Installation Guide: RE524X Wireless to Wireless Translator™

Features

• Selectable wireless panel and sensor compatibility

• Translator or repeater operation

• Rechargeable backup battery

• Cover tamper

• Certied to UL1023 and ULC1023

Quick Setup

1

MOUNT AND WIRE

A Select a mounting position and location.

B Connect the power supply to the translator.

2

TRANSLATOR CONFIGURATION

A Select the brand of panel that the translator must

talk to using the “PANEL SELECT” knob.

B Select the brand of sensors that the translator must

listen to using the “SENSOR SELECT” knob.

C Translator conguration

a) Press the “CONFIGURE” button to enter conguration mode.

b) Tamper or trip all sensors to be translated.

c) Press the “CONFIGURE” button to exit conguration mode.

PANEL ENROLLMENT

3

(For full sensor enrollment instructions, refer to Advanced Setup, step 3)

A Enroll Translator into Panel.

• Trip the translator tamper to enroll the translator into the panel (For Honeywell® and 2GIG® panels select loop 1).

-or-

• Enter ID into panel. The translator’s ID is printed on the bar code label.

B Enroll Sensors into Panel

• With the translator cover open, trip each sensor to enroll it into to the panel.

• Finish setup of each sensor at the panel.

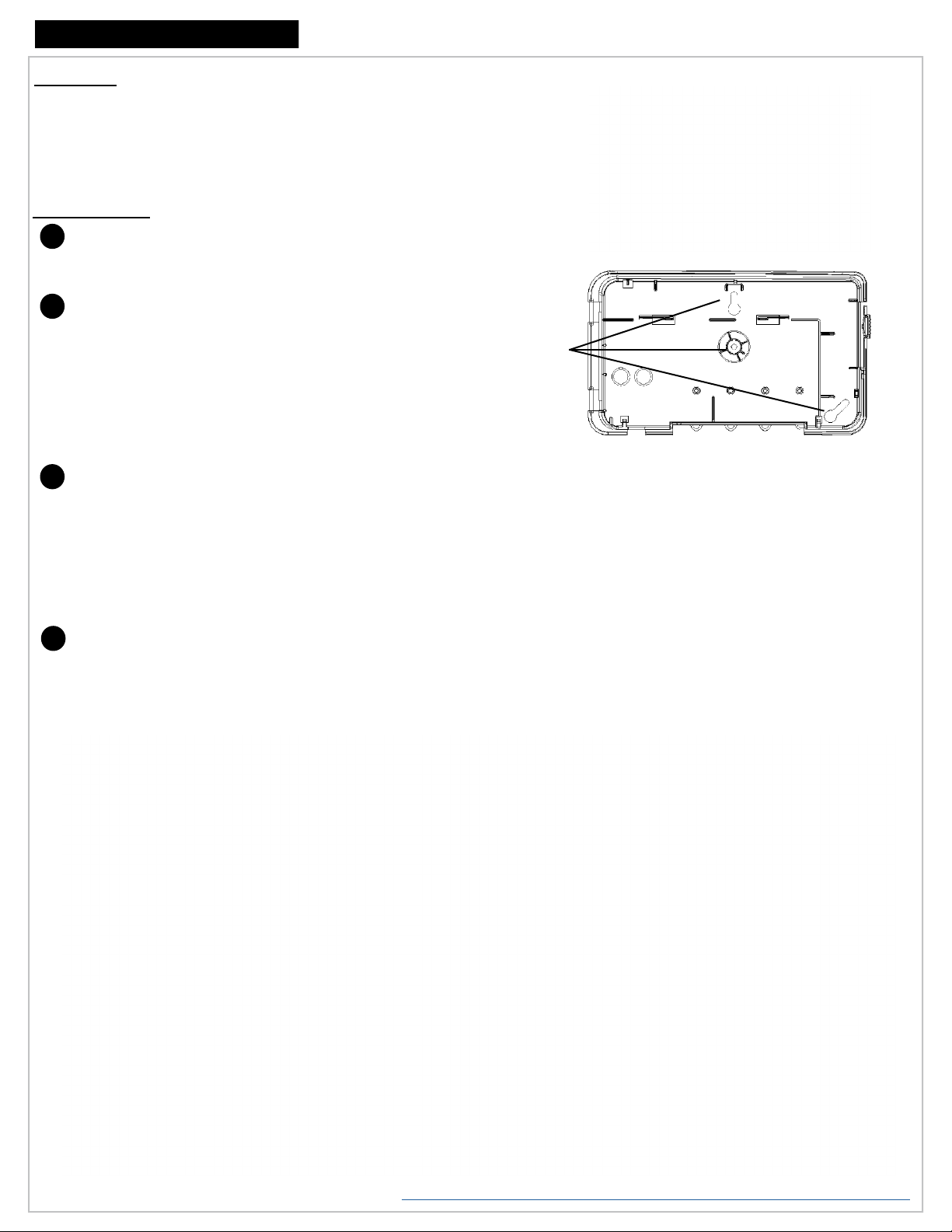

Wall mounting

screw locations

(Mounting hardware not included. Use two

#4 or # 6 screws for mounting )

4

FINISH

A With the translator cover open, perform a panel sensor test.

B Close the cover. Test and verify proper operation of the sensors at the panel.

C Cut the lock wire to lock the translator (For more information on locking, refer to Advanced Setup, step 4).

D Secure cover with screw.

DIAGRAM

INSTALLATION VIDEOS and PRODUCT INFORMATION: http://resolutionproducts.com/products/translators-repeaters/universal-translator/

Advanced Setup

1

MOUNT AND WIRE

A Select a mounting position and location.

• Mount the translator at least 5 feet from the Control Panel’s

receiver.

• Do NOT mount the translator in a metal can or on a metal

surface.

• Verify adequate RF signal strength at the panel before

permanently mounting.

PANEL ENROLLMENT (continued)

3

B Enroll Sensors into panel:

• Tamper or trip each sensor to send an enrollable

transmission to the panel.

• Installations using Interlogix (formerly GE) panels require

the translator cover to be open so sensor tamper signals

are sent on sensors that do not have a tamper switch.

• Finish setup of each sensor at the panel.

B Connect the power supply to the translator using either the

supplied barrel connector or ying leads.

• Rotate the barrel plug down to the right so the wires exit the

enclosure through the strain relief area.

• Ensure the backup battery connector is plugged into the

translator.

• The power transformer must be plugged into a non-

switched outlet.

• In the United States, the transformer must be secured to

an outlet.

• In Canada, the transformer must NOT be secured to the

outlet.

2

TRANSLATOR CONFIGURATION

A Select the brand of panel that the translator must talk to

using the “PANEL SELECT” knob.

B Select the brand of sensors that the translator must listen to

using the “SENSOR SELECT” knob.

C Translator Conguration

a) Press and release the CONFIGURE button to enter

translator conguration mode. The yellow LED will turn on

when translator conguration mode is entered.

b) Tamper or trip all the sensors to be translated. The

translator beeps for each sensor that is included in the

system.

c) Press CONFIGURE button to exit translator conguration

mode. The yellow LED will turn off when the translator

conguration mode is exited.

• Conguration mode ends automatically when the cover

is closed or 30 minutes after the last action.

• Sensors may be enrolled directly into the panel while in

conguration mode.

• Conguration mode is locked out 24 hours after power up.

To re-enable conguration mode, the translator must be

power cycled by removing both 12VDC input power and

backup battery for at least 5 seconds.

• When re-entering translator conguration mode, previously

congured sensors are retained. There is no need to recongure every sensor if the intention is to add a sensor.

• Conguration data is retained even if both the 12VDC

input power and battery backup power are lost.

• When both the panel and sensor selection knobs are set to

the same brand the translator will act as a repeater.

3

PANEL ENROLLMENT

A Enroll Translator into Panel:

• Trip the cover tamper to enroll the translator into the

panel.

-or-

• Enter ID into panel. The translator’s base ID is printed on

the bar code label.

(For Honeywell® and 2GIG® panels, select loop 1)

Below are guidelines on how to enroll the translator and sensors

into your panel. Refer to the panel installation manual for

complete panel instructions.

Interlogix ® (formerly GE ®)

Translator enrollment:

Enter Learn Sensor mode.

At the Trip Sensor prompt: Trip the translator’s cover

tamper to enroll the translator into the panel.

Select Group 13 instant perimeter

Sensor enrollment:

Enter Learn Sensor mode.

At the Trip Sensor prompt: Tamper each sensor to enroll

it. If the sensor does not have a tamper switch trip the

sensor with translator cover open to enroll it.

• For the rst 24 hours after power-up, all Interlogix

sensor trips will transmit a temporary tamper for

enrollment if the translator cover is open.

Set up the sensor for the desired behavior.

Honeywell ®

Translator enrollment:

Enter Programming mode.

Zone Type: 3 (Perimeter).

Input Type: 3 (Supervised RF).

When prompted:

• Trip the translator’s cover tamper multiple times.

-or-

• Enter the translator’s ID number, which is printed on

the unit.

Change the sensor to loop 1.

Sensor enrollment:

Enter Programming mode.

3

Set up the sensor for the desired behavior.

When prompted, perform the typical Honeywell

enrollment sequence.

The translator does not support multiple loops on

Honewell sensors. Ony one loop may be used.

2GIG ®

Translator enrollment:

Enter RF enrollment mode

Sensor Type: (03) perimeter

Equipment Code: (0862) DW10-345.

At “Enter RF Serial Number”:

• [press SHIFT, Learn, Trip the translator’s cover tamper].

-or-

• Enter the translator’s ID number, which is printed on

the unit.

Equipment Age: (0) new

Loop Number: (1)

Sensor enrollment:

Enter RF enrollment mode.

Set up the sensor for the desired behavior.

When prompted, perform the typical 2GIG enrollment

sequence.

PANEL ENROLLMENT (continued)

3

Notes

DSC ®

Translator enrollment:

Enter Wireless Enrollment mode.

Trip the translator cover tamper to enroll the translator.

Zone Type: 03 (instant)

• For the rst 24 hours after power-up, all translator

tamper trips will send a temporary “open” for

enrollment purposes.

Sensor enrollment:

Enter Wireless Enrollment Mode.

Trip each sensor to initiate enrollment.

Set up the sensor for the desired behavior.

Qolsys ®

• Qolsys IQ panel uses Interlogix 319.5MHz protocol.

• DSC Touch panel made by Qolsys uses DSC 433.92MHz

protocol.

4

FINISH

4

A With the translator cover open, perform a panel sensor test.

• When the translator cover is open the translator will only

send sensor transmissions to the panel if the received sensor transmissions have enough signal margin to be reliably

received by the translator.

• Closing the translator cover exits translator sensor test

mode. When the translator is not in sensor test mode all

received sensor transmissions are sent to the panel.

• Translator sensor test mode is locked out 24 hours after

power up. To re-enable sensor test mode, the translator

must be power cycled by removing both 12VDC input

power and backup battery for at least 5 seconds.

SENSORS

• If the translator loses both 12VDC input power and battery back

up power, sensor conguration data is retained.

• Low battery, tamper, and supervisory signals are reported by the

translator on its ID.

• Low battery signals from the translator are suppressed in the rst

24 hours after power-up. However, a missing battery condition is

reported right away.

• The translator does not support multiple loops on Honeywell

sensors. Ony one loop may be used.

FAULT CONDITIONS

• 12VDC input overvoltage fault: Continually ashes and beeps on

the green LED and sounder.

• 12VDC input removed fault: Green LED turns off and the

sounder makes a long beep.

FACTORY DEFAULT

• To return the translator to a factory default condition, press and

hold the congure button. After a couple seconds, the sounder

will start beeping rapidly. Continue holding the button until the

sounder stops beeping.

• Factory default is not possible if the translator is locked.

B Close the cover. Test and verify proper operation at the

panel. Ensure all sensor alarms are reported properly to the

central station.

C Translator Locking: Locking the translator locks all

translator conguration settings and provides takeover pro-

tection.

a) Ensure all sensors are functioning as desired.

b) Carefully review the effects of translator locking before

proceeding:

• Translator can not be factory defaulted.

• Existing sensor congurations can not be changed.

• Panel selection can not be changed.

• Sensor selection can not be changed.

• Translator LOCKING CAN NOT BE UNDONE.

c) Open the translator cover and cut the lock wire. The

green and red LED will ash, and the sounder will beep to

conrm.

d) The translator locks automatically after 30 days of

continuous operation.

D With the cover closed, insert the cover securing screw into the

screw hole near the cover latch.

KEY FOB MAPPING

PANEL FUNCTION

HONEYWELL

Right (loop 1)

2GIG

Panic (Away+Unlock)

INTERLOGIX

Panic (Lock+Unlock)

DSC

Specications

Off (loop 2)

On (loop 3)

Left (loop 4)

No action

Unlock

Away

Stay

Star

No action

Unlock

Lock

Lock+Lock

No action

Off

Away

Home

Panic

No action

KEYFOB

HONEYWELL 2GIG INTERLOGIX DSC NAPCO

Off

On

Left

Right

-

-

Off

On or Left

On

Right

-

Off

On

Left

Right

-

Unlock

Away

Stay

Away+Unlock

Star

Unlock

Away or Stay

Away

Away+Unlock

Star

Unlock

Away

Stay

Away+Unlock

Star

Unlock

Lock

Lights

Lock+Unlock

Star

Unlock

Lock

-

Lock+Unlock

Star

Lights

Unlock

Lock

Star

Lock+Unlock

Lights

Off

Away

Home

Panic

-

Off

Away

Home

Panic

-

-

Off

Away or Home

Away

Panic

-

Off

On

Left (A1)

Right (A2)

-

Off

On

Left (A1)

Right (A2)

-

-

Off

On or Left (A1)

On

Right (A2)

-

Off

On

Left (A1)

Right (A2)

-

Notices

PHYSICAL

Housing Dimensions

Weight with Battery

Tamper Activation

Mounting Screws

ENVIRONMENTAL

Operating Temperature

Storage Temperature

Maximum Humidity

POWER

Power Transformer

Input

Output

Part Number

Battery

Backup

Specications

Part Number

Trickle Charge

Fast Charge

WIRELESS RADIO

RF Frequency

Compatibility

CERTIFICATIONS

ETL Listings

Other

8.5 x 5.0 x 1.3 inches

16.0 Ounces

Cover Opening

#4 or #6

32 to 120˚F (0 to 49˚C)

-4 to 86˚F (-20 to 30˚C), Long-Term

85% relative humidity, non-condensing

100-240VAC 50/60Hz 0.5A

12VDC 1A

RE012-6

24 hours minimum

6VDC 800mAh NiMH

RE030

8mA

32mA

319.5MHz, 345MHz, 433.92MHz

Interlogix

® (formerly GE®), 2GIG®

Honeywell®, DSC®, Qolsys®, Napco®

UL 1023, ORD-C1023-1974

FCC, IC

“GE”, “INTERLOGIX”, “HONEYWELL”, “DSC”, “2GIG”, “QOLSYS” AND “NAPCO” ARE TRADEMARKS OWNED

BY GENERAL ELECTRIC COMPANY, UNITED TECHNOLOGIES ELECTRONIC CONTROLS INC.,

HONEYWELL INTERNATIONAL INC., TYCO SAFETY PRODUCTS CANADA LTD, NORTEK SECURITY &

CONTROL LLC, TYCO SAFETY PRODUCTS CANADA LTD, AND NAPCO SECURITY TECHNOLOGIES, INC.

RESPECTIVELY.

RESOLUTION PRODUCTS, INC. PRODUCTS WILL FUNCTION WITH ONE OF EITHER INTERLOGIX (FORMERLY GE), HONEYWELL, DSC, 2GIG OR QOLSYS SYSTEMS. HOWEVER, NO RESOLUTION PRODUCT

IS PRODUCED BY, ENDORSED BY, NOR IS OFFICIALLY ASSOCIATED WITH INTERLOGIX (FORMERLY

GE), HONEYWELL, DSC, 2GIG, QOLSYS OR NAPCO. RESOLUTION RECOMMENDS VERIFYING PROPER

ENROLLMENT AND OPERATION, PER CONTROL PANEL INSTALLATION INSTRUCTIONS, AT INSTALLATION.

WARRANTY

RESOLUTION PRODUCTS, INC. WILL REPLACE PRODUCTS THAT ARE DEFECTIVE IN THEIR FIRST FIVE

(5) YEARS.

FCC NOTICE

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS SUBJECT TO THE

FOLLOWING TWO CONDITIONS:

(1) THIS DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE.

(2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE THAT MAY BE RECEIVED, INCLUDING

INTERFERENCE THAT MAY CAUSE UNDESIRED OPERATION.

CHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED BY RESOLUTION PRODUCTS, INC. COULD

VOID THE USER’S AUTHORITY TO OPERATE THIS EQUIPMENT.

FCC ID: U5X-RE524X

IC NOTICE

THIS DEVICE COMPLIES WITH INDUSTRY CANADA LICENSE-EXEMPT RSS STANDARD(S).

OPERATION IS SUBJECT TO THE FOLLOWING TWO CONDITIONS:

(1) THIS DEVICE MAY NOT CAUSE INTERFERENCE, AND

(2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE, INCLUDING INTERFERENCE THAT MAY

CAUSE UNDESIRED OPERATION OF THE DEVICE.

LE PRÉSENT APPAREIL EST CONFORME AUX CNR D’INDUSTRIE CANADA APPLICABLES AUX APPAREILS

RADIO EXEMPTS DE LICENCE. L’EXPLOITATION EST AUTORISÉE AUX DEUX CONDITIONS SUIVANTES :

(1) L’APPAREIL NE DOIT PAS PRODUIRE DE BROUILLAGE, ET

(2) L’UTILISATEUR DE L’APPAREIL DOIT ACCEPTER TOUT BROUILLAGE RADIOÉLECTRIQUE SUBI,

MÊME SI LE BROUILLAGE EST SUSCEPTIBLE D’EN COMPROMETTRE LE FONCTIONNEMENT.

IC: 8310A-RE524X

PATENTS

8,456,278

OTHER PATENTS PENDING

Specications subject to change without notice.

This product is NOT for use with life safety sensors, such as Smoke, Heat, or CO detectors.

Manual: 47-0014-00 REV A

Date: 15-Feb-16

24-Hour Tech Support Line: (877)260-5578

www.ResolutionProducts.com

Loading...

Loading...