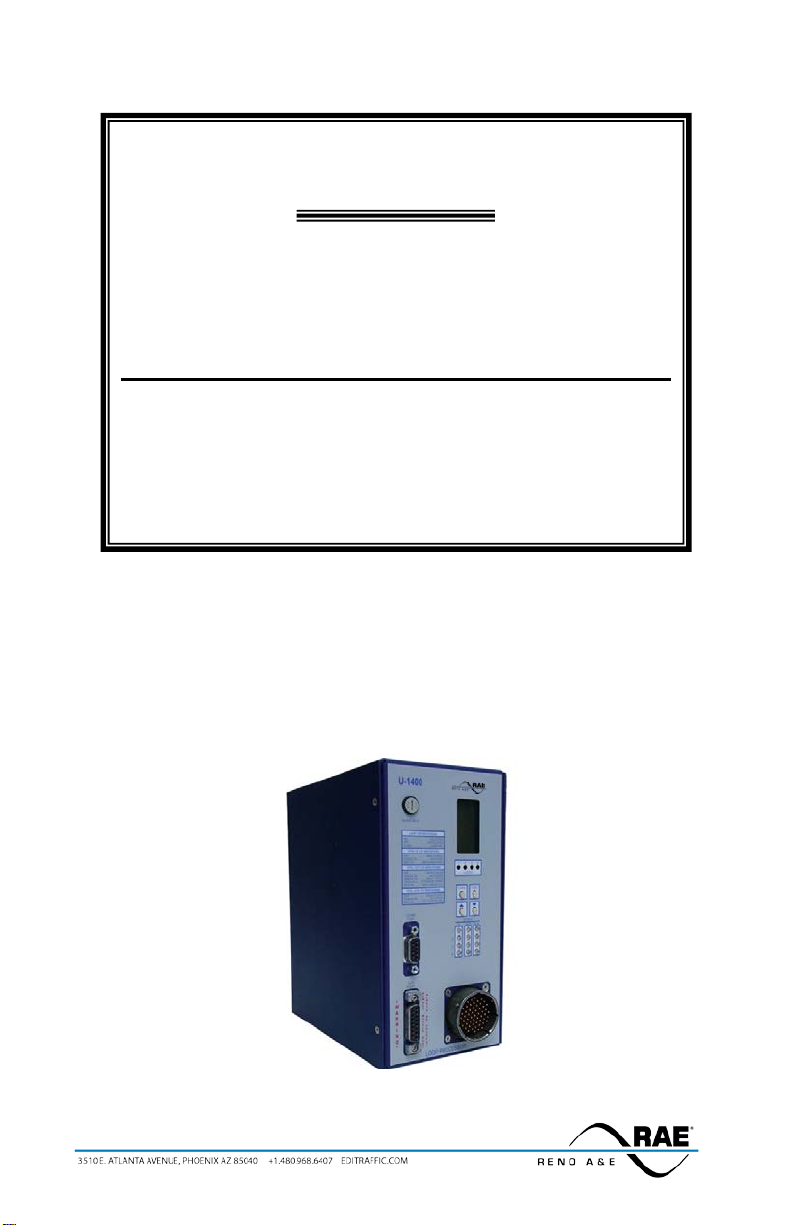

Reno A&E U-1400 Operations Manual

Model U-1400

Loop Detector

Firmware Version 3.07

Operations Manual

Four Channe l Menu Drive Programmable Inductive Loop Vehicle

Detector Designed for Railroad Applications

Four Loop Inputs, Eight Vital Outputs, and Four Vital Inputs

Built-in Loop Analyzer for Each Channel

This manual contains technical in formation for the

Model U-1400 Loop Detector

pn 889-2106-02 Revision: April 2020

THE FOLLOWING PRODUCT WAS DESIGNED, INSPECTED , TESTED AND

MANUFACTURED IN THE USA BY EBERLE DESIGN, INC. IN PHOENIX, ARIZONA.

INFORMATION CONTAINED HEREIN IS PROPR IETARY TECHNICAL INFORMATION OF

EBERLE DESIGN, INC. PUBLICATION, REPRODUCTION OR USE IN WHOLE OR PART IS

NOT PERMITTED EXCEPT UNDER TERMS AGREED UPON IN WRITING. ALL

REGISTERED TRADEMARKS OF EBERLE DESIGN INC. ARE UNDER

IT IS AN EBERLE DESIGN, INC. RECOMMENDATION THAT EACH UNIT BE TESTED

AT LEAST ANNUALLY TO ENSURE COMPLIANCE WIT H FACT O RY

SPECIFICATIONS AND MEETS PROPER OPERATIONAL STANDARDS. THE

RESULTS OF THIS TESTING WILL BE DOCU MEN TED.

© COPYRIGHT

MAINTENANCE NOTE

Model U-1400 Operations Manual

Table of Contents

Section 1 General Description .......................................................................................................... 1

Section 2 General Characteristics .................................................................................................... 2

2.1 Loop Frequency ..................................................................................................................... 2

2.2 Sensitivity .............................................................................................................................. 2

2.3 Option 1: Loop Inductance Display ....................................................................................... 2

2.4 Option 2: Loop Inductance -∆L/L Display ............................................................................. 2

2.5 Option 3: Noise Filter ............................................................................................................ 2

2.6 Option 4: Detection Zone Tracking ........................................................................................ 2

2.7 Option 5: Sensitivity Boost .................................................................................................... 3

2.8 Option 6: Audible Detect Signal ............................................................................................ 3

2.9 Loop Check ............................................................................................................................ 3

2.10 Detector ID .......................................................................................................................... 3

2.11 Option 7: Synch Feature....................................................................................................... 4

2.12 Primary Vital Output Delay ................................................................................................. 4

2.13 Primary Vital Output Extension ........................................................................................... 4

2.14 Input / O ut put Mapping ........................................................................................................ 4

2.15 Full Restore to Factory Default Settings .............................................................................. 4

2.16 Diagnostic Features Activation ............................................................................................ 4

Section 3 Specifications ..................................................................................................................... 5

3.1 Physical .................................................................................................................................. 5

3.2 Electrical ................................................................................................................................ 5

3.3 Operational ............................................................................................................................ 5

3.4 Table: Sensitivity, -∆L/L, and Response Time ....................................................................... 8

3.5 Table: Default Settings ........................................................................................................... 8

3.6 Table: Pin Assignments ......................................................................................................... 9

3.7 Table: Pin Assignments / Wire Colors ................................................................................. 11

Section 4 User In t erface .................................................................................................................. 12

Section 5 Installation and Set-Up ................................................................................................... 13

5.1 Initial Installation Start-Up Mod e Display Scr e ens .............................................................. 15

5.2 Program Mode Display Screens ........................................................................................... 17

5.2.1 Primary Vital Output Mapping Screens ..................................................................... 20

5.2.2 Auxiliary Vital Output Mapping Screens ................................................................... 23

5.3 Normal Mode Display Screens ............................................................................................ 27

5.4 Error Message Display Sc reens ............................................................................................ 28

5.5 Loop Check Pass / Fail Indications ...................................................................................... 30

5.6 Vital Input (VITAL IN) Status / Fail Indications ................................................................. 30

5.7 Primary Vital Output (VITAL OUT) Status / Fail Indications ............................................. 31

5.8 Auxiliary Vital Output (VITAL AUX) Status / Fail Indications .......................................... 31

5.9 Synch Fail Indications .......................................................................................................... 31

5.9.1 Series Synch Fail Indications ..................................................................................... 31

5.9.2 Parallel Synch Fail Indications ................................................................................... 31

5.10 Loop Fail Indications ......................................................................................................... 32

5.11 Setting Sensitivity Using the Bargraph .............................................................................. 32

5.12 Full Restore to Factory Default Settings ............................................................................ 33

5.13 Diagnostic Features Activation .......................................................................................... 33

5.14 Display Test ....................................................................................................................... 33

5.15 Changing or Reloca ting Detectors...................................................................................... 33

Section 6 Block Diagram ................................................................................................................ 34

Section 7 The o ry of Operati on ....................................................................................................... 35

Section 8 Maintenance and Troubleshooting ................................................................................ 36

8.1 Basic Troublshooting Tips ................................................................................................... 36

8.2 Things to Know About Loops .............................................................................................. 37

Section 1 General Description

This product manual was written for people installing, operating, a nd maintaining the Reno A&E Model U-1400

inductive loop vehicle detector. The Model U-1400 is a stand-alo ne , box type, four-channel inductive loop vehicle

detector. It is designed to be used in applications requiring detection of railway vehicles in large detection areas

typically required in classification yard switch and sideswipe protection, interlocking and moveable bridge

occupancy detection, or detection of roadway vehicles and/or railway vehicles in at-grade crossing sites.

The Model U-1400 monitors and processes signals from four loop / lead-in circuits, four check loop circuits, and

four Vital inputs. T hese inputs can b e progra mmed to control e ight Vital o utputs, four pr imary Vital o utputs and

four a uxili ary V ital o utp uts. Each o f the fou r pri mary V ita l outp uts c an be cont rolle d by a ny c ombi nat ion of the

four loop inputs and/or any combination of the four Vital inputs. In addit ion to the four loop inp uts and four Vital

inputs (as described above), the four auxiliary Vital outputs c an be controlled b y the four loop Hea lth Status inputs

that are continuously monitored b y t he processor. A loop failure will deactivate the Vital output that the loop

status input and/or loop Health Status input is programmed to control. The check loop circuits can be programmed

to simulate a vehicle detection (every 1 to 255 minutes) in the loop area as a means of verifying proper loop

operation. The Vital outp uts a nd Vita l inputs a re monitored to e nsure t hey are in t he correct s tate. If t he state o f a

Vital input is not correct, the front panel LED indicator corresponding to that input will tu rn red and all Vital

outputs will be deactivated. If the state of any Vital output is not correct, the front panel LED corresponding to

that output will turn red and all Vital outputs will be deactivated.

A Liquid Crystal Displa y (LCD), sixtee n LEDs, and fou r fr o nt pa ne l p us hb utt ons a re us ed to dis p la y and p ro gra m

all detector functions. The Model U-1400 also incorporates a series of front panel mounted connectors to facilitate

set-up and operation. A 55 pin circular connector is used for detector input and out put c onnec tio ns, a 15 p in Dsubminiature connector is used to allow connection of an external EEPROM memory module, and a nine pin RS232 connector is used for communication with a laptop computer.

The use of a LCD is one feature that distinguishes this detector from that of other ma nufacturers. It allows for

more information, never before a vailable, to be displayed to the user during normal operat ion of the detector.

Several diagnostic modes are available to aid the technic ian in troubleshooting detection proble ms. It also allows

easy viewing and setting of all programmable values in the detector. The detector cont inues to operate normally

while being programmed. An eight-segment bargraph at the top of the LCD provides a graphical representation of

the relative change of inductance as seen by the detector. This automatically takes into account loop size, loop

inductance, number of loops, number of turns, geometry, lead-in length, etc. The first bargraph segment represents

the minimum inductance change necessary for the detector to output a call. Larger inductance changes will be

indicated by more segments. Each additional segment represents the next sensitivity level exceeded. Therefore,

the bargraph indicates if t he sensitivit y is set too high or too low, easily facilitating t he ideal setting of sensit ivity

level.

All programmed settings are stored in non-volatile memory and can only be changed by programming new

settin gs. M emor y stor age c ons ists o f an i nter nal EE PROM and a n exte rna l EEPRO M memory module. Settin gs

programmed on either component must match those progra mmed on the ot her for the detector to operate. Loss o f

power or a detector reset will not change the programmed settings. I f a loop failure occurs, the LCD will display

the type of loop failure as L lo (for -25% change or shorted loop conditions) or L hi (for +25% change or open loop

conditions). Each loop failure is counted (up to a maximum of 255 failures) and accu mulated in the Loop Failure

Memor y. I nfor matio n on t he number of failures since the last detector reset or power interruption is very useful

during analysis of problems due to intermittent loop operation.

The Model U-1400 detector is a scanning detector. The scanning operation sequentially activates the ON and OFF

cycle of each detector channel’s oscillator. Because only one channel’s input loop(s) is (are) active at a given time,

crosstalk between adjacent loops connected to t he same scanning detector is minimize d. Several Model U-1400

detectors can be linked together via the Synch In and Synch Out lines. This allows loops connected to different

detectors to be scanned in series or para llel . When in Progra m Mode, the Mode l U-1400 detector displays the real

time lo op fre que ncy r ead ing fo r eac h cha nnel. The eight frequency levels can be incremented or decremented to

provide precise frequency settings. This re moves the guesswork when changing frequency sett ings to eliminate

crosstalk. NOTE: Adjacent loops connected to different channels of a non-scanning detector or different sca nning

detectors should be set to different frequencies with the maximum separation possible.

The Reno A&E Model U-1400 utilize s the first major innovat ion in inductive loop det ectors since the intro duction

of digital detectors. The programming of all of the detector’s para meters with four normally open pushbutton

switches not only simplifies setup by removing binary coded rotary or DIP switches, but also increases the

reliability of the detector by removing t he dependence on switch co ntacts during normal op eration. The deta iled

descriptions displayed on the LCD eliminate the interpretation of numerous LED flash rates to determine the

detector status.

889-2106-02 Model U-1400 Operations Manual Rev Apr 2020 Page 1 of 37

Section 2 General Characteristics

2.1 LOOP FREQUENCY

There are eight selectable loop frequency settings (normally in the range of 20 to 100 kilohertz ) per loop input.

The actual loop operating frequency is a function of the loop / lead-in network and the components of the loop

oscillator circuit. The digital display of t he actual loop operating frequency for each setting makes it easy to

quickly identify and elimina te crosstalk in the most difficult to configure installations. The freque ncy display is

typically very stable when the loop is vacant and vehicles are not passing close to the loops. If the reading is

varying by more than ±1 in the last digit, this is an indication of possible crosstalk between loops.

2.2 SENSITIVITY

There are ten selectable sensitivit y levels per loop input, plus Continuous-Call a nd Loop-Off. The sensiti vity

levels are designed so that a one level increase actually doubles the sensitivity and a one level decrease halves the

sensitivity. A unique bargraph displayed on the LCD makes it easy to quickly set sensitivity at the ideal level for

any loop / lead-in network situation. (See Section 3.4 for actual detection levels at each sensitivity level.)

C

ONTINUOUS-CALL: When set to the Co ntinuous-Call state, the Loop Status is continuo usly in the Call state

regardless of the presence or absence of vehicles over the loop. If the Loop Status Input is assigned to a Vital

Output , the Cont inuo us-Call state w ill deactivate the V ital Output. The loop oscilla tor is disa bled when in the

Continuous-Call State. This state is indicated by Call flashing on the LCD. This option can be selected from

the Sensitivity menu in Progra m Mode a nd is useful for checking contro ller response and other t roubleshooting

activities.

L

OOP-OFF: When set to the Loop-Off state, the Loop Status is cont inuously in the No -Call state regardless of

the presence or absence of vehicles over the loop. If the Loop Status Input is assigned to a Vital Output, the

Loop-Off state will not affect the Vital Output. The loop oscillator is disabled when in the Loop-Off State. This

state is indicated by OFF flashing on the LCD. This option can be selected from the Sensitivity menu in

Program Mode and is useful for checking controller response and other troubleshooting act ivit ies.

2.3 OPTION 1: LOOP INDUCTANCE DISPLAY

The Loo p I nd uc ta nce D isplay setting can be toggled ON or OFF by momenta r il y p r es s i ng either the (UP) or

(DOWN) pus hbu tto n. W hen t his opt io n is enab led ( ON), the LCD d isp lays the tot al loop ind ucta nce (ac tua l lo op

inductance plus actual lead-in inducta nce) in microhe nries for loop inductance values in the range of 20 to 2500

microhenries. By recording the inductance of the loop / lead-in circuit when it is first installed, the actual

inductance can be compared to the expected inductance to help identify defective loop / lead-in circuits. Loop /

lead-in inductance can be easily estimated using the simple formulas included in Section 8.2 of this manual.

NOTE: Enabling this option activates it for a ll loop inputs. T his opt ion is a utomatically d isabled 15 minutes a fter

activation or on loss of power.

2.4 OPTION 2: LOOP INDUCTANCE -∆L/L DISPLAY

The Loop Inductance -ΔL/L Display setting can be toggled ON or OFF by mo mentar ily pres sing eit her the

(UP) or (DOWN) pushbutton. When this option is enabled (ON), the LCD displays the percentage of

induct ance cha nge (-ΔL/L value) during the Ca ll state. To facilitate the viewing of the maximum amount of

change in the -ΔL/ L value while traffic is in motion over the detection zone, the channel holds the peak -ΔL/L

value for a period of two seconds. NOTE: Enabling this option act ivates it for all loop inputs. This option is

automatically disabled 15 minutes after activation or on loss of power.

2.5 OPTION 3: NOISE FILTER

Each loop input’s Option 3 has four settings ranging from 3.00 to 3. 03. When Optio n 3 is set to 3.00, the option is

disab led (OFF), a nd normal noise filtering is used. W hen Option 3 is set to 3.01, 3.02, or 3.03 the option is ON,

and increased filtering of the loop signa l is used to eliminate problems assoc iated with particular types of noise.

Turning this option ON when not required can degrade the performance of the detector. The default setting o f t his

option is 3.00 (OFF). This option s h ould only be turned ON at the advice of Reno A&E. NOTE: Each loop ca n

be enabled independently.

3.00 = 250 milliseconds filter.

3.01 = 1 second filter.

3.02 = 2 seconds filter.

3.03 = 10 seconds filter.

2.6 OPTION 4: DETECTION ZONE TRACKING

Each loop input’s Option 4 has eight settings ranging from 4.00 to 4.07. T his option allows the user to select a

detection zone tracking setting that will maintain detection zone occupancy for an extended period of time. When

889-2106-02 Model U-1400 Operations Manual Rev Apr 2020 Page 2 of 37

Option 4 is set to 4.00, the detector will track out the vehicle (i.e. drop the detectio n of the vehicle) in four minutes

to several hours depending on the amount of inductance change (-ΔL/L) caused by the vehicle when it is detected.

The greater the change caused by the vehicle, the longer the time needed to track out the vehicle. When Option 4

is set to 4.01, 4.02, 4.03, 4.04, 4.05, 4.06, or 4.07 t he option is ON, and the detector will provide extended

detection times.

There are many factors that influence the proper setting of this option. A full explanat io n of how to d et er mine t he

correct setting is beyond the scope of this manual. Contact a Technical Support representative at Reno A&E

regarding proper setting of this option.

NOTE: Using this option in a long loop application is not r ecommended. The detector will drop the c all prior to

the vehicle totally exiting the loop.

4.00 = Tracking Rate 0.

4.01 = Tracking Rate 1.

4.02 = Tracking Rate 2.

4.03 = Tracking Rate 3.

4.04 = Tracking Rate 4.

4.05 = Tracking Rate 5.

4.06 = Tracking Rate 6.

4.07 Tracking Rate 7.

2.7 OPTION 5: SENSITIVITY BOOST

Each loop input’s Option 5 has five settings ranging from 5. 00 to 5.04. W hen Optio n 5 is set to 5. 00, the opt ion is

disab led (OFF), a nd no sensitivity boost is added. W hen Option 5 is set to 5.01, 5.02, 5.03, or 5.04 the option is

ON, and sensitivity boost is enabled. A fter detect ion, the se nsitivity is boosted to t he currently se lected se nsitivit y

level plus th e n umbe r o f le ve l(s) se lect ed. T he ma xi mum s e nsit ivi ty leve l w hic h ca n b e ob ta ined wit h or wi tho ut

sensitivity boost is level 10.

5.00 = Off (no sensitivity boost).

5.01 = 1 level of sensitivity boost.

5.02 = 2 levels of sensitivity boost.

5.03 = 3 levels of sensitivity boost.

5.04 = 4 levels of sensitivity boost.

2.8 OPTION 6: AUDIBLE DETE CT SIGNAL

Each loop input’s Audib le Detect Signa l setting can be toggled ON or OFF by mome nta ri ly p res s in g e ithe r t he

(UP) or (DOWN) pus hbutton. Only one loop input can be turned ON at a t ime. Turning this option ON for one

loop i nput auto matica lly turns it OFF for the other loop inputs. When this option is enabled (ON), an audi ble

signal will be activated whenever the detection zone for the selected loop input is occupied. The audible signal

indicates actual occupancy of the loop detection zone. This feature allows a technician to watch the detection zo ne

and confirm correct detector operation without having to look at the detector disp lay as well. NOTE: This option

is automatically disabled 15 minutes after activation or on loss of power.

2.9 LOOP CHECK

The Loop C heck feature provides a means of automatically verifying the proper operation of each loop circuit.

The Loop Check Timer can be set for an interval ranging from 0 to 255 minutes in one-minute incre ments. A

setting of 000 indicates that the Loop Check feature is off.

2.10 DETECTOR ID

This feature is used in conjunction with the Synch feature (Option 7) and is also used as a means of providing each

detector with a unique identification signature for communication purposes. Detector ID settings can range from

000 to 255. If, however, t he detec tor is set to an ID value of 255, it is co ns idered to be in an uninitialized state a nd

the detector will not save any power down data. When a detector with an ID setting of 255 is powered up, the

LCD will alternate between id and 255 until the ID setting is changed to so mething other than 255 and the new

setting is saved in detector memor y. Whe n a ny detecto r is first initialized, its ID setting is, by default, 255.

889-2106-02 Model U-1400 Operations Manual Rev Apr 2020 Page 3 of 37

2.11 OPTION 7: SYNCH FEATURE

This option provides a means of linking together up to four (4) U-1400 detectors. Each detector’s Option 7 has

three settings ranging from 7.00 to 7.02. T here are two modes of Synch, Ser ies Synch and Para llel Synch. W hen

set to operate in Series Synch mode, one detector channel in the entire detector system is active at any given time.

This has the advantage of mini mizing crosstalk between adjacent loops co nnected to different U-1400 detectors.

When set to operate in Parallel Synch mode, all detectors scan their respective channel 1, 2, 3, or 4 inputs at the

same time. Parallel Synch offers a faster response time than Series Synch, however the potential for crosstalk is

greater.

7.00 = Off.

7.01 = Series Synch.

7.02 = Parallel Synch.

NOTE: When operating in either Series or Parallel Synch mode, all linked detectors m ust have Option 7 set to the

same setting.

2.12 PRIMARY VITAL OUTPUT DELAY

Each Primary Vital Output can be conditioned with a Delay time that is adjustable from 0.0 to 25.5 seconds in 0.1second steps. Primary Vital O utput Delay time starts counting down when a Call state is received from the Loop

Status Input or Vital Input that is mapped to the Primary Vital Output. When the timer reaches zero, the Primary

Vital Output is deactivated. Primary V ital Output Delay does not condition the Auxili ary V ital Outputs.

2.13 PRIMARY VITAL OUTPUT EXTENSION

Each Primary Vital Output can be conditione d with an Extension time that is adjustable fr om 0.0 to 25.5 seconds i n

0.1-second steps. Primary V ital Output Extension t ime starts c ounting down when a Call state is cleared from the

Loop Status Input or Vital Input that is mapped to t he Primary Vital Output. The Primary Vital Output will remain

off until the Extension time reaches zero. Any vehicle enter ing the loop detect ion zone during the Exte ns ion t ime

period causes the Primary Vital Output to remain in the off state, and later, when the last vehicle clears the loop

detection zone, the full Primary Vital Output Extension time starts co unting down again. Primar y Vital Output

Extension does not co ndition the Auxiliary Vital Outputs.

2.14 INPUT / OUTPUT MAPPING

The Loop Status Inputs a nd/o r Vital Inputs can be assigned to one or more of the Primary Vita l a nd Auxiliary Vital

Outputs. Health Status can only be mapped to the Auxiliary Vital Outputs.

2.15 FULL RESTORE TO FACTORY DEFAULT SETTINGS

Pressi ng all four fr ont pa nel pus hbutt on sw itches simult aneo usly a nd con tinuo usly f or five (5) se conds reset s the

detector and restores all the factory default settings. The countdown of the five second period is displayed on the

LCD. Releasing any of the switc hes before the countdown e nds aborts the Full Restore ope ration. (See Section

3.5 for default settings). NOTE: A factory default reset will clear any previously mapped output(s).

2.16 DIAGNOSTIC FEATURES ACTIVATION

When the detector is operating in normal mode, pressing either the (UP) or (DOWN) pushb utton will

temporarily activate Option 1 (Loop Inductance Display) and Opt ion 2 (Loop Inductance -ΔL/L Display) for all

loop inputs and Option 6 (Audib le Detect S ignal) for the loop input ind icated in the lower port io n of the LCD. All

three of these diagnostic options will remain active for 15 minutes.

889-2106-02 Model U-1400 Operations Manual Rev Apr 2020 Page 4 of 37

Section 3 Specifications

3.1 PHYSICAL

WEIGHT: 2.73 lb (43.6 oz) (1236 gm).

S

IZE: 7.65 inches (19.43 cm) high x 3.90 inches (9.91 cm) wide x 7.13 inches (18.11 cm) deep including

connectors.

O

PERATING TEMPERATURE: -40°F to +180°F (-40°C to +82°C).

C

IRCUIT BOARD: Printed circuit boards are 0.062 inch thick FR4 material with 2 oz. copper on both sides and

plated through holes.

C

ONNECTORS:

P

RIMARY INTERFACE CONNECTOR: MS type, 55 Pin, Circular, Male, 71-570128-55M.

AUX

PORT CONNECTOR: DB-15, 15 pin, right angle, PC Board mount, metal shell, D subminiature receptac le

with gold plated female contacts and latching blocks.

COMM

PORT CONNECTOR: DB-9, nine pin, right angle, PC Board mount, metal shell, D subminiature

receptacle with gold plated female contacts and nuts for retaining screws.

3.2 ELECTRICAL

POWER: 9.5 to 18 VDC, 3.0 Amps maximum.

F

USE: 3 amp, 3AG type (Slo-Blow) type located in a fuse holder mounted on the front panel.

P

OWER DOWN: W he n the DC voltage drops below the low power detection threshold (7.8 VDC), the detector will

save all needed information to hold calls thro ugh the power down seque nce. Upon power res toration (a minimu m

of 9.0 VDC), the detector will use this saved data to determine the correct occupancy state of all loops.

L

OOP FEEDER LENGTH: Up to 1500 feet (450 m) maximum with proper feeder cable and appropriate loops.

L

OOP INDUCTANCE RANGE: 20 to 2500 micro Henries w ith a Q factor of 5 or greater.

L

OOP INPUTS: Transformer isolated. The minimum capacitance added by the detector is 0.068 microFarad.

L

IGHTNING PROTECTION: The detector can tolerate, without damage, a 10 microFarad capacitor charged to 2,000

volts being discharged directly into the loop input terminals, or a 10 microFarad capacitor charged to 2,000 volts

being d ischar ged between either loop termina l and earth ground.

R

ESET: Application of a 30 millisecond low state (relative to +12 VDC) to Pin Z of the primary interface

connector resets all loops. Each loop input channel can be manually reset by selecting the loop input channel then

press ing and hold ing the front p anel CHAN pushb utto n for t hree se conds, or by c hangi ng the s ensit ivit y or loo p

frequency of t he loop input channel.

S

YNCHRONIZE SCAN CONTROL: The SYNCH IN inp ut a nd SYNCH OUT output allow the loops from different

detectors to be scanned seq uentially, either in series or parallel. This feature can be used to eliminate crosstalk

between adjacent loops connected to different U-1400 detectors. NOTE: Response times will vary depending on

the number of detectors (up to a maximum of four) on the Synch Line. (See Section 3.4.)

V

ITAL OUTPUTS: T he Pr imar y and Auxilia r y Vital Outputs are transformer isolated and are capable of sourcing 200

mA at 12 VDC. Opto-isolated circ uitry verifies t hat the Vital Ou tput is in the des ired state. If either Vital Outp ut

fails its self-check, both of the detector’s Vital Outputs will be deactivated.

V

ITAL INPUTS: 12 volt inputs isolated from the detector. Opto-isolated c ircuitry verifies t hat the Vital Inputs are

operational.

C

HECK LOOP RELAYS: Contacts rated for 6.0 Amps maximum, 150 VDC, 300 V AC, and 500 VA maximum

switched power.

3.3 OPERATIONAL

LOOP STATUS INDICATORS: Eac h loop input has a s uper high intens ity red light emitt ing diode ( LED) to ind icate a

Call (vehicle detected over loop) or failed loop.

889-2106-02 Model U-1400 Operations Manual Rev Apr 2020 Page 5 of 37

INPUT / OUTPUT INDICATORS: The detector has three dual color (green / red) LEDs to indicate the following:

VITAL IN LED Status Meaning

OFF Vital Input is deactivated (low voltage level).

ON (GREEN) Vital Input is activated (high volta ge leve l).

ON (RED) Vital Input has failed its self-check (Vital Input, Primary Vital

Output, and Auxiliary Vital Outp ut reve rt to OFF state).

VITAL OUT LED Status Meaning

OFF Primary Vital Output is deactivated (low voltage level).

ON (GREEN) Primary Vital Output is activated (high voltage level).

2Hz FLASHING (GREEN) Timing Delay act ivated and Primary Vital Output is wo rking

(high voltage level until delay ti mes out).

5Hz FLASHING (GREEN) Timing Extension activated and Primary Vital Output is

worki ng (low voltage level until extension t imes out) .

ON (RED) Primary Vital Output has failed its self-check (Vital Input,

Primary Vital Output, and A uxilia ry Vita l Outp ut reve rt to O FF

state).

VITAL AUX LED Status Meaning

OFF Auxiliary Vital Output is deact ivated ( low voltage level).

ON (GREEN) Auxiliary Vital Output is activated (high voltage level).

ON (RED) Auxiliary Vital Output has failed its self-check (Vital Input,

Primary Vital Output, and A uxilia ry Vita l Outp ut reve rt to O FF

state).

R

ESPONSE TIME: See Section 3.4 for response times.

S

ELF-TUNING: Eac h loop circuit tunes and is operational within two seconds after a pplication of power or after

being reset. Full sensitivity and hold time require 30 seconds of operation.

E

NVIRONMENTAL & TRACKING: The detector is fully self-compensating for environmenta l changes and loop drift

over t he full te mperature range and the entire loop inductance r ange.

G

ROUNDED LOOP OPERATION: The loop is olation transformer allows operation with poor qualit y loops (which may

include one short to ground at a single point).

L

OOP (FAIL) MONITOR: If the tota l ind ucta nce o f a channel’s loop input network goes out of the range spec ified for

the detector, or rapidly changes by more t han ±25%, and the Loop and/or Healt h status outputs are mapped, the

Loop and/or Health status outputs will immedia tely enter Fail-Safe mo de a nd t he LC D wi ll d isp lay LOOP F AIL.

The type of loop failure will a lso be displayed as L lo (for -25% change or shorted loop conditions) or L hi (for

+25% change or open loop conditions). T his will continue as long as t he loop fault exists. At the time of a loop

failure, the Loop status LED will begin to flash at a rate of three flashes per sec ond. The LED will continue this

display pattern until the loop input channel is manually reset or power is re moved. If the loop self-hea ls, the

LOOP FAIL message on the LCD will extinguish a nd the loop input channel will resume operation in a normal

manner; except the Loop stat us LED will continue the three flas hes per second display patter n, thus provid ing an

alert that a prior Loop Fail conditio n has occurred. Each loop failure for the loop input channel is counted and

accumulated into the Loop Fail Memory. The total number of loop failures written into the Loop Fail Memory

(since the last power interruption or manual reset) can be seen by stepping through the loop input channel’s

detector functions in Program Mode to the LOOP FAIL mes sage. Whe n the status of one or more loops is

assigned to a Vital Outp ut, a loop failure will deactivate t he Vital Output and the correspo nding VITAL OUT

LED will turn from green to OFF to ind icate the failure. W hen a Health Status is assigned to a n Auxiliary Vital

Output, a loop failure will deactivate the Auxiliary V ital Output and the corresponding VITAL AUX LED w ill

turn off.

L

OOP CHECK: This feature is used as a means of verifying proper operation of each inductive loop connected to a

detector. In a typical installation, a separate loop of wire called a check loop will be wound around the perimeter

of each inductive loop. The Loop Check Timer can be programmed with a value ranging from 1 to 255 minutes.

Once this time interval has elapsed, the detector will automatically short the check loop simulating vehicle

detection in the induct ive loop. If this initial loop check test fails, t he detector will enter a verification mode to

make certain that the loop failure is indeed due to a loop related problem. While operating in this verification

mode, the detector will perform a series of ten verification tests and the LCD will flash Pcl. If the te n l oo p c hec k

verification tests all fail, the Vital Output(s) to which the Loop Status Input (s) and/or Health Status Input(s) is (are)

mapped will be deactivated. The loop check test will be repeated at regular intervals depending on the value

programmed into the Loop Check Timer. The Vital Output(s) to which the Loop Status Input(s) and/or Hea lth

Status Input(s) is (are) mapped will not be activated until the problem with the check loop is corrected and the

channel reset or until the Loop Check function is turned off. During a check loop failure the LCD will flash Lcl.

NOTE: If the Loop Check Timer is set to 0 minutes, the Loop Check function is off.

889-2106-02 Model U-1400 Operations Manual Rev Apr 2020 Page 6 of 37

(ID 000)

Synch

Out

Synch

In

Detector

2

Detector

Detector

4

Synch

In

Synch

Out

Synch

In

Synch

Out

Synch

In

Synch

Out

Reset

Reset

Reset

Reset + - + - + - + -

Series Synch Connections

Detector

(ID 000)

Synch

Out

Synch

In

Detector

2

Detector

3

Detector

4

Synch

In

Synch

Out

Synch

In

Synch

Out

Synch

In

Reset

Reset

Reset

Reset

+ - + - + - +

-

Synch

Out

Parallel Synch

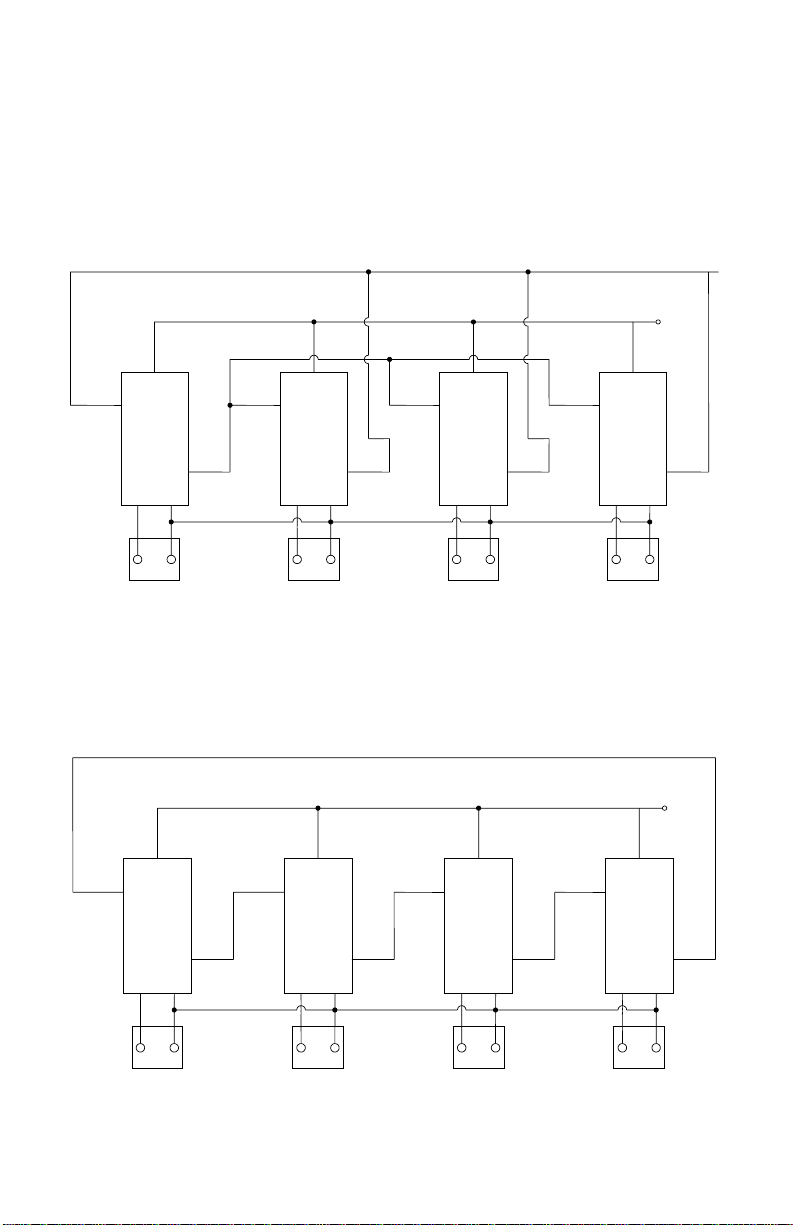

SYNCH MODE: The Synch feature provides a means of linking up to four U-1400 detectors together. There are two

modes in which the detectors can be configured to operate, Series Synch or Parallel Synch.

Series Synch mode can be used to eliminate the possibility of crosstalk between adjacent loops. Series Synch will

activate one loop at a time, c ycling through all loops config ured to detect in the Series Synch mode. When the

detector system is configured to operate in Series Synch mode, it is necessary for one detector to be identified as

the master unit, i.e. the detector that starts the Synch pulse. This master unit must be assigned a Detector ID value

of 000. The scanning sequence of detector loop input channels is Detector ID 000 channel 1, Detector ID 000

channel 2, Detector ID 000 channel 3, Detector ID 000 channel 4, second detector channel 1, second detector

channel 2, second detector channel 3, second dete ctor channe l 4, a nd so on until the s ynch p ulse re tu rns to t he first

detector. The Synch-out of the first (master) unit is connected to the Synch-in of the second detector; the Synchout of the second detector is connected to the Synch-in of the third detector. This connection scheme is continued

until the Synch-out of the last detector is connected to the Synch in of the first (master) detector.

When set to operate in Parallel Synch mode, all detectors configured to operate in Parallel Synch mode start

scanning their respective channel 1 loop inputs at the same time and then proceed to sequentially scan their

respective channel 2, 3, and 4 loop inputs. When the detector system is co nfigured to operate in Parallel Synch

mode, it is necessary for one detector to be identified as the master unit. This master unit must be assigned a

Detector ID value of 000. Connections between detectors d iffer fro m those in Se ries Sync h mode in t hat the

Synch-out o f first detector is connected to the Synch-in o f the other detec t o r s a nd t he S y nc h-in of the first detector

is connected to the Synch-out of the other detectors.

889-2106-02 Model U-1400 Operations Manual Rev Apr 2020 Page 7 of 37

Loading...

Loading...