Respironics Millennium H600, Millennium H605, Millennium M10600, Millennium M10605, Millennium Enhanced M600 Service And Technical Reference Manual

...Page 1

Millennium

TM

Oxygen Concentrators

Service & Technical Information

Page 2

© 2007, Respironics, Inc. and affiliates. All rights reserved.

COPYRIGHT & WARRANTY - PAGE 11041826, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 3

LIMITED WARRANTY

Respironics, Inc. warrants that the system shall be free from defects of workmanship and materials and will

perform in accordance with the product specifications for a period of three (3) years from the date of sale by

Respironics, Inc. to the dealer. Respironics accessories are warranted to be free of defects in materials and

workmanship for a period of 90 days from the time of purchase. If the product fails to perform in accordance

with the product specifications, Respironics, Inc. will repair or replace – at its option – the defective material or

part. Respironics, Inc. will pay customary freight charges from Respironics, Inc. to the dealer location only. This

warranty does not cover damage caused by accident, misuse, abuse, alteration, and other defects not related

to material or workmanship.

Respironics, Inc. disclaims all liability for economic loss, loss of profits, overhead, or consequential damages

which may be claimed to arise from any sale or use of this product. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty is given in lieu of all other express or implied warranties, including the implied warranties of

merchantability and fitness for a particular purpose. In addition, in no event shall Respironics be liable for lost

profits, loss of good will, or incidential or consequential damages, even if Respironics has been advised of the

possibility of the same. Some states or provinces do not allow the exclusion of limitation of implied warranties

or the disclaimer of incidental and consequential damages. Accordingly, the laws of your state or province may

give you additional protections.

To exercise your rights under this warranty, contact your local authorized Respironics, Inc. dealer or contact

Respironics, Inc. at:

Visit Respironics Home Page on the World Wide Web at:

www.respironics.com

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1001 Murry Ridge Lane

Murrysville, PA 15668 USA

1041826, REV. 00PAGE 2 - COPYRIGHT & WARRANTY

Page 4

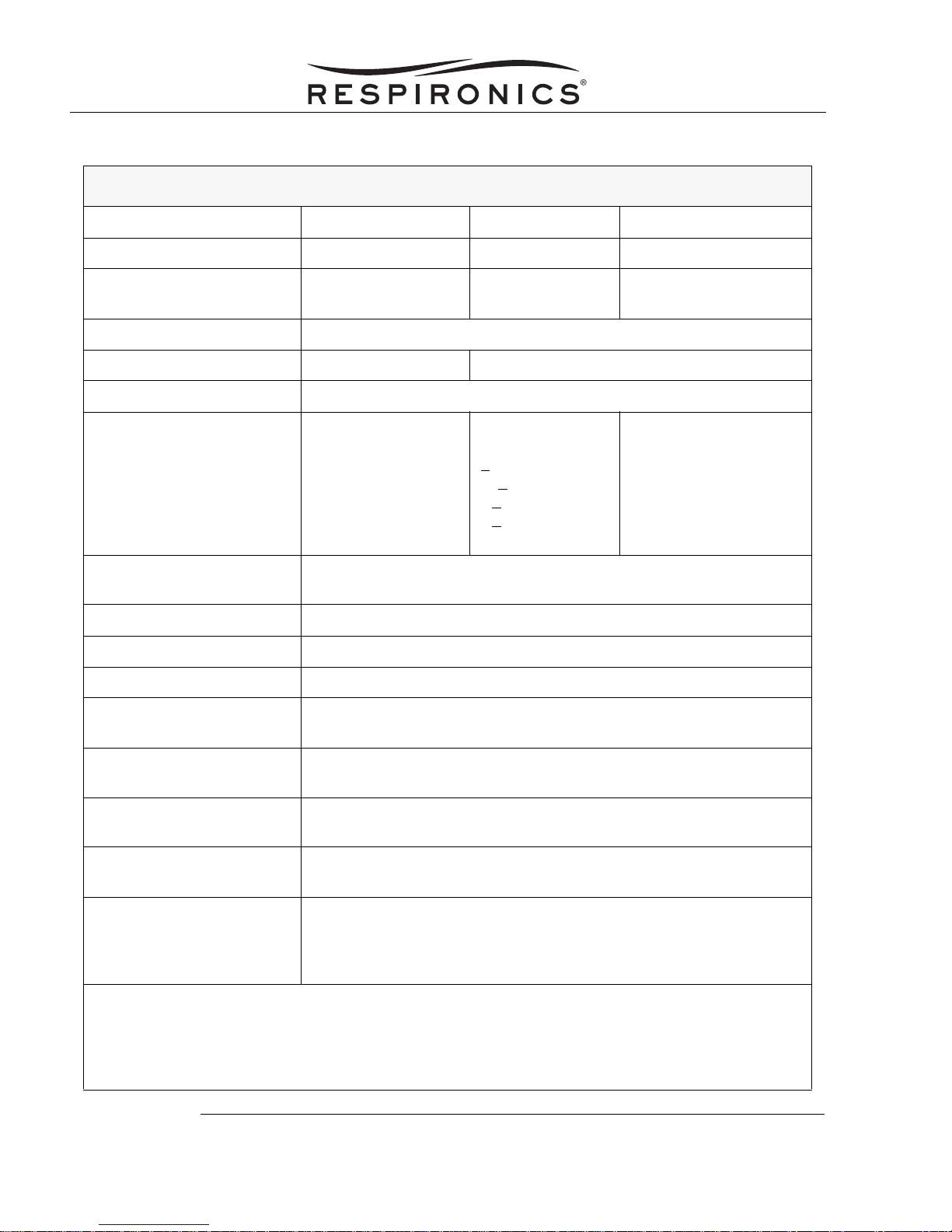

REVISION HISTORY

SECTION NAME (NO.) REV. # DATE DESCRIPTION

Copyright & Warranty (1041826) 00 5/5/2007 Initial Revision

Revision History (1041845) 01 5/5/2007 Initial Revision

Table of Contents (1041909) 00 5/5/2007 Initial Revision

Introduction (1041846) 00 5/5/2007 Initial Revision

Warnings & Cautions (1041847) 00 5/5/2007 Initial Revision

Specifications & Features (1041848) 00 5/5/2007 Initial Revision

System Setup (1041812) 00 5/5/2007 Initial Revision

Theory of Operation (1041905) 00 5/5/2007 Initial Revision

Maintenance (1041813) 00 5/5/2007 Initial Revision

Troubleshooting (1041814) 00 5/5/2007 Initial Revision

H600/605 Repair & Replacement (1041895) 00 5/5/2007 Initial Revision

M600/605 Repair & Replacement (1041896) 00 5/5/2007 Initial Revision

M10600/M10605 Repair & Replacement (1041898) 01 5/5/2007 Initial Revision

Enhanced M600/M605/M10600/M10605 Repair &

Replacement (1041897)

Repair Kits (1041901) 00 5/5/2007 Initial Revision

H600/605/M600/605/Enhanced M600/605 Testing

(1041903)

M10600/M10605/Enhanced M10600/M10605

Testing (1041900)

Tools & Equipment (1041902) 00 5/5/2007 Initial Revision

Schematics (1041904) 00 5/5/2007 Initial Revision

00 5/5/2007 Initial Revision

00 5/5/2007 Initial Revision

00 5/5/2007 Initial Revision

REVISION HISTORY - PAGE 11041845, REV. 01

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 5

This page intentionally blank.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041845, REV. 01PAGE 2 - REVISION HISTORY

Page 6

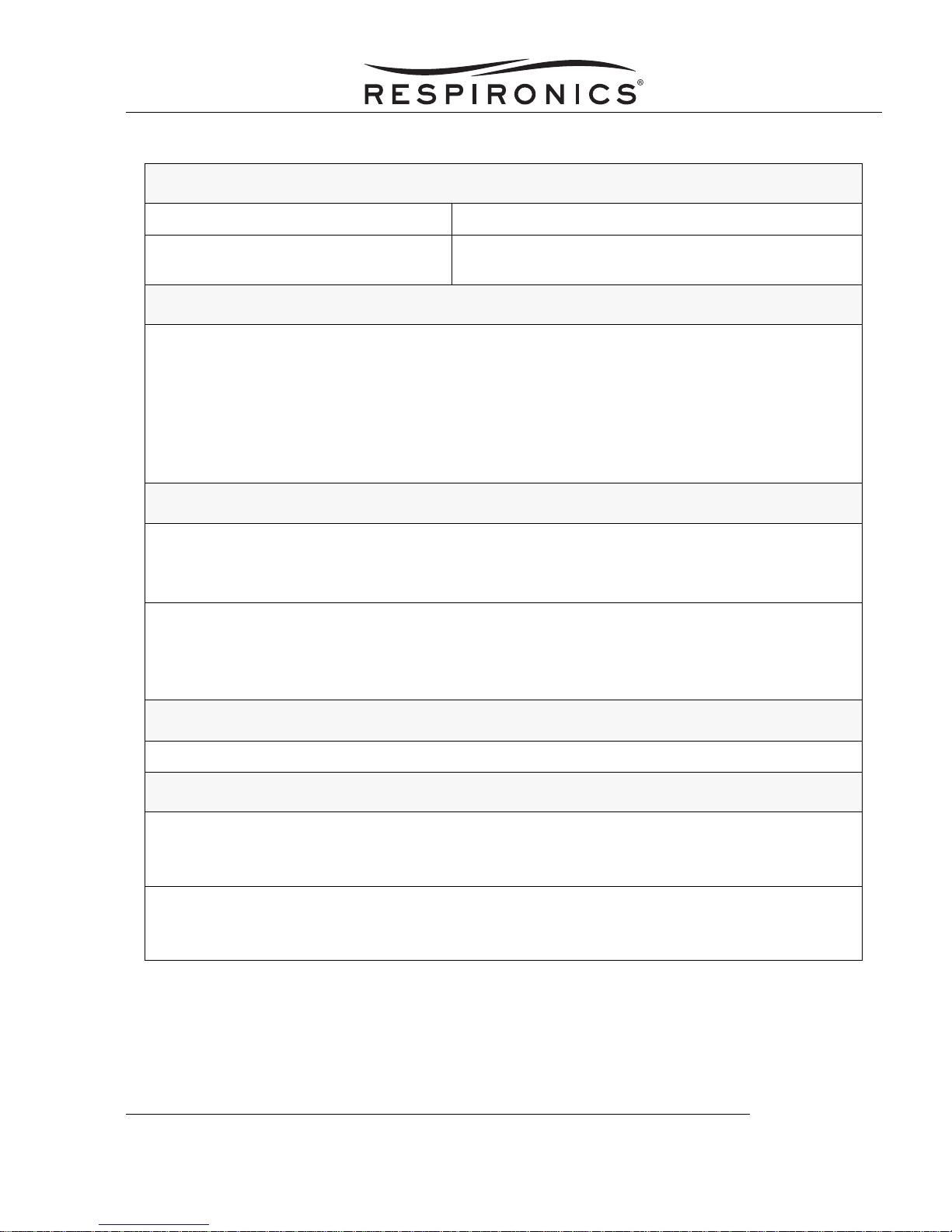

INTRODUCTION

MILLENNIUM OXYGEN CONCENTRATOR OVERVIEW....................................................................1

TYPES OF CONCENTRATORS ....................................................................................................1

SERVICE NOTICE......................................................................................................................2

SERVICE TRAINING...................................................................................................................2

SERVICE/TECHNICAL SUPPORT STATEMENT..............................................................................2

WARNINGS & CAUTIONS

SECTION OVERVIEW.................................................................................................................1

WARNINGS...............................................................................................................................1

CAUTIONS................................................................................................................................2

SPECIFICATIONS & FEATURES

SECTION OVERVIEW.................................................................................................................1

H600/605, M600/605, & ENHANCED M600/605 SPECIFICATIONS ............................................2

M10600/M10605 & ENHANCED M10600/M10605 SPECIFICATIONS ........................................4

FRONT CABINET FEATURES......................................................................................................6

REAR AND SIDE CABINET FEATURES........................................................................................6

CONTROL PANEL FEATURES ....................................................................................................7

SYSTEM SETUP

SECTION OVERVIEW.................................................................................................................1

SYSTEM SETUP........................................................................................................................1

THEORY OF OPERATION

SECTION OVERVIEW.................................................................................................................1

H600/605; M600/605; E

H600/605; M600/605; E

M10600/M10605; ENHANCED M10600/M10605 CONCENTRATOR PNEUMATIC OPERATION ......3

M10600/M10605; ENHANCED M10600/M10605 ELECTRICAL OPERATION...............................4

NHANCED M600/605 CONCENTRATOR PNEUMATIC OPERATION ........1

NHANCED M600/605 CONCENTRATOR ELECTRICAL OPERATION .........2

MAINTENANCE

MAINTENANCE INTERVALS........................................................................................................1

TROUBLESHOOTING

SECTION OVERVIEW.................................................................................................................1

PAGE 1 - TABLE OF CONTENTS1041909, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 7

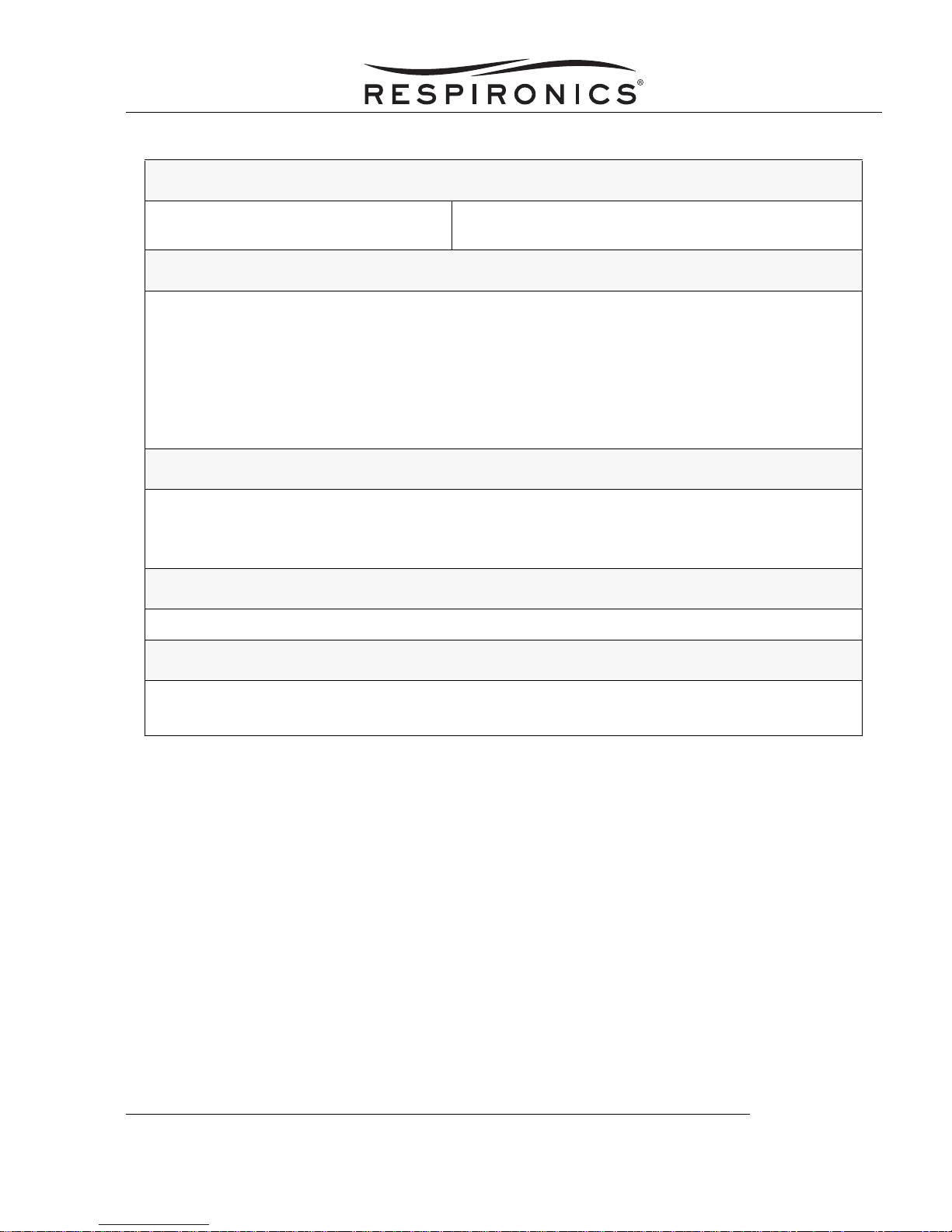

H600/605 CONCENTRATOR REPAIR & REPLACEMENT

SECTION OVERVIEW.................................................................................................................1

OVERLAY REPLACEMENT .........................................................................................................2

CASTER REPLACEMENT ...........................................................................................................3

BASE CABINET PAN REPLACEMENT .........................................................................................4

REAR CABINET REPLACEMENT.................................................................................................6

FLOW METER REPLACEMENT ...................................................................................................8

DISS OUTLET FITTING REPLACEMENT ...................................................................................11

POWER SWITCH REPLACEMENT .............................................................................................13

MAIN PCB FUSE REPLACEMENT ............................................................................................15

MAIN PCB REPLACEMENT .....................................................................................................16

OPI WIRING HARNESS REPLACEMENT (MODEL H605 ONLY) ..................................................18

OPI BOARD REPLACEMENT (MODEL H605 ONLY)..................................................................19

POWER SWITCH WIRING HARNESS REPLACEMENT .................................................................21

O2/SOLENOID/BATTERY WIRING HARNESS.............................................................................24

FRONT CABINET REPLACEMENT .............................................................................................27

COOLING FAN REPLACEMENT ................................................................................................29

PERFORATED CANOPY REPLACEMENT ...................................................................................31

COMPRESSOR COVER REPLACEMENT.....................................................................................32

MAIN POWER WIRING HARNESS REPLACEMENT .....................................................................33

MOTOR START/RUN CAPACITOR ............................................................................................36

PRESSURE RELIEF VALVE REPLACEMENT ..............................................................................37

COMPRESSOR ASSEMBLY REPLACEMENT...............................................................................38

IN-LINE MUFFLER REPLACEMENT ...........................................................................................41

HOUR METER REPLACEMENT .................................................................................................43

VALVE/SOLENOID REPLACEMENT ...........................................................................................45

PRESSURE REGULATOR REPLACEMENT..................................................................................47

SIEVE CANISTER ASSEMBLY REPLACEMENT...........................................................................48

BLOW DOWN MUFFLER REPLACEMENT ..................................................................................50

OWER CORD REPLACEMENT ................................................................................................52

P

M600/M605 CONCENTRATOR REPAIR & REPLACEMENT

SECTION OVERVIEW.................................................................................................................1

O

VERLAY REPLACEMENT .........................................................................................................2

ASTER REPLACEMENT ...........................................................................................................3

C

BASE CABINET PAN REPLACEMENT .........................................................................................4

R

EAR CABINET REPLACEMENT.................................................................................................5

LOW METER REPLACEMENT ...................................................................................................7

F

DISS O

POWER SWITCH REPLACEMENT ...............................................................................................9

AIN PCB FUSE REPLACEMENT ............................................................................................11

M

M

AIN PCB REPLACEMENT .....................................................................................................12

OPI W

OPI BOARD REPLACEMENT (MODEL M605 ONLY) .................................................................15

UTLET FITTING REPLACEMENT .....................................................................................8

IRING HARNESS REPLACEMENT (MODEL M605 ONLY) .................................................14

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041909, REV. 00PAGE 2 - TABLE OF CONTENTS

Page 8

POWER SWITCH WIRING HARNESS REPLACEMENT..................................................................17

O2/SOLENOID/BATTERY WIRING HARNESS.............................................................................20

FRONT CABINET REPLACEMENT .............................................................................................23

COOLING FAN REPLACEMENT ................................................................................................25

PERFORATED CANOPY REPLACEMENT....................................................................................27

COMPRESSOR COVER REPLACEMENT.....................................................................................28

MAIN POWER WIRING HARNESS REPLACEMENT......................................................................29

MOTOR START/RUN CAPACITOR ............................................................................................31

COMPRESSOR ASSEMBLY REPLACEMENT ...............................................................................32

IN-LINE MUFFLER REPLACEMENT............................................................................................34

HOUR METER REPLACEMENT .................................................................................................36

VALVE/SOLENOID REPLACEMENT ...........................................................................................37

PRESSURE REGULATOR REPLACEMENT..................................................................................39

SIEVE CANISTER ASSEMBLY REPLACEMENT ...........................................................................40

BLOW DOWN MUFFLER REPLACEMENT ..................................................................................42

POWER CORD REPLACEMENT ................................................................................................44

M10600/M10605 CONCENTRATOR REPAIR & REPLACEMENT

SECTION OVERVIEW.................................................................................................................1

OVERLAY REPLACEMENT .........................................................................................................2

CASTER REPLACEMENT ...........................................................................................................3

BASE CABINET PAN REPLACEMENT .........................................................................................4

REAR CABINET REPLACEMENT.................................................................................................5

FLOW METER REPLACEMENT ...................................................................................................7

DISS OUTLET FITTING REPLACEMENT......................................................................................9

POWER SWITCH REPLACEMENT..............................................................................................11

MAIN PCB FUSE REPLACEMENT ............................................................................................14

MAIN PCB REPLACEMENT .....................................................................................................15

OPI W

OPI B

P

O2/SOLENOID/BATTERY WIRING HARNESS.............................................................................23

FRONT CABINET REPLACEMENT .............................................................................................25

C

P

COMPRESSOR COVER REPLACEMENT.....................................................................................28

M

C

COMPRESSOR ASSEMBLY REPLACEMENT ...............................................................................32

I

N-LINE MUFFLER REPLACEMENT............................................................................................34

H

V

P

SIEVE CANISTER ASSEMBLY REPLACEMENT ...........................................................................40

IRING HARNESS REPLACEMENT (MODEL M10605 ONLY)..............................................17

OARD REPLACEMENT (MODEL M10605 ONLY)..............................................................18

OWER SWITCH WIRING HARNESS REPLACEMENT..................................................................20

OOLING FAN REPLACEMENT ................................................................................................26

ERFORATED CANOPY REPLACEMENT....................................................................................27

AIN POWER WIRING HARNESS REPLACEMENT......................................................................29

APACITOR REPLACEMENT ....................................................................................................31

OUR METER REPLACEMENT .................................................................................................36

ALVE/SOLENOID REPLACEMENT ...........................................................................................38

RESSURE REGULATOR REPLACEMENT..................................................................................39

PAGE 3 - TABLE OF CONTENTS1041909, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 9

BLOW DOWN MUFFLER REPLACEMENT ..................................................................................41

POWER CORD REPLACEMENT ................................................................................................42

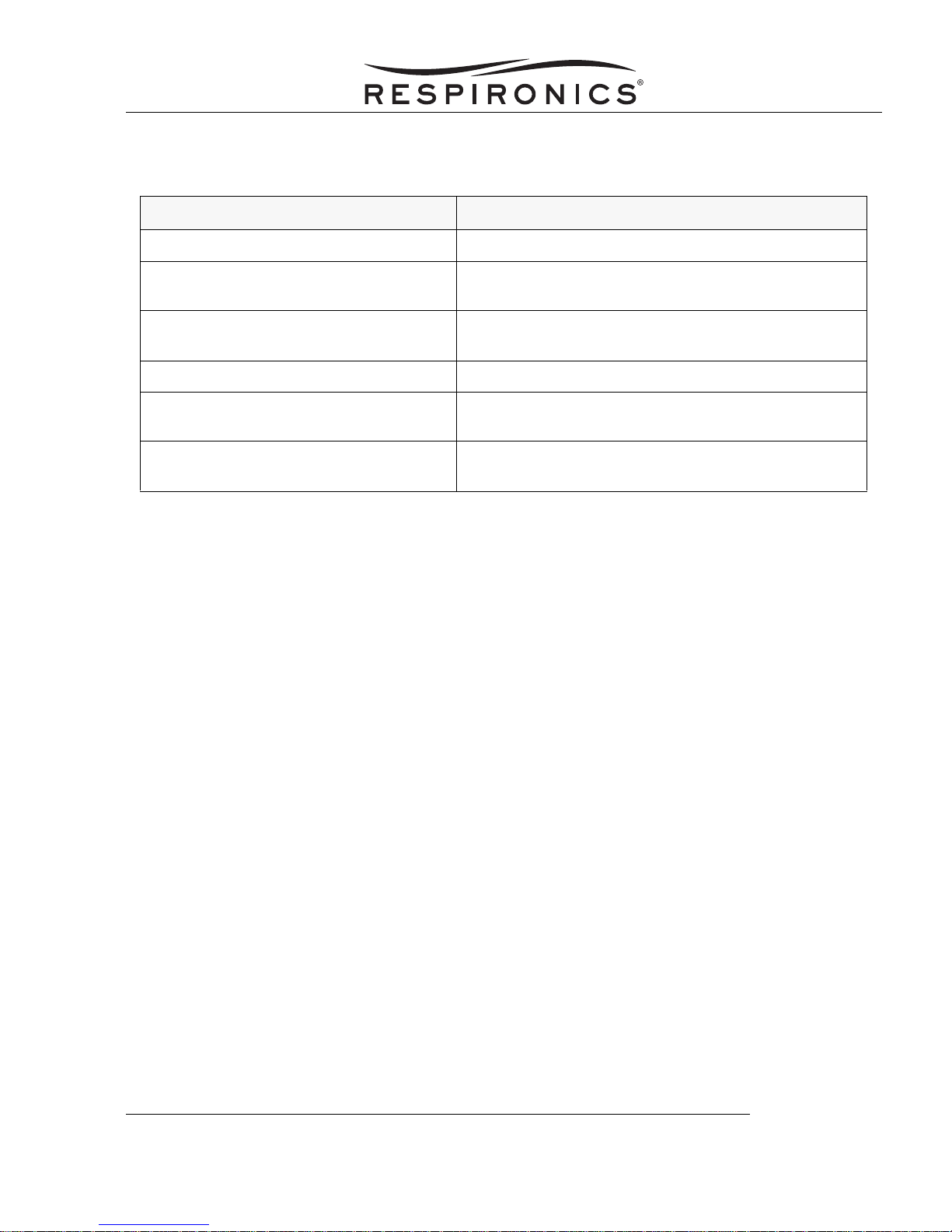

ENHANCED M600/M605; ENHANCED M10600/M10605 CONCENTRATOR REPAIR &

REPLACEMENT

SECTION OVERVIEW.................................................................................................................1

OVERLAY REPLACEMENT .........................................................................................................2

CASTER REPLACEMENT ...........................................................................................................3

BASE CABINET PAN REPLACEMENT .........................................................................................4

REAR CABINET REPLACEMENT.................................................................................................5

FLOW METER REPLACEMENT ...................................................................................................7

DISS OUTLET FITTING REPLACEMENT .....................................................................................9

POWER SWITCH REPLACEMENT .............................................................................................10

MAIN PCB TO POWER SWITCH WIRING REPLACEMENT ........................................................11

MAIN PCB TO BATTERY WIRING REPLACEMENT.....................................................................12

MAIN PCB FUSE REPLACEMENT ............................................................................................13

MAIN PCB REPLACEMENT .....................................................................................................14

OPI PCB REPLACEMENT (MODEL 605 ONLY)........................................................................17

OPI WIRING HARNESS REPLACEMENT (MODEL 605 ONLY) ....................................................19

FRONT CABINET REPLACEMENT .............................................................................................20

COOLING FAN REPLACEMENT ................................................................................................22

MAIN PCB TO COOLING FAN WIRING REPLACEMENT .............................................................23

PERFORATED CANOPY REPLACEMENT ...................................................................................24

COMPRESSOR COVER REPLACEMENT.....................................................................................25

MOTOR START/RUN CAPACITOR REPLACEMENT.....................................................................27

COMPRESSOR ASSEMBLY REPLACEMENT...............................................................................28

MAIN PCB TO COMPRESSOR WIRING REPLACEMENT .............................................................31

THERMAL PROTECTION SWITCH REPLACEMENT ......................................................................33

N-LINE MUFFLER REPLACEMENT ...........................................................................................34

I

H

OUR METER REPLACEMENT .................................................................................................36

ALVE/SOLENOID REPLACEMENT ...........................................................................................38

V

PRESSURE REGULATOR REPLACEMENT..................................................................................41

SIEVE CANISTER ASSEMBLY REPLACEMENT...........................................................................43

B

LOW DOWN MUFFLER REPLACEMENT ..................................................................................45

OWER CORD REPLACEMENT ................................................................................................47

P

BASE CABINET REPLACEMENT...............................................................................................48

REPAIR KITS

SECTION OVERVIEW.................................................................................................................1

Q

UICK REFERENCE TABLE.......................................................................................................2

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041909, REV. 00PAGE 4 - TABLE OF CONTENTS

Page 10

H600/605; M600/605; ENHANCED M600/605 TESTING

SYSTEM VERIFICATION PROCEDURES .......................................................................................1

MILLENNIUM SYSTEM FINAL TEST.............................................................................................6

MODEL 605 TEST DATA SHEET................................................................................................8

MODEL 600 TEST DATA SHEET................................................................................................9

M10600/M10605 & ENHANCED M10600/M10605 TESTING

SYSTEM VERIFICATION PROCEDURES .......................................................................................1

MILLENNIUM SYSTEM FINAL TEST.............................................................................................5

MODEL M10605 TEST DATA SHEET.........................................................................................7

MODEL M10600 TEST DATA SHEET.........................................................................................8

TOOLS & TEST EQUIPMENT

SERVICE TOOLS & SUPPLIES ...................................................................................................1

ACCEPTABLE TEST EQUIPMENT................................................................................................2

SCHEMATICS

SCHEMATICS STATEMENT.........................................................................................................1

PAGE 5 - TABLE OF CONTENTS1041909, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 11

This page intentionally left blank.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041909, REV. 00PAGE 6 - TABLE OF CONTENTS

Page 12

INTRODUCTION

This section provides an introduction to the Millennium Oxygen Concentrator devices as well as contact and

service training information.

CAUTION

U.S. federal law restricts this device to sale by or on the order of a physician.

MILLENNIUM OXYGEN CONCENTRATOR OVERVIEW

The Millennium Oxygen Concentrator is intended to provide supplemental oxygen to persons requiring low flow

oxygen therapy. This device is not intended to be life supporting nor life sustaining. The Millennium Oxygen

Concentrator produces concentrated oxygen from room air for delivery to a patient. The oxygen from the air is

concentrated using a molecular sieve and a pressure swing adsorption process.

TYPES OF CONCENTRATORS

MILLENNIUM H600/H605 CONCENTRATORS

The Millennium H600/605 Concentrators are equipped with a green cabinet and a fluted Base Cabinet.

MILLENNIUM M600/M605/M10600/M10605 CONCENTRATORS

The Millennium M600/M605/M10600/M10605 Concentrators comes equipped with a grey cabinet, a black

Base Cabinet, and the Hour Meter is located in the Base Cabinet.

MILLENNIUM ENHANCED M600/M605/M10600/M10605 CONCENTRATORS

The Millennium Enhanced M600/M605/M10600/M10605 Concentrators comes equipped with a grey cabinet, a

black Base Cabinet, and the Hour Meter is located on the front panel of the Front Cabinet.

Enhanced

H600/H605 Concentrator

M600/M605

M10600/M10605

Concentrator

M600/M605

M10600/M10605

Concentrator

INTRODUCTION - PAGE 11041846, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 13

SERVICE NOTICE

The Millennium is designed so that trained Service Technicians can perform repair and testing procedures. The

information provided in this manual will allow service technicians to perform the service and maintenance

required on the Millennium. The individual(s) using this manual should have prior training or experience

servicing oxygen concentrators.

SERVICE TRAINING

Respironics offers service training for the Millennium Concentrators. Training includes complete disassembly

of the device, troubleshooting subassemblies and components, and performance testing. For more

information, contact the Service Marketing department at:

E-mail: service.operations@respironics.com

Phone: (724) 755-8220

Fax: (724) 755-8230

SERVICE/TECHNICAL SUPPORT STATEMENT

For technical assistance, please contact Respironics Customer Service.

U.S.A. and Canada

Phone:1-800-345-6443

Fax: 1-800-886-0245

International

Phone: 1-724-387-4000

Fax: 1-724-387-5012

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041846, REV. 00PAGE 2 - INTRODUCTION

Page 14

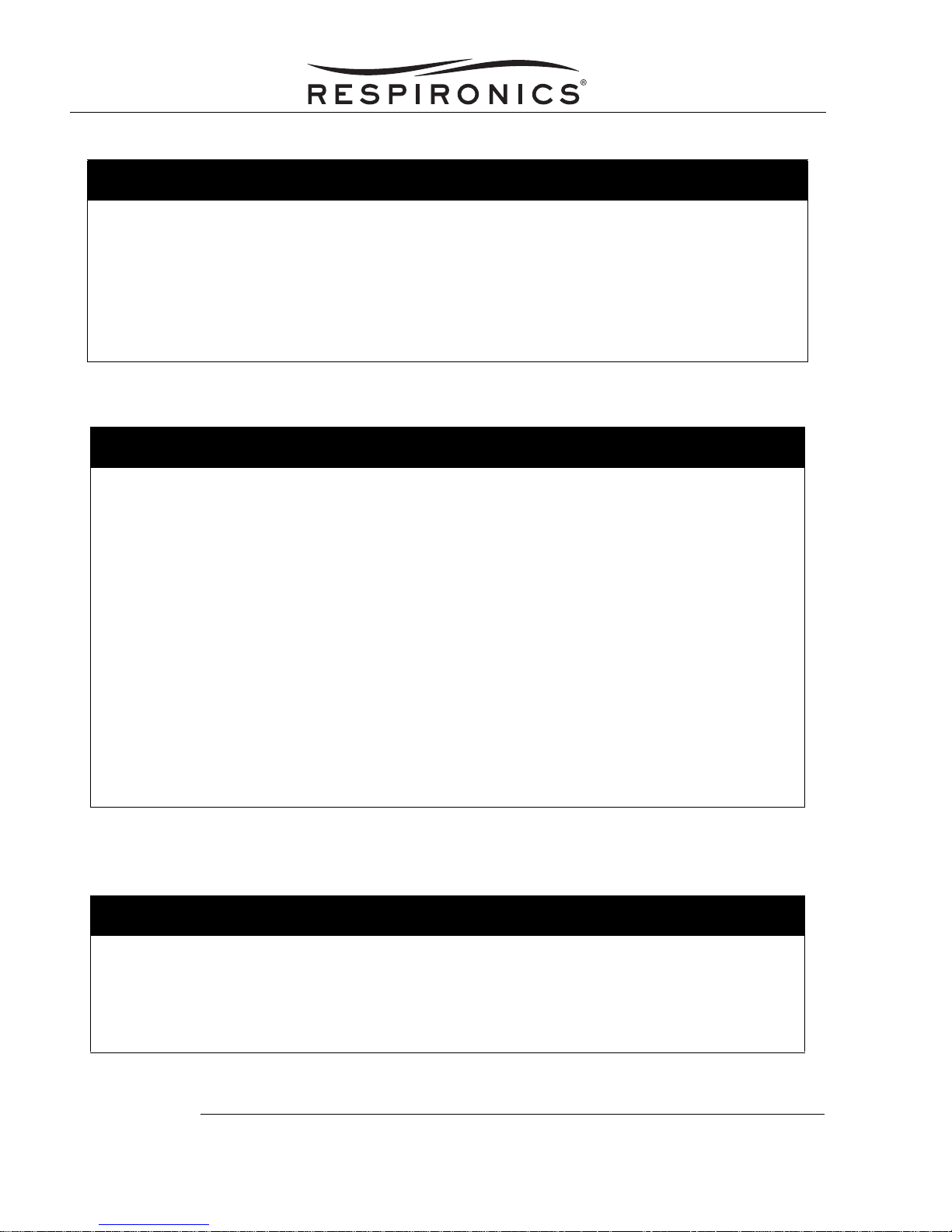

WARNINGS & CAUTIONS

SECTION OVERVIEW

Warnings and Cautions, are used throughout this manual to identify possible safety hazards, conditions that

may result in equipment or property damage, and important information that must be considered when

performing service and testing procedures on the Millennium Oxygen Concentrators.

Please read this section carefully before servicing the Millennium Oxygen Concentrators.

WARNING

Warnings indicate the possibility of injury to the patient, operator, or technician.

CAUTION

Cautions indicate the possibility of damage to the device

NOTE

Notes are used to emphasize a characteristic or important consideration.

WARNINGS

WARNINGS

• Oxygen generated by this concentrator is supplemental and should not be considered life

supporting or life sustaining. In certain circumstances, oxygen therapy can be hazardous; any

user should seek medical advice prior to using this device.

• Where the prescribing physician has determined that an interruption in the supply of oxygen, for

any reason, may have serious consequences to the user, an alternate source of oxygen should

be available for immediate use.

• Keep the unit away from heat and/or open flame as oxygen greatly accelerates combustion.

• Do not smoke when the concentrator is operating or patient is using the oxygen.

• Do not use greases, oils, or any petroleum based solvent or cleaner on or near the unit.

• Use extreme caution when handling the Compressor Capacitor as it holds an electrical charge

until it is properly discharged.

• Avoid handling the molecular sieve material. Respironics recommends the return of the Sieve

Canister Assembly to Respironics for any service that involves sieve disposal.

• Never modify the Power Cord or use adapters, extension cords, etc. The unit is double insulated

and uses a 2-prong not a 3-prong Power Cord. Any modification to the Power Cord could alter

the safety feature.

WARNINGS & CAUTIONS - PAGE 11041847, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 15

WARNINGS (CONT’D)

• A physician must prescribe use of a humidifier with the Millennium. Use of only bubble type

humidifiers is recommended and connections must be secure and free of leaks.

• If the Millennium Oxygen Concentrator has been subjected to hot or cold temperatures for an

extended period of time, it should be allowed to warm up to the stated operating temperatures

before power up. Failure to do so could result in improper performance and or alarm conditions

until the unit reaches normal operating temperatures.

• Do not turn on the unit while any filter is wet or moist.

CAUTIONS

CAUTIONS

• U.S. federal law restricts this device to sale by or on the order of a physician.

• Place the unit where cooling airflow is unrestricted. Be sure to inform the user not to position the

unit close to drapery or curtains that might restrict the airflow.

• When using a liquid leak detector, be careful not to allow it to contact electrical parts.

• Make sure connections of fittings, tubing, and hoses are secure.

• Be cautious when using thread sealants because they can cause extensive damage to the

internal parts of the unit if allowed within tubing or fittings.

• Device operation above or outside of the Voltage, LPM, Temperature, Humidity and /or Altitude

values specified in the manual may decrease oxygen concentration levels.

• Clean all exterior cabinet surfaces periodically by wiping with a damp cloth, using a mild detergent

and/or hospital disinfectant.

• If the 25-foot tubing, connector, and high flow cannula supplied with the Millennium M10 Oxygen

Concentrator are not used, 10 LPM of oxygen flow may not be achieved.

• Use only Respironics or factory-authorized replacement parts and accessories.

NOTES

• Make sure the Flow Meter is set at the patient’s prescribed flow rate once patient circuitry is

attached.

• Make sure there are no kinks in the user’s oxygen tubing. If necessary, use a non-kink style

delivery tube (unit will go into an audible and visual alarm if the tubing is kinked or the flowmeter is

turned completely off).

MILLENNIUM SERVICE & TECHNICAL INFORMATION

NOTES

1041847, REV. 00PAGE 2 - WARNINGS & CAUTIONS

Page 16

SPECIFICATIONS & FEATURES

SECTION OVERVIEW

This section identifies the specifications and features of the Millennium Oxygen Concentrator.

SPECIFICATIONS & FEATURES - PAGE 11041848, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 17

H600/605, M600/605, & ENHANCED M600/605 SPECIFICATIONS

SPECIFICATIONS

Input Voltage 120 VAC 230 VAC 230VAC

Input Frequency 60 Hz 50 Hz 50 Hz

Average Power

Consumption

Dimensions 18.9”(L) × 13.3” (W) × 26.8” (H) (48.0 x 33.78 x 68.07 cm)

Weight 50 lbs, 22.7 kg 54 lbs, 24.7 kg

Flow Rate Variable from 0.5 to 5 lpm

Oxygen Concentration* H600/605

Enhanced M600/605

Oxygen Outlet Pressure (No

Flow)

Regulated Pressure @ 5 lpm 5.5 ± 0.25 psig

Operating Pressure 70-186 kPa

Operating Temperature 55-90° F (13-32° C)

Storage/transport

Temperature

460W 420/480W 360W

M600/605

Concentrator

92 ± 4% @ 5 lpm

94 ± 2% @ 2 lpm

H600/H605

Concentrator

>

92 @ .5 to 3 lpm

>

87 @ 4 lpm

>

89 @ 4 lpm**

>

87 @ 5 lpm**

6.0 ± 1.0 psig

-30-160° F (-34-71° C)

M600/605; Enhanced

M600/605 Concentrator

94 ± 2% @ 0.5 to 4 lpm

M605-70; Enhanced

M605-70 Concentrator

94 ± 4% @ 5 lpm

88 ± 4% @ 5 lpm

Storage/transport Humidity

Operating Humidity

Storage/Transport

Atmospheric Pressure

Altitude Up to 7,545 ft.

Sound Pressure Level (dBA) H600/605; M600/605; Enhanced M600/605 120V: 60Hz-49.8 dBA

M600/605; Enhanced M600/605 230V (except M605-70): <43dBA

M600/605; Enhanced M605-70: <40dBA

H600/605 230V <42dBA

* Oxygen concentration levels are for operation within specified temperatures and altitude ranges.

Operation outside specified ranges may decrease oxygen concentration levels.

** Specifications achieved only at the following operating parameters: 20 ° C (68 ° F), 50% relative

humidity, and 1017 mbar.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Up to 95% non-condensing

790-525 mm Hg

Up to 2300 m

1041848, REV. 00PAGE 2 - SPECIFICATIONS & FEATURES

Page 18

SAFETY

Pressure Relief Valve 40 ± 3 psig (303 ± 20.7 kPa)

Compressor Compartment Thermal

Protection with Self Reset

149° F (65° C)

ALARM CONDITIONS

Visual Red Light Emitting Diode (LED) and audible sound alert:

• Start-up test;

• Power failure;

• Main PCB failure; and

• High and low pressure

Oxygen percentage indicator (Model 605 only): O

< 70%

2

ALERT CONDITIONS

H600/605 Concentrators have a yellow visual LED with intermittent audible alarm and red LED:

• No oxygen flow

Oxygen percentage indicator (model 605): 70% < O

M600/605; Enhanced M600/605 Concentrators have a yellow LED with intermittent audible alarm and

red LED:

< 85%

2

• No oxygen flow

Oxygen percentage indicator (model 605): 70% < O

< 82%

2

POWER INDICATION

Visual, green LED (next to Power Switch).

OXYGEN PERCENTAGE INDICATOR (MODEL 605)

H605 Concentrators

Warnings Conditions: Blinking yellow LED after unit is turned on and until O

Normal Oxygen: Visual green LED when O

M605; Enhanced M605 Concentrators

Warnings Conditions: Blinking yellow LED after unit is turned on and until O

Normal Oxygen: Visual green LED when O

MILLENNIUM SERVICE & TECHNICAL INFORMATION

> 85%.

2

> 82%.

2

SPECIFICATIONS & FEATURES - PAGE 31041848, REV. 00

> 85%.

2

> 82%.

2

Page 19

M10600/M10605 & ENHANCED M10600/M10605 SPECIFICATIONS

SPECIFICATIONS

Input Voltage 120 VAC

Input Frequency 60 Hz

Average Power Consumption 600W

Dimensions 19”(L) × 13” (W) × 27” (H) (48.0 x 33.0 x 69.0 cm)

Weight 53 ± 0.5 lbs, (24 ± 0.23 kg)

Flow Rate Variable from 1 to 10 lpm

Oxygen Concentration* 92 ± 4% @ 8 - 10 lpm

94 ± 2% @ 3 - 7 lpm

92 ± 4% @ 1 - 2 lpm

Oxygen Outlet Pressure (No Flow) 6.0 ± 1.0 psig

Regulated Pressure @ 10 lpm 5.5 ± 0.25 psig

Operating Pressure 10 - 30 psig

Operating Temperature 55-90° F (15-32° C)

Storage/transport Temperature -30-160° F (-34-71° C)

Storage/Transport/Operating

Humidity

Storage/Transport Atmospheric

Pressure

Altitude Up to 1,368 ft.

Sound Pressure Level (dBA) <50 dBA

* Oxygen concentration levels are for operation within specified voltages, lpm,

temperatures and altitude ranges. Operation outside specified ranges may decrease

oxygen concentration levels.

Up to 95% non-condensing

790-525 mm Hg

Up to 417 m

Verify flow and purity at higher altitudes.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041848, REV. 00PAGE 4 - SPECIFICATIONS & FEATURES

Page 20

SAFETY

Compressor Compartment Thermal

Protection with Self Reset

149° F (65° C)

ALARM CONDITIONS

Visual Red LED and audible sound alert:

• Start-up test;

• Power failure;

• Main PCB failure; and

• High and low pressure

Oxygen percentage indicator (M10605): O

<70%)

2

ALERT CONDITIONS

Concentrators have a have a yellow visual LED with intermittent audible alarm and red LED:

• No oxygen flow

Oxygen percentage indicator (M10605): 70% <O

< 82%

2

POWER INDICATION

Visual, green LED (below to Power Switch).

OXYGEN PERCENTAGE INDICATOR (MODEL 605)

Warnings Conditions: Blinking yellow LED after unit is turned on and until O2 > 82%.

Normal Oxygen: Visual green LED when O

> 82%.

2

SPECIFICATIONS & FEATURES - PAGE 51041848, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 21

FRONT CABINET FEATURES

FLOW METER

Used to set and indicate amount of oxygen flowing from unit to patient. Adjustable from 0.5 to 5 or 10 lpm,

depending on the concentrator.

DISS OUTLET FITTING

A male DISS fitting used to connect the mating connector from the humidifier bottle or the patient’s cannula.

POWER SWITCH

Used to turn the device On and Off.

CONTROL OVERLAY

Indicates the red alarm light, the green ON light, and the Oxygen percentage (Model 605 and M10605 Only).

HOUR METER (ENHANCED M600/605; ENHANCED M10600/M10605 MODEL ONLY)

Indicates cumulative hours of unit operation.

REAR AND SIDE CABINET FEATURES

SERIAL PLATE

Lists model and serial numbers, requirements, and specifications.

HOUR METER (H600/605; M600/605; M10600/M10605)

Indicates cumulative hours of unit operation.

PRE-INLET FILTER

Filters the air that enters the concentrator.

REAR ACCESS DOOR

Allows access to the following:

• Inlet pre-filter, inlet filter configuration, Silencer, or

• Long Life Filter Configuration (Enhanced M10600/M10605), and

• Battery

POWER CORD

Used to connect concentrator to AC power receptacle.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041848, REV. 00PAGE 6 - SPECIFICATIONS & FEATURES

Page 22

CONTROL PANEL FEATURES

CONDITIONS CAUSE

AC Power Solid Green LED

Normal Oxygen Condition OPI units only (Model 605); solid green LED with no

alarm sound

Low Oxygen Alert Condition with Red LED Solid yellow LED with intermittent (every 2 seconds)

audible alarm

Alarm Condition Solid red LED and continuous audible

Start-up Test Light all LED’s and sound audible alarm for 2 seconds

after power on

Warm-up Condition OPI units only (Model 605); blinking yellow LED with no

alarm sound.

SPECIFICATIONS & FEATURES - PAGE 71041848, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 23

This page intentionally left blank.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041848, REV. 00PAGE 8 - SPECIFICATIONS & FEATURES

Page 24

SYSTEM SETUP

SECTION OVERVIEW

This section describes the procedures that should be performed prior to patient use and periodically to ensure

proper setup and operation.

SYSTEM SETUP

1. Remove the rear access door and verify that the proper filters are in place.

2. Ensure that filters are secure. Twist the filter while firmly pressing downwards.

3. Before connecting the unit to a power source, perform the following procedure to check battery

condition and alarm function.

a. Move the Power Switch to the ON (I) position. The alarm should sound and the red LED

should illuminate.

b. Move the Power Switch to the OFF (0) position. The alarm and the red LED light should go

off.

4. Connect the Power Cord to a power source.

5. Turn on the unit by moving the Power Switch to the ON (I) position and verify the following:

• all LED’s illuminate and audible alarm sounds for two seconds;

• the unit starts running; and

• the green power LED remains illuminated.

NOTE

If you have a Model 605, which is equipped with the oxygen percentage indicator (OPI), the yellow

LED light will blink until the oxygen purity is above 85% for H600/605 Concentrators and above

82% for M600/605; Enhanced M600/605 Concentrators. The green normal oxygen LED

illuminates, once appropriate O

6. Adjust the Flow Meter to max. 5 or 10 lpm depending on the concentrator. Turning the Flow Meter

clockwise decreases the flow, and turning it counter-clockwise increases the flow.

7. If the items above are working properly, proceed to step 8. If there is a problem refer to the Troubleshooting section.

8. Attach a calibrated Oxygen Analyzer to the DISS outlet fitting. The oxygen concentration should

be as specified in the Specifications section.

purity is achieved.

2

SYSTEM SETUP - PAGE 11041812, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 25

This page intentionally blank.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041812, REV. 00PAGE 2 - SYSTEM SETUP

Page 26

THEORY OF OPERATION

SECTION OVERVIEW

This section describes the theory of operation for the Millennium Oxygen Concentrators.

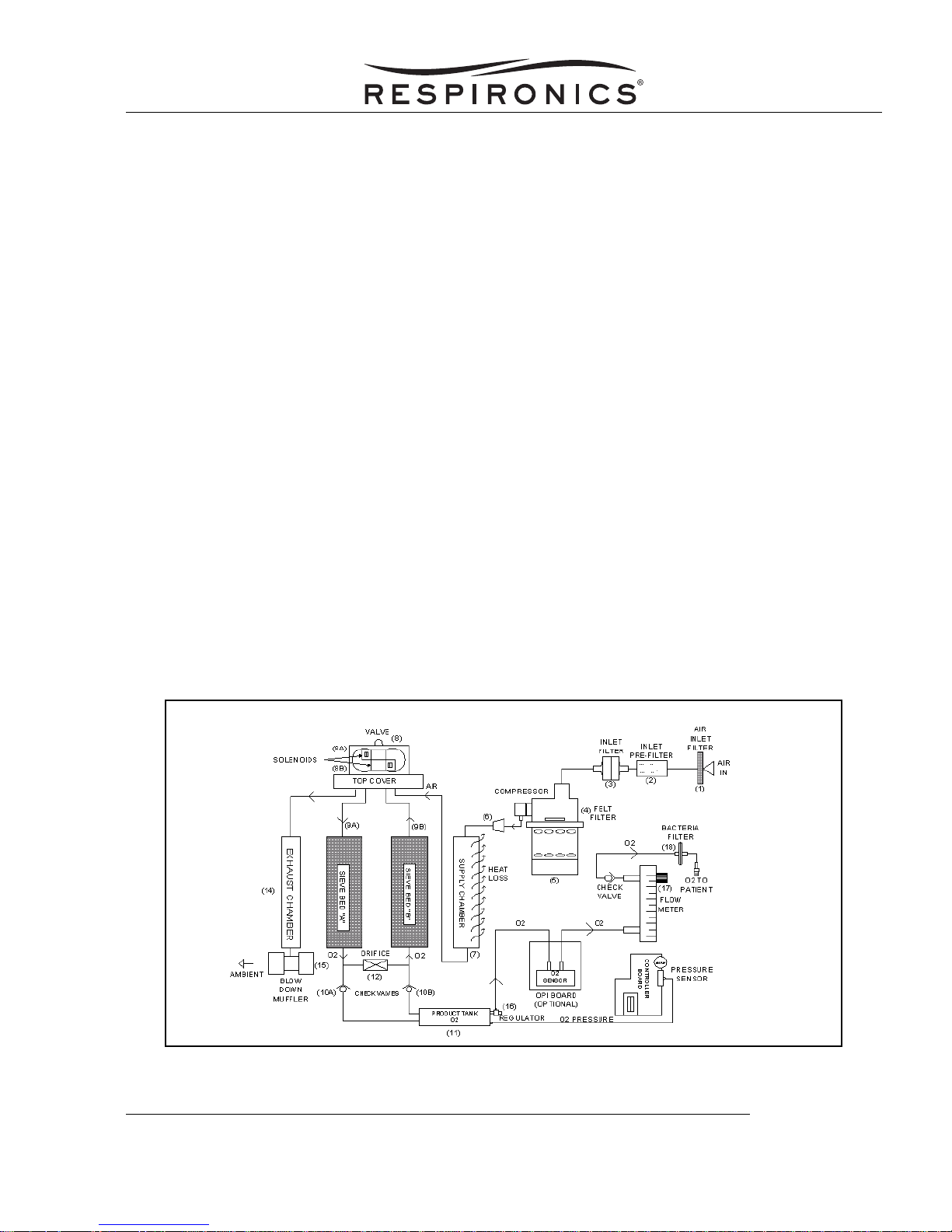

H600/605; M600/605; ENHANCED M600/605 CONCENTRATOR PNEUMATIC

PERATION

O

Room air enters through a foam air inlet filter (1) mounted on the side of the cabinet. The primary system air is

drawn through the inlet pre-filter, (2) the inlet filter (3) and then through the felt filter (4) by the Compressor (5).

The exhaust air then passes through the In-line Muffler (6) to the supply chamber.

The Compressor exhaust air is cooled by the supply chamber (7) and distributed using a pneumatic Valve/

Solenoid Assembly (8). At start up, valve (8) is de-energized allowing compressed air to flow into both Sieve

Canisters (9) until the pressure sensor builds up to switching pressure. At switching pressure, a 12 volt signal

is received at Valve/Solenoid(8a) closing the input and allowing compressed air to continue through sieve bed

(9a) for 6.25 seconds absorbing the Nitrogen and allowing the Oxygen to flow through check valve (10a) and

into the product tank (11).

At 5 liters of flow approximately 1/3 of the Oxygen is deposited into the product tank and 2/3 is passed through

orifice (12) in to sieve bed (9b) to purge the Nitrogen from the sieve bed, which exits through the exhaust port

of the Valve/Solenoid(8b) to exhaust chamber (14) through Blow Down Muffler (15) to outside air in a time of

6.25 seconds.

At the end of this cycle the unit will balance for 1 second which de-energizes valve / solenoid (8b) and allows

compressed air to flow into both Sieve Canisters. The pressure reaches the max switching pressure and sends

a 12 volt signal to valve / solenoid (8b) and the adsorption cycle starts over in the Sieve Canister (9b). Oxygen

is in a continuous flow from the product can (11) through the regulator (16) through the Flow Meter (17) to the

bacteria filter (18) to the patient.

F

IGURE A: H600/605; M600/605; ENHANCED M600/605 PNEUMATIC BLOCK DESIGN

THEORY OF OPERATION - PAGE 11041905, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 27

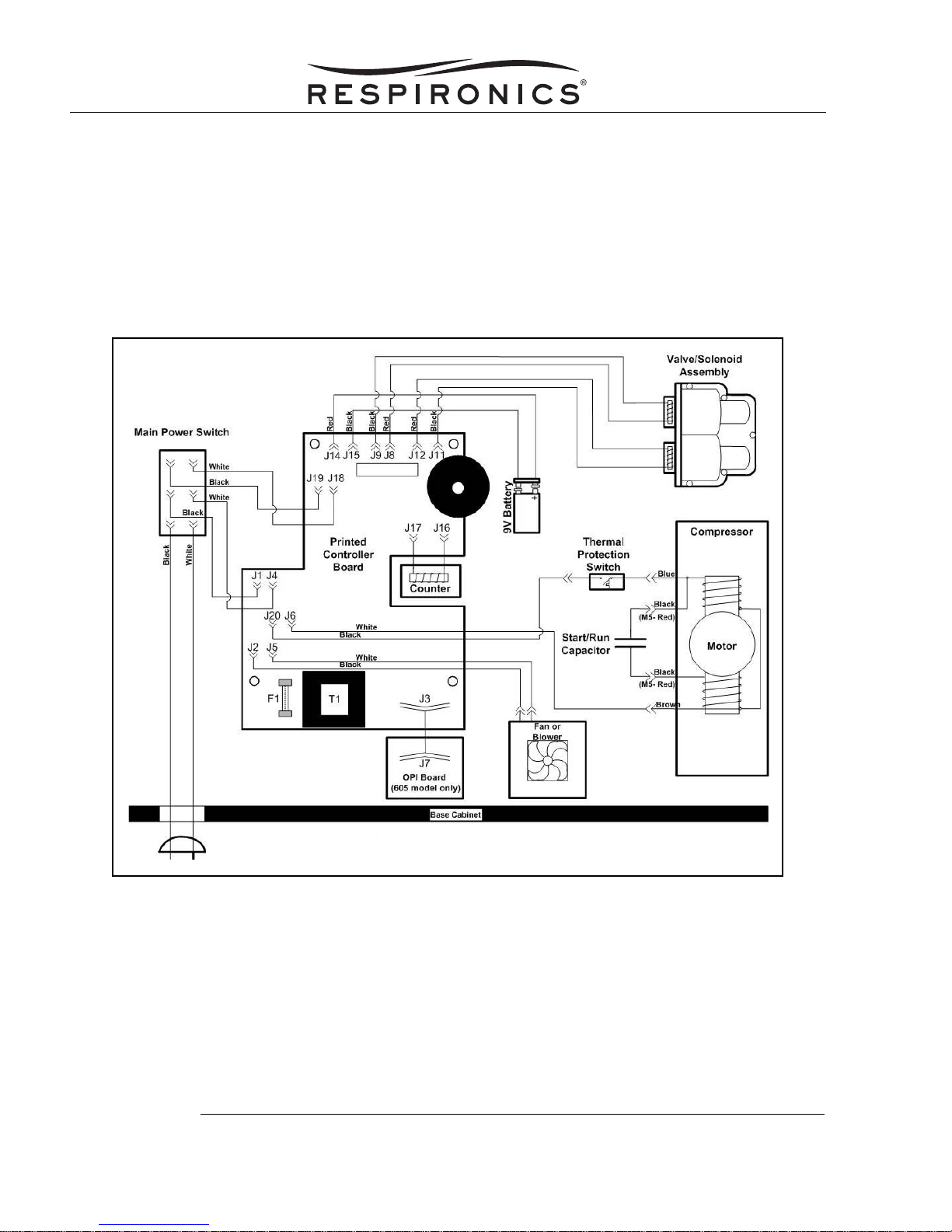

H600/605; M600/605; ENHANCED M600/605 CONCENTRATOR ELECTRICAL

PERATION

O

Power is supplied from the two-prong plug to the Power Switch. When the Power Switch is ON, 120 VAC/230

VAC power is supplied to the Compressor motor, Hour Meter, cooling fan, and the main circuit board.

The main circuit board consists of a linear power supply, pressure sensor, software driven microprocessor,

green, yellow, and red LED’s and audible alarm.

The 9-volt battery provides a power source to operate the audible alarm and the red LED alarm light in the

event of an AC power failure.

F

IGURE B: H600/605; M600/605; ENHANCED M600/605 ELECTRONIC COMPONENT BLOCK DIAGRAM

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041905, REV. 00PAGE 2 - THEORY OF OPERATION

Page 28

M10600/M10605; ENHANCED M10600/M10605 CONCENTRATOR PNEUMATIC

PERATION

O

Room air is drawn through a foam air inlet filter (1) mounted on the side of the cabinet. The primary system air

is drawn through the inlet pre-filter, (2) the inlet filter w/ silencer (3) by the Compressor (5). The exhaust air

then passes through the In-line Muffler (6) to the supply chamber.

The Compressor exhaust air is cooled by the supply chamber (7) and distributed using a pneumatic Valve/

Solenoid Assembly (8). At start up, valve (8) is de-energized allowing compressed air to flow into both Sieve

Canisters (9) until the pressure sensor builds up to switching pressure. At switching pressure, a 12 volt signal

is received at Valve/Solenoid(8a) closing the input and allowing compressed air to continue through sieve bed

(9a) for 6.25 seconds absorbing the Nitrogen and allowing the Oxygen to flow through check valve (10a) and

into the product tank (11).

At 5 liters of flow approximately 1/3 of the Oxygen is deposited into the product tank and 2/3 is passed through

orifice (12) in to sieve bed (9b) to purge the Nitrogen from the sieve bed, which exits through the exhaust port

of the Valve/Solenoid(8b) to exhaust chamber (14) through Blow Down Muffler (15) to outside air in a time of

6.25 seconds.

At the end of this cycle the unit will balance for 1 second which de-energizes valve / solenoid (8b) and allows

compressed air to flow into both Sieve Canisters. The pressure reaches the max switching pressure and sends

a 12 volt signal to valve / solenoid (8b) and the adsorption cycle starts over in the Sieve Canister (9b). Oxygen

is in a continuous flow from the product can (11) through the regulator (16) through the Flow Meter (17) to the

bacteria filter (18) to the patient.

F

IGURE C: M10600/M10605; ENHANCED M10600/M10605 PNEUMATIC BLOCK DESIGN

THEORY OF OPERATION - PAGE 31041905, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 29

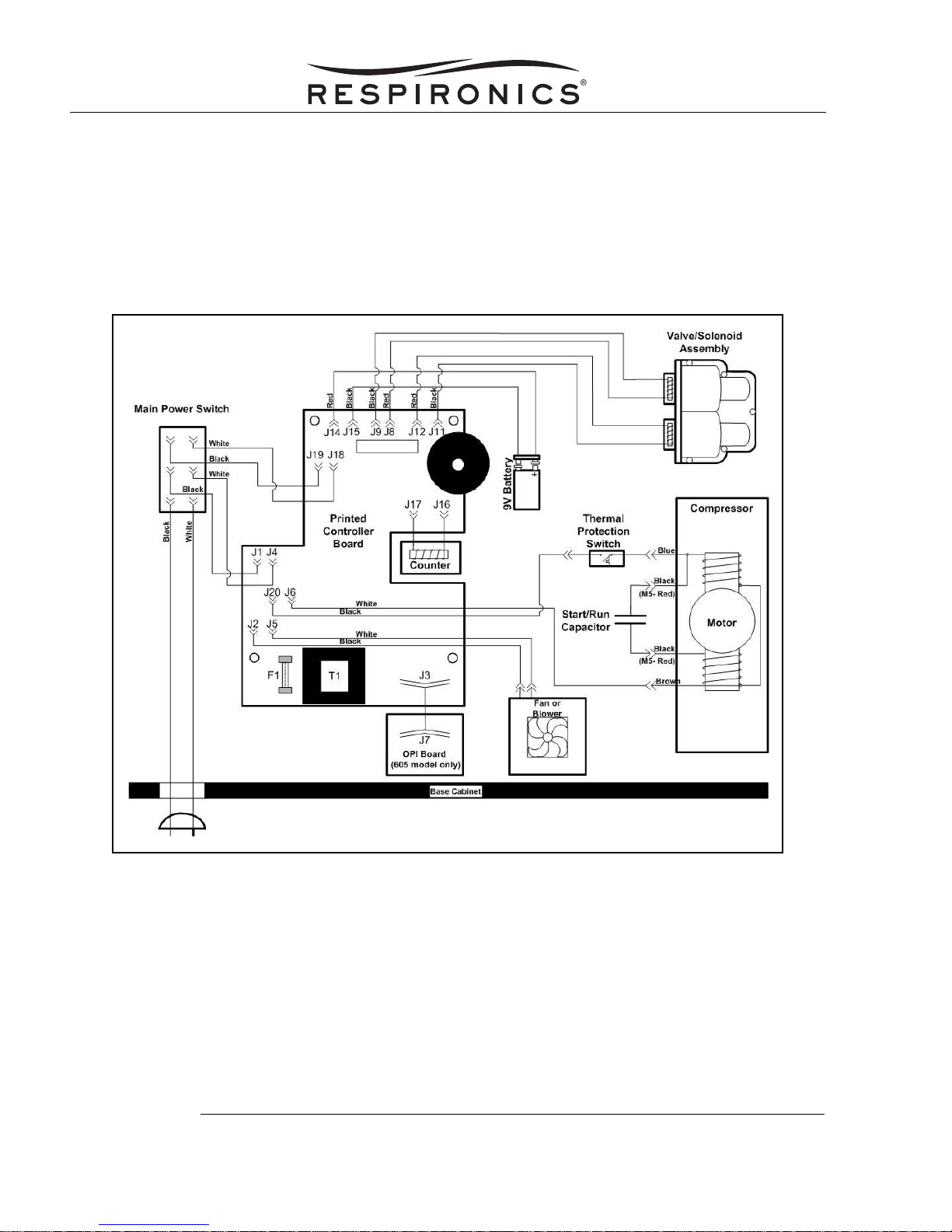

M10600/M10605; ENHANCED M10600/M10605 ELECTRICAL OPERATION

Power is supplied from the two-prong plug to the Power Switch. When the Power Switch is ON, 120 VAC

power is supplied to the Compressor motor, Hour Meter, cooling fan, and the main circuit board.

The main circuit board consists of a linear power supply, pressure sensor, software driven microprocessor,

green, yellow, and red LED’s and audible alarm.

The 9-volt battery provides a power source to operate the audible alarm and the red LED alarm light in the

event of an AC power failure.

F

IGURE D: M10600/M10605; ENHANCED M10600/M10605 ELECTRONIC COMPONENT BLOCK DIAGRAM

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041905, REV. 00PAGE 4 - THEORY OF OPERATION

Page 30

MAINTENANCE

This section describes the scheduled and routine maintenance procedures. The maintenance procedures

must be performed on the Millennium Oxygen Concentrator System as part of the normal care of the unit.

Maintenance is very important in prolonging dependability and in reducing costly repairs. Long-term

maintenance and regular checking of the filters helps assure the efficient operation of the unit. The user

should be instructed on how to clean the accessible filters. An authorized technician should perform all other

maintenance.

MAINTENANCE INTERVALS

WEEKLY USER MAINTENANCE

Weekly user maintenance consists of inspecting and cleaning the Inlet Filter.

DEALER ANNUAL MAINTENANCE

Annual maintenance shall be performed by the Home Care Dealer, or at a Respironics service facility. Annual

maintenance includes the following.

• Checking the condition of the Filters (change if necessary).

• Cleaning the cabinet.

• Verifying the oxygen concentration with a calibrated oxygen analyzer. This procedure must be

performed once a year or between patients. Refer to the Testing Section for more detail.

• Perform a power interrupt alarm test, and replace the 9-volt battery if necessary. Refer to the Test-

ing Section for more detail.

• Perform a start-up LED and audible alarm test. Refer to the Testing Section for more detail.

NOTE

For units equipped with the Long Life Filter, Respironics recommends

checking and replacing the Long Life Filter every two (2) years. For all other

Maintenance follow the Dealer Annual Maintenance Guidelines listed above.

MAINTENANCE - PAGE 11041813, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 31

DEALER PERIODIC MAINTENANCE

Periodic maintenance shall be performed by the Home Care Dealer, or at a Respironics service facility.

Periodic maintenance includes the following:

• Checking the final patient bacteria filter and replacing if necessary.

• Measuring the product canister pressure.

NOTE

If the product canister pressure is lower than normal, but the unit has clean

filters and no leaks, then Compressor maintenance should be performed.

DEALER COMPRESSOR MAINTENANCE

NOTE

The Compressor can be returned to the Compressor manufacturer to be recertified.

Compressor maintenance shall be performed by the Home Care Dealer, or at a Respironics service facility.

Compressor maintenance is required by Respironics to prolong dependability of the concentrator. However,

the need for this maintenance varies depending on the operating conditions and the environment where the

unit is used. Some signs of poor Compressor performance are:

• low oxygen readings,

• low pressure readings, and

• increased noise level.

Compressor maintenance shall be performed at intervals commensurate with hospital or home care provider

guidelines. Compressor Maintenance includes the following:

A. C

LEANING THE AIR INLET FILTER

1. Remove the Air Inlet Filter from the side of the unit.

2. Vacuum or wash the Air Inlet Filter with a mild detergent and tap water.

3. If washed, allow the Air Inlet filter to air dry completely before installing it on the unit.

F

IGURE A: LOCATION OF THE AIR INLET FILTER

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041813, REV. 00PAGE 2 - MAINTENANCE

Page 32

B. CLEANING THE PRE-INLET FILTER & INLET FILTER

1. Remove the rear access door from the unit.

IGURE B: REMOVING THE REAR ACCESS DOOR

F

2. Remove the Pre-inlet Filter and the Inlet Filter from the unit.

3. Remove the Pre-inlet Filter from the Inlet filter.

4. Wash the foam Pre-inlet Filter with a mild detergent and tap water. Allow it to air dry completely.

5. Inspect the Inlet filter and replace if necessary.

6. Place the assembled filters on the filter cover. While firmly pressing down on the filter assembly,

turn the filter assembly clock-wise to assure of a tight fit between the filter assembly and the filter

cover.

7. Install the rear access door.

F

IGURE C: FILTER LOCATIONS

MILLENNIUM SERVICE & TECHNICAL INFORMATION

MAINTENANCE - PAGE 31041813, REV. 00

Page 33

C. CLEANING THE CABINET

1. Disconnect the unit from the power source.

2. Using a mild detergent and disinfectant, clean all exterior surfaces of the cabinet.

CAUTION

Do not allow any liquid to enter the unit.

3. Ensure that the cabinet is dry before placing in service.

D. M

ICRO-DISK FILTER MAINTENANCE

The Micro-disk filter is the final component in the filtering system before the concentrated oxygen is delivered

to the patient. Check and replace this filter as necessary.

PART NUMBER: H621

Included in Kit Tools Required

Procedure

1. Remove the Rear Cabinet.

Micro-disk Filter (x6)

Wire Ties (x2)

Phillips Screwdriver

(No. 2 Medium w/ long shaft)

Diagonals (wire cutters)

WARNING

Electrical shock hazard; Disconnect the electrical supply before attempting to make

any repairs.

CAUTION

Electronic components used in this device are subject to damage from static

electricity. Repairs made to this device must be performed only in an antistatic,

ESD protected environment.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041813, REV. 00PAGE 4 - MAINTENANCE

Page 34

2. Remove the Front Cabinet, and separate it from the unit.

IGURE D: MICRO-DISK FILTER LOCATION

F

3. Using the diagonals, cut the wire ties that secure the pressure tubing to the Micro-disk filter.

4. Remove the pressure tubing from the inlet and outlet ports of the Micro-disk filter.

5. Slide the pressure tubing onto the inlet and outlet ports of the new Micro-disk filter.

6. Using the wire ties provided, secure the pressure tubing to the new Micro-disk filter.

7. Use the diagonals to cut off the excess from the wire ties.

MAINTENANCE - PAGE 51041813, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 35

E. H00/605 (120V/230V); M600/605 (120V); ENHANCED M600/605 (120V) COMPRESSOR MAINTENANCE

PART NUMBER: H610

Included in Kit Tools Required

• Piston Cup

• Piston cup retainer

• Valve keeper / restraint (exhaust)

• Valve keeper (intake)

• Cylinder Sleeve

• Valve flapper (exhaust)

• Valve flapper (intake)

• O-ring (sleeve)

• O-ring (intake filter cover)

• Gasket (valve plate)

• Cork gasket

• Filter (felt)

• Screw (valve keeper x2)

• Screw (piston cup retainer x4)

• In-line Muffler (molded fittings)

• Clamp (one ear x3)

• Hose (3/8 ID Braided)

• Millennium Screwdriver (RI p/n H646)

• Flat blade screwdriver (medium)

• T-15, T-20, T-25 Torx bits (Included with

Millennium screwdriver)

• Torque wrench, 30 in.-lbs (RI p/n 1033057)

• One Ear Clamp Pliers (RI p/n H645)

NOTE

Respironics requires that all components of the Compressor maintenance kit be used to ensure

that the Compressor will function properly after Compressor maintenance has been performed.

WARNING

Electrical shock hazard; Disconnect the electrical supply

before attempting to make any repairs to the device.

CAUTION

Electronic components used in this device are subject to damage from

static electricity. Repairs made to this device must be performed only

in an antistatic, ESD-protected environment.

1041813, REV. 00PAGE 6 - MAINTENANCE

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 36

Procedure

1. Remove the Rear Cabinet. Refer to the proper Repair & Replacement section for detailed instruc-

2. Remove the Front Cabinet. Refer to the proper Repair & Replacement section for detailed instruc-

3. Remove the Compressor Cover/ Perforated Canopy. Refer to the proper Repair & Replacement

4. Remove the four screws securing the filter cover using a T-20 or 7/64 Torx bit.

tions.

tions.

section for detailed instructions.

F

IGURE E: SCREW LOCATION

5. Remove and replace the felt filter inside the filter cover.

IGURE F: FELT FILTER

F

MAINTENANCE - PAGE 71041813, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 37

6. Remove and replace the O-ring on the bottom side of the filter body.

F

IGURE G: O-RING LOCATION

7. Remove the four screws securing the Compressor head using a T-25 or 1/8 Torx bit.

IGURE H: COMPRESSOR HEAD SCREW LOCATIONS

F

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041813, REV. 00PAGE 8 - MAINTENANCE

Page 38

8. Remove the valve plate and cylinder sleeve.

IGURE I: REMOVING THE VALVE PLATE AND CYLINDER SLEEVE

F

9. Separate the cylinder sleeve from the valve plate, and discard the sleeve and O-ring.

IGURE J: SEPARATING THE CYLINDER SLEEVE AND VALVE PLATE

F

MAINTENANCE - PAGE 91041813, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 39

10. Remove the screws, and replace the valve flappers on the valve plate using a 1/4 in. nut driver.

Valve Keeper

Strips

Valve Gasket

IGURE K: FLAPPER VALVE REMOVAL

F

NOTE

The Valve flappers are located under the keeper strips.

11. Remove and replace the gasket on the valve plate.

12. Using a T-20 torx bit, remove and discard the four screws, the piston cup, the retainer plate and

the cork gasket from the connecting rod assembly.

NOTE

A heat gun may be used to loosen the loctite on the screws.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041813, REV. 00PAGE 10 - MAINTENANCE

Page 40

FIGURE L: LOCATION OF THE PISTON CUP RETAINER SCREWS

13. Place the new cork gasket on the connecting rod assembly, making sure the cork fits around the

pins on the connecting rod assembly.

IGURE M: INSTALLING THE CORK GASKET

F

MILLENNIUM SERVICE & TECHNICAL INFORMATION

MAINTENANCE - PAGE 111041813, REV. 00

Page 41

14. Place the new piston cup on the back of the new retainer plate. Using the new screws provided,

secure the retainer to the connecting rod assembly and torque screws to 30 in.-lbs.

F

IGURE N: INSTALLING THE PISTON CUP & RETAINER

15. Set the new sleeve in place with the O-ring away from the piston. Slide the sleeve down over the

piston cup using your fingers to guide the sleeve without damaging the piston cup.

F

IGURE O: INSTALLING THE CYLINDER SLEEVE

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041813, REV. 00PAGE 12 - MAINTENANCE

Page 42

FIGURE P: CYLINDER SLEEVE IN PLACE

16. Press the valve plate onto the cylinder sleeve making sure not to pinch the O-ring on the cylinder

sleeve. The valve plate must be positioned properly to ensure proper alignment with the Compressor head. Place the valve gasket in the groove of the valve plate.

Alignment

Holes

Valve Gasket

F

IGURE Q: VALVE GASKET & ALIGNMENT HOLES

MILLENNIUM SERVICE & TECHNICAL INFORMATION

MAINTENANCE - PAGE 131041813, REV. 00

Page 43

17. Place the Compressor head onto the valve plate. Using a T-25 Torx bit and a torque wrench,

tighten the Compressor head bolts to 30 in.-lbs.

IGURE R: COMPRESSOR HEAD IN PLACE

F

18. Place the new Felt filter and the O-ring on the Intake filter body.

19. Connect the In-line Muffler to the bottom of the Compressor head and secure with a clamp.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041813, REV. 00PAGE 14 - MAINTENANCE

Page 44

M600/605 (230V); ENHANCED M600/605 (230V); M10600/M10605; ENHANCED M10600/M10605 COMPRESSOR

M

AINTENANCE

PART NUMBER: 1018249

Included in Kit Tools Required Applicable Concentrator

• Piston Cup (x2)

• Cylinder Sleeve (x2)

• Cylinder O-ring (x2)

• Head Screws (x8)

• Head Gasket (x2)

• Cup Retainer Screws

(x2)

• Valve Restraint (x2)

• Valve Keeper (x4)

• Valve (x4)

• Valve Screw (x4)

• Dynamic Backer (x2)

• Millennium Screwdriver (w/bits) (RI p/n

H646)

• Cutting Pliers

• Heat Gun (acceptable ranges, 200°F

thru 900°F)

• 3/8” Drive Hex Bit Holder (RI p/n

1040446)

• 1/4” Drive Hex bit holder (RI p/n

1033058)

• Torque Wrench, 18in-lbs (RI p/n

1018495)

• Torque Wrench, 55 in-lbs (RI p/n

1018490)

• Torque Wrench, 100 in-lbs (RI p/n

1024064)

• Torque Wrench, 125 in-lbs (RI p/n

1024062)

• 1/8” Allen wrench or Hex bit

• 5/32” Allen Wrench or Hex bit

• T-25 and T-27 Torx bit

• M10600/M10605

• Enhanced M10600/

M10605

• Vice

• Socket wrench

• Soft cloth

• One Ear Clamp Pliers (RI p/n H645)

MILLENNIUM SERVICE & TECHNICAL INFORMATION

MAINTENANCE - PAGE 151041813, REV. 00

Page 45

PART NUMBER: 1015569

Included in Kit Tools Required Applicable

Concentrator

• Piston Cup (x2)

• Cylinder Sleeve (x2)

• Cylinder O-ring (x2)

• Head Screws (x8)

• Head Gasket (x2)

• Cup Retainer Screws

(x2)

• Valve Restraint (x2)

• Valve Keeper (x4)

• Valve (x4)

• Valve Screw (x4)

• Instruction Sheet

• Dynamic Backer (x2)

• Millennium Screwdriver (w/bits) (RI p/n

H646)

• Cutting Pliers

• Heat Gun (acceptable ranges, 200°F thru

900°F)

• 3/8” Drive Hex Bit Holder (RI p/n 1040446)

• 1/4” Drive Hex bit holder (RI p/n 1033058)

• Torque Wrench, 18in-lbs (RI p/n 1018495)

• Torque Wrench, 55 in-lbs (RI p/n 1018490)

• Torque Wrench, 100 in-lbs (RI p/n

1024064)

• Torque Wrench, 125 in-lbs (RI p/n

1024062)

• 1/8” Allen wrench or Hex bit

• 5/32” Allen Wrench or Hex bit

• T-25 and T-27 Torx bit

• Vice

• Socket wrench

• Soft cloth

• One Ear Clamp Pliers (RI p/n H645)

• M600/605 230V

• Enhanced

M600/M605

230V

Respironics requires that all components of the Compressor maintenance kit be used to ensure

that the Compressor will function properly after Compressor maintenance has been performed. It

is also recommended that the In-line Muffler be replaced (RI p/n 1018460)

Electrical shock hazard; Disconnect the electrical supply before

attempting to make any repairs to the device.

Electronic components used in this device are subject to damage from static electricity. Repairs

made to this device must be performed only in an antistatic, ESD-protected environment.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

NOTE

WARNING

CAUTION

1041813, REV. 00PAGE 16 - MAINTENANCE

Page 46

Procedure

1. Remove the Rear Cabinet. Refer to the proper Repair & Replacement section for detailed instruc-

2. Remove the Front Cabinet. Refer to the proper Repair & Replacement section for detailed instruc-

3. Remove the Compressor Cover/ Perforated Canopy. Refer to the proper Repair & Replacement

4. Disconnect the exhaust tubing, Capacitor wires and input power wiring from the Compressor

5. Using a 1/8” Allen wrench or 1/8” Hex bit, remove the four Compressor mounts.

tions.

tions.

section for detailed instructions.

assembly.

F

IGURE S: COMPRESSOR MOUNTS (2 OF 4 SHOWN)

6. Lift the Compressor assembly out of the Millennium Base.

7. Before disassembly, mark the outside corners on one side of the Compressor to ensure proper

valve plate and Compressor head orientation during reassembly.

F

IGURE T: CORNER MARKINGS

MAINTENANCE - PAGE 171041813, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 47

8. Remove the eight screws securing the Compressor head cover using a T-25 Torx bit or flathead

screwdriver. Remove the Compressor head cover.

IGURE U: SCREW LOCATIONS

F

9. Remove both valve plates from the Compressor.

10. Remove the flapper screw from the Compressor head side of the valve plate. Take note of the cutouts on the flapper. The new flapper must be placed in the same fashion during assembly. Discard the old flapper, keeper, restraint, and gasket.

11. Clean the plate with a soft cloth. Install the new flapper. Place the new restraint on top of the flapper. The keeper should be placed on top of the restraint so the word “UP” is visible. Tighten the

flapper screw to 18 in-lbs. Install the new gasket.

12. Perform this procedure on the second valve plate.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

IGURE V: VALVE PLATE

F

1041813, REV. 00PAGE 18 - MAINTENANCE

Page 48

13. Turn the valve plate over to the cylinder side.

IGURE W: CYLINDER SIDE OF VALVE PLATE

F

14. Remove the flapper screw. Once again, ensure to note the flapper cutouts before disassembly.

Discard the flapper keeper and O-ring.

15. Clean the plate with a clean cloth.

16. Install the new flapper. Place the keeper on top of the flapper so that the word “UP” is visible.

Tighten the screw to 18 in-lbs. Install the new O-ring.

17. Perform this procedure on the second valve plate and set aside the valve plates.

18. Remove and discard both cylinder sleeves.

F

IGURE X: REMOVING THE CYLINDER SLEEVE

MILLENNIUM SERVICE & TECHNICAL INFORMATION

MAINTENANCE - PAGE 191041813, REV. 00

Page 49

19. Use Figure Y as a reference to ensure proper fan orientation.

20. Pull upwards from the center of the fan. It may be necessary to rock the fan back and forth while

pulling upwards to remove it from the shaft.

Do not attempt to pull up on the outside edges of the fan blades.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

IGURE Y: PROPER FAN ORIENTATION

F

CAUTION

1041813, REV. 00PAGE 20 - MAINTENANCE

Page 50

21. To remove the connecting rod assembly from the shaft, rotate the eccentric until the set screw

lines up with the Compressor housing access hole. Insert the 5/32” Allen wrench or hex bit

through the access hole and loosen the set screw 1/4 turn. Rotate the eccentric to top dead center

(180°), and slide the connecting rod/eccentric assembly off of the shaft.

F

IGURE Z: REMOVING THE ECCENTRIC

22. Wrap the neck of the connecting rod assembly with a cloth, and secure the assembly in a vice

being cautious not to clamp down on the eccentric and or bearings.

IGURE AA: CONNECTING ROD ASSEMBLY IN VICE

F

MAINTENANCE - PAGE 211041813, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 51

NOTE

Considerable care must be taken while removing the piston cup retainer screw. The screw has been

tightened to 100 in-lbs with Loctite® on the threads and may become stripped if not removed properly.

23. Heat the screw with a heat gun for approximately one minute.

During this procedure, parts will become hot. Do not touch any parts with

your bare hands. Use pliers to handle the parts until they have cooled.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

IGURE AB: HEATING THE SCREW

F

CAUTION

1041813, REV. 00PAGE 22 - MAINTENANCE

Page 52

24. Connect the T-27 Trox bit to the socket wrench. Press down on the wrench and turn counter

clockwise to loosen the screw. If the screw does not start to turn or the bit begins to slip, reapply

heat for one minute. Continue this process until the screw is removed. Once the parts have

cooled, discard the piston cup and screw.

F

IGURE AC: SCREW REMOVAL

25. Place a new cylinder sleeve over the piston head. Place a new piston cup on the back of the cup

retainer plate. Note the locations of the alignment pin on the back of the plate and the alignment

hole on the piston head.

26. Press the plate into the cylinder sleeve being careful not to crimp the piston cup. Once the plate is

seated on top of the piston, rotate the plate until the plate pin seats into the piston alignment hole.

Tighten the new T-27 plate screw to 100 in-lbs. Remove the rod assembly from the vice.

27. With the eccentric side of the connecting rod/eccentric assembly facing away from the Compressor, slide the assembly onto the shaft until the assembly is flush against the motor assembly.

F

IGURE AD: REPLACE PISTON CUP

MILLENNIUM SERVICE & TECHNICAL INFORMATION

MAINTENANCE - PAGE 231041813, REV. 00

Page 53

Rotate the eccentric until the set screw lines up with the housing access hole. Rotate the shaft

until the flat side of the shaft aligns with the set screw, and tighten the screw to 125 in-lbs.

28. Slide the fan onto the shaft until the fan is flush against the eccentric. Note the reference mark you

made on the fan blade in step 19 of this procedure.

29. Turn over the Compressor for access to the second connecting rod/eccentric assembly. Repeat

Steps 19 through Step 28.

30. Place the valve plates on the cylinders (O-ring side face down). The marks that were made before

disassembly must be aligned. Check the valve gaskets for proper alignment.

31. Place the Compressor head on top of the plates so that the marks align in the corners. Install the

head screws and tighten the screws to 55 in-lbs.

NOTE

If replacing the In-line Muffler, perform muffler replacement before installing the Compressor.

32. Place the Compressor on the mounts in the Base Cabinet. Make sure the springs are seated

properly.

33. Align the holes of the Compressor assembly with the standoffs in the Base Cabinet. Ensure

proper orientation of the Compressor assembly. Tighten the mounts to the base.

34. Reconnect the tubing to the Compressor exhaust port.

35. Reconnect the Compressor wires to the Capacitor and input power wiring. Proceed with final testing.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041813, REV. 00PAGE 24 - MAINTENANCE

Page 54

MILLENNIUM OXYGEN CONCENTRATOR MAINTENANCE RECORD

Model Number: __________ Serial Number: __________ Date Purchased: __________

FILTERS COMPRESSOR

DATE HOURS LPM

Record at each check Clean and replace as needed Check and perform maintenance

9V BATTERY

Check and replace

as needed

Air Inlet1Pre-Inlet

2

OXYGEN

CONCENTRATION

Check Level Check lights

2

Inlet

2

2

Micro-disk Compressor

OPI

at start up

MOTOR START/

RUN CAPACITOR

Check and replace as

Rebuild

as recommended

recommended

In-line

Muffler

1

Patients should be instructed to position the unit so that proper

ventilation for the unit is maintained, and to clean the air inlet filter weekly.

2

Respironics requires that routine maintenance be performed annually.

NOTE

MAINTENANCE - PAGE 251041813, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 55

This page intentionally left blank.

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041813, REV. 00PAGE 26 - MAINTENANCE

Page 56

TROUBLESHOOTING

SECTION OVERVIEW

This section is intended to help the service technician determine what is wrong with the Millennium Oxygen

Concentrator System. This section should also be used to determine what parts, if any, need to be replaced.

SYMPTOM CAUSE VERIFICATION CORRECTIVE ACTION

• Pressure relief

valve activating

• Low pressure alarm

• Audible and visual

alarm

• Pressure relief

valve activating

• Fluctuations in

oxygen pressure

• Fluctuations in flow

ball

Unit will not turn on

• Audible alert

(steady)

• Red LED on

(steady)

Canister to Compressor

tubing failure

• Tubing disconnected,

kinked, or hole in

tubing

• Verify the tubing

between the

canister and

Compressor is

connected

• Verify the tubing is

not kinked or

pinched

• Verify there are no

holes in the tubing

Fuse Fails

• Open fuse on Main

PCB

Pressure regulator

failure

Component failure

• Verify the audible

and visual alarm

due to battery

• Verify the flow

from regulator is

correct

• Preform Oxygen

Outlet/Regulated

Pressure Test

• No power to the unit • Verify the Power

Cord is connected

to the wall outlet

• Verify there is

power in the wall

outlet

• Verify if the outlet

is connected to a

light switch and

the switch is in the

ON position

• Reconnect the tubing

• Reposition the tubing

• Replace the tubing

• Replace the fuse

• Replace the regulator

• Connect the Power Cord

to the wall outlet

• Check the household fuse

or circuit breaker

• Move the Power Switch to

the ON position

TROUBLESHOOTING - PAGE 11041814, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 57

SYMPTOM CAUSE VERIFICATION CORRECTIVE ACTION

Unit will not alarm

(Red LED)

• Power Cord is

connected

• Power Switch in the

ON position

• No Audible Alert

• No Red LED

LED failure (Models

600 and 605)

• Red LED

inoperable

• Green LED

inoperable

• Yellow LED

inoperable

• No power to the

alarm

• Verify the battery

voltage is 5 volts

or higher

• Verify the battery

connector is

correctly seated

on the battery

• Verify the wiring

harness is

connected to the

Power Switch

• Verify the wiring

harness is

connected to the

Main PCB

• No power to LEDs • Verify the Power

Cord is plugged in

• Verify the battery

voltage is greater

than 5 volts

• Verify that all

wiring harnesses

are connected

• Verify the Main

PCB is not

damaged

• Verify the OPI

board is not

damaged (Model

605 only)

• Replace the 9 volt battery

• Connect the wiring

harness

• Connect the wiring

harness

• Connect the wiring

harness

• Replace the Main PCB

• Connect the Power Cord

to AC power source

• Replace the 9 volt battery

• Connect all wiring

harnesses

• Replace the Main PCB

• Replace the OPI board

MILLENNIUM SERVICE & TECHNICAL INFORMATION

1041814, REV. 00PAGE 2 - TROUBLESHOOTING

Page 58

SYMPTOM CAUSE VERIFICATION CORRECTIVE ACTION

• Unit is inoperable

• Start-up-alarms

inoperable

• No audible or visual

alarm while turning

Power Switch On

with the Power Cord

unplugged

Main PCB failure

• Intermittent power up

• High/Low pressure

alarm

• No power

Piezoelectric speaker

failure

• No audible alarm

Battery Failure

• No audible or visual

alarm during poweroff.

• Verify the wiring

harnesses are

connected

• Verify the wiring

harness is not

damaged

• Verify the

condition of the

fuse on Main PCB

• Verify the solder

joints are not

faulty on Main

PCB

• Verify there are no

component

failures on Main

PCB

• Verify the wiring

harnesses are

connected

• Verify the solder

joints are not

faulty on the Main

PCB

• Verify there are no

component

failures on the

Main PCB

• Verify the battery

is connected

• Verify the battery

voltage is greater

than 5 VDC

• Verify the wiring

harness has

continuity

• Connect the wiring

harnesses

• Check the wiring

harnesses for continuity

• Test the fuse for electrical

continuity

• Replace the Main PCB

• Replace the Main PCB

• Reconnect the wiring

harnesses

• Replace the Main PCB

• Replace the OPI PCB

• Replace the Main PCB

• Connect the battery

• Replace the 9 volt battery

• Replace wire harness, O

solenoid/battery

/

2

TROUBLESHOOTING - PAGE 31041814, REV. 00

MILLENNIUM SERVICE & TECHNICAL INFORMATION

Page 59

SYMPTOM CAUSE VERIFICATION CORRECTIVE ACTION

• Low pressure alarm

• High pressure

alarm

• Low oxygen output

• Oxygen percentage

indicator alarm

(Model 605)

• Oxygen percentage

indicator not

functioning

• Continuous red

LED

Compressor failure

• Fluctuating or no

oxygen production

Pressure relief valve

• Relief valve activated

Sieve bed contaminated

• Low or no oxygen

production

OPI power control

board failure

• Oxygen output

readings out of

calibration

• Verify the thermal

switch is not open

• Verify if the

Compressor need

to be rebuilt

• Verify if the In-line

Muffler is cracked

• Verify the tubing is

not kinked or

pinched

• Verify the tubing is

not damaged

• Verify the valve

wiring harness is

connected at the

Main PCB and

valve

• Verify the oxygen

output with an

oxygen analyzer

• Verify the

Compressor is

working properly

• Verify all wiring

harnesses are

connected

• Verify there are no

faulty solder joints

on OPI

• Verify the OPI

voltage outputs

and compare with

OPI Voltage

Verification Chart

(Model 605)

• Replace wire harness,

main power (blower)