ROVER

SERIES

20A | 30A | 40A

Version 1.5

Important Safety Instructions

Please save these instructions.

This manual contains important safety, installation, and operating instructions for the charge

controller. The following symbols are used throughout the manual to indicate potentially

dangerous conditions or important safety information.

WARNING

Indicates a potentially dangerous condition. Use extreme caution

when performing this task

CAUTION

NOTE

Indicates a critical procedure for safe and proper operation of the

controller

Indicates a procedure or function that is important to the safe and

proper operation of the controller

General Safety Information

Read all of the instructions and cautions in the manual before beginning the installation.

There are no serviceable parts for this controller. Do NOT disassemble or attempt to repair

the controller.

Do

NOT

allow water to enter the controller.

Make sure all connections going into and from the controller are tight.

Charge Controller Safety

NEVER connect the solar panel array to the controller without a battery. Battery must be

connected first.

Ensure input voltage does not exceed 100 VDC to prevent permanent damage. Use the

Open Circuit Voltage (Voc) to make sure the voltage does not exceed this value when

connecting panels together.

01

Battery Safety

Use only sealed lead-acid, flooded, gel or lithium batteries which

must be deep cycle.

Explosive battery gases may be present while charging. Be certain there is enough

ventilation to release the gases.

Be careful when working with large lead acid batteries. Wear eye protection and have

fresh water available in case there is contact with the battery acid.

Carefully read battery manuals before operation.

Do

NOT

let the positive (+) and negative (-) terminals of the battery touch each other.

Recycle battery when it is replaced.

Over-charging and excessive gas precipitation may damage the battery plates and

activate material shedding on them. Too high of an equalizing charge or too long of one

may cause damage. Please carefully review the specific requirements of the battery

used in the system.

Equalization is carried out only for non-sealed / vented/ flooded / wet cell lead acid

batteries.

Do

NOT

equalize VRLA type AGM / Gel / Lithium cell batteries UNLESS permitted by

battery manufacturer.

Default charging parameters in Li mode are programmed for 12.8V Lithium Iron

Phosphate (LFP) Battery only. Before using Rover to charge other types of lithium

battery, set the parameters according to the suggestions from battery manufacturer.

Please set the correct battery type the first time you use.

WARNING

Connect battery terminals to the charge controller BEFORE connecting

the solar panel(s) to the charge controller. NEVER connect solar panels to

charge controller until the battery is connected.

Do NOT connect any inverters or battery charger into the load terminal of

the charge controller.

Once equalization is active in the battery charging, it will not exit this stage

unless there is adequate charging current from the solar panel. There

should be NO load on the batteries when in equalization charging stage.

02

Table of Contents

General Information

Additional Components

Optional Components

Identification of Parts

Installation

Operation

LED Indicators

Rover Protections

System Status Troubleshooting

Error Codes

Maintenance

Fusing

Technical Specifications

Electrical Parameters

04

08

08

09

10

17

22

24

25

25

26

26

27

27

General

Battery Charging Parameters

ROVER: PV Power – Conversion Efficiency Curves

Dimensions

03

27

28

29

30

General Information

The Rover Series charge controllers are intelligent controllers suitable for various off-grid solar

applications. It protects the battery from being over-charged by the solar modules and

over-discharged by the loads. The controller features a smart tracking algorithm that maximizes the

energy from the solar PV module(s) and charge the battery. At the same time, the low voltage

disconnect function (LVD) will prevent the battery from over discharging.

The Rover's charging process has been optimized for long battery life and improved system

performance. The comprehensive self-diagnostics and electronic protection functions can prevent

damage from installation mistakes or system faults.

Key Features

Automatically detect

Innovative MPPT technology with high tracking efficiency up to 99% and peak

conversion efficiency of 98%

Deep cycle Sealed, Gel, Flooded and Lithium (12.8V LFP) battery option ready

Electronic protection: Overcharging, over-discharging, overload, and short circuit

Reverse protection: Any combination of solar module and battery, without causing

damage to any component

Customizable charging voltages

Charges over-discharged lithium batteries

RS232 port to communicate with BT-1 Bluetooth module

12V or 24V DC system voltages

MPPT Technology

The MPPT Charge Controller utilizes Maximum Power Point Tracking technology to extract

maximum power from the solar module(s). The tracking algorithm is fully automatic and

does not require user adjustment. MPPT technology will track the array’smaximum power point

voltage (Vmp) as it varies with weather conditions, ensuring that the maximum power is

harvested from the array throughout the course of the day.

Current Boost

In many cases, the MPPT charge controller will “boost” up the current in the solar system. The

current does not come out of thin air. Instead, the power generated in the solar panels is the

same power that is transmitted into the battery bank. Power is the product of Voltage (V) x

Amperage (A).

04

Therefore, assuming 100% efficiency:

Volts In * Amps In = Volts out * Amps out

Power In = Power Out

Although MPPT controllers are not 100% efficient, they are very close at about 92-95% efficient.

Therefore, when the user has a solar system whose Vmp is greater than the battery bank

voltage, then that potential difference is proportional to the current boost. The voltage generated

at the solar module needs to be stepped down to a rate that could charge the battery in a stable

fashion by which the amperage is boosted accordingly to the drop. It is entirely possible to have

a solar module generate 8 amps going into the charge controller and likewise have the charge

controller send 10 amps to the battery bank. This is the essence of the MPPT charge controllers

and their advantage over traditional charge controllers. In traditional charge controllers, that

stepped down voltage amount is wasted because the controller algorithm can only dissipate it

as heat. The following demonstrates a graphical point regarding the output of MPPT technology.

Current vs. Voltage (12V System) Output Power(12V System)

Typical Battery

Voltage Range

CURRENT

10 15 17

Maximum

Power Point

VOLTAGE

Maximum

Traditional

Controller

Operating

Range

CURRENT

10 15 17

Power Point

VOLTAGE

Limiting Effectiveness

Temperature is a huge enemy of solar modules. As the environmental temperature

increases, the operating voltage (Vmp

) is reduced and limits the power generation of the solar

module. Despite the effectiveness of MPPT technology, the charging algorithm will

not have much to work with and therefore there is an inevitable decrease in

In this scenario, it would be preferred to have modules with higher nominal

despite the drop in performance of the panel, the battery is still receiving

performance.

voltage, so that

a current boost

because of the proportional drop in module voltage.

05

possibly

Four Charging Stages

The Rover MPPT charge controller has a 4-stage battery charging algorithm for a rapid,

efficient, and safe battery charging. They include: Bulk Charge, Boost Charge, Float Charge,

and Equalization.

Battery

Voltage

Equalize

Boost

Float

Recharge

Battery

Current

A B C

Bulk Charge

Max Current

Constant charging

Duration Time:2h

(Range:10-180min)

Cumulative Time:3h

Float Charge

Boost

Bulk

Time

Time

Bulk Charge: This algorithm is used for day to day charging. It uses 100% of available solar

power to recharge the battery and is equivalent to constant current. In this stage the battery

voltage has not yet reached constant voltage (Equalize or Boost), the controller operates in

constant current mode, delivering its maximum current to the batteries (MPPT Charging) .

Constant Charging: When the battery reaches the constant voltage set point, the controller

will start to operate in constant charging mode, where it is no longer MPPT charging. The current

will drop gradually. This has two stages, equalize and boost and they are not carried out

constantly in a full charge process to avoid too much gas precipitation or overheating of the

battery.

Boost Charge: Boost stage maintains a charge for 2 hours by default. The user

can adjust the constant time and preset value of boost per their demand.

Float Charge: After the constant voltage stage, the controller will reduce the battery voltage

to a float voltage set point. Once the battery is fully charged, there will be no more chemical

reactions and all the charge current would turn into heat or gas. Because of this,

06

The charge controller will reduce the voltage charge to smaller quantity, while lightly charging

the battery. The purpose for this is to offset the power consumption while maintaining a full

battery storage capacity. In the event that a load drawn from the battery exceeds the charge

current, the controller will no longer be able to maintain the battery to a Float set point and the

controller will end the float charge stage and refer back to bulk charging.

Equalization: Is carried out every 28 days of the month. It is intentional overcharging of

the battery for a controlled period of time. Certain types of batteries benefit from periodic

equalizing charge, which can stir the electrolyte, balance battery voltage and complete

chemical reaction. Equalizing charge increases the battery voltage, higher than the standard

complement voltage, which gasifies the battery electrolyte.

WARNING

Once equalization is active in the battery charging, it will not exit this stage unless

there is adequate charging current from the solar panel. There should be NO load

on the batteries when in equalization charging stage.

WARNING

Over-charging and excessive gas precipitation may damage the battery plates

and activate material shedding on them. Too high of equalizing charge or for too

long may cause damage. Please carefully review the specific requirements of the

battery used in the system.

WARNING

Equalization may increase battery voltage to a level damaging to sensitive DC

loads. Ensure that all load allowable input voltages are greater than the equalizing

charging set point voltage.

Lithium Battery Activation

The Rover MPPT charge controller has a reactivation feature to awaken a sleeping lithium

battery. The protection circuit of lithium battery will typically turn the battery off and make it

unusable if over-discharged. This can happen when storing a lithium battery pack in a

discharged state for any length of time as self-discharge would gradually deplete the remaining

charge. Without the wake-up feature to reactivate and recharge batteries, these batteries would

become unserviceable and the packs would be discarded. The Rover will apply a small charge

current to activate the protection circuit and if a correct cell voltage can be reached, it starts a

normal charge.

CAUTION

When using the Rover to charge a 24V lithium battery bank, set the system

voltage to 24V instead of auto recognition. If auto recognition is accidently

selected the Rover will allow you to change it to 24V when the lithium battery

activation. In the activation interface press and hold the enter button to

trigger the system voltage selector. To change the system voltage, press the

Up or Down buttons then long press Enter to save the selected system voltage.

07

Additional Components

Additional components included in the package:

Remote Temperature Sensor:

This sensor measures the temperature at the battery and uses this

data for very accurate temperature compensation.The sensor is

supplied with a 9.8ft cable length that connects to the charge

controller.Simply connect the cable and adhere the sensor on top

or the side of the battery to record ambient temperature around the

battery.

NOTE

Do Not use this sensor when charging lithium battery.

Mounting Brackets

These brackets can be used to mount the Rover charge

controller on any flat surface. The screws to mount the

brackets to the charge controller are included, screws to

mount charge controller to surface are not included.

Mounting Oval:7.66 x 4.70mm (0.30 x 0.18in)

Optional Components

Optional components that require a separate purchase:

Renogy BT-1 Bluetooth Module:

The BT-1 Bluetooth module is a great addition to any Renogy charge

controllers with a RS232 port and is used to pair charge controllers with the

Renogy DC Home App. After pairing is done you can monitor your system

and change parameters directly from you cell phone or tablet. No more

wondering how your system is performing, now you can see performance

in real time without the need of checking on the controller’s LCD.

Renogy DM-1 4G Data Module:

The DM-1 4G Module is capable of connecting to select Renogy charge

controllers through an RS232, and is used to pair charge controllers with

Renogy 4G monitoring app. This app allows you to conveniently monitor

your system and charge syeters parameters remotely from anywhere 4G

LTE network service is available.

08

1

2

3

4

5

6

Identification of Parts

9 10 11

8

Key Parts

7

12

1. PV LED Indicator

2. Battery LED Indicator

3. Load LED Indicator

4. System Error LED Indicator

5. LCD Screen

6. Operating Keys

7. Mounting Holes

8. Remote Temperature Sensor Port (optional accessory)

9. PV Terminals

10. Battery Terminals

11. Load Terminals

12. RS-232 Port (optional accessory)

09

Installation

CHARGER

HIGH AMP

DRAWING DEVICE

Recommended tools to have before installation:

WARNING

WARNING

Screwdriver

Multi-Meter

Connect battery terminal wires to the charge controller FIRST then connect the

solar panel(s) to the charge controller. NEVER connect solar panel to charge

controller before the battery.

Do NOT connect any inverters or battery chargers into the LOAD TERMINAL of

the charge controller.

INVERTER

BATTERY

CAUTION

CAUTION

Do not over tighten the screw terminals. This could potentially break the

piece that holds the wire to the charge controller.

Refer to the technical specifications for max wire sizes on the controller and

for the maximum amperage going through wires.

You are now ready to begin connecting your battery to your charge controller.

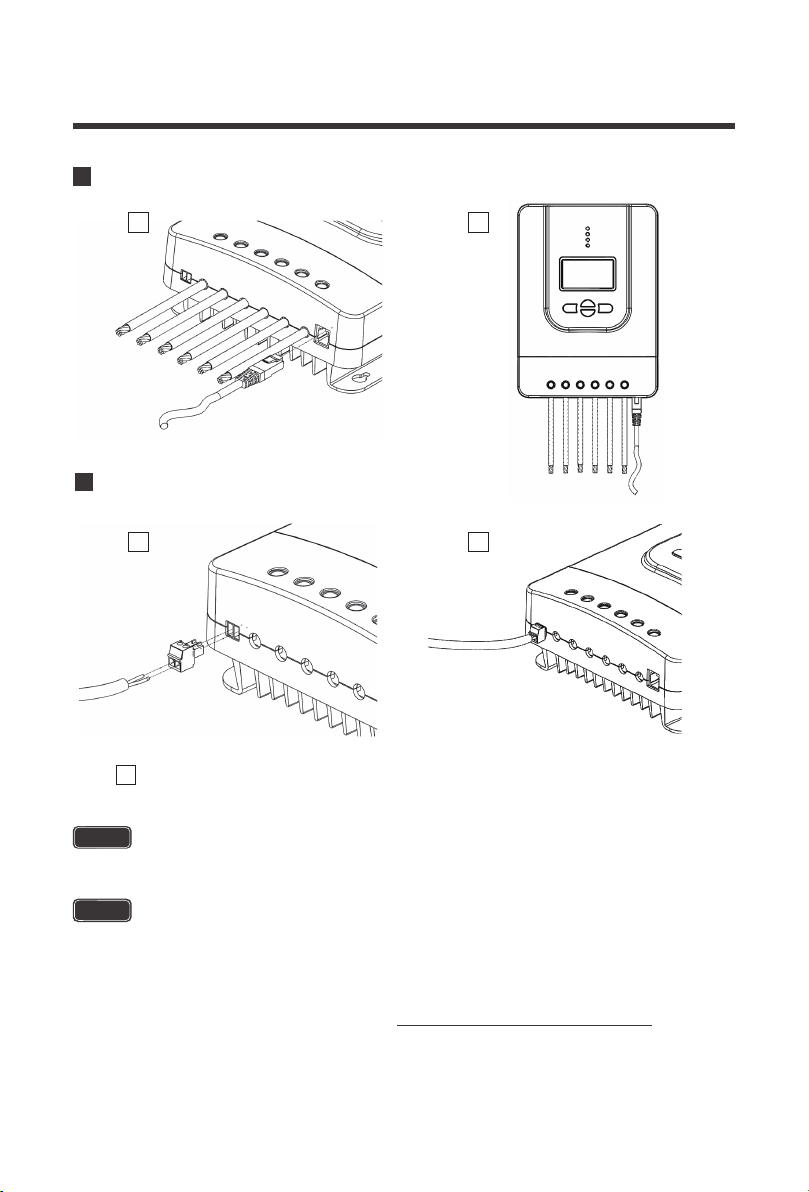

10

Battery

1 2

3

11

Load (optional)

1 2

Solar Panels

1 2

12

Bluetooth Module communication (optional)

1 2

Temperature Sensor (optional, not polarity sensitive)

1 2

3

Place the sensor close to the battery

NOTE

Do NOT place the Temperature Sensor lug inside the battery cell.

Mounting Recommendations

WARNING

Never install the controller in a sealed enclosure with flooded batteries. Gas can accumulate

and there is a risk of explosion.

1. Choose Mounting Location—place the controller on a vertical surface protected from

direct sunlight, high temperatures, and water. Make sure there is good ventilation.

13

2. Check for Clearance—verify that there is sufficient room to run wires, as well as clearance

above and below the controller for ventilation. The clearance should be at least 6 inches (150mm).

3. Mark Holes

4. Drill Holes

5. Secure the charge controller.

6 inches

(150mm)

warm air

6 inches

(150mm)

Mounting Methods

The controller can be mounted using the existing mounting holes or using the included mounting

brackets.

cool air

14

Using Mounting Hole

Step 1.

Measure the distance between each

mounting hole on the Rover. Using that

distance drill 4 screws onto desired surface.

Step 2.

Align the Rovers mounting holes with the

screws

Step 3.

Verify all screw heads are inside the

mounting holes. Release controller and

check if mounting feels secure.

15

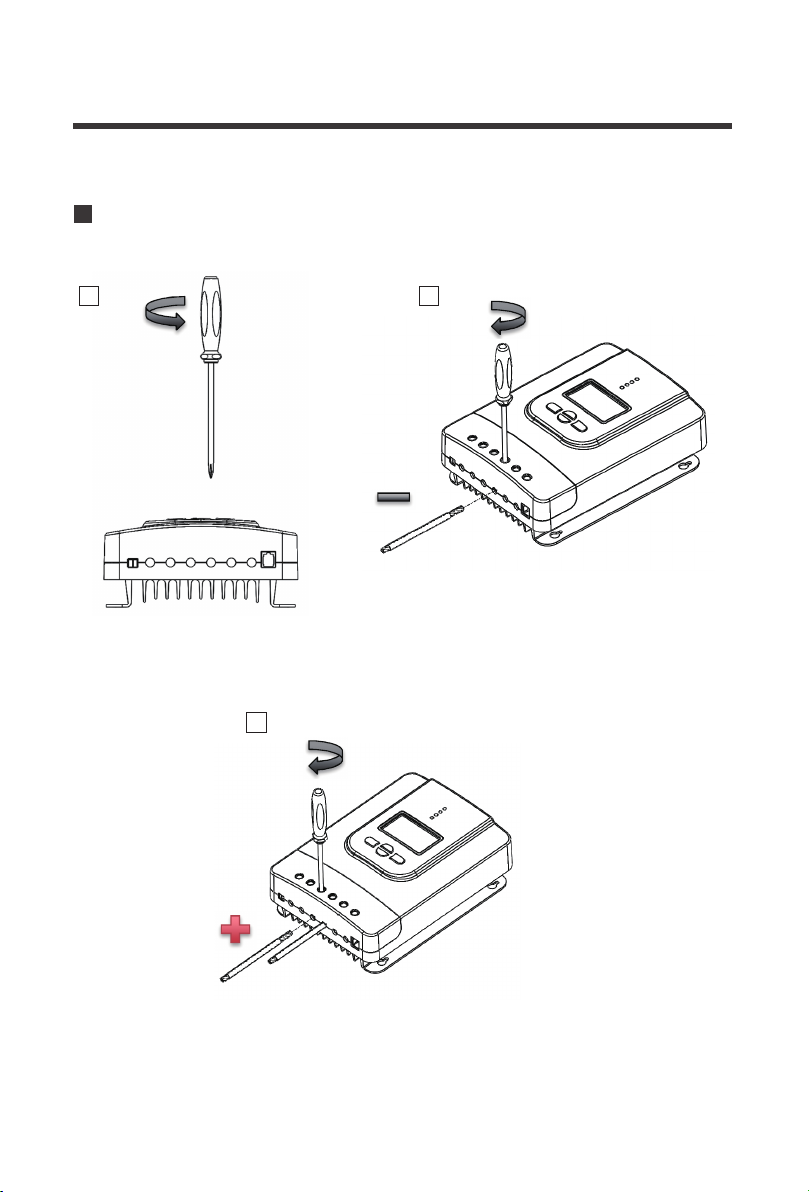

Using Mounting Brackets

Step 1.

Install the brackets using the provided

components

Step 2.

Align the mounting brackets to desired

surface and use the appropriate screws to drill

into surface (screws not included)

Step 3.

Verify mounting is secure

16

Operation

Rover is very simple to use. Simply connect the batteries, and the controller will automatically

determine the battery voltage. The controller comes equipped with an LCD screen and 4

buttons to maneuver though the menus.

NOTE:Please set the correct battery type the first time you use.

Startup Interface

Main Display

NOTE

The Battery Capacity (SOC%) is estimated based on the charging voltage.

Error Code

Load mode

Main Screen

Solar Panel Voltage

Battery Voltage

Load Current

Controller

Temperature

Charging Current

Accumulated AH

Battery Capacity

Discharged AH

17

/

/ -

Page Up/ Increase parameter value

Page Down/ Decrease parameter value

Return to the previous menu

ENTER/

Enter sub menu/ save parameter value/

turn load on or off in manual mode

18

Programming Battery Type

To enter the battery programming settings hover over the Battery Voltage screen and press

down the Enter button .When the battery type starts to flash press the Select button to cycle

through the battery types and press Enter to finalize selection .When selecting the Lithium

setting the user can change battery voltage from 12V to 24V and select the charging voltage.

Li

12V

SLD

GEL

FLD

USE

24V

12V / 24V

19

Programming Parameters

Battery type System voltage Equalizing voltage

Over-discharge voltage

Over-discharge

return voltage

Float voltage

Boost voltage

To enter the programming interface simply press and hold the right arrow button. After entering

this feature press the Enter/Right button to switch between parameters. To change the

parameters, press the Up or Down button. To save the parameter press and hold the

Enter/Right button.

The charging parameter setting (Equalizing voltage, Boost voltage, Floating charging voltage,

over-discharge return voltage, Over-discharge voltage) are only available under the battery

“USER” mode. Press and hold the right arrow to enter the programming settings and continue

pressing the right arrow button until you see the desired voltage screen.

NOTE

Battery charging parameters can also be programmed using the Renogy DC Home APP.

Read the corresponding user manuals for more information.

20

Programming Load Terminal

1 2 3 4

1. This screen is displaying the current Load Mode.

2. To enter screen 2 press and hold t

he Enter button. This screen will allow you to change

the load mode.

3. To change the load mode press the up or down button.

Once you have selected the desired load mode press the Enter button to save the setting.

4.

5. To exit the programming setting press the left button.

Load Mode Options

Setting Mode Description

The load will turn on at night when the solar

0 Automatic(On/Off)

panel is no longer producing any power

after a short time delay. The load will turn

off when the panel starts producing power.

When the panel is no longer producing

1-14

Time control

power the load will be ON for 1-14 hours

or until the panel starts producing power.

In this mode, the user can turn the Load

15 Manual

On/Off by pressing the Enter button at any

time.

Used to troubleshoot load terminal (No

16 Test

Time Delay). When voltage is detected

load will be off and when no voltage is

detected load will be on.

17

21

24Hr

The load will be on for 24 hours a day.

LCD Indicators

nighttime daytime solar panel charging

charging stage system voltage setting serial port bluetooth abnormality battery type unit

LED Indicators

battery discharging load parameter value

①---PV array indicator

①

②---BAT indicator

②

③

③---LOAD indicator

④

④---ERROR indicator

Indicating the controller's current

charging mode.

Indicating the battery's current state.

Indicating the loads' On/ Off state.

Indicating whether the controller is

functioning normally.

22

PV Indicator (1)

Status

Solid

White

White Slow Flashing

White Single Flashing

White Fast Flashing

White Double Flashing

Off

BATT Indicator (2)

White Solid

White Slow Flashing

White Fast Flashing

LOAD Indicator (3)

White Solid

White Fast Flashing

The PV system is charging the battery bank

The Controller is undergoing boost stage

The Controller is undergoing float stage

The Controller is undergoing equalization stage

The oversized PV system is charging the battery

bank at the rated current.

The PV system is not charging the battery bank.

PV not detected.

Status

Battery is normal

Battery over-discharged

Battery over-voltage

Status

Load is on

Load is over-loaded or short-circuited

Off

ERROR Indicator (4)

White Solid

System Error. Please check LCD for Error code

Off

23

Load is off

Status

System is operating normally

Rover Protections

Protection Behavior

PV Array Short Circuit

PV Overvoltage

PV Overcurrent

Load Overload

Load Short Circuit

PV Reverse Polarity

Battery Reverse Polarity

When PV shot circuit occurs, the controller will stop charging.

Clear it to resume normal operation.

if the PV voltage is larger than maximum input open voltage

100VDC. PV will remain disconnected until the voltage drops

below 100VDC.

The controller will limit the battery charging current to the

maximum battery current rating. Therefore, an over-sized

solar array will not operate at peak power.

If the current exceeds the maximum load current rating 1.05

times, the controller will disconnect the load. Overloading

must be cleared up by reducing the load and restarting the

controller.

Fully protected against the load wiring short-circuit. Once the

load short (more than quadruple rate current), the load short

protection will start automatically. After 5 automatic load

reconnect attempts, the faults must be cleared by restarting

the controller.

The controller will not operate if the PV wires are switched.

Wire them correctly to resume normal controller operation.

The controller will not operate if the battery wires are

switched. Wire them correctly to resume normal controller

operation.

Over-Temperature

If the temperature of the controller heat sink exceeds 65℃,

the controller will automatically start reducing the charging

current. The controller will shut down when the temperature

exceeds 85℃.

24

System Status Troubleshooting

PV indicator Troubleshoot

Ensure that the PV wires are correctly and tightly secured inside

Off during daylight

BATT Indicator Troubleshoot

White Slow Flashing

the charge controller PV terminals. Use a multi-meter to make

sure the poles are correctly connected to the charge controller.

Disconnect loads, if any, and let the PV modules charge the battery

bank. Use a multi-meter to frequently check on any change in battery

voltage to see if condition improves. This should ensure a fast charge.

Otherwise, monitor the system and check to see if system improves.

White Fast Flashing

Load Indicator Troubleshoot

White Fast Flashing

Error Indicator Troubleshoot

WhiteSolid System Error. Please check LCD for Error code

Using a multimeter check the battery voltage and verify it is not

exceeding 32 volts.

The Load circuit on the controller is being shorted or

overloaded. Please ensure the device is properly connected to

the controller and make sure it does not exceed 20A (DC).

Error Codes

Error Number Description

E0

E1

E2

E3

E4 Load short circuit

E5 Load overloaded

E6

E8

E10

No error detected

Battery over-discharged

Battery over-voltage

Battery under-voltage

Controller over-temperature

PV input over-current

PV over-voltage

25

Maintenance

WARNING

For best controller performance, it is recommended that these tasks be performed from time to time.

1. Check that controller is mounted in a clean, dry, and ventilated area.

2. Check wiring going into the charge controller and make sure there is no wire damage or wear.

3. Tighten all terminals and inspect any loose, broken, or burnt up connections.

4. Make sure LED readings are consistent. Take necessary corrective action.

5. Check to make sure none of the terminals have any corrosion, insulation damage, high

temperature, or any burnt/discoloration marks.

Risk of Electric Shock! Make sure that all power is turned off before touching the

terminals on the charge controller.

Fusing

Fusing is recommended in PV systems to provide a safety measure for connections going from

panel to controller and controller to battery. Remember to always use the recommended wire

gauge size based on the PV system and the controller.

NEC Maximum Current for different Copper Wire Sizes

AWG 16 14 12 10 8 6 4 2 0

Max.

Current

Note: The NEC code requires the overcurrent protection shall not exceed 15A for 14AWG, 20A

for 12 AWG, and 30A for 10AWG copper wire.

Controller to Battery Fuse = Current Rating of Charge Controller

Ex. 20A MPPT CC = 20A fuse from Controller to Battery

Fuse from Controller to Battery

55A40A30A25A18A

75A 95A 130A 170A

Fuse from Solar Panel(s) to Controller

Ex. 200W; 2 X 100 W panels

NOTE

Different safety factors could be used. The purpose is to oversize.

Series:

Total Amperage= Isc1 = Isc2 * SF

= 5.75A * 1.56 = 8.97 =(5.75A + 5.75A)* 1.56 = 17.94

**Utilize 1.56 Sizing Factor (SF)

Parallel

Total Amperage= (Isc1 + Isc2) * SF

Fuse = 18A fuse Fuse = 9A fuse

26

Electrical Parameters

Technical Specifications

Model

Nominal system voltage

Rated Battery Current

Rated Load Current

Max. Battery Voltage

Max Solar Input Voltage

Max. Solar Input Power

Self-Consumption

Charge circuit voltage drop

Discharge circuit voltage drop ≤ 0.15V

Temp. Compensation

32V

≤ 0.26V

RVR-20 RVR-30 RVR-40

12V/24V Auto Recognition

20A

20A

12V @ 260W

24V @ 520W

-3mV/°C/2V (default)

30A

20A

100 VDC

12V @ 400W

24V @ 800W

≤100mA @ 12V

≤58mA @ 24V

General

Dimensions

Mounting Oval

Max Terminal Size

Net Weight

Model

RVR-20 RVR-30/40

210*151*68.2mm

8.27*5.95*2.69in

7.66 x 4.70mm

0.30 x 0.18in

2

10mm

8 AWG

1.4kg

3.08 lb.

24V @ 1040W

238*172*77.3mm

9.38*6.78*3.05in

10mm

8 AWG

2.0kg

4.41 lb.

40A

20A

12V @ 520W

2

Working Temperature

Storage Temperature

Rated Load Current

Humidity Range

Enclosure IP32

Altitude < 3000m

Communication

Certification

27

FCC Part 15 Class B; CE; RoHS; RCM

-35°C to +45°C

-35°C to +75°C

10% to 90% NC

≤ 95% (NC)

RS232

This equipment has been tested and found to comply with the limits for a class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver.

•Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

•Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

Battery Charging Parameters

Battery GEL SEALED FLOODED LI (LFP) USER

Over-voltage

Warning

Equalization

Voltage

Boost Voltage

Float Voltage 13.8 V 13.8 V 13.8 V -----

Boost Return

Voltage

Under Voltage

Warning

Under Voltage

Recover

Low Voltage

Disconnect

Low Voltage

Reconnect

Equalization

Duration

Boost Duration

16 V 16 V 16 V 16 V

-----

14.6 V

-----

14.4 V14.6 V 14.4 V 14.2 V

13.2 V 13.2 V 13.2 V 13.2 V

12V 12V 12V 12V

12.2 V 12.2 V 12.2 V 12.2 V

11.0V 11.0V 11.0V 11.0V

12.6 V 12.6 V 12.6 V 12.6 V

-----

2 hours 2 hours 2 hours

2 hours 2 hours

-----

-----

9-17 V

9-17 V14.8V

9-17 V

9-17 V

9-17 V

9-17 V

9-17 V

9-17 V

9-17 V

0-10 Hrs.

1-10 Hrs.

*Battery charging parameters in USER mode can be programmed using the Renogy DC

Home App.

**Default charging parameters in LI mode are programmed for 12.8V LFP battery. Before

using Rover to charge other types of lithium battery, set the parameters according to the

suggestions from battery manufacturer.

***Parameters are multiplied by 2 for 24V systems.

28

Rover– Conversion Efficiency Curves

2

1.12 Volt System Conversion Efficiency

MPPT 12V conversion efficiency (12V battery)

96%

95%

Conversion efficiency Conversion efficiency

94%

93%

92%

91%

90%

89%

88%

87%

525 500 475 450 425 400

550

Output power(W)

2. 24 Volt System Conversion Efficiency

MPPT 24V conversion efficiency (24V battery)

87%

Temp 25℃Illumination Intensity: 1000W/ m

20 Vmp

40 Vmp

60 Vmp

75 Vmp

375 350 300 250 200 150 100 50

96%

94%

92%

90%

40 Vmp

50 Vmp

60 Vmp

75 Vmp

88%

86%

1100 1000 900 800 600 500 300 100

Output power(W)

29

Dimensions

RVR-20

210

RVR-30/40

238

151

13.87

150.40

R4.0

68.20 131

154.00

R2.25

Product dimensions:210*151*68.2mm

117.32

143.63

172 77.30 147

Maximum Wire Gauge 8 AWG

R2.60

R4.50

24.30

R2.60

R2.25

R4.0

18

123.46

167.60

Product dimensions:238*172*77.3mm

Maximum Wire Gauge 8 AWG

NOTE

Dimensions in millimeters (mm)

R5.00

30

RENOGY.COM

Renogy reserves the right to change

the contents of this manual without notice.

US

CN

JP

CA

AU

UK

DE

2775 E Philadelphia St, Ontario, CA 91761, USA

909-287-7111

www.renogy.com

support@renogy.com

苏州高新区科技城培源路1号5号楼-4

400-6636-695

https://www.renogy.cn

support@renogy.cn

https://www.renogy.jp

supportjp@renogy.com

https://ca.renogy.com

supportca@renogy.com

https://au.renogy.com

supportau@renogy.com

https://uk.renogy.com

supportuk@renogy.com

https://de.renogy.com

supportde@renogy.com

ROVER

SERIES

20A | 30A | 40A

Version 1.5

Wichtige Sicherheitshinweise

Bitte beachten Sie die folgenden Hinweise.

Die folgenden Symbole veranschaulichen die Verwendung des gesamten Handbuchs, um

anzuzeigen, dass eine potenziell gefährliche Situation in einer Operation oder eine wichtige

sichere Prozedur vorhanden sein kann, die berücksichtigt werden muss.

WARNUNG

Weist auf einen möglicherweise gefährlichen Betrieb

hin, der zu Verletzungen führen kann.

ACHTUNG

HINWEIS

Zeigt ein kritisches Verfahren für den sicheren und ordnungsgemäßen

Betrieb des Solarladereglers.

Zeigt die wichtigen Spezifikationen und Verfahren für die Verwendung

dieses Solarladereglers an.

Allgemeine Sicherheitshinweise

Lesen Sie alle Anweisungen und Vorsichtsmaßnahmen im Handbuch vor der Installation.

Innerhalb des Solarladereglers ist keine Wartung oder Reparatur erforderlich. Zerlegen

und warten Sie den Solarladeregler nicht selbst.

Verhindern, dass Wasser in das Innere des Solarladereglers eindringt.

Stellen Sie sicher,dass alle Leitungsverbindungen dicht sind.

Sicherheitshinweise zum Laderegler

Stellen Sie sicher, dass die Batterie vor der Installation korrekt angeschlossen ist.

Stellen Sie sicher, dass die Eingangsspannung weniger als 100 V beträgt, um dauerhafte

Schäden zu vermeiden. Schalten Sie den Leerlauf Spannung (Voc)ein, um sicherzustellen,

dass er unter dieser Spannung liegt,wenn er an Solarmodule angeschlossen wird.

31

Sicherheitshinweise der Batterie

Verwenden Sie nur Batterie mit hohen Zyklus: versiegelte Blei-Säure-, Flut-, Gel- oder

Lithium-Batterien.

Zum Zeitpunkt des Ladevorgangs kann das Batterie-Blasgas vorhanden sein, wodurch

ausreichend Raum zum Freisetzen des Gases sichergestellt wird.

Seien Sie vorsichtig, wenn Sie eine große Kapazität von Blei-Säure-Batterien

benutzen. Tragen Sie eine Schutzbrille. Wenn Batteriesäure in die Augen gelangt,

spülen Sie bitte mit sauberem Wasser ab.

Lesen Sie die Anweisungen des Akkus sorgfältig durch, bevor Sie fortfahren.

Lassen Sie nicht die positiven (+) und negativen (-) Anschlüsse der Batterie

miteinander berühren.Recyceln Sie die Batterie, wenn sie ersetzt wird.

Bitte recyceln Sie die Batterie, wenn er ersetzt wird

Übermäßige Ladephase Überschüssige Gasfällung kann die Batterieplatte

beschädigen und dazu führen, dass das aktive Material abfällt. Zur hohen oder langen

Ausgleichsladung führen zu einer Beschädigung der Batterie. Bitte überprüfen Sie

sorgfältig die spezifischen Anforderungen für die Batterie im System.

Der Ausgleich wird nur für nicht verschlossene / belüftete / geflutete /

Nasszellen-Blei-Säure-Batterien durchgeführt.

NICHT ausgleichen VRLA-Batterien vom Typ AGM / Gel / Lithiumzellen, WENN NICHT

vom Batteriehersteller zugelassen.

Die voreingestellten Ladeparameter im Li-Modus sind nur für 12,8

V-Lithium-Eisenphosphat-Akkus (LFP) programmiert. Bevor Sie Rover zum Laden

anderer Lithiumbatterietypen verwenden, stellen Sie die Parameter gemäß den

Empfehlungen des Batterieherstellers ein

Bitte stellen Sie beim ersten Verwenden den richtigen Batterietyp ein.

WARNUNG

Verbinden Sie die Batterieklemmen mit dem Laderegler, BEVOR Sie

Solarmodul an den Laderegler anschließen. NIEMALS Solarmodule an

den Laderegler anschließen ohne die Verbindung von der Batterie.

Schließen Sie nicht Wechselrichter oder Ladegeräte an den

Lastanschluss des Ladereglers an

Als der Ausgleich beim Aufladen der Batterie aktiv ist, wird er diese Stufe

nicht verlassen, es sei denn, ein ausreichender Ladestrom vom

Solarpanel ist vorhanden. Die Batterien dürfen während des

Ausgleichsladezustands KEINE Last haben

32

Gliederung

Informationen

Zusatzkomponenten

Optionale Zubehöre

Identifizierung der Komponenten

Installation

Betrieb

LED-Anzeige

Rover-Schutz

Systemstatusüberholung

Fehlercodes

Wartung und Reparatur

Sicherung

Technische Parameter

Elektrische Parameter

34

38

38

39

40

47

52

54

55

55

56

56

57

57

Allgemein

Batterieladeparameter

ROVER: Leistungskurve der PV-Leistungsumwandlung

Maße

33

57

58

59

60

Informationen

Die Laderegler der Rover -Serie eignen sich für verschiedene netzunabhängige

Solaranwendungen. Sie schützt die Batterie vor Überladung des Solarmoduls und die Überlastung

durch die Lasten. Die Steuerung verwendet einen intelligenten Verfolgungsalgorithmus, um die

vom PV-Modul gewonnene Energie zu maximieren und die Batterie aufzuladen. Zur gleichen Zeit,

Niederspannung trennt die Funktion (LVD), um übermäßige Batterieentladung zu verhindern.

Das Ladeprogramm von Rover ist optimiert, um die Batterielaufzeit zu verlängern und die

Systemleistung zu verbessern.Umfassende Selbstdiagnose und elektronische

Schutzfunktionen können Schäden an einem Installationsfehler oder Systemausfall

verhindern.

Hauptmerkmale

Automatische Erkennung von 12V oder 24V DC Systemspannung

Innovative MPPT-Technologie mit einer hohen Tracking-Effizienz von bis zu 99% und

einem maximalen Effizienz der Wirkungsgrad von bis zu 98%

Tieftopfdichtung, Kolloid, reichflüssige und Lithium-Eisen-Phosphat-Batterie(12,8V) bereit

Elektronischer Schutz: Überladung, Überentladung, Überlastung und Kurzschluss

Rückwärtsschutz: JEs gibt Schutz in der Verbindung zwischen Solarmodulen und

Batterien

Die Ladespannung kann eingestellt werden

Es kann auf überentladene Lithium-Eisenphosphat-Batterie geladen werden

RS232-Anschluss für die Verbindung von BT-1 Bluetooth Modul

MPPT-Technik

Der MPPT-Solarladeregler nutzt die Technologie der maximalen Leistungspunktverfolgung,

um die maximale Leistung aus dem Solarmodul zu extrahieren, und die Batterie aufzuladen.

Der Tracking-Algorithmus ist vollständig automatisch und erfordert keine

Benutzeranpassung. MPPT-Technologie verfolgt die Arrays maximale Leistung Punkt

Spannung (Vmp), wie es mit den Wetterbedingungen variiert, so dass die im Laufe des

Tages wird die maximale Leistung aus dem Array gewonnen.

Stromerhöhung

In den meisten Fällen wird der Ladestrom der Solaranlage durch die Technologie der

maximalen Leistungspunktverfolgung "verbessert". Der Strom ist nicht aus der Luft

gekommen,im Gegenteil, die Leistung von Solarmodule und Batterie Sendeleistung sind

gleich erzeugt. Die Leistung ist multiplizierte Wert von Spannung (V) und Strom (A).

34

Nehmen wir daher unter 100% Effizienzbedingungen an:

Eingangsspannung * Eingangsstrom = Ausgangsspannung * Ausgangsstrom

Eingangsleistung = Ausgangsleistung

Obwohl der Wirkungsgrad des MPPT-Solarladereglers nicht 100% beträgt, liegt seine Effizienz

dennoch bei 92-95%.Wenn die Solarkomponente eine Spitzenleistungspunktspannung

(Vmp) hat, die größer als die Batteriespannung ist kann es den Batterieladestrom proportional

größer als der Ausgangsstrom des Solarmoduls führen. Die vom Solarmodul erzeugte

Spannung muss auf den vorgesehenen Wert reduziert werden, um das Aufladen der Batterie

zu stabilisieren. Dies kann der Fall sein, wenn das Solarpanel einen Strom von 8A an die

Steuerung erzeugt aber die Steuerung der Batterie einen Ladestrom von 10A gibt. Dies ist das

Grundprinzip des MPPT-Solarladereglers und seine Vorteile gegenüber herkömmlichen

Solarladereglern. Der Einsatz des traditionellen Solarladereglers für die Abnehmende

Strommenge kann nur in Form von Wärme erfolgen, so dass die Umwandlungsrate relativ

gering ist. Die folgende Abbildung zeigt die Eigenschaften der MPPT-Technologie.

Strom und Spannung (12V-System) Ausgangsleistung (12V-System)

Typischer

Batteriespannungsbereich

Maximale

konventioneller

Leistungspunkt

SolarladereglerBetriebsbereich

10 15 17

Spannung

Strom

10 15 17

Maximaler

Leistungspunkt

Spannung

Strom

Effizienzlimit

Temperatur ist der Feind der Solarmodule": Die Temperatur wird sich die Effizienz der

Solarmodule auswirken. Trotz der hohen Effizienz der MPPT-Technologie kann der

Ladealgorithmus immer noch viele gute Bedingungen fehlt, so dass die

Steuerungsleistung unvermeidbar reduziert wird. In diesem Fall ist es vorzuziehen, eine

höhere Nennspannungskomponente zu haben, so dass die Batterie trotz der

Leistungsverschlechterung der Komponente aufgrund des proportionalen Abfalls der

Komponentenspannung immer noch eine Stromverstärkung empfängt.

35

Vierstufige Ladestufe

Der Solarregler Rover MPPT verfügt über vier schnelle, effiziente und sichere

Batterieladeverfahren. Sie umfassen: schnelles Aufladen, Anhebendes

Aufladen,Schwebeladung und ausgeglichenes Aufladen in vier Stufen.

Batteriespannung

Ausgleichserhöhung

Ladungsrückkehrspannung

Ladestrom

Schnelle Ladephase: für die tägliche Aufladung. Der Regler liefert 100% der zur Verfügung

A B C

Schnelle Ladung

Maximaler

Strom

behaltende Ladung

behaltende zeit:2 St.

(Anwendungsbereich:10-180 Min.

Akkumulierte Zeit: 3 St.

Erhaltungsladung

Boost

Bulk

Time

Time

stehenden Solarenergie zur Batterieladung, konstante strom-äquivalent.In dieser Phase hat

sich die Batteriespannung eine konstante Spannung (Ausgleichs- oder boost) nicht erreicht

wird, arbeitet Steuerung im konstanten Strom-Modus, der maximale Strom für die Batterie liefert

(MPPT Aufladung).

Behaltende Ladephase: Wenn die Batterie auf den Sollwert der konstanten Spannung

aufgeladen wird, wird die Steuerung startet bei einem konstanten Aufladung und ist nicht mehr

Ladung MPPT.Zu diesem Zeitpunkt wird der Strom allmählich abnehmen, aufgeteilt in zwei

Stufen des Ausgleichens und des Hebens, um das Überhitzen der Batterie zu verhindern und

die Erzeugung von Gas zu vermeiden, wird sie einen vollständigen Ladevorgang nicht

fortsetzen.

Hebephase : U m die Ladephase der allgemeinen Standarddauer von 2 Stunden zu

verbessern, kann der Benutzer auch die behaltende Zeit anpassen und den

Spannungspunkt des Standardwerts aufwerten. Wenn die Dauer den eingestellten

Wert erreicht, wird das System auf die Erhaltungsladung übertragen.

Erhaltungsladungsphase: Wenn die Batterie-Konstante Strom-Ladephase abgeschlossen

ist, schaltet der Solarladeregler in die Erhaltungsladephase.Wenn die Batterie vollständig

aufgeladen ist, gibt es keine elektrochemische Reaktion mehr. Zu diesem Zeitpunkt wird der

gesamte Ladestrom in Wärme und Niederschlaggas umgewandelt.Zu diesem Zeitpunkt wird die

Erhaltungsladungsphase ausgeführt, und die Batterie wird sehr schwach mit einer kleineren

Spannung und einem kleineren Strom aufgeladen.

36

Der Zweck der Erhaltungsladung besteht darin,die Batterie aufgrund der Selbstentladung zu kompensieren

und das System durch den Stromverbrauch eine geringere Last zu erzeugen, während die

Batteriespeicherkraft voll gehalten wird. Während der Erhaltungsladungsphase kann die Last weiterhin

Energie von der Batterie aufnehmen.Wenn die Systemlast den Solarladestrom überschreitet, kann die

Steuerung die Batteriespannung nicht mehr im eingestellten Erhaltungsladewert halten.Wenn die

Batteriespannung niedriger als die Ladungsrückgewinnungseinstellung ist, verlässt die Steuerung die

Erhaltungsladungsphase und kehrt zur Schnellladephase zurück.

Gleichgewichtsphasen: 28 Tage automatisch einmal ausgeführt, Es kann man aber auch manuell erfolgen.Einige

Batterietypen profitieren von regulärem Ausgleichsladen,können den Elektrolyten rühren, die Batteriespannung

ausgleichen und die chemische Reaktion abschließen.Die ausgeglichene Ladung erhöht die Batteriespannung damit

siehöher als die Standardkomplementärspannung und führt zur Elektrolytvergasung der Batterie.

WARNUNG

Wenn die Batterieladung ausgeglichen ist, wird das Gerät nicht verlassen, es sei denn, das Solarmodul

hat genügend Ladestrom. Während der ausgeglichenen Ladephase darf die Batterie nicht belastet

werden.

Überladung und übermäßige Gasniederschläge können die Batterieplatten beschädigen und

Materialablagerungen bewirken. Eine zu hohe oder zu lange Ausgleichsladung kann zu Schäden führen.

Bitte überprüfen Sie sorgfältig die spezifischen Anforderungen der im System verwendeten Batterie.

Eine ausgeglichene Ladung kann die Batteriespannung auf einen Wert erhöhen,der die empfindliche

Gleichstromlast beschädigen könnte. Stellen Sie sicher,dass alle im System zulassende Eingangsspannung der

Lasten größer als die Batterieausgleichsladungseinstellung ist.

Aktivierung der Lithium-Eisenphosphat-Batterie

Rover MPPT-Solarregler mit Lithium-Eisenphosphat-Batterie-Aktivierungsfunktion, können Sie den

Schlafzustand der Lithium-Eisenphosphat-Batterie aktivieren.Wenn es übermäßige entlädt,

Lithium-Eisen-Phosphat-Batterie-Schutzschaltung wird in der Regel die Batterie Entladeschaltung

abgeschnitten, so dass es nicht verwendet werden kann.Der Hauptgrund für diese Situation ist, dass der

Benutzer die Lithium-Eisenphosphat-Batterie zu dem Überentladungsschutzpunkt oder in der Nähe des

Freigabeschutzpunkts überbeansprucht. Dann wird die Selbstentladung der Lithiumeisenphosphatbatterie

allmählich von der verbleibenden Energie zu einem Überentladungsschutz ausgehen.Wenn es keine

Aktivierungsfunktion zum Neustart der Batterie gibt, können diese Batterien möglicherweise nicht verwendet

oder sogar beschädigt werden.Die Rover PG-Batteriesteuerung liefert einen kleinen Strom zum Aktivieren der

Batterie Wenn die Batteriespannung den Überentladungs-Wiederherstellungsstandard erreicht.

HINWEIS

Wenn Sie Rover zum Laden einer 24-V-Lithium-Eisenphosphat-Batterie verwenden, stellen Sie die

Systemspannung auf 24 V ein, anstatt sie automatisch zu erkennen.Wenn Sie versehentlich Auto

Recognition ausgewählt haben, können Sie mit Rover die Systemspannung an der aktiven

Schnittstelle auf 24 V ändern.Die Lithium-Phosphat-Batterie-Aktivierungsfunktion kann normal

verwendet werden.Drücken Sie in der Aktivierungsschnittstelle lange auf die rechte Seite der

"Bestätigen" -Taste, um die oben ausgewählten Systemspannungseinstellungen auszulösen.Um

die Systemspannung zu ändern, drücken Sie die Taste "Auf" oder "Ab" und drücken Sie die Taste

"OK", um die Systemspannung zu speichern. Wenn die Taste "OK" nicht gedrückt wird, speichert

der Rover automatisch Die ausgewählte Systemspannung.

37

Enthaltende Komponenten

Ferntemperatursensor:

Dieser Sensor kann die Temperatur der Batterie messen und diese

Daten verwenden, um eine sehr genaue Temperaturkompensation zu

erhalten. Der Sensor ist mit einem 298,7cm(9,8ft) langen Kabel

ausgestattet. Schließen Sie das Kabel einfach an und kleben Sie den

Sensor oben oder seitlich auf die Batterie, um die

Umgebungstemperatur um die Batterie herum aufzuzeichnen.

Zusatzkomponente

Hinweis

Halterungen

Mit diesen Halterungen kann der Rover-Laderegler auf jeder ebenen

Fläche montiert werden. Die Schrauben zur Befestigung der

Halterungen am Laderegler sind im Lieferumfang enthalten.

Montage Oval:7,66 x 4,70mm

Verwenden Sie den Sensor nicht beim Laden einer

Lithium-Eisenphosphat-Batterie.

Optionale Komponente

Optionale Komponente enthalten nicht. Bitte kaufen Sie nach Ihre Bedürfnisse.

Renogy BT-1 Bluetooth Modul:

Das BT-1 Bluetooth-Modul ist eine großartige Ergänzung zu allen

Renogy-Ladereglern mit RS232-Anschluss und wird zum Koppeln von

Ladereglern mit der Renogy DC Home App verwendet. Nach dem Pairing

können Sie Ihr System überwachen und Parameter direkt von Ihrem Handy

oder Tablet aus ändern. Sie müssen sich nicht mehr fragen, wie sich Ihr

System verhält. Jetzt können Sie die Leistung in Echtzeit sehen, ohne dass

Sie die LCD-Anzeige des Relgers überprüfen müssen.

Renogy DM-1 4G-Daten-Modul:

Das DM-1 4G-Daten-Modul kann mit einem RS232-Solarkabel für die

Verbindung mit ausgewählten Renogy-Ladereglern und für die Kopplung

mit der Renogy 4G-Überwachungs-App. Mit dieser App können Sie Ihr

System fern überwachen und Syeter-Parameter einstellen, wo 4G

LTE-Netzwerkdienst verfügbar ist .

38

Identifizierung der Komponenten

1

2

3

4

5

6

8

Schlüsselwörter

9 10 11

12

7

1. PV LED-Leuchten

2. Batterie-LED Leuchten

3. Last LED Leuchten

4. Systemfehler-LED Leuchten

5. LCD-Anzeige

6. Bedientaste

7. Montagelöcher

8. Ferntemperatursensoranschluss (optional)

9. PV-Klemmen

10. Batterieklemmen

11. Lastanschluss

12. RS-232 Anschluss (optional)

39

Installation

Installation Empfohlene Werkzeuge:

WARNUNG

WARNUNG

Schraubendreher

Multimeter

Schließen Sie das Batteriekabel zuerst an den Solarladeregler an und schließen

Sie dann das Solarpanel an den Solarladeregler an. Schließen Sie das Solarpanel

Schließen Sie keinen Wechselrichter oder Ladegerät an die Lastklemme des

Solarladereglers an.

Wechselrichter

Ladegerät

Stromtraktionsausrüstung

Hohe

HINWEIS

HINWEIS

Ziehen Sie die Schraubklemmen nicht zu fest an. Dies kann den Draht des

Solarladereglers beschädigen.

Beachten Sie die maximale Leitungsgröße am Solarladeregler und die

maximale Stromstärke der Leitung anhand der technischen Daten.

Sie können nun beginnen, die Batterie an die Ladesteuerung anzuschließen.

40

Batterie

1 2

3

41

Last (optional)

1 2

Solarmodule

1 2

42

Bluetoothe-Modul für Kommunikation (optional)

1 2

Temperatursensor (optional, nicht polar empfindlich)

1 2

3

Bitte legen Sie in der Nähe der Batterie

HINWEIS

Bitte legen Sie in der Nähe der Batterie

Montageempfehlung

WARNUNG

Installieren Sie das Steuergerät nicht in einem abgedichteten Raum mit einer satten

Flüssigkeitsbatterie.Das Gas kann sich ansammeln und es besteht Explosionsgefahr.

1. Wählen sie den Installationsort—bitte installieren Sie auf der vertikalen Oberfläche, um

direktes Sonnenlicht, hohe Temperaturen und Wasser zu vermeiden. Und um eine gute

Belüftung gewährzuleisten.

43

2. Überprüfen Sie den Abstand—bitte bestätigen Sie, ob genügend Platz für die Installation des

Kabel vorhanden ist und der Solarregler oben und unten über genügend Lüftungsabstand verfügt.

Der Spalt sollten mindestens 150 mm betragen.

3. Markieren Sie das Loch

4. Bohren

5. Befestigen Sie den Solarregler

6 inches

(150mm)

Warmluft

6 inches

(150mm)

Befestigungsarten

Der Regler kann mithilfe der vorhandenen Montagebohrungen oder mithilfe der mitgelieferten

Montagehalterungen montiert werden

kühle Luft

44

Using Mounting Hole

Schritt 1,

Bitte messen Sie den Abstand zwischen den

einzelnen Montagelöchern am Rover. Mit

diesem Abstand bohren Sie 4 Schrauben auf

die gewünschte Oberfläche.

Schritt 2,

Richten Sie die Rovers-Befestigungslöcher an

den Schrauben aus.

Schritt 3,

Bitte checken Sie, ob alle Schraubenköpfe in

den Befestigunglöchern gelegt worden ist.

Lassen Sie den Regler los und prüfen Sie, ob

sich die Montage sicher anfühlt.

45

Halterung benutzen

Schritt 1,

Installieren Sie die Halterungen mit den

mitgelieferten Komponenten

Schritt 2,

Richten Sie die Montagehalterungen an der

gewünschten Oberfläche aus und bohren Sie

mit den entsprechenden Schrauben in die

Oberfläche. (Schrauben nicht im

Lieferumfang enthalten)

Schritt 3,

Die Überprüfung der Montage ist sicher

46

Betrieb

Weil Rover einfach zu verwendet ist, man kann leicht mit der Batterie verbinden. Der

Laderegler erkennt automatisch die Batteriespannung. Der Regler verfügt über auch einen

LCD-Bildschirm und vier Taste, um die Parameter vom Solarsystem leicht einzustellen.

Bitte stellen Sie beim ersten Verwenden den richtigen Batterietyp ein.

Startseite

Hauptseite

HINWEIS

Hauptüberwachungsseite

Fehlercodehinweise

Lademodus Entladekapazität AH

Solarmodulspannung

Batteriespannung

Laststrom

Gerätetemperatur

Batterieleistung

Ladekapazität Ah

Ladestrom

Die Batteriekapazität (SOC%) basiert auf der Ladungsspannungsschätzung.

47

/

Das Menü scrollt nach oben / Unter den

Einstellung-Modus die Parameter ansteigen

/ -

ENTER/

Das Menü scrollt nach unten / Unter den

Einstellung-Modus die Parameter abnehmen

Zurück zum vorherigen Menü

Programmierdichtung Untermenü aufrufen / Parameterwert

speichern Schalten Sie die Last im manuellen Modus ein oder aus

48

Programmieren des Batterietyps

Wenn die Batteriespannung auf dem Bildschirm angezeigt wird, drücken Sie die Eingabetaste.

Wenn der Batterietyp blinkt, drücken Sie die Auswahltaste, um den Batterietyp zu wählen. Bei

Auswahl der Lithium-Einstellung kann der Benutzer die Batteriespannung von 12 V auf 24 V

ändern und die Ladespannung auswählen.

Li

12V

SLD

GEL

FLD

USE

24V

12V / 24V

49

Programmierparameter

Batterietyp Systemspannung Ausgleichsspannung

Überspannung Überdruck-Rücklauf

Erhaltungsspannung

Erhöhungsspannung

Drücken Sie nach der Auswahl der Programmoberfläche die Eingabetaste „Enter“, um

zwischen den Parametern zu wechseln, die Sie einstellen möchten.Um die Parameter zu

ändern, drücken Sie die Taste Auf / Ab. Um die Parameter zu speichern, halten Sie die

Eingabetaste gedrückt.

Die Einstellung der Ladeparameter (Ausgleichsspannung, Ladespannung,

Floating-Ladespannung, Überentladungsrückspannung, Überentladungsspannung) ist nur im

Batteriebetrieb "USER" verfügbar. Halten Sie die rechte Pfeiltaste gedrückt, um die

Programmiereinstellungen einzugeben, und drücken Sie die rechte Pfeiltaste weiter, bis die

gewünschte Spannungsanzeige angezeigt wird.

HINWEIS

Batterieladeparameter können auch mit der Renogy DC Home APP programmiert werden.

Weitere Informationen finden Sie in den entsprechenden Benutzerhandbüchern.

50

Einstellung von Lastmodus

1 2 3 4

1, Dieser Bildschirm zeigt den aktuellen Lademodus an

2, Um in Bildschirm 2 zu gelangen, halten Sie die Eingabetaste gedrückt, um den Betriebsmodus zu ändern.

3, Um den Lademodus zu ändern, schließen Sie die Auf- oder Ab-Taste an.

4, Nachdem Sie den gewünschten Lademodus ausgewählt haben, drücken Sie die Eingabetaste, um

die Einstellungen zu speichern.

5, Um die Programmeinstellungen zu verlassen, gehen Sie zur linken Schalttaste.

Lademodus-Optionen

Einstellungen Modus Description

Die Last schaltet sich nachts ein, wenn das

0

Automatisch

(ein / aus)

Solarmodul nach kurzer Zeit keine Leistung

mehr erzeugt. Die Last wird ausgeschaltet,

wenn das Panel Strom erzeugt.

Wenn die Sonnenkollektoren keinen Strom

1-14

Zeitsteuerung

mehr erzeugen, läuft die Last innerhalb von 1

bis 14 Stunden oder bis der Solarreis wieder

anfängt zu arbeiten.

In diesem Modus kann der Benutzer

15 Manueller Modus

jederzeit Enter drücken, um die Ladung

auszuschalten.

Es wird zur Fehlerbehebung des Ladeterminals

verwendet (keine Zeitverzögerung).Wenn die

16 Testmodus

17

51

24 Stunden

eingeschalteter Modus

Spannung erkannt wird, wird die Last

ausgeschaltet und die Last wird eingeschaltet,

wenn keine Spannung erkannt wird.

Die Ladung ist 24 Stunden täglich eingeschaltet.

LCD-Anzeige

Nachtanzeige

Tagesanzeige

Solarpanelanzeige

Ladeanzeige

Batterie Entladung Last Parameter

Ladephasen

Systemspannung

①

②

③

④

Einstellungen

Anweisungen für

den seriellen Port

BluetoothAnzeige

LED-Anzeige

①---PV-Array Indikator

②---BAT-Indikator

③---LAST-Indikator

④---Fehler-Indikator

Batterietyp Einheitsanzeigebereich

Abweichung

Aktuellen Ladenmodus vom

Laderegler ausgeben.

Aktuelle Situation von Batterie ausgeben.

Die Situation von On/off ausgeben.

Die Situation ausgeben, ob gut

funktioniert.

52

PV-Indikator (1)

Weißes Licht

eingeschaltet

Weißes Licht

langsames Blinken

Zustand

Die PV-Indikator lädt den Akku auf

Solarladeregler steigert Ladungsstufe

Weißer Einzelblitz

Weißer Schnellblitz

Weißes Doppelblitz

Licht aus

Akkuanzeige (2)

Weißes Licht

eingeschaltet

Weißes Licht

langsames Blinken

Weißer Schnellblitz

Akkuanzeige (3)

Weißes Licht

eingeschaltet

Weißer Schnellblitz

Geschlossen

Fehleranzeige (4)

Weißes Licht

eingeschaltet

Geschlossen

Solarladeregler in der schwimmenden Stufe

Der Solarladeregler befindet sich in der

Ausgleichsladephase

Die überdimensionierte Solaranlage ist für

Aufladen der Batteriebank mit dem Nennstrom.

Die PV-Indikator lädt den Akku nicht auf und

erkennt PV nicht

Zustand

Die Batterie ist normal

Übermäßige Batterienentladung

Batterieüberspannung

Zustand

elastung beginnt

Lastüberlastung oder Kurzschluss

Belastung endet

Zustand

Systemfehler. Bitte überprüfen Sie

den LCD-Fehlercode

System funktioniert gut

53

Rover Schutz

Schutz Verhalten

Photovoltaik-Array-

Kurzschluss

PV-Überspannung

PV-Überlauf

Lastüberlastung

Last Kurzschluss

PV-Rückwärtsgang

Batterie Rückwärtsgang

Wenn die PV kurzgeschlossen ist, hört die Steuerung auf zu

laden. Fehlerbehebung, um den normalen Betrieb wieder

aufzunehmen.

wenn die PV-Spannung größer als die maximale

Eingangs-Öffnungsspannung 100VDC ist. PV bleibt getrennt,

bis die Spannung unter 100VDC fällt.

Der Solarladeregler begrenzt den Batterieladestrom auf den

maximalen Nennstrom der Batterie. Infolgedessen arbeiten

übermäßige Solarmodule nicht mit Spitzenleistung.

Wenn der Strom den maximalen Laststrom von 1,05 mal

überschreitet, trennt die Steuerung die Last. Überlast muss

aufgelöst werden, indem die Last reduziert und der

Solarladeregler neu gestartet wird.

Muss vollständig geschützt werden, um Lastkurzschluss zu

vermeiden, sobald der Lastkurzschluss (mehr als viermal die

Rate des Stromes), Lastkurzschlussschutz automatisch

beginnt. Nach fünf Wiederanlaufversuchen zur

automatischen Last müssen Sie die Steuerung beheben,

indem Sie die Steuerung neu starten.

Wenn die PV-Leitung umgekehrt wird, funktioniert die Steuerung

nicht. Korrigieren Sie die Verdrahtung, um die ordnungsgemäße

Funktion des Solarladereglers wiederherzustellen.

Wenn das Batteriekabel umgekehrt ist, läuft der Solarladeregler

nicht. Korrigieren Sie die Verdrahtung, um den normalen Betrieb

des Solarladereglers wiederherzustellen.

Übertemperatur

Wenn die Temperatur des Reglers 65 ° C überschreitet,

reduziert der Laderegler automatisch den Ladestrom. Der Regler

schaltet sich ab, wenn die Temperatur 85 ° C überschreitet.

54

Systemstatusüberholung

PV-Anzeige Fehlerbehebung

Arbeiten nicht

während des Tages

Akkuanzeige Fehlerbehebung

Weißer langsamer Blitz

Weißes Blitzlicht

Belastungsanzeige Fehlerbehebung

Vergewissern Sie sich, dass die PV-Kabel ordnungsgemäß und am

PV-Solarladeregler im Solarladeregler befestigt sind.Verwenden Sie

ein Multimeter, um sicherzustellen, dass die positiven und negativen

Anschlüsse ordnungsgemäß mit dem Solarladeregler verbunden sind.

Trennen Sie die Last (falls vorhanden) und lassen Sie das PV-Modul den

Akku laden.Überprüfen Sie mit dem Multimeter die Änderung der

Batteriespannung, um festzustellen, ob die Bedingung verbessert

ist.Dies wird ein schnelles Laden sicherstellen, andernfalls muss das

System überwachen und überprüfen, ob es verbessert hat.

Verwenden Sie ein Multimeter, um die Batteriespannung zu prüfen

und zu bestätigen, dass diese 32 Volt nicht überschreitet.

Weißer Schnellblitz

Fehleranzeige Fehlerbehebung

Weiß einschalten Systemfehler. Bitte überprüfen Sie am LCD die Fehlercode.

Der Laststrom am Solarladeregler ist Kurzschluss oder überlastet.Vergewissern

Sie sich, dass das Gerät ordnungsgemäß an die Steuerung angeschlossen

ist.Und seine Stromstärke darf 20A nicht überschreiten.

Fehlercodes

Fehlernummer Beschreibung

E0

E1

E2

E3

E4

E5

E6

E8

E10

Keine Fehler erkannt

Übermäßige Batterieentladung

Batterieüberspannung

Batteriespannung ist unzureichend

Last Kurzschluss

Lastüberlastung

Übertemperaturregler

übermäßiger PV Eingangsstrom

PV-Überdruck

55

Wartung und Reparatur

WARNUNG

Um die beste Leistung des Solarladereglers zu erzielen, ist es ratsam, diese Aufgaben von Zeit zu Zeit durchzuführen.

1. Überprüfen Sie, ob der Solarladeregler in einem sauberen, trockenen und belüfteten Bereich installiert ist.

2 Überprüfen Sie die Verdrahtung des Solarladereglers, um sicherzustellen, dass keine Kabel beschädigt oder

verschlissen sind.

3. Ziehen Sie alle Anschlüsse fest und prüfen Sie auf lose, beschädigte oder verbrannte Verbindungen.

4. Stellen Sie sicher, dass die LED-Anzeigen übereinstimmen.Ergreifen Sie die notwendigen

Korrekturmaßnahmen.

5. Stellen Sie sicher, dass die Anschlüsse frei von Korrosion, Isolationsschäden, hohen Temperaturen oder

Verbrennungs- / Verfärbungsspuren sind.

WARNUNG GEFAHR DES ELEKTRISCHEN SCHLAGS!Vergewissern Sie sich, dass alle

Netzteile ausgeschaltet sind, bevor Sie die Anschlüsse an der Ladesteuerung berühren.

Sicherung

Sicherungen werden für den Einsatz in Photovoltaik- oder Solarsystemen empfohlen, da sie

eine wichtige Rolle bei der Verbindung der Solarenergie mit dem Solarladeregler, der

Steuerung und der Batterie spielen. Denken Sie daran, nach entsprechender Größe der

Solaranlage und des Solarladereglers die empfohlene Größe zu verwenden.

NEC Spitzenstrom für verschiedene Kupferdrahtgrößen

Amerikanischer Drahtanzeiger

Spitzenstrom

Erklärung: NEC-Code erfordert Überstromschutz sollte 15A 14AWG, 20A 12AWG und 30A

10AWG Kupferdraht nicht überschreiten.

Von der Steuerung zur Batteriesicherung

Solarladeregler zu Batteriesicherung = Nennstrom des Solarladereglers

Ex. 20A MPPT CC = 20A Sicherung zwischen Laderegler und Batterie

16 14 12 10 8 6 4 2 0

55A40A30A25A18A

75A 95A 130A 170A

Vom Solarpanel zur Sicherung des Reglers

Zum Beispiel 200W: 2 × 100 W Sonnenkollektoren

Verwenden Sie 1,56 Größenfaktor (SF)

Hinweis Sie können verschiedene Sicherheitsfaktoren verwenden.

Erklärung

Der Zweck ist zu überdimensionieren

Reihenschaltung: Parallelschaltung:

Ampere-Gesamtmenge= Isc1 = Isc2 * SF

Ampere-Gesamtmenge= (Isc1 + Isc2) * SF

= 5,75A * 1,56 = 8,97 =(5,75A + 5,75A)* 1,56 = 17,94

Sicherung = 18A Sicherung Sicherung = 9A Sicherung

56

Elektronische Parameter

Technische Parameter

Model

Nennspannung des Systems

Bemessungs-Batteriestrom

Nennlaststrom

Max. Batteriespannung

Max. Solar-Eingangsspannung

32V

Max.Solar-Eingangsleistung

Eigenverbrauch

Ladeschaltung Spannungsabfall

Entladungskreis Spannungsabfall

Temp. Kompensation

≤ 0,26V

Mechanische Parameter

Maximale Größe

Model

Befestigung oval

Maximale

Terminalgröße

Nettogewicht

RVR-20 RVR-30 RVR-40

12V/24V Auto-Erkennung

20A

20A

30A

20A

100 VDC

12V @ 260W

24V @ 520W

12V @ 400W

24V @ 800W

≤100mA @ 12V

≤58mA @ 24V

≤ 0,15V

-3mV/°C/2V (default)

RVR-20 RVR-30/40

210*151*68,2mm

8,27*5,95*2,69in

10mm

7.66 x 4.70mm

0.30 x 0.18in

2

8 AWG

1.4kg

3,08 lb.

40A

20A

12V @ 520W

24V @ 1040W

238*172*77,3mm

9,38*6,78*3,05in

2

10mm

8 AWG

2.0kg

4,41 lb.

Lagertemperatur

Lagertemperatur

Bemessungslaststrom

Luftfeuchtigkeit

Schutzgehäuse IP32

Höhe < 3000m

Kommunikationsanschluss

Zertifikation

FCC Teil 15, Klasse B, CE, RoHS, RCM

57

-35°C to +45°C

-35°C to +75°C

10% to 90% NC

≤ 95% (NC)

RS232

Dieses Gerät wurde getestet und erfüllt die Grenzwerte für ein digitales Gerät der Klasse B

gemäß Teil 15 der FCC-Bestimmungen. Diese Grenzwerte bieten einen angemessenen

Schutz gegen schädliche Interferenzen in einer Wohninstallation. Dieses Gerät verwendet

Radiofrequenzenergie und soll gemäß den Anweisungen installiert werden.Außerdem gibt es

Störungen der Funkkommunikation. Es kann jedoch nicht garantiert werden, dass bei einer

bestimmten Installation keine Interferenzen auftreten. Wenn dieses Gerät den Radio- oder

Fernsehempfang stört, was durch das Aus- und Einschalten des Geräts festgestellt werden

kann, sollte der Benutzer versuchen, die Störung durch eine oder mehrere der folgenden

Maßnahmen zu beheben:

*Richten Sie die Empfangsantenne neu aus

*Erhöhen Sie den Abstand zwischen Gerät und Empfänger

Schließen Sie das Gerät an eine Steckdose an, deren Stromkreis sich von dem des Empfängers unterscheidet

*

*Wenden Sie sich an den Händler oder einen erfahrenen Radio- / Fernsehtechniker

Das Gerät entspricht Teil 15 der FCC-Bestimmungen. Der Betrieb unterliegt den folgenden

zwei Bedingungen: (1) Dieses Gerät darf keine schädlichen Interferenzen verursachen, und

(2) dieses Gerät muss alle empfangenen Interferenzen akzeptieren und Interferenzen

verursachen, die einen unerwünschten Betrieb verursachen.

Batterieladeparameter

Battery GEL SEALED FLOODED LFP(Li) USER

Überspannungswarnung

Egalisations-

-spannung

Anhebungs-

-spannung

Erhaltungsspannung 13,8 V 13,8 V 13,8 V -----

Rückkehrs-

-spannung

Unterspannungswarnung

Unterspannungserholung

Tiefentladeschutz

Niederspannungs

wiederverbindung

Dauer vom Ausgleich 2 hours 2 hours

Dauer von Anhebung 2 hours 2 hours 2 hours -----

*Mit der Renogy DC Home App kann die Batterieladeparameter im USER-Modus programmiert werden.

**Die voreingestellten Ladeparameter im LI-Modus sind für 12,8 V-LFP-Akkus programmiert. Bevor Sie

Rover zum Laden anderer Lithiumbatterietypen verwenden, stellen Sie die Parameter gemäß den

Empfehlungen des Batterieherstellers ein.

***Parameter werden für 24-V-Systeme mit 2 multipliziert

16 V 16 V 16 V 16 V

-----

14,6 V

-----

14.4 V14,6 V 14,4 V 14,2 V

13.2 V 13.2 V 13,2 V 13,2 V

12 V 12 V 12 V 12 V

12,2V 12,2V 12,2V 12,2V

11,0V 11,0V 11,0V 11,0V

12,6 V 12,6 V 12,6 V 12,6 V

-----

-----

*9-17 V

9-17 V14,8V

9-17 V

9-17 V

*9-17 V

9-17 V

*9-17 V

9-17 V

*9-17 V

*0-10 Hrs.

*1-10 Hrs.

58

Rover PG– Stromerzeugung-Umwandlungskurve

2

1.12 Volt System Conversion Efficiency

MPPT 12V conversion efficiency (12V battery)

96%

95%

Conversion efficiency Conversion efficiency

94%

93%

92%

91%

90%

89%

88%

87%

525 500 475 450 425 400

550

Output power(W)

2. 24 Volt System Conversion Efficiency

MPPT 24V conversion efficiency (24V battery)

87%

96%

94%

92%

90%

88%

86%

1100 1000 900 800 600 500 300 100

Output power(W)

Luftfeuchtigkeit:25℃Lichtintensität: 1000W/ m

20 Vmp

40 Vmp

60 Vmp

75 Vmp

375 350 300 250 200 150 100 50

40 Vmp

50 Vmp

60 Vmp

75 Vmp

59

Maße

RVR-20

210

RVR-30/40

238

151

13,87

150,40

R4,0

68,20 131

154,00

R2,25

Maße:210*151*68,2mm

117,32

143,63

172 77,30 147

Maximale Drahtstärke 8 AWG

R2,60

R4,50

24,30

R2,60

R2,25

R4,0

18

123,46

167,60

Maße:238*172*77,3mm

Maximale Drahtstärke 8 AWG

HINWEIS

Maße im Millimeter (mm)

R5,00

60

RENOGY.COM

Renogy reserves the right to change

the contents of this manual without notice.

US

CN

JP

CA

AU

UK

DE

2775 E Philadelphia St, Ontario, CA 91761, USA

909-287-7111

www.renogy.com

support@renogy.com

苏州高新区科技城培源路1号5号楼-4

400-6636-695

https://www.renogy.cn

support@renogy.cn

https://www.renogy.jp

supportjp@renogy.com

https://ca.renogy.com

supportca@renogy.com

https://au.renogy.com

supportau@renogy.com

https://uk.renogy.com

supportuk@renogy.com

https://de.renogy.com

supportde@renogy.com

Loading...

Loading...