Operating Instructions

REOTRON MEW

Single Phase Power Controller

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

REO UK LTD Publication No.: 2022_GBANL.doc

Units 8 -10 Long Lane Industrial Estate 08/99

Craven Arms, Shropshire SY7 8DU

Tel: 01588 673411

Fax: 01588 672718

http://www.reo.co.uk

eMail: main@reo.co.uk

Operating Instructions REOTRON MEW

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

Technical Safety Information for the User

This description co nta ins th e nec es s ar y inf ormation for the correct app lication of the product desc r ibe d

below. It is intended for use by technically qualified personal.

Qualified personnel are persons who, because of their training, experience and position as well as

their knowledge of appropriate standards, regulations, health and safety requirements and working

conditions, are authorised to be responsible for the safety of the equipment, at all times, whilst carrying

out their normal duties and are therefore aware of, and can report, possible hazards (Definition of

specialist according to IEC 364).

Safety Instructions

The following instr uctions are provided for the personal safety of operators and also for the

!

protection of the described product and connected equipment.

Warning!

Hazardous Voltage

Failure to observe can kill, cause serious injury or damage

• Isolate from mains before installation or dismantling work, as well as for fuse changes or post

installation modifications.

• Observe the prescribed accident prevention and safety rules for the specific application.

• Before putting into operation check if the rated voltage for the unit conforms with the local

supply voltage.

• Emergency stop devices must be provided for all applications. Operation of the emergency

stop must inhibit any further uncontrolled operation.

Prescribed Use

The units described herein are electrically powered for use in industrial applications. They are

designed for power adjustment of resistive or inductive loads.

REO UK LTD 2

Operating Instructions REOTRON MEW

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

Contents Page

1.0 General 4

2.0 Function Description 4

2.1 Effective Current Value 5

2.2 Effective Voltage Value 5

2.3 Current Regulation 5

2.4 Voltage Regulation 5

2.5 Pulse Generation 5

2.6 Temperature Monitoring 5

3.0 Control Inputs and Outputs 5

3.1 Setpoint Input U 6

3.2 Setpoint Input I 6

3.3 Enable (Regulator Inhibit) 6

3.4 Actual Voltage Output (Option) 6

3.5 Actual Current Output (Option) 6

3.6 Fault Indication 6

4.0 Construction 6

5.0 Adjustment Facilities 7

6.0 Adjustment Instructions 7

7.0 Technical Data 9

8.0 Ordering Codes 10

9.0 Adjustment Components 11

10.0 Fuse Change 12

11.0 Installation Guidelines 12

12.0 Guidelines on Electromagnetic Interference 12

13.0 Connection Diagrams 13

14.0 Dimension Drawing 14

14.1 Dimension Drawing MEW 150/XXX 15

REO UK LTD 3

Operating Instructions REOTRON MEW

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

1.0 General

The range of REOTRON MEW Thyristor Regulat ors are microprocessor based units for controll ing

the power to resisti ve and inductive loads . In essence the units comprise inverse para llel connected

power semiconductors (thyristors) and the control and regulation electronics. The units have a

regulated, AC output. The inverse parallel connected thyristors operate as contact free, power

controllers using the ph ase angle control or the f ull wave principles. In t he phase angle control m ode

(symetrical load) the equipment can be used as a voltage or current regulator and also there is an

option for power regulation. The set point value for the current and voltage can be provided by an

external control vo ltage of 0-10 V, 0-20 mA, DC or a potentiom eter. The lowest set point has priority.

The effective value is f ed back internall y from a voltage or curr ent transformer. The m aximum current

limit of the unit c annot be exceeded in a ll regulation modes , using phase angle control. Applications

with a wide load resistance variation Rcold/Rwarm are possible, and an overloading of the unit is

prevented.

Typical Applications

Industrial Ovens Steam Generators Lighting Installations

Infra Red Emitters (Dryers) Preheating Plants Air Conditioning Plant

Tunnel Heaters Room Heating Equipment Fan Heating Systems

Plastic Moulding Equipment Extruders

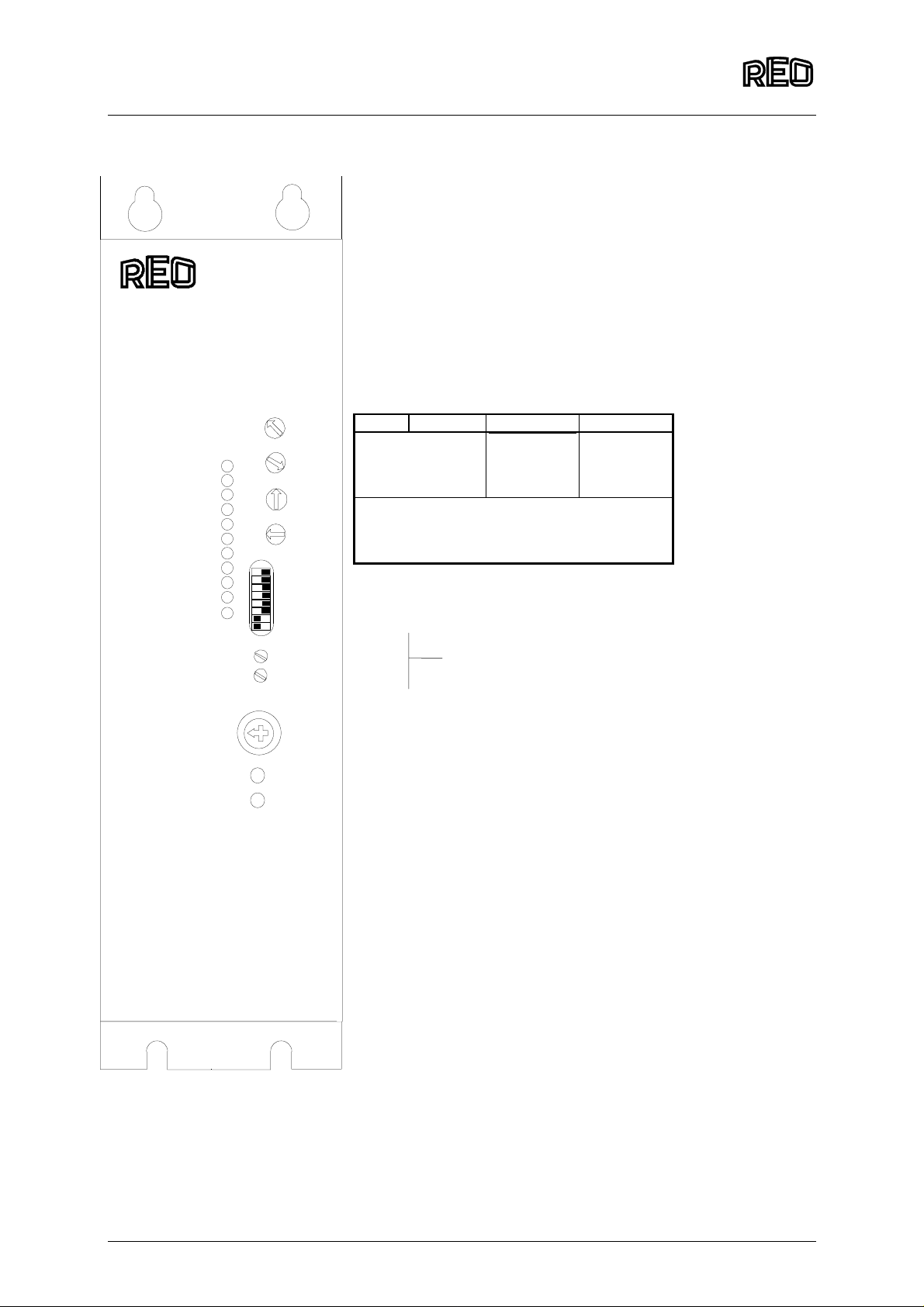

2.0 Function description

Mains connection

L1 L2 (N)

F1

The MEW thyristor contro l unit was desig ned to oper ate with a

symetrical load. Th ey include a voltage and current regu lator.

In the voltage regulation m ode the output voltage determ ined

by the set point is held constant by an internal circuit, therefore

load or mains variations have no influence on the output

PULSE

GENERATION

R

C

voltage. The selected maximum current, however, cannot be

exceeded in this mode (current limiting). If the unit is used as a

current regulator then the output current of the unit is

compared with the setpoint and regulated accordingly. The

Fault

output voltage can incr ease to the selected voltage set point.

LED's illuminate if the limit Imax or adjustment limits are

exceeded.

If both set points are adjusted during operation, th e regulator

always gives the lower set point priority. During voltage

Actual

Current

Actual

Voltage

Actual

Output

(Option)

regulation, with underlying current regulation, the voltage

regulation is alwa ys in operation providing the a llowed current

limit is not exceeded. If the current limit is reached then the

current regulator has priority. Should the unit be used as a

pure voltage or current r egulator, the other availa ble set point

must be linked to the reference voltage (10V DC).

Current

Setpoint

Voltage

Setpoint

Enable

Control

Electronics

I

U

Output

REO UK LTD 4

Operating Instructions REOTRON MEW

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

2.1 Effective Current Value

The effective current value is measured inside the u nit through a current transformer and a burden

resistor. The interna l microprocess or determines the ef fective value of th e output current and adjusts

this using a PI regulator.

2.2 Effective Voltage Value

The effective vo ltage value is also meas ured internally using a v oltage transformer and the effective

value is controlled by the microprocessor using a PI regulator.

2.3 Current Regulator

Microprocessor controller with PI Characteristics; the P portion is adjustable externally by using

trimmer P4. The units m aximum output cur rent (Rated Current) is factor y set. If the thyristor controller

is to be adapted for a small load current, then a correction can be made by using trimmer Imax.

BEWARE: It is possible t o obtain an outpu t current which is higher than the rat ed current bec ause of

component and manuf acturing tolerances, however, for s afety, it is essential that the current lim it is

not set higher than the rated current

In current regulation mode the LED Imax is permanently illuminated.

2.4 Voltage Regulator

Microprocessor controller with PI Characteristics; the P portion is adjustable externally by using

trimmer P3. The units maximum voltage output is factory set to the rated voltage (for 100% set point).

Therefore, the setpoint cannot be f ully used during voltage regulation s ince this would not allow for

any over voltage. In this oper ating mode ( voltage regulation) ei ther the setpoint m ust be limited or the

maximum unit output voltage must be reduced by using the trimmer Umax.

2.5 Pulse Generation

The pulses required f or the control of the thyristors are generated by the m icroprocessor and are fed

to amplifiers prior t o the pulse conductors. The sec ondary windings of the pulse cond uctors directly

control the thyristors.

2.6 Temperature Monitoring

A temperature switc h is fitted into the heat sink to monitor its temperature and this switches off the

thyristor controller , permanently, if the tem perature exceeds a maxim um of 80oC. Fault indication is

provided by the general fault relay and displayed by the LED on the front panel.

3.0 Control Inputs and Outputs

Control Inputs

Setpoint Input U 0(4)...20 mA, 0-10V DC or Potentiometer 10kΩ

Setpoint Input I 0(4)...20 mA, 0-10V DC or Potentiometer 10kΩ

Enable 12-24V DC or contacts

Outputs:

Effective Current Value 0-10V DC corresponding to 0-100% (Option)

Effective Voltage Value 0-10V DC corresponding to 0-100% (Option)

Fault Indication Relay Contact 250V/1A (Change over)

REO UK LTD 5

(

)

g

Operating Instructions REOTRON MEW

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

3.1 Setpoint Input U

With power regulation here the power setpoint is determined

switch S1/6=ON

The value of the outp ut voltage is determ ined by the s etpoint inp ut U. The setp oint can b e provided in

the form of 0-10 V, 0-20mA, DC or with a 10kΩ Potentiometer. A +10V ref erence voltage is prov ided

for potentiometer operation.

With setpoint 4...20 mA, put the switch “S1/5” to “ON”.

3.2 Setpoint Input I

The strength of the output current is determined by the set point input "I". The setpoint can be provided

in the form of 0-10 V, 0- 20mA, DC or wit h a 10k Potentiom eter. A +10V r eference vo ltage is pro vided

for potentiometer operation.

With setpoint 4...20 mA, put the switch “S1/5” to “ON”.

3.3 Enable (Regulator Inhibit)

A control voltage (12-24V DC) must be applied to terminals 9+ and 15-, to enable the unit, or a

connection made between terminals 9 and 10 by using a switch. A permanent link between terminals 9

and 10 is used for operation without an external enable. The firing pulses are inhibited whilst the

enable input is not closed.

3.4 Actual Voltage Output (Option)

With power regulation the actual power is given

instead of the actual volta

e.

A 0-10 V DC output signal is pr ovided and this corresponds to the units m omentary voltage output.

This generates 10V for 100% of the units possible output voltage (using the Umax set value).

3.5 Actual Current Output (Option)

A 0-10 V DC output signal is provided and this cor responds to the units mom entary current output.

This generates 10V for 100% of the units possible output current (using the Imax set value).

3.6 Fault Indication

Relay changeover contacts are provided for indicating that there has been a unit fault.

The following fault conditions energise the relay and cause the unit to switch off:

Over temperature of the power unit

Mains synchronisation not possible

A fault condition must be cancelled with the RESET push button.

4.0 Construction

The thyristor regulator un it is a completely wired, function tes ted, compact unit. The unit is des igned

for panel mounting. T he co nnections for th e m ains s uppl y and l oad ar e bro ught out t o scr ew term inals

and the control signals to plug-in screw terminals. The unit front panel incorporates the adjustment

components (trimmers, switch and light diodes) to display and control the operating conditions.

The fuses for protecting th e sem iconductors is built into the f ront panel are ac cessed b y removin g the

front panel.

REO UK LTD 6

Operating Instructions REOTRON MEW

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

5.0 Adjustment Facilities

The following parameters can be adjusted on the unit: Umax - Maximum Output Voltage Umin - Minimum Output Voltage

Imax - Maximum Output Current Imin - Minimum Output Current

P - Characteristic of the Voltage Regulator P - Characteristic of the Current Regulator

Ramp up time Ramp down time

The trimmers are adjustable through the front panel.

6.0 Adjustment Instructions

Preparatory Steps

Connect unit according to connection

drawing, disconnect the enable and

adjust set point to zero. The unit will

now operate with the basic factory

settings: output curr ent = rated current,

output voltage = rated in put voltage1), Umin = 0,

phase angle control, regulation mode.

The setpoint control c urve can be det ermined by

using trimmers Umin/Umax and Imin/Imax ie the

setpoint control range. At this stage, it is also

possible, to make permanent adjustments,

without external setpoints.

The range minimum always ex tends from zero to

the adjusted range maximum. The maximum

value must be set first.

Adjustment of the MAX - Values

Umax

Hint: If the output voltage is to be regulated at the maximum set point, then the maximum output

voltage must be limited at a value which reduces the regulation range.

Switch on the m ains voltag e and enab le the uni t. Set the cur rent set po int to m axim um. Now increase

the voltage set point unti l the required output voltage level is reached (obs erve current lim it indicator) .

If the set point source is no t yet at m aximum , then the output volt age must be reduced ag ain by using

trimmer Umax and then t he voltage s et point can be further incr eased until the maximum value of the

voltage set point is ac hieved. If there is no risk of dam aging the load with an over voltage th en the

output voltage can be set by using trimmer Umax with the set point turned fully up. Anticlockwise

adjustment increases the output voltage.

Imax

Remove the unit enable. Adjust voltage set point to maximum and current setpoint to zero. Turn

trimmer Imax fully clockwise (10 turn pot). Next enable the unit and adjust the current setpoint to

maximum. Set the maximum current value by turning trimmer Imax anti-clockwise.

REO UK LTD 7

Operating Instructions REOTRON MEW

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

Adjustment of the MIN - Values:

Umin

Trimmers P1 and P2 ar e used to adjust the MIN va lue, however these trim mers are used for vari ous

other functions. Below is the recommended adjustment procedure.

Set rotary switch 'S2' on the f ront panel to pos ition '1' and press the RES ET butto n. Next

adjust the trimmers P1 (coarse) and P2 (fine) to the required minimum voltage and

afterwards press th e SETUP button. T o return to normal operat ion put the r otary switch

'S2' back to '0' and press the RESET button.

Imin

This adjustment is only meaningful for pure current contro l, if a current f ree condition of the loa d is to

be avoided.

This adjustment is als o carried out by using trimm ers P1 and P2. Set rotary switch 'S2' o n the front

panel to position '2' and pres s the RESET button. Next adjust the trimmers P1 (c oarse)

and P2 (fine) to the requir ed minimum current and af terwards press the S ETUP button.

To return to normal op eration put th e rotar y switch 'S2' bac k to '0' and pres s the RES ET

button.

Ramp up /down times

The ramp up time f or when the unit is switched o n, using the enable input ( set point 100%) or when

the set point sudden ly rises, giving 0 to 1 00% of the maximum output value, and also t he run down

time to reach an output value for a set point change in the direction of zero.

This adjustment is similarly achieved using the trimmer P1 for Ramp up and P2 for Ramp down times.

With the voltage set point at zero and the current set point at maximum.

Set rotary switch 'S2' on the front panel to position '3' and press the RESET button. Next set the

required ram p time (0.1-10s) using trimmer P1 and test for a set point change from

zero to 100%; afterwards set the ramp down time with trimmer P2 and again test by

changing the set point. W hen the required val ues have been chosen, once again press

the "SETUP" button, return rotary switch 'S2' back to '0' and press the RESET button.

Proportional Characteristic Voltage Regulation

The speed of regulation (sensitivity) of the voltage regulator. Adjust, using the actual load, using

trimmer P3.

Proportional Characteristic Current Regulation

The speed of regulation (sensitivity) of the current regulator. Adjust, using the actual load, using

trimmer P4.

Hint

To return the unit to the factory settings, the procedure is as follows:Rotate selector switch "S2" to position "F" an d press the RESET butto n. After wards press the SETUP

button and return select or switch "S2" to position "0" and press the RE SET button once more. The

factory settings are now reinstated.

Selector Switch S1 (Operating Mode)

S1/1 OFF = Phase angle control ON = Full wave control

1

2

3

4

5

6

7

8

OFF

S1/2 not active

S1/3 not active

S1/4 not active

S1/5 OFF = 0...20 mA ON = 4...20 mA (Setpoint)

S1/6 OFF = U/I - Regulation ON = Power Regulation

S1/7 OFF = Without data interface ON = with data interface

S1/8 OFF = Reserved

ON

The RESET button must be pressed before a change of the switch settings.

REO UK LTD 8

Operating Instructions REOTRON MEW

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

7.0 Technical Data

TYPE Rated Voltage Output Voltage2) Output Current

50/60 Hz MAX.

MEW 10/230 230 V +6% -10% 0-230 V 10 A

MEW 10/400 400 V +6% -10% 0-400 V 10 A

MEW 20/230 230 V +6% -10% 0-230 V 20 A

MEW 20/400 400 V +6% -10% 0-400 V 20 A

MEW 50/230 230 V +6% -10% 0-230 V 50 A

MEW 50/400 400 V +6% -10% 0-400 V 50 A

MEW 80/230 230 V +6% -10% 0-230 V 80 A

MEW 80/400 400 V +6% -10% 0-400 V 80 A

MEW 110/230 230 V +6% -10% 0-230 V 110 A

MEW 110/400 400 V +6% -10% 0-400 V 110 A

MEW 150/400 400 V +6% -10% 0-400 V 150 A

Load Types resistive / resistive - inductive; for transformers max. induction 1,45 Tesla

Setpoint source 5 / 10 kΩ Potentiometer

0-10V, DC

0-20 mA

Ramp up/down time 0,1 - 10 sec.

Enable Switch 12-24 V, DC

Actual value output I 0-10 V, DC

Actual value output U 0-10 V, DC

Fault relay 1 change over contacts 250 V, 1 A

Ambient temp. 0-45 °C

Dimensions approx. (HxBxD)

MEW 10/XXX MEW 20/XXX MEW 50/XXX MEW 80/XXX MEW110/XXX MEW150/XXX

290x70x205 290x110x205 290x110x205 320x150x205 320x180x205 320x180x205

2)

The output voltage is subject to a voltage loss across the semiconductors.

REO UK LTD 9

Operating Instructions REOTRON MEW

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

8.0 Ordering Codes

Type ID-Number Description

REOTRON MEW 10/230 6311 10 A/230 V Standard unit

REOTRON MEW 10/400 6312 10 A/400 V Standard unit

REOTRON MEW 10/230 DA 6316 10 A/400 V with D/A-Module

REOTRON MEW 10/400 DA 6317 10 A/400 V with D/A-Module

REOTRON MEW 10/230 RS 6315 10 A/400 V with RS 232 Interface

REOTRON MEW 10/400 RS 6318 10 A/400 V with RS 232 Interface

REOTRON MEW 10/230 IS 6313 10 A/400 V with INTERBUS-S Interface

REOTRON MEW 10/400 IS 6314 10 A/400 V with INTERBUS-S Interface

REOTRON MEW 20/230 6321 20 A/230 V Standard unit

REOTRON MEW 20/400 6322 20 A/400 V Standard unit

REOTRON MEW 20/230 DA 6328 20 A/230 V with D/A-Module

REOTRON MEW 20/400 DA 6327 20 A/400 V with D/A-Module

REOTRON MEW 20/230 RS 6329 20 A/230 V with RS 232 Interface

REOTRON MEW 20/400 RS 63210 20 A/400 V with RS 232 Interface

REOTRON MEW 20/230 IS 6324 20 A/230 V with INTERBUS-S Interface

REOTRON MEW 20/400 IS 6325 20 A/400V with INTERBUS-S Interface

REOTRON MEW 50/230 6331 50 A/230 V Standard unit

REOTRON MEW 50/400 6332 50 A/400 V Standard unit

REOTRON MEW 50/230 DA 6338 50 A/230 V with D/A-Module

REOTRON MEW 50/400 DA 6337 50 A/400 V with D/A-Module

REOTRON MEW 50/230 RS 6339 50 A/230 V with RS 232 Interface

REOTRON MEW 50/400 RS 63310 50 A/400 V with RS 232 Interface

REOTRON MEW 50/230 IS 6333 50 A/400 V with INTERBUS-S Interface

REOTRON MEW 50/400 IS 6334 50 A/400 V with INTERBUS-S Interface

REOTRON MEW 80/230 6341 80 A/230 V Standard unit

REOTRON MEW 80/400 6342 80 A/400 V Standard unit

REOTRON MEW 80/230 DA 6348 80 A/230 V with D/A-Module

REOTRON MEW 80/400 DA 6347 80 A/400 V with D/A-Module

REOTRON MEW 80/230 RS 63410 80 A/400 V with RS 232 Interface

REOTRON MEW 80/400 RS 6349 80 A/400 V with RS 232 Interface

REOTRON MEW 80/230 IS 6343 80 A/400 V with INTERBUS-S Interface

REOTRON MEW 80/400 IS 6344 80 A/400 V with INTERBUS-S Interface

REOTRON MEW 110/230 6351 110 A/230 V Standard unit

REOTRON MEW 110/400 6352 110 A/400 V Standard unit

REOTRON MEW 110/230 DA 6358 110 A/4 00 V with D/A- M od ule

REOTRON MEW 110/400 DA 6357 110 A/4 00 V with D/A- M od ule

REOTRON MEW 110/230 RS 6355 110 A/4 00 V with RS 232 I nterf ac e

REOTRON MEW 110/400 RS 6356 110 A/4 00 V with RS 232 I nterf ac e

REOTRON MEW 110/230 IS 6353 110 A/400 V with INTERBUS-S Interface

REOTRON MEW 110/400 IS 6354 110 A/400 V with INTERBUS-S Interface

REOTRON MEW 150/400 DA 2057 150 A/4 00 V with D/A- M od ule

REO UK LTD 10

Operating Instructions REOTRON MEW

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

9.0 Adjustment Components

LED Indicator Functions

ERROR System fault

TEMP Over temperature

SYNC Mains synchronisation fault

I-Max Current limit reached ie current regulator active

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

LOAD Impedance fault / peak current reached

MAX Max. a djustment limit reached

INIT Initialisation phase

READY Ready to operate

ENABLE Enable

IN1 External Input 1 (Reserved)

IN2 External Input 2 (Reserved)

S2 S2 = 1 S2 = 2 S2=3

P1 =Umin/coarse

P2 = Umin/fine

Imin/coarse

Imin/fine

Ramp up

Ramp down

times

P3 = P-Characteristic voltage regulator

P4 = P-Characteristic current regualtor

Selector Switch S1

S1/1 - OFF = Phase angle control ON = Full wave control

S1/2 -

S1/3 - Reserved for curent controller

S1/4 -

S1/5 – OFF = 0...20 mA ON = 4...20 mA (Setpoint)

S1/6 - OFF = I/U-Regulation ON = Power regulation

S1/7 - OFF = without data interface ON = with data interface

S1/8 - OFF = Reserved

Selector Switch S2

0 = Normal operation (Regulator)

1 = Adjus tment Umin

2 = Adjustment Imin

3 = Adjustment ramp up/down times

4 = Reserved

5 = Uncontrolled operation (no regulation / no current limiting)

6-E = Reserved

F = Reinstate factory settings

ERROR

TEMP

SYNC

I-max

LOAD

MAX

INIT

READY

ENABLE

IN1

IN2

P1

P2

P3

P4

1

2

3

4

S1

5

6

7

8

ONOFF

U-max

I-max

4

5

3

6

2

7

1

8

0

S2

9

F

A

E

B

D

C

RESET

SETUP

RESET = System reset-Button

SETUP = Enter new parameters

REOTR ON

MEW

REO UK LTD 11

Operating Instructions REOTRON MEW

10.0 Fuse change

Switch unit off before changing fuse!

!

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

The semiconductor f use can be found in the left han d section of the f ront panel. T o change the fuse

the two screws marked "x" must be loosened. The cover can then be removed by sliding it to the right.

For MEW/xxx type units the fuse can be found in the front panel.

Fuse Types:

MEW 10/xxx FF 16

MEW 20/xxx ET 35

MEW 50/xxx ET 80

MEW 80/xxx EET 140

MEW 110/xxx EET 160

MEW 150/xxx 6.6 URB 000 BS88/250

When ordering spare fuses use capital letters for fuse types.

11.0 Installation Guidelines

The unit is desi gned for p anel m ounting. It sho uld be i nstalled ver tically wit h the t erminals at

the bottom. Ensure that there is sufficient air space in unventilated cabinets.

The units can be place d side by side with a minimum clearanc e of 30mm. If the units are

mounted one over the other, then there must be a clearance of approximately 250mm.

The control cables should be shielded and the shield should be connected to earth.

12.0 Guidelines on Electromagnetic Interference

INTERBUS-S is a serial data transfer system which was conceived for app lications in an industrial

environment. When correctly installed, INTERBUS-S complies with all the requirements specified in

the standard IEC 801 for data trans fer system s in a harsh in dustrial enviro nment. W hen the interface

module is used in an electromagnetic, interference prone, area, then the possible sources of

interference should be suppressed.

Interference can be due, in particu lar, to:

• Protection devices

• Switching of inductive loads

• Solenoid valves

RC networks and var istors suppress interference. Ma nufacturers supply correctly si zed components

for suppressing solenoid coils.

Electrical spikes, which can affect bus cables in an industrial environment, can be suppressed by a

correctly fitted screen. The following measures provide the best screening results:

• Cover fixing screws of bus cable plugs and conductors at equal potentials.

• Only use connectors with a metal or metalised housing.

• Spread out the screen in connectors.

REO UK LTD 12

Operating Instructions REOTRON MEW

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

13.0 Connection Diagrams

Control Terminals

00

1 2 34 5 6 7 8 910

Voltage setpoint Current setpoint Enable

(Power setpoint)

+10V +10V

10k 10k

Potentiometer setpoint source

12 345678910

00+++

0 - 20mA 0 - 20mA

Setpoint Voltage Setpoint Current

(Power setpoint)

Enable

24V, DC

(to terminal 15)

12 345678910

00++

0 - 10V, DC 0 - 10V, DC

Setpoint Voltage Setpoint Current

(Setpoint power)

Setpoint source using

0-10 V, DC control voltage

11 12

0 - 10V 0 - 10V

Actual value

Voltage

(Actual value power)

13

14 15 16 17 18 19 20

00++

Actual value

Current

(Optional)

NC C NO

Enable

Setpoint source using

0-20 mA control current

Power terminals

230V, 50/60Hz

400V, 50/60Hz

L1 (L)

L2 (N)

PE

21 22 23 24 25 26

L1 L2 PE PE V U(N)(L) (N) (U)

Load

REO UK LTD 13

Operating Instructions REOTRON MEW

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

14.0 Dimensions

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

P1

ERROR

TEMP

SYNC

I-max

LOAD

MAX

INIT

READY

ENABLE

IN1

e

IN2

P2

P3

P4

1

2

3

4

S1

5

6

7

8

ONOFF

U-max

I-max

4

5

3

6

2

7

1

8

0

S2

9

F

A

E

B

D

C

RESET

SETUP

d

REOTRON

MEW

a

b

c

x

205

Dimension MEW10 MEW20 MEW50 MEW80 MEW110

a - 70 70 60 90

b 35 15 15 30 30

c 70 110 110 150 180

d 290 290 290 320 320

e 280 280 280 304 304

x - 5 5 5 10

REO UK LTD 14

Operating Instructions REOTRON MEW

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

14.1 Dimensions MEW 150/XXX

ELEKTRONIK

ELEKTRONIK

ELEKTRONIKELEKTRONIK

P1

P2

P3

P4

1

2

3

4

S1

5

6

7

8

ONOFF

U-max

I-max

4

7

1

8

S2

F

RESET

SETUP

320

290

FOR CONTINUED FIRE

PROTECTION REPLACE

ONLY WITH SPECIFIED

TYPE AND RATED FUSE

DISCONNEC T POWER

INPUT BEFORE

REPLACING F USE

ERROR

TEMP

SYNC

I-max

LOAD

MAX

INIT

READY

ENABLE

IN1

IN2

REOTRON

MEW

90

180

2

21

22

5

11 12 13 14 15 16 17 18 19 20

26

25

23

12 345678910

3

1 Control terminals

2 Power terminal Input L1

3 Power terminal Input L2 (N)

8

4 Power terminal Output V (N )

5 Power terminal Output U (U)

6 PE

7 PE

8 Plexiglass cover

6

24

1

4

7

REO UK LTD 15

Loading...

Loading...