS-850AF

Load capacity: 15.4 lbs. (7 kg)

Dimensions: 3.5˝ × 2.75˝ × 33.5˝ (9 × 7 × 84.3 cm)

Weight: 2.5 lbs. (1.13 kg)

Height adjustment: 0.5˝ (1 cm)

RS-1200AF

Load capacity: 11 lbs. (5 kg)

Dimensions: 3.5˝ × 2.75˝ × 47.2˝ (9 × 7 × 120 cm)

Weight: 3.18 lbs. (1.44 kg)

Height adjustment: 0.5˝ (1 cm)

Visit revocinegear.com for more information on

our complete line of video mounting products.

Page 6

Warnings

Please read and follow these instructions, and keep this

manual in a safe place.

Handle the unit with care.

Camera sliding rail may have sharp edges

Clean the unit with a soft, dry cloth.

Use only parts provided by the manufacturer.

Make sure everything is secure before proceeding.

Make sure the item is intact and that there are no

missing parts.

Do not exceed the maximum load capacity.

All photos are for illustrative purposes only.

One-Year Limited Warranty

This REVO product is warranted to the original purchaser to be

free from defects in materials and workmanship under normal

consumer use for a period of one (1) year from the original

purchase date or thirty (30) days after replacement, whichever

occurs later. The warranty provider’s responsibility with respect to

this limited warranty shall be limited solely to repair or replacement, at the provider’s discretion, of any product that fails during

normal use of this product in its intended manner and in its

intended environment. Inoperability of the product or part(s) shall

be determined by the warranty provider. If the product has been

discontinued, the warranty provider reserves the right to replace it

with a model of equivalent quality and function.

This warranty does not cover damage or defect caused by misuse,

neglect, accident, alteration, abuse, improper installation or

maintenance. EXCEPT AS PROVIDED HEREIN, THE WARRANTY PROVIDER MAKES NEITHER ANY EXPRESS WARRANTIES

NOR ANY IMPLIED WARRANTIES, INCLUDING BUT NOT

LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. This warranty

provides you with specific legal rights, and you may also have

additional rights that vary from state to state.

To obtain warranty coverage, contact the Revo Customer Service

Department to obtain a return merchandise authorization

(“RMA”) number, and return the defective product to Revo along

with the RMA number and proof of purchase. Shipment of the

defective product is at the purchaser’s own risk and expense.

For more information or to arrange service, visit www.revocinegear.com

or call Customer Service at 212-594-2353.

Product warranty provided by the Gradus Group.

www.gradusgroup.com

TM

REVO

A Gradus Group Brand

REVO is a registered trademark of the Gradus Group.

© 2015 Gradus Group LLC. All Rights Reserved.

GG1

Loading...

Loading...