Page 1

T - 210 Series

Two Channel Shelf Mount Detector

• Meets and exceeds NEMA TS 1 specication.

• Six front panel DIP switches for each channel provide:

• Seven levels of sensitivity plus off.

• Presence or Pulse mode.

• Four loop frequencies.

• Loops are sequentially scanned to eliminate crosstalk.

• Loop Fail Event Monitor remembers and indicates intermittent and

current loop failures.

• Detector is self tuning and provides complete environmental

®

tracking.

• Dual color, high intensity LED:

• Green indicates detect.

• Red indicates loop fail.

• Complete built-in detector integrity test.

• Space provided on front panel to label detector.

• Audible detect signal (buzzer) facilitates loop and/or detector

With Audible Detect Signal

troubleshooting.

• Call Delay and Call Extension timing.

Ordering Information:

Model T-210-R Two channel detector with Relay Outputs, Call Delay, and Call Extension

Model T-210-SS Two channel detector with Solid State Outputs, Call Delay, and Call Extension

The Model T-210 series is designed to meet or exceed NEMA Standards TS 1-1989. Model T-210 Detectors are

two channel, shelf mount type loop detectors with Delay and Extension timing. Individual channel detect and

loop fail indications are provided via two dual color, high intensity LEDs. Available with both Relay and Solid

State outputs, the Model T-210 series offers advanced multiple channel detection capabilities in a compact

package.

3510 E. ATLANTA AVENUE, PHOENIX AZ 85040 +1.480.968.6407 EDITRAFFIC.COM

Page 2

T-210 Series Specications

This is a Performance Specication. It is not intended to be used as Operating Instructions.

Loop Frequency: Each channel has four (4) DIP switch selectable loop frequencies (normally in the

range of 20 to 100 kilohertz) that are a function of the actual loop / lead-in network.

Sensitivity: Seven (7) sensitivity levels (plus off) are available for each channel. The eight settings are

selectable using three (3) front panel mounted DIP switches. Each of the seven sensitivity levels are

binary encoded from 1 to 7 (lowest to highest sensitivity). A setting of 0 turns the channel off. The

sensitivity level selected determines the percentage of negative inductance change of the loop circuit

required for a CALL output signal. See SENSITIVITY, -∆L/L, & RESPONSE TIME table.

Presence / Pulse Mode: Each channel can be independently set to operate in one of two modes by

means of front panel mounted DIP switches.

Presence Mode: Call hold time is a minimum of four minutes regardless of vehicle size, and is typically

one to three hours for an automobile or truck.

Pulse Mode: A pulse of 125 ±10 milliseconds duration is generated for each vehicle entering the loop

detection zone. Each vehicle detected is instantly tuned out if it remains in the loop detection zone

longer than two seconds. This feature allows detection of vehicles subsequently entering the detection

zone. After each vehicle leaves the loop detection zone, the channel resumes full detection sensitivity

within one second. Changing the setting of the Presence / Pulse Mode switch will RESET the channel.

Call Delay: Each channel’s Call Delay is adjustable from 0 to 63 seconds in one-second steps by means

of six (6) front panel mounted DIP switches. Call Delay time starts counting down when a vehicle rst

enters the loop detection zone. If the Delay feature is activated, the output will only be turned on after

the selected delay time has passed with a vehicle continuously present in the loop detection area. If

a vehicle leaves the loop detection area during the delay interval, detection is aborted and the next

vehicle to enter the loop detection area will initiate a new full delay interval. The detector indicates that

a vehicle is being detected but that the outputs are being delayed by ashing the channel’s Detect / Fail

LED (green) at four Hz with a 50% duty cycle.

Call Extension: Each channel’s Call Extension is adjustable from 0 to 15.75 seconds in 1/4-second

steps by means of six (6) front panel mounted DIP switches. Call Extension time starts counting down

when the last vehicle leaves the loop detection zone. In the event a vehicle enters the loop detection

zone before the extension time expires, the detector will return to the detect state (regardless of the

setting of the delay timer) and the extension timer will be reset. When the last vehicle leaves the loop

detection zone, full Extension time is reestablished and the detector begins counting down again. The

detector will indicate that the extension interval is currently timing by ashing the channel’s Detect /

Fail LED (green) at 16 Hz with a 50% duty cycle.

Audible Detect Signal: A front panel mounted push button is used to enable an audible detect signal

that is emitted any time a given channel’s detection zone is occupied.

Detect / Fail Indicator: Each channel has a super bright, high intensity, dual color (Red / Green) LED

that indicates a Call output and/or the status of any current or prior loop fault condition for that channel.

A continuous ON (green) state indicates a CALL output. A continuous ON (red) state indicates that a

current open loop failure condition or an inductance change condition of greater than +25% condition

exists. This indication is also generates a CALL output. A one Hz (red) ash rate indicates that a current

shorted loop failure condition or an inductance change condition of greater than -25% condition exists.

This indication is also generates a CALL output. A ash rate of three 50 millisecond (red) pulses

indicates a prior loop failure condition. A ash rate of three 50 millisecond (red) pulses followed by a

750 millisecond (green) pulse indicates a prior loop failure condition and a current CALL output (detect

state). If the audible detect signal is activated, any detect indication that would normally be displayed

as green will be displayed as orange.

Loop Fail (Event) Monitor: If the total inductance of a channel’s loop input network goes out of the

range specied for the detector, or rapidly changes by more than ±25%, the affected channel will

immediately enter the Fail-Safe mode of operation. Fail-Safe operation generates a continuous call

output in Presence or Pulse mode. The channel’s Detect / Fail LED will provide an indication of the type

of loop failure (see Detect / Fail Indicator, above) and will continue to do so as long as the loop fault

exists. If the loop self-heals, the channel will resume operation in a normal manner, but the Detect / Fail

LED of the channel will begin to ash at a rate of three ashes per second (red) as a means of indicating

a prior Loop Fail condition. The Detect / Fail LED will continue its indication of a prior loop failure until

the detector channel is reset, the detector is reset, or power is removed.

Loop Inductance Range: 20 to 2000 microhenries with a Q factor of 5 or greater.

Loop Feeder Length: Up to 5000 feet (1500m) maximum with proper feeder cable and appropriate

loops.

Loop Input: Transformer isolated. The minimum capacitance added by the detector is 0.068 microfarad.

Scanning: The loop(s) connected to each detector channel are activated alternately to minimize

crosstalk between adjacent loops connected to the same detector.

Lightning Protection: The detector can tolerate, without damage, a 10 microfarad capacitor charged

to 2,000 volts being discharged directly into the loop input terminals, or a 10 microfarad capacitor

charged to 2,000 volts being discharged between either loop terminal and earth (chassis) ground.

Detector Reset: Changing the position of either channel’s DIP switches (except the Frequency

switches or Call Delay / Call Extension switches) will reset that detector channel. Pressing the front

panel mounted reset switch will reset the detector. Reapplication of power after a power loss will

also cause the detector to reset. After changing either channel’s Frequency selection switches (DIP

switches 1 & 2), the channel will require a reset.

Phase Green Inputs: Also known as Delay Inhibit inputs. Meets or exceeds NEMA TS 1 requirements.

The application of an ON state voltage (75 to 130 VAC) to the Phase Green Input pin (Pin J) of the

Channel 1 or Channel 2 connector will cause that channel’s delay timer to abort its delay timing function.

Solid State Outputs: Optically isolated. 30 VDC max. collector (drain) to emitter (source). 100 mA max.

saturation current. 2 VDC max. transistor saturation voltage. The output is protected with a 33-volt

Zener diode connected between the collector (drain) and emitter (source).

Relay Outputs: The relay contacts are rated for 6 Amps max., 150 VDC max., and 180 Watts max.

switched power.

Response Time: The response time of any channel is 65 ± 25 milliseconds regardless of the

sensitivity level setting. See SENSITIVITY, - ∆L/L, & RESPONSE TIME table.

Self Tuning: The detector automatically self tunes and is operational within two seconds after

application of power or after being reset. Full sensitivit y and hold time requires 30 seconds of

operation.

Environmental & Tracking: The detector is fully self-compensating for environmental changes and

loop drift over the full temperature range and the entire loop inductance range.

Grounded Loop Operation: The loop isolation transformer allows operation with poor quality

loops (which may include one short to ground at a single point).

Detect Outputs: A detection output (CALL) is indicated by a closed relay contact (Relay output)

or a conducting state (Solid State output). A channel’s output defaults to a CALL state for any loop

failure condition on that channel or upon loss of power.

Test Mode: A PCB mounted jumper enables Test Mode. Test Mode provides a means of verifying

proper operation of the detector’s controls and indicators (switches and LEDs). Each channel’s

loop oscillator circuit is also checked to verify the correct frequency in each of the four frequency

settings. The frequency portion of testing requires that each channel be connected to a 100

microhenry loop; if other inductance values are used, the frequency test results will be invalid.

Weight: 27 oz (765.5 gm).

Size: 6.45 inches (16.38 cm) high x 2.50 inches (6.35 cm) wide x 6.35 inches (16.13 cm) deep

(excluding connector). Connector adds .675 inches (1.71 cm) to depth measurement.

Operating Temperature: -40ºF to +180ºF (-40ºC to +82ºC).

Circuit Board: Printed circuit boards are 0.062 inch thick FR4 material with 2 oz. copper on

both sides and plated through holes. Circuit boards and components are conformal coated with

polyurethane.

Connectors: Two (2) MS 3102A-18-1P 10 pin male. See PIN ASSIGNMENTS table.

Power: 89 to 135 VAC, 50/60 Hz, 6 Watts max.

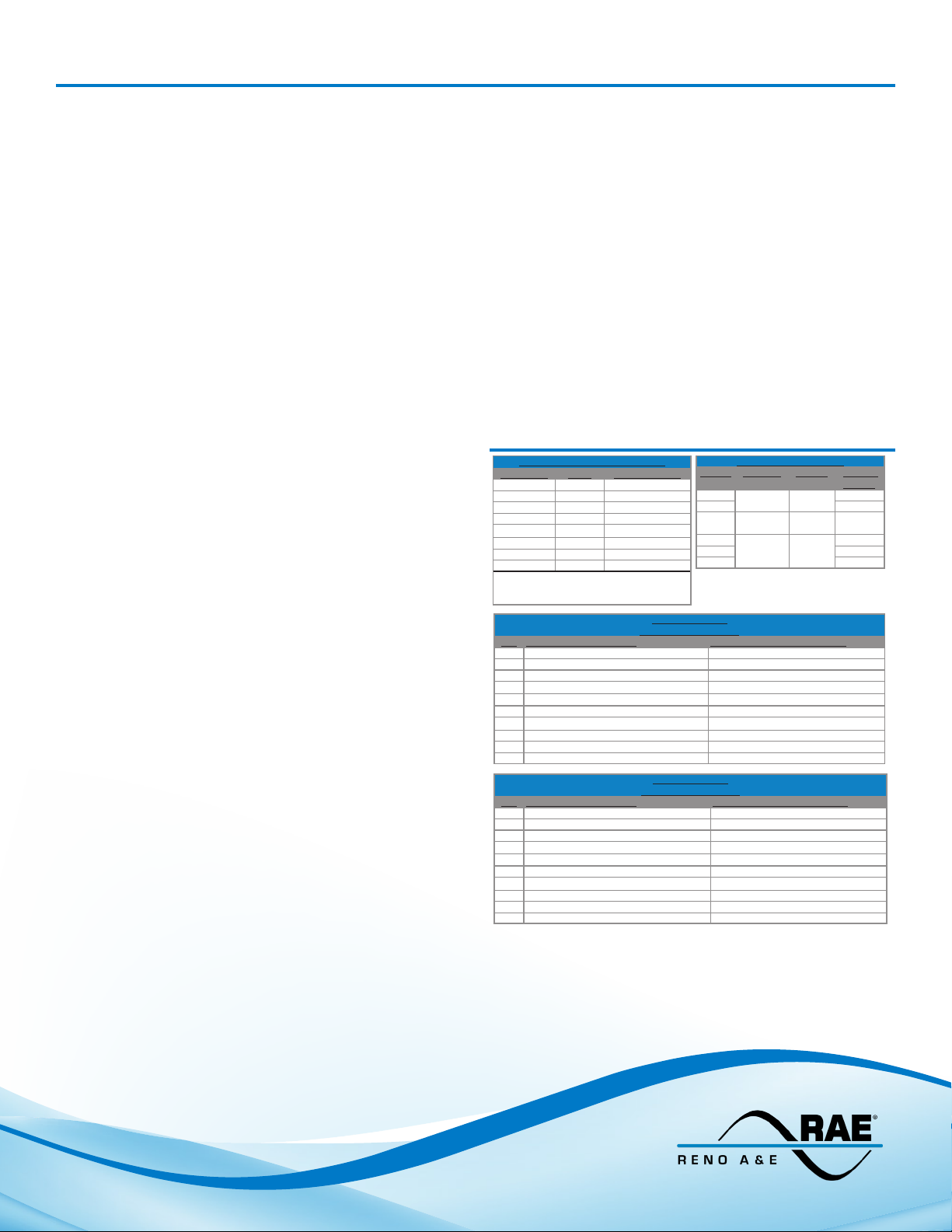

Sensitivity, -∆L/L, Response Time

Sensitivity -∆L/L Response Time

0 OFF N/A

1 0.64% 65 +/- 25 ms

2 0.32% 65 +/- 25 ms

3 0.16% 65 +/- 25 ms

4 0.08% 65 +/- 25 ms

5 0.04% 65 +/- 25 ms

6* 0.02%* 65 +/- 25 ms*

7 0.01% 65 +/- 25 ms

* Denotes Factory Default

Notes: Changing a sensitivity switch will

RESET the detector.

PIN Assignments

PIN Function (Relay Outputs) Function (Solid State Outputs)

A Power, Neutral, 120 VAC Power, Neutral, 120 VAC

B Channel 1 Output, Relay Common Channel 1 Output, Emitter (Source)

C Power, Line, 120 VAC Power, Line, 120 VAC

D Channel 1 Loop Input Channel 1 Loop Input

E Channel 1 Loop Input Channel 1 Loop Input

F Channel 1 Output, Relay N.O. Channel 1 Output, Collector (Drain)

G Channel 1 Output, Relay N.C. No Connection

H Chassis Ground Chassis Ground

I No Connection No Connection

J Channel 1 Phase Green Input Channel 1 Phase Green Input

PIN Function (Relay Outputs) Function (Solid State Outputs)

A No Connection No Connection

B Channel 2 Output, Relay Common Channel 2 Output, Emitter (Source)

C No Connection No Connection

D Channel 2 Loop Input Channel 2 Loop Input

E Channel 2 Loop Input Channel 2 Loop Input

F Channel 2 Output, Relay N.O. Channel 2 Output, Collector (Drain)

G Channel 2 Output, Relay N.C. No Connection

H Chassis Ground Chassis Ground

I No Connection No Connection

J Channel 2 Phase Green Input Channel 2 Phase Green Input

(Channel 1 Connector)

PIN Assignments

(Channel 2 Connector)

Factory Default Settings

Switch Function Setting Factory

1 Frequency 0 OFF

2 OFF

3 Presence /

4

5 ON

Sensitivity 6

6 ON

Pulse

Presence ON

Default

OFF

Model T-210 (551-2005-00) 03/23/2020

© COPYRIGHT 2020. Eberle Design, Inc. All Rights Reserved.

Loading...

Loading...