Page 1

BGUIDE

®

MANUAL

1

Page 2

Using your new BGUIDE® you will be able to guide and docu ment your buffing and cushion gum application, with its

combination of advanced sensor and computer technology.

BGUIDE

® gives you an until now unseen positioning accuracy in order to avoid crashing into the steel belt during final

buffing sequences, as the BGUIDE

® gives you the precise distance between the buffed tyre surface and the steel belt /

breaker on the full crown area, with an accuracy of +/- 0,3 mm

If you uses your BGUIDE

® for cushion gum application control the measuring accuracy is +/- 0,0 mm.

The BGUIDE

® performs 30 individual measurements per sec. at a distance up 6.5 mm from the buffed surface.

Contents:

1 pc BGUIDE®

1 pc Charge holder, Charger and cable 24 Volt

1 pc Transport security Box

Function of the BGUIDE®

DISPLAY

DUAL FUNCTION

BUTTON

ON /OFF

BUTTON

ON / OFF BUTTON:

The ON / OFF button allows the operator to turn the

BGUIDE

® ON and OFF in order to minimize consumption

of power from the batteries.

In order to obtain full accuracy the BGUIDE

® should be

powered ON for a period of app. 40 minutes before

operation. (Used before 40 minutes could add +/- 0,2 mm

to the accuracy)

Please note that for recharging of batteries the BGUIDE

®

should be turned ON.

2

Page 3

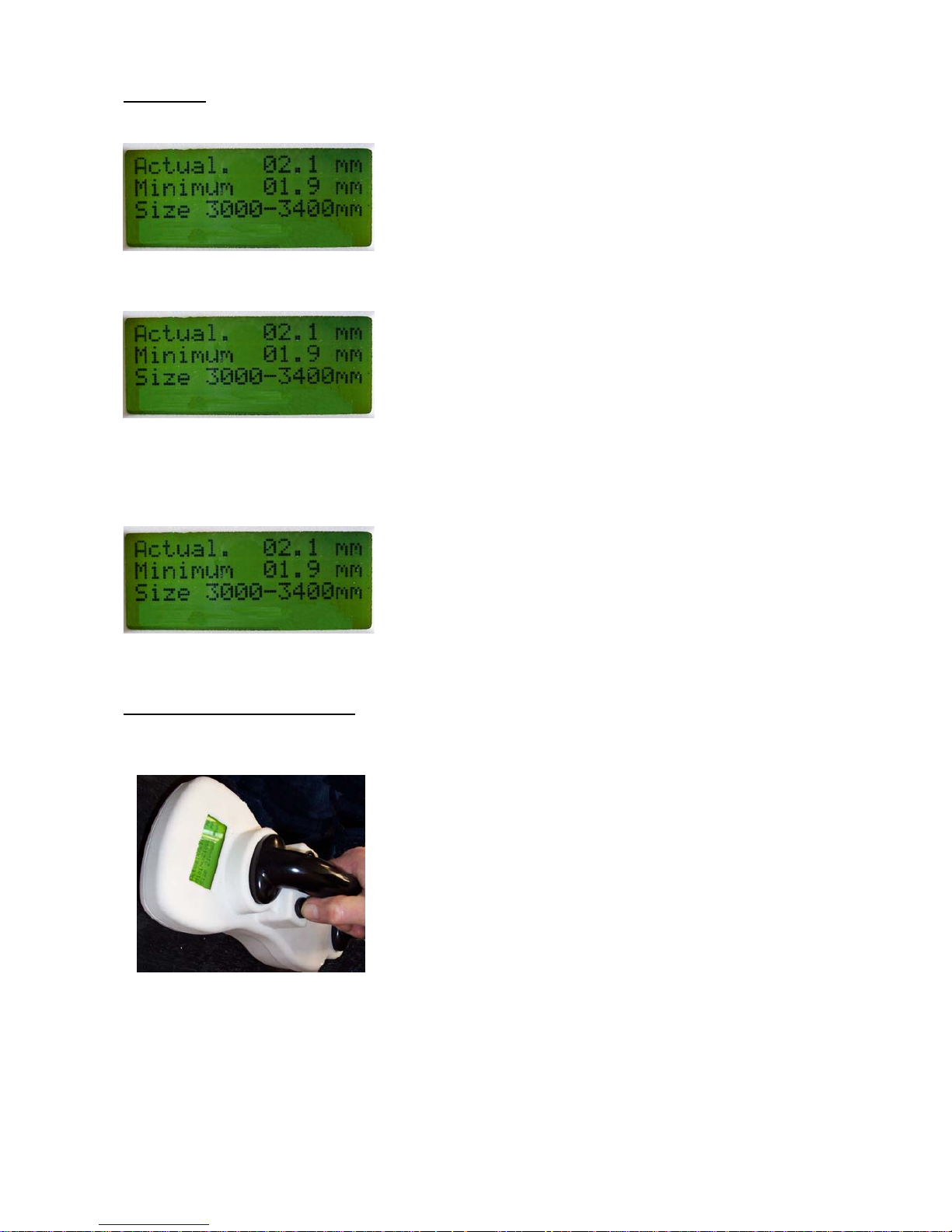

DISPLAY:

Actual

: This figure shows the actual distance between the

surface and the steel belt.

OBS 1 If the distance is above the measuring

range “

--- “ will show in the display.

OBS 2 Just behind the “l” a flashing dot appears

indicating that the measuring circuit is

operational. If the dot disappears reset

the BGUIDE (see below)

Minimum: This figure shows the minimum measured distance

between the surface and the steel belt since last

resetting.

The measured minimum value will show until a

manual resetting is performed. (for resetting see

below ).

Size

: In this line the selected size of casing measured

by circumference is shown. For resetting of size

see below.

DUAL FUNCTION BUTTON:

First function: A short push on the button the will make the latest

registered Minimum value disappear and “ - - - “

will appear, ready to measure e new minimum

value.

OBS. Every new measurement should start with

the resetting as described above.

Second function: In order to increase the overall accuracy,

measuring with the BGUIDE

® is carried out in 4

different areas, each related to the actual tyre

circumference.

The different areas are shown in the line Size.

The 4 areas are:

Area 1: 2100 – 2400 mm

Area 2: 2401 – 2700 mm

Area 3: 2701 – 3000 mm

Area 4: 3001 – 3500 mm

3

Page 4

Selecting the wanted areas is done via the dualfunction buttons scroll-function. Keeping pressure

on the button will shift the area, and when the

wanted area shows in the display, take the

pressure off the button.

OPERATION:

BUFFING CONTROL

(Only start measuring after any pattern has been buffed off)

Step 1. Take the BGUIDE

® out of the charge holder / Turn the

BGUIDE

® ON

Step 2. Reset the minimum value with a short push on the Dual

Function Button.

Step 3. Choose the relevant Size / area of the tyre by means of the

Dual Function Button

Step 4. Hold the BGUIDE® onto the tyre when it is

rotating, as illustrated, and make sure that all 4

wheels are in contact with the tyre surface.

Move the BGUIDE

® sideways over the

selected crown area, and observe the figures

shown in the display.

Use the values shown to guide your remaining

buffing.

Make sure that the tyre has made at least one

full rotation when the BGUIDE

® has been

moved sideways over the crown area, in order

to have as reliable a measurement as possible.

Hints:

• The more rotations → the more measured points.

• More measured points = higher accuracy.

• One rotation per 2 seconds = 60 measuring points.

• Worn rasp knives increase the distance between tyre surface and steel belt; caused by rough

surface.

Warning: in order to protect the operator from being hit by part of the tyre; actual measuring

with the BGUIDE

® should not be performed when rasp knives are in direct contact with the tyre.

4

Page 5

CUSHION GUM CONTROL:

1)Mount the casing on the Extruder

(extruder/builder combination)

Left

2) Hold the BGUIDE® on to the casing and let

it rotate full 360º in minimum 3 positions:

Middle

Right

3) Make a note of the “Min value” for each of

the 3 positions.

4) Apply cushion Gum

Left

5) Rotate the casing again, and place the

BGUIDE® on to the casing again on same

3 positions as described above:

Middle

Right

5

Page 6

6) Make a note of the “Min value” for each of

the 3 positions.

7) Compare the values noted under paragraph

3 and the ones noted under paragraph 6.

Differences are equal to the cushion gum

thickness.

General information:

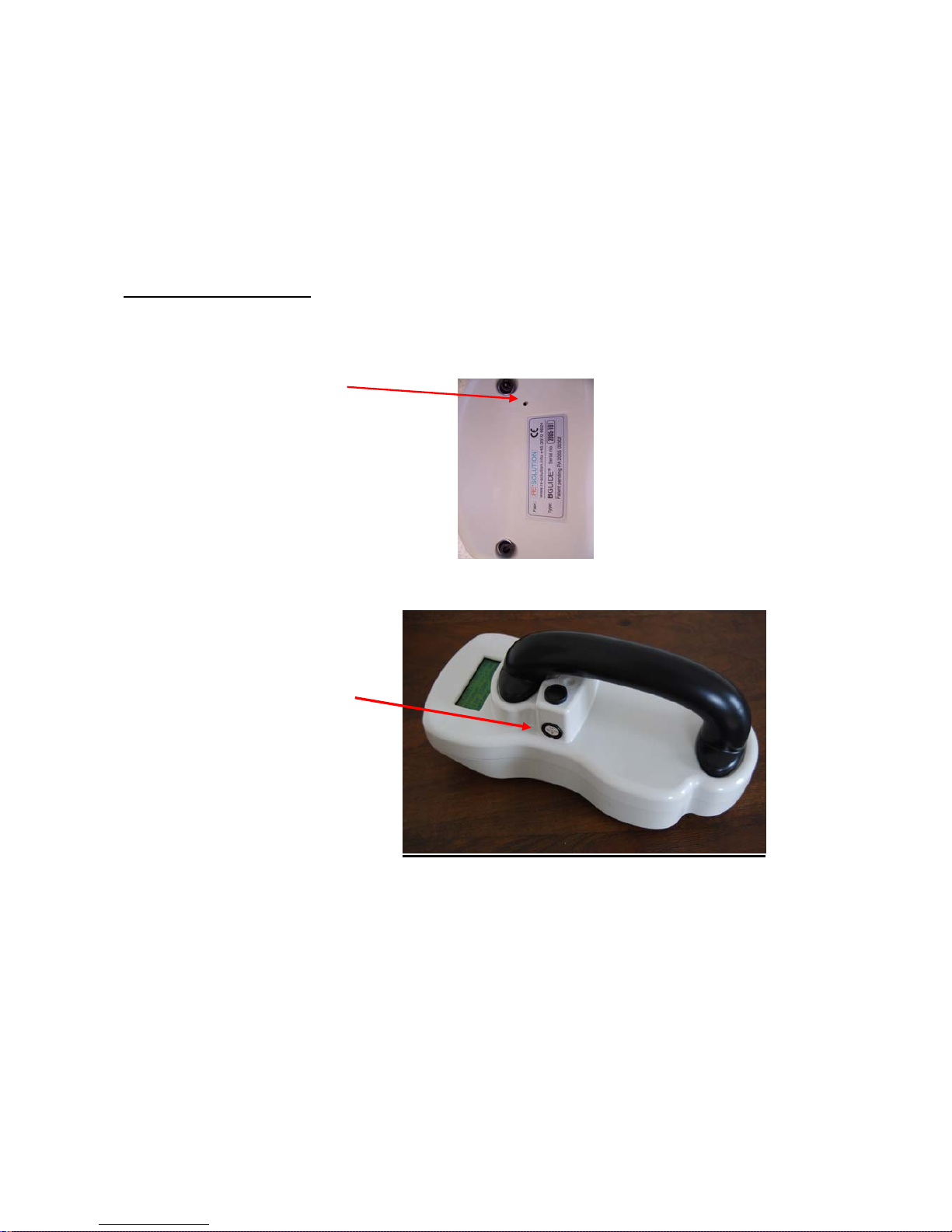

Resetting:

For resetting a “resetting button” is

placed inside the device and can be

reached via a small hole placed just

above the type identification.

For any resetting use a small pick (tooth)

or similar.

Resetting should only be necessary in

very special cases – such as a freezing

display or similar.

DIN socket:

The DIN socket is fitted for internal

calibration of the BGUIDE

® only.

6

Page 7

Mounting of charge holder:

It is advised to “park” the BGUIDE® in the charge holder when not in use.

The charge holder should be mounted with screws through the

3 holes.

OBS: When selecting a place to for the charge holder access to 230/110 Volt power supply

should be taken into consideration.

If for any reason the BGUIDE® has not been kept recharged for more than 5 hours recharging in accordance with point

1 ( below ) should be carried out.

If the rechargeable batteries have to be replaced, follow the procedure below.

Handling batteries:

Recharging can only take place when the BGUIDE® is placed in the charge holder, the BGUIDE® is turned ON, and

the charge unit is connected to the main power system.

The BGUIDE

® is powered via 10 1.5 Volt rechargeable batteries type AA. These batteries have to be recharged

following these instructions:

1. For a 100 % ( full ) recharge, the batteries should be recharged for a period of minimum 24 hours.

2. When not using it for measuring purposes place the BGUIDE

® in the charge holder and it will automatically

be kept recharged at operational level.

1.

Place the

BGUIDE® upside

down and remove the 5 Allen

screws. Then take off the bottom

cover plate.

2.

Disconnect the battery cassette

from the wire connector. Replace

the used batteries with new ones of

same rechargeable type. Make sure

that new batteries are placed

exactly as illustrated on the battery

cassette (+/-)

3.

Remount the wire connector and

remount the battery cassette in its

base position, between the special

guides

.

4. Finally remount the bottom

cover plate, and tighten the 5 Allen

screws.

7

Page 8

Technical specification:

Length: 290 mm

Width: 130 mm

Height: 150 mm

Weight: 1,8 kg

Power: 100 - 230Volt / 24 Volt – 50 HZ

Battery: 10 pc – 1.5 Volt rechargeable type AA

Contact:

Vellingvej 9

DK- 8654 Bryrup

Denmark

Phone: +45 35 10 66 24

Mail: contact@re-solution.info

8

Loading...

Loading...