REVELL Dale Earnhardt, Jr. Chance 2 Motorsports User Manual [nl, it, gr, da, no, fi, sv, es, pt, hr, et, fi, hu, lv, lt, pl, ro, RU, sr, sk, sl, cs, tr, bg, uk, he, hi, id, kk, ms, fa, th, vi, sq, mk]

KIT 2843 85284300200

Dale Earnhardt, Jr.

Chance 2 Motorsports

“DMP” MONTE CARLO

™

Having a NASCAR® race team in the 21st century is far

different than in the sport’s earliest days 50+ years ago.

nod to his grandfather Ralph Earnhardt who ran the dirt bull-

rings of NASCAR® in the 50’s.

Sponsor contracts, television contracts, even the weekly

race purse all have the words "multi-million dollar" in front of

them. If that wasn’t enough pressure to perform, there’s 42

other teams, better organized and better financed than ever,

looking to pass you by every week. Ask anyone associated

with a race team and they’ll confirm that it’s a tremendous

amount of stress.

Then again, your name could be Dale Earnhardt, Jr.

This third generation driver has dealt with all of these pressures as well as the overwhelming burden of being the son

of, in the eyes of millions of fans, the greatest stock car

driver ever.

In addition to the solid racing skills Junior learned from

his late father, the family heritage is also apparent in that the

With the tragic 2001 season behind him, Junior has matured

and has stepped up to take his place among racing’s elite.

While not entirely leaving behind the persona of the wisecracking young gun with the Budweiser® hat on backwards,

he’s brought together the scores of talented people working

the red & black #8 as well as DEI’s two other Cup teams,

keeping all three legitimate threats to clinch the win every

race. Perhaps more than anyone else, Dale Jr. has also

brought together the fans of the veteran drivers that were

rookies 10 and 20 years ago with the "new breed" of fans

cheering on the younger generation of NASCAR® competitors. The future not only looks bright, it looks like there will

be no shortage of Earnhardts in Victory Lane any time soon.

Budweiser® Monte Carlo™ wears the number 8, a respectful

* REPEAT SEVERAL TIMES

* A REPETER PLUSIEURS FOIS

READ THIS BEFORE YOU BEGIN LIRE CE QUI SUIT AVANT DE COMMENCER

* Study the assembly drawings.

* Each plastic part is identified by a number.

* In the assembly drawings, some parts will be

marked by a star (★) to indicate chrome

plated plastic.

* For better paint and decal adhesion, wash

the plastic parts in a mild detergent solution.

Rinse and let air dry.

* Check the fit of each piece before cementing

in place.

* Use only cement for polystyrene plastic.

* Scrape plating and paint from areas to be

cemented.

* Allow paint to dry thoroughly before

handling parts.

* Any unused parts may be discarded.

DECAL APPLICATION INSTRUCTIONS

1. Cut desired decal from sheet.

2. Dip decal in water for a few seconds.

3. Place wet decal on paper towel.

4. Wait until decal is movable on paper backing.

5. Place decal in position on model, face up

and slide backing away.

6. Press out air bubbles with a soft damp cloth.

7. Milkiness that may appear is for better decal

adhesion and will dry clear. Wipe away any

excess adhesive.

8. Do not touch decal until fully dry.

9. Allow the decals 48 hours to dry before

applying clear coat.

NOTE: Decals are compatible with

setting solutions or solvents.

* OPTIONAL PARTS

* PIECES EN OPTION

* DECAL

* DECAL COMANIE

* Etudier les schémas de montage.

* Chaque pièce en plastique est identifiée par un numéro.

* Sur les schémas de montage, certaines pièces sont mar

quées d'une étoile (★) pour indiquer qu'elles sont en

plastique chromé.

* Pour une meilleure prise de la peinture et des autocollants,

laver les pièces en plastique avec une solution détergente

peu concentrée. Les rincer et les laisser sécher à l'air.

* Vérifier que chaque pièce s'ajuste bien avant de la coller

en place.

* N'utiliser que de la colle pour polystyrène.

* Gratter les parties à coller pour enlever le chrome et la peinture.

* Laisser la peinture bien sécher avant de manipuler les pièces.

* Toute pièce inutilisée peut être jetée.

DIRECTIVES D'APPLICATION DES AUTOCOLLANTS

1. Découper l'autocollant désiré de la feuille.

2. Tremper l'autocollant dans de l'eau pendant quelques secondes.

3. Placer l'autocollant mouillé sur une serviette en papier.

4. Attendez que l'autocollant puisse être déplacé sur son sup

port en papier.

5. Mettre l'autocollant en position sur le modèle face sur le

dessus et faire glisser le support pour l'enlever.

6. Appuyer avec un chiffon doux humide pour éliminer les bulles

d'air.

7. La substance laiteuse qui peut apparaître est destinée à

améliorer l'adhésion de l'autocollant et devient incolore au

séchage. Essuyer pour enlever tout excédent d'adhésif.

8. Ne pas toucher l'autocollant tant qu'il n'est pas bien sec.

9. Laisser l'autocollant sécher pendant 48 heures avant

d'appliquer une couche transparente.

* ALTERNATIVE ASSEMBLY

* ENSEMBLAGE ALTERNATIVE

Through it all, Dale Jr. rises to meet the challenges.

* CEMENT TOGETHER

* A COLLER

* REMOVE AND THROW AWAY

* A RETIRER ET JETER

This paint guide is provided to

complete this kit as shown on the box

Ce guide de peinture est fourni pour reproduire le

modèle réduit qui apparaît sur la boîte.

Aluminum

Flat Black

Flat White

Flat Yellow

Gloss Black

Gloss Red

Gloss White

Light Gray

Satin White

Semigloss Black

Silver

Steel

* DO NOT CEMENT

* NE PAS COLLER

Aluminum

Noir mat

Blanc mat

Jaune mat

Noir brilliant

Rouge brilliant

Blanc brilliant

Gris clair

Blanc satiné

Noir satiné

Argent

Acier

.

If you have any questions or comments, call our hotline at: (800) 833-3570

or, please write to:

Revell-Monogram Consumer Service Department, 725 Landwehr, Northbrook, Illinois 60062

Be sure to include the plan number (85284300200), part number, description, your return address and phone number.

Visit our website: www.revell-monogram.com

REVELL-MONOGRAM, LLC Northbrook, IL. Copyright © 2003. All rights reserved.

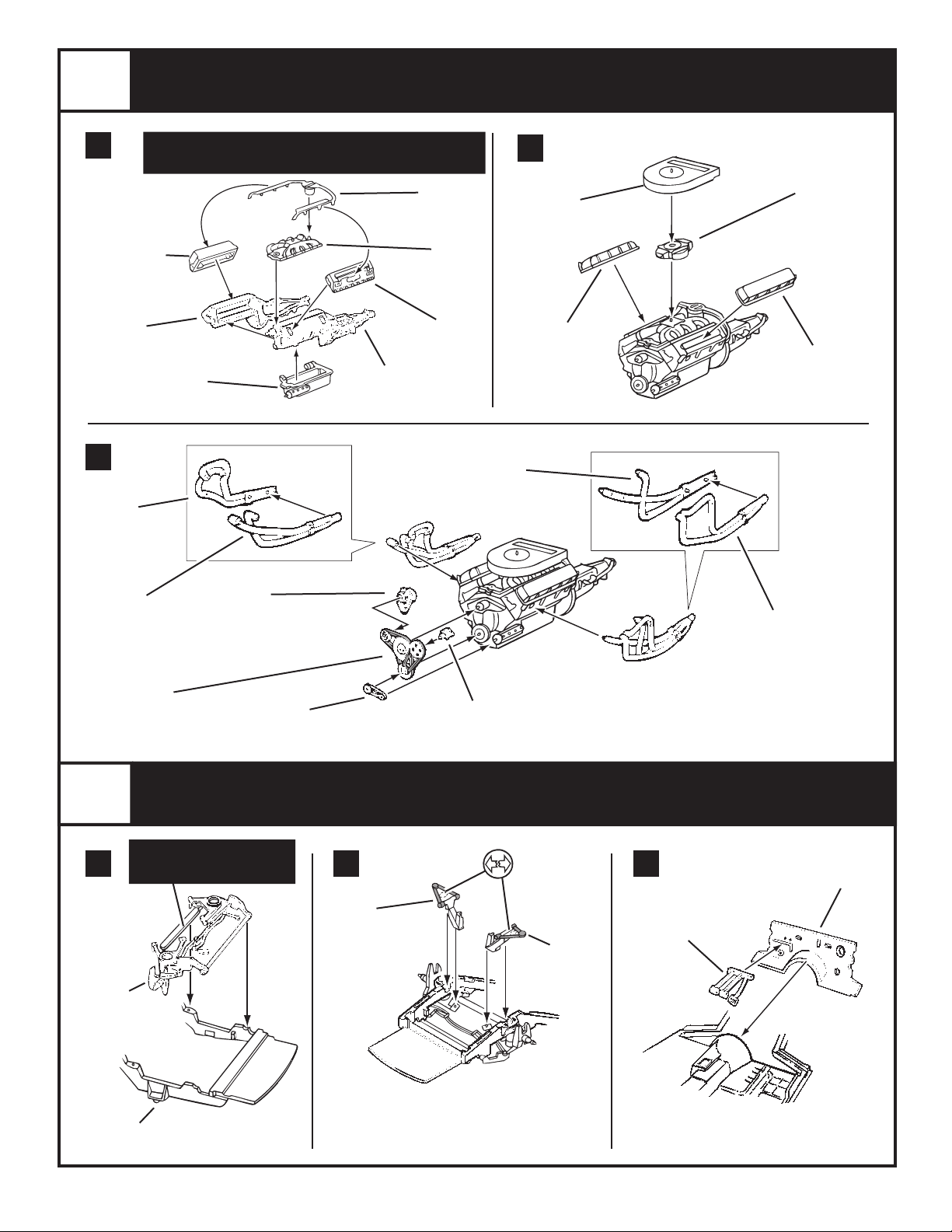

1

A

ENGINE ASSEMBLY

NOTE: BEND PLUG WIRES SO THAT LONG TABS ON

✱

WIRES FIT INTO DEPRESSIONS ON CYLINDER HEADS

DISTRIBUTOR / WIRES

65

CYLINDER

HEAD

ALUMINUM

✱

✱

36

FLAT BLACK

(PAINT WIRES YELLOW)

69

INTAKE

MANIFOLD

ALUMINUM

B

93

AIR CLEANER

ALUMINUM

70

CARBURETOR

ALUMINUM

30

ENGINE HALF

ALUMINUM

C

41

HEADER

STEEL

40

HEADER

STEEL

BELT ASSEMBLY

FLAT BLACK

OIL PAN

ALUMINUM

32

35

64

ALTERNATOR

ALUMINUM

SUMP BELT

FLAT BLACK

65

CYLINDER

HEAD

ALUMINUM

29

ENGINE HALF

ALUMINUM

39

HEADER

STEEL

33

POWER STEERING PUMP

34

ALUMINUM

67

ROCKER

COVER

ALUMINUM

38

HEADER

STEEL

66

ROCKER

COVER

ALUMINUM

2

A

LOWER FRONT

SUSPENSION

SEMIGLOSS BLACK

LEAVE SUPPORT STRAP IN

14

4

FRAME

LIGHT GRAY

CHASSIS / INTERIOR ASSEMBLY

NOTE:

PLACE UNTIL STEP 4A

B C

15

RIGHT UPPER

ARM

LIGHT GRAY

(SHADED AREA

GLOSS BLACK)

SEMI-

96

LEFT UPPER ARM

LIGHT GRAY

(SHADED AREA SEMI-

GLOSS BLACK)

44

PEDALS

ALUMINUM

7

FIREWALL

LIGHT GRAY

2

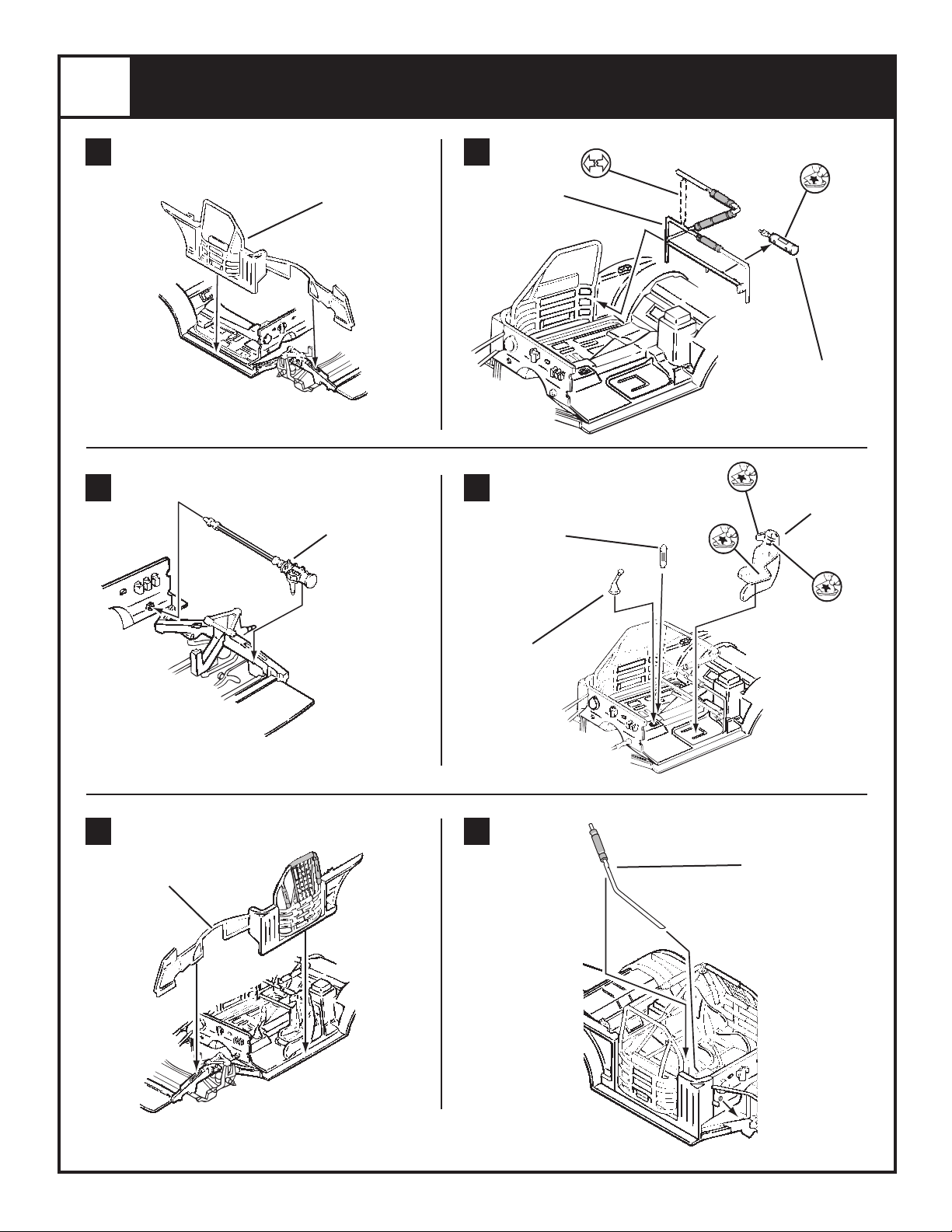

CHASSIS / INTERIOR ASSEMBLY

D E

6

CAGE SIDE

LIGHT GRAY

8

ROLL BAR

LIGHT GRAY

(PAINT SHADED AREA

FLAT BLACK)

CONTINUED

3

F G

25

STEERING

SHAFT

STEEL

11

STIFFENER

BRACE

LIGHT GRAY

(SHADED AREA

FLAT BLACK)

52

SHIFTER

FLAT BLACK

FIRE EXTINGUISHER

2

4

49

GLOSS RED

47

SEAT

SEMIGLOSS BLACK

1

H

5

CAGE SIDE

LIGHT GRAY

(SHADED AREAS

FLAT BLACK)

I

10

STIFFENER

BAR

LIGHT GRAY

(SHADED AREA

FLAT BLACK)

2

CHASSIS / INTERIOR ASSEMBLY

CONTINUED

J K

57

PETTY BAR

LIGHT GRAY

L

TOP STIFFENER BAR

(SHADED AREA FLAT BLACK)

73

LIGHT GRAY

FIRST

9

TOP BRACE

LIGHT GRAY

(SHADED AREA

FLAT BLACK)

SECOND

72

MIRROR

FLAT BLACK

(MIRROR FACE SILVER)

FUEL CELL

LIGHT GRAY

(PAINT SHADED

AREA ALUMINUM)

FLAT BLACK

M

13

FLAT BLACK

51

HOSE

56

REAR SHELF

SEMIGLOSS

BLACK

THIRD

50

HOSE

12

KICKER BAR

ASSEMBLY

LIGHT GRAY

SECOND

REAR SUSPENSION

ADJUSTMENT TUBES

48

HOSE

FLAT BLACK

61

HOSE

FLAT BLACK

92

LIGHT GRAY

3

A

FIRST

SUSPENSION / CHASSIS ASSEMBLY

59

OILER TANK

ALUMINUM

(SHADED AREA ALUMINUM)

22

SHOCK ASSEMBLY

LIGHT GRAY

3

SUSPENSION / CHASSIS ASSEMBLY

CONTINUED

B

(PAINT SHADED AREA SEMIGLOSS BLACK)

21

SPRING

SEMIGLOSS

BLACK

17

ARM ASSEMBLY

LIGHT GRAY

C

21

SPRING

SEMIGLOSS

BLACK

18

REAR AXLE

SEMIGLOSS BLACK

19

FRONT AXLE

SEMIGLOSS

BLACK

4

A

37

PUMP BELT

FLAT BLACK

20

COOLANT PUMP

ALUMINUM

CHASSIS DETAIL ASSEMBLY

B

EXHAUST

90

STEEL

THIRD

16

EXHAUST

OUTLET HALF

STEEL

SECOND

DRIVE SHAFT

SATIN WHITE

(SHADED AREAS STEEL)

FIRST

43

4

CHASSIS DETAIL ASSEMBLY

CONTINUED

C D

31

E

FAN SHROUD

ALUMINUM

54

FRAME

BRACE

LIGHT GRAY

54

FRAME

BRACE

LIGHT GRAY

63

PILLAR

BRACE

LIGHT GRAY

75

PILLAR

BRACE

LIGHT GRAY

F

STEERING

COLUMN

FLAT BLACK

104

DASHBOARD

TOP

FLAT BLACK

PAINT GAUGE FACES GLOSS

BLACK WITH SILVER DETAILS

53

46

STEERING

WHEEL

FLAT BLACK

23

DASHBOARD

FRONT

FLAT BLACK

27

UPPER HOSE

ALUMINUM

(PAINT SHADED

AREAS FLAT BLACK)

G

62

RADIATOR

ALUMINUM

FLAT BLACK

28

LOWER HOSE

ALUMINUM

16

SHOCK ASSEMBLY

LIGHT GRAY

(PAINT SHADED ALUMINUM)

5

REMOVE

0

0

60

0

R

E

M

O

V

E

0

0

6

0

0

R

E

M

O

V

E

0 0600

A

BODY

GLOSS WHITE

FINAL ASSEMBLY

2

HOOD

GLOSS WHITE

B

REAR WINDOW

114

REAR SIDE

WINDOW

CLEAR

✱

115

SIDE WINDOW

CLEAR

111

CLEAR

✱

✱

✱

✱

NOTE: PAINT ALL WINDOW TRIM

113

REAR SIDE

WINDOW

CLEAR

✱

✱

SEMIGLOSS BLACK

✱

110

WINDSHIELD

CLEAR

112

VENT DUCT

CLEAR

✱

C

76

OUTER WHEEL

(BACK)

GLOSS BLACK

26

OUTER WHEEL

(FRONT)

GLOSS BLACK

TIRE

D

95

DISC BRAKE

ALUMINUM

24

INNER WHEEL

(FRONT)

FLAT BLACK

12

INNER WHEEL

(BACK)

FLAT BLACK

6

APPLY A-P IN ORDER FIRST!

DECALS 1, 2, 3, AND 4 ARE

FOR INTERIOR USE ONLY

DECAL PLACEMENT

85284300200

Loading...

Loading...