*11208917*

11208917

Thank you for buying this RESOL product.

Please read this manual carefully to get the best performance from this unit.

Please keep this manual carefully.

TT2

Thermostat controller with timer

Manual for the

specialised craftsman

Installation

Operation

Functions and options

Troubleshooting

www.resol.com

Manual

en

2

en

© 20160907_11208917_TT2.monen.indd

Target group

These instructions are exclusively addressed to authorised skilled personnel.

Only qualied electricians should carry out electrical works.

Initial installation must be effected by the system owner or qualied personnel

named by the system owner.

Description of symbols

WARNING!

Warnings are indicated with a warning triangle!

Î They contain information on how to avoid the danger

described.

Signal words describe the danger that may occur, when it is not avoided.

• WARNING means that injury, possibly life-threatening injury, can occur.

• ATTENTION means that damage to the appliance can occur.

Note:

Notes are indicated with an information symbol.

Î Arrows indicate instruction steps that should be carried out.

Disposal

• Dispose of the packaging in an environmentally sound manner.

• Dispose of old appliances in an environmentally sound manner. Upon request

we will take back your old appliances bought from us and guarantee an environmentally sound disposal of the devices.

Safety advice

Please pay attention to the following safety advice in order to avoid danger and

damage to people and property.

Instructions

Attention must be paid to the valid local standards, regulations and directives!

Information about the product

Proper usage

The thermostat controller is designed for use in standard solar thermal systems,

thermosiphon systems and heating systems with electric afterheating (electric im-

mersion heater) in compliance with the technical data specied in this manual.

Improper use excludes all liability claims.

CE Declaration of conformity

The product complies with the relevant directives and is therefore labelled with the CE mark. The Declaration of Conformity is available

upon request, please contact RESOL.

Note:

Strong electromagnetic elds can impair the function of the controller.

Î Make sure the controller as well as the system are not exposed to

strong electromagnetic elds.

Subject to technical change. Errors excepted.

3

en

Thermostat controller with timer

The TT2 Thermostat controller is equipped with 2 high-current relays to which an

electric immersion heater of up to 3.6 kW (230 V~) can be connected.

Thus, the TT2 manages the time and temperature control of the electric backup

heating for a DHW store. The rapid heat-up function makes for extra comfort. A

wireline remote control with an integrated LED (RESOL RCTT) enables a comfortable operation of the rapid heat-up function.

Contents

1 Overview ...............................................................................................4

2 Installation ............................................................................................5

2.1 Mounting .........................................................................................................................5

2.2 Electrical connection ....................................................................................................6

3 Operation and function .......................................................................7

3.1 Buttons ............................................................................................................................7

3.2 Operation........................................................................................................................7

4 System-Monitoring-Display .................................................................7

4.1 Menu structure ..............................................................................................................8

5 Display and adjustment channels ........................................................8

5.1 Controller time ..............................................................................................................8

5.2 Thermostat function .....................................................................................................9

5.3 Timer ............................................................................................................................. 10

5.4 Rapid heat-up .............................................................................................................. 10

5.5 Manual mode ............................................................................................................... 11

6 RCTT Remote control (accessory) ..................................................11

4

en

1 Overview

• Direct connection of an electric immersion heater up to

3.6 kW (230 V~)

• Time and temperature control of the electric backup heating

• Rapid heat-up function with optional remote control activation

• Intuitive operating concept

• Energy-efcient switch-mode power supply

• Thermosiphon systems

Technical data

Inputs: 1 Pt1000 temperature sensor, 1 input for RCTT Remote control

Outputs: 2 high-current relays for electric immersion heater

Switching capacity: 16 (3) A 240 V~ (high-current relay)

Power supply: 100 … 240 V~ (50 … 60 Hz)

Supply connection: type Y attachment

Standby: 0.44 W

Mode of operation: type 1.C action

Rated impulse voltage: 2.5 kV

Functions:

time-controlled thermostat function, DHW heating with rapid heat-up function

Housing: plastic, PC-ABS and PMMA

Mounting: wall mounting, also suitable for mounting into patch panels

Display: LC display, multi-functional combined display with pictograms, two 2-digit

text elds and two 4-digit 7-segment displays

Operation: 3 buttons at the front of the housing

Protection type: IP 20 / DIN EN 60529

Protection class: II

Ambient temperature: 0 … 50 °C

Degree of pollution: 2

Dimensions: 172 x110 x 46 mm

Weight: 330 g

110

30

62

172

46

130

Upper fastening

Lower fastening

5

en

2 Installation

2.1 Mounting

WARNING!

Electric shock!

Upon opening the housing, live parts are exposed!

Î Always disconnect the device from power supply

before opening the housing!

Note:

Strong electromagnetic elds can impair the function of the controller.

Î Make sure the controller as well as the system are not exposed to

strong electromagnetic elds.

The unit must only be located in dry interior rooms.

The controller must additionally be supplied from a double pole switch with con-

tact gap of at least 3 mm.

Please pay attention to separate routing of sensor cables and mains cables.

N

R1-N

R1-L

21

T1A

100 ... 240 V~

50-60 Hz

S1

L

IP 20

1011987

6

453

R1 | 16(3) A 240 V~

Temp. Sensor

Pt1000

RC TT

1

2

3

4

6

7

130 mm

Electrical connection see chap. 2.2

In order to mount the device to the wall, carry out the following steps:

6

en

2.2 Electrical connection

WARNING!

Electric shock!

Upon opening the housing, live parts are exposed!

Î Always disconnect the device from power supply be-

fore opening the housing!

WARNING!

ESD damage!

Electrostatic discharge can lead to damage to electronic components!

Î Take care to discharge properly before touching the

inside of the device!

Note:

The mains connection must be carried out with the common ground of

the building to which the pipework of the system is connected.

Note:

Connecting the device to the power supply must always be the last step

of the installation!

Note:

It must be possible to disconnect the device from the mains at any time.

Î Install the mains plug such that it is accessible at any time.

Î If this is not possible, install a switch that can be accessed.

Do not use the device if it is visibly damaged!

The power supply of the device must be 100 … 240 V~ (50 … 60 Hz). Attach exible

cables to the housing with the enclosed strain relief and the corresponding screws.

The mains connection is at the following terminals:

9 = Neutral conductor N

11 = Conductor L

7 = Grounding terminal ⌯

Connect the temperature sensor (S1) to the following terminals with either

polarity:

1 / 2 = Sensor 1 (e. g. store sensor)

Connect the RCTT Remote control (accessory) to the following terminals:

3 Switching input RCTT Remote control

4 GND RCTT Remote control

5 Signal LED output RCTT Remote control

The controller is equipped with 2 high-current relays (16 A) for connecting an

electric immersion heater (up to 3.6 kW at 230 V~ or up to 1.8 kW at 115 V~

respectively):

6 Grounding terminal ⌯

10 Conductor electric immersion heater

8 Neutral conductor electric immersion heater

S1

RC TT

100... 240

V~

N

R1-N

R1-L

10L11987

6

21453

R1 | 16(3) A 240 V~

T1A

100 ... 240 V~

50-60 Hz

Temp. Sensor

Pt1000

S1

RC TT

Made in Germany

TT2

IP 20

7

en

3 Operation and function

3.1 Buttons

Scrolling downwards / reducing

adjustment values (-)

Scrolling upwards / increasing

adjustment values (+)

Selection / adjustment mode / con rming

1

3

2

3.2 Operation

Accessing the adjustment mode

Adjustment mode

Changing a value

(Scrolling upwards / downwards)

Con rming a value &

to the next parameter

To the next channel

Selecting a channel

3 s

3 s

Note:

If the adjustment mode is active and if no button is pressed for 10 s, the

controller will automatically quit the adjustment mode.

4 System-Monitoring-Display

The System-Monitoring-Display consists of 2 blocks: channel display and tool bar.

Channel display

The channel display consists of 2 lines. In the 16-segment displays, parameter names

are displayed. In the 7-segment displays, values are displayed.

Tool bar

The additional symbols in the tool bar indicate the current system state.

Permanently

shown

Flashing Status indications

⓵

Backup heating active, relay 1 switched on

⓵ + ☛

Rapid heat-up active, relay 1 switched on

3 x ☛

Rapid heat-up not possible, because switch-off temperature

exceeded

⓵ + ☛ ⚠

Manual mode active, relay 1 switched on (ON)

☛ ⚠

Manual mode active, relay 1 switched off (OFF)

⚠ + ☍

Sensor fault

8

en

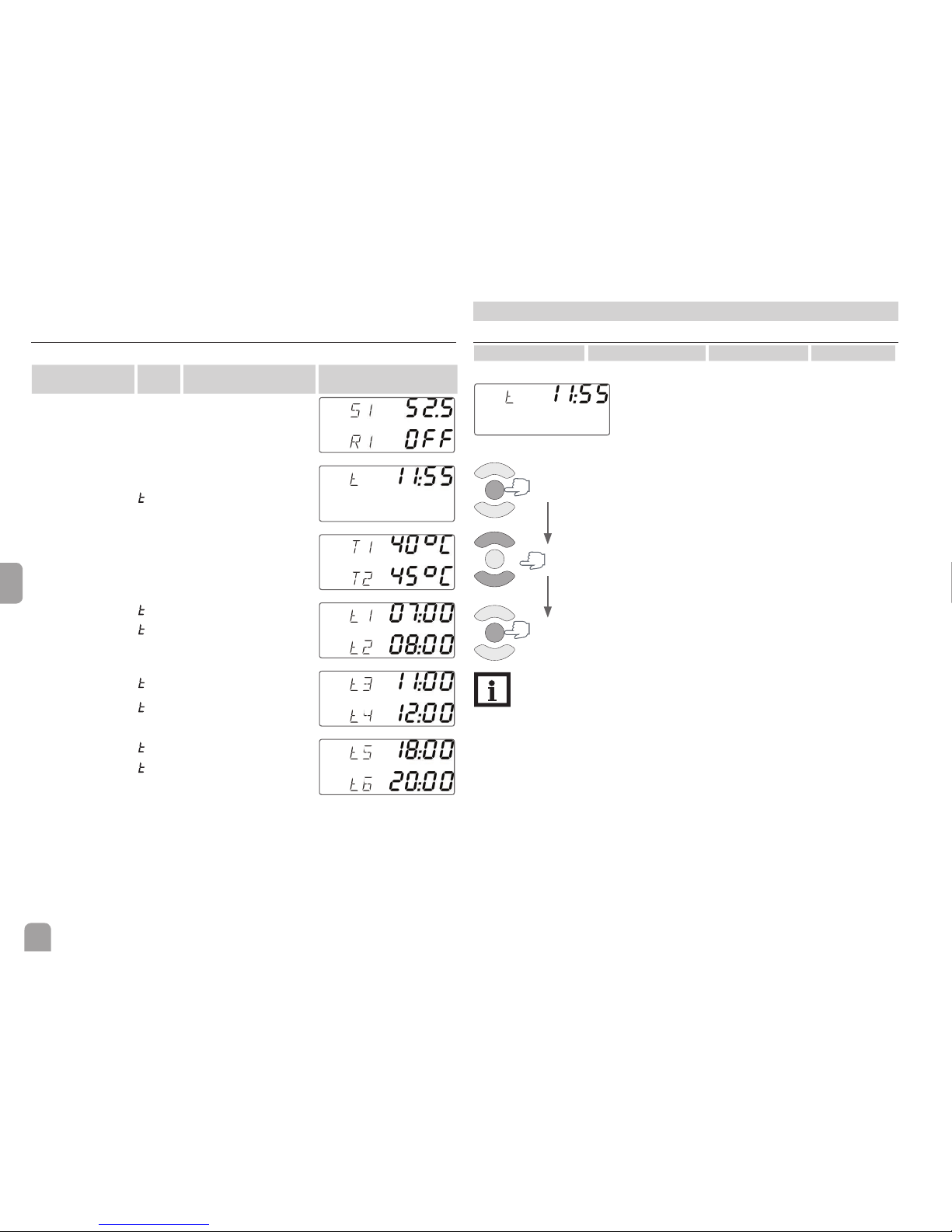

4.1 Menu structure

The menu is structured as follows:

Channel

Parameter

Description Display

Display channel 1

S1

Temperature sensor 1 / store

R1

Status relay / electric

immersion heater

Display channel 2

Current time

Adjustment channel 1

t1

Switch-on temperature

t2

Switch-off temperature

Adjustment channel 2

1

Time frame 1 switch-on time

2

Time frame 1 switch-off time

Adjustment channel 3

3

Time frame 2 switch-on time

4

Time frame 2 switch-off time

Adjustment channel 4

5

Time frame 3 switch-on time

6

Time frame 3 switch-off time

5 Display and adjustment channels

5.1 Controller time

Adjustment channel Description Adjustment range Factory setting

t Time 00:00 … 23:59

Indicates the current clock time.

Adjustment mode

Con rming a value &

to the next parameter

Adjusting the time

3 s

3 s

Note:

Adjust the current time so that the controller can function properly.

9

en

5.2 Thermostat function

Adjustment channel

Description Adjustment range Factory setting

T1

Switch-on temperature 0 … 90°C 40°C

T2

Switch-off temperature 5 … 95°C 45°C

The thermostat function is used for controlling the backup heating.

If the temperature at sensor S1 falls below the adjusted switch-on temperature T1,

backup heating will be switched on. If the temperature at sensor S1 reaches the

adjusted switch-off temperature T2, backup heating will be switched off.

In order to prevent the backup heating from being switched on and off too often,

the switch-on and switch-off temperatures T1 and T2 are blocked against each

other.

T1

25 30 35 40 45 50 55 60 65

T2

25 30 35 40 45 50 55 60 65

T1

T2

25 30 35 40 45 50 55 60 65

T1

T2

T1

25 30 35 40 45 50 55 60 65

T2

T1

25 30 35 40 45 50 55 60 65

T2

Automatic upward shift of T2, if T1 reaches

the limit (T2 - 5K)

If T2 decreases, it is blocked against

(T1 + 5K)

In order to avoid, but permit if necessary, long switch-on times of the backup heating, the switch-on and switch-off temperatures T1 and T2 are linked to each other.

T1

25 30 35 40 45 50 55 60 65

T2

25 30 35 40 45 50 55 60 65

T1

T2

25 30 35 40 45 50 55 60 65

T1

T2

T1

25 30 35 40 45 50 55 60 65

T2

25 30 35 40 45 50 55 60 65

T1

T2

Automatic downward shift of T2, if T1

reaches the limit (T2 - 15K)

Automatic downward shift of T2, only if it is

within (T2 - 15K) before the adjustment

T1

25 30 35 40 45 50 55 60 65

T2

25 30 35 40 45 50 55 60 65

T1

T2

T2 can be freely increased

Changing a value

(Scrolling upwards / downwards)

Con rming a value &

to the next parameter

To the next channel

3 s

10

en

5.3 Timer

Adjustment

channel

Description

Adjustment

range

Factory

setting

t1 Time frame 1 switch-on time 00:00 … 23:45 07:00

t2 Time frame 1 switch-off time 00:00 … 23:45 08:00

t3 Time frame 2 switch-on time 00:00 … 23:45 11:00

t4 Time frame 2 switch-off time 00:00 … 23:45 12:00

t5 Time frame 3 switch-on time 00:00 … 23:45 18:00

t6 Time frame 3 switch-off time 00:00 … 23:45 20:00

In order to block the thermostat function for a certain period, there are 3 time

frames. They can be adjusted by means of the parameters switch-on and switch-off

times (see table).

If the thermostat function is supposed to run from 06:00 a.m. to 09:00 a.m., adjust

t3 to 06:00 a.m. and t4 to 09:00 a.m. Outside these time frames the backup heating

is blocked and can be activated via the rapid heat-up function only.

If the switch-on and switch-off times of a time frame are set to an identical value,

the time frame will be inactive. If all time frames are set to 00:00, the thermostat

function is solely temperature dependent.

Changing a value

(Scrolling upwards / downwards)

Con rming a value &

to the next parameter

To the next channel

3 s

Note:

The time frames are not blocked against each other. If the values of 2 time

frames overlap, they will be considered as 1 common time frame.

5.4 Rapid heat-up

Rapid heat-up enables immediate heating of the store even outside the adjusted

time frames.

If rapid heat-up is activated, the controller will switch on the backup heating of

the store. Rapid heat-up of the store will stop, if the switch-off temperature T2 is

reached at sensor S1.

In order to activate the rapid heat-up, scroll to the rst display channel, press

and hold down button 1 for 3 s. It is also possible to press the button of the

RCTT Remote control (accessory) instead.

3 s

In order to deactivate the rapid heat-up, press and hold down the controller button 1 again for 3 s. It is also possible to press the button of the RCTT Remote

control again instead.

Note:

If the temperature at sensor S1 exceeds the adjusted switch-off temperature T2 while rapid heat-up is being activated, rapid heat-up will be

blocked. The controller will give feedback, see page 7 and page 11.

Note:

If the temperature at sensor S1 does not reach the switch-off temperature within 120 min after the rapid heat-up has started, the controller

will switch off the backup heating of the store for safety reasons.

11

en

5.5 Manual mode

Adjustment channel Description Adjustment range Factory setting

R1 Manual mode On, Auto, Off Auto

For control and service work, the operating mode of the relay can be manually

adjusted. For this purpose, select the adjustment channel R1 in which the following

adjustments can be made:

Adjustment mode of the manual mode

OFF : Relay off ⚠ ( ashing) + ☛

Auto : Relay in automatic operation

ON : Relay on ⚠ ( ashing) + ☛ + ⓵

In order to access the adjustment channel R1 for adjusting the manual mode, scroll

to the rst display channel, press and hold down button 3 for 3 s.

3 s

WARNING!

Electric shock!

Upon opening the housing, live parts are exposed!

Î Always disconnect the device from power supply be-

fore opening the housing!

Note:

Danger of high currents (16 A), if the manual mode is set to ON.

Note:

If the manual mode is set to ON, the controller will switch the manual

mode back to Auto after 30 s for safety reasons.

6 RCTT Remote control (accessory)

The RCTT Remote control enables rapid heat-up activation via the button without having to access the controller menu. It is connected to the controller with a

3-wire cable (see page 6).

If the button of the RCTT is pressed, rapid heat-up will be activated on the controller. If rapid heat-up is already active, it will be deactivated.

If rapid heat-up is active on the controller, the LED of the RCTT will be permanently red.

If rapid heat-up is not possible, because the temperature at sensor S1 has exceeded

the switch-off temperature T2, the LED of the RCTT will brie y ash 3 times.

In the case of a sensor fault, the LED of the RCTT will be ashing continuously.

The RCTT Remote control has to be connected to the controller according to the

installation instructions mentioned in the RCTT Remote control manual.

Distributed by:

RESOL – Elektronische Regelungen GmbH

Heiskampstraße 10

45527 Hattingen / Germany

Tel.: +49 (0) 23 24 / 96 48 - 0

Fax: +49 (0) 23 24 / 96 48 - 755

www.resol.com

info@resol.com

Important note

The texts and drawings in this manual are correct to the best of our knowledge. As

faults can never be excluded, please note:

Your own calculations and plans, under consideration of the current standards and

directions should only be basis for your projects. We do not offer a guarantee for

the completeness of the drawings and texts of this manual - they only represent

some examples. They can only be used at your own risk. No liability is assumed for

incorrect, incomplete or false information and / or the resulting damages.

Note

The design and the specications can be changed without notice.

The illustrations may differ from the original product.

Imprint

This mounting- and operation manual including all parts is copyrighted. Another

use outside the copyright requires the approval of RESOL – Elektronische Rege-

lungen GmbH. This especially applies for copies, translations, micro lms and the

storage into electronic systems.

© RESOL – Elektronische Regelungen GmbH

Loading...

Loading...