REVELL Tom Daniel Ice T User Manual [en, fr, nl, it, gr, da, no, fi, sv, es, pt, de, en, hr, et, fi, hu, lv, lt, nl, pl, ro, ru, sr, sk, sl, cs, tr, gr, bg, uk, ch, he, ar, ja, ch, ch, ko, hi, id, kk, ms, fa, pt, es, th, vi, sq, mk]

Page 1

BOOK

OPENING

FRAME

15

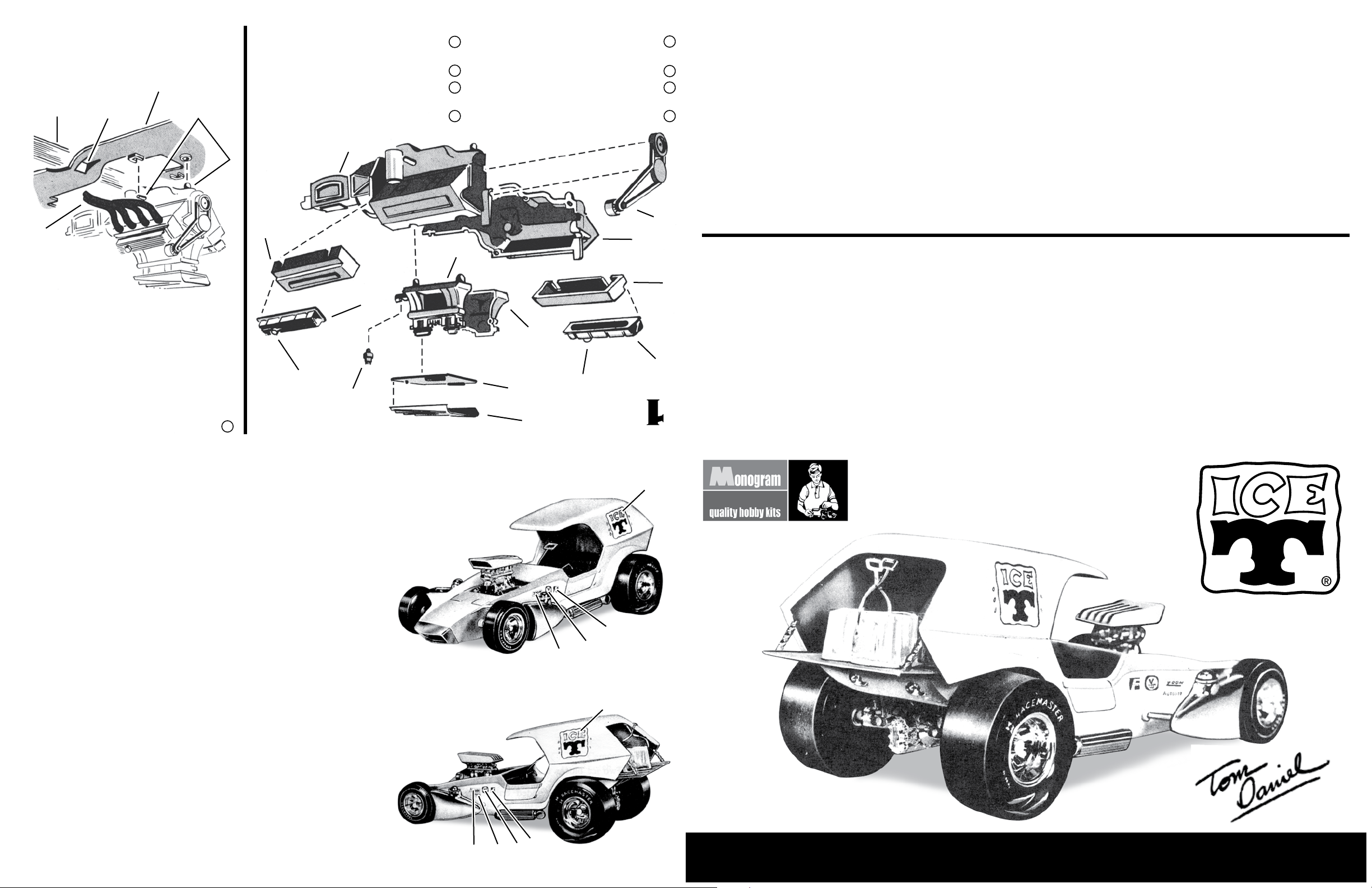

CEMENT WILL NOT STICK TO PLATING.

PLATING WHERE CEMENT MUST GO.

CHROME PLATED PART. SCRAPE

CEMENT

APPLY

H

together and attach to top of intake.

8. Cement air scoop halves 11 and 12

front.

7. Attach pulley assembly 10 to engine

6. Cement high riser to top of engine.

rear of high riser.

5. Cement distributor 9 into hole in tab on

1

8H together.

4. Next, cement high riser halves 7H and

as shown.

3. Cement two rocker covers 5H to heads

2. Cement two heads 3 and 4 to engine.

and 2 together

1. Begin by cementing engine halves 1

The car comes complete with melting ice blocks and tongs.

chopped roof, groovy dished hood, and out-of-sight interior.

of competition car. Check out the side exhausts, forward rake,

The body has that low mean look that Tom gives to this kind

quick ller knock-off caps.

scoop. Go juice is carried in two chromed side tanks with

Manifold, giant gas gulpin’ 4 barrel jug, and a slick looking

It’s big thumpin’ V-8 mill is topped by the latest Hi-Rise

like those seen on hot machinery at drag strips everywhere.

This beauty rides on huge real-looking wrinkle slicks, just

creation is stuffed with mouth watering glitter.

latest trend in show/go rod styling, Tom Daniel’s newest

OF A. The Ice “T” comes on like strong. Designed for the

FASTED AND QUICKEST ICE WAGON IN THE U.S.

13

cement it drying.

does not touch the table while the

books so that the bottom of the eingine

openings. Rest the frame between two

pipes should be centered in frame

engine on frame 15. Ends of exhaurst

places indicated on sketch and position

wet on exhaust pipes, add cement to

heads. While cement is still slightly

9. Cement exhaust pipes 13 and 14 to

3

BREATHER CAP

9

PAINTING

Use only PAINT FOR PLASTICS or an ENAMEL for the parts you may wish to paint.

Refer to the box illustrations and the detailed color scheme below.

It is best to paint some of the smaller parts before removing them from the plastic

trees. Use a small pointed brush for the small parts and a 1/4 inch soft brush for larger

areas.

Allow the paint to dry thoroughly before handling the parts. Paint should be scraped

from the areas to be cemented because cement will not adhere to the paint.

GLOSS YELLOW - Body, back pan and scoop.

SEMI GLOSS BLACK - Entire engine assembly including exhaust pipes, entire

frame except bed portion, belts on pulley assembly ve ribs on top of air scoop, ends

of exhaust pipes 25 and 26, surfaces between coil springs on front suspension, entire

front seat and oorboard and inside of air scoop.

LIGHT BROWN (Wood) - Bed portion of frame (this is the portion which carries

the ice).

SILVER - Seven metal strips on bed portion, pulleys and alternator on pulley

assembly and six instruments on front of oorboard.

TRANSPARENT RED - Tail light lenses.

TRANSPARENT BLUE - ICE BLOCKS.

WHITE - Lettering on outside of front and rear tires and narrow stripe on sidewall

of front tire.

®

THE ICE “T”

10

2

7H

check off each step as completed.

4

8. DO NOT RUSH assembly. FOLLOW instructions and

5H

NOT stick to plating.

7. SCRAPE PLATING from plastic parts. Cement WILL

Some parts must be painted before cementing.

3. Read PAINTING INSTRUCTIONS before assembly.

for use. All parts are identified by a number.

2. DO NOT REMOVE parts from trees until ready

8H

Become familiar with your Monogram kit.

STUDY the drawings.

1. READ the instructions.

MODEL BUILDING

EIGHT STEPS TO SUCCESSFUL

11

12

TOWARDS REAR

BREATHER CAP

Too much cement can damage your model.

5H

6. Apply cement with a TOOTHPICK on small areas.

5. CHECK FIT of part before cementing into place.

4. CUT parts from trees, breaking off may damage part.

1

KIT 4266 85426600200

6

3

5

1

DECALS

Use as many decals as you like and locate them to suit your individual taste. The

photos show suggested decal locations. For a neat job, work with one subject at a time

and trim each close to the color outline. Dip in water for a few seconds. When decal

can slide off sheet, slide into position on model and let dry before handling.

5 4

Designed By

6

3

or, please write to: Revell Inc Consumer Service Department, 1850 Howard Street Unit A, Elk Grove Village, Illinois 60007

Be sure to include the plan number (85426600200), part number, description, your return address and phone number.

If you have any questions or comments, call our hotline at: (800) 833-3570

Visit our website: www.revell.com Revell Inc Elk Grove Village, IL. Copyright © 2010. All rights reserved.

Page 2

21H

16H

22H

27H

28

24H

26H

HOLE FOR PIN

ON RADIUS ROD

25H

FRAME

OPENING

RIB FOR

EXHAUST PIPE

19H

SCRAPE PLATING

FROM AXLE AS

SHOWN BY SHADING

17H

20H

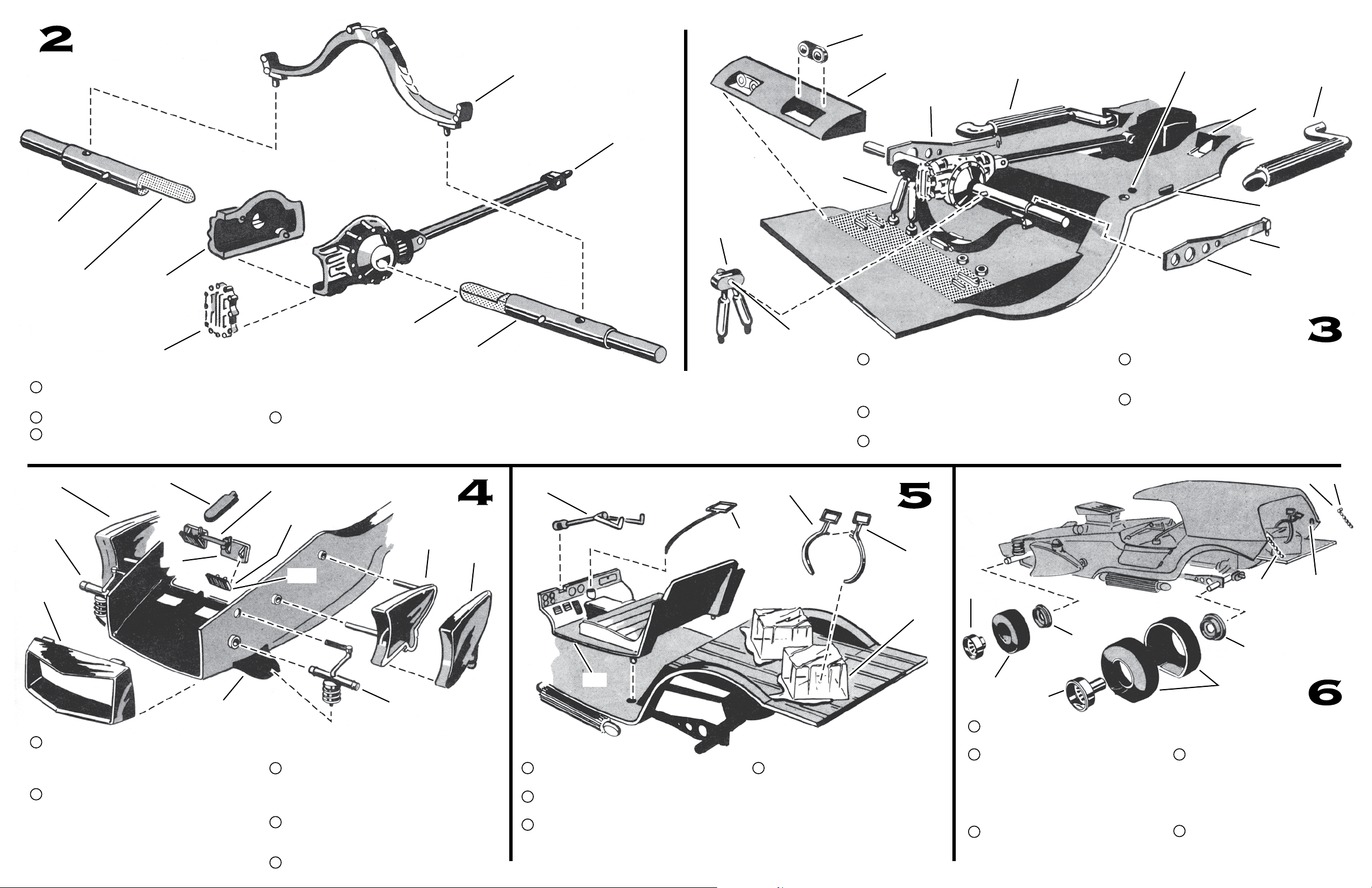

10. Cement quick change halves 16H and 17H

together.

11. Attach cover 20H to quick change halves.

12. Cement axle halves 18H and 19H into “D”

34H

31

35H

33H

30

38H

shaped holes as shown. Make sure holes for

springs in axle face up as shown.

13. Cement spring 21H into holes in axle. While

CENTER ROD

BEVELED

EDGE

29H

SCRAPE PLATING

FROM AXLE AS

SHOWN BY SHADING

cement is slightly wet proceed to next step.

18H

36H

37H

39

22H

CHROME PLATED PART. SCRAPE PLATING

H

WHERE CEMENT MUST GO. CEMENT WILL

NOT STICK TO PLATING.

41H

HOLE FITS

OVER PIN

ON AXLE

42H

14. Now take frame and engine assembly

assembled in Step 1 and turn upside down as

shown. Cement end of driveshaft into engine

and spring between ribs on frame.

15. Cement two shock absorber units 22H to pins

on axle and into holes as shown.

16. Attach two rear radius rods 23H and 24H as

indicated.

43H

45H

ICE

BLOCK

RADIUS ROD

23H

17. Cement pipes 25H and 26H to frame. Front

end of pipe t into frame opening. Rib on frame

ts into notch in exhausts.

18. Next, cement two tailight units 27H ito notches

in back pan 28. Cement back pan to frame in

position as indicated by shaded area. Edge of

back pan rests against the mounts for the shock

absorber units.

PIN

48H

48H

“U” NOTCH FOR

PIN ON CHAIN

SUSPENSION

SUPPORT

19. Cement two headlights 29H against triangular

stops on headlight backs 30. Make certain that

the beveled edge of headlight is in position

shown in sketch before cementing in place.

20. Locate (do not cement) rod on headlight back

between two ribs on body. Now carefully

cement retainer 31 to body. Add cement only

to where retainer touches body. DO NOT

put cement near rod so that headlights will

operate properly. Hold 31 tightly in place

until cement sets.

32H

Do not operate headlights until cement has

dried overnight.

21. Cement two front axles suspensions 32H and

33H to side in body as shown It is best to insert

axle into hole in body, THEN insert small pin

on spring into hold in suspension support.

22. Cement fuel tank halves 34H and 35H together

and cement to body as shown. Repeat for

remaining tank halves 36H and 37H.

23. Next, cement nose piece 38H to front of body.

40

24. Cement steering column 39 into notch in

oorboard 40.

25. Next, cement shift lever 41H into oorboard as

indicated, then cement oorboard to frame.

26. Cement ice tong halves 42H and 43H together.

Pin on one half ts between two pins on other

half. Cement tongs to one ice block.

27. Two ice blocks are now cemented

to the frame as shown. Cement

should be added only to the block

edges not the “puddle” portions.

The arrangement shown may be

changed to suit. It is best to check

for clearance with the body before

cementing into nal position.

44

FRONT

TIRE

28. Cement completed frame assembly and

29. Press inside wheel half 44 into front tire.

30. Fit slick halves together (do not

46H

body together.

Then apply cement to outside wheel

half 45H and press into other side of

tire. Hold wheel halves together until

cement sets. Cement wheels to front

axle.

cement) lining up the “at” wrinkled

portion. One slick half has a rib around

47

SLICK

the inside which ts into the groove

around the inside of the other half.

31. Fit the outside rear wheels 46H into

the assembled slicks and cement

the wheels to the inner wheel

halves 47. Now cement wheel to

rear axle. Flat portion of slick lies

at on table.

32. Complete your model by cementing

two tailgate chains 48H in place as

indicated.

Loading...

Loading...