Page 1

DreamStation

Service & Technical Reference Manual

Page 2

1117539, VER. 07

CHAPTER 1: INTRODUCTION

1.0 CPAP/BIPAP SYSTEM OVERVIEW................................................................................. 1-2

1.1 HUMIDIFIER SYSTEM OVERVIEW...................................................................................... 1-4

1.2 SERVICE NOTICE............................................................................................................1-5

1.3 SERVICE TRAINING......................................................................................................... 1-5

1.4 PRODUCT SUPPORT STATEMENT.................................................................................... 1-5

CHAPTER 2: WARNINGS, CAUTIONS, & NOTES

CHAPTER 3: SPECIFICATIONS & CLASSIFICATIONS

CHAPTER 4: SETUP

4.0 SUPPLYING DC POWER TO THE DEVICE.......................................................................... 4-1

4.1 SUPPLYING AC POWER TO THE DEVICE.......................................................................... 4-2

4.2 CONNECTING THE TUBING TO THE PAP DEVICE.............................................................. 4-3

4.3 CONNECTING THE HUMIDIFIER TO THE PAP DEVICE........................................................ 4-4

4.4 CONNECTING THE TUBING TO THE HUMIDIFIER................................................................ 4-5

4.5 DISCONNECTING THE TUBING .........................................................................................4-6

4.6 DISCONNECTING THE DEVICES........................................................................................ 4-6

4.7 CHECKING THE HUMIDIFIER LID SEAL ............................................................................. 4-7

NSTALLING/REPLACING THE AIR FILTERS....................................................................... 4-8

4.8 I

4.9 STARTING THE DEVICE ................................................................................................... 4-9

4.10 NAVIGATING THE DEVICE SCREENS ............................................................................ 4-10

4.10.1 User Menu Navigation (Therapy On) and Optional Humidification Settings...............4-11

4.10.2 User Menu Navigation (Therapy Off)...............................................................................4-12

4.10.3 Accessing Provider Mode Screens.................................................................................4-18

4.10.4 Navigating the Provider Mode Screens..........................................................................4-18

4.11 PERFORMANCE CHECK DEVICE SCREENING TOOL...................................................... 4-28

4.12 B

LUETOOTH WIRELESS TECHNOLOGY ........................................................................ 4-28

4.12.1 Pairing to your Bluetooth enabled Mobile Device.........................................................4-28

4.13 ACCESSORIES............................................................................................................ 4-29

4.13.1 Humidifier with or without Heated Tubing......................................................................4-30

4.13.2 SD Card..............................................................................................................................4-30

Page 3

1117539, VER. 07

4.13.3 Link Module .......................................................................................................................4-30

CHAPTER 5: TROUBLESHOOTING AND ERROR CODES

5.0 INTRODUCTION................................................................................................................5-1

5.1 BENCH CHECKOUT .........................................................................................................5-1

5.1.1 PAP Device:...........................................................................................................................5-1

5.1.2 Humidifier:.............................................................................................................................5-1

5.2 VERIFYING PRESSURE.....................................................................................................5-2

5.3 SERVICE CENTER TOOLS SUITE ......................................................................................5-3

5.3.1 Service Center Tools Suite Installation and Device Connection Process...................... 5-4

5.3.2 Clearing the Error and Device Logs....................................................................................5-6

5.3.3 Clearing Therapy Hours and Blower Hours.......................................................................5-6

5.3.4 Setting the Session ID..........................................................................................................5-6

5.4 DEVICE ERROR CODES ...................................................................................................5-8

5.5 FAILURE MODE TROUBLESHOOTING ..............................................................................5-17

5.6 DEVICE ALERTS............................................................................................................5-23

CHAPTER 6: REPAIR & REPLACEMENT

6.0 REPLACEMENT PART (RP) KITS......................................................................................6-2

6.1 REPLACEMENT INSTRUCTIONS.........................................................................................6-4

6.1.1 Replacing the Accessory Module and SD Flip Doors.......................................................6-4

6.1.2 Replacing the SD Card.........................................................................................................6-5

6.1.3 Replacing the Upper Enclosure/Keypad:...........................................................................6-5

6.1.4 Replacing the UI Panel.........................................................................................................6-7

6.1.5 Replacing the PCA................................................................................................................6-9

6.1.6 Replacing the Flow and Pressure Sensor Seals..............................................................6-11

6.1.7 Replacing the Blower Upper Cap......................................................................................6-12

6.1.8 Replacing the Blower, Blower Box Assembly, and Rear Panel .....................................6-14

6.1.9 Replacing the Blower Outlet Seal and Blower Isolators.................................................6-22

6.1.10 Replacing the DC Power Cable and DC Jack Color Insert............................................6-24

6.1.11 Replacing the Bottom Enclosure....................................................................................6-25

6.2 CREATING THE SERIAL/MODEL NUMBER LABEL.............................................................6-26

6.2.1 Equipment (Printer)............................................................................................................6-26

6.2.2 Software...............................................................................................................................6-26

6.2.3 Label Printing Options.......................................................................................................6-27

6.3 CLEANING THE THERAPY DEVICE FOR ONE USER .........................................................6-28

Page 4

1117539, VER. 07

6.4 CLEANING FOR MULTIPLE USERS ................................................................................. 6-28

6.5 CLEANING OR REPLACING THE FILTERS........................................................................ 6-29

6.6 CLEANING THE TUBING ................................................................................................6-30

6.7 PREVENTIVE MAINTENANCE.......................................................................................... 6-30

CHAPTER 7: HUMIDIFIER REPAIR AND REPLACEMENT

7.0 HUMIDIFIER REPLACEMENT PART (RP) KITS...................................................................7-1

7.1 REPLACEMENT INSTRUCTIONS........................................................................................ 7-2

7.1.1 Replacing the Water Tank Assembly..................................................................................7-2

7.1.2 Replacing the Flip Lid and Dry Box Inlet Seals..................................................................7-3

7.1.3 Replacing the Dry Box Assembly........................................................................................7-4

7.1.4 Replacing the Wire Guard....................................................................................................7-5

7.1.5 Replacing the Back Panel Assembly..................................................................................7-8

7.1.6 Replacing the Flip Lid Latch................................................................................................7-9

7.1.7 Replacing the Lifting Tray..................................................................................................7-10

7.1.8 Replacing the Bottom Cover..............................................................................................7-13

7.1.9 Replacing the Heat Shield..................................................................................................7-14

7.1.10 Replacing the Heater Plate O-Ring..................................................................................7-15

7.1.11 Replacing the Bottom/Flip Lid Assembly.......................................................................7-16

7.2 CLEANING THE WATER TANK ....................................................................................... 7-21

7.3 CLEANING THE HUMIDIFIER BASE ................................................................................. 7-21

7.4 CLEANING THE HEATED TUBING ................................................................................... 7-22

OSPITAL AND INSTITUTION DISINFECTION: WATER TANK, SEAL AND HEATED TUBING.. 7-22

7.5 H

7.5.1 Cleaning Prior to Disinfection ...........................................................................................7-22

7.5.2 Disinfection .........................................................................................................................7-23

7.5.3 After Disinfection................................................................................................................7-23

CHAPTER 8: TESTING AND CALIBRATION

8.1 REQUIRED EQUIPMENT...................................................................................................8-1

ESTING PREREQUISITES ...............................................................................................8-2

8.2 T

8.3 T

ESTING ENVIRONMENT SPECIFICATIONS ........................................................................ 8-2

INAL TESTING PROCEDURE........................................................................................... 8-2

8.4 F

Page 5

1117539, VER. 07

This page intentionally blank.

Page 6

PAGE 1-11117539, VER. 07

© 2016 Koninklijke Philips N.V. All rights reserved.

Page 7

PAGE 1-2

CHAPTER 1: INTRODUCTION

CAUTION

U.S. federal law restricts this device to sale by or on

the order of a physician.

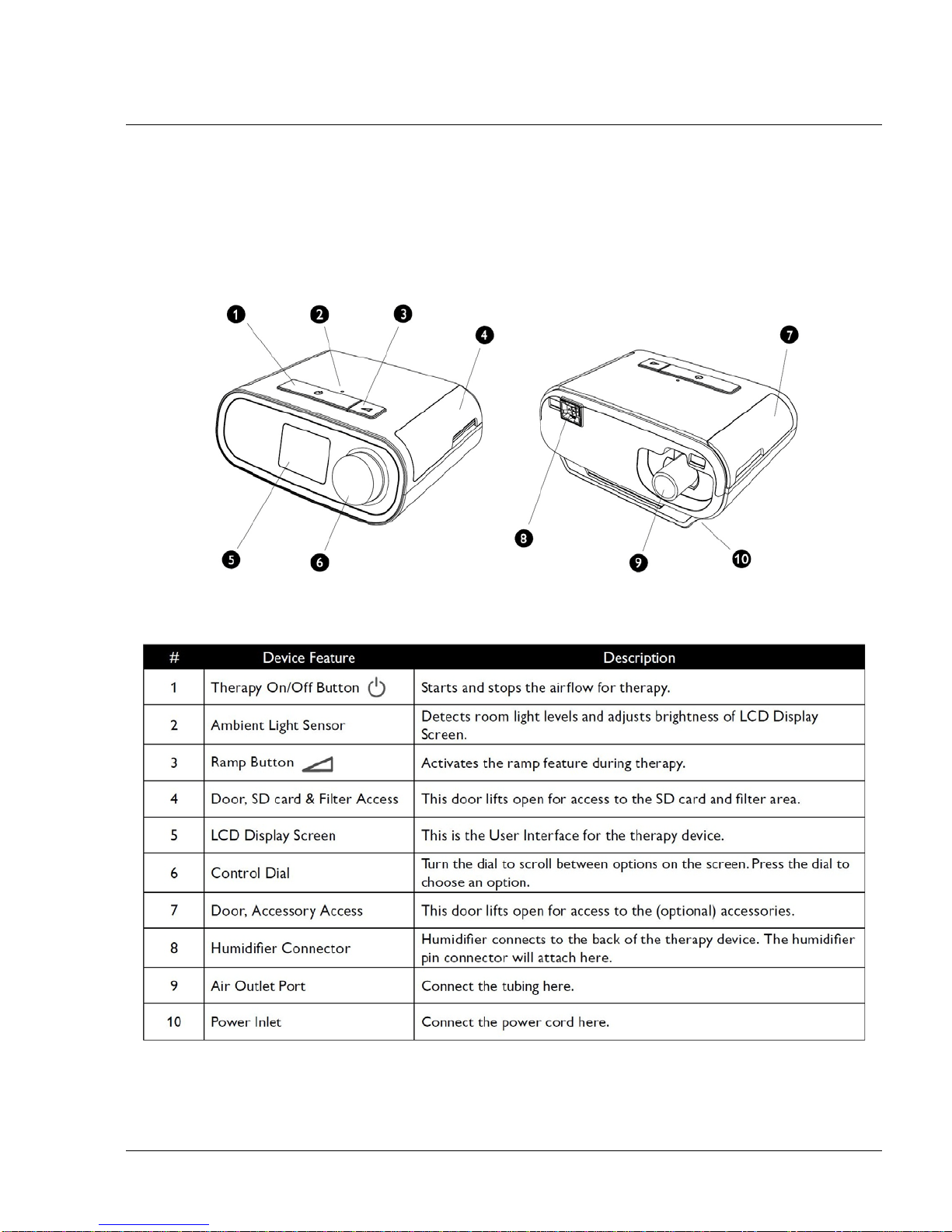

1.0 CPAP/BIPAP SYSTEM OVERVIEW

DEVICE DESCRIPTION MODEL NUMBER SERIES*

DreamStation CPAP yyX200Szz

DreamStation CPAP w/ Humidifier and Standard Tube yyX200Hzz

DreamStation CPAP w/ Humidifier and Heated Tube yyX200Tzz

DreamStation CPAP Pro yyX400Szz

DreamStation CPAP Pro w/ Humidifier and Standard Tube yyX400Hzz

DreamStation CPAP Pro w/ Humidifier and Heated Tube yyX400Tzz

1117539, V

ER. 07

DreamStation Auto CPAP yyX500Szz

DreamStation Auto CPAP w/ Humidifier and Standard Tube yyX500Hzz

DreamStation Auto CPAP w/ Humidifier and Heated Tube yyX500Tzz

DreamStation BiPAP Pro yyX600Szz

DreamStation BiPAP Pro w/ Humidifier and Standard Tube yyX600Hzz

DreamStation BiPAP Pro w/ Humidifier and Heated Tube yyX600Tzz

DreamStation Auto BiPAP yyX700Szz

DreamStation Auto BiPAP w/ Humidifier and Standard Tube yyX700Hzz

DreamStation Auto BiPAP w/ Humidifier and Heated Tube yyX700Tzz

DreamStation Humidifier yyXH

DreamStation Humidifier, Core Pack yyXHCP

*yy and zz are variables that represent regional configurations, i.e. DOM or INTL mode

X is fixed an

The DreamStation CPAP is a Continuous Positive Airway Pressure therapy device designed for the treatment

of Obstructive Sleep Apnea (OSA). The DreamStation CPAP Pro can also deliver CPAP-check therapy, and

the DreamStation Auto CPAP can also deliver CPAP-Check and Auto-CPAP therapy.

d represents the DreamStation platform.

ls.

The DreamStation BiPAP Pro can be set up as a Bi-level device, which delivers two different positive pressure

levels: IPAP (Inspiratory Positive Airway Pressure) and EPAP (Expiratory Positive Airway Pressure). The

DreamStation BiPAP Auto can also be set up as an Auto Bi-level device. Both BiPAP systems can also be set

up as a CPAP (Continuous Positive Airway Pressure) device.

Page 8

PAGE 1-31117539, VER. 07

The devices provide several special features to help make therapy more comfortable. The ramp function

allows the user to lower the pressure when they are trying to fall asleep. The air pressure will gradually

increase until their prescription pressure is reached. Also, the Flex comfort feature provides the user with

pressure relief when they exhale during therapy.

Several accessories are also available for use with the devices.

F

IGURE 1-1: DEVICE OVERVIEW AS DESCRIBED IN THE BELOW TABLE

Page 9

PAGE 1-4

1117539, V

ER. 07

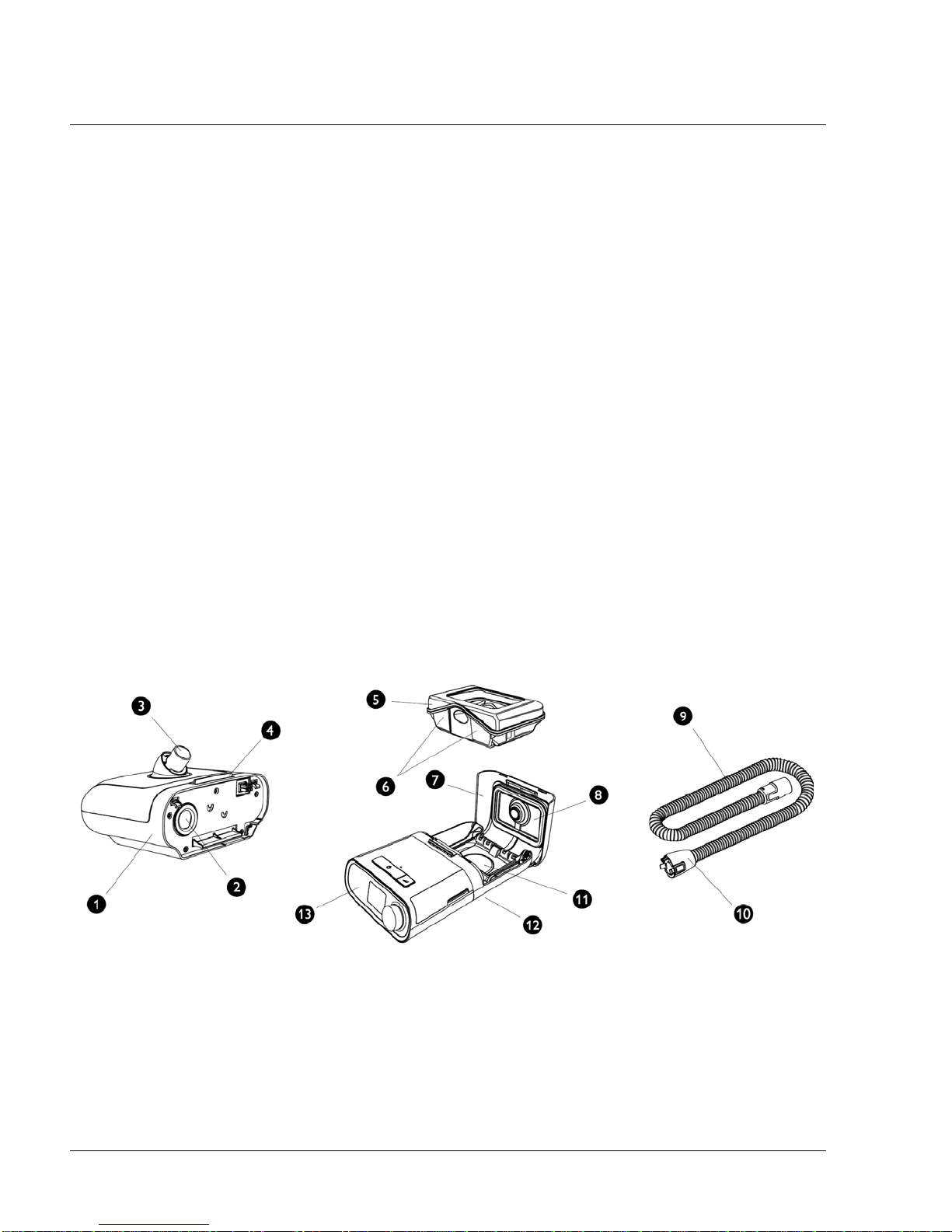

1.1 HUMIDIFIER SYSTEM OVERVIEW

The DreamStation Heated Humidifier attaches to the therapy device and provides an air outlet port to connect

a breathing circuit. The breathing circuit is comprised of patient tubing, a mask, and in some instances a

separate exhalation device. The patient tubing can be Respironics heated tubing, 22 mm (non-heated)

performance tubing or 15 mm (non-heated) performance tubing.

The DreamSt ation Heated Humidifie r with Heated Tubing is designed to deliver humidification to provide ad ded

comfort during therapy. This humidification level is controlled through the output of the heated humidifier as

well as the temperature of the optional heated tubing. Use of these two accessories allows for a comfortable

level of humidity to be maintained at the mask.

The DreamStation Heated Humidifier is comprised of the following components:

• Heated Humidifier - The heated humidifier is the primary source of humidification. Humidification

is controlled by adjusting the temperature of the heater plate . The heater plate is then used to hea

water

found in the water tank. This manual includes instructions that explain how to set up an

t

ake care of the heated humidifier . For instructions on how to adjust the heated humidifier settings

refer

to the instructions for use that accompanied the therapy device.

• Water Tank - The water tank stores the water that will be used by the heated humidifier . This man-

ual includes instructions that cover how to use and take care of the water tank.

• Heated Tubing - The heated tubing is an optional accessory that is used, along with the heated

humidifier

ture of the air in order to ensure that it does not cool down pr ior to reaching the mask. This manu

in

cludes instructions that cover how to connect and t ake care of the hea ted tubing. For instruction s

on how to adjust the temperature of the heated tubing, refer to the instructions for use that accompanied the therapy device.

, to control the provided humidification. This is accomplished by controlling the tempera-

d

al

t

,

IGURE 1-2: HUMIDIFIER OVERVIEW AS DESCRIBED IN THE FOLLOWING TABLE

F

Page 10

1.2 SERVICE NOTICE

PAGE 1-51117539, VER. 07

The service technician should have a good working knowledge and understanding of the principles of

operation and repair of electro-mechanical sleep therapy devices. By using the most cu rrent version of the

service manual (found on my.respironics.com) and the latest testing software, all repairs and testing can be

performed. If service training is desired, contact the Philips Respironics service location in your area to

schedule training.

1.3 SERVICE TRAINING

Philips Respironics offers service training for the devices. Training includes complete disassembly of the

device, troubleshooting sub-assemblies and components, and necessary safety testing. For more information,

log onto my.respironics.com, and download the Service Training Schedule brochure from the Service Software

and Documentation link.

1.4 PRODUCT SUPPORT STATEMENT

For product support, please contact Philips Respironics Customer Satisfaction.

U.S.A. and Canada

Phone:1-800-345-6443

Fax: 1-800-886-0245

International

Phone: 1-724-387-4000

Fax: 1-724-387-5012

Page 11

PAGE 1-6

This page intentionally blank.

1117539, V

ER. 07

Page 12

PAGE 2-11117539, VER. 07

CHAPTER 2: WARNINGS, CAUTIONS, & NOTES

Warnings, cautions, and notes are used throughout this manual to identify possible safety hazards, conditions

that may result in equipment or property damage, and important information that must be considered when

performing service and testing procedures on the device.

WARNING

Warnings indicate the possibility of injury to people.

CAUTION

Cautions indicate the possibility of damage to equipment.

NOTE

Notes are used to emphasize a characteristic or

important consideration.

Refer to the devices’ User and Provider Manuals for warnings, cautions and notes.

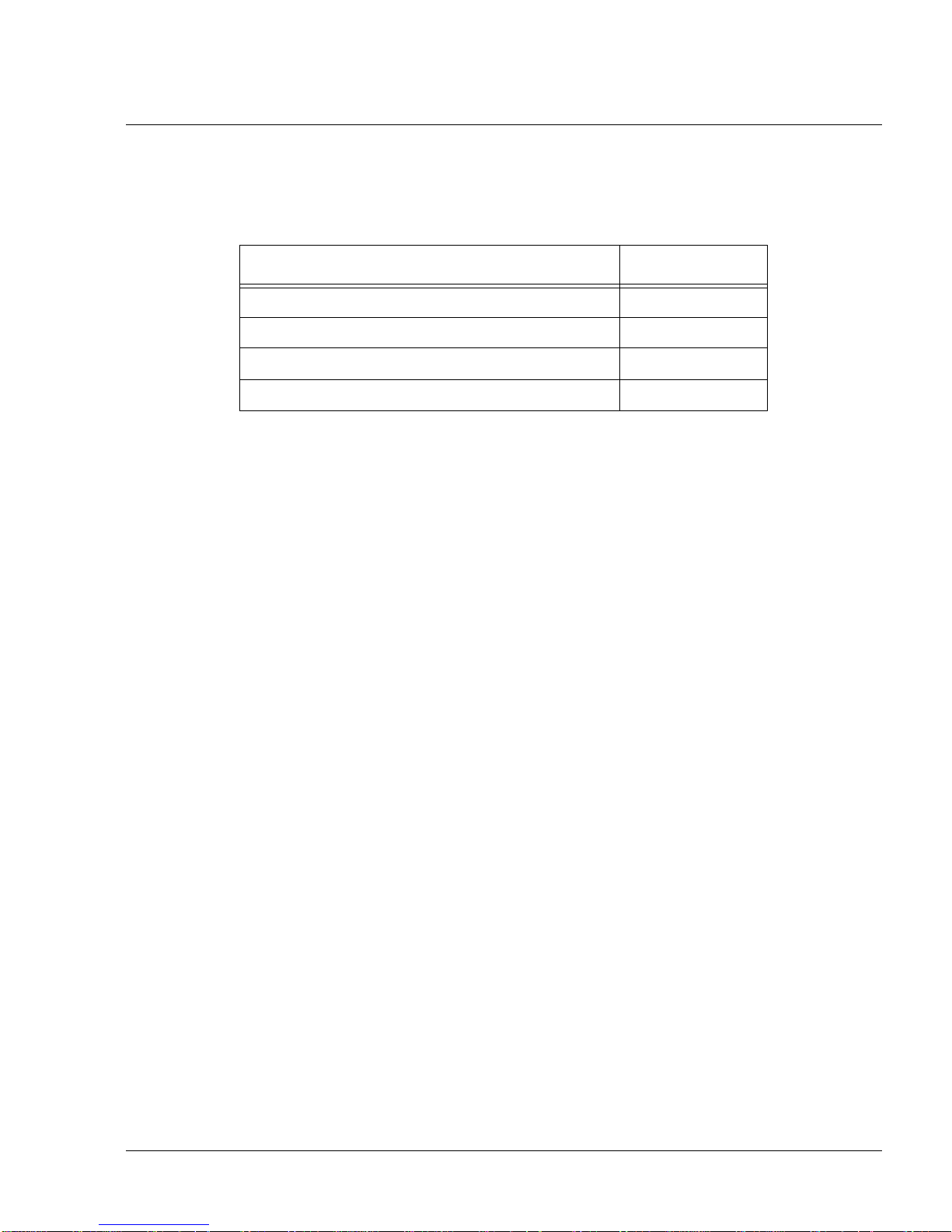

TABLE 2-1: USER & PROVIDER MANUALS

DESCRIPTION PART NUMBER

DreamStation CPAP, User Manual, EN-INTL CE 1121981

DreamStation BiPAP, User Manual, EN-INTL CE 1121982

DreamStation Humid, User Man ual, EN-INTL CE 1121984

DreamStation, Provider Guide, EN-INTL CE 1121983

Page 13

PAGE 2-2

1117539, V

ER. 07

This page intentionally blank.

Page 14

CHAPTER 3: SPECIFICATIONS & CLASSIFICATIONS

Refer to the devices’ User and Provider Manuals for specifications and classifications.

TABLE 3-1: USER & PROVIDER MANUALS

DESCRIPTION PART NUMBER

DreamStation CPAP, User Manual, EN-INTL CE 1121981

DreamStation BiPAP, User Manual, EN-INTL CE 1121982

DreamStation Humid, User Man ual, EN-INTL CE 1121984

DreamStation, Provider Guide, EN-INTL CE 1121983

PAGE 3-11117539, VER. 07

Page 15

PAGE 3-2

1117539, V

ER. 07

This page intentionally blank.

Page 16

PAGE 4-11117539, VER. 07

CHAPTER 4: SETUP

This chapter provides an overview of the system setup including introductory information on the User and

Provider modes and menus. Please refer to the device’s User Manual for further information.

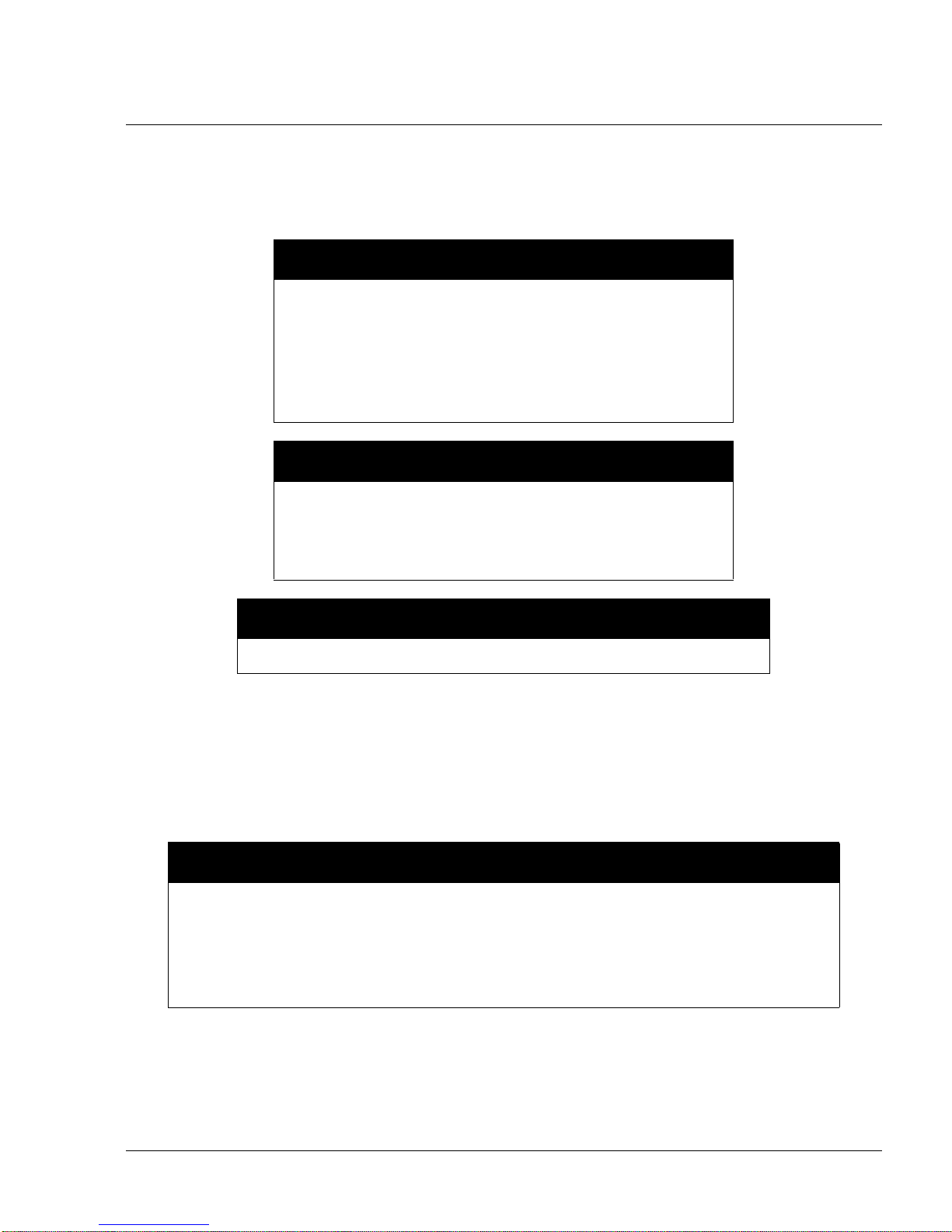

WARNING

• Inspect the power cord often for any signs of damage.

Replace a damaged power cord immediately.

• Be sure to route the power cord to the outlet in a way that

will prevent the cord from being tripped over or interfered

with by chairs or other furniture.

• This device is activated when the power cord is connected.

CAUTION

• If the device has been exposed to either very hot or very

cold temperatures, allow it to adjust to room temperature

(approximately two hours) before beginning setup.

• Do not use extension cords with this device.

NOTE

• Please refer to the Clinical Manual for additional information.

4.0 SUPPLYING DC POWER TO THE DEVICE

A Philips Respironics DC power cord can be used to operate this device in a stationary recreational vehicle,

boat, or motor home. In addition, a Philips Respironics DC battery adapter cable, when used with a DC power

cord, allows the device to be operated from a 12 VDC free-standing battery.

CAUTION

• Always ensure that the DC power cord securely fits into the th erapy device prior to use.

• When DC power is obtained from a vehicle battery, the device should not be used while the

vehicle’s engine is running. Damage to the device may occur.

• Only use a Philips Respironics DC Power Cord and Battery Adapter Cable. Use of any

other system may cause damage to the device.

Page 17

PAGE 4-2

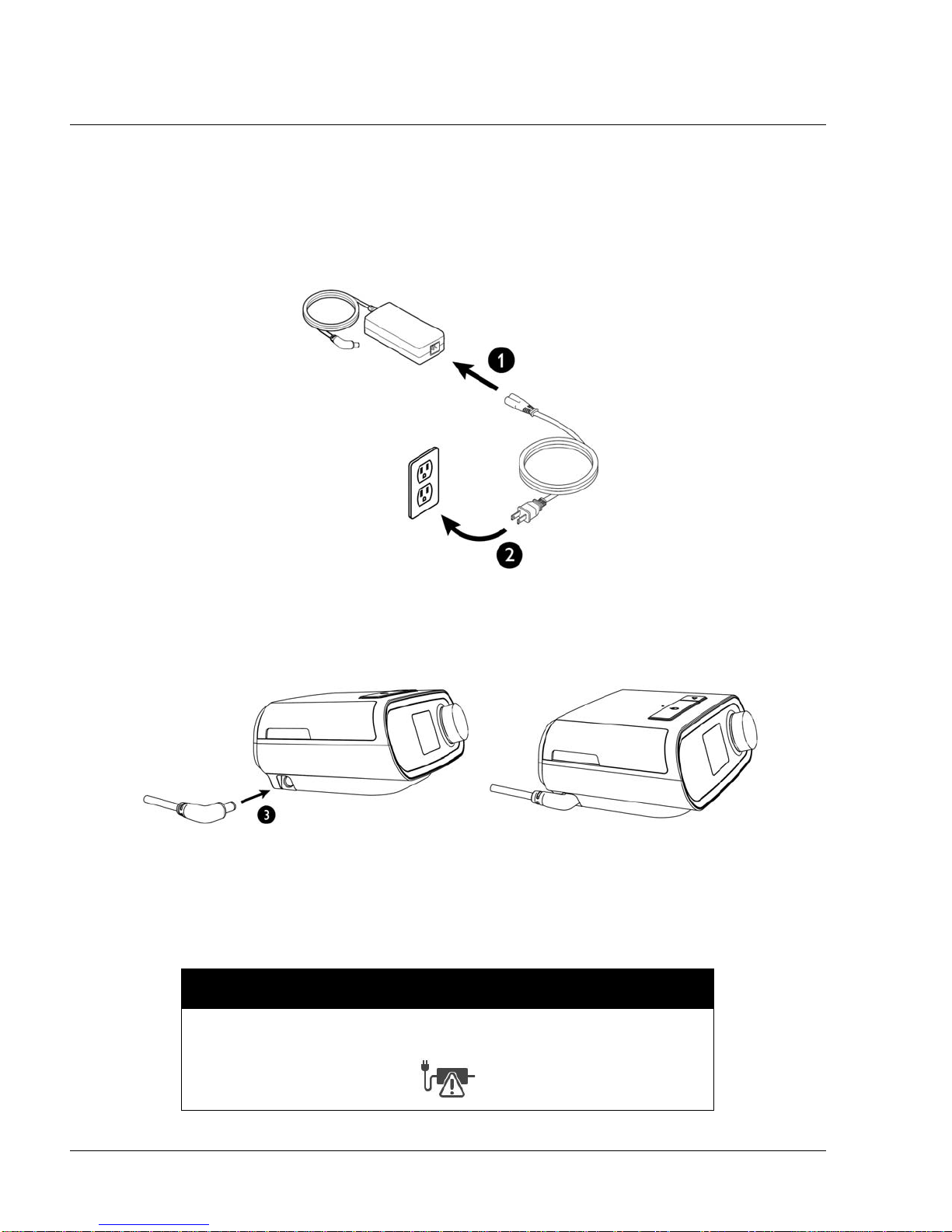

4.1 SUPPLYING AC POWER TO THE DEVICE

Complete the following steps to operate the device using AC power:

1. Plug the socket end of the AC power cord (included) into the power supply (also included).

2. Plug the pronged end of the AC power cord into an electrical outlet that is not controlled by a wall

switch.

.

1117539, V

ER. 07

F

IGURE 4-1: CONNECTING THE AC POWER CORD AND POWER SUPPLY

3. Plug the power supply cord’s connector into the power inlet on the side of the device.

IGURE 4-2: SUPPLYING POWER TO THE DEVICE

F

4. Verify that the plug at the side of the device, at the power supply, and at the electrical outlet are

fully inserted. This will help to ensure that a secure, reliable electrical connection has been made.

NOTE

If the following Incorrect Power Supply icon appears on the screen, please

repeat step 4.

Page 18

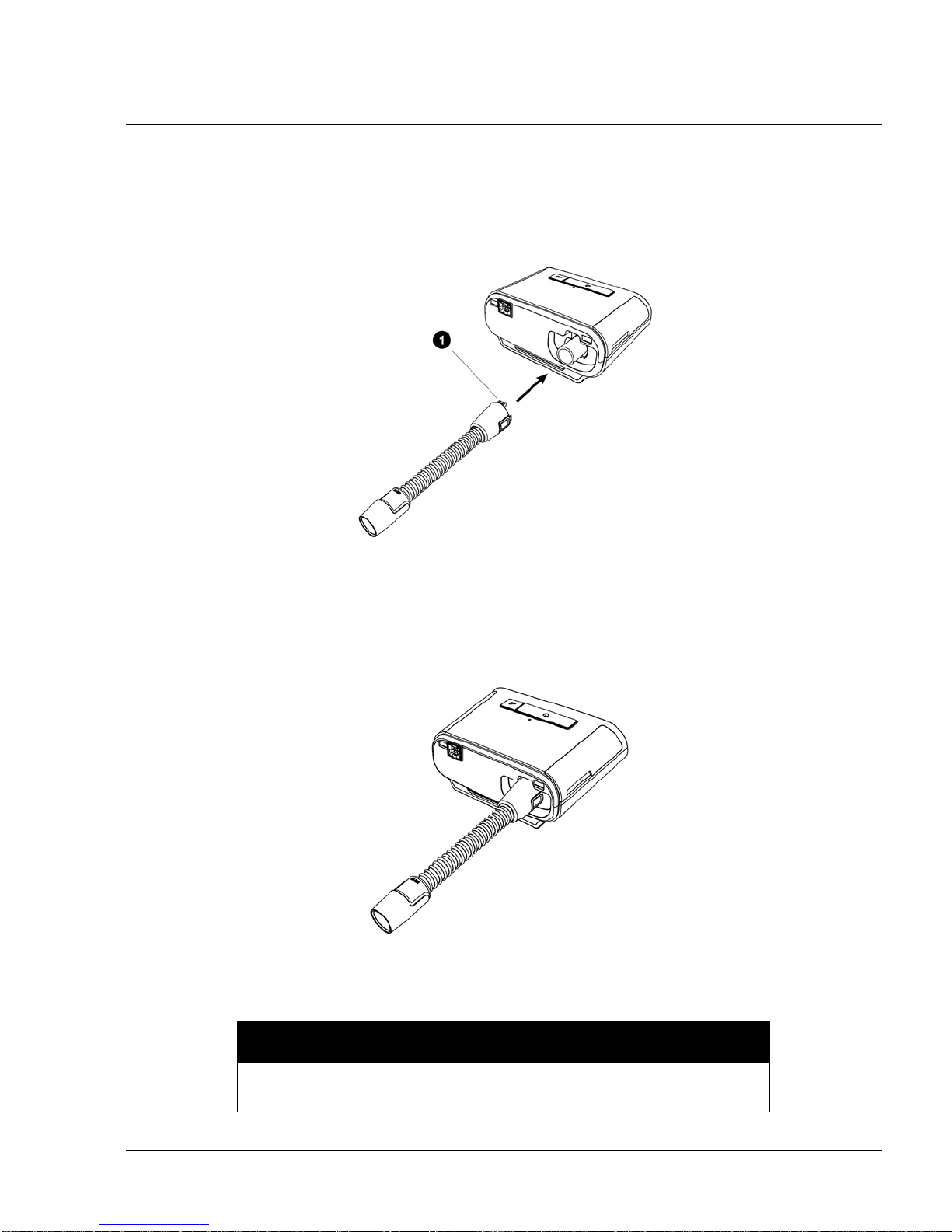

4.2 CONNECTING THE TUBING TO THE PAP DEVICE

To connect the Tubing to the device, complete the following steps:

1. Connect the flexible tubing to the air outlet on the back of the therapy device. Line up the connector (1) at the top of the heated tube to the top of the air out l et por t on th e ba ck of the devic e.

F

IGURE 4-3: CONNECTING THE TUBING TO THE PAP DEVICE

PAGE 4-31117539, VER. 07

2. Press the tubing into place over the air outlet port until the tabs on the side of the tube click into

place in the slots on the sides of the outlet port.

F

IGURE 4-4: TUBING CONNECTED TO THE PAP DEVICE

NOTE

If you are using a standard tube (not shown) instead of a heated tube,

simply slide the tubing over the air outlet port on the therapy device.

Page 19

PAGE 4-4

WARNINGS

• Do not pull or stretch the tubing. This could result in circuit leaks.

• Inspect the tubing for damage or wear. Discard and replace the tubing as

necessary.

• If the device is used by multiple persons (such as rental devices), a low-

resistance, main flow bacteria filter should be installed in-line between the

device and the circuit tubing to prevent contamination.

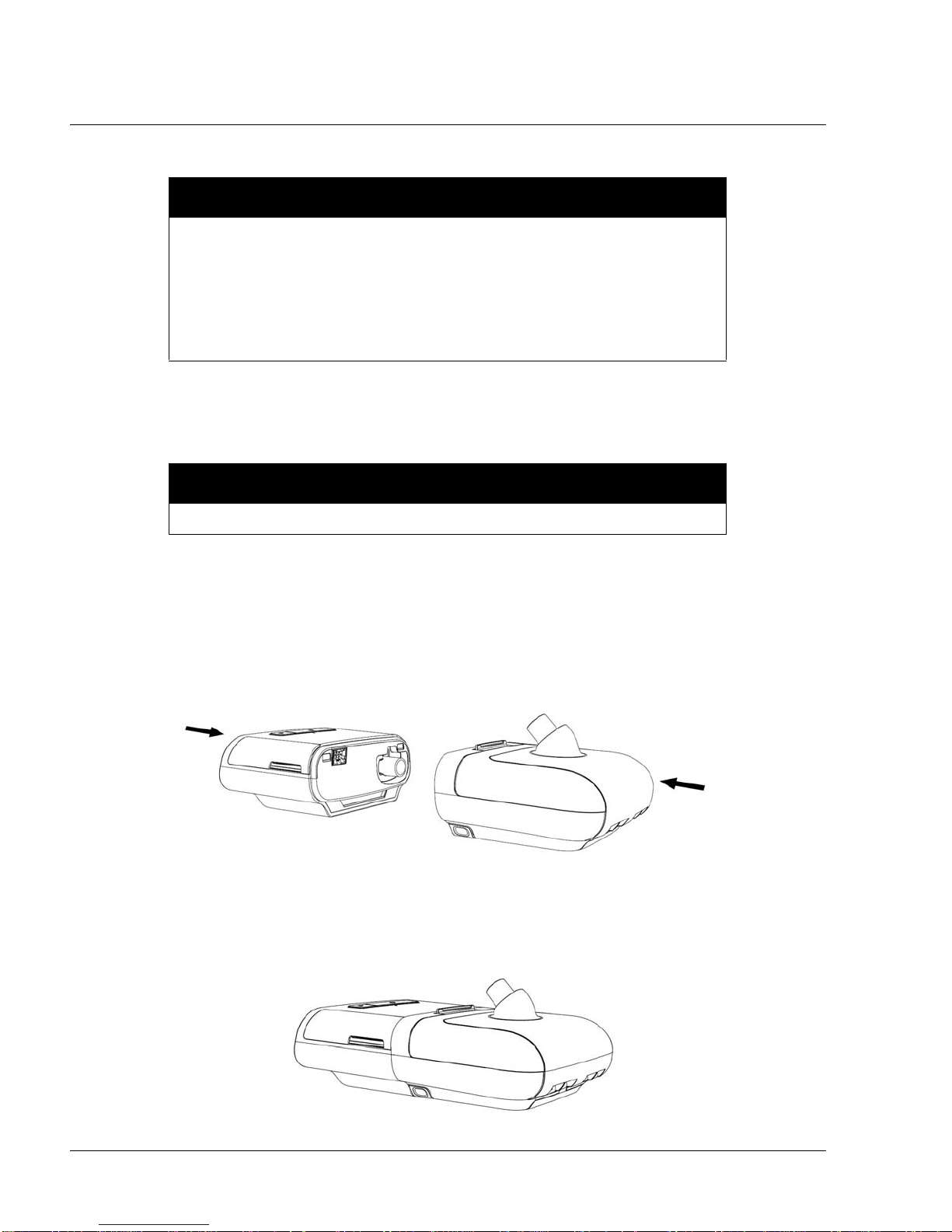

4.3 CONNECTING THE HUMIDIFIER TO THE PAP DEVICE

CAUTION

Do not move the humidifier while the water tank has water in it.

1117539, V

ER. 07

1. Place the therapy device and heated humidifier (with an empty water tank) on a firm, flat surface.

2. Line up the back of the therapy device to the front (top lid release latch side) of the heated humidifier.

3. Make sure the air outlet port on the therapy device lines up with the air inlet port on the humidifier

(not shown).

4. Slide the two units together until they snap into place.

F

IGURE 4-5: CONNECTING THE HUMIDIFIER

5. Make sure that the therap y de vice an d the hu mid ifier are completely seated against each other.

F

IGURE 4-6: HUMIDIFIER CONNECTED

Page 20

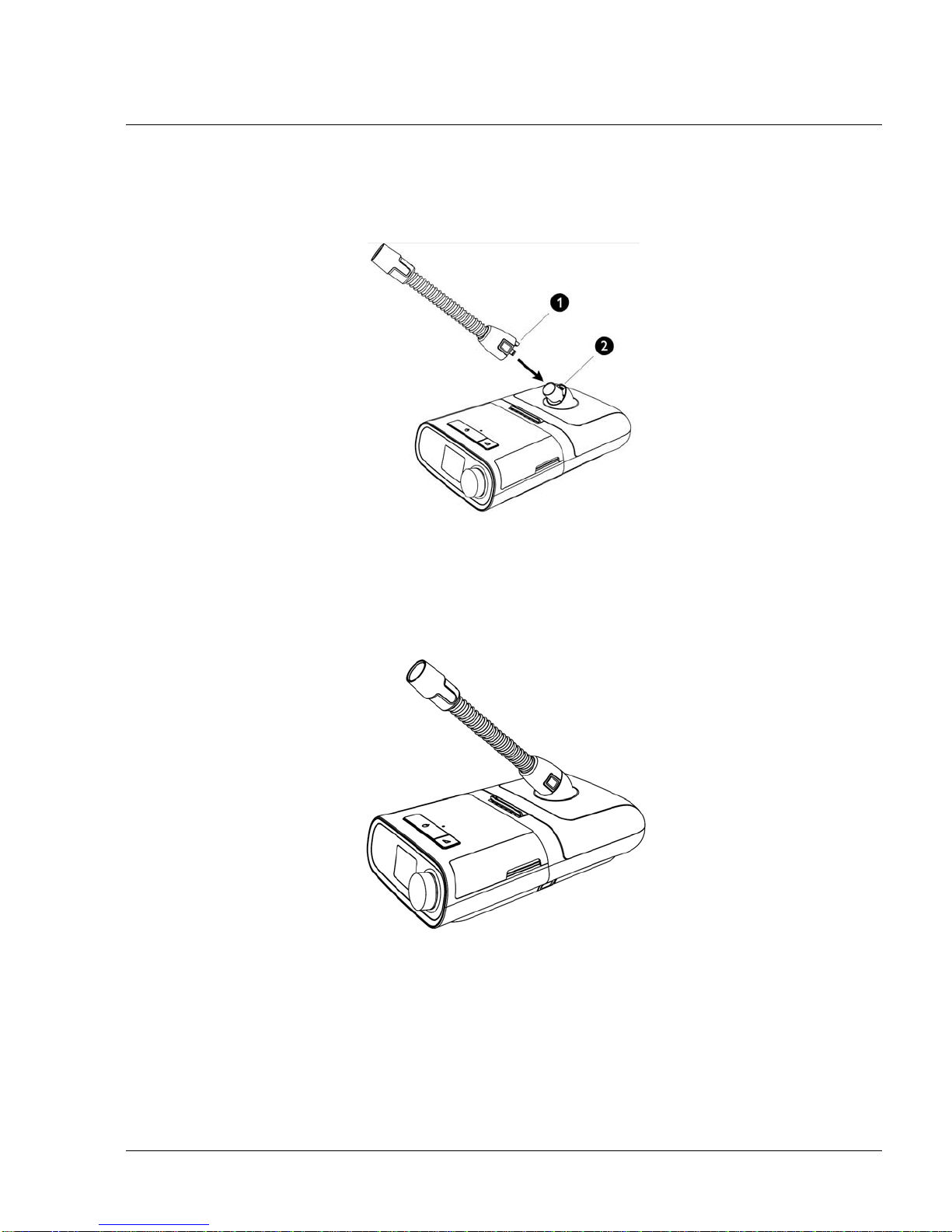

4.4 CONNECTING THE TUBING TO THE HUMIDIFIER

1. To attach the heated tube to the heated humidifier, line up the connector (1) at the top of the

heated tube to the top of the air outlet port (2) on the humidifier.

F

IGURE 4-7: CONNECTING THE TUBING TO THE HUMIDIFIER

PAGE 4-51117539, VER. 07

2. Press the tubing into place over the air outlet port until the tabs on the side of the tube click into

place in the slots on the sides of the outlet port.

IGURE 4-8: TUBING CONNECTED TO THE HUMIDIFIER

F

3. If you are using a standard tube (not shown) instead of a heated tube, simply slide the tubing over

the air outlet port on the heated humidifier.

Page 21

PAGE 4-6

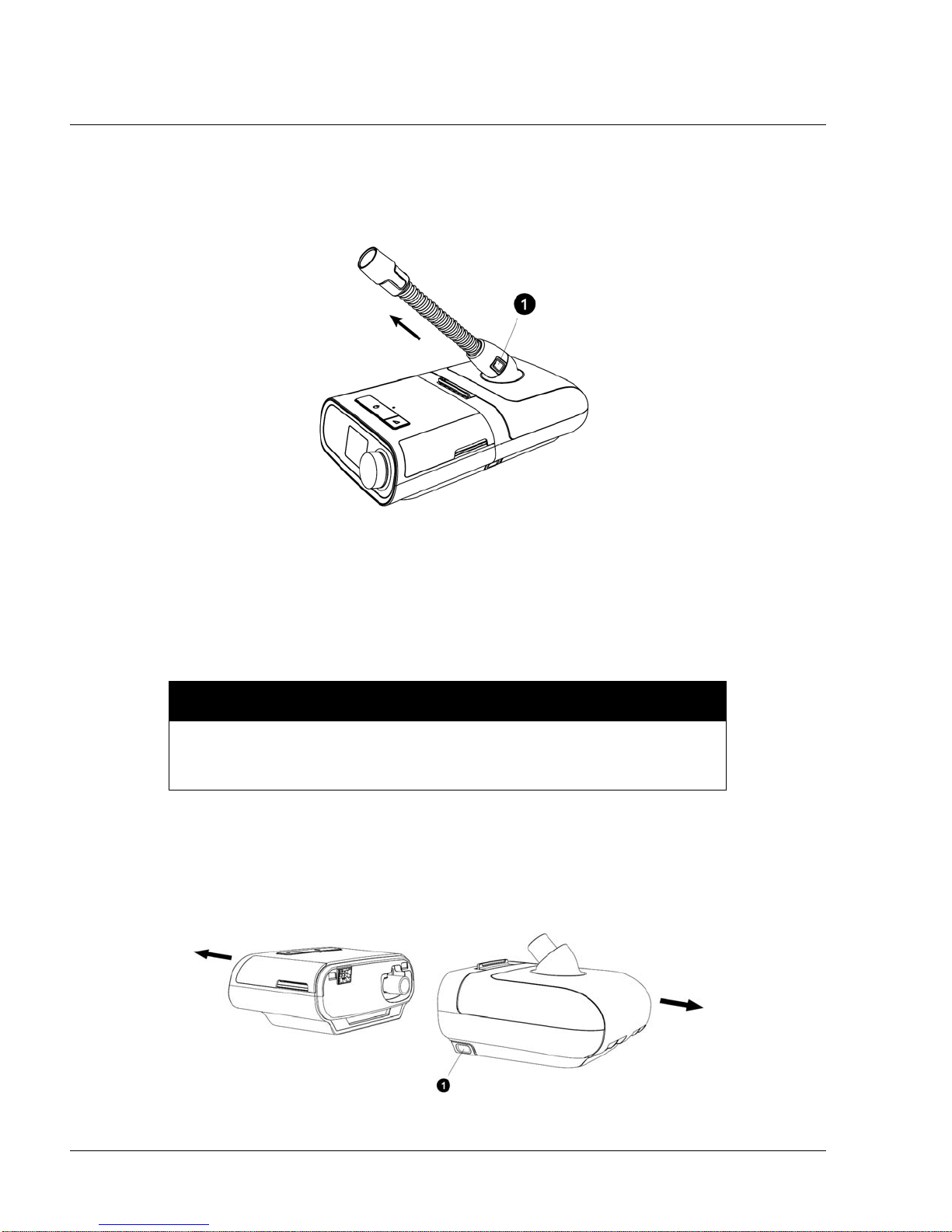

4.5 DISCONNECTING THE TUBING

1. To remove the heated tubing, press in the tabs (1) on the side of the tubing connector and pull the

tubing away from the outlet port.

F

IGURE 4-9: DISCONNECTING THE TUBING

1117539, V

ER. 07

2. If you are using a standard tube (not shown) instead of a heated tube, simply pull the tubing away

from the outlet port.

4.6 DISCONNECTING THE DEVICES

To avoid spilling, do not disconnect the humidifier from the therapy device with

water in the tank. Remove the water tank from the humidifier before

disconnecting the therapy device.

1. Disconnect power to the therapy device.

2. Pick up the system.

3. Place one hand on the therapy device and the other on the humidifier.

4. Press the humidifier release button (1) and pull apart to separate.

CAUTION

F

IGURE 4-10: DISCONNECTING THE DEVICES

Page 22

PAGE 4-71117539, VER. 07

4.7 CHECKING THE HUMIDIFIER LID SEAL

Under normal use, the humidifier lid seal should not require any maintenance or replacement. The seal may be

cleaned as needed by wiping it with a damp cloth. If necessary, the humidifier lid seal may be removed for

further cleaning. Gently peel the seal from the humidifier lid and clean it in a solution of warm water and a mild

liquid dish-washing detergent. Rinse with clean water. Wipe completely on both sides. Allow the seal to air dry.

Inspect the seal for damage. If the humidifier lid seal show signs of wear or damage, it should be replaced.

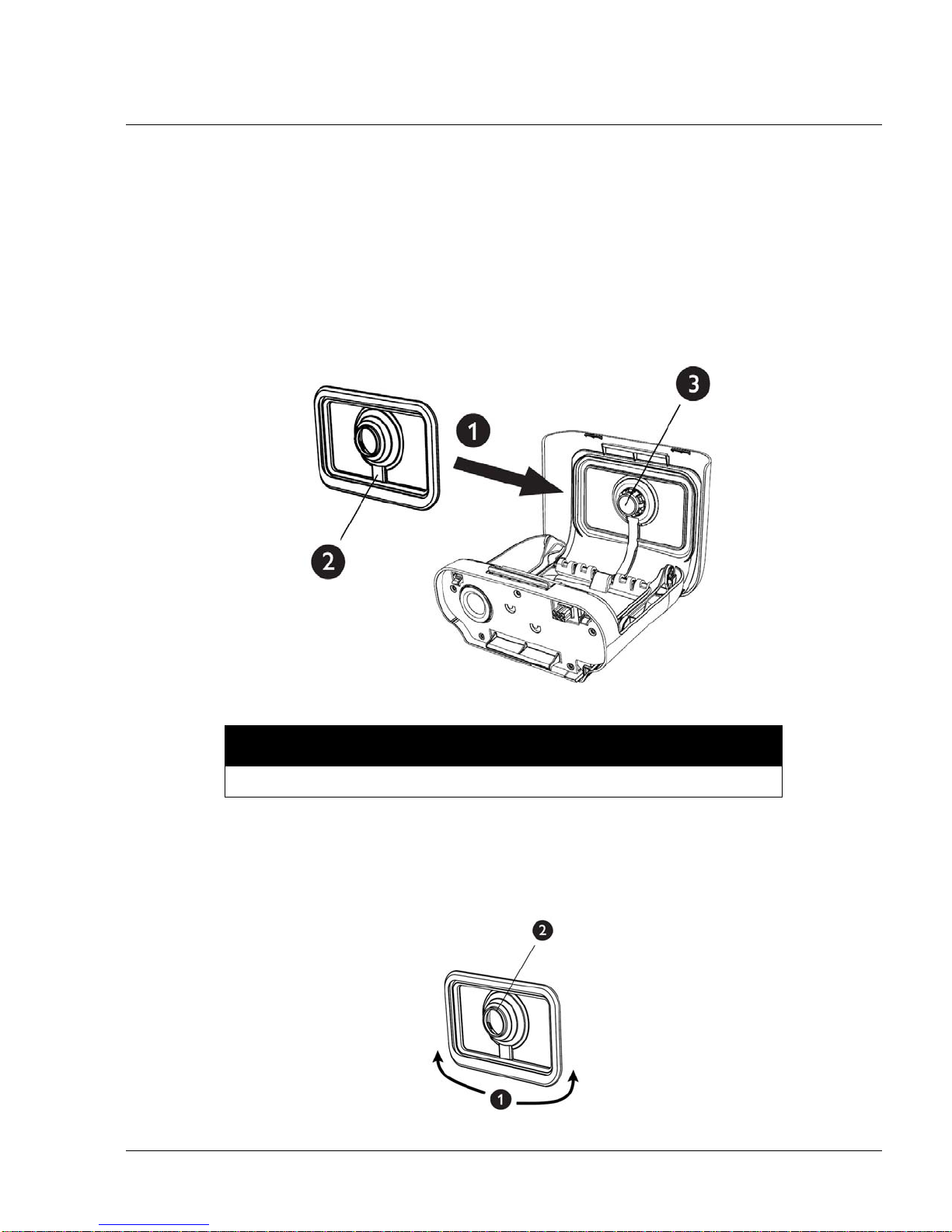

To install or reseat your humidifier lid seal, fully open the humidifier lid. Position the seal (1) against the inside

of the lid so the seal’s center hole aligns with the humidifier outlet port. Confirm that the seal is p ositioned so

the wire channel (2) in the seal is below the humidifier outlet port (3).

F

IGURE 4-11: CHECKING THE HUMIDIFIER LID SEAL

NOTE

The seal only fits properly in one orientation.

With the seal loosely in place, start at the bottom (1) and gently press the edges of the seal into the channel in

the lid of the humidifier. Continue sliding your fingers all around the rectangular perimeter of the seal until the

outer edge is completely seated. Next, press the seal around the humidifier outlet port (2) until the center of the

seal is fully seated. Finally, go back and run your fingers around the rectangular perimeter of the humidifier lid

seal once more to confirm it has not become dislodged.

F

IGURE 4-12: FLIP LID SEAL

Page 23

PAGE 4-8

1117539, V

ER. 07

4.8 INSTALLING/REPLACING THE AIR FILTERS

CAUTION

A properly installed, undamaged Philips Respironics blue pollen filter is

required for proper operation.

The device uses a blue pollen filter that is washable and reusable, and a light-blue ultra-fine filter that is

disposable.

The reusable blue filter screens out normal household dust and pollens, while the light-blue ultra-fine filter

provides more complete filtration of very fine particles. The reusable blue filter must be in place at all times

when the device is operating. The ultra-f ine filter is recommended for people who are sensitive to tobacco

smoke or other small particles.

The reusable blue filter is supplied with the device. A disposable light-blue ul tra-fine filter ma y also be include d.

If your filter is not already installed when you receive your device, you must at least install the reusable filter

before using the device.

This device has an automatic air filter reminder. Every 30 days, the device will display a message reminding

you to check your filters and replace them as directed.

NOTE

This message is a reminder only. The device does not detect the performance

of the filters nor does it recognize when a filter has been cleaned or replaced.

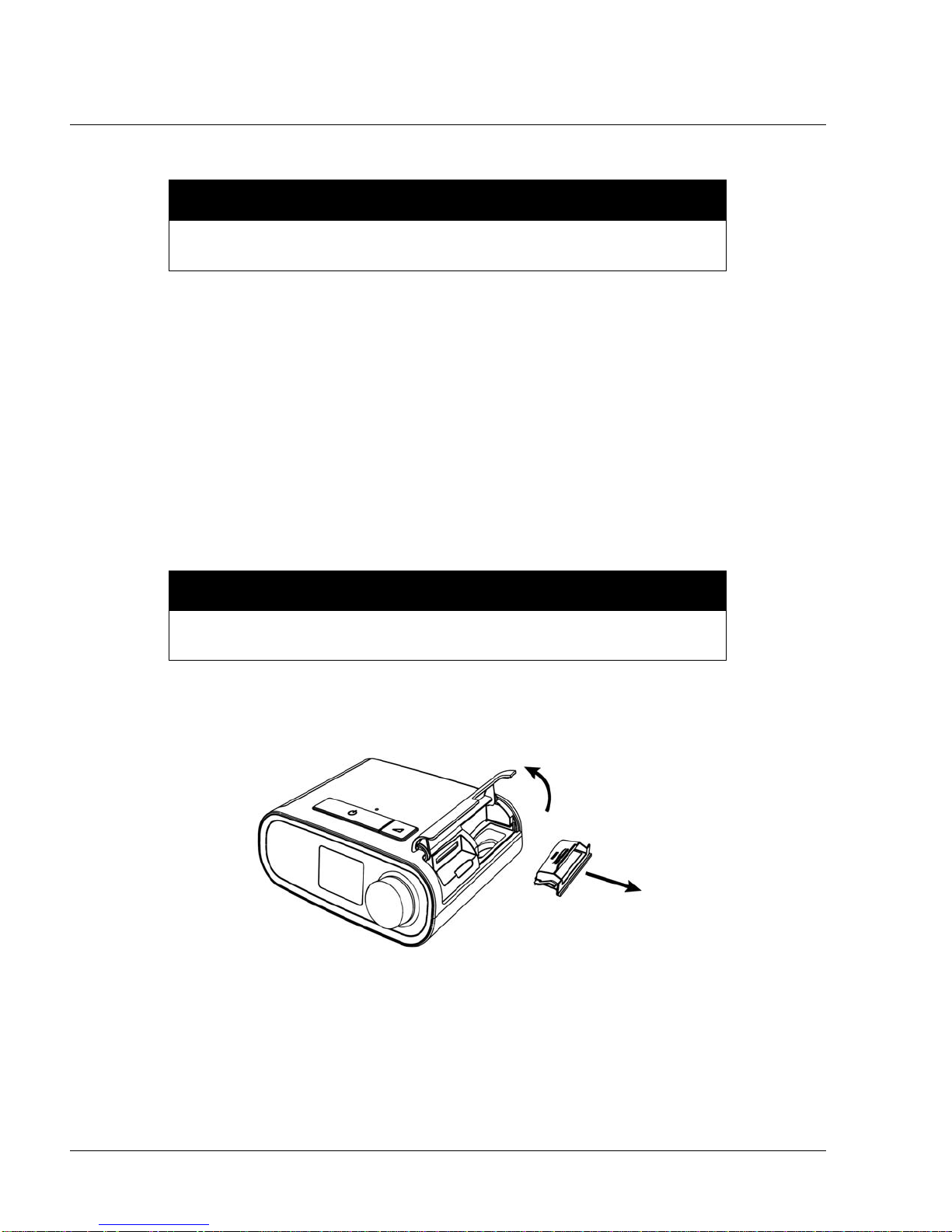

1. Lift up on the filter access door and swing open. If replacing, pull out the old filter assembly.

F

IGURE 4-13: REMOVING THE FILTER

Page 24

PAGE 4-91117539, VER. 07

2. If applicable, place a clean, reusable blue pollen filter (1) on top of a new, optional disposable lightblue ultra-fine filter (2) and firmly snap them together.

IGURE 4-14: POLLEN AND ULTRA-FINE FILTERS

F

3. Place the new filter assembly back in the side of the therapy device. Swing the door closed.

IGURE 4-15: INSTALLING THE FILTER

F

4.9 STARTING THE DEVICE

1. Ensure power is supplied to the device. The first screen to display will be the Philips Respironics

logo, followed by the device model screen, and then the Home screen.

F

IGURE 4-16: HOME SCREEN

The first time the device is powered on, a pop-up will prompt you to set the time on the device. The default

setting is Greenwich Mean Time, but you may adjust the ti m e in 30 minute in creme nts to match your local time

zone. If you choose to skip this initial time setting, the time can always be adjusted under the “My Setup” menu.

Note: This time setting is not displayed as a clock function on the device. It is only used to align

therapy data for Provider’s data reports.

Page 25

PAGE 4-10

2. Press the Therapy button on top of the device to turn on airflow and begin therapy. The current

delivered pressure will display on the screen.

3. Make sure that no air is leaking from the system.

4. Press the Therapy button again to turn off therapy.

NOTE

During therapy, it there is a mains interruption (i.e. power loss) the device will

return to the Home screen once power is restored. You may resume therapy a s

needed.

4.10 NAVIGATING THE DEVICE SCREENS

NOTE

The display is not a touch screen. You must use the control dial to navigate the

device menu.

1117539, V

ER. 07

The User Interface (UI) on this device allows you to adjust the device settings and view information about your

therapy. The UI is comprised of the display screen and the control dial. Rotate the control dial in either di rection

to scroll through the menu options on the display screen.

To adjust a setting:

1. Rotate the control dial to your desired menu option.

2. Press the control dial to select that setting.

3. Rotate the control dial to change the setting.

4. Press the control dial ag ain to sav e th e cha n ge.

.

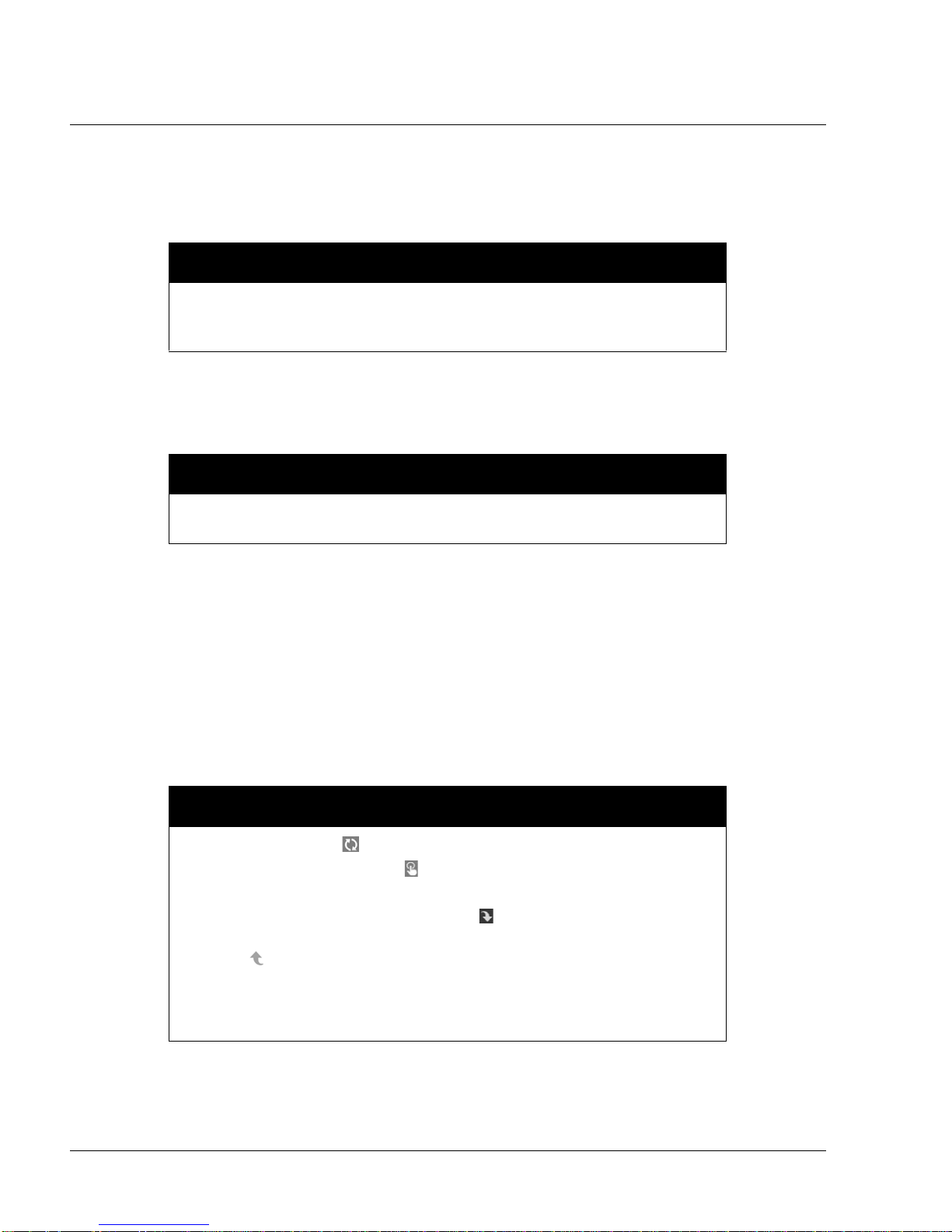

NOTES

•

The rotate dial icon on any screen indicates to rotate the dial to perform

an action. The click dial icon

perform an action.

on any screen indicates to press the dial to

• Pressing the dial when the down arrow appears on any screen will take

you to a sub-menu with more menu options. Pressing the dial when the up

arrow

appears on any sub-menu will return you back to the main menu.

• The screens shown throughout this manual are examples for reference

only. Actual screens may vary based upon device model and provider

settings.

Page 26

PAGE 4-111117539, VER. 07

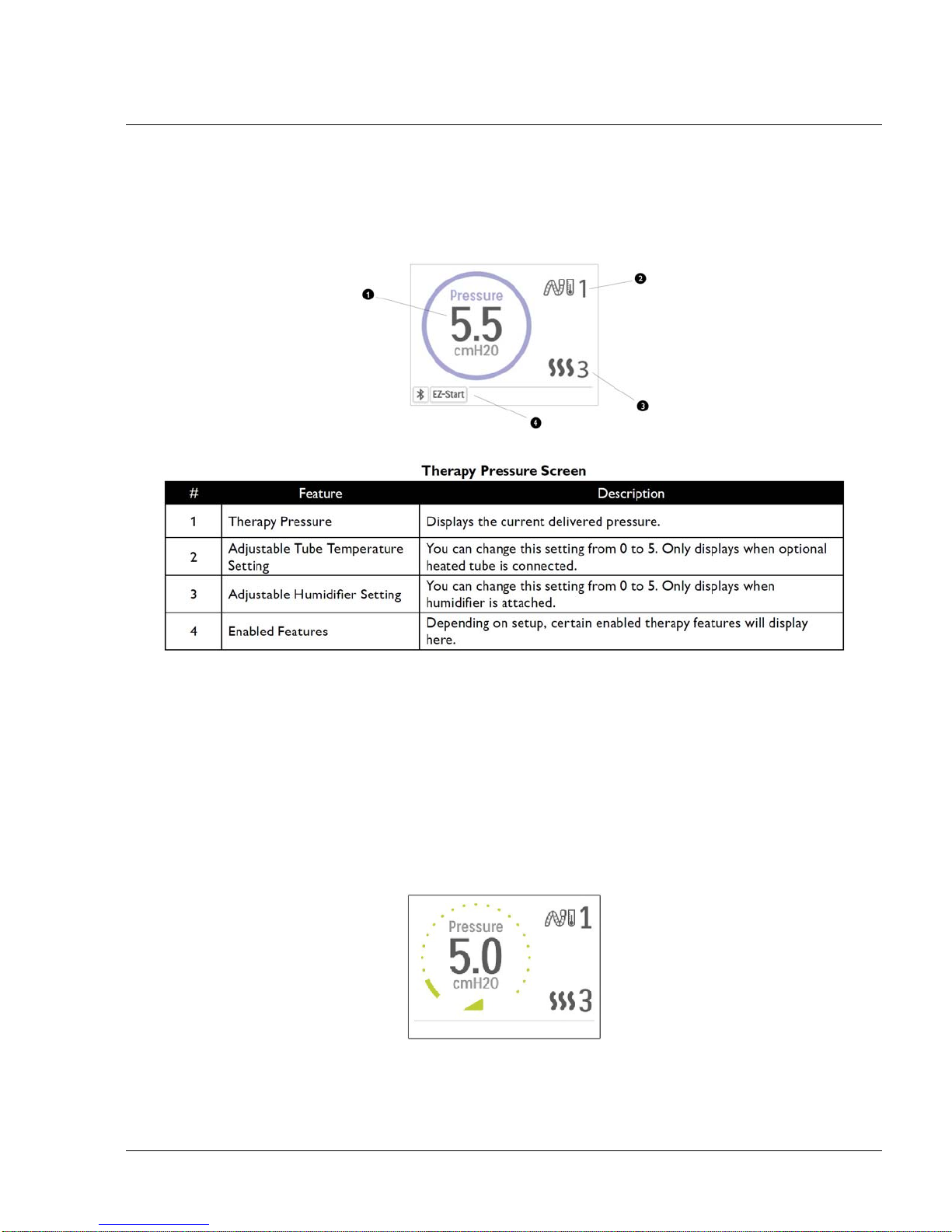

4.10.1 USER MENU NAVIGATION (THERAPY ON) AND OPTIONAL HUMIDIFICATION SETTINGS

While the device is delivering therapy, you can adjust Tube Temperature or Humidifier Settings . Rotate the

control dial to choose either setting. Press and rotate the dial to change the setting.

Note: If you are using the Humidifier without the Heated Tube, simply just rotate the control dial to change the

Humidifier setting.

F

IGURE 4-17: THERAPY PRESSURE SCREEN

Ramp Feature

The device is equipped with an optional ramp feature that can be enabled or d isabled. Th is feature reduces the

air pressure when you are trying to fall asleep and then gradually increases (ramps) the pressure until your

prescription setting is reached, allowing you to fall asleep more comfortably.

If ramp is enabled on your device, after you tur n on the ai rflow, press the Ramp button on the top of the device.

You can use the Ramp button as often as you wish during the night.

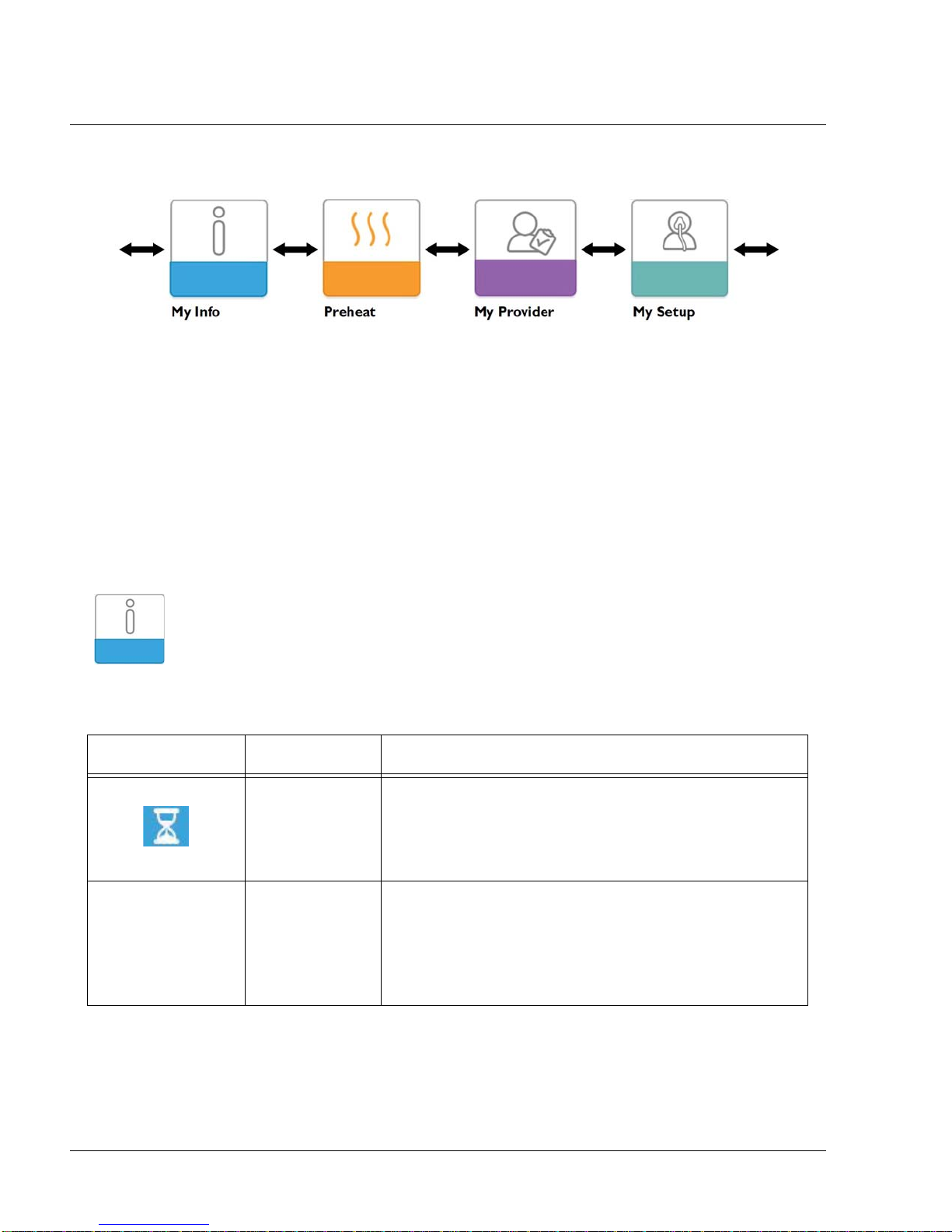

When you click the ramp button, the Therapy screen will change to reflect the Ramp pressure, and the green

circle will reflect the gradual increase in pressure.

F

IGURE 4-18: RAMP PRESSURE SCREEN

The device has two ramp modes. The standard ramp mode increases pressure at a steady rate. Alternately,

the SmartRamp mode maintains a constant lower pressure until the device detects that you require more

pressure.

Page 27

PAGE 4-12

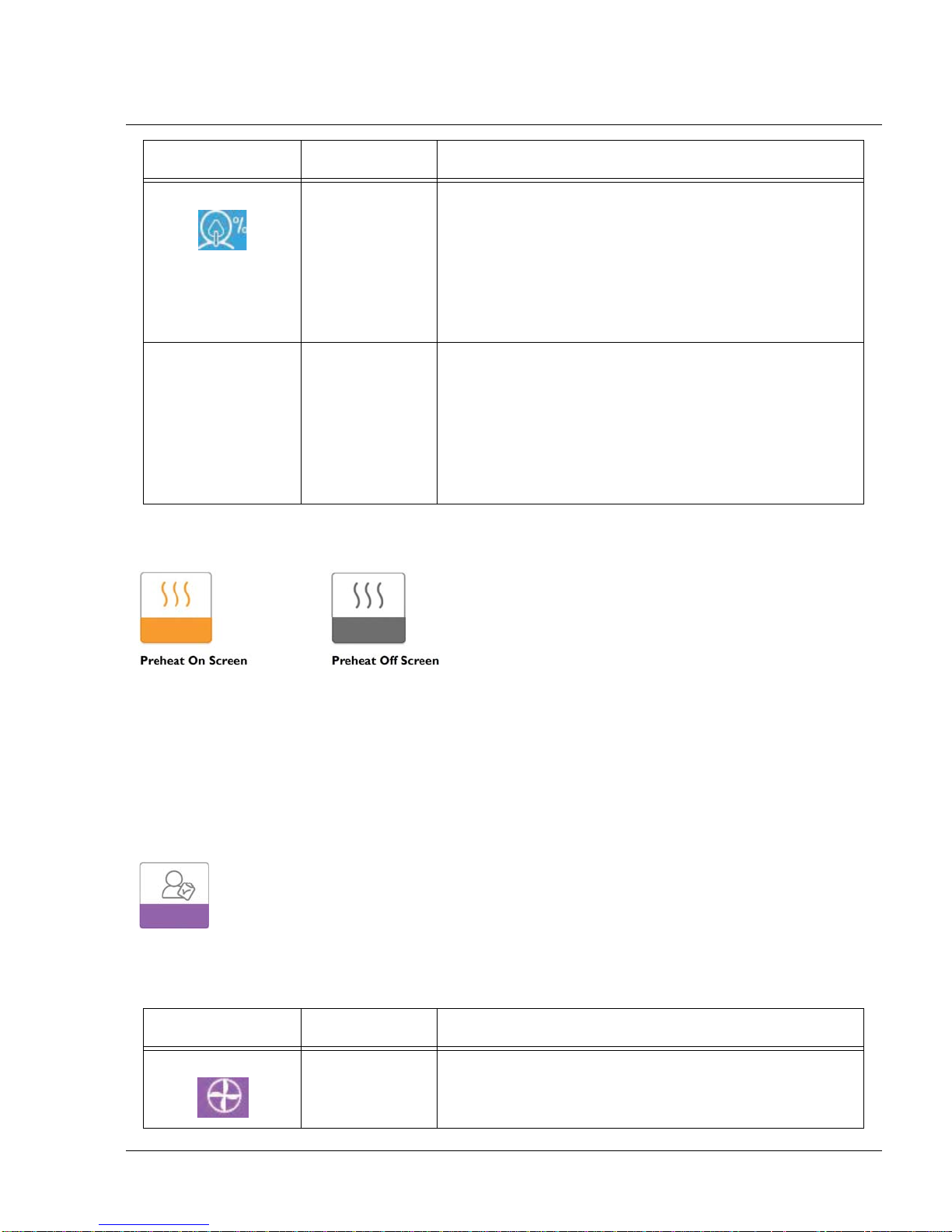

4.10.2 USER MENU NAVIGATION (THERAPY OFF)

From the Home screen, you can scroll between the following four options:

F

IGURE 4-19: USER MENU (THERAPY OFF)

• My Info: This menu provides summary statistics of your therapy use.

• Preheat: This function lets you warm up your humidifier for 30 minutes before starting a therapy

session.

• My Provider: This menu contains informatio n that the provider may direct the user to r ead to them

so they can better assist them over the phone.

• My Setup: This menu contains comfort settings that you can adjust as needed.

1117539, V

ER. 07

My Info:

When you select “My Info”, you will be able to view the following screens. You cannot change settings in the

Info menu. These screens are only for reference.

ICON TEXT DESCRIPTION

Therapy Hours This screen displays the amount of time the user is actually

receiving therapy on the device for the most recent 1 day

time frame. It also displays the average amount of time the

patient is actually receiving therapy over the last 7 days and

30 days.

AHI AHI This screen displays the nightly Apnea/Hypopnea indices

(AHI) value for the most recent 1 day time frame. It also

displays the average of these individual nightly AHI values

over a 7 day and a 30 day time frame. This screen only

displays if your home care provider has enabled it. Only

available on CPAP Pro and Auto CPAP devices.

Page 28

ICON TEXT DESCRIPTION

Mask Fit Displays the value “100% minus Large Leak”. Large Leak is

the percentage of time that the mask leak was so high that it

is no longer possible for the device to identify respiratory

events with statistical accuracy. Displays the value for the

most recent 1 day, as well as the values over last 7 days

and 30 days. This screen only displays if your home care

provider has enabled it. Only available on CPAP Pro and

Auto CPAP devices.

PAGE 4-131117539, VER. 07

Periodic

Breathing

Preheat:

When using a humidifier, the device can preheat the water tank for up to 30 minutes prior to starting therapy. In

order to activate the preheat mode, the blower must be “off” and a humidifier must be attached. When

“Preheat” is selected, you will be able to turn the control dial to choose between “on” or “off”. Press the control

dial again to make your selection. During the 30 minute preheat, you will still be able to use the control dial to

select other menu options from the Home screen.

Note: This screen only displays when a humidifier is attached.

Periodic

Breathing

Displays the percentage of time that the user exp erienced

periodic breathing. Displays the value for the most recent 1

day time frame, as well as values for the last 7 days and 30

days. If you observe a large increase in the percent of time

in periodic breathing indicated her, contact your home care

provider for assistance. This screen only displays if your

home care provider has enabled it. Only availa b le on CPAP

Pro and Auto CPAP devices.

My Provider:

When you select “My Provider”, you will be able to view the following screens. You cannot change settings in

the Provider menu.These screens are only for reference.

ICON TEXT DESCRIPTION

Device Info This screen displays your therapy device information: serial

number, model and software version.

Page 29

PAGE 4-14

ICON TEXT DESCRIPTION

1117539, V

ER. 07

Provider Contact

Info

This screen will display the contact information for your

provider if it has been uploaded to your device.

Phone-In This screen displays the total therapy hours for the device,

the total blower hours, the total number of days used when

the sessions were greater than 4 hours, and a compliance

check number used by your home care provider to validate

that the data provided by you is the data taken from this

screen.

Compliance This screen displays your start date, the total number of

days used when the sessions were greater than 4 hours,

and a check code number used by your home care

provider.

VIC90 VIC 90 This Visual Inspection Check screen will display a check

code number created from information gathered over the

most recent 90 day period. This 15 digit number will display

as: xxx.xxxx.xxxx.xxxx. Your home care provider may

periodically ask you for this information.

A-TRIAL A-Trial If Auto-Trial mode is available, this screen displays Days:

xx/xx (where xx/xx is the number of accumulated trial days /

number of selected trial days). Available on the Pr o, Auto,

BiPAP Pro, and BiPAP Auto models.

90%

Pressure

IPAP: 90%

Pressure

EPAP: 90%

Pressure

90% Pressure This screen displays the nightly value of 90% Pressure for

the most recent 1 day time frame. It also displays the

average of these individual nightly values of 90% Pressure

over a 7 day and a 30 day time frame. Availab le on the Auto

model.

IPAP: 90%

Pressure

Displays the value of 90% inhalation pressure for the mo st

recent 1 day, as well as the average values over the last 7

days and 30 days. Available on the BiPAP Auto model.

EPAP: 90%

Pressure

Displays the value of 90% exhalation pressure for the most

recent 1 day, as well as the average values over the last 7

days and 30 days. Available on the BiPAP Auto model.

Upload Allows user to initiate a modem call when an optional

Cellular or Wi-Fi Accessory is installed. After the modem

upload has finished, the screen will either display a green

checkmark with the text “Completed” to indicate a

successful upload, or a red X with the text “Failed” to

indicate an unsuccessful upload. If the upload fails, initiate

an upload a second time, or contact your home care

provider if the issue persists. This screen is locked if

modem is off.

Page 30

ICON TEXT DESCRIPTION

PAGE 4-151117539, VER. 07

Performance

Check

My Setup:

When you select “My Setup”, you will be able to view the following screens. Y ou can change the settings in the

Setup menu. These screens will only display if they are available and enabled on the device.

Your device is equipped with a self-diagnostic tool called

“Performance Check.” This tool can evaluate your device

for certain errors. It also allows you to share key device

settings with your home care provider. Use Performance

Check when directed to by your home care provider.

At conclusion of the scan, the screen displays a green

checkmark if no issue is detected. If device displays a red

“X”, please contact your home care provider for assistance.

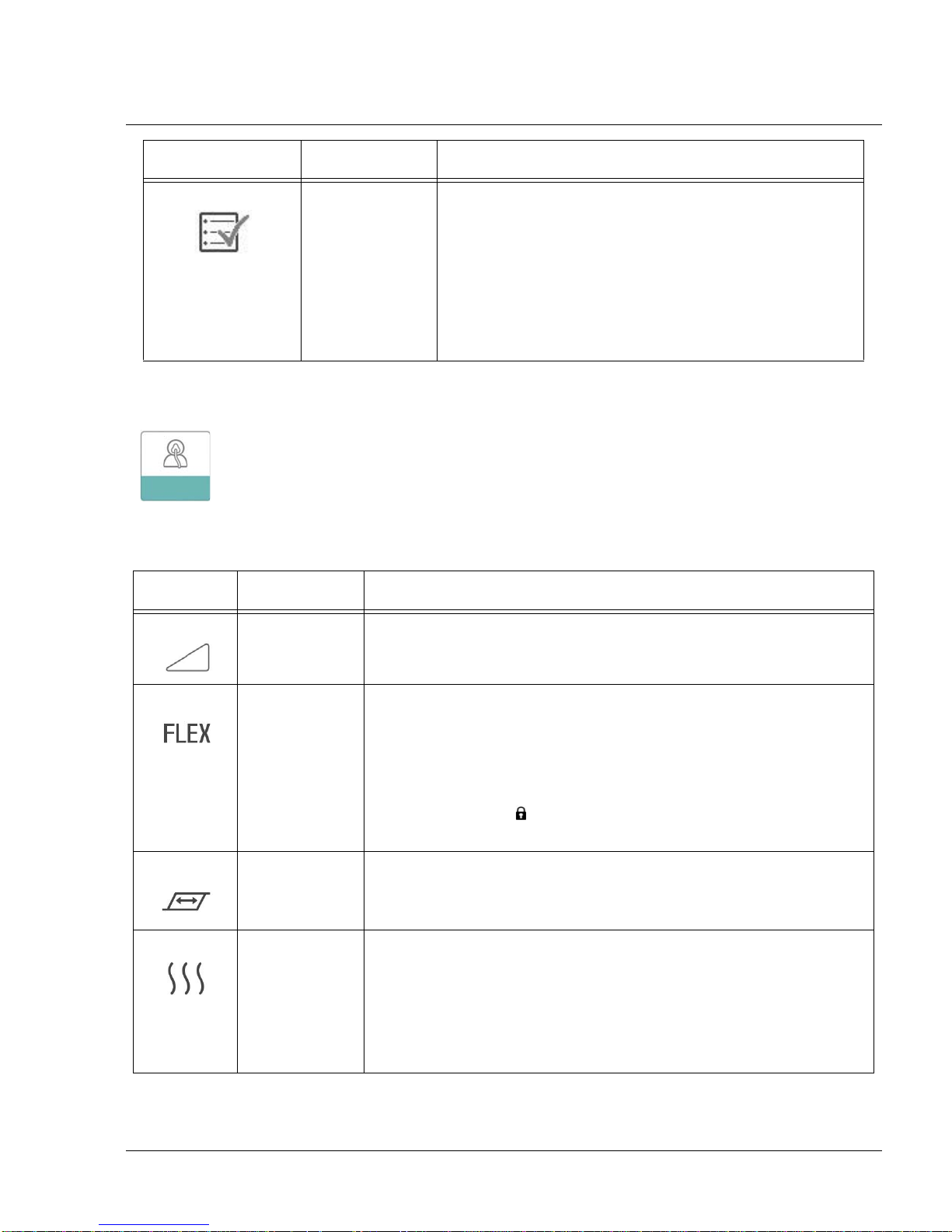

ICON TEXT DESCRIPTION

Ramp This dis plays t he ram p starting pr essu re. You can increase or decrease

the ramp starting pressure in 0.5 cm H2O increments.

Flex This allows you to adjust the level of air pressure relief that you feel

when you exhale during therapy. Your home care provider can enable

or disable this feature. When your provider enables Flex, a level will

already be set for you on the device. You can increase or decrease the

setting from 1 to 3. The setting of “1” provides a small amount of

pressure relief, with higher numbers providing additional relief.

Note: If a lock icon

provider has locked this setting and you cannot change it.

Rise Time Rise time is the time it takes for the device to change from EPAP to

IPAP. This screen allows you to adjust the rise time so you can find the

desired setting.

Humidification This displays the Humidification Mode being used. You can choose

between Fixed or Adaptive Humidification. If a heated tube is being

used, the device will automatically switch to Heated Tube Humidification

Mode. A “lock” symbol will appear next to the mode setting indicating

that so long as the heated tube is attached to the device, this mode

cannot be changed. However, the heater plate and tube temperature

settings can still be adjusted on the device Therapy screen as normal.

is displayed on this screen, it indicates that yo ur

Page 31

PAGE 4-16

ICON TEXT DESCRIPTION

Mask Type This setting allows you to adjust the level of air pressure relief based on

the specific Philips Respironics mask. Each Philips Respironics mask

may have a “System One” resistance control setting. Contact your

home care provider if you cannot find this resistance setting for your

mask.

Note: If a lock icon

provider has locked this setting and you cannot change it.

Tube Type This setting allows you to select the correct size diameter tubing that

you are using with the device. You can choose either (22) for the Philips

Respironics 22 mm tubing, or (15) for the Philips Respironics 15 mm

tubing. When using Heated T ubing, the device will automatically change

this setting to the appropriate tubing type (15H) and you will not be able

to change it.

Note: Tubing is identified on the cuff with the tubing identifier symbol:

“15”, “22” or “15H”.

Note: If a lock icon is displayed on this screen, it indicates that your

provider has locked this setting and you cannot change it.

Language This feature allows you to choose which language to display on the

interface. You can also turn off (0) text mode which means the device

will display the “Icon Mode” on the interface.

is displayed on this screen, it indicates that your

1117539, V

ER. 07

Check Mask Fit This feature allows you to check the fit of your mask prior to starting

therapy. This is done by measuring the amount of leak.

Modem Allows you to turn modem off temporarily or turn it back on. When

modem is turned off, it will automatically turn on again after 3 days. Only

displays when modem is installed.

Bluetooth Allows you to turn Bluetooth off and on. Also, it allows you to clear the

pairing with a compatible Bluetooth device.

Time Allows you to adjust the time. The default setting is Greenwich Mean

Time, but you may adjust the time in 30 minute increments to match

your local time zone.

Note: This time setting is not displayed as a clock function on the

device. It is only used to align your therapy data for your Provider’s data

reports.

Page 32

PAGE 4-171117539, VER. 07

Check Mask Fit

The optional check mask fit feature can be enabled or disabled by the home care provider. This feature allows

you to check the fit of your mask prior to startin g ther apy. This is done by measuring the amount of leak. Put on

your mask assembly. Refer to your mask instructions if needed. Navigate to the Check Mask Fit screen under

“My Setup” and press the control dial to initiate the check.

The device will deliver a test pressure while the screen counts down 40 seconds. A green bar indicates good

fit, while a red bar indicates improvement is needed. After the test, normal therapy will start and the screen will

either display a green checkmark or a red “X”. The green checkmark indicates that the leak found allows for

optimal performance of the device. The red “X” indicates that the leak may affect device performance,

however, the device will remain functional and deliver therapy.

F

IGURE 4-20: CHECK MASK FIT SCREEN

Sleep Progress

The device provides summary information about therapy use each time the therapy is turned off. The first

screen displays “Three Night Summary.” It shows nightly usage for the last 3 sleep sessions (measured in 24

hour periods, ending at noon each day). The most recent session is displayed in the right hand bar, labeled

with the number of hours slept. A green bar indica tes that the per son sle pt more tha n 4 hour s, and a yellow bar

indicates less than 4 hours of use.

The second screen shows the total number of 4+ hour nights that the person had slept in the last 30 days. It

provides a goal of sleeping at least 4 hours per night for 70% of the last 30 nigh ts. Therefore the goal is 21

“good nights” of use. This screen provides a simple way to track progress. The screen will stop displaying

when the goal is reached, or after the first 90 days of use has passed, whichever comes first.

Altitude Compensation

This device automatically compensates for altitude up to 7,500 feet. No manual adjustment is necessary.

Page 33

PAGE 4-18

1117539, V

4.10.3 ACCESSING PROVIDER MODE SCREENS

Accessing provider mode unlocks settings that cannot be modified by the user. To access provider mode:

1. Supply power to the device. First, plug the socket end of the AC power cord into the power sup ply.

Then plug the pronged end of the AC power co rd in to a n electrical o utlet that is not controlled b y a

wall switch. Finally, plug the power supply cord’s connector into the power inlet on the back of the

device.

2. Once the device is powered, press and hold both the control dial and the Ramp button on the

device for at least 5 seconds.

3. Y ou are now in provider mode. You can choose between the following Provider mode screens.

4.10.4 NAVIGATING THE PROVIDER MODE SCREENS

The following sections will describe the options available from the Provider screens:

ER. 07

Therapy Settings:

Choosing this screen will take you to a sub-menu where you can adjust the device therapy modes and

pressure settings. These settings are described here.

F

IGURE 4-21: SAMPLE THERAPY SUB-MENU

Note: Not all settings shown here will display on the device. The display will vary based on therapy device

model and device settings.

Page 34

ICON TEXT DESCRIPTION

PAGE 4-191117539, VER. 07

CPAP

C-Check

Auto

Bi-Level

AutoB

Opti-Start Opti-Start This feature starts an Auto-CPAP therapy session at a starting

EZ-Start EZ-Start This feature reduces the therapy pressure setting for the first

Mode This screen displays the therapy mode setting. Depending on

the therapy device model, you can select CPAP mode, CPAPCheck (C-Check) mode, Auto-CPAP (Auto) mode, Bi-Level

mode, or Auto Bi-Level (AutoB) mode.

Note: CPAP-Check mode (C-Check) delivers CPAP therapy

while automatically adjusting the pressure level to meet

patient needs over the long term. Every 30 hours of therapy

use, the therapy device evaluates patient obstructive

respiratory disturbance index (ORDI) and increments pressure

± 1 cm H2O if needed. The range of adjustment that can be

made over time is limited to ± 3 cm H2O of the CPAPCheck

pressure setting, in 1 cm H2O increments.

pressure that is closer to the previous session’s 90%

pressure, in order to reduce the likelihood of any residual

events at the beginning of a therapy session. You can enable

or disable this feature.

few days of operation and gradually increases this setting until

the prescription therapy pressure is reached. The initial

pressure will be half of the prescription pressure, but no lower

than 5 cm H2O. After each day of successful use (the session

was greater than 4 hours), the therapy pressure will increase

by 1 cm H2O until the prescription pressure is reached.

From that point forward, the therapy device would operate in

normal CPAP or CPAP-Check mode. If the patient has not

reached their prescription pressure after 30 days of EZ-Start,

then the therapy pressure will increase by 1 cm H2O per day

until the prescription pressure is reached. You can enable or

disable EZ-Start only if CPAP or CPAP-Check mode is

enabled.

A-TRIAL A-Trial This Auto-Trial feature will enable the device to deliver Auto-

A-Trial Days This screen allows you to adjust the duration of the Auto-Trial

Auto Min This screen allows you to modify the Auto minimum pressure

CPAP therapy for a selectable number of days of patient use.

You can enable or disable this feature.

feature in number of days. You can set this from 3 to 30 days.

The default is 7 days. This setting only displays if Auto-Trial

mode is available and enabled. When you reach the last

available Auto-Trial period, the text for this selection will

appear in red font.

setting. You can adjust this setting from 4 cm H2O to the Auto

maximum pressure setting. This setting only displays if AutoCPAP mode is enabled or if the Auto-Trial feature is available

and enabled.

Page 35

PAGE 4-20

1117539, V

ICON TEXT DESCRIPTION

Auto Max This screen allows you to modify the Aut o maximum pressu re

setting. You can adjust this setting from the Auto minimum

pressure setting to 20 cm H2O. This screen only displays if

Auto-CPAP mode is enabled or if the Auto-Trial feature is

available and enabled.

cmH

O Pressure This screen allows you to adjust the CPAP pressure, or the

2

IPAP IPAP This screen allows you to modify the IPAP setting. The initial

EPAP EPAP This screen allows you to modify the EPAP setting. The initial

CPAP-Check mode starting pressure. If Auto-Trial mode was

used, you can choose the 90% pressure setting determined

from the Auto-Trial mode, or you can adjust this setting from 4

to 20 cm H2O. If the Auto-Trial mode was not used, this

screen allows you to only adjust the pressure setting from 4 to

20 cm H2O.

default setting is 20 cm H2O. You can adjust the setting from

the EPAP setting to 25 cm H2O. This screen only displays if

Bi-level mode is enabled.

default setting is 4 cm H2O. You can adjust the setting from 4

cm H2O to the IPAP setting. This screen only displays if Bilevel mode is enabled.

ER. 07

IPAP Max This screen allows you to modify the Maximum IPAP setting.

The setting you specify here will be the maximum level of

pressure applied during the inspiratory breath phase. You may

adjust the setting from the Minimum EPAP setting to 25 cm

H2O. This screen only displays if Auto Bi-level mode is

enabled.

EPAP Max This screen allows you to modify the Minimum EPAP setting.

The setting specified here will be the minimum level of

pressure applied during the expiratory breath phase. You may

adjust the setting from 4 cm H2O to the Maximum IPAP

setting. This screen only displays if Auto Bi-level mode is

enabled.

PS Min This screen allows you to modify the Minimum Pressure

Support setting. This setting is the minimum difference that is

permitted between IPAP and EPAP while Auto

Bi-level therapy mode is active. You may adjust the setting

from 0 cm H2O to the Maximum Pressure Support setting.

This screen only displays if Auto Bi-level mode is enabled.

PS Max This screen allows you to modify the Maximum Pressure

Support setting. This setting is the maximum difference that is

permitted between IPAP and EPAP while Auto Bi-level therapy

mode is active. You may adjust the setting from 0 cm H2O to

the minimum value of either 8 cm H2O, or the difference

between Max IPAP and Min EPAP. This screen only displays if

Auto Bi-level mode is enabled.

Page 36

PAGE 4-211117539, VER. 07

Comfort Settings:

Choosing this screen will take you to a sub-menu where you can adjust the humidification and pressure

comfort settings. These settings are described here.

IGURE 4-22: SAMPLE COMFORT SUB-MENU

F

Note: Not all settings shown here will display on the device. The display will vary based on therapy device

model and device settings.

ICON TEXT DESCRIPTION

Humidification This setting allows you to select the Humidification Mode

being used. You can choose between Fixed or Adaptive (A)

Humidification. If a heated tube is attached to the device, then

the device will automatically switch to Heated Tube

Humidification Mode.

Fixed mode applies a constant heat on the humidifier heater

plate. Under certain conditions and settings, this mode can

allow condensation to occur in the tube.

Adaptive mode adapts the heater plate temperature to the

ambient conditions in the room, and is designed to not allow

condensation to occur in the tube.

Humidifier This setting allows you to choose the desired humidity setting

for the humidifier: 0, 1, 2, 3, 4 or 5.

Tube

Temperature

This setting allows you to choose the desired temperature for

the heated tube: 0, 1, 2, 3, 4 or 5.

Page 37

PAGE 4-22

ICON TEXT DESCRIPTION

SmartRamp When SmartRamp mode is enabled, the therapy device’s

ramp function utilizes an Auto titrating algorithm during the

ramp period. It allows patients the ability to stay at lower

pressures during the ramp period, to improve their acclimation

to therapy.

SmartRamp mode functions differently, depending on the

therapy mode that the device is using.

*In CPAP or CPAP-Check mode, the SmartRamp applies the

Auto-CPAP algorithm during the ramp period. The Ramp Start

pressure becomes the Auto Minimum pressure during the

ramp period. The Auto Maximum pressure during ramp is the

CPAP or CPAP-Check pressure.

*In Auto mode, the SmartRamp applies the Auto-CPAP

algorithm during the ramp period. The Ramp Start pressure

becomes the Auto Minimum pressure during the ramp period.

The Auto Maximum pressure during ramp is the Auto

Minimum under normal Auto mode.

*In BiPAP or Auto-BiPAP mode, the SmartRamp applies the a

modified version of the Auto-BiPAP algorithm during the ramp

period. The Ramp Start pressure becomes the EPAP

Minimum pressure, and the Pressure Support Minimum

pressured is applied.

The IPAP Maximum pressure during ramp is the EPAP or

EPAP Minimum under normal BiPAP or Auto-BiPAP mode.

The SmartRamp period will terminate in either of two ways:

1) If SmartRamp pressure reaches the minimum pressure of

the therapy mode selected, then SmartRamp ends, and the

device continues to deliver therapy under the selected therapy

mode, or:

2) If SmartRamp pressure does not reach the minimum

pressure of the therapy mode selected by the end of the

Ramp Time, then pressure is increased at a rate of

approximately 1 cm H2O per minute. Once the pressure

reaches the minimum pressure of the therapy mode selected,

then the device will continue to deliver therapy for that mode.

If SmartRamp mode is not enabled, then the standard, linear

pressure ramp mode is active.

1117539, V

ER. 07

Ramp Time When you set the Ramp time, the device increases the

therapy pressure from the value set on the Ramp start screen

to the therapy pressure setting over the length of time

specified here. If the therapy pressure is set to 4 cm H2O (the

minimum setting), this screen will not display.

Note: Depending on the therapy mode, the therapy pressure

setting could be CPAP pressure, CPAP-Check pressure, Auto

min pressure, EPAP pressure, or EPAP min pressure.

Note: If the Ramp time is set to 0, Ramp start will not display.

Page 38

ICON TEXT DESCRIPTION

Ramp Start This displays the Ramp starting pr essure . You can increase or

decrease the Ramp starting pressure in 0.5 cm H2O

increments. This is only available if Ramp time has been set to

>0 and therapy pressure >4 cm H2O.

Note: Depending on the therapy mode, the therapy pressure

setting could be CPAP pressure, CPAP-Check pressure, Auto

min pressure, EPAP pressure, or EPAP min pressure.

Flex This screen displays the comfort mode setting. You can select

None, C-Flex, or C-Flex+ (if in CPAP or CPAP-Check mode).

You can select None, C-Flex, or A-Flex (if in Auto-CPAP or

Auto-Trial mode).

Flex Setting You can modify the Flex setting (1, 2 or 3) on this screen if you

enabled Flex. The setting of “1” provides a small amount of

pressure relief, with higher numbers providing additional relie f.

Flex Lock This enables you to lock the Flex setting if you do not want the

patient to change it.

PAGE 4-231117539, VER. 07

Rise Time Rise time is the time it takes for the device to change from

EPAP to IPAP. This screen allows you to adjust the rise time

so you can find the desired setting. This is only available if

Flex has been disabled and the device is in Bi-level or Auto Bilevel mode.

• 0 (off) reduces the Rise Time feature to the lowest setting

(off = 150 msec).

• 1 sets Rise Time to 1 (200 msec).

• 2 sets Rise Time to 2 (300 msec).

• 3 sets Rise Time to 3 (400 msec).

Rise Time Lock This enables you to lock the Rise Time setting if you do not

want the patient to change it.

Tube Type This setting allows you to select the correct size diameter

tubing that you are using with the device. You can choose

either (22) for the Philips Respironics 22 mm tubing, or (15) for

the Philips Respironics 15 mm tubing. When using Heated

Tubing, the device will automatically change this setting to the

appropriate tubing type (15H).

Tube Type Lock This enables you to lock the Tubing type setting for either the

15 mm or the 22 mm tubing if you do not want the patient to

change it.

Page 39

PAGE 4-24

ICON TEXT DESCRIPTION

Mask Type This setting allows you to select the appropriate Mask Type

resistance setting (also known as System One Resistance

Control) for your Philips Respironics mask. This feature allows

the device to adjust the level of pressure compensation to

match your mask. Refer to the packaging of your mask to

identify the resistance setting for your mask.

Note: It is important to use the appropriate “Mask Type”

resistance setting to ensure proper pressure delivery to the

patient.

Mask Type Lock This enables you to lock the Mask Type resistance setting if

you do not want the patient to change it.

Check Mask Fit You can enable or disable the check mask fit setting. This

feature allows the patient to check the fit of their mask prior to

starting therapy. This is done by measuring the amount of leak

in the patient circuit.

1117539, V

ER. 07

Device Settings:

Choosing this screen will take you to a sub-menu where you can adjust the way the device displays

information. These settings are described here.

F

IGURE 4-23: SAMPLE DEVICE SUB-MENU

Note: Not all settings shown here will display on the device. The display will vary based on therapy device

model and device settings.

Page 40

ICON TEXT DESCRIPTION

PAGE 4-251117539, VER. 07

AHI Show

AHI/Fit/PB

You can select whether or not the Apnea/Hypopnea index,

Mask Fit averages, and Periodic Breathing averages are

displayed on the Patient Info screens.

cmH

O Pressure Units If enabled on the device, you will have the option to choose

2

the units of pressure that are displayed. You can choose

between “cm H2O” or “hPa”.

Automatic On You can enable or disable this feature if you want the device

to automatically turn the airflow on whenever the patient

applies the interface (mask) to their airway.

Automatic Off You can enable or disable this feature if you want the device

to automatically turn the airflow off whenever the patient

removes the interface (mask) from their airway.

Language This feature allows you to choose which language to display

on the interface. You can choose English or Spanish.

Clear Default

Reminders

This setting turns off the default patient reminders that are

enabled in the therapy device from the factory.

Note: This does not turn off additional reminders that you

may have activated in Encore. Encore messages must be

cleared or modified in Encore.

Reset Data Use the Reset Data function to clear patient data from the

therapy device, as well as an SD card and modem (if

installed). After you click to execute Reset Data, the device

will display a message asking you to confirm the reset. Click

again to reset data in the device.

Note: Reset Data resets Blower Hours that are visible to the

patient, but it does not reset Machine Hours in the Provider

Menu.

Page 41

PAGE 4-26

1117539, V

ER. 07

Info Screens:

Choosing this screen will take you to a sub-menu where you can view information on patient usage. These info

screens are described here.

Note: Not all the screens shown here will display on the device. The display will vary based on therapy device

model and device settings.

ICON TEXT DESCRIPTION

Phone In This screen displays the total therapy hours for the device, the

total blower hours, and the total number of days used when the

sessions were greater than 4 hours since the device was last

reset. This screen also displays a compliance check number

you can use to validate that the data provided to you is the da t a

taken from this screen.

Compliance This screen displays the start day and the total number of days

used when the sessions were greater than 4 hours. This

screen also displays a check code number you can use to

validate that the data provided to you is the dat a taken fr om this

screen.

VIC90 VIC90 This Visual Inspection Check screen will display a check code

number created from information gathered over the most

recent 90 day period. This 15 digit number will display as:

xxx.xxxx.xxxx.xxxx.

Days>4 Days Greater

Than 4

This screen displays the cumulative number of device therapy

sessions that exceeded 4 hours over a 1 day, a 7 day, and a 30

day time frame.

Therapy Hours The device is capable of recognizing the difference between

the time the patient is actually receiving therapy and the time

when the blower is simply running. This screen displays the

amount of time the patient is actually receiving therapy on the

device for the most recent 1 day time frame. It also displays the

average amount of time the pati ent is actually receiving th erapy

on the device over a 7 day and a 30 day time

frame (provided the device has at least 7 or 30 days of data

respectively). If the device has only 5 days of data to use for

the calculation, the 5 day average value will be seen under the

7 day display.

Device Hours This screen displays the number of hours that the blower has

been active over the life of the device.

Page 42

PAGE 4-271117539, VER. 07

ICON TEXT DESCRIPTION

Mask Fit Displays the value “100 - % Large Leak”. % Large Leak is the

percentage of time that the mask leak was so high that it is no

longer possible for the device to identify respiratory events with

statistical accuracy. Displays the value for the most recent 1

day, as well as the values over last 7 days and 30 days.

AHI AHI The device accumulates individual Apnea/Hypopnea indices

(AHI) for each session the patient used the device. This screen

displays the nightly AHI value for the most recent 1 day time

frame. It also displays the average of these individual nightly

AHI values over a 7 day and a 30 day time frame (provided the

device has at least 7 or 30 days of data respectively). If the

device has only 5 days of data to use for the calculation, the 5

day average value will be seen under the 7 day display.

CSR Periodic

Breathing

90% 90% Pressure During any given night, the device recognizes the 90%

During any given night, the device recognize s the percentage

of time the patient was experiencing periodic breathing. This

screen displays the nightly value of periodic breathing for the

most recent 1 day time frame. It also displays the average of

these individual nightly values of periodic breathing over a 7

day and a 30 day time frame (provided the d evice has at least 7

or 30 days of data respectively). If the device has only 5 days of

data to use for the calculation, the 5 day average value will be

seen under the 7 day display.

Pressure achieved by the Auto Algorithm. 90% Pressure is

defined as the pressure at which the device spent 90% of the

session time at or below. For example, if the device recognized

airflow for 10 hours, and 9 hours were spent at or below 11 cm

H2O, and 1 hour was spent above 11 cm H2O, then the 90%

Pressure would be 11 cm H2O. This screen displays the nightly

value of 90% Pressure for the most recent 1 day time frame. It

also displays the average of these individual nightly values of

90% Pressure over a 7 day and a 30 day time frame (provided

the device has at least 7 or 30 days of data respectively). If the

device has only 5 days of data to use for the calculation, the 5

day average value will be seen under the 7 day display. This

screen only displays if the device is in Auto- CPAP or Auto-Trial

therapy mode.

IPAP 90% IPAP:

90% Pressure

EPAP 90% EPAP:

90% Pressure

A-Trial A-Trial If Auto-Trial mode is available and enabled, this screen

Displays the value of 90% inhalation pressure for the most

recent 1 day, as well as the average values over the last 7 days

and 30 days. Available on the Auto BiPAP model.

Displays the value of 90% exhalation pressure for the most

recent 1 day, as well as the average values over the last 7 days

and 30 days. Available on the Auto BiPAP model.

displays Days: xx/xx (where xx/xx is the number of completed

trial days / number of selected trial days).

Page 43

PAGE 4-28

Return to Patient Mode:

Choosing this screen will exit Provider mode and the device will return to the Patient mode. Provider mode will

also time out after 5 minutes of inactivity and automatically return to the Patient mode.

1117539, V

ER. 07

4.11 PERFORMANCE CHECK DEVICE SCREENING TOOL

Performance Check troubleshooting tool is a self-diagnostic utility built into the therapy device. It allows you to

quickly evaluate a therapy de vice remotely. If a patient calls indicating that their therapy does not seem to be

operating properly, just direct them to click on Performance Check in the patient’s My Provider menu. The

check operates the blower and screens the device for any operation errors. The screen then displays whether

the device passed the check (displays a green check mark) or should be returned for service (displays a red

X). If a modem is installed, Performance Check will automatically upload a troubleshooting dashboard to the

Encore Anywhere patient management softwa re. Th is dashboar d gives you an over view of key device settin gs

and statistics to help make troubleshooting over the phone easier. If there is not a modem installed in the

therapy device, you can direct the patient to read you the five codes off the Performance Check screen over

the phone. You can decode these codes in EncoreAnywhere, EncorePro or Encore Basic to populate the

troubleshooting dashboard.

4.12 BLUETOOTH WIRELESS TECHNOLOGY

The device may be equipped with Bluetooth wireless technology. If available, you can pair the therapy device

to a mobile device that has the DreamMapper app installed. DreamMapper is a mobile and web-based system

designed to help Obstructive Sleep Apnea (OSA) patients enhance their sleep therapy experience.

4.12.1 PAIRING TO YOUR BLUETOOTH ENABLED MOBILE DEVICE

NOTES

• You can only pair your therapy device to one mobile device at any given

time.

• Pairing works best when your therapy device and mobile device are in the

same room.

Follow the steps below to manually pair to your mobile phone or tablet.

1. To pair to your mobile device, first ensure that the Bluetooth setting is turned ON on your mobile

device. Refer to your mobile device’s instruction manual for more information.

2. If you need to select from a list of available Bluetooth devices, the therapy device will appear as

“PR BT XXXX” (XXXX will be the last four digits of the serial number listed on your therapy

device).

3. When your therapy device is powered up but the blower is off, initiate pairing from your mobile

device.

4. If your mobile device is in range, one of the following two steps will apply:

Page 44

PAGE 4-291117539, VER. 07

• Your mobile device has Bluetooth Secure Simple Pairing (SSP)

The following icon will pop-up on your therapy device screen with a 6 digit number and “Pair?”:

This number is a six digit passkey generated during SSP. Verify that the six digit SSP passkey is the same on

both the mobile device and therapy device. Rotate the Control Dial between “yes” or “no”, and then press the

Control Dial to choose. If “no” is selected, or the pop-up screen times out after 30 seconds, the device will

reject the pair request. If “yes” is selected, the therapy device will acknowledge the six digit SSP passkey. If the

mobile device also acknowledges the request, the two will now be paired and ready to connect using

DreamMapper.

• Your Bluetooth enabled mobile device does not support Bluetooth SSP

Your mobile device will prompt you to enter a pin code. Enter “1008” on your mobile device. The following icon

will pop-up on your therapy device screen with the number “001008” and “Pair?”:

Rotate the Control Dial between “yes” or “no”, and then press the Control Dial to choose. If “no” is selected, or

the pop-up screen times out after 30 seconds, the device will reject the pair request. If “yes” is selected, the

therapy device will acknowledge the 001008 passkey. If the mobile device also acknowledges the request, the

two will now be paired and ready to connect using DreamMapper.

Note: Do NOT select “yes” on the pop-up screen unless you are currently trying to pair your devic es. This will

ensure that only your mobile device connects to your therapy device.

4.13 ACCESSORIES

There are several accessories available for the DreamStation system such as a Humidifier, Cellular Modem,

Wi-Fi Accessory or a Link Module. When using optional accessories, always follow the instructions enclosed

with the accessories.

CAUTION

Pins of connectors should not be touched. Connections should not be made to these

connectors unless ESD precautionary procedures are used. Precautionary procedures include

methods to prevent build-up of electrostatic charge (e.g., air conditioning, humidification,

conductive floor coverings, non-synthetic clothing), discharging one’s body to the frame of the

equipment or system or to earth or a large metal object, and bonding oneself by means of a

wrist strap to the equipment or system or to earth.

Page 45

PAGE 4-30

1117539, V

ER. 07

4.13.1 HUMIDIFIER WITH OR WITHOUT HEATED TUBING

You can use the heated humidifier and the hea ted tube wi th the device. A humidifier may reduce na sal dryness

and irritation by adding moisture to the airflow.

WARNING

For safe operation, the humidifier must always be positioned below the breathing circuit

connection at the mask. The humidifier must be level for proper operation.

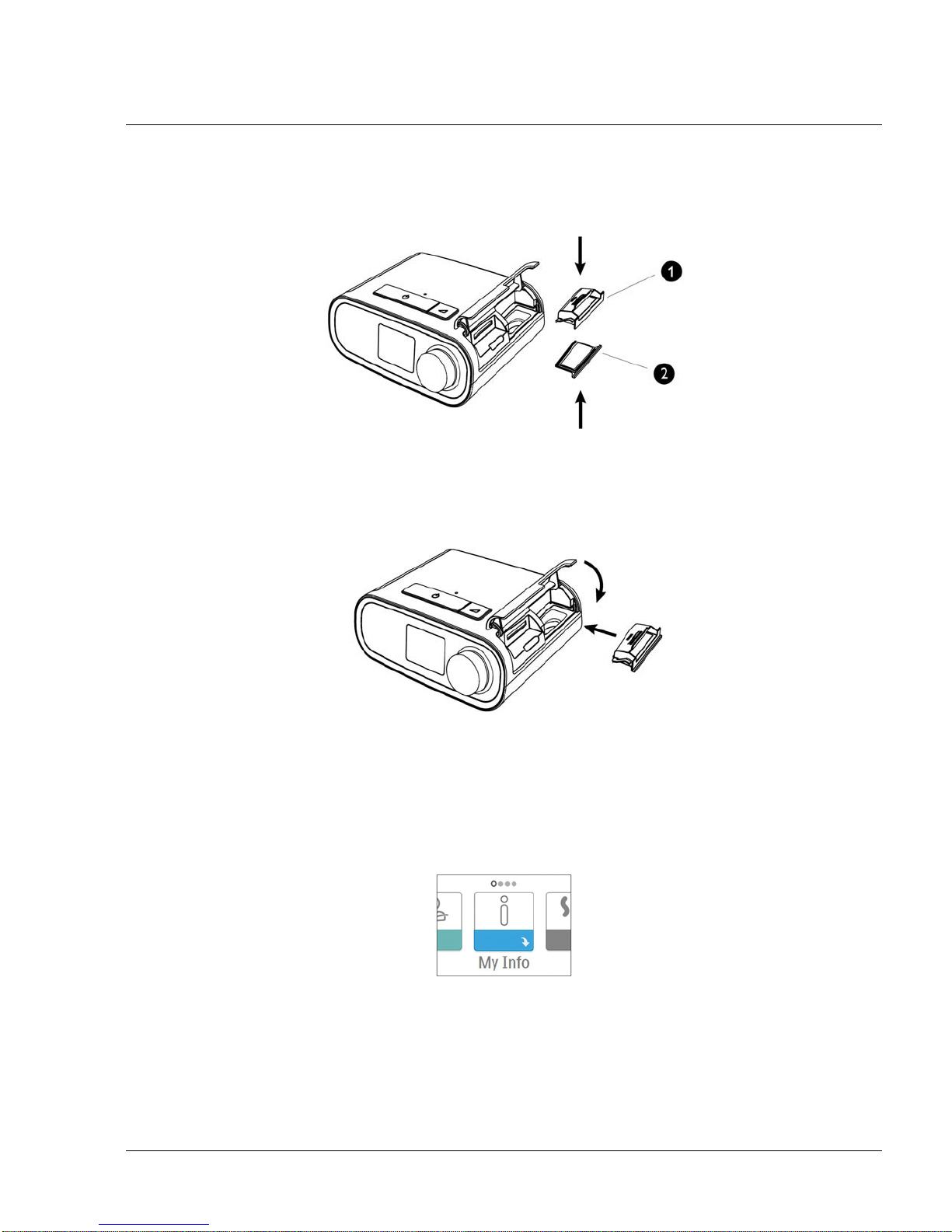

4.13.2 SD CARD

The DreamStation system comes with an SD card inserted in the SD card slot on the side of the device to

record information for the home care provider.

4.13.3 LINK MODULE

The Link Module is able to receive oximetry data and transfer it to the therapy device for home use or in a

laboratory setting. For use in Service or in a laboratory setting, the Link Module also includes an RS-232 (or

“DB9”) port to allow remote control of the DreamStation Sleep Therapy Device by a personal computer.

NOTES

• Please refer below for Link Module installation and removal instructions.

• There are no SpO2 alarms available.

• Oximetry data is not displayed.

To clean the module, remove the module from the therapy device. Wipe the outside of the device with a cloth

slightly dampened with water and a mild detergent. Let the device dry completely before reinstalling into the

therapy device.

C

ONNECTING/DISCONNECTING THE LINK MODULE

Refer to the illustrations below to connect/disconnect the Link Module to the device.

Page 46

PAGE 5-11117539, VER. 07

CHAPTER 5: TROUBLESHOOTING AND ERROR CODES

5.0 INTRODUCTION

This section provides an overview of device troubleshooting, along with corrective action s to t ake based on the

outcome. You will also find bench checkout procedures, along with tables that include error codes and

descriptions. In addition, you will find troubleshooting guidance based on issues unrelated to error codes.

5.1 BENCH CHECKOUT

5.1.1 PAP DEVICE:

If the PAP device was returned with a Humidifier, perform these steps with and without the Humidifier if

necessary.

1. Visually inspect the outside of the device for physical damage and broken/missing parts.

2. Verify all components are aligned/seated properly, and not damaged.

3. Apply power to the device and verify the buttons are functioning properl y and are properly back-lit,

and the LCD is working.

4. If the device was returned with a power cord and power supply, verify that they function properly

with/without the device.

5. Turn on the device and verify proper operation of the unit.

6. Verify the device pressure by using a manometer (refer to section 5.2).

7. Listen to the device for noisy operation or loose components.

8. Refer to section 5.2 to retrieve the device Error Log, and refer to the chart for troublesh ooting guidance based on the Error.

9. Check all other components for physical damage.

10. Perform repairs to the device as necessary.

5.1.2 HUMIDIFIER:

If the Humidifier was returned with a PAP device, perform thes e steps with the returned PAP device.

1. Visually inspect the outside of the device for physical damage and broken/missing parts.

2. Verify all seals and all other components are aligned/seated properly, and not damaged.

3. Connect the Humidifier to the PAP device and apply power.

4. If the device was returned with a power cord and power supply, verify that they function properly

with/without the device.

5. Turn on the PAP device and adjust heater plate setting using the UI Knob to an y setting but 0, and

let the device run for at least 15 seconds.

6. If a Heated Tube was returned, connect the T ube to the Hu midifier, adjust the Heated Tube setting

using the UI Knob to any setting but 0, and verify the Tube is warming.

7. Verify the pressure at the Humidifier ISO Port by using a manometer.

8. Verify that the heater plate is heating.

9. Check all other components for physical damage.

10. Perform any repairs as necessary.

Page 47

PAGE 5-2

5.2 VERIFYING PRESSURE

• If the device fails to perform within the stated specifications, have the

system serviced by a qualified Philips Respironics-approved service

facility.

• You will need the following equipment to verify the pressure:

• Philips Respironics Pressure Calibration Kit

Kit Includes:

• Philips Respironics Whisper Swivel II (1)

• Philips Respironics O2 Enrichment Final Assembly (2)

• Closed end cap (3)