Membrane System

User Manual

RF – Series

4–Stage, 5–Stage,

5–Stage with Booster Pump

REVERSE OSMOSIS SYSTEM PICTURED

5-STAGE RESIDENTIAL

This page intentionally

left blank

RF – Series User Manual

MKTF – 167-C 2 05/17

TABLE OF CONTENTS

TOOLS AND MATERIALS FOR INSTALLATION ...................................................................... 4

ESTIMATED REPLACEMENT AND FILTER CHANGE ............................................................ 4

PRE–INSTALLATION INSPECTION ......................................................................................... 4

OPERATION PARAMETERS ................................................................................................... 5

MEMBRANE AND FLOW RESTRICTOR ASSEMBLY PROCESS ........................................... 6

PREPARING FOR INSTALLATION .......................................................................................... 9

FAUCET INSTALLATION ......................................................................................................... 9

INSTALLATION AND FEEDWATER ADAPTER ..................................................................... 11

INSTALLATION OF DRAIN SADLE ........................................................................................ 13

POSITIONING THE TANK ...................................................................................................... 13

REVERSE OSMOSIS UNIT PLACEMENT AND MOUNTING ................................................. 13

TUBING CONNECTIONS ....................................................................................................... 14

SYSTEM START–UP.............................................................................................................. 14

FLUSHING THE REVERSE OSMOSIS SYSTEM ................................................................... 15

TROUBLESHOOTING ............................................................................................................ 16

SYSTEM DRAWINGS............................................................................................................. 18

SYSTEM WARRANTY ............................................................................................................ 21

RF – Series User Manual

MKTF – 167-C 3 05/17

PLEASE READ CAREFULLY BEFORE PROCEEDING WITH INSTALLATION

TOOLS AND MATERIALS FOR INSTALLATION:

Variable speed (VS) drill

Carbide grinding burr

1/4" (6mm) drill bit

7/16” (11mm) drill bit

1/2" (13mm) and 5/8” (16mm) open–end wrenches (or adjustable)

Phillips screwdriver

Flashlight or droplight

Teflon tape

Protective eyewear (i.e. goggles)

If the above tools are not available, contact your local dealer/distributor for assistance.

ESTIMATED REPLACEMENT AND FILTER CHANGE:

Sediment Prefilters: 6 months – 1 year

Carbon Prefilters: 6 months – 1 year

Carbon Postfilter: 6 months – 1 year

Reverse Osmosis Membrane: 1 – 2 years

NOTE: The life of the filters and membrane depend on the quality of water supplied to the

reverse osmosis system.

PRE–INSTALLATION INSPECTION:

After opening the shipping container, locate the following items:

1. Reverse osmosis system

2. Membrane and flow restrictor

3. Storage tank

4. Faucet with mounting hardware

5. Installation packet containing: drain saddle, tank ball valve, two mounting screws and

other installation pieces depending on system.

RF – Series User Manual

MKTF – 167-C 4 05/17

OPERATION PARAMETERS:

WARNING!! The following conditions for feedwater supply must be met or warranty will be void.

1. System must be connected to a municipal or well water source that is treated and

tested on a regular basis to insure water is microbiologically safe.

2. Operating outside temperatures:

Maximum 90 F

Minimum 40 F

CAUTION!! Do not allow system to freeze. The membrane always contains water and will be

destroyed if frozen.

WARNING!! Do not plumb system to hot water. This will destroy the membrane and void the

warranty and manufacturer’s responsibility.

3. Operating pressure:

Maximum 80 PSI

Minimum 40 PSI

This reverse osmosis system is designed to operate at a water pressure in the range of 40 to 80

PSI. At pressures lower than this, the quantity as well as quality will be reduced. At higher

pressure, severe damage to the system may result. A pressure regulator must be installed on

the feedwater source, which reduces the water pressure coming into the system.

WARNING!! Warranty voided and manufacturer assumes no responsibility for damage to

system or property if pressure exceeds 80 PSI.

4. Turbidity: <1 NTU

5. pH: 4 to 11

6. Recommended hardness not to exceed 7 grains per gallon or 120 PPM.

RECOMMENDATION – If your water hardness exceeds 7 grains per gallon or 120 PPM you

may wish to purchase a water softener. Contact your local dealer or distributor for pricing and

availability.

7. Recommended Total Dissolved Solids (TDS) not to exceed 1000 PPM.

WARNING!!! The installer is responsible and liable for any leaks resulting from installation of

tubing or related fittings. The installer must check over the entire system completely while under

pressure to ensure system is not leaking and functioning properly. Liability resulting from failure

to check for leaks under pressure is the sole responsibility of the installer.

RF – Series User Manual

MKTF – 167-C 5 05/17

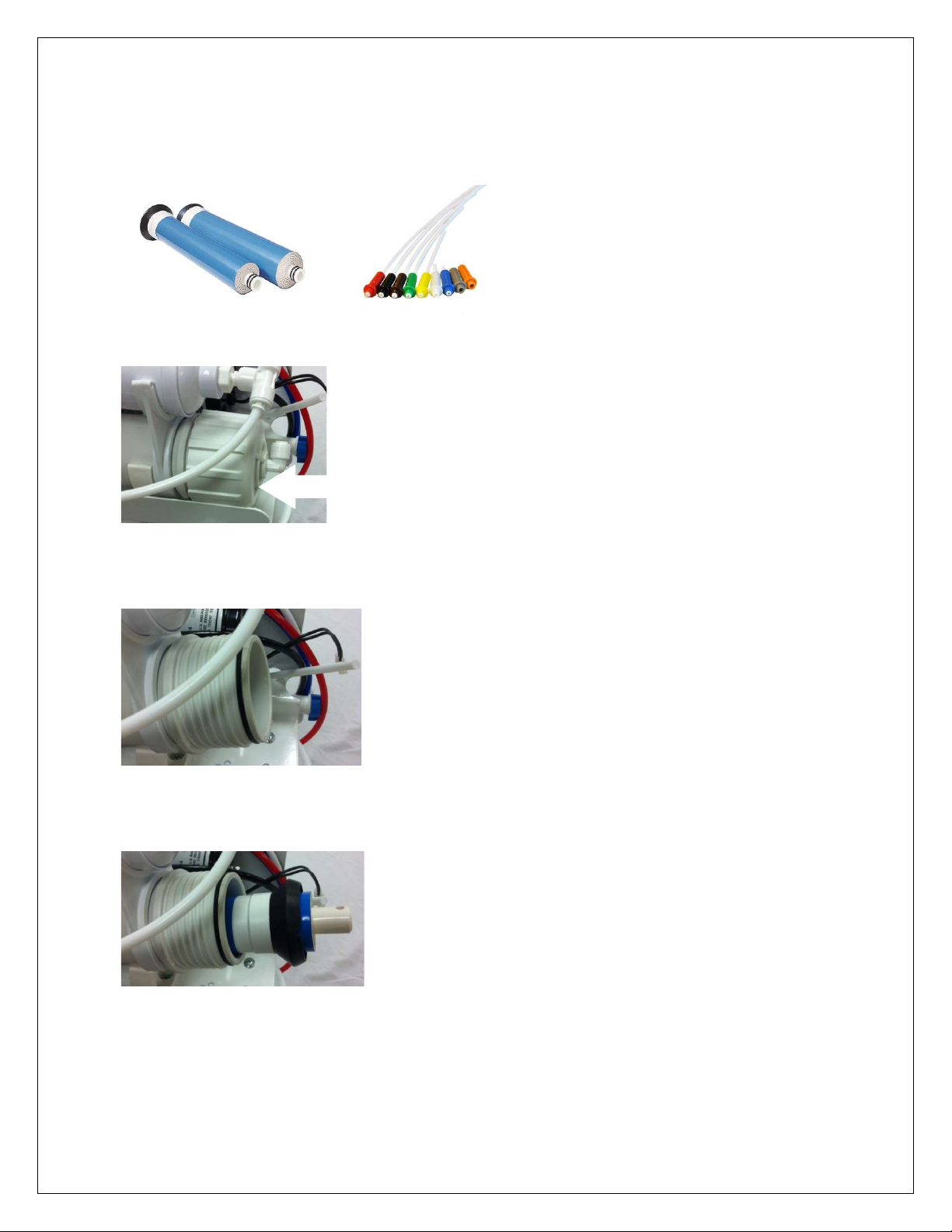

MEMBRANE AND FLOW RESTRICTOR ASSEMBLY PROCESS:

1) Identify membrane element and flow restrictor (color and type depends on membrane

being used) included in box:

2) Identify membrane vessel feed cap:

3) Remove feed cap as shown (turn counter clockwise):

4) Insert membrane in direction as shown:

RF – Series User Manual

MKTF – 167-C 6 05/17

5) Push membrane in as shown:

6) Place feed cap back on as shown (turn clockwise until hand tight):

7) Connect tube to cap as shown:

8) Identify black concentrate (drain) tube:

RF – Series User Manual

MKTF – 167-C 7 05/17

9) Disconnect black tube by following instructions below:

10) Insert flow restrictor in tube:

11) Push in flow restrictor until flush with tube end as shown:

12) Reinsert black tube as shown:

RF – Series User Manual

MKTF – 167-C 8 05/17

1

2

Preparing for Installation

Preparing for installation:

1. This system includes a standard sink top

faucet without an air–gap. In localities where

plumbing codes require installation of an air–

gap, contact your local distributor to obtain a

code approved drain line adapter.

2. The reverse osmosis system may be mounted

to the side of the sink cabinet or set on the

floor of the sink cabinet. It must be positioned

to allow access for service and filter changes.

The assembly should be relatively near the

faucet to maximize flow rate. See Diagram A

for a positioning example.

3. The storage tank should be located where it

can be removed if necessary. The storage

tank may be placed in either the vertical or

horizontal position without affecting the system

performance. If there is insufficient space

under the sink for placement, the tank may be

located in an adjacent cupboard up to 50 ft.

away. See Diagram A for a positioning

example.

4. The faucet should be positioned to allow a free

flow pattern into the sink. It must be positioned

to allow ready access to the mounting

hardware under the sink. See Diagram A for a

positioning example.

RF – Series User Manual

MKTF – 167-C 9 05/17

Diagram A

CAUTION!! Extreme care must be

taken in drilling the hole for the sink–top

faucet. The surface material of most

sinks is extremely hard and brittle and

can be easily chipped or cracked. If you

are uncomfortable performing the

following procedure, it is recommended

that your local distributor be consulted

for techniques and other assistance.

The system’s manufacturer accepts no

responsibility for sink top damage

resulting from system installation.

CAUTION!! Before grinding or drilling,

put on appropriate eye protection (i.e.,

goggles) to protect yourself from

porcelain or metal chips.

CAUTION!! Before grinding or drilling,

ensure that the drill you are using is UL

Laboratories approved and properly

grounded to prevent electrical shock.

DO NOT USE DRILL WHILE USING

OR STANDING IN WATER!!

1. BEFORE DRILLING: Check under the

sink in the area that you plan to install

the faucet and make sure that there is a

flat surface to secure the mounting

hardware. A flat space of approximately

two inches in diameter is needed.

RECOMMENDATION: Before drilling or

grinding mask off the immediate area,

surround the grinding/drilling location,

preferably with duct tape or if duct tape

is unavailable masking tape may be

used. This procedure should help

prevent scratching of the sink surface.

2. Remove everything from inside the sink

and surrounding area. Place paper

towels in the sink to catch the shavings

from the grinding and drilling.

CAUTION!! Porcelain or enamel must

be completely removed in the drilling

Faucet Installation

UP FOR

CONSTANT

FULL FLOW

DOWN FOR

CONTROLLED

MIDDLE POSITION

STAR LOCK WASHER

BRASS INLET NIPPLE

area to prevent immediate dulling of drill

bit.

3. Remove everything from under the sink.

4. Place newspaper or paper towels directly

under drilling location in order to catch the

drill shavings.

5. Using the 1/4” (6mm) drill bit, drill a

centering or pilot hole in the center of the

desired faucet location. Note: this

centering/pilot hole will make it easier for

the 7/16" (11mm) drill bit to cut through the

sink. Operate the drill slowly and carefully

— especially when the drill bit is about to

penetrate the metal. Otherwise, damage to

sink may occur. Use lubricating oil to keep

the drill bit cool while drilling.

6. Discard paper towels and newspaper used

in sink and below sink. Be very careful not

to drop any shavings in sink or on the floor

as they will oxidize and stain surfaces very

quickly.

7. Using a variable speed (VS) drill with a

carbide grinding burr, gently grind away

enough porcelain or enamel to

accommodate the 7/16” (11mm) drill bit,

approximately the size of a dime. Enough

surface material must be removed to

expose the base metal.

HELPFUL HINT: If you notice any rust

spots from dropped shavings you should be

able to get rid of them by scrubbing them

with a cleaning chemical.

8. Cover the drilled hole with your finger. BE

VERY CAREFUL NOT TO CUT

YOURSELF ON SHARP EDGES! Rinse

sink then scrub with cleaner to prevent any

rusting from shavings and to prepare for

faucet installation. Plug hole again while

rinsing off cleaner. Hole must be plugged in

order to avoid water dripping below into

sink cabinet, which may cause damage.

9. Remove faucet from package.

For steps 11–14 refer to Diagram B.

10. Slip the small, thin rubber gasket over the

faucet shank. Next, slip the chrome trim

plate (escutcheon plate) over the faucet

shank. Finally, slip the large, thin rubber

gasket over the faucet shank.

RF – Series User Manual

MKTF – 167-C 10 05/17

11. Take the faucet spigot and insert it into the

faucet base in the hole next to the faucet

handle. Push the faucet spigot in until it

stops.

12. Place the faucet shank through the drill

hole completely, with only the hardware

described in step 11.

13. From under the sink, slip the large, black

plastic locating washer over the faucet

shank. Next, slip the lock washer over the

faucet shank followed by the thin brass

nut.

14. While holding the faucet assembly above

the sink, tighten the thin brass nut below

the sink with an adjustable wrench.

Tighten the brass nut until the faucet

assembly does not move.

CAUTION!! Do not over tighten the brass

nut. Over tightening can cause damage to

the sink or faucet assembly.

Faucet Diagram

BLACK WASHER

CHROME WASHER

RUBBER GASKET

FOR OFF

FLOW

WASHER

BRASS NUT

INLET LINE

COMPRESSION NUT

BRASS SLEEVE

DIAGRAM B

If you have a self

-

piercer assembly

, skip to step # 8.

Self-P

iercer Installation Instructions

3

Installation of Feedwater Adapter

CAUTION!! For your safety and protection, do

not use where water is microbiologically unsafe

or of unknown quality. The water supply to your

system MUST be from the COLD WATER LINE!

Hot water will severely damage your reverse

osmosis system!

Note: In some cases, the supply valve may leak

or may not work at all. If this happens, turn off

the water at the main water shut off for the entire

house. In extreme cases, the house shut off

valve does not work. If this happens, shut the

water off at the street and replace the defective

valves immediately.

Locate the type of shut off valve you have under

your sink and follow that step for connecting the

feedwater.

1. Turn off cold water supply to the sink using

the supply valve located under the sink.

2. Some shut off valves have an extra port for

an icemaker hookup. You will not need the

feed water adapter for this type of installation.

See Diagram C.

3. On some shut off valves, you can install the

feed water adapter directly to the valve. Slip

the black washer into the feedwater adapter.

Tighten feedwater adapter to the valve with

an adjustable wrench. Tighten until snug.

Insert the 1/4” brass straight fitting into the

feed water adapter. TIGHTEN BY HAND

ONLY! DO NOT OVERTIGHTEN!

See Diagram D.

4. Most under sink shut off valves have a built in

smooth or corrugated riser going up to the

faucet. Refer to Diagram E for help with this

type of valve. Secure an adjustable wrench to

the fitting on the cold water side of the sink

faucet – NOT THE REVERSE OSMOSIS

RF – Series User Manual

MKTF – 167-C 11 05/17

FAUCET! Secure another adjustable wrench

to the smooth /corrugated riser line nut.

Gently undo the riser line from the sink

faucet. Do not be alarmed! There will be

water left in the line—this is normal.

However, if the flow does not stop you

probably haven’t shut the water off properly.

(See the Note in Step # 1, Section # 3 if you

need help with water shut off.)

5. Insert the black rubber washer into the

feedwater adapter. Screw the adapter onto

the fitting coming from the cold water side of

the sink faucet. Using two adjustable

wrenches, tighten the feedwater adapter to

the cold water line. Take extreme care not to

twist or damage the connection to the cold

water connection.

CAUTION!! Tightening the connector

improperly to the faucet could cause

irreparable damage to the faucet.

6. Connect the riser from the water shut off

valve to the feedwater adapter. Ensure that

the cone washer on the riser tube is in good

condition. With one adjustable wrench on the

feedwater adapter and another adjustable

wrench on the riser nut, connect the riser to

the feed water adapter.

DO NOT OVER TIGHTEN! This can cause

damage to the riser connection.

7. Insert the 1/4” brass straight fitting into the

feed water adapter. TIGHTEN BY HAND

ONLY! DO NOT OVERTIGHTEN!

Use new cone washer if needed

Connect metal ball valve to the

Insert black washer into bottom

DIAGRAM D

Insert tubing into adaptor for ice maker.

Cold water line

Reversible

Valve handle

Plastic insert

Saddle

back plate

Tightening

screw

Plastic ferrule

Compression nut

Tubing to inlet

Self–piercer valve

NOTE: Self–piercer assembly can only be

installed on smooth riser lines.

8. Clamp the self–piercer onto the riser tube. Fit

the adjustable aluminum bracket to the size of

your riser tube. Then tighten locking nut until

clamp is firmly attached to riser line.

CAUTION!! DO NOT OVER TIGHTEN!! This will

crush the riser tube and destroy it.

9. To pierce the line, simply screw the T–handle

valve clockwise until it stops.

NOTE: If hole in copper tube (cold water line) is

not adequately pierced, this may prevent

sufficient cold water supply to the system and

reduce the performance of reverse osmosis

processing. In this event, open and close the

self–piercing valve several times.

Feedwater Diagrams

DIAGRAM C

feed water connector

of the feed water connector

REMEMBER

TURN OFF WATER FIRST!

Insert black washer into bottom of

the feed water connector

Connect metal ball valve to the

feed water connector

Use new cone washer if needed

RF – Series User Manual

MKTF – 167-C 12 05/17

REMEMBER

TURN OFF WATER FIRST!

DIAGRAM E

4

5

6

Drain Pipe

Installation of Drain Saddle

1. Open the package containing the drain

saddle. See Diagram F.

2. Peel the protective film off of the sponge

gasket. Apply gasket to inside of drain

saddle, using care to align sponge gasket

hole with drain port.

3. Position the drain saddle on the vertical or

horizontal drainpipe from your sink.

Position as far away from the garbage

disposal as possible.

DANGER!! The drain saddle MUST be

installed on the side of the P–trap that goes

to the sink drain! If installed on the wrong

side of the P–trap, sewer gas could enter

the unit and damage it.

4. Drill 1/4” (6mm) hole into the drainpipe.

CAUTION!! Be very careful when drilling into

drainpipe to not drill all the way through—

stop after piercing the first wall of the pipe.

5. Mount the drain saddle. Align the drain

saddle port with the 1/4” drilled hole using a

small drill bit or other small straight object.

6. GENTLY TIGHTEN the two screws evenly

on both sides of the clamp until the clamp

is snug on the pipe.

CAUTION!! To avoid breaking plastic

saddle or crushing drainpipe DO NOT

OVER TIGHTEN!

RF – Series User Manual

MKTF – 167-C 13 05/17

Black Drain

Line

Diagram F

Sponge Gasket

1. Wrap four to five wraps of Teflon tape

2. Hand tighten the plastic shut off ball valve

3. The storage tank should be located where

1. Determine if mounting of the reverse

Positioning the Tank

around the tank threads at the top of the

tank.

to tank stem.

CAUTION!! Hand tighten the valve only!

DO NOT OVERTIGHTEN! If valve is over

tightened it will crack and will leak.

IMPORTANT!! The tank pressure must be

between 8 – 10 PSI when measured

empty. This must be measured with a

good dial or digital pressure gauge. A

pop–up tire gauge will not give you an

accurate reading. If you do not have

access to a good gauge, contact your

local distributor to purchase one.

If your tank pressure is above 10 PSI, use

the tank valve to release pressure until

there is between 8 – 10 PSI. If your tank

pressure is below 8 PSI, use a bicycle

pump to increase pressure between 8 –

10 PSI.

it can be removed if necessary. The

storage tank may be placed in either the

vertical or horizontal position without

affecting the system performance. If there

is insufficient space under the sink for

placement, the tank may be located in an

adjacent cupboard up to 50 feet away.

Reverse Osmosis Unit Placement

and Mounting

osmosis system is necessary or desired.

The system does not need to be mounted

on the wall of the cabinet if there is room

for it to sit on the floor. However, if it is

mounted to the side of the cabinet it is

7

8

easier to change the filters and does not

take up floor space.

IMPORTANT!! Be very careful not to kink any

of the tubing on the reverse osmosis system.

If tubing is kinked, the tubing can rupture and

leak.

2. Position the system on the wall at the desired

mounting location. Using the bracket holes on

the back of the bracket, mark on the wall with

a pencil where the screws need to be

inserted.

3. Set the system aside.

4. Screw the two (2) Phillip head screws

(supplied in the installation packet) into the

wall at the marked positions.

NOTE: Let the screw heads protrude from

the wall enough to hang the reverse osmosis

system safely.

5. Mount the reverse osmosis system onto the

screws.

IMPORTANT!! Be very careful not to kink

any of the tubing on the reverse osmosis

system. If tubing is kinked the tubing can

rupture and leak.

CONNECTING THE FAUCET:

(Blue Line)

1. Connect the blue tubing to the faucet by

slipping the 1/4” brass nut over the tubing

followed by the nylon ferrule.

Note: It is not necessary to have a 1/4” nylon

insert in this line as it would restrict the flow

through the faucet.

2. Push the blue line all the way into the faucet

stem and tighten the brass nut. DO NOT

OVERTIGHTEN!!

Tubing Connections

CONNECTING THE FEEDWATER:

(Red Line)

1. If you installed the feedwater adapter using

step # 3 or # 4 in Section # 3, simply slip a

white 1/4” nylon nut over the red line and

insert the 1/4” nylon insert into the end of the

tubing. Then insert the tubing into the nylon

fitting on the feedwater adapter. Tighten the

nylon nut securely.

DO NOT OVERTIGHTEN!

2. If you have the connection for the icemaker

tee as in Step # 2 of Section # 3 simply slide

the 1/4” brass nut over the red tubing. Slip

the nylon ferrule over the red tubing and

insert the 1/4” nylon insert into the tubing

end. Insert tubing into the cold water shut off

valve and tighten securely.

DO NOT OVERTIGHTEN!

CONNECTING THE TANK:

(White Line)

1. Push in the white tubing and insert it into the

1/4” push pull fitting. Then insert the tubing

into the ball valve on the top of the storage

tank. Tighten securely.

DO NOT OVERTIGHTEN!

CONNECTING THE DRAIN SADDLE LINE:

(Black Line)

1. Slip the 1/4” black nylon nut over the black

tubing and insert into the drain saddle.

Tighten securely. DO NOT OVERTIGHTEN!

Note: It is not necessary to have a 1/4” nylon

insert in this line as there is no pressure on

this line.

1. With all connections complete, turn on the

cold water supply to the reverse osmosis

system.

IMPORTANT!! The Reverse Osmosis Main

Water Shut Off Valve (indicated by the bright

orange tag at the side of the unit) must be

open. This means the blue handle on the

valve must be in line with the red tubing; not

pointing straight up.

2. Immediately check entire reverse osmosis

system and tank for leaks. If you notice any

System Start-Up

RF – Series User Manual

MKTF – 167-C 14 05/17

9

leaks, turn off cold water supply and fix the

leak.

IMPORTANT!! Ensure that the ball valve on

the storage tank is open. This means that the

valve handle is in line with the white tubing.

1. Lift the reverse osmosis faucet handle until it

2. After the tank has filled, open the faucet and

Reverse Osmosis System

locks in the upright position. Let the water

drip for two hours. After 2 hours, turn off the

reverse osmosis faucet. The tank will now fill,

which takes approximately four to five hours.

drain all the water from the tank until it is

empty.

CAUTION!! DO NOT USE FIRST TANK OF

WATER FROM YOUR SYSTEM! The

membrane contains a food grade

preservative to protect it while in storage.

This preservative is not harmful; however, it

does not have a pleasant taste. Therefore, do

not use the first tank of water, which flushes

the entire system removing any preservatives

used during storage and preparing it to

produce quality water.

Flushing the

3. Within two to three hours after draining the

first tank of water, the water is ready for

drinking.

RF – Series User Manual

MKTF – 167-C 15 05/17

Not Enough Water From Holding Tank

Possible Cause

Solution

Low Water Pressure From Dispensing Faucet

Possible Cause

Solution

12

TROUBLESHOOTING

Feedwater valve is plugged or

closed.

Sediment/carbon prefilter or carbon

post filter is clogged.

Low incoming water pressure.

Reverse osmosis membrane is

fouled.

Air pressure in holding tank is

incorrect.

Air bladder in holding tank is

ruptured.

Holding tank valve is closed. Open valve.

No water to drain. Drain flow

restrictor is clogged.

No water to drain. Air gap faucet is

clogged.

Check valve on the reverse

osmosis membrane housing is

stuck.

The automatic shut–off valve is

malfunctioning.

Open valve or unclog.

Replace filters.

Incoming water pressure must be above 40 PSI. Install a booster pump or

permeate pump.

Make sure incoming water pressure is within operating limits. Make sure drain

line is not clogged. (See High TDS) Correct cause of fouling and replace

reverse osmosis membrane.

Empty water from holding tank. Air pressure in valve stem should be between

8 – 10 PSI.

Replace holding tank.

Replace drain flow restrictor.

Clear or replace air gap faucet.

Replace check valve.

Replace automatic shut–off valve.

Air pressure in holding tank is

incorrect.

This is the #1 reason for low flow

from reverse osmosis faucet.

Carbon post filter is clogged. Replace post filter

Holding tank valve is partially

closed.

The faucet is out of adjustment or

faulty.

Heavy water use. Holding tank is

empty.

RF – Series User Manual

MKTF – 167-C 16 05/17

Open faucet and empty water from holding tank. Shut off feedwater to system

and remove holding tank from under sink. (The tank is easier to work on.)

Locate the air valve stem (just like on a car or bicycle tire) and add air. If there

is still water in the tank, continue to add air until all the water is removed.

Once all the water is removed, continue to add air and pressurize to 8 PSI.

Re–install the tank under the sink, turn on the feed supply to the system and

allow the tank to fill.

Open valve.

Repair or replace faucet.

Allow holding tank to refill.

Low Quantity of Water

f

rom Holding Tank

Product Water is High in Total Dissolved Solids (TDS)

Possible Cause

Solution

Tastes and Odors in Product Water

Possible Cause

Solution

High TDS in Product Water

Drain Water Overflows at the Air Gap Faucet

Possible Cause

Solution

Faucet Leaks or Drips

Possible Cause

Solution

Low water production. See section on

Clogged prefilter. Replace filter.

Low incoming water pressure.

Reverse osmosis membrane is not

correctly sealed in membrane housing.

Reverse osmosis membrane is

expended.

Product water and drain water lines are

reversed.

No water to drain. Drain flow restrictor is

clogged.

No water to drain. Air gap faucet is

clogged.

The automatic shut–off valve is not

closing.

New carbon postfilter has not been

rinsed completely.

The incoming feedwater TDS has

increased.

Incoming water pressure must be above 40 PSI. Install a booster pump

or permeate pump.

Check that the reverse osmosis membrane is correctly installed.

If membrane life is unusually short, find and correct the problem.

(Average life is two to three years.) Replace Reverse Osmosis

membrane.

Correct plumbing.

Replace drain flow restrictor.

Clear or replace air gap faucet.

Repair or replace automatic shut–off valve.

Drain holding tank twice to rinse new carbon postfilter.

An increase in feedwater TDS will also give an increase in product water

TDS.

.

Carbon post filter is exhausted. Replace filter.

There is foreign matter in holding tank. Clean, flush and sanitize the holding tank. Replace filters.

Product water and drain water lines are reversed. Correct plumbing.

Dissolved gases in feedwater. Pre–treat feedwater to remove gasses.

Increase in product water TDS. See

Section

Air gap is clogged. Clear air gap

Drain line is clogged. Clear tubing.

Drain flow rate is too high. Replace flow restrictor.

Water leaks from

faucet spout.

Leaks from beneath

the handle.

Adjust faucet by turning the tee bar located under the handle to provide a small amount of

free play in the handle when shut off. Should this not work, repair or replace the faucet.

Repair or replace the faucet.

RF – Series User Manual

MKTF – 167-C 17 05/17

SYSTEM DRAWINGS

RF – Series User Manual

MKTF – 167-C 18 05/17

RF – Series User Manual

MKTF – 167-C 19 05/17

RF – Series User Manual

MKTF – 167-C 20 05/17

SYSTEM WARRANTY

One–Year Limited Warranty

Warranty Terms

Subject to the terms and conditions set forth hereinafter, manufacturer (hereafter “Manufacturer”) warrants to the

original purchaser (hereafter the “Customer”) that the systems and products manufactured by the Manufacturer are

free from defects in material and in workmanship for twelve (12) months from the Warranty Commencement Date

(as defined below) only when used strictly in accordance with the applicable operating instructions and within the

range of the operating conditions specified by the Manufacturer for each such product.

In order to maintain the Manufacturer’s Warranty, an operating log must be maintained and copies will need to be

sent to your local dealer or distributor for review. This Warranty does not extend to systems, equipment, or

components manufactured by others, nor to systems, equipment, or components manufactured by others and

distributed by the Manufacturer. This Warranty does not extend to equipment or components manufactured by

others which have been incorporated into a product by the Manufacturer but, if allowable, the Manufacturer hereby

assigns, without Warranty, to the Customer its interest, if any, under any Warranty made by the Manufacturer of

such equipment or component. This Warranty does not cover disposable items such as fuses, o–rings, regeneration

materials/chemicals, or other such disposable items, which must be replaced periodically under the normal and

foreseeable operating conditions of the goods warranted hereby.

Warranty Commencement Date

The Warranty Commencement Date for each product by the Manufacturer shall be the later of the date of: (1) receipt

by the Customer, or (2) the date of installation at the Customer’s premises provided that such installation must occur

within three (3) months of shipment from the Manufacturer’s manufacturing facility. In no event shall the Warranty

Commencement Date exceed three (3) months from the shipment from Manufacturer’s facility. The Customer shall

provide proof of purchase in order to exercise rights granted under this Warranty. If requested by the Manufacturer,

the Customer must also provide proof of the installation date. Proof of installation shall be returned by Customer to

the Manufacturer within thirty (30) days after installation by virtue of supplying a Warranty Validation Card supplied

with each Manufacturer product fully completed and signed in ink by the Customer and the authorized installer of

the product.

Warranty Service

MANUFACTURER’S OBLIGATION UNDER THIS WARRANTY IS LIMITED TO THE REPAIR OR REPLACEMENT

(AT MANUFACTURER’S SOLE DISCRETION) OF ANY PRODUCT, OR COMPONENT THEREOF, PROVED TO

BE DEFECTIVE IN MATERIAL OR WORKMANSHIP WITHIN THE COVERED WARRANTY PERIOD.

The Customer, at the Customer’s risk and expense, shall be responsible for returning such product or component,

only after obtaining a Return Goods Authorization (RGA) number from the Manufacturer, arranging for freight

prepaid, and in conformance with any special packaging and shipping instructions set forth on the operation

documentation or RGA instructions, or as otherwise reasonably required, to Manufacturer’s address, together with

(1) RGA number issued by the Manufacturer at Customer’s request; (2) proof of purchase and, if necessary, proof

of installation date; (3) a Return Goods Authorization Form; (4) a description of the suspected defects; (5) the serial

number of the Manufacturer product alleged to be defective; and (6) a description of the type of water and

pretreatment equipment which has been utilized in connection with the product, if any; (7) an operating log, which

can be found in the product manual. Manufacturer shall, in Manufacturer’s reasonable discretion, be the sole judge

of whether a returned product or component is defective in material or workmanship.

RF – Series User Manual

MKTF – 167-C 21 05/17

Required or replaced products or components shall be returned surface freight. In genuine emergency situations,

Manufacturer will at Manufacturer’s sole discretion) forward replacement parts to Customer without waiting for

authorized return of the questionable part(s). In such cases, Customer will issue a purchase order or other payment

guarantee prior to shipment. If the returned part is found to have been misused or abused, or the defective part is

not received by Manufacturer within thirty (30) days; the Customer will be invoiced for the replacement part(s)

provided. This Warranty does not cover or include labor and/or travel to the Customer’s premise or location or any

other location. Charges of $1000 per day plus associated travel expenses will be incurred by the Customer in

providing the Warranty Service at any location other than Manufacturer’s main headquarters; that is if the

Manufacturer deems that the product is not covered by said Warranty. The Manufacturer reserves the right to

precondition such travel to Customer’s premises upon prepayment of Manufacturer’s anticipated costs of attending

such premises.

Voidability of Warranty

This Warranty shall be void and unenforceable as to any Manufacturer product which has been damaged by

accident, mishandling, abuse or has been repaired, modified, altered, disassembled or otherwise tampered with by

anyone other than Manufacturer or an authorized Manufacturer service representative; or, if any replacement parts

are not authorized by Manufacturer have been used, or, the product has not been installed, operated and maintained

in strict accordance and adherence with the operating documentation and manuals for such product. Any expressed

Warranty, or similar representation of performance set forth in the operation documentation for media or resin

incorporated into a product by the Manufacturer shall be void and unenforceable unless the feed water requirements

set forth in the operating documentation for such product are unequivocally and strictly adhered to.

Limitations and Exclusions

THIS WARRANTY AND REMEDIES DESCRIBED HEREIN AND HEREINABOVE ARE EXCLUSIVE AND IN LIEU

OF ANY AND ALL OTHER WARRANTY OR REMEDIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT SHALL THE MANUFACTURER BE LIABLE FOR ANY CONSEQUENTIAL,

INCIDENTAL OR OTHER SIMILAR TYPES OF DAMAGES, FOR DAMAGES FOR THE LOSS OF PRODUCTION

OR PROFITS, OR INJURY TO PERSON OR PROPERTY. NO PERSON HAS ANY AUTHORITY TO BIND THE

MANUFACTURER TO OTHER THAN WHAT IS SET FORTH ABOVE.

THIS WARRANTY GIVES THE CUSTOMER SPECIFIC LEGAL RIGHTS AND THE CUSTOMER MAY ALSO HAVE

OTHER RIGHTS WHICH VARY FROM JURISDICTION TO JURISDICTION. THE PARTIES RECOGNIZE AND

AGREE, THAT IN ALL RESPECTS THE LAWS OF THE STATE OF CALIFORNIA SHALL APPLY TO AND SHALL

GOVERN ANY INTERPRETATION OR LEGAL SIGNIFICANCE OF THIS DOCUMENT.

NO WARRANTY OR OTHER LIABILITY OF THE MANUFACTURER TO CUSTOMER UNDER THIS AGREEMENT

OR OTHERWISE WILL IN ANY EVENT EXCEED THE COST OF REPLACEMENT OF THE APPLICABLE

MANUFACTURER PRODUCT, PART, OR ACCESSORY THAT IS SUBJECT TO ANY BREACH OF

MANUFACTURER’S WARRANTY. MANUFACTURER WILL NOT BE LIABLE FOR ANY DAMAGE TO ANY

PROPERTY OF CUSTOMER OR TO CUSTOMER’S CUSTOMERS FOR ANY CONSEQUENTIAL, INCIDENTAL,

OR ECONOMIC LOSS OR COMMERCIAL DAMAGE WHATSOEVER. REMEDIES HEREIN PROVIDED ARE

EXPRESSLY MADE THE SOLE AND EXCLUSIVE REMEDIES FOR BREACH OF ANY WARRANTY OR OTHER

OBLIGATION HEREUNDER EXPRESS OR IMPLIED OR FROM THE OPERATION OF LAW.

RF – Series User Manual

MKTF – 167-C 22 05/17

Loading...

Loading...