Page 1

Service

Manual

Page 2

Page 3

The BiPAP Vision Ventilatory Support System is the subject of U.S. patents #5148802,

#5239995, #5313937, #5433193, and other pending U.S. and foreign patents. BiPAP is a registered trademark of Respironics.

Copyright © 1998-2007 Respironics. All rights reserved.

BiPAP Vision Service Manual

1045049

Page 4

Limited Warranty

Respironics warrants that the BiPAP® VisionTM Ventilatory Support System (BiPAP Vision) shall be free from defects

of workmanship and materials and will perform in accordance with the product specifications for a period of one year

from the date of sale by Respironics. If the product fails to perform in accordance with the product specifications,

Respironics will repair or replace—at its option—the defective material or part. Respironics will pay customary

freight charges from Respironics to the dealer location only. This warranty does not cover damage caused by

accident, misuse, abuse, alteration, and other defects not related to materials or workmanship.

Respironics disclaims all liability for economic loss, loss of profits, overhead or consequential damages which may

be claimed to arise from any sale or use of this product. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty is given in lieu of all other express warranties. In addition, any implied warranty, including any

warranty of merchantability or fitness for the particular purpose, is limited to one year. Some states do not allow

limitations on how long an implied warranty lasts, so the above limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

The warranty for repairs is 90 days for labor and one year on the part(s) that was replaced.

To exercise your right under this warranty, contact your local authorized Respironics dealer or contact Respironics

at:

1045049

Visit Respironics Home Page on the World Wide Web at:

http://www.respironics.com

BiPAP Vision Service Manual

Page 5

Table of Contents

Chapter 1: Introduction .......................................................................................1-1

1.1 BiPAP Vision Ventilatory Support System Overview .............................................. 1-2

1.2 Service Notice ................................................................................................................. 1-3

1.3 Technical Support .......................................................................................................... 1-3

Chapter 2: Warnings, Cautions, and Notes ....................................................2-1

2.1 Warnings.......................................................................................................................... 2-2

2.2 Cautions........................................................................................................................... 2-3

2.3 Notes ................................................................................................................................ 2-4

Chapter 3: Description and Theory of Operation ........................................3-1

3.1 BiPAP Vision System ..................................................................................................... 3-2

3.2 Power Supply Subsystem (PSS) ................................................................................... 3-6

3.3 Main Control (MC) ........................................................................................................3-8

3.4 Pressure Control (PC) ....................................................................................................3-9

3.5 Display Control (DC) ................................................................................................... 3-11

3.6 Airflow Module (AFM) ............................................................................................... 3-14

3.7 Oxygen Module (OM) ................................................................................................. 3-16

3.8 Description of Ventilator Modes................................................................................ 3-17

3.9 Nurse Call / Remote Alarm ....................................................................................... 3-19

3.10 Patient Disconnect Alarm Description ...................................................................... 3-21

Chapter 4: Specifications and Control Ranges..............................................4-1

4.1 Specifications .................................................................................................................. 4-2

4.2 Control Ranges and Increments ................................................................................... 4-5

Chapter 5: Routine Maintenance......................................................................5-1

5.1 Cleaning........................................................................................................................... 5-2

5.2 Replacing the Inlet Filter............................................................................................... 5-3

5.3 Cleaning / Replacing the Nylon Mesh Inlet Filter ................................................... 5-4

5.4 Replacing the Oxygen Regulator Filter ...................................................................... 5-6

5.5 Changing the System Fuses ..........................................................................................5-8

5.6 Voltage and Fuse Selection ......................................................................................... 5-10

5.7 Power Cord Inspection................................................................................................5-10

5.8 Internal Alarm Battery ................................................................................................. 5-11

5.9 Preventive Maintenance Schedule ............................................................................ 5-14

Chapter 6: Troubleshooting ................................................................................6-1

6.1 Overview......................................................................................................................... 6-2

6.2 Description of System Alarms......................................................................................6-5

6.3 Alarm Indicators............................................................................................................6-7

6.4 Troubleshooting ............................................................................................................. 6-8

6.5 Error Codes ................................................................................................................... 6-12

6.6 Vent Inop Errors ........................................................................................................... 6-14

i

Page 6

Chapter 7: Repair and Replacement ................................................................7-1

7.1 Contact Information ....................................................................................................... 7-2

7.2 Exploded View...............................................................................................................7-3

7.3 BiPAP Vision Repair Kits ............................................................................................. 7-5

7.4 Mobile Stand II & III Repair Parts..............................................................................7-10

7.5 Replacement Identification Photos ........................................................................... 7-11

7.6 Touch Pad Replacement Instructions ........................................................................ 7-59

Chapter 8: Testing and Calibration ..................................................................8-1

8.1 Overview ........................................................................................................................... 8-2

8.2 Recommended Testing after Part(s) Replacement .................................................... 8-3

8.3 Exhalation Port Test ....................................................................................................... 8-5

8.4 Total Operating Hours Transfer Procedure ............................................................... 8-8

8.5 Blower / Valve Calibration Procedure..................................................................... 8-10

8.6 Performance Verification............................................................................................. 8-12

8.7 Run-In Cycle Procedure .............................................................................................. 8-16

8.8 System Final Test.......................................................................................................... 8-18

8.9 PC/Laptop Set-up Procedure ....................................................................................8-37

8.10 Test Cable Usage Definitions ..................................................................................... 8-40

8.11 Oxygen Flow Module Test ......................................................................................... 8-41

Chapter 9: Option Instructions ..........................................................................9-1

9.1 PAV/T Mode Installation or EPROM Upgrade ........................................................ 9-2

9.2 Oxygen Baffle Installation Instructions .......................................................................9-6

Chapter 10: Summary of Upgrades for Repairs of Vision units with Serial

Numbers 100500 to 106000......................................................... 10-1

10.1 Summary of upgrades for repairs of Vision units w/ serial numbers

100500 to 106000...........................................................................................................10-2

10.2 Repair Kits No Longer Manufactured ..................................................................... 10-5

10.3 Installation/Upgrade Instructions for Repair Parts ............................................... 10-6

Appendix A: Tools and Equipment................................................................ A-1

A.1 Service Tools and Supplies.......................................................................................... A-2

A.2 Acceptable Test Equipment......................................................................................... A-3

A.3 TSI, Inc. Certifier Test System ..................................................................................A-6

Appendix B: Schematics .................................................................................... B-1

B.1 Schematic Statement .................................................................................................... B-2

B.2 Main Control (MC) ...................................................................................................... B-3

B.3 Display Control (DC) .................................................................................................. B-9

B.4 Pressure Control (PC) ................................................................................................ B-20

B.5 Air Flow Module (AFM) ............................................................................................ B-25

B.6 Oxygen Module (OM) ................................................................................................ B-26

B.7 Power Supply ............................................................................................................. B-27

ii

Page 7

Chapter 1: Introduction

1-1

Chapter 1: Introduction

1.1 BiPAP Vision Ventilatory Support System Overview ..........1-2

1.2 Service Notice.............................................................................. 1-3

1.3 Technical Support ....................................................................... 1-3

Chp. 1

BiPAP Vision Service Manual

1045049

Page 8

1-2

Chapter 1: Introduction

Chapter 1: Introduction

®

1.1 BiPAP

The BiPAP Vision Ventilatory Support System (BiPAP Vision), shown in Figure 1-1, is a microprocessor-controlled, positive pressure ventilatory assist system. The BiPAP Vision incorporates a user interface with multifunction keys, real time graphic displays, and integral patient and system alarms.

The BiPAP Vision features a centrifugal blower to generate airflow, as well as hardware and software platforms

that can be upgraded with an oxygen module and additional patient alarms. The system operates in the Continuous Positive Airway Pressure (CPAP), Pressure Support (S/T), and optional Proportional Assist Ventilation/Timed (PAV/T) modes.

The BiPAP Vision contains a variety of integrated safety and self-diagnostic features. All system functions are

checked at start-up and during operation. Errors are reported by visual and/or audible indicators.

Pressure regulation is achieved by monitoring proximal airway pressure and adjusting flows accordingly to

ensure that the proximal pressure equals the set pressure.

Vision™ Ventilatory Support System Overview

EPAP

6

cm H

O

2

Rate

12

BPM

V

T

1000

IPAP

15

MODE: S/T MONITORING

cm H

O

2

P (cm H

Vol (ml)

Flow (L/min)

ml

MinVent

O)

2

PS = 9

%O

2

cm H

2

O

55

%

14

L/min

PIP

15

cm H

O

2

Options

Figure 1-1

The BiPAP Vision Ventilator

1045049

BiPAP Vision Service Manual

Page 9

Chapter 1: Introduction

1-3

1.2 Service Notice

This service manual was prepared by Respironics primarily for use by qualified technicians

required to service the BiPAP Vision.

1.3 Technical Support

Respironics is committed to customer satisfaction, and may be contacted with any questions or for technical

support at the following numbers:

U.S. and Canada

Phone: 1-800-345-6443

Fax: 1-800-866-0245

International

Phone: 1-724-387-4000

Fax: 1-724-387-5012

Chp. 1

E-Mail service@respironics.com

Visit Respironics Home Page on the World Wide Web at:

http://www.respironics.com

BiPAP Vision Service Manual

1045049

Page 10

Page 11

Chapter 2: Warnings, Cautions, and Notes

Chapter 2: Warnings, Cautions, and

Notes

2.1 Warnings ........................................................................................ 2-2

2.2 Cautions ......................................................................................... 2-3

2. 3 Notes ..............................................................................................2-4

2-1

BiPAP Vision Service Manual

1045049

Page 12

2-2

Chapter 2: Warnings, Cautions, and Notes

Chapter 2: Warnings, Cautions, and Notes

WARNING: Indicates the possibility of injury.

CAUTION: Indicates the possibility of damage to the device.

NOTE: Places emphasis on an operating or procedural characteristic.

2.1 WARNINGS

2.1.1 Safety

• Do not use the BiPAP Vision in the presence of a flammable anesthetic mixture with

air, oxygen, or nitrous oxide.

• Oxygen supports combustion. Do not use oxygen while smoking or in the presence of

an open flame.

• When using the optional oxygen module, the BiPAP Vision does not provide an oxygen

sensor to monitor oxygen concentrations delivered to the patient circuit. Therefore, the

use of oxygen with the BiPAP Vision should be monitored through oximetry.

NOTE: Refer to the Clinical Manual for guidelines on Applications and Operation.

2.1.2 Operational

• If the “Ventilator Inoperable” indicator illuminates, refer to Chapter 6 of this manual for

troubleshooting guidelines.

• Never attach oxygen tubing or any positive pressure source to the pressure port on the

front panel of the BiPAP Vision.

1045049

BiPAP Vision Service Manual

Page 13

Chapter 2: Warnings, Cautions, and Notes

Warnings (Continued)

2.1.3 Service

CAUTION: Electronic components used in this device are subject to damage from static

electricity. Repairs made to this device must be performed only in an antistatic,

ESD-protected environment.

• Do not attempt to make connection to the diagnostic RS232 connector on the back panel of

the BiPAP Vision to obtain repair information while the unit is operating on a patient.

• To assure the safety of the service technician and specified performance of the device,

Respironics recommends that only qualified technicians perform repairs to the BiPAP

Vision. Contact Respironics Technical Service for service training and authorization

information.

• High voltages are present inside this device. To avoid electrical shock, disconnect the

electrical supply before attempting any repairs on the device.

• For continued protection against risk of fire, replace fuses with those of the same type

and rating only.

2-3

2.1.4 Cleaning

• To avoid electrical shock, unplug the BiPAP Vision unit before cleaning it.

2.2 CAUTIONS

• While cleaning the unit, do not allow any liquid to enter the cabinet or the inlet filter.

• Care should be taken to avoid exposing the BiPAP Vision to operating, storage, and

transport temperatures near the extremes specified in Chapter 4. If exposed to such

temperatures, allow the unit to cool or warm to room temperature before turning it on.

• The unit must be positioned on its base for proper operation.

• Always use an inlet filter when the BiPAP Vision is in use.

• If using the oxygen module, do not exceed 100 psig oxygen supply pressure.

BiPAP Vision Service Manual

1045049

Page 14

2-4

Chapter 2: Warnings, Cautions, and Notes

2.3 NOTES

• This device contains a rechargeable nickel-cadmium (NiCAD) battery which is used by

the alarms in the event of a power failure.

• Refer to the BiPAP Vision Clinical Manual for a complete list of operational Warnings,

Cautions, and Notes.

Additional WARNINGS, CAUTIONS, and NOTES are located throughout this manual.

1045049

BiPAP Vision Service Manual

Page 15

Chapter 3: Description and Theory of Operation

Chapter 3: Description and Theory of

Operation

3.1 BiPAP Vision Ventilatory Support System ............................... 3-2

3.2 Power Supply Subsystem (PSS) ................................................ 3-6

3.3 Main Control (MC)...................................................................... 3-8

3.4 Pressure Control (PC) ................................................................. 3-9

3.5 Display Control (DC)................................................................ 3-11

3-1

3.6 Airflow Module (AFM) ............................................................ 3-14

3.7 Oxygen Module (OM) .............................................................. 3-16

3.8 Description of Ventilator Modes ............................................. 3-17

3.9 Nurse Call / Remote Alarm .................................................... 3-19

3.10 Patient Disconnect Alarm ........................................................ 3-21

BiPAP Vision Service Manual

1045049

Page 16

3-2

Chapter 3: Description and Theory of Operation

Chapter 3: Description and Theory of Operation

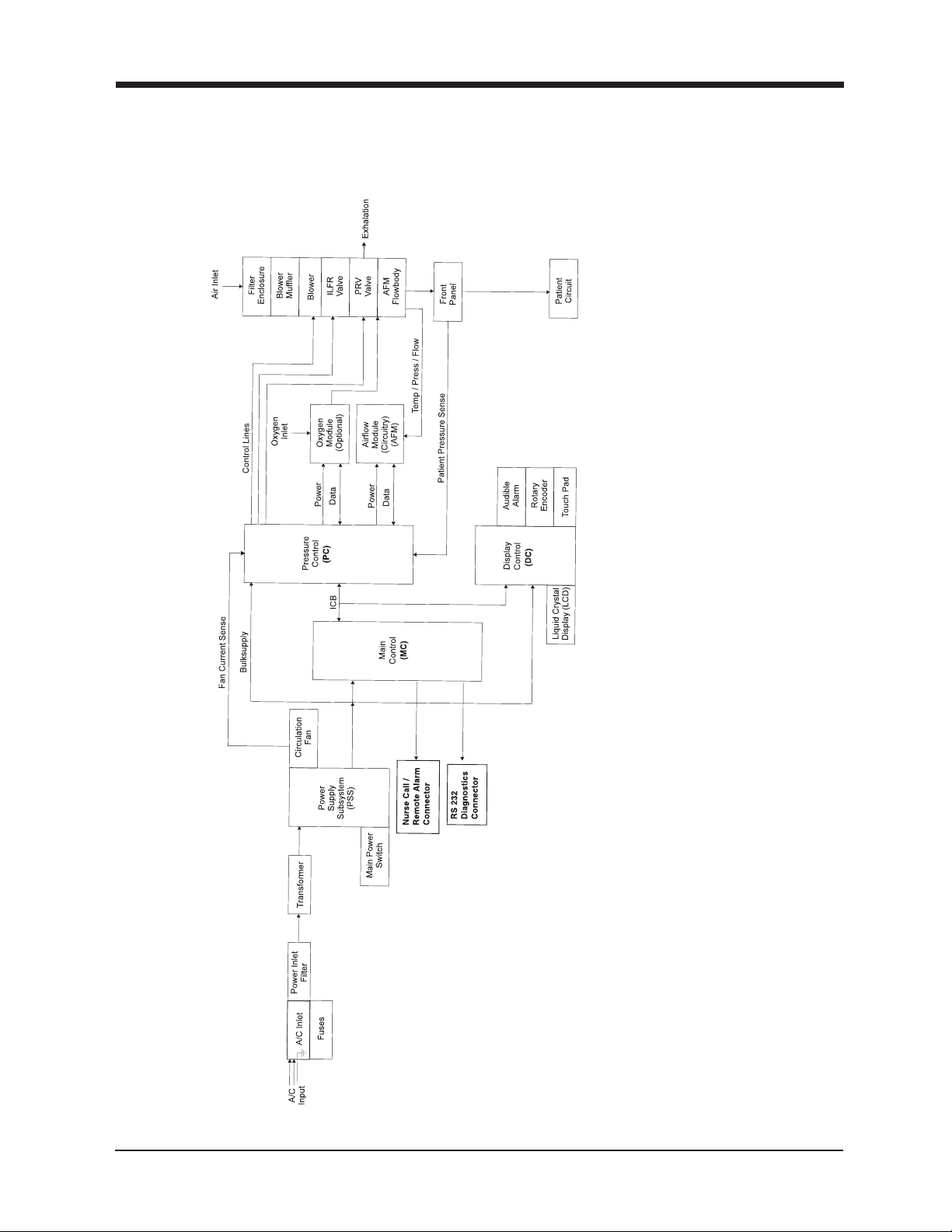

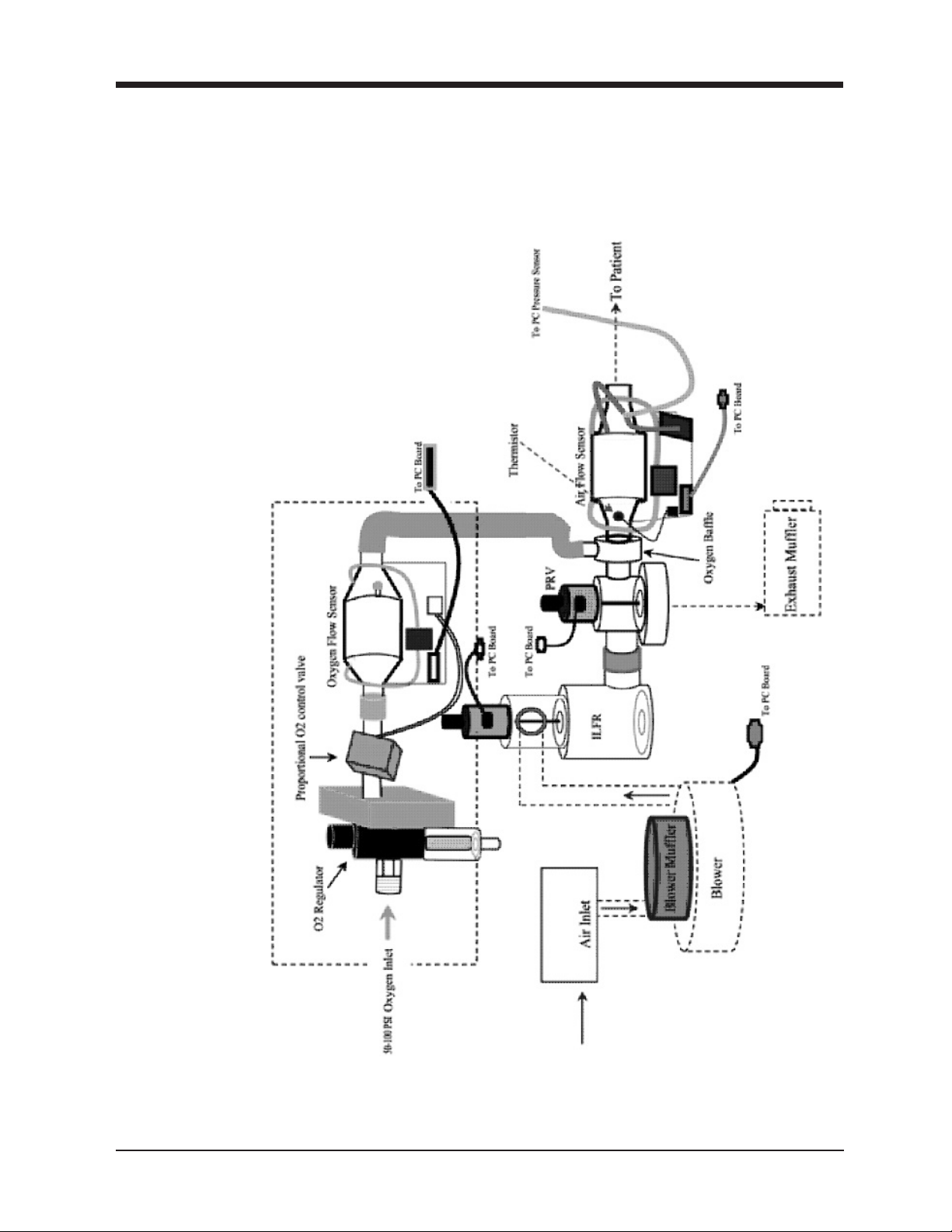

3.1 BiPAP Vision Ventilatory Support System

The BiPAP Vision is a microprocessor-controlled, positive pressure ventilatory assist system. The

system’s integral air intake filter draws in ambient air which is then pressurized by the system’s centrifugal blower assembly. The In-Line Flow Restrictor (ILFR) valve and Pressure Regulation Valve (PRV),

which are both located in the blower discharge airway, regulate total flow and pressure at the blower

discharge system. An oxygen module can be installed to add a controlled source of supplemental oxygen,

up to 100%, to the patient.

The Pressure Control (PC) board continuously monitors the readings from the Airflow Module (AFM) of

total gas flow, temperature, generated pressure, and patient circuit pressure to ensure prescribed therapy

to the patient. The PC board transmits process data to the Main Control (MC) board which then provides

overall control of the BiPAP Vision, including conveying instructions to the PC board regarding required

valve stem position and blower speed.

The unique design and operation of the ventilator makes it especially suited for mask applications.

Designed with the BiPAP

conditions, the ventilator is capable of ensuring optimum patient-ventilator synchronicity despite changes

in breathing patterns and circuit leaks. (Refer to the BiPAP Vision Clinical Manual.)

A liquid crystal display (LCD) screen is mounted on the front enclosure of the BiPAP Vision. The LCD

and the Display Control (DC) board provide the primary user interface with the ventilator, including the

visual presentation of data, control features, and visual and audible presentation of alarm conditions. The

user interacts with the ventilator through the touch pad and rotation of the rotary encoder while observing the results of this input on the display. The information provided on the display varies depending on

the state of the ventilator and / or the operations being performed.

The BiPAP Vision incorporates a number of safety features and self-diagnostic systems. System internal

functions are checked automatically at start-up, and periodically throughout normal operation. An

audible and visual alarm announces failures of principal subsystems. Integrated patient alarms are also

provided and are announced on a visual message display area as well as with an audible tone.

The following sections of this chapter describe in more detail the major subsystems and components that

make up the BiPAP Vision and its basic theory of operation.

Auto-Trak Sensitivity

TM

feature that automatically adjusts to changing circuit

1045049

BiPAP Vision Service Manual

Page 17

Chapter 3: Description and Theory of Operation

BiPAP Vision Ventilatory Support System (Continued)

3-3

Subsystem

PSS The Power Supply Subsystem (PSS) provides DC power to the BiPAP Vision

from an AC source.

MC The Main Control (MC) board or Main Control Subsystem (MCS) performs all control,

or data acquisition, and calculations required for the user-selected parameters. In addition,

MCS the MC performs the start-up test and reports all errors.

PC The Pressure Control (PC) board or Pressure Airflow Subsystem (PAS) controls the blower

or and valves to generate and regulate the system pressure. The PAS senses the outlet

PAS pressure and the patient pressure and regulates the outlet pressure to the patient circuit.

DC Through the touch pad, the Display Control (DC) board or Display/Control

or Subsystem (D/CS) evaluates user inputs and passes valid parameters to the MC. The DC

D/CS receives display data from the MC. The DC also has its own internal functions; the

results of which are reported to the MC.

AFM The Airflow Module (AFM), including the mass airflow sensor in the airstream,

provides an airflow measurement interface to the PC, allowing the PC to

measure total flow, temperature, and system pressure.

Function

ILFR The In-Line Flow Restrictor (ILFR) valve assembly regulates the total flow

from the blower discharge.

PRV The Pressure Regulation Valve (PRV) assembly is opened during exhalation to

allow the patient flow to be exhausted.

OM The Oxygen Module (OM) subassembly regulates and proportions the oxygen released

into the air from the blower according to the oxygen concentration level set on the

parameters screen.

BiPAP Vision Service Manual

1045049

Page 18

3-4

*

*

Chapter 3: Description and Theory of Operation

BiPAP Vision Ventilatory Support System (Continued)

BiPAP Vision Block Diagram

Figure 3-1

BiPAP Vision Block Diagram

*

*

* For S/N 106001 and greater

1045049

BiPAP Vision Service Manual

Page 19

Chapter 3: Description and Theory of Operation

3-5

Pneumatics Block Diagram

BiPAP Vision Service Manual

1045049

Page 20

3-6

Chapter 3: Description and Theory of Operation

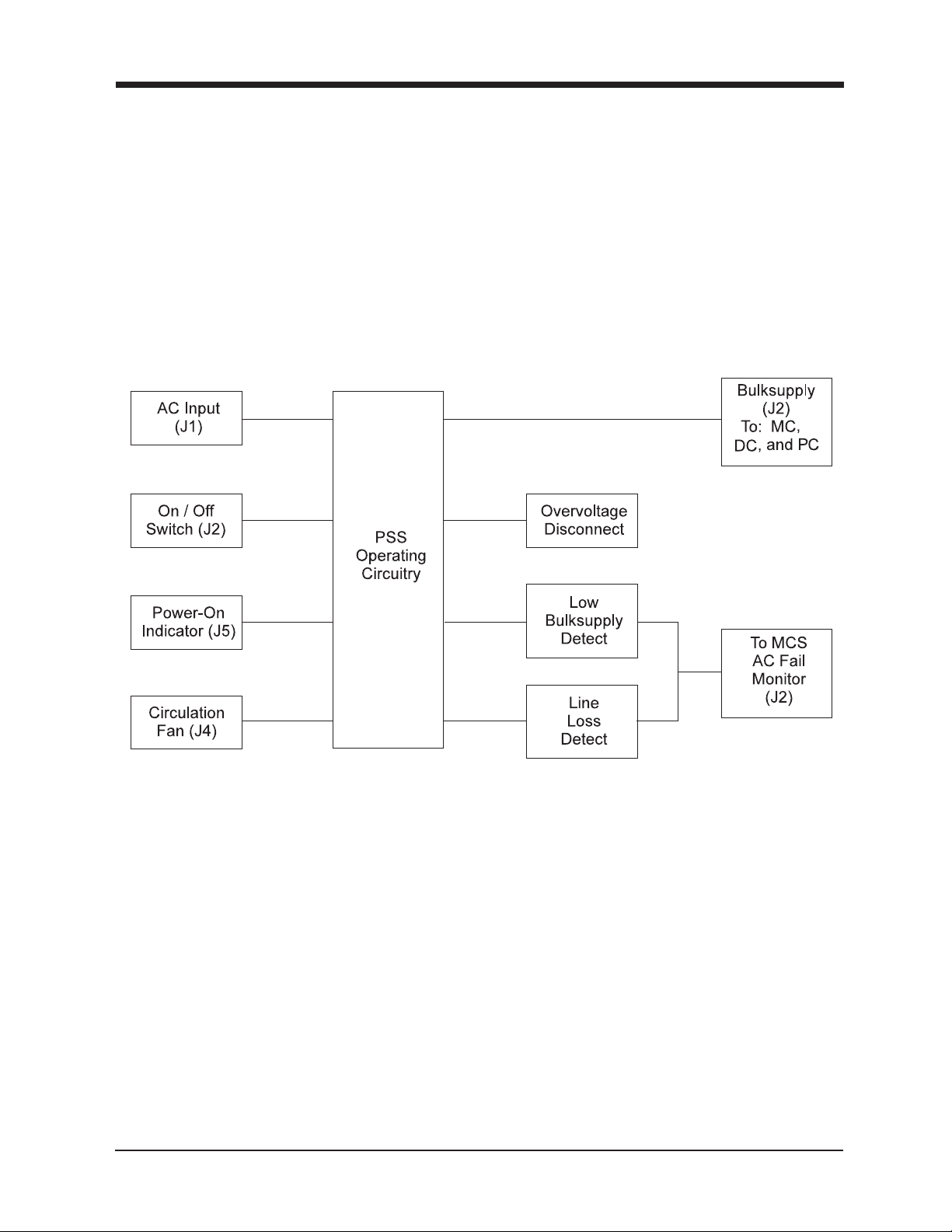

3.2 Power Supply Subsystem (PSS)

The PSS supplies the Main Control (MC), Pressure Control (PC), and the Display Control (DC) with the

proper DC supply voltage. Safety features designed into the circuitry include an overvoltage disconnect,

low voltage supply detect, and line loss detect. Other features include “power-on” indicator voltage,

circulation fan power, and an On/Off switch connection.

1045049

Figure 3-2

PSS Block Diagram

BiPAP Vision Service Manual

Page 21

Chapter 3: Description and Theory of Operation

Power Supply Subsystem (PSS) (Continued)

3.2.1 Input Range

The BiPAP Vision can operate with an AC input of 100, 120, 230, or 240 VAC (±10%) depending on the

model.

3.2.2 DC Supply

The output DC supply is fused at 30 amps and delivers between 20.6 VDC and 35 VDC with a maximum

ripple of 1 vpp (peak-to-peak voltage) to the MC, PC, and DC.

3.2.3 Overvoltage Disconnect

The overvoltage disconnect is used to remove the DC supply output when it exceeds 36 VDC and reconnects it when the level returns to an acceptable value.

3.2.4 AC Fail

The MC module monitors the level of DC supply voltage and the AC voltage output from the transformer

supply winding to determine if an AC fail condition exists.

3-7

Low DC supply detect – If the DC supply voltage drops to 19.38 VDC or lower (nominal), an AC fail

condition will be triggered.

Line loss detect – The AC voltage output from the transformer supply winding is monitored for a loss-ofcycle condition. Both legs of the winding are input to the monitoring circuitry. Whenever AC is lost, the

AC fail signal is activated.

3.2.5 Outputs

The PSS module also includes the following:

a. Front panel “power-on” indicator voltage (J5)

b. Circulation fan power (J4)

c. On / Off switch (part of J2)

d. Circulation fan current sense information to (J12) on the PC subsystem.

BiPAP Vision Service Manual

1045049

Page 22

3-8

Chapter 3: Description and Theory of Operation

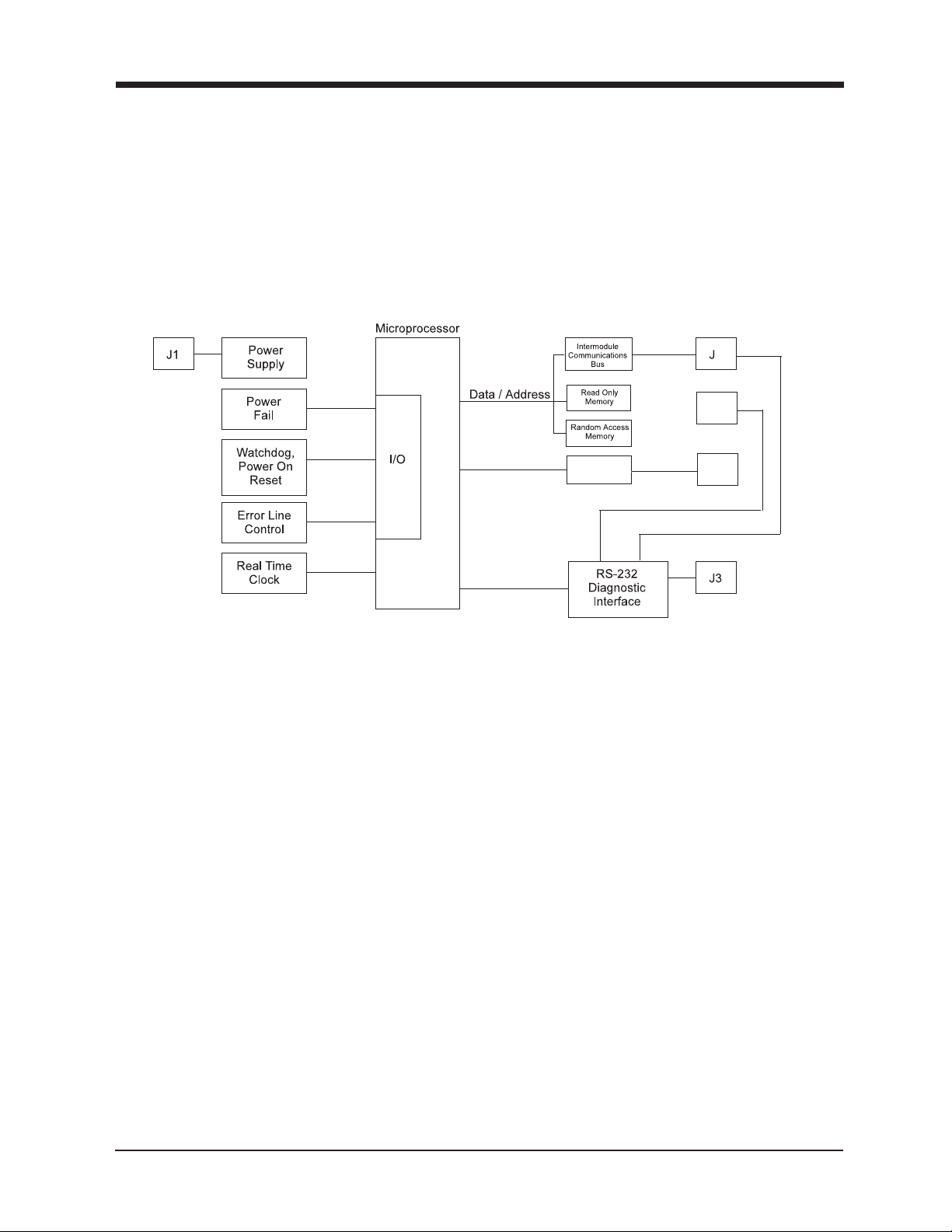

3.3 Main Control Subsystem (MC)

The MC is microcontroller-based and provides overall system control and supervision by monitoring the

activity of all the other system modules and providing commands to these modules based on user and

system input. The MC also acts as the bus controller for all subsystem communications using the

Intermodule Communications Bus (ICB).

4

J6

Nurse Call /

Remote Alarm *

*

DCS RX / TX

J5

PAS RX / TX

1045049

Figure 3-3

MC Block Diagram

* For S/N units >106K

BiPAP Vision Service Manual

Page 23

Chapter 3: Description and Theory of Operation

3.4 Pressure Control Subsystem (PC)

The PC functions through a microcontroller to:

a. Communicate with the Main Controller Subsystem (MC)

b. Communicate to a terminal / PC for diagnostics

c. Acquire sensor data through an Analog-to-Digital Converters (ADC, A / D)

d. Control valves and the blower motor through a Digital-to-Analog Converter (DAC)

e. Respond to or invoke an error signal

3-9

or

J15*

*

* For Units Serial Number <106K

*

*

PC

*

Figure 3-4

PC Block Diagram

BiPAP Vision Service Manual

1045049

Page 24

3-10

Chapter 3: Description and Theory of Operation

Pressure Control Subsystem (PC) (Continued)

3.4.1 Microcontroller Interface

Programmable Array Logic (PAL) memory device decodes the chip selects in such a way that the program code is retrieved from the EEPROM and data is retrieved from the RAM. An additional PAL

provides the interface for the Intermodule Communications Bus (ICB). The microprocessor monitors:

oxygen and gas temperatures; Airflow Module (AFM) and Oxygen Module (OM) detection; In-Line Flow

Restrictor (ILFR), Pressure Regulation Valve (PRV), and oxygen valve DAC control voltage; blower DAC

control voltage; and power supply and reference voltages.

3.4.2 Blower Motor Drive

The complete motor controller includes closed loop speed control via analog circuitry. When the desired

speed and actual speed are known by the processor, the speed is adjusted by increasing or decreasing the

DAC converter output to achieve proper pressure and flow.

3.4.3 Pressure Regulation Valve (PRV) and In-Line Flow Restrictor

(ILFR) Drives

The valve drives have closed loop control via the microprocessor. The microprocessor reads seven

pressure, flow, and temperature sensors through the PC hardware, and receives prescription parameters

from the MC. The microprocessor then adjusts analog DAC voltages to control the PRV and ILFR valves

as required to meet the prescription.

3.4.4 Pressure Sensors

The PC module has two dual pressure sensors (MT1 and MT2) and a single sensor (MT3). They measure

patient pressure, unit outlet pressure, and barometric pressure. These sensors are subject to calibration

with their calculated slope and intercept values stored in the on-board EEPROM. MT3 is a backup outlet

pressure sensor that provides a redundant check of the primary outlet sensor located on the AFM.

NOTE: Calibration is factory programmed and field adjustment is not required.

3.4.5 Error Line Control (ELC) Circuit

The ELC circuit is designed to simply detect a failure from, or signal a failure to, the MC and Display

Control (DC) modules. If the ELC line activates, only a power On / Off of the ventilator can clear this

latched circuit state.

3.4.6 Diagnostics Connector

The diagnostic connector (J3) interfaces with the microprocessor to view PC functions and system errors

on units from serial number 100500 to 105999, unless upgraded. For units greater than this, the diagnostic connector is on the rear of the unit.

1045049

BiPAP Vision Service Manual

Page 25

Chapter 3: Description and Theory of Operation

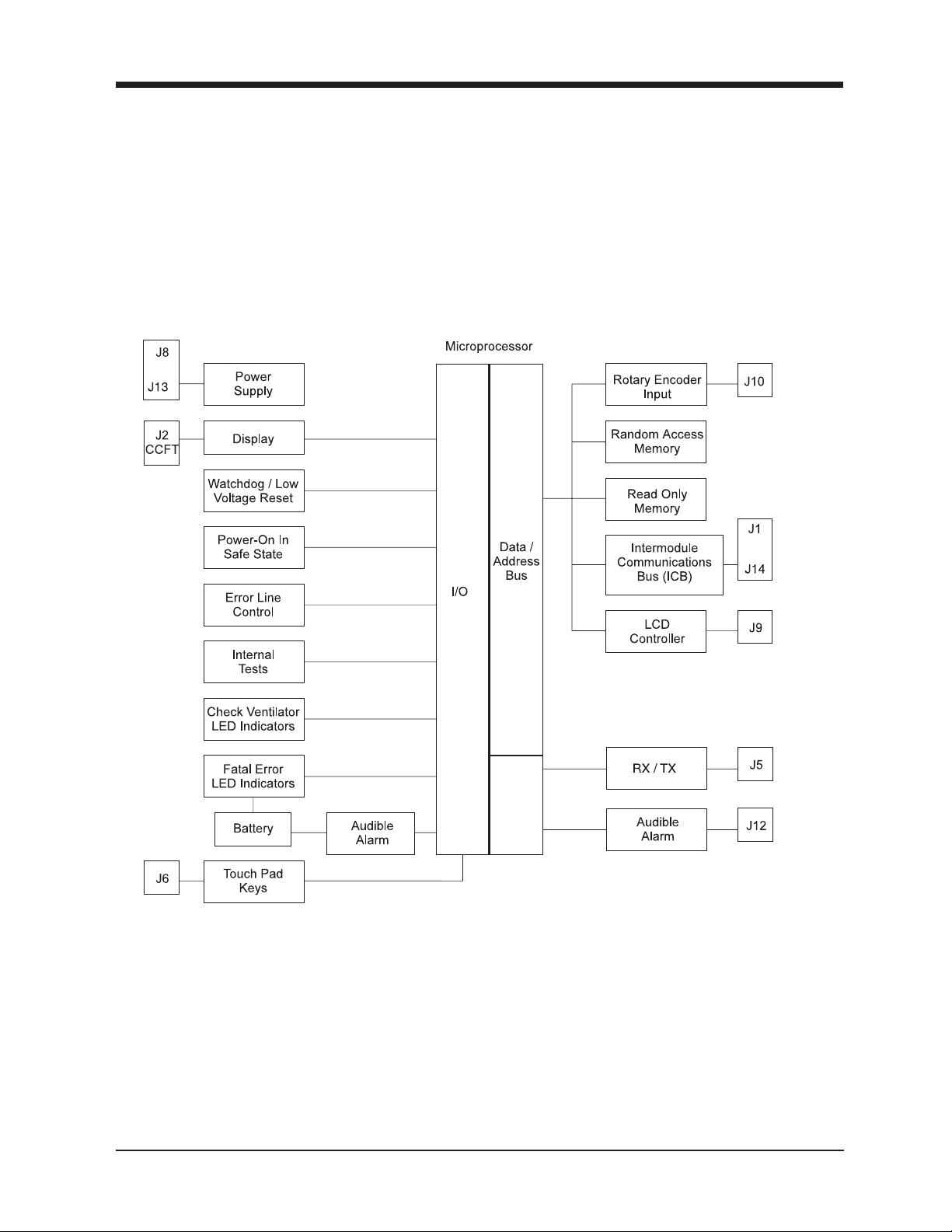

3.5 Display Control Subsystem (DC)

The DC provides a means of displaying the operating mode, measured and calculated operating parameters, parameter setpoints, alarm limits, real-time graphics, and general status information. The DC also

provides the necessary user interface controls to modify the operating mode, parameter set points, alarm

limits, and graphical scales; and to reset or silence the audible alarm, and freeze or unfreeze graphics.

The displays and controls are described in more detail in the following subsections.

*

or

*

3-11

or

*

* For Units Serial Number < 106K

Figure 3-5

DC Block Diagram

BiPAP Vision Service Manual

1045049

Page 26

3-12

Chapter 3: Description and Theory of Operation

Display Control (DC) (Continued)

3.5.1 DC/DC Converter

The DC/DC converter reduces the +24 VDC bulk supply to a +5 VDC logic level. (S/N <106K)

3.5.2 Display Backlight and Contrast Adjustment

A serial 8-bit D/A converter provides two, 0 to +5 VDC which originate in the MCU for these controls.

3.5.3 Display Voltage DC/DC Converter

This adjustable negative voltage converter reduces the level of bulk supply voltage needed to operate the

Liquid Crystal Display (LCD) contrast control.

3.5.4 Cold Cathode Fluorescent Tube (CCFT) Inverter

The DC design has a DC to AC inverter that typically provides 390 VAC to the fluorescent tube in the

display through (J2). The current varies to adjust the brightness of the fluorescent tube.

3.5.5 Reference Voltage Checks

This circuit compares reference voltages to determine if they are at the appropriate level.

3.5.6 Power Failure Alarm Battery Enable

This control detects a power failure from the DC supply.

3.5.7 Alarm Battery Voltage Cutout/Check

The battery voltage cutout /check monitors the battery voltage level and cuts it out if it drops to a level of

approximately 3VDC.

3.5.8 Backup Battery/Charger

The DC contains a 3.6 V nickel cadmium rechargeable battery that operates the audible and visual alarm

indicators for at least 20 minutes, when fully charged, when the Error Line Control (ELC) is active, and

the DC supply has been removed. The battery output is compared to a reference voltage and the battery

is recharged as required through a charging circuit. If necessary, refer to page 5-12 to recharge the

battery.

3.5.9 Check Ventilator Light Emitting Diode (LED) Enable Current

Check

An internal test is performed to verify that the Check Ventilator LED current is acceptable.

3.5.10 Vent Inop LED Current Check

An internal test is performed to verify the Ventilator Inoperative LED current is acceptable.

3.5.11 Error Line Control (ELC) Circuits

The DC contains redundant error signaling circuitry to communicate error conditions among the subsystems. The circuitry’s redundant and diverse nature minimizes the chance of communication failures.

1045049

BiPAP Vision Service Manual

Page 27

Chapter 3: Description and Theory of Operation

Display / Control Subsystem (D / CS) (Continued)

3.5.12 Error LED

The error LED indicates that an error condition was detected, and it illuminates to make unit diagnosis

easier.

3.5.13 Diagnostic Interface

The diagnostic connector interface (J5) interfaces with the MCU to provide a means for the DC to download diagnostic data to a terminal or PC.

3.5.14 EEPROM

A serial EEPROM stores the setpoints for the backlighting and contrast and also for the appropriate

diagnostic data.

3.5.15 LCD Controller

The DC circuit contains an LCD controller that interfaces with the display.

3-13

3.5.16 Debouncing / Keypad Matrix

The matrix keys are debounced and then the microprocessor scans the matrix to determine what key was

depressed.

3.5.17 Rotary Encoder Control

The rotary encoder control circuit detects relative position, direction, and speed of the rotary encoder, all

within one detent of movement.

3.5.18 Audible Alarm Activation

The audible alarm is activated by either an input from the ELC, the power fail circuitry, or the test alarm

signal from the MCU. It will also occur when the wrong key has been depressed, an adjustable parameter

has reached its limit, or the error signal has been activated.

3.5.19 Audible Alarm Current Check

An internal test is performed to verify the audible alarm current is acceptable.

3.5.20 “Power-on“ in Safe State

The DC contains circuitry that causes the hardware to “power-on” in a safe state; which is when the

backlight is off, the display is off, and the Intermodule Communications Bus (ICB) is terminated. When

the MCU determines that no Vent Inop error exists, it lets the unit resume operation under normal

operating conditions.

3.5.21 Watchdog and Low Voltage Reset

The watchdog function has to be periodically reset by the microprocessor if a time-out period has been

exceeded. This function is designed to reset the processor if the software gets lost. When a low logic level

is detected, the ELC will be activated resulting in a system shutdown.

BiPAP Vision Service Manual

1045049

Page 28

3-14

Chapter 3: Description and Theory of Operation

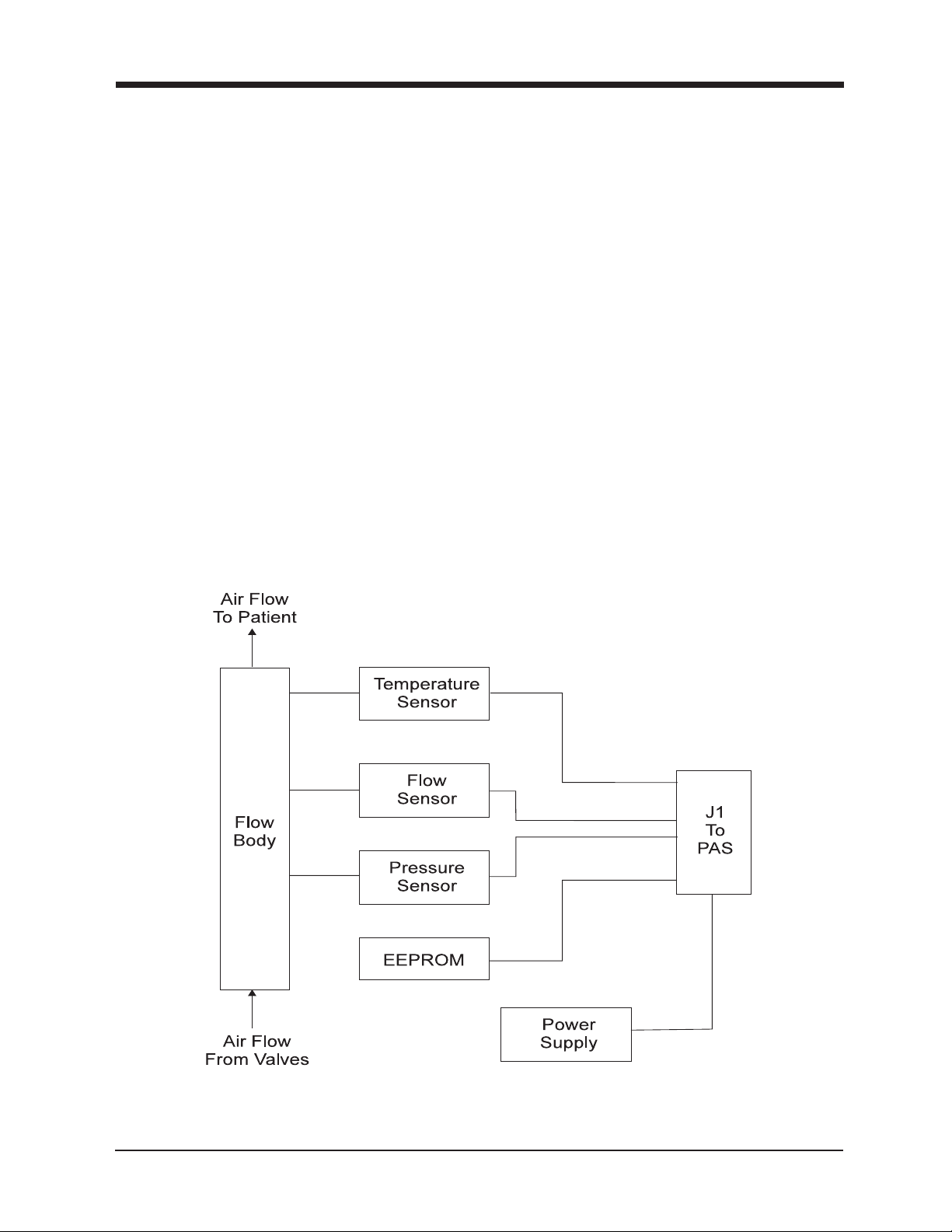

3.6 Airflow Module (AFM)

The AFM is a submodule of the Pressure Control (PC). The AFM receives power from the PC and provides the following analog signals to the PAS:

a. Gas flow indication

b. Pressure indication

c. Temperature indication

To provide indications accurate enough for system requirements, the AFM must be calibrated. Calibration data is stored in a nonvolatile memory that is part of the AFM. The flow, pressure, and temperature

indications are for the ventilator gas stream flowing through a “flow body” attached to the AFM circuit

board.

3.6.1 Flow Body

The flow body, with laminar flow element, is added to the ventilator gas stream, creating a small pressure

differential to short a fraction of the flow through the AFM sensor. Inlet, outlet, and pressure ports are

part of the flow body for tubing attachment to the AFM electronic sensors. Also, a hole is molded into the

flow body to position the temperature sensor. The body has molded feet for attaching it to the AFM

circuit board assembly.

1045049

And/Or Oxygen Supply

Figure 3-6

AFM Block Diagram

BiPAP Vision Service Manual

Page 29

Chapter 3: Description and Theory of Operation

Airflow Module (AFM) (Continued)

3.6.2 Analog Reference

The PC provides the AFM with power in the form of +12 VDC, –12 VDC, analog ground, +5 VDC, and

digital ground. An analog voltage reference supply is derived from the +12 VDC to power the pressure

and flow sensors so their bridge outputs can be factory calibrated.

3.6.3 Flow Indication

Total gas flow indication is provided by MT1. It is then amplified by an instrumentation amplifier, lowpass filtered, and sent to the PC board for conversion.

3.6.4 Pressure Indication

MT2, a precision compensated pressure sensor, provides unit outlet pressure indication. The sensor is

followed by a low-pass filter and a differential amplifier, and then sent to the PC board for conversion.

3.6.5 Temperature Measurement

The temperature is measured using a sensor inserted into a molded hole in the flow body. The BiPAP

Vision requires temperature indication to correct air density and detect an undesirable temperature rise in

the patient circuit.

3-15

3.6.6 Calibration

A data acquisition system, operating on a personal computer, is the control platform for AFM calibration

of temperature, pressure, and flow. Correction factors are derived and stored in the AFM module in an

EEPROM, with calibration accomplished by balancing the flow transducer bridge with an EEPOT. The

PAS uses temperature, pressure, and flow to correct for actual operating conditions. Once calibrated, the

AFM is interchangeable with other AFM assemblies.

NOTE: Calibration is factory programmed only.

3.6.7 Module Detection

The PC must know the AFM is connected, since it is required for normal operation of the ventilator. An

extra line pulls a PC microcontroller line near zero volts. If the line is above two volts, the AFM is not

connected, and the PC will transition to the error state.

BiPAP Vision Service Manual

1045049

Page 30

3-16

Chapter 3: Description and Theory of Operation

3.7 Oxygen Module (OM)

The OM is an optional submodule of the Pressure Control (PC). It receives power from the PC and

provides an analog signal to the PC for oxygen flow indication. To provide indications accurate enough

for system requirements, the OM must be calibrated. Calibration data is stored in a nonvolatile memory

that is part of the OM. The flow indication is for the ventilator pure oxygen stream flowing through a flow

body attached to the OM circuit board.

Figure 3-7

OM Block Diagram

PC

1045049

BiPAP Vision Service Manual

Page 31

Chapter 3: Description and Theory of Operation

3.8 Description of Ventilator Modes

The BiPAP Vision comes standard with two operating modes: Continuous Positive Airway Pressure

(CPAP) and Spontaneous/Timed (S/T). A third, optional, Proportional Assist Ventilation/Timed (PAV/

T) is also available.

3.8.1 Continuous Positive Airway Pressure (CPAP)

CPAP provides a constant pressure level delivered over the complete range of the patient’s spontaneous

breathing cycle. Pressure is controlled and maintained. Flow is available to meet changing patient

demands and automatically compensate for leaks. The mode delivers the prescribed level of pressure

that has been set with the CPAP control (Range: 4 to 20 cm H2O).

3.8.2 Spontaneous/Timed (S/T)

The S/T mode provides either pressure support during spontaneous breaths or time-triggered, pressurelimited, time-cycled machine breaths.

3-17

Spontaneous Breaths

Two pressure levels are set: an EPAP level (range 4 to 20 cm H2O) to establish a baseline pressure and an

IPAP level (range 4 to 40 cm H2O) that determines the amount of pressure support delivered with each

breath (PS = IPAP– EPAP). During the inspiratory phase, the BiPAP Vision responds as necessary to

satisfy the patient’s flow requirements while maintaining the preset IPAP pressure. Under these conditions, the patient is active in determining inspiratory time and tidal volume. The delivered tidal volume

will be dependent upon the pressure differential between the IPAP and EPAP levels, patient effort, and

the combined resistance and compliance of the circuit and the patient. If the patient does not actively

participate, the BiPAP Vision responds appropriately.

Timed Breaths

The S/T mode can also provide a time-triggered, pressure-limited, time-cycled machine breath, when the

spontaneous respiratory rate drops below the Rate control setting. If the ventilator does not detect a

spontaneous trigger within the interval determined by the Rate control setting, it will activate a timetriggered machine breath and deliver the IPAP level. Machine breaths are not synchronized with patient

effort, and once triggered to IPAP, the balance of the cycle is determined by the Timed Insp. Control

setting. A maximum Timed Inspiratory setting of 3.0 seconds can be set, as long as the I:E Ratio does not

exceed 1:1, as determined by the Rate setting. For example, see Figure 3-12. If the Rate control is set at 10

BPM, the total respiratory cycle is six seconds. If a spontaneous trigger occurs before the six-second cycle

time has elapsed, a spontaneously-triggered, pressure support breath occurs, a timed trigger will not

occur, and the timer is reset for a new six second interval. If a six second interval passes without a

spontaneous trigger, a timed trigger will be initiated and IPAP will be delivered for the duration of time

set by the Timed Inspiration setting.

BiPAP Vision Service Manual

1045049

Page 32

3-18

Chapter 3: Description and Theory of Operation

Description of Ventilator Modes (Continued)

Figure 3-12

Timed Breath Example

3.8.3 Proportional Assist Ventilation / Timed Mode (PAV/T)

For a detailed description of functioning of the Proportional Assist Ventilation/Timed (PAV/T) Mode,

refer to the appropriate BiPAP Vision Clinical manual. This mode utilizes the design features of S/T

mode and is a software enhancement only.

1045049

BiPAP Vision Service Manual

Page 33

Chapter 3: Description and Theory of Operation

3.9 Nurse Call/Remote Alarm Feature Operation (for s/n units

greater than 106000 only)

The unit will activate a remote signal for system shutdowns, patient alarms, and Loss of AC Power conditions which inhibit therapy. Note that a Check Vent condition does not activate the nurse call signal. The

nurse call signal can be silenced via the Alarm Silence key for the same amount of time that the audible

alarm on the Vision is silenced (two minutes). The signal can also be cleared by selection of the Alarm

Reset key. The nurse call signal will automatically terminate when a patient alarm self-cancels.

The Nurse Call/Remote Alarm feature is meant to be a backup with the main Vision alarm system being

the primary alarm/alert mechanism.

The Nurse Call or Remote Alarm signal is generated on the MC board and then can be connected to a

hospital nursing station. This signal is opto-isolated and used to switch a relay to provide open or closed

contacts to the remote station circuit. The arrangement of the two jumpers (JP1 and JP2) on the MC determine the output configuration that is utilized by a common connector on the rear panel of the Vision.

3-19

The Nurse Call Adapter (RI P/N 1014280) along with the Nurse Call Cable (RI P/N 1003742) can be used

to connect the Vision to a Nurse Call station.

The jumper configuration on the MC circuit board can be selected to meet requirements according to the

following table. Refer to the photo for jumper location.

Option JP1 JP2 No Alarm Output Alarm Option System Requiring

1 2,3 2,3 51.1K Open Respironics Remote Alarm

2 2,3 1,2 Closed Open Central Alarm System

3 1,2 1,2 Open Closed Central Alarm System

NOTE: Option 2 is the original factory set configuration for S/N 106001 to 106368.

Option 3 is the original factory set configuration for S/N 106369 and greater.

JP 2

BiPAP Vision Service Manual

JP1

1045049

Page 34

3-20

Chapter 3: Description and Theory of Operation

Nurse Call / Remote Alarm (Continued)

Details of option selections:

Option 1:

For use with Respironics Remote Alarm ( RI p/n 34003, or equivalent).

Option 2:

For use with alarm systems requiring NORMALLY OPEN contacts for an “alarm” condition and CLOSED contacts

for a “no alarm” condition.

Option 3:

For use with alarm systems requiring NORMALLY CLOSED contacts for an “alarm” condition and OPEN contacts

for a “no alarm” condition.

Caution: The Vision Nurse Call/Remote Alarm port shall be connected to nurse call systems that meet the relevant

local safety standards. Secondly, the nurse call port shall be connected to a low voltage circuit (less or

equal to 42.4V peak ac or 50V dc). The leakage currents from the low voltage circuit shall not cause the

Vision leakage currents to exceed acceptable levels. Lastly, the rated output current of the low voltage

circuit shall not exceed 1A.

1045049

BiPAP Vision Service Manual

Page 35

Chapter 3: Description and Theory of Operation

3.10 BiPAP Vision Patient Disconnect Alarm Description of

Operation

The patient disconnect alarm (“Disconnect”) is based on the flow limit control algorithm in the Vision. The mitigation for the Disconnect alarm is to put the unit into flow limit control. This same action is done when the user selects

the Standby key.

3.10.1 Detection

The unit determines that a patient is not connected to the circuit anymore based on flow for the given pressure. This

is implemented via a look-up table, with a flow entry for every generated pressure. The range of flows is 95 to 180

LPM, with 180 LPM being the low limit for any pressure above 9 cmH2O. If the unit detects flow greater than the

threshold at any given pressure for more than 10 seconds (3 seconds in for software earlier than 13.2), the unit puts

itself into the Flow Limit Control state. In this state, the unit attempts to limit the flow coming out of the mask in

order to make putting the mask back on the patient easier and more comfortable for the patient.

3-21

Also, for safety concerns, the oxygen valve closes to discontinue oxygen delivery during this condition.

When the Standby key is selected by the user, the unit automatically enters the FLC state, regardless of the flow at

the time the Standby key is selected.

In order to limit the flow, the unit drops the pressure to 4 cmH2O. The algorithm was enhanced to work with the Full

Face Mask a while ago. The Full Face Mask has a flap that will close the patient circuit and open the mask to

atmosphere upon loss of flow and pressure. This flap must be kept in a position during FLC so that the patient

circuit is not occluded. This allows the unit to detect when the patient is reconnected. The enhancement to the

algorithm consists of the pressure being slowly increased to keep the flow at 160-170 LPM. The pressure level is

limited to 10 cmH2O for software 11.2 and 11.3 (15 cmH2O for software 11.3a and higher), regardless of how much

flow is being generated. Therefore, the unit will either output 160-170 LPM at some pressure or will be limited to

some lesser flow at 10 cmH2O for software 11.2 and 11.3 (15 cmH2O for software 11.3a and higher).

3.10.2 Termination

There are two termination stages to FLC. During the first stage, as the pressure is being increased from 4 cmH2O to

its maximum of 10 cmH2O for software 11.2 and 11.3 (15 cmH2O for software 11.3a and higher), FLC will be

automatically terminated if the unit detects negative flow (i.e., the patient breaths back into the unit). This pressure

increase takes about 10 – 12 seconds for software versions earlier than 13.2, depending on how soon the flow set

point is reached. There have been two enhancements in software version 13.2 in this area. The first is that the

pressure is increased faster (1 cmH2O per 40 ms instead of the previous ¼ cmH2O per 40 ms) to shorten the amount

of time in stage one. The second change concerns the flow range processing. In software versions earlier than 13.2,

when the pressure is dropped to 4 cmH2O and the flow is greater than the desired flow range (160-170 LPM), the

flow limit algorithm attempts to decrement the pressure to get the flow into that desired range. In software version

13.2, that was changed to immediately enter stage 2 under that condition.

BiPAP Vision Service Manual

1045049

Page 36

3-22

Chapter 3: Description and Theory of Operation

Once either the flow set point or the maximum pressure is reached, the unit will automatically terminate

FLC for either the detection of negative flow or if flow varies from the current flow by more than 40 LPM

in software versions prior to 13.2 and 20 LPM for software version 13.2. For instance, if the 160-170 LPM

set point has been reached, the unit will terminate FLC if the flow drops below 120 LPM or goes above

210 LPM in older software and 140-190 LPM in the new software.

If the flow set point has not been reached, the current flow at 10 cmH2O for software 11.3 and 11.3 (15

cmH2O for software 11.3a and higher) is used as the set point. For instance, if only 80 LPM can be

reached at 10 cmH2O for software 11.3 and 11.3 (15 cmH2O for software 11.3a and higher), the thresholds

for automatic termination of FLC will be 40 LPM and 120 LPM in older software and 60-100 LPM in new

software.

This allows FLC to be terminated without the patient necessarily breathing back into the machine but by

the simple act of refitting the mask to the patient.

The Standby condition, besides being terminated automatically by the above methods, can also be

manually terminated by reselecting the highlighted Standby soft key on the Monitoring screen.

When FLC is terminated during a “Disconnect” alarm period, the alarm is self-cancelled. That means

that the audible component of the alarm is silenced but the visual component of the alarm remains

displayed on the screen. That can be cleared by selecting the Alarm Reset key.

Note: During FLC, the oxygen parameter setting reduces to 21%, regardless of the setting.

1045049

BiPAP Vision Service Manual

Page 37

Chapter 4: Specifications and Control Ranges

Chapter 4: Specifications and

Control Ranges

4.1 Specifications ...............................................................................4-2

4.2 Control Ranges and Increments .............................................. 4-5

4-1

BiPAP Vision Service Manual

1045049

Page 38

4-2

Chapter 4: Specifications and Control Ranges

Chapter 4: Specifications and Control Ranges

4.1 Specifications

ENVIRONMENTAL:

Temperature ....................................... Operating: 40° F to 104° F (4.4° C to 40° C)

Transport / Storage: –4° F to 140°F (–20o C to 60o C)

Humidity ............................................ Storage and Operating: 0 to 95% Relative Humidity

PHYSICAL:

Dimensions ........................................ At the base: 16" (L) × 14 3/8" (W) × 10 5/8" (H)

(40.6 cm x 36.5 cm x 27cm)

Weight ................................................ 34 lbs (15.4 kg)

ELECTRICAL:

AC Input Voltage (VAC) ................. 100/120/230/ 240 VAC

Single Phase

±10%

Fuses ................................................... 100 – 120 VAC ~ T 3.5 A, 5 × 20 mm, Time Lag (×2)

(For serial no.’s 100500 and higher –

Respironics Reorder # 1000749)

115 VAC ~ T 3.0 A, 250 V, ¼” × 1¼”

(For serial no.’s 100499 and lower –

Respironics Recorder # 582100)

220 VAC, 230 VAC and 240 VAC ~ T 1.6 A, 250 V, 5 × 20 mm

(For all serial no.’s – Respironics Recorder # 1000750)

Power Consumption ........................ 300 VA max.

AC Current ........................................ 3.0 A maximum

AC Frequency .................................... 50/60 Hz

Class ................................................... Protection Against Electrical Shock: Class I

1045049

BiPAP Vision Service Manual

Page 39

Chapter 4: Specifications and Control Ranges

Specifications (Continued)

Type .................................................... BF

Degree of Protection Against Harmful Ingress of Water:

Ordinary Equipment, IPX0

Electromagnetic

Compatibility ..................................... The BiPAP Vision meets the requirements of IEC 601-1-2

Earth Resistance ................................ Less than 0.10 ohms

Earth Leakage Current ......................

Normal Pole, No Earth, L2 ........ Less than 300 µA

Reverse Pole, No Earth, L2 ........ Less than 300 µA

Reverse Pole, No Earth, No L2.. Less than 1000 µA

Normal Pole, No Earth, No L2 .. Less than 1000 µA

Insulation Resistance ........................ Greater than 2 megaohms

Noise Level ......................................... No specification is given because various test instruments, test

procedures, and unit operating conditions produce varying

results.

4-3

Alarm Sound Level ........................... Between 70 and 85 dBA peak at a distance of 1 meter.

PRESSURE:

Output ................................................. 4 to 40 cm H2O

Dynamic Regulation.......................... ± 2 cm H2O at sinusoidal flow @ ± 100 L/min

Static Regulation ................................ ± 2 cm H2O from –60 to 120 L/min

Elevation.............................................. 0 to 5000 ft above sea level

CONTROL ACCURACY:

Timed Inspiration.............................. ± 0.2 sec of the set point

Rate ...................................................... ± 1 BPM of the set point

Oxygen Concentration ....................... The greater of ± 3% or ±10% of the set point

DISPLAY ACCURACY:

Pressure ............................................... ± 1 cm H2O

Volume ................................................ ± 10% (during stable conditions)

Flow ..................................................... ± 10% (during stable conditions)

BiPAP Vision Service Manual

1045049

Page 40

4-4

Chapter 4: Specifications and Control Ranges

Specifications (Continued)

TRIGGER SENSITIVITY:

(Refer to BiPAP Vision Clinical Manual Auto-Trak section for more details)

Spontaneous Trigger ......................... Shape Trigger

Volume 6 cc above

Spontaneous Cycle ............................ Spontaneous Expiratory Threshold (SET)

Shape Cycle

IPAP maximum of 3.0 sec

Flow Reversal

OXYGEN MODULE INLET:

Pressure Range .................................. 50 to 100 psig

Inlet Fitting ......................................... DISS male oxygen connector

INTERNAL BATTERIES:

Alarm Battery ..................................... NiCAD

Location: D/C

3.6 VDC, 110 mAh

Rechargeable (See Section 5.9.3 for details)

(RI P/N 1012819)

V

leak

Data Retention Battery Type: Lithium Cell

(for original MCS board)

Data Retention Battery Type: Lithium Cell

(for current MC Board ) Location: MCS

Location: MCS

+3 VDC, 300 mAh

Not Rechargeable

(RI P/N 1001988)

+3 VDC, 300 mAh

Not Rechargeable

(RI P/N 1006005)

1045049

BiPAP Vision Service Manual

Page 41

Chapter 4: Specifications and Control Ranges

4.2 Control Ranges and Increments

NOTE: Refer to the applicable BiPAP Vision Clinical Manual for PAV/T information.

4.2.1 Parameters

4-5

*With optional Oxygen Module

4.2.2 Alarms (Adjustable)

Alarm Control Control

High Pressure 5 to 50 cm H201 cm H

Low Pressure Disabled to 40 cm H20 1 cm H20

Low Pressure Delay 0 to 60 sec. 1 cm H20

Apnea Disabled; 20 to 40 sec. 4 set points;

Low Minute Disabled to 99 L/min. 1 L/min.

Ventilation*

High Rate* 4 to 120 BPM 1 BPM

Low Rate* 4 to 120 BPM 1 BPM

*With optional Alarm Module

Range Increments

0

2

Disabled, 20, 30, 40 sec.

BiPAP Vision Service Manual

1045049

Page 42

4-6

Chapter 4: Specifications and Control Ranges

Control Ranges and Increments (Continued)

4.2.3 Display Ranges & Increments

PARAMETER DISPLAY DISPLAY

RANGE RESOLUTION

IPAP 0 TO 50 CM H

EPAP 0 TO 50 CM H

CPAP 0 TO 50 CM H

O 1 CM H

2

O 1 CM H

2

O 1 CM H

2

2

2

2

RATE 0 TO 150 BPM 1 BPM

EXHALED TIDAL 0 TO 4000 ML 1 ML

VOLUME (VT)

MINUTE VENTILATION 0 TO 99 L /MIN 1 L / MIN

(MIN VENT)

TOTAL LEAK (TOT LEAK)0 TO 300 L/MIN 1 L / MIN

PATIENT LEAK 0 TO 300 L /MIN 1 L /MIN

(PT. LEAK)

O

O

O

1045049

PEAK INSPIRATORY 0 TO 50 CM H

O 1 CM H

2

PRESSURE (PIP)

PERCENT OF PATIENT 0 TO 100% 1%

TRIGGERED B REATHS

(PT.TRIG)

TI/TTOT 0 TO 100% 1%

BiPAP Vision Service Manual

O

2

Page 43

Chapter 5: Routine Maintenance

Chapter 5: Routine Maintenance

5.1 Cleaning the BiPAP Vision ....................................................... 5-2

5.2 Replacing the Inlet Filter........................................................... 5-3

5.3 Cleaning / Replacing the Nylon Mesh Inlet Filter ..............5-4

5.4 Replacing the Oxygen Regulator Filter ................................. 5-6

5.5 Changing the System Fuses...................................................... 5-8

5.6 Voltage Selection.......................................................................5-10

5.7 Power Cord Inspection ............................................................5-10

5-1

5.8 Internal Alarm Battery ............................................................ 5-11

5.9 Preventive Maintenance Schedule ........................................5-14

BiPAP Vision Service Manual

1045049

Page 44

5-2

Chapter 5: Routine Maintenance

5. 1 Cleaning the BiPAP

CAUTION: Do not immerse the BiPAP Vision in water or allow any liquid to enter the cabinet or

the inlet filter.

NOTE: The following guidelines for cleaning refer to the BiPAP Vision only. Refer to the

individual instructions for cleaning accessories.

Vision

5.1.1 Cleaning the Front Panel

Clean the front panel as needed by wiping with water or 70% isopropyl alcohol only.

5.1.2 Cleaning the Enclosure

Clean the exterior of the enclosure as needed by wiping with any anti-bacterial agent.

CAUTION: Do not allow any liquid to enter the cabinet or the inlet filter.

NOTE: Do not clean the Auto-Trak sticker with anything except mild soap and water.

1045049

BiPAP Vision Service Manual

Page 45

Chapter 5: Routine Maintenance

5.2 Replacing the Inlet Filter

CAUTION: A dirty inlet filter may cause high operating temperatures, and may affect ventilator

performance. Examine the inlet filter for integrity and cleanliness before each use, and

as required during operation.

Step 1 Turn the BiPAP Vision OFF and unplug the electrical cord from the wall outlet and from the

back of the unit.

Removing the Filter

Step 2 Remove the inlet filter cap by pinching the latch, then rotate the cap until the hinge is

free from its slot.

NOTE: The inlet filter is disposable. Do not attempt to clean the inlet filter. When the filter is

dirty replace it with a new filter. Use only Respironics filters; see Chapter 7 for

the filter reorder number.

5-3

(P/N 582101 x6)

Figure 5-1

Removing the Filter Cap

(P/N 1003444)

Installing the Filter

Step 3 Place the filter inside the cap, then reverse Step 2 to reinstall the filter cap.

NOTE: To clean any of the accessories, refer to each accessory’s instruction sheet.

BiPAP Vision Service Manual

1045049

Page 46

5-4

Chapter 5: Routine Maintenance

5. 3 Cleaning/Replacing the Nylon Mesh Inlet Filter

CAUTION: A dirty nylon mesh inlet filter may cause high operating temperatures

and may affect ventilator performance.

Step 1 Turn the BiPAP Vision off and unplug the electrical cord from the wall outlet and

from the back of the unit.

Step 2 Remove the filter cap and inlet filter. (See Section 5.2 for more detailed instructions on

removing the filter cap and inlet filter.)

Step 3 Using a medium Phillips screwdriver, remove the two screws that secure the nylon mesh

inlet filter to the filter enclosure. Remove the nylon mesh inlet filter.

Figure 5-2

Removing the Nylon Mesh Filter

NOTE: Depending on the condition of the nylon mesh inlet filter, it may be cleaned and

reused. If the filter is in good shape, follow the cleaning instructions in Step 4. If the

filter must be replaced, proceed to Step 5.

NOTE: If the nylon mesh inlet filter is to be cleaned, care should be taken to protect the

adhesive on the edges of the filter. If the adhesive is damaged, the filter may not

correctly seal when reinstalled.

1045049

BiPAP Vision Service Manual

Page 47

Chapter 5: Routine Maintenance

Cleaning / Replacing the Nylon Mesh Inlet Filter (Continued)

Step 4 Using a solution of mild soap and water, carefully clean then thoroughly rinse the nylon

mesh inlet filter. Insure that the filter is completely dry before reinstalling it in the unit.

Step 5 If necessary, remove the protective backing from the nylon mesh inlet filter. Align the new

cleaned nylon mesh inlet filter with the filter enclosure. Press the edges of the filter firmly in

place. Secure the filter to the filter enclosure using the two Phillips screws.

5-5

BiPAP Vision Service Manual

1045049

Page 48

5-6

Chapter 5: Routine Maintenance

5.4 Replacing the Oxygen Regulator Filter

CAUTION: A dirty Oxygen Regulator filter may reduce system performance. Examine the filter

for integrity and cleanliness before each use.

NOTE: Replace the filter as necessary to ensure normal operation.

Step 1 Position the BiPAP Vision so that the back is easily accessible.

Step 2 Disconnect the Oxygen Module (OM) input line.

Step 3 Firmly grasp the plastic body of the regulator bowl and rotate it counterclockwise to

remove it. (Direction is referenced from the bottom of the unit.)

NOTE: The regulator bowl has a standard right-hand thread.

(shown is for original Oxygen Module)

Step 4 Remove the original filter.

Figure 5-3

Removing the OM Regulator Bowl

1045049

BiPAP Vision Service Manual

Page 49

Chapter 5: Routine Maintenance

Replacing the Oxygen Regulator Filter (Continued)

(shown is for original Oxygen Module)

5-7

Figure 5-4

Removing the OM Filter

Step 5 Insert the new filter.

Step 6 If necessary, clean the regulator bowl with mild soap and water and dry completely.

Step 7 Put the regulator bowl in place and rotate it clockwise until securely tightened.

Step 8 Connect the oxygen input line to the OM.

BiPAP Vision Oxygen Module Regulator Filter and Regulator Bowl Compatibility

Note: Refer to the information below for compatibility when ordering Oxygen bowl and filter

replacements.

Oxygen Module (OM) Manifold / Regulator Bowl For Oxygen Module S/N < 300000, use part

number 582154

For Oxygen Module S/N > 299999, use part

number 1007546*

Oxygen Module (OM) Manifold / Regulator Bowl filter (x5)

For Oxygen Module S/N < 300000, use part

number 582153

For Oxygen Module S/N > 299999, use part

number 1007547*

* This part is also for the Oxygen Modules that do not have a serial number on the Oxygen Module cover.

BiPAP Vision Service Manual

1045049

Page 50

5-8

Chapter 5: Routine Maintenance

5.5 Changing the System Fuses

WARNING: Unplug the BiPAP Vision before changing the fuses.

NOTE: This procedure applies to Vision S/N’s 100500 and greater.

Step 1 Unplug the AC power cord from the wall outlet and from the power entry module on the

rear of the BiPAP Vision.

Step 2 With a small, flat-blade screwdriver, gently pry open the fuse holder door from the top. The

door hinges downward.

Figure 5-5

Opening the Fuse Door

Step 3 Pry the fuse drawers loose and slide them out of the power entry module.

Step 4 Pull the fuses out of the fuse drawers.

1045049

BiPAP Vision Service Manual

Page 51

Chapter 5: Routine Maintenance

Changing the System Fuses / Operating Voltage Selection (Continued)

5-9

Figure 5-6

Replacing the Fuses

Step 5 Replace both fuses.

Step 6 Place the new fuses in the fuse drawers and slide the fuse drawers back into the power entry

module with the arrows on the front of the drawers pointing to the right.

Step 7 Select the proper operating voltage by removing the drum and reinserting it with the

desired voltage displayed.

NOTE: Use only Respironics approved fuses. See Section 5.6 for fuse part numbers.

Step 8 Swing the fuse drawer door shut and snap it into place.

Step 9 Plug the AC power cord into the BiPAP Vision and the wall outlet.

BiPAP Vision Service Manual

1045049

Page 52

5-10

Chapter 5: Routine Maintenance

5.6 Voltage and Fuse Selection

The voltage selection is originally set at the factory. If you wish to use the BiPAP Vision with a different

operating voltage, refer to Section 5.5.

NOTE 1: Vision S / N’s 100500 and greater:

• For operating voltages of 100 and 120 VAC, use RI P/N 1000749 fuses.

• For operating voltages of 230 and 240 VAC, use RI P/N 1000750 fuses.

NOTE 2: Visions S / N’s 100499 and less:

• For operating voltage of 115 VAC, use RI P/N 582100 fuses.

• For operating voltage of 220 and 240 VAC, use RI P/N 1000750 fuses.

5.7 Power Cord Inspection

Inspect the power cord and replace if damaged or shows signs of wear.

1045049

BiPAP Vision Service Manual

Page 53

Chapter 5: Routine Maintenance

5.8 Internal Alarm Battery

5.8.1 Battery Function

The BiPAP Vision contains an internal NiCAD battery located on the DC (P/N 1012819) to activate the

Ventilator Inoperative visual and audible alarm indicators if an error occurs. A fully charged battery can

maintain the audible alarm for up to 20 minutes.

5.8.2 Low Battery Condition

The NiCAD battery can lose its charge if the BiPAP Vision is not used for an extended time. In a typical

environment, a fully charged battery can be stored approximately six months before losing its charge, but

the discharge rate depends heavily on temperature.

5-11

NOTE: The BiPAP Vision internal alarm battery should be charged prior to use if it has been

stored for longer than three months.

If the battery voltage is too low to support the alarm indicators, the Check Ventilator visual (Eye icon) and

audible alarm indicators will activate. The time that the audible alarm operates may be short due to the

low voltage of the battery. The BiPAP Vision also generates error code 205.

To check the error code:

Step 1 Silence the audible alarm component by pressing the Alarm Reset key.

The audible component will not sound again.

Step 2 Press the Monitoring hard key if you are not already in the Monitoring screen.

Step 3 Press the Options soft key.

Step 4 In the Options screen, press the Error soft key.

Check vent error codes are displayed in the top line of the Options/Message area.

BiPAP Vision Service Manual

1045049

Page 54

5-12

Chapter 5: Routine Maintenance

Internal Alarm Battery Maintenance (Continued)

5.8.3 Charging the Internal Battery

There are two methods used to recharge the NiCAD battery on the DCS circuit board that is used to sound the

audible alarm, fast charge and normal.

1. Fast Charge Method (Check Vent/Error 205 Being Displayed)

A fast charge will be initiated at first time initialization and when a low internal battery error is detected. Fast charging

is available when the unit is in the Setup Screen and when it is providing therapy (i.e., the unit can sit in the diagnostic mode and still fast charge). Fast charge time is 6 hours to sufficiently charge the battery to support the audible

alarm for 20 minutes.

If the unit is powered off during a fast charge sequence, the sequence will pick up where it left off when the unit is

powered back on unless a low battery error is detected during the start-up testing (i.e., the unit was off long enough

to discharge the battery). In that case, a new 6-hour fast charge sequence will be initiated. The functionality of the

Check Ventilator error 205 remains unchanged - the error code will be able to be cleared approximately 1 minute after

the status indicates a good battery.

Note: If the status never indicates a good battery (i.e., the battery is actually bad and will not take a charge),

the fast charge sequence will run continuously. The user will be able to detect this by not being able to

clear the 205 error even after a full fast charge cycle.

Charging Process:

1. Remove the unit from patient use.

2. Plug the unit into an AC source and start the unit. The Self Diagnostics will begin.

3. Allow the unit to remain in the Exhalation Port/Language Screen.

4. Or, allow the unit to be in therapy or Standby mode. Press the alarm reset to silence the audible alarm.

5. Leave in one of these conditions for approximately 6 hours to fully charge the battery.

2. Normal Method (No Check Vent/Error 205)

If there is no Check Vent error 205, the charging circuit will continue to charge the battery on a regular basis while in

the Test Exhalation/Language screen or during therapy use. It will take approximately 24 hours to fully charge the

battery to support the audible alarm for up to twenty minutes.

Charging Process:

1. Remove the unit from patient use.

2. Plug the unit into an AC source and start the unit. The Self Diagnostics will begin.

3. Allow the unit to remain in the Exhalation Port/Language selection screen.

4. Or, allow the unit to be in therapy or Standby mode.

5. Leave in one of these conditions for approximately 24 hours to fully charge the battery.

1045049

BiPAP Vision Service Manual

Page 55

Chapter 5: Routine Maintenance

Charging Verification:

1. A minimum of two hours is required to charge a fully discharged battery to a voltage at which the alarm will

not be activated. At this time, the unit can be operated and will continue to trickle charge the battery while it is

in operation.

2. Press Monitoring to begin operation.

3. Wait two minutes to determine if the Check Vent alarm activates with an error 205 in the Error Message screen.

If not, then the unit is ready for use.

CAUTION: Prolonged storage of the BiPAP Vision at high temperatures, above 80 ºF (27 ºC) can

result in premature battery failure. Failure to recharge a battery when it is being stored for

long periods will cause a loss of battery life, activate the Check Ventilator alarm, and

generate error code 205.

5-13

BiPAP Vision Service Manual

1045049

Page 56

5-14

Chapter 5: Routine Maintenance

5.9 Preventive Maintenance Schedule

The Maintenance Schedule lists the items that are recommended to be periodically inspected or tested. The

service interval may be decreased as internal protocol specifies. The user should be aware of any local or

national regulations that may deviate from the schedule as described below. Use the log to record the dates

the maintenance items are performed.

5.9.1 Vision Preventive Maintenance Schedule (Factory Recommended)

Model # ______________ Serial # ______________

Maintenance Item Verification Reference Service Interval Date

Record hours of Displayed on Options 1 Year

operation Screen

Replace inlet filter Section 5.2 As required

Replace oxygen Section 5.4 As required

regulator filter

Audible Alarm Visual, verify by activating 1 Year

Test Alarms.

Run Blower Valve Section 8.5

Calibration

Perform “System Section 8.8

Final Test”

Inspect Power

Cord

Cleaning

Section 5.7 As required

Section 5.1

1 Year

1 Year

As required

1045049

Tested by: ________________________________ Date: _______________

BiPAP Vision Service Manual

Page 57

Chapter 6: Troubleshooting

6.1 Overview .....................................................................................6-2

6.2 Description of System Alarms .................................................6-5

6.3 Alarm Indicators ........................................................................6-7

6.4 Troubleshooting ..........................................................................6-8

6.5 Check Vent Error Codes ..........................................................6-12

6-1

Chapter 6: Troubleshooting

6.6 Vent Inop Errors........................................................................6-14

BiPAP Vision Service Manual

1045049

Page 58

6-2

Chapter 6: Troubleshooting

Chapter 6: Troubleshooting

6.1 Overview

Purpose

This chapter outlines a general procedure for troubleshooting the BiPAP Vision. Problems shall be investigated to the major component or subassembly as indicated on the specific error code charts found in this

chapter.

Process

Step 1 If a Patient Alarm activates and it is not possible to eliminate it, refer to the Alarm

Descriptions beginning on page 6-8 for detailed descriptions, possible causes, and corrective

action.

Step 2 If the Check Ventilator icon illuminates along with the audible alarm, refer to the Check

Vent Error Flow Chart on page 6-12 for the recommended troubleshooting sequence to

follow. Refer to the “Check Vent” Error Codes chart on page 6-13 for descriptions and

possible corrective actions.

Step 3 If the Ventilator Inoperative icon illuminates along with the audible alarm, refer to the Vent

Inop Errors Flow Charts on pages 6-14 and 6-15 for the recommended troubleshooting

sequence to follow. Refer to the Common System (page 6-16), PC Specific (page 6-18), MC

Specific (page 6-22), and the DC Specific (page 6-24) Error Codes Charts for descriptions and

possible corrective actions.

Step 4 Use the chart on page 6-3 to diagnose Common System Level Problems.

Step 5 Use the “Error Codes Chart Abbreviation Definitions” on pages 6-25 and 6-26 for the

definition of terms used throughout all of the Error Code Charts.