MDW_700_EN_ANL_34-13.doc

21.08.2013

REOTRON

Electronic Power Controller

MDW 700

3-Phase-Thyristor Power Controller

REOTRON MDW 700

Operating instructions

1

Contents

Technical Information for the User ............................................................................................................... 2

1.0 General ................................................................................................................................................... 3

2.0 Construction ........................................................................................................................................... 3

3.0 Functions ................................................................................................................................................ 4

3.1 Modes ................................................................................................................................................. 4

3.2 Regulation mode ................................................................................................................................. 5

3.3 Set point .............................................................................................................................................. 5

3.4 Feedback ............................................................................................................................................ 6

3.5 Control functions ................................................................................................................................. 6

4.0 Technical Data ........................................................................................................................................ 7

4.1 Limited the output voltage by using line input from 230V or 240V ..................................................... 7

5.0 Declaration of Conformity ....................................................................................................................... 7

6.0 Ordering codes ....................................................................................................................................... 8

7.0 Operation ................................................................................................................................................ 9

7.1 Adjustment .......................................................................................................................................... 9

7.2 Adjustment Procedure ........................................................................................................................ 9

7.3 Indications on display........................................................................................................................ 10

7.4 Error Messages ................................................................................................................................. 10

8.0 Settings ................................................................................................................................................. 11

9.0 Setting up instructions .......................................................................................................................... 12

9.1 Internal set point ............................................................................................................................... 12

9.2 Unit configuration .............................................................................................................................. 12

9.2.1 Service menu ................................................................................................................................. 13

9.2.2 Display effective values measured inside unit ............................................................................... 13

9.3 Setting Up Procedures ...................................................................................................................... 14

9.4 Select Interface ................................................................................................................................. 14

9.5 Save current settings ........................................................................................................................ 15

9.6 Restore parameter settings .............................................................................................................. 15

9.7 Software version ............................................................................................................................... 15

9.8 Hide parameter menus ..................................................................................................................... 15

10.0 Connection diagram ........................................................................................................................... 16

10.1 Connection details .......................................................................................................................... 17

11.0 Dimensions ......................................................................................................................................... 18

12.0 Putting into service ............................................................................................................................. 22

12.1 Preliminaries ................................................................................................................................... 22

12.2 Measurements and Settings ........................................................................................................... 22

12.3 Putting into service without a proper load ....................................................................................... 22

13.0 Installation of Thyristor Control Units ................................................................................................. 23

13.1 Fuses .............................................................................................................................................. 23

13.2 Incoming breaker ............................................................................................................................ 23

13.3 Output Breaker ................................................................................................................................ 23

13.4 Installation and climatic Conditions ................................................................................................. 23

13.5 Signal cables ................................................................................................................................... 23

14.0 Interference prevention....................................................................................................................... 24

14.1 Earthing ........................................................................................................................................... 24

14.2 Control cables ................................................................................................................................. 24

14.3 Interference protection of other external components and equipment ........................................... 24

15.0 Engineering notes ............................................................................................................................... 25

REOTRON MDW 700

Operating instructions

2

Technical Information for the User

This description contains the necessary information for the correct application of the product described

below. It is intended for use by technically qualified personal.

Qualified personnel are persons who, because of their training, experience and position as well as their

knowledge of appropriate standards, regulations, health and safety requirements and working conditions,

are authorised to be responsible for the safety of the equipment, at all times, whilst carrying out their normal duties and are therefore aware of, and can report, possible hazards (Definition of specialist according

to IEC 364).

Safety Instructions

The following instructions are provided for the personal safety of operators and also for the protection of

the described product and connected equipment.

Warning!

Hazardous Voltage

Failure to observe can kill, cause serious injury or damage

• Isolate from mains before installation or dismantling work, as well as for fuse changes or post

installation modifications.

• Observe the prescribed accident prevention and safety rules for the specific application.

• Before putting into operation check if the rated voltage for the unit conforms with the local

supply voltage.

• Emergency stop devices must be provided for all applications. Operation of the emergency

stop must inhibit any further uncontrolled operation.

• Electrical connections must be covered

• Earth bonding must be tested prior to operation

Prescribed Use

The units described herein are electrically powered for use in industrial applications. They are designed

for power adjustment of resistive or inductive loads

These units comply with Directive 2004/108/EC

EMC Directive

!

RoHS

COMPLAINT

REOTRON MDW 700

Operating instructions

3

1.0 General

The range of REOTRON MDW Thyristor Regulators are microprocessor based units for controlling the

power to resistive and inductive loads. In essence the units comprise inverse parallel connected power

semiconductors (thyristors) and the control and regulation electronics. The units have a regulated, AC

output. The inverse parallel connected thyristors operate as contact free, power controllers using the

phase angle control or the full wave principles. In the phase angle control mode the equipment can be

used as a voltage or current regulator and also there is an option for power regulation. The set point value

for the current and voltage can be provided by an external control voltage of 0-10 V, 0(4)-20 mA, DC or a

potentiometer. The lowest set point has priority. The effective value is fed back internally from a voltage

or current transformer. The maximum current limit of the unit cannot be exceeded in all regulation modes,

using phase angle control. Applications with a wide load resistance variation Rcold/Rwarm are possible,

and an overloading of the unit is prevented.

Typical Applications

Industrial Ovens Steam Generators Lighting Installations

Infra Red Emitters (Dryers) Preheating Plants Air Conditioning Plant

Tunnel Heaters Room Heating Equipment Fan Heating Systems

Plastic Moulding Equipment Extruders

2.0 Construction

The REOTRON -MDW 700 thyristor controller is a completely functional, compact, unit. It has been designed for building into an enclosure. All connections for the supply, power output, feedback signals and

the supply for the isolator are made through screw terminals. A touch panel with an LED display and setting up keys is incorporated in the front panel. There are connectors provided for analogue signals and

optional a field bus interface. Inside the unit there is a printed circuit, control card and a power card, comprising the semiconductors, firing and regulating circuits and the system power supply.

Overview

Display

Output

Controlterminals

Input

* MDW 25 A

27

28

2625

24 23 22 21

DO NOT USE

WITHOUT COVER

REOTRON

MDW

www.reo.de

F I

0P

FOR CONTINUED FIRE

PROTECTION REPLACE

ONLY WITH SPECIFIED

TYPE AND RATED FUSE

DISCONNECT POWER

INPUT BEFORE

REPLACING FUSE

REOTRON MDW 700

Operating instructions

4

3.0 Functions

Features:

Mode:

1. Phase angle control

2. Full wave principle

Regulation mode:

1. Current regulation RMS

2. Voltage regulation RMS

3. Power regulation Real power

Set point inputs:

1. Voltage or Power Potentiometer 10 kR, 0...+10 V, 0(4)...20 mA,

internal Keypad

2. Current

Potentiometer 10 kR, 0...+10 V, 0(4)...20 mA,

internal Keypad

Option interface Set point via interface

Feedback monitoring:

1. Voltage or Power Voltage 0...+10 V, DC correspond 0...100% RMS

2. Current Current 0...+10 V, DC correspond 0...100% RMS

Status

Enable (ON/OFF) Contact or 24 V, DC

Fault relay Change over contact

Interface: Option

Serial RS 232

Fieldbus Profibus-DP

Fieldbus CAN-Bus

Fieldbus DeviceNet

3.1 Modes

Phase angle control

In the phase angle control mode the mains voltage half waves are more or less cut in function of the given set point.

This mode of operation is suitable for resistive, inductive and resistive-inductive loads.

The benefits with this mode of operation are the continuous adjustment, the fine dosing and the high

regulating dynamics. A dynamic current limitation is possible only with this mode of operation.

Full wave control

In the full wave principle mode of operation, always full sinus waves are switched in function of the set

point. In this operating mode almost no harmonics are produced, however, the dynamic regulation is not

possible. This mode of operation is suitable in particular for loads with high thermal inertia.

REOTRON MDW 700

Operating instructions

5

3.2 Regulation mode

The REOTRON MDW Thyristor Regulator range include 3 regulators, ie. voltage, current and power

regulator. All the regulators always work in combination, ie. with voltage regulation for example, the current regulation operates like a cascade control and limits the output current in case of overload on the

rated current. In case of current regulation mode, the maximum voltage limit can be prescribed over the

voltage set point. With power regulation, the current limit is also effective as cascade.

In case both the voltage and current regulation are used, the set point of the power regulator must be set

to 100 % (over display, in menu „C 002“, parameter „P“).

Voltage regulation

Microprocessor controller with PI Characteristics; the P portion is adjustable externally by using the keyPad. The units maximum voltage output is factory set to the rated voltage (for 100% set point).

Parameter setting

Parameter Code Setting

Output power „P.“ C 020 100%

Set point current „I.“ Display

or Set point current connection 7 u. 8

C 020

100%, or smaller

bridge = 100%

Current regulation

Microprocessor controller with PI Characteristics; the P portion is adjustable externally by using the KeyPad. The units maximum output current (Rated Current) is factory set.

Parameter setting

Parameter Code Settings

Output power „P.“ C 020 100%

Set point voltage „U.“ Display

or Set point current connection 3 u. 4

C 020

100%, or smaller

bridge = 100%

Power regulation

With power regulation, the real power value is controlled. In this case, the input that is normally coordinated to the voltage set point is now used as set point input. This set point input corresponds to 0...100

% of the unit output power. The current set point must be set to 100 % or to the required limit value. Setting over display or link between terminals 7 and 8.

Parameter setting

Parameter Code Settings

Output power „P.“ C 020 0%

Set point voltage „U.“ Display C 020 100%, or smaller

Set point voltage „I.“ Display

or Set point current connection 7 u. 8

C 020

100%, or smaller

bridge = 100%

Power regulation „E.F.P.“ C 003 1

3.3 Set point

External signals

Two inputs for set points are available

Set point input U, P 0-10V DC, 0(4)…20 mA or Potentiometer 10kΩ

Set point input I 0-10V DC, 0(4)…20 mA or Potentiometer 10kΩ

Set point over display

All set points can be set over the internal Key-Panel

REOTRON MDW 700

Operating instructions

6

3.4 Feedback

Current feedback

The current is measured, in one phase, with an internal current transformer. The internal microprocessor

determines the effective value of the output current and makes adjustments through a PI loop.

Voltage feedback

The effective voltage is measured with an internal Transformer. It is converted in an analogue input stage

and then fed to the internal microprocessor. The effective value is thus determined and applied used for

PI regulation using software.

Using an external feedback signal of 0..5V is also possible. (See connection diagram)

Output monitor

Effective Voltage 0…10 V, DC correspond 0…100 % output voltage or output power.

Effective Current 0…10 V, DC correspond 0…100 % output current

3.5 Control functions

Enable

Run / Stop input.

A control voltage (24V DC) must be applied to terminals 32(+) and 31(-), to enable the unit, or a connection made between terminals 32 and 33 by using a switch. A permanent link between terminals 32 and 33

is used for operation without an external enable. The firing pulses are inhibited whilst the enable input is

not closed.

Start ramp / Stop ramp

This function reduces surges on the mains supply

when the load is switched on and off.

Set point control (min / max)

The set-point control characteristics can be

adjusted to match the subsequent process

controller or automation system, by setting the

lower and upper values

Status / Ready relay (clamp 41, 42, 43)

For monitoring the actual status, an internal relay can be used. In case of applied input voltage and enabled power output, clamp 42 – 43 closes.

For using this relay as a “READY” signal point “r.b.” in Code “C 003” has to be set to 1. In case of an error

like “LO.PO.”, clamp 42 – 43 opens.

Clamp assignment:

41 normally close (NC)

42 change-over contact (CO)

43 normally open (NO)

run-up

run-down

Output

U,I,P

Time

0

10 20 30 40 50 60 70 80 90 100

[%]

10

20

30

40

50

60

70

80

90

100

[%]

Output-

voltage

Set point

Umin

Umax

adjustment range

Set point

0...100%

REOTRON MDW 700

Operating instructions

7

Failure relay (clamp 44, 45, 46)

In case of an error (for example “Error Hot”) the contact 45 – 46 closes.

Clamp assignment:

44 normally close (NC)

45 change-over contact (CO)

46 normally open (NO)

4.0 Technical Data

Type Input voltage [V] Output voltage [V] Output current[A]

MDW 700-10/230 - 400

230 – 400 V +/-10% 50/60Hz

Ue – 3 V

0…10

MDW 700-25/230 – 400 0...25

MDW 700-50/230 - 400 0…50

MDW 700-80/230 - 400 0…80

MDW 700-110/230 - 400 0…110

MDW 700-150/230 - 400 0…150

MDW 700-200/230 - 400 0…200

MDW 700-300/230 – 400 0...300

MDW WK 700-115/230 - 400 0…115

MDW WK 700-160/230 - 400 0…160

MDW WK 700-250/230 - 400 0…250

MDW WK 700-350/230 - 400 0…350

MDW WK 700-450/230 - 400 0…450

MDW WK 700-600/230 - 400 0…600

Load R / RL, Transformer Load max. Induction 1,45 Tesla

Set point Inputs

current

voltage or power

0...+10 V 22 kR

0(4)...20 mA 100 R

Potentiometer 10 KR, internal Display

External feedback U 0...+/-5 V 22 kR

External feedback I 0...+/-5 V 22 kR

Feedback monitor / U or P 0...+10 V, DC 5 mA

Feedback monitor I 0...+10 V, DC 5 mA

Enable Contact 5 mA or 24 V, DC 5 mA

Faulty relay Change over contact 250 V, 1 A

Protection IP 20

Operating temperature 0... + 45 °C

Liquid temperature WK Type 25 °C Input

Liquid quantity H2O, 6 ltr/min

Storing temperature -20...+75 °C

Rel. air humidity 93 % without condensation and surface water coning

Contamination level degree 1 (IEC 664)

Mounting direction Vertical (Connections below)

Mounting height 1000 m, 0,5 % rated current reduction for each additional 100 m

WK = water-cooled

4.1 Limited the output voltage by using line input from 230V or 240V

By using the controller at line input from 230 or 240V you must limited the output voltage under

Code 020 – point „u“. At line= 230V to 57% and at line= 240V to 60%.

5.0 Declaration of Conformity

In order to comply with the EMC requirements, when using phase angle controllers it is necessary to build

in a suitable filter in the line input, e.g. Book-style filter CNW 207 or CNW 107.

(further information in Section 15.0, "Engineering notes")

REOTRON MDW 700

Operating instructions

8

6.0 Ordering codes

Type

ID.-No.:

Input voltage

[V]

Output current

[A]

REOTRON MDW 700-10/230 – 400 6401.01

230 – 400 3x 10

REOTRON MDW 700-10/230 – 400 Profibus DP 6401.10

230 – 400 3x 10

REOTRON MDW 700-10/230 – 400 RS-232 6401.30

230 – 400 3x 10

REOTRON MDW 700-25/230 – 400 6402.01

230 – 400 3x 25

REOTRON MDW 700-25/230 – 400 Profibus DP 6402.10

230 – 400 3x 25

REOTRON MDW 700-25/230 – 400 RS-232 6402.30

230 – 400 3x 25

REOTRON MDW 700-50/230 – 400 6403.01

230 – 400 3x 50

REOTRON MDW 700-50/230 – 400 Profibus DP 6403.10

230 – 400 3x 50

REOTRON MDW 700-50/230 – 400 RS-232 6403.30

230 – 400 3x 50

REOTRON MDW 700-80/230 – 400 6404.01

230 – 400 3x 80

REOTRON MDW 700-80/230 – 400 Profibus DP 6404.10

230 – 400 3x 80

REOTRON MDW 700-80/230 – 400 RS-232 6404.30

230 – 400 3x 80

REOTRON MDW 700-110/230 – 400 6405.01

230 – 400 3x110

REOTRON MDW 700-110/230 – 400 Profibus DP 6405.10

230 – 400 3x110

REOTRON MDW 700-110/230 – 400 RS-232 6405.30

230 – 400 3x110

REOTRON MDW 700-150/230 – 400 6406.01

230 – 400 3x 150

REOTRON MDW 700-150/230 – 400 Profibus DP 6406.10

230 – 400 3x 150

REOTRON MDW 700-150/230 – 400 RS-232 6406.30

230 – 400 3x 150

REOTRON MDW 700-200/230 – 400 6407.01

230 – 400 3x 200

REOTRON MDW 700-200/230 – 400 Profibus DP 6407.10

230 – 400 3x 200

REOTRON MDW 700-200/230 – 400 RS-232 6407.30

230 – 400 3x 200

REOTRON MDW 700-300/230 – 400 6409.01

230 – 400 3x 300

REOTRON MDW 700-300/230 – 400 Profibus DP 6409.10

230 – 400 3x 300

REOTRON MDW 700-300/230 – 400 RS-232 6409.30

230 – 400 3x 300

REOTRON MDW-WK 700-115/230 – 400

6337.01

230 – 400 3x 115

REOTRON MDW-WK 700-115/230 – 400 Profibus DP

6337.10

230 – 400 3x 115

REOTRON MDW-WK 700-115/230 – 400 RS-232

6337.30

230 – 400 3x 115

REOTRON MDW-

WK

700-160/230 – 400

6338.01

230 – 400 3x 160

REOTRON MDW-WK 700-160/230 – 400 Profibus DP

6338.10

230 – 400 3x 160

REOTRON MDW-WK 700-160/230 – 400 RS-232

6338.30

230 – 400 3x 160

REOTRON MDW-WK 700-250/230 – 400

6339.01

230 – 400 3x 250

REOTRON MDW-

W

K

700-250/230 – 400 Profibus DP

6339.10

230 – 400 3x 250

REOTRON MDW-WK 700-250/230 – 400 RS-232

6339.30

230 – 400 3x 250

REOTRON MDW-WK 700-350/230 – 400

6340.01

230 – 400 3x 350

REOTRON MDW-WK 700-350/230 – 400 Profibus DP

6340.10

230 – 400 3x 350

REOTRON MDW-WK 700-350/230 – 400 RS-232

6340.30

230 – 400 3x 350

REOTRON MDW-WK 700-450/230 – 400

6341.01

230 – 400 3x 450

REOTRON MDW-WK 700-450/230 – 400 Profibus DP

6341.10

230 – 400 3x 450

REOTRON MDW-WK 700-450/230 – 400 RS-232

6341.30

230 – 400 3x 450

REOTRON MDW-WK 700-600/230 – 400 Profibus DP

0203.06

230 – 400 3x 600

WK = water-cooled

REOTRON MDW 700

Operating instructions

9

7.0 Operation

The six buttons and a LED display found in the front panel,

are used for operating and setting up the unit. All operating

methods and adjustable parameters can be set up through

this panel.

The “I“ and “O“ buttons are used for switching the unit

ON and OFF, however, these do not provide mains isolation, they simply inhibit the power semiconductors

The “P“, “F“ and “Cursor Buttons“ are used for parameter

adjustment. Parameters are set by using menu controls

which are called up by entering operator codes. A capital

letter is used to indicate the selected function.

The display value can be increased or decreased by units, or

tenths of units, by a short press of the cursor buttons. Holding

the buttons down will cause the display to change in units of

ten.

7.1 Adjustment

To prevent accidental or unauthorized adjustment the adjustment parameters, in the user menus, are

protected. A code must be entered to open the user menus. There are different pass codes for each function group.

Setting adjustments are automatically saved upon leaving the programming mode or if no button

is pressed for a period of 100 seconds.

7.2 Adjustment Procedure

All setting routines are commenced by pressing the programming button “P“. The following diagram

should clarify the sequence in which keys are pressed:

1. Press the “P“ key.

2. Select the code number with the cursor keys.

3. Press the “P“ key. This displays the first menu point. The required menu point can be found by re-

peatedly pressing the “P“ key (scrolling).

4. The value in the menu point can be changed with the cursor keys.

5. Scroll to the next menu point or to the end of the menu, which returns the display to the set point val-

ue, by pressing the “P“ key. To exit the menu and return back to the normal display quickly, depress

the “P“ key for 5 seconds.

6. To return back to the previous position in the menu, press the “F“ key

I

0

P

F

ON

OFF

DISPLAY

PROGRAMMING

MODE / ENTER

UP

DOWN

BACK

P

Example

F

P

P

P

P

P

P

P

REOTRON MDW 700

Operating instructions

10

7.3 Indications on display

During normal running mode ‘run’ is shown in the LED display.

In the programming mode an abbreviation for the corresponding parameter (see setting up instructions)

and the setting values, are displayed. Setting changes are stored upon leaving the programming mode or

after a pause of 100 seconds.

Initialisation Phase. When the supply voltage is connected (Left decimal point

blinks)

Normal Operation

Unit is not enabled

Left decimal point is present. Current regulation is active. The maximum current of

the unit or the regulated current set point value has been reached.

The two upper vertical segments of the first digit illuminate. Peak value limiter.

This is caused by a fault condition on either the load or by the externally generated effective value, feedback signal. The load impedance is too low, for example,

or the effective value is too high.

The upper horizontal segment of the first digit illuminates. Maximum control limit of

the controller has been reached. The unit has no more regulation range available

and so the output voltage is near to the supply voltage.

Lower horizontal of the first digit illuminates. Maximum power limit has been

reached

Under Voltage, input voltage to too low.

7.4 Error Messages

Over temperature of the power semi-conductors, output is

inhibited. Use `C009` to reset

Overvoltage, input voltage too high, output is inhibited. Use

`C009` to reset

Error messages must be reset in menu `C009`

REOTRON MDW 700

Operating instructions

11

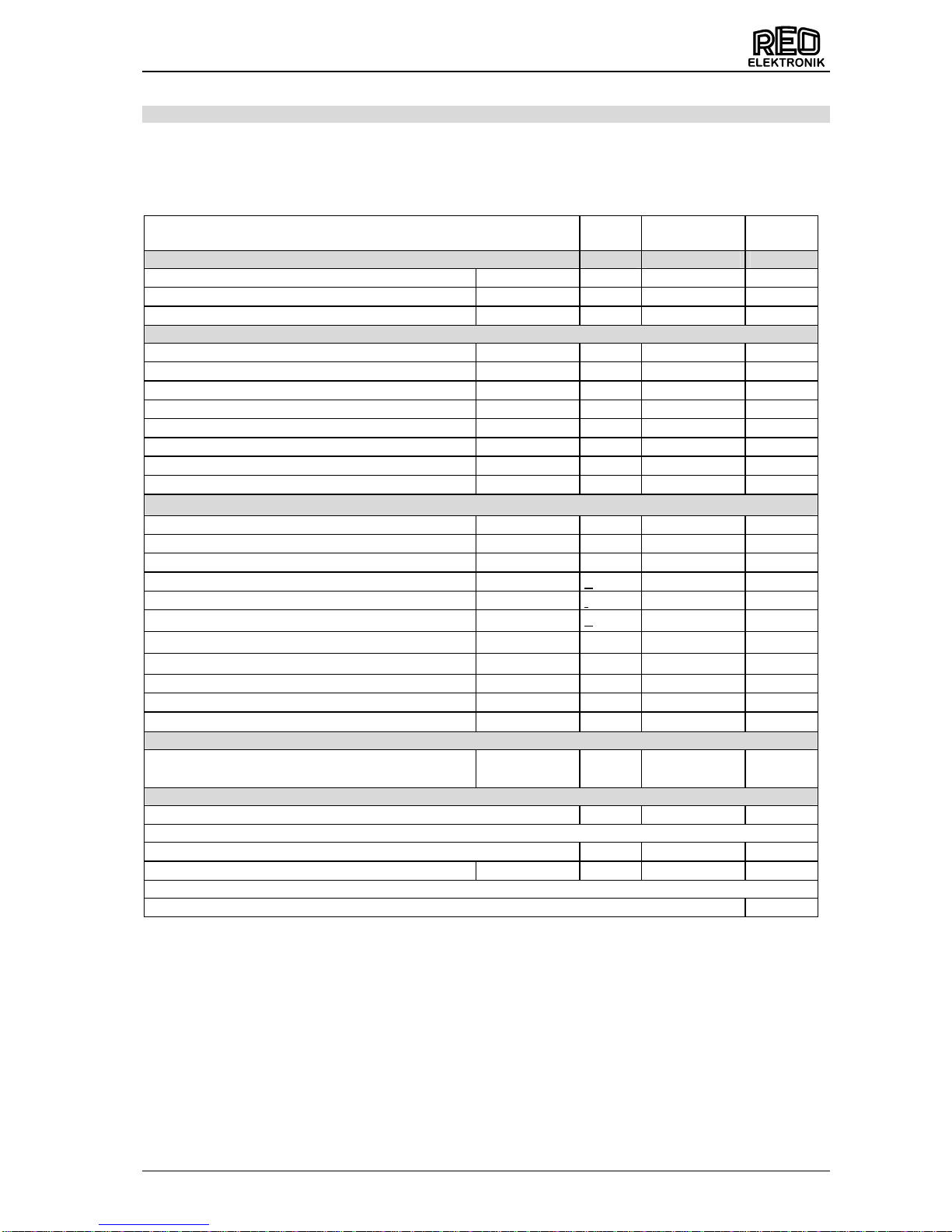

8.0 Settings

The following table contains all the available key settable parameters.

The unit is supplied with factory settings that can be recalled from access code “C210” under FAC. User

codes can be saved under code “C143” and then recalled with code “C210” under USPA.

Parameter: Code

Factory

Default

Menu

Code

Set point

–

when internal

set point

is selected only!

• Voltage set point

0...100 % U. 0 % 002

• Current set point

0...100 % I. 0 % 002

• Power set point

0…100 % P. 100 % 002

Configuration

• External set point OFF

0 / I E.S.O 0 003

• 4...20 mA (only when E.S.O. = 0)

0 / I 4.20 0 003

• Enable Inverse

0 / I -En. 0 003

• External Voltage set point

0 / I E.F.U. 0 003

• External Current set point

0 / I E.F.I. 0 003

• Power regulation

0 / I E.F.P 0 003

• Full wave control

0 / I F.S.P 0 003

• Ready relay

0 / I r.b 0 003

Parameter

• Minimum Output Voltage (without set point)

0...100 % U. 0 % 020

• Minimum Output Current (without set point)

0...100 % I. 0 % 020

• Minimum Output Power (without set point)

0...100 % P. 100 % 020

• Maximum Output Voltage (Limit)

25...100 % u 100 % 020

• Maximum Output Current (Limit)

25...100 % i 100 % 020

• Maximum Output Power (Limit)

25...100 % p 100 % 020

• Voltage Regulator – P Characteristic

1...100 P.U. 20 020

• Current Regulator - P Characteristic

1...100 P.I. 15 020

• Power Regulator - P Characteristic

1...100 P.P. 15 020

• Soft Start (ramp)

0...60 Sec. /. 0,1 020

• Soft Stop (ramp)

0...60 Sec. \ 0,1 020

Interface

• Interface ON

0 / I S.I.F. 0 017

Service

• Save User Parameter

PUSH 143

• Restore Factory Default Settings

FAC. 210

• Enable advanced Service mode

0 / I En.S. 0 127

• Display software version

001

REOTRON MDW 700

Operating instructions

12

9.0 Setting up instructions

9.1 Internal set point

Code C 002

9.2 Unit configuration

Code 003

P

P

P

P

P

P

P P

P P

P P

P

P

P

P

P P

P P

U.P.A. = 0 = Regulation mode

U.P.A. = I = control mode

Only in Service Mode

C 127 En.S. = I

E.S.O. = 0 = External Set point

E.S.O. = I = Internal Set point (Keys)

4.20 = 0 = External Set point 0...20 mA / 0...10V

4.20 = I = External Set point 4...20 mA

E.F.U.= 0 = internal feedback voltage

E.F.U. = I = external feedback voltage

Running mode

E.F.P. = 0 = Voltage- / Current regulation

E.F.P. = I = Power regulation set point

F.S.P. = 0 = Phase angle control

F.S.P. = I = Full wave control

r.b. = 0 = Relay = Status function

r.b. = I = Relay = Fault function

-E.n. = 0 = Invert Enable Off

-E.n. = I = Invert Enable On

E.F.I. = 0 = internal feedback current

E.F.I. = I = external feedback current

P

Set point 1, Voltage [%]

Set point 2, Current [%]

F

P

P

P

P

P

Running mode

Set point 3, Power [%]

P

P

REOTRON MDW 700

Operating instructions

13

9.2.1 Service menu

Display set-points sent to the unit.

9.2.2 Display effective values measured inside unit

P

Code 050

Display set point voltage [%]

Display set point power [%]

F

P

P

P

Running mode

Display set point current [%]

P

P

Code 051

Display feedback voltage [%]

Display feedback power [%]

F

P

P

P

Running mode

Display feedback current [%]

P

REOTRON MDW 700

Operating instructions

14

9.3 Setting Up Procedures

9.4 Select Interface

Code C 017 Interface (Option)

Communication using the interface is activated by setting parameter “S.I.F.” to “I”. Should there be a need

to run under manual control e.g. for testing, then this parameter should be set to “0”.

P P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

Code 020

P

P

P P

P P

Min ouptput voltage [%]

(without external set point)

Min output current [%]

(without external set point)

Output voltage limit [%]

Umax

Start ramp time [Sec.]

Running mode

Output current limit [%]

Imax

P-Char current regulation

Stop ramp time [Sec.]

Min output power [%]

(without external set point)

P-Char power regulation

Output power limit [%]

Pmax

P-Char voltage regulation

0 = Interface OFF

I = Interface ON

Running mode

P

P P

P

REOTRON MDW 700

Operating instructions

15

9.5 Save current settings

Code C 143

9.6 Restore parameter settings

Code C 210

9.7 Software version

9.8 Hide parameter menus

Code C 117

If Hd.C. = I all parameter menus are hide. Set Hd.C to "0" again for change parameters.

Save current parameter settings

Running mode

P P

P

P

Restore factory settings

Running mode

Restore user settings

(previously saved in "C 143"

P

P

P

P

P

P

Hd.C. = 1= Hide menus

Running mode

P P

P

P

Code 001

Version

Date

Running mode

P P

P

P

P

P

REOTRON MDW 700

Operating instructions

16

10.0 Connection diagram

0(4)...20 mA

0...+10 V

Pot. 10 KR

SETPOINTS

VOLTAGE CURRENT

-

+

+10V

+10V

-

+

-

+

-

+

24 V

ENABLE

EXTERNAL

FILTER

EXTERNAL

FEEDBACK

0...5V

AC/DC

0...10V

DC

0...10V

DC

U U I

ACTUAL VALUE

OUTPUT

RELAY

STATUS

LOAD

I

U

PE

L1 L2

L3L2

W

1

2 3

4

5

6 7 8 3332

31

15 16 17 18 11 12 13

14

41 42 43

+

-

+

-

V

PE

PE

L1

U

L3

FAILURE

44

45 46

3 AC 230/400 V 50/60 Hz

I

INTERFACE

OPTION

Interface

24 V

DC

+

-

CONTROL LOGIC

3635

34

RELAY

Fan

(MDW 50-300)

U

MDW 700

0...5V

AC/DC

I

(21)

(22) (23)

(26)

(27)

(28)

(24)

(25)

230/240V AC

50/60Hz

(T=Fan test

connector)

NTL

REOTRON MDW 700

Operating instructions

17

10.1 Connection details

0...+10 V

0(4)...20 mA

Set point

voltage

Set point

current

Pot. 10 K

1

2

3 456

7 8

+10V

+10V

1

2 3 456 7 8

1

2

3 4 5 6

7 8

0...+10 V0(4)...20 mA

Set point

voltage

Pot. 10 K

1

2

3 456

7 8

+10V

+10V

1

2

3 456

7 8

1

2 3 456 7 8

0...+10 V0(4)...20 mA

Set point

current

Pot. 10 K

1

2

3 456

7 8

+10V

+10V

1

2

3 456

7 8

1

2

3 456

7 8

+10V

+10V

+10V

+10V

+10V

+10V

+10V +10V

Voltage and current regulation

Voltage regulation

Current regulation

0...+10 V0(4)...20 mA

Set point

power

Pot. 10 K

1

2

3 456

7 8

+10V

+10V

1

2

3 456

7 8

1

2

3 456

7 8

+10V

+10V

+10V

+10V

Power regulation

If using 4...20 mA signal, set parameter 4.20 = I in Menu " C003"

If using 4...20 mA signal, set parameter 4.20 = I in Menu " C003"

If using 4...20 mA signal, set parameter 4.20 = I in Menu " C003"

If using 4...20 mA signal, set parameter 4.20 = I in Menu " C003"

Actual

output

value

Current 0...10 V, DC

Voltage 0...10 V, DC

power

RESERVE

11 13 14 15 16 17 1812

RESERVE

44 45

46

Fault

Relay

Internal Relay

41 42

43

Internal Relay

Relay

Reserve

REOTRON MDW 700

Operating instructions

18

255

L1 L2 L3 PE

U V W PE

REOTRON

MDW

PROFIBUS

DP

24V DC

Us

BA

1

ADR.

8

PE

FOR CONTINUED FIRE

PROTECTION REPLACE

ONLY WITH SPECIFIED

TYPE AND RATED FUSE

DISCONNECT POWER

INPUT BEFORE

REPLACING FUSE

REOTRON

MDW

230V

AC

I

0

P

F

210

320

37,5

217,5

8

312

6,5 mm

14,5 mm

6,5 mm

Option

11.0 Dimensions

MDW 700 10 A / 25 A

MDW 700 50A / 80A

Attention connect the fan!

REOTRON

MDW

PROFIBUS

DP

24V DC

Us

BA

1

ADR.

8

PE

41 42 43 44 45 46 11 12 13 14 15 16 17 18 1 2 3 4 5 6 7 831 32 33 34 35 36

FOR CONTINUED FIRE

PROTECTION REPLACE

ONLY WITH SPECIFIED

TYPE AND RATED FUSE

DISCONNECT POWER

INPUT BEFORE

REPLACING FUSE

I

0

P

F

Option

PE L1

L2 L3

PE U

V W

290

B

5

285

A

210

5 mm

5 mm

9 mm

15

Type

MDW 25

MDW 10 with Interface

130

110

MDW 10

A

MDW 25 with Interface

160

160

B

70

90

90

90

REOTRON MDW 700

Operating instructions

19

MDW 700 110A / 150A / 200A

Attention connect the fan!

7,5

4

1

5

4

3

0

255

210

231 12

Ø6

Ø6

Ø8,5

Ø8,5

1

6

2

7

3

8

4

9

5

L1 L2 L3

U V W

DO NOT USE

WITHOUT COVER

PROFIBUS

DP

24V DC

Us

BA

1

ADR.

8

PE

REOTRON

MDW

www.reo.de

FOR CONTINUED FIRE

PROTECTION REPLACE

ONLY WITH SPECIFIED

TYPE AND RATED FUSE

DISCONNECT POWER

INPUT BEFORE

REPLACING FUSE

P

F

I

0

PE

230V

AC

REOTRON MDW 700

Operating instructions

20

MDW 700 300A

Attention connect the fan!

Ø5,0

6

2

5

9

320

362

300

33414301

312

Schraube

M10x40 / 933

Input 230V

50/60Hz

REOTRON

MDW

L1L2L3

U V W

www.reo.de

P

F

I

0

1 2 3

U

L1

VL2W

L3

Ø8,5

Ø8,5

Input air cooling

Input air cooling

Output air cooling

2

7

3

8

4

9

5

1

6

DP 24

PROFIBUS

DP

24V DC

ADR.

1

8

U

BA

RESET

PE

PROFIBUS-DP

PE

REOTRON MDW 700

Operating instructions

21

MDW 700 WK (water-cooled)

Type A B

MDW - WK 115, 160, 250, 350 400 380

MDW - WK 450, 600 550 530

REOTRON

MDW

L1L2L3

U

www.reo.de

P

F

I

0

UL1VL2W

L3

Ø 9,0

Ø 19,0

2

0

2

2

1

2

A

B

8

180

300

330

2

7

3

8

4

9

5 1

6

DP 24

PROFIBUS

DP

24V DC

ADR.

1

8

U

BA

RESET

PE

PROFIBUS-DP

PE

Ø 9,0

REOTRON MDW 700

Operating instructions

22

12.0 Putting into service

Safety Instruction

Qualified personnel only, are permitted to install electronic equipment

Because attenuation capacitors (Y-capacitors) are used, leakage current flows through the case to protective earth (PE). Therefore, units must be earthed.

12.1 Preliminaries

• Check if the local supply voltage is the same as the rated voltage for the unit (rating plate) and that the

load is within the permitted power range.

• Connect the control unit in accordance with the connection diagram.

• Adjust set-points to zero.

• Switch off enable (if used)

• Check if cables are connected correctly.

The control unit is now ready for operation and can be switched on (power supply, enable).

The unit is factory set according to the rating plate i.e. 100% set point equals 100% voltage, current or power.

Set-point control only can be used, in which case no other settings are necessary.

12.2 Measurements and Settings

Because of the phase-angle-control, the shapes of the supply voltage and current sine curves are

changed. The output voltage and current must be measured with effective value meter (true-RMS).

12.3 Putting into service without a proper load

A thyristor can only be switched ("fired") into a conducting state, if the current level is sufficiently high

enough. It will only switch-off, if the current is lower than the threshold current (every time the current

goes through the zero-crossing point). When the thyristor controller is put into service, without a proper

load, realistic measurements such as the voltage, for example, cannot be obtained. Even the setting of

the output current i.e. limit, can only be done with a proper load and not by short circuiting the output of

the thyristor controller. This is because the thyristor, once “fired”, cannot be turned off. The current has to

pass through "zero" for the thyristor to switch off. Using a low impedance load it is not possible to evaluate the current level from the internal current flow.

If a proper load is not available or not possible to carry out the correct commissioning procedure then a

makeshift test can be carried by connecting a resistive load, such as incandescent lamps to the output of

the thyristor controller.

!

REOTRON MDW 700

Operating instructions

23

13.0 Installation of Thyristor Control Units

13.1 Fuses

The REOTRON MDW... series of thyristor controllers are fitted with semiconductor fuses, which protect

the power semiconductors (thyristors) from damage when there is a short-circuit on the output. These

fuses are selected for the permitted peak current of the semiconductors and are not provided for protection against overload or line faults! Fuses are provided only in the current-carrying circuits with thyristors.

Fuses for overload, line and earth fault protections should be fitted to the incoming power side.

13.2 Incoming breaker

An isolator must be connected in front of a thyristor-controller, mounted inside a control panel (VDE

0160/6.3.1) because of the leakage-current from a high-impedance thyristor and hence the current flow

through the protection circuit. This can be used to disconnect the unit from mains supply before a routine

shut-down.

Because all REOTRON thyristor-controllers have an enable input, it is possible to inhibit the input pulses,

and hence firing of the thyristors, until the main contactors have securely closed or before the contactors

open again when shutting down.

When enable inputs are used in this way, the contactors can be rated for current-free switching, in which

case AC1 would be suitable. If direct-on-line switching is used i.e. by switching the thyristor controller,

without using the enable, the rating of the contactors must be in accordance with AC3.

13.3 Output Breaker

A circuit-breaker on the output of the thyristor controller should be avoided, because it cannot operate

without a load. Current or voltage monitoring in the output of the thyristor controller must be used to control the circuit-breaker at the input side.

Current-free switching of the thyristor controllers’ output (e.g. load switching) is possible, however, by

using the enable input.

13.4 Installation and climatic Conditions

The mounting base should be free of vibration, if possible. Note that the temperature of the heat-sink

rises when a power controller is operating. The heat-sink must be mounted vertically to ensure efficient

cooling. The ambient temperature range allowed below the heat-sink is 0°...+45°C. The relative air humidity is < 75% without dew. The clearance below the unit should be at least100mm and above at least

150mm. There must be a clearance of 50mm between units mounted next to each other. For altitudes

above 1000m the power must be derated by 0,5% per 100m additional height.

13.5 Signal cables

Set Points

If external voltage (0...10V) or current (0(4)...20mA) set-points are used; care should be taken to ensure

that all equipment is connected through equal-potential bonding. If the bonding is earthed, then this

should be at a single point, thus avoiding earthing loops and possible coupled interference.

REOTRON MDW 700

Operating instructions

24

14.0 Interference prevention

14.1 Earthing

Correct earthing of electronic controls is highly important for two reasons:

First it ensures the safety of operators and service personnel, and secondly it provides a fail-safe operation of the equipment. Therefore, in addition to providing protective earthing, in accordance to DIN standards, it also provides an earth path for pulse interference produced during operation. For the latter, controllers that are mounted onto a chassis–plate in a control panel should be bonded to earth with the

shortest possible connection and the largest possible earth contact area and also, for example, onto the

centrally bonded chassis-plate. The reason for this is to ground high-frequency interferences produced by

switching on the mains (contactors, relays, switches) before they cause fault conditions. If the earth conductors are too long and if they run together with other cables, in one cable duct, then they are unsuitable

for grounding high-frequency noise.

The more complex the unit and the more "intelligent" the functions - especially serial bus connections –

then the more important it is to use correct earthing techniques.

14.2 Control cables

Control cables also are "antennas" that receive interference produced by other loads. Signal cables that

are run alongside power cables can generate voltage spikes through inductive and capacitive crosscoupling. Therefore control conductors should not be mixed with power cables in the same cable ducting.

If this cannot be avoided then shielded cables should be used. In particular cables from inverters to motors are very critical because of the presence of high-speed switching. There should be maximum distance between control cables output cables from frequency inverters. The shielding around the control

conductors should be grounded onto a large contact area (earthed mounting plate) at the equipment end.

14.3 Interference protection of other external components and equipment

Contactors produce extreme Burst-interferences on switching. Contactor coils must be connected with

RC-snubbers. Suitable RC-snubbers can be obtained from switch manufacturers.

Magnets / magnetic valves are also interference sources in the same way as contactors. RC- snubbers

and varistors can be components and varistors can be connected across these components

Frequency inverters are to connect to a mains filter recommended by the manufacturer.

Motor wires should be shielded and routed away from control cables.

REOTRON MDW 700

Operating instructions

25

15.0 Engineering notes

Type

connection terminal

(power)

connection terminal

(control)

REOTRON MDW 700-10 4 mm2 1,5 mm2

REOTRON MDW 700-25 4 mm2 1,5 mm2

REOTRON MDW 700-50 16 mm2 1,5 mm2

REOTRON MDW 700-80 35 mm2 1,5 mm2

REOTRON MDW 700-110 50 mm2 1,5 mm2

REOTRON MDW 700-150 70 mm2 1,5 mm2

REOTRON MDW 700-200 95 mm2 1,5 mm2

REOTRON MDW-WK 700-115 copper bar 10,5 mm hole 1,5 mm2

REOTRON MDW-WK 700-160 copper bar 10,5 mm hole 1,5 mm2

REOTRON MDW-WK 700-250 copper bar 10,5 mm hole 1,5 mm2

REOTRON MDW-WK 700-350 copper bar 10,5 mm hole 1,5 mm2

REOTRON MDW-WK 700-450 copper bar 10,5 mm hole 1,5 mm2

Type

recommended line filter in the mains input

REOTRON MDW 700-10 CNW 207 / 10

REOTRON MDW 700-25 CNW 207 / 35

REOTRON MDW 700-50 CNW 207 / 50

REOTRON MDW 700-80 CNW 207 / 80

REOTRON MDW 700-110 CNW 207 / 150

REOTRON MDW 700-150 CNW 207 / 200

REOTRON MDW 700-200 CNW 207 / 200

REOTRON MDW-WK 700-115 CNW 207 / 150

REOTRON MDW-WK 700-160 CNW 207 / 200

REOTRON MDW-WK 700-250 CNW 107 / 280

REOTRON MDW-WK 700-350 CNW 107 / 500

REOTRON MDW-WK 700-450 CNW 107 / 500

Type

weight in kg

min. cable cross

-

section

Power loss

REOTRON MDW 700-10 4 1,5 mm2 40 W

REOTRON MDW 700-25 5 4 mm

2

100 W

REOTRON MDW 700-50 8,5 16 mm

2

180 W

REOTRON MDW 700-80 9,5 35 mm

2

310 W

REOTRON MDW 700-110 11 50 mm2 480 W

REOTRON MDW 700-150 14,5 70 mm

2

540 W

REOTRON MDW 700-200 16 95 mm2 660 W

REOTRON MDW-WK 700-115 7 70 mm2 500 W

REOTRON MDW-WK 700-160 8 95 mm

2

580 W

REOTRON MDW-WK 700-250 10,5 120 mm

2

900 W

REOTRON MDW-WK 700-350 13 185 mm2 1260 W

REOTRON MDW-WK 700-450 16 300 mm2 1620 W

Type

recommended input

fuse: Type: gl / gG

internal semiconductor fuse

REOTRON MDW 700-10 16 A SI 16 FF ordering number: 0900 10

REOTRON MDW 700-25 25 A SI 35 ET ordering number: 0900 17

REOTRON MDW 700-50 63 A SI 80 ET ordering number: 0900 19

REOTRON MDW 700-80 100 A SI 140 EET ordering number: 0900 20

REOTRON MDW 700-110 125 A SI 160 EET ordering number: 0900 21

REOTRON MDW 700-150 160 A SI 250 EET ordering number: 0900 22

REOTRON MDW 700-200 200 A SI 315 EET ordering number: 0900 23

REOTRON MDW-WK 700-115 125 A non-existent

REOTRON MDW-WK 700-160 200 A non-existent

REOTRON MDW-WK 700-250 250 A non-existent

REOTRON MDW-WK 700-350 400 A non-existent

REOTRON MDW-WK 700-450 500 A non-existent

REOTRON MDW 700

Operating instructions

26

Headquarters

- Germany

REO ELEKTRONIK AG

Brühler Straße 100 · D-42657 Solingen

Tel.: +49 (0)212 8804 0 · Fax: +49 (0)212 8804 188

REO INDUCTIVE COMPONENTS AG

Brühler Straße 100 · D-42657 Solingen

Tel.: +49 (0)212 8804 0 · Fax: +49 (0)212 8804 188

E-Mail: info@reo.de

Internet:

www.reo.de

China

REO Shanghai Inductive Components Co., Ltd

No. 536 ShangFeng Road · Pudong, 201201 Shanghai · China

Tel.: +86 (0)21 5858 0686 · Fax: +86 (0)21 5858 0289

E-Mail: info@reo.cn · Internet: www.reo.cn

France

REO VARIAC S.A.R.L.

ZAC Du Clos aux Pois 1 · 6/8 rue de la Closerie-LISSES· F-91048 Evry Cédex

Tel.: +33 (0)1 6911 1898 · Fax: +33 (0)1 6911 0918

E-Mail: reovariac@reo.fr · Internet: www.reo.fr

Great Britain

REO (UK) Ltd.

Units 2-4 Callow Hill Road · Craven Arms · Shropshire SY7 8NT · UK

Tel.: +44 (0)1588 673 411 · Fax: +44 (0)1588 672 718

E-Mail: main@reo.co.uk · Internet: www.reo.co.uk

India

REO GPD INDUCTIVE COMPONENTS PVT. LTD

2/202 Luna Road · Village Luna · Taluka Padra

Vadodara - 391440 · India

Tel.: +91 (2662) 221723

E-Mail: info@reogpd.com · Internet: www.reo-ag.in

Italy

REO ITALIA S.r.l.

Via Treponti, 29 · I-25086 Rezzato (BS)

Tel.: +39 030 279 3883 · Fax: +39 030 279 0600

E-Mail: info@reoitalia.it · Internet: www.reoitalia.it

Poland

REO CROMA Sp.zo.o

ul. Pozaryskiego 28, bud 20 · PL-04-703 Warszawa

Tel.: +48 (0)22 812 3066 · Fax: +48 (0)22 815 6906

E-Mail: croma@croma.com.pl · Internet: www.croma.com.pl

Spain

REO ESPAÑA 2002 S.A.

C/Manuel Ventura i Campeny 21B · local 9 · E-08339 Vilassar de Dalt (Barcelona)

Tel.: +34 937 509 994 · Fax: +34 937 509 995

E-Mail: info@reospain.com · Internet: www.reospain.com

Switzerland

REO ELEKTRONIK AG

Im Halbiacker 5a · CH-8352 Elsau

Tel.: +41 (0)52 363 2820 · Fax: +41 (0)52 363 1241

E-Mail: info@reo.ch · Internet: www.reo.ch

Turkey

REOTURKEY ELEKTRONİK San. ve Tic. Ltd. Şti.

Halil Rıfatpasa Mah. · Darülceze CD Perpa Tic Merkezi

B Blok Kat 8 No:1095 · TR-34384 Sisli – Istanbul

Tel.: +90 (0)212 2215 118 · Fax: +90 (0)212 2215 119

E-Mail: info@reo-turkey.com · Internet: www.reo-turkey.com

USA

REO-USA, Inc.

8450 E. 47th St · USA-Indianapolis, IN 46226

Tel.: +1 317 8991 395 · Fax: +1 317 8991 396

E-Mail: info@reo-usa.com · Internet: www.reo-usa.com

Divisions

- Germany

REO INDUCTIVE COMPONENTS AG

TrainTechnologies Division

Centre of Competence Berlin

Erasmusstraße 14 · D-10553 Berlin

Tel.: +49 (0)30 3670236t 0 · Fax: +49 (0)30 3670236 10

E-Mail: zentrale.berlin@reo.de · Internet: www.reo.de

Fertigung /Production

TrainTechnologies Division

Eduard-Maurer-Straße 13 · D-16761 Hennigsdorf

IBK Drives Division

Holzhausener Straße 52 · D-16866 Kyritz

Tel.: +49 (0)33971 485 0 · Fax: +49 (0)33971 485 90

E-Mail: ibk@reo.de · Internet: www.reo.de

Setzermann Medical Division

Schuldholzinger Weg 7 · D-84347 Pfarrkirchen

Tel.: +49 (0)8561 9886 0 · Fax: +49 (0)8561 9886 40

E-Mail: setzermann@reo.de · Internet: www.reo.de

Test and PowerQuality Division

Brühler Straße 100 · D-42657 Solingen

Tel.: +49 (0)212 8804 0 · Fax: +49 (0)212 8804 188

E-Mail: main@reo.de · Internet: www.reo.de

Loading...

Loading...