Page 1

Model S-1300 Series

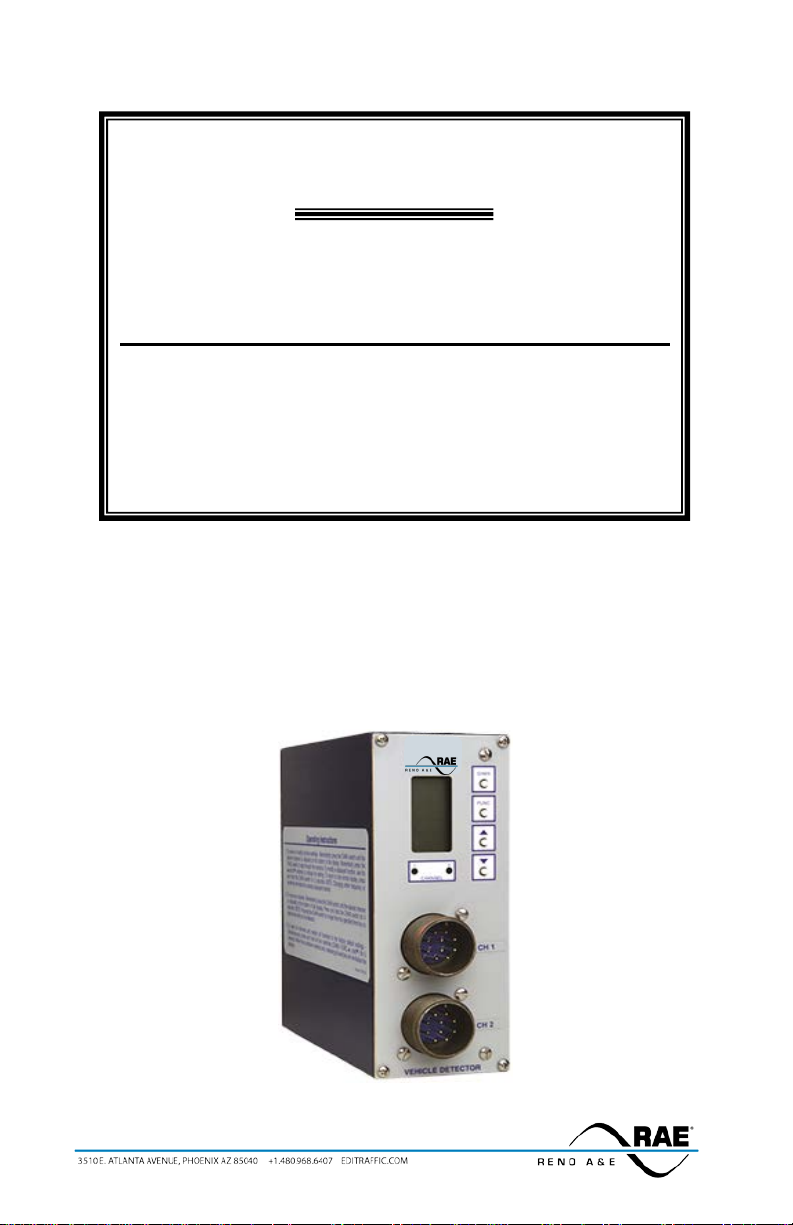

MODEL S-1300

Loop Detector

Operations Manual

Two Channel Menu Driven Programmable Inductive Loop

Detector

Built-in Loop Analyzer for Each Channel

This manual contains technical in formation for the

Model S-1300 Loop Detector

pn 889-1908-00 Revision: April 2020

Page 2

Page 3

THE FOLLOWING PRODUCT WAS DESIGNED, INSPECTED , TESTED AND

MANUFACTURED IN THE USA BY EBERLE DESIGN, INC. IN PHOENIX, ARIZONA.

INFORMATION CONTAINED HEREIN IS PROPR IETARY TECHNICAL INFORMATION OF

EBERLE DESIGN, INC. PUBLICATION, REPRODUCTION OR USE IN WHOLE OR PART IS

NOT PERMITTED EXCEPT UNDER TERMS AGREED UPON IN WRITING. ALL

REGISTERED TRADEMARKS OF EBERLE DESIGN INC. ARE UNDER

IT IS AN EBERLE DESIGN, INC. RECOMMENDATION THAT EACH UNIT BE TESTED

AT LEAST ANNUALLY TO ENSURE COMPLIANCE WITH FACTO RY

SPECIFICATIONS AND MEETS PROPER OPERATIONAL STANDARDS. THE

RESULTS OF THIS TESTING WILL BE DOCU M EN T ED .

© COPYRIGHT

MAINTENANCE NOTE

Page 4

Page 5

Model S-1300 Operations Manual

Table of Contents

Section 1 General Description .......................................................................................................... 1

Section 2 General Characteristics .................................................................................................... 2

2.1 Loop Frequency ..................................................................................................................... 2

2.2 Sensitivity .............................................................................................................................. 2

2.3 Presence / Pulse ..................................................................................................................... 2

2.4 Call Delay .............................................................................................................................. 2

2.5 Call Exte ns ion ........................................................................................................................ 2

2.6 Max Presence Timer .............................................................................................................. 2

2.7 End-Of-Green (EOG) ............................................................................................................. 3

2.8 Option 1: Loop Inductance Display ....................................................................................... 3

2.9 Option 2: Loop Inductance -∆L/ L Display ............................................................................. 3

2.10 Option 3: Call Ext ension Control ......................................................................................... 3

2.11 Option 4: Noise Filter Disable ............................................................................................. 3

2.12 Option 5: Phase Green Loop Compensation ........................................................................ 4

2.13 Option 9: Third Car Passage ................................................................................................ 4

2.14 Option 10: Direc tional Logic ............................................................................................... 4

2.15 Option 11, Audible Detect Signal ........................................................................................ 5

2.16 Option 12: Detector Disconnect ........................................................................................... 5

2.17 Option 13: True Presence ..................................................................................................... 6

2.18 Option 14: Sensitivity Boost ................................................................................................ 6

Section 3 Specifications ..................................................................................................................... 7

3.1 Physical .................................................................................................................................. 7

3.2 Electrical ................................................................................................................................ 7

3.3 Operational ............................................................................................................................ 7

3.4 Table: Sensitivity, -∆L/L, and Response Time ....................................................................... 8

3.5 Table: Default Settings ........................................................................................................... 8

3.6 Table: Pin Assignments ......................................................................................................... 9

Section 4 User Interface .................................................................................................................. 10

Section 5 Installation and Set-Up ................................................................................................... 11

5.1 Program Mode Display Screens ........................................................................................... 11

5.2 Normal Mode Display Screens ............................................................................................ 15

5.3 Loop Fail Indications ........................................................................................................... 17

5.4 Setting Sensitivity using the Bargraph ................................................................................. 18

5.5 Setting Sensitivity for Motorcycle Detection using the Bargraph ........................................ 19

5.6 Full Restore to Factory Default Settings .............................................................................. 19

5.7 Display Test ......................................................................................................................... 19

Section 6 Block Diagram ................................................................................................................ 20

Section 7 The o ry of Operation ....................................................................................................... 21

Section 8 Maintenance and Troubleshooting ................................................................................ 22

8.1 Troubleshooting Power Problems ........................................................................................ 22

8.2 Troubleshooting Initialization Problems .............................................................................. 22

8.3 Troubleshooting Loop Fail Problems ................................................................................... 23

8.4 Troubleshooting Intermittent Loop Fail Problems ............................................................... 24

8.5 Troubleshooting Intermittent Detector Lock-Ups ................................................................ 24

8.6 Troubleshooting Delay Problems ......................................................................................... 25

8.7 Things to Know About Loops .............................................................................................. 25

Page 6

Page 7

Section 1 General Description

This Operation Manual was written for people installing, operat ing, and maintaining Reno A & E Model S-1300

Series inductive loop vehicle detectors. The Model S-1300 is a two channel, shelf mount type, inductive loop

vehicle detector designed to meet or exceed NEMA Standards TS 1-1989.

The Model S-1300 incorporates a microcontroller that monitors and process es signals from two separate

loop / lead-in circuits and two Phase Green Inp uts. The microcontroller uses these inputs to determine

how to c ontro l the detec tor o utp uts. A Liqu id Crysta l Disp lay ( LCD), two light e mitt ing diodes (LEDs),

and four front panel pushbuttons are used to display and program all detector functions. Several

diagnostic modes are available to aid technicians and service personnel in troubleshooting detection

problems.

The use of a LCD is what distinguishes this detector from that of other manufacturers. It allows more informat ion,

never before available, to be displa yed to t he use r during normal operation of the detector. The LCD makes it easy

to view and adjust all programmable detector opt ions and settings. It is no longer necessary to check o r change

detector settings with DIP sw itches. An eight-segment bargraph at the top of the L CD can be used to provide a

graphical representation of the relative change of inductance as seen by the detector at the current sensitivity level.

The bargraph automatically takes into account loop size, loop inductance, nu mber of loops, number of turns, loop

geometry, lead-in lengt h, e tc. The bargraph functions as a sliding scale that relates to the programmed Sensitivity

Level. The first (left-most) bargraph segment represents the minimum inductance change necessary for the

detector to output a call at the currently selected sensitivity leve l. Larger i nducta nce chan ges will i ndicate more

segments. Each additional segment indicates that the next sensitivity level has also been met or exceeded. When

used in t his manne r, the bar graph prov ides an ind ication of whether t he sensiti vity is set too high or too low,

facilitating the ideal setting of the se ns itivity level.

All programmed settings are stored in non-volatile memory and can only be changed by programming new

settings. Loss of power or a de tector reset will not change any of t he p rogrammed settings. If a loop failure

occurs, the LCD will display the type of lo op failure as L lo (for -25% change or shorted loop conditions) or L hi

(for +25% change or open loop c onditions). Each loop failure is counte d and accumulated in the Loop Failure

Memory. The number of loop failures since the last detector reset or power interruption is very useful information

to have available during analysis of intermittent loop operation.

The Model S-1300 Series detector is a scanning detector. The scanning operation sequentially activates t he ON

and OFF cycle of each channel’s oscillator. Since only one channel’s loop(s) is (are) active at a given time,

crosstalk between adjacent loops connected to the same scanning detector is mini mize d. The Model S-1300

Series’ unique scanning process a lso disconnects the capac itors and dampe ns the oscillator during t he OFF cycle.

This eliminates oscillation past the OFF po int (ringing or dec ay) every time the loop circuit is sca nned, which can

result in crosstalk. W hen operating in the Program Mode, t he Model S-1300 Series disp lays t he rea l time loop

frequency reading for each channel. T he eight frequency settings ca n be incremented or decremented to p rovide

precise frequency readings, removing any guesswork when changing frequency settings to eli minate crosstalk.

NOTE: Adjacent loops connected to different c hannels of a non-scanning dete ctor or d ifferent scanning dete ctors

should be set to different frequencies with maximum separation.

The Reno A & E Model S-1300 Series utilizes the first major innovatio n in inductive loop detectors since the

introduction of digital detecto rs. The programming of all of the detector’s para meters with four normally open

pushbutton switches not o nly simplifies setup by removing binary coded DIP switches, but also increases the

reliability of the detector by eliminating the dependence on switch contacts during normal operation. The detailed

descriptions displayed on the LCD eliminate the interpretation of numerous LED flash rates to determine the

detector status. In addition, the Model S-1300 offers t he versatility of softwa re control. Special funct ions are

possible with a simple change of the s ocket-mounted microprocessor. Special functions are de fined as unique

optio ns (e. g. Opt ion 6, Option 12, etc. ). Special opt ion functions are activated through t he use of the LCD menu

option programming.

The Model S-1300 Series is comprised of the following detectors:

S-1300-R For NEMA TS 1-1989 applications calling for a two channel, 120 volt AC,

S-1300-SS For NEMA TS 1-1989 applications calling for a two channel, 120 volt AC,

S-1300-R-12D For NEMA TS 1-1989 applicat ions calling for a two channel, 12 volt DC,

S-1300-SS-12D For NEMA TS 1-1989 applicat ions calling for a two channel, 12 volt DC,

shelf mount detector with relay outputs and an audible detect signal

(buzzer).

shelf mount detector with so lid state outputs and an audible detect signa l

(buzzer).

shelf mount detector with relay outputs and an audible detect signal

(buzzer).

shelf mount detector with so lid state outputs and an audible detect signa l

(buzzer).

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 1 of 25

Page 8

Section 2 General Characteristics

2.1 LOOP FREQUENCY

There are eight (8) selectable loop frequency settings (nor mally in the range of 20 to 100 kilohertz) per c hannel.

The actual loop operating frequency is a function of the loop / lead-in network and the components of the loop

oscillator circuit. The d igital display of the actual loop operating frequency for each setting makes it easy to

quickly identify and eliminate crossta lk in the most difficult to configure intersections. The frequency display is

typica lly very stab le when the loop is vacant and veh icles are not passing nearby the loops. If the reading is

varyin g by more than ±1 in the last digit, this is an indication of possible crossta lk betwee n loops.

2.2 SENSITIVITY

There are nine (9) selectable sensitivity levels per channel, plus Continuous-Call and Cha nne l-O f f. T he s ensitiv i t y

levels are designed so that a one level increase actually doubles the sensitivity and a one level decrease halves the

sensitivity. A unique bargraph d isplayed on t he LCD makes it eas y to quickly set sensitivity at t he ideal leve l for

any loop / lead-in network configuration. (See Section 3.4 for actual detection levels at each sensitivity level.)

C

ONTINUOUS-CALL: Whe n se t t o t he Co nt in uo us -Call state , the c hannel ou tput is co ntinuous ly in t he Call state

regardless of t he presence or absence of vehicles o ver the loop. The loop oscillator is d isabled when in the

Continuous-Call state. T his state is indicated b y CALL flashing on the LCD. This option is selected from the

Sensitivity menu in Program Mode and is useful for checking co ntroller response and other troubleshooting

activities.

C

HANNEL-OFF: When s et to the Channel-O ff state, the channel output is cont inuously in the No Call state

regardless of the presence or absence of vehicles over the loop. The loop oscillator is disabled when in the

Channel-Off State. This sta te is indicated by OFF flashing on t he LCD. This option is selected from the

Sensitivity menu in Program Mode and is useful for checking co ntroller response and other troubleshooting

activities.

2.3 PRESENCE / PULSE

One of two mutually exclusive modes of operation for each channel is available. Presence or Pulse mode is

toggled by momentarily pressing e ither the (UP) or (DOWN) button.

P

RESENCE MODE: Provides a call hold time of at least four min utes (regardless of vehicle size) and typically one

to three hours for an automobile or truck.

P

ULSE MODE: An output Pulse of 125 ±10 milliseconds duration is generated for each vehicle entering the loop

detection zone. Each detected vehicle is instantly tuned out if it remains in the loop detection zone longer than

two seconds. This enables detection of subsequent vehicles entering the loop detection zone. After each vehicle

leaves the loop detection zone, the cha nnel resumes full sensitivity within 0.5 seconds.

2.4 CALL DELAY

Each channel’s Call Delay is ad justab le from 0 t o 255 seconds in one-second steps. Call Delay time starts counting

down when a vehicle enters the loop detection zo ne. The remaining Ca ll Delay time i s continuous ly displayed on

the LCD . W he ne ver a P has e Gr ee n I np ut ( C all D e lay O ve rr id e) si gna l (p i n J o f t he M S co nne ct or of c ha nne l 1 or

2) is active, the Call Delay func tion for the channel is aborted and the Call Delay time is forced to zero.

2.5 CALL EXTENSION

Each channel’s Call Extension is adjustable from 0 to 255 sec onds in one-second steps. Extension time sta rts

counting down when the last vehicle clears the loop detection zone. The remaining Call Extension time is

contin uous ly d isp la yed o n the LCD. Any veh icle ente r ing t he lo op de tec tio n zo ne d uri ng t he Ca ll E xtens io n ti me

period causes the channel to return to the Detect state, and later, when the last vehicle clears the loop detection

zone, the full Call Exte nsion time starts counting down again. (See Option 3, Call Extension Contro l, for an

alternate mode of operation for Call E xtension.)

2.6 MAX PRESENCE TIMER

When activated, each channel’s Max Presence timer is adjustable from 1 to 999 seconds in one-second steps. A

setting of OFF turns the Max Presence timer off. The Max Presence function is used to limit presence time, by

automatically resetting the channel. If this function is enabled (ON), the Max Pre sence timer begins counting

down when a call is initiated and t he remaining ti me is continuously displaye d on the LCD. If t he loop becomes

vacant before the Max Presence timer reaches zero, the call is dropped and no automatic reset occurs. If the EndOf-Green (EO G) func tion is no t enab led (O FF) and th e call is s till pre sent when the Max Presence timer reaches

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 2 of 25

Page 9

zero, the cha nnel then is aut omatically reset. If the EOG functi on is e nabled (ON) and the call is still present w hen

the Max Presence timer reaches zero, the channel enters a Wait state. The Wait state continues until either the loop

becomes vacant or the Phase Green Input signal for a channel (pin J of the MS connector) transitions from green to

not green with the call still present. If the loop becomes vacant first, the call is dropped and no automatic reset

occurs. If the Phase Green Input transitions from green to not green while a cha nne l is in a Wait state, the channel

is automatically reset. The signals on pin J of the MS connectors of channels 1 and 2 are also called Call Delay

Overrides. (See Section 3.2, Phase Green Input specification for voltage levels.)

2.7 END-OF-GREEN (EOG)

Each channel’s EOG setting can be toggled O N or OFF b y moment arily pr essing either the (UP) or (DOWN)

button. The EOG function is used to synchronize resetting of a detector with the termination of t he associated

phase green. The assumption is that t his is the sa fest point in t ime to reset the c hannel. T his assumption is based

on the premise that at the termination of t he as s ociated p hase green, traffic should be moving, and therefore, a reset

would not result in the loss of a ca ll when traffic comes to rest over the loop(s). The EOG function is only

available when the Max Presence function is set between 1 and 999 seconds. It is not available when the Max

Presence function is OFF. When the EOG function is enab led (ON), the channel will automatically be reset at the

same time the Phase Green Input signal (pin J of the MS connector) transitions from the ON state to the OFF state,

if the Max Presence Time has counted down to zero and is resting in the wait state. The signa ls on pin J of the MS

connectors of channels 1 and 2 are also called Call Delay Override. (See Section 3.2, Phase Green Input

specifications for voltage levels.)

2.8 OPTION 1: LOOP INDUCTANCE DISPLAY

Each cha n ne l’s Loo p Induc ta nce D isp la y se tt in g ca n be to gg led O N o r O FF b y mome nt ar il y pre ss i ng e it he r the

(UP) or (DO W N ) b u t to n. W hen this option is e na b le d (ON), t he LCD d is p lays the to t al lo o p i nd uc t a nc e (a c t ua l

loop inductance plus actual lead-in inductanc e) in micro henrie s for lo op ind uctance values in the r ange of 2 0 to

2500 microhenries. By recording the inductance of the loop / lead-in circuit when it is first insta lled, the actual

inductance can be compared to the expected ind uctance to help identify defective loop / lead -in circuits. Loop /

lead-in inductance can be easily estimated using the simple formulas included in Section 8.7 of this manual.

NOTE: Enabling this option activates i t for both channe ls. Th is option is automat ica lly disabled 15 m inutes after

activation or on loss of power.

2.9 OPTION 2: LOOP INDUCTANCE -∆L/L DISPLAY

Each cha n ne l’s Loo p I nd uct a nce -∆L/L Display sett ing can be toggled ON or OFF by momentarily press ing either

the (UP) or (DOWN ) button. When this o ption is enab led (ON), the LCD dis plays the per centage of

induct ance change (-∆L/L value) during the Call state. To fac ilitate the viewing of the maximum amount of

change in the -∆L/L value w hile traffic is in motion over the detection zone, the channel holds the peak -∆L/L

value for a period of two seconds. NOTE: Enabling t his option activates it for both channels. This option is

automatically disabled 15 minutes after activation or on loss of power.

2.10 OPTION 3: CA L L EXTENSION CONTROL

Each cha nnel’ s Cal l Exte nsion C ontro l set ting ca n be to ggled O N or OF F by mo mentar ily pre ssin g eithe r the

(UP) or (DO WN ) b ut to n. W he n t h is o pt io n is e nab led (O N) , t he c ha n nel w ill e x tend ca l ls f or t he pr o gra mme d

extens ion t ime only whe n the Phase Green Input signal (pin J of the MS connector) is active. When this option is

OFF, the channel extends ALL calls for the programmed extension time. The signals on pin J of the MS

connectors of channels 1 and 2 are also called Call Delay Overrides. (See Section 3.2, Phase Green Input

specifications for voltage levels.)

2.11 OPTION 4: NOISE FILTER DISABLE

The detector’s Noise Filter Disable setting can be toggled ON or OFF by momentarily pressing either the (UP)

or ( DO WN ) b utt o n. W he n Op t io n 4 is e nab led (ON), internal noise filtering is disabled thus provid ing a faster

response time. When this option is O FF, internal noise filtering is utilized. W hen the detector is used in speed

and/or occupancy applications, the noise filter should be disabled (i.e. Option 4 ON) to provide the most accurate

data possible. It is recommended t hat this option not be activated. The factory default setting o f OFF provides

stable operation in high crosstalk e nvironments. NOTE: Enabling this option activates it for both channels.

Changing the setting of this feature will reset both detector channels.

The Loop Fail Count is not reset when the setting of Option 4 is changed. Also, changing the setting of Option 4

will not cause the prior Loop Fail indication to cease (see Section 5.3, Loop Fail Indications).

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 3 of 25

Page 10

Loop B

Loop A

2.12 OPTION 5: PHASE GREEN LOOP COMPENSATION

Each channel’s Phase Green Loop Co mpensation setting can be toggled ON or OFF by mo mentarily pressing

either the (UP) o r (DOWN) bu t ton. When Op t io n 5 is e na b le d ( O N) , no rmal loop compe nsation is used until

the Phase Green Input signal (pin J of the MS connector) becomes active (low). Once the Phase Gr een Input sign al

is active (high), the channel desensitizes the loop. Maximum desensitization is 0.05% (-∆L/L). This

desensitization tunes out small changes, such as adjacent lane pickup, therefore minimizing the chance of max

timing an empty lane. Note: A small motorcycle may also be tuned out in a short period of time following the star t

of Phase Green. This option is useful in minimizing false detec tion resulting from adjacent lane pickup when a

channel must be run with a high sensitivity setting. When Option 5 is not enabled (OFF), normal loop

compensation is used.

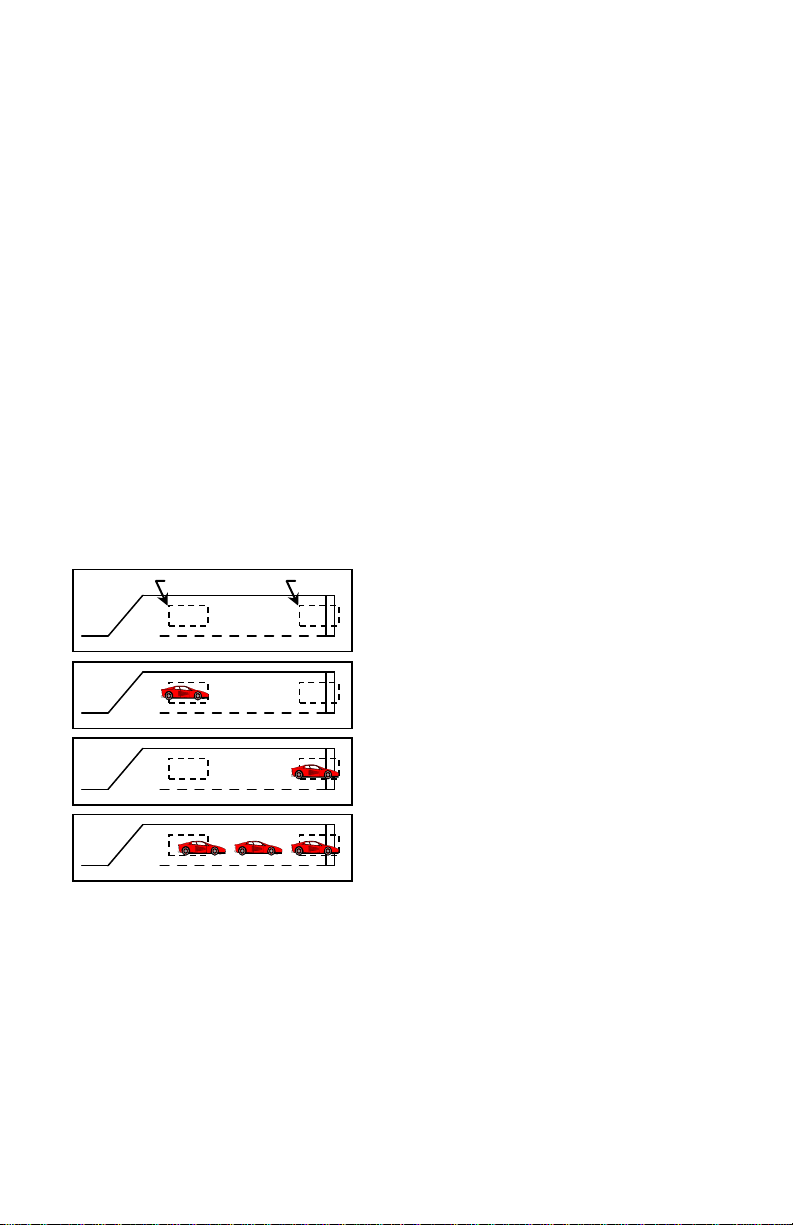

2.13 OPTION 9: THIRD CAR PASSAGE

Each channel’s Third Car Passage setting can be toggled O N or O FF b y momentarily pressing either the (UP) or

(DO WN ) b ut to n. O p tio n 9 is a p a ire d cha nne l opt io n. Th is me ans t hat it ta ke s t w o c ha nne ls to imp le me nt the

feature. Therefore, when this option is toggled ON or OFF in one channel, its paired channe l is also set to the same

state. In the Model S-1300, Channel 1 is paired with Channel 2. NOTE: Option 9 is mut ually exclusive with

Optio n 10. Turning ON one option will automatically turn OFF the other option.

When Op t ion 9 is e nab led (ON ) , t he o utp u t o f the tw o pa ir ed c ha n ne ls a re log ic a lly AND ed t o get he r. Th is mea ns

that while the loops for both of the paired channels are occ upied, a call will be output on both channe ls. While

only o ne c han ne l is oc cupied, or neither channel is occupied, a c all will not be output for either channel. The first

channel with detection will enter a pend ing state w hile wait ing for detect ion on the ot her pa ired cha nnel. While in

the pending state, the LCD will show Pnd on the display.

This feature is intended to be used in Pro tected / Permissive left turn situations. The expected ins tallation is a stop

bar loop for the left turn lane connected to one c hanne l, a queue detect ion loop (with a s mall amount o f delay ti me

programmed) for the left turn lane connected to the other channel, and the output of eithe r channel conne cted to the

Vehicle Call input for the protected movement of the traffic controller.

Basic Installation - Loop A is the Queue Detec tion lo op and

Loop B is the Stop Bar loop.

Car enters Loop A - No ca ll is o utp ut.

Car proceeds to Loop B - No call is output.

Addit io na l c ars ente r t he left tur n lane - When the bac k o f t he

queue reaches Loop A while a car is still over Loop B, a call

will be output.

When T hird Car P assage is turned o n, as the f irst vehi cle enter s the lef t turn la ne it will d rive ove r the queue

detection loop. Since there is no vehic le over the stop bar loop, there is no call output genera ted. The vehicle

advances to the stop bar loop. Still, no output is generated because there is no vehicle over the queue detection

loop. If the vehicle traffic in the left turn lane backs up to the queue detection loop, then the stop bar loop and the

queue detection loop will both be occupied at the same time. This will cause the detector to generate a ca ll to t he

traffic controller to service the protected movement for the left turn. This should help clear the que ue of vehicles

in the left turn lane. The spacing between the stop bar loop and the queue detection loop controls the size of the

queue needed to generate a call to the protected movement of the controller. The delay time on the Queue

Detection loop should be sufficiently long that vehic les driving over this loop to enter the queue do not generate a

call.

2.14 OPTION 10: DIRECTIONAL LOGIC

Each channel’s Directional Logic setting can be toggled ON or OFF by momentarily pressing either t he (UP) or

(DOWN) button. Option 10 is a paired c hannel option. This means that it takes two channe ls to implement t he

feature. Therefore, when this option is toggled ON or OFF in one channel, its paired channe l is a lso set to the sa me

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 4 of 25

Page 11

Loop B

Loop A

Basic Ins tallat ion

Car enters Loop A - No call is output

Car enters Loop B - No c all is

Car proceeds to Loop B

Call is output o n C hannel B

Car proceeds to Loop A

Call is output o n C hannel A

state. In the Model S-1300, Cha nnel 1 is pair ed wit h Cha nnel 2. NOTE: Op tion 1 0 is mut ually e xclus ive w ith

Optio n 9. Turni ng ON one o ption will auto matica lly turn O F F the other option.

When Option 10 is enabled (ON), directional logic is enabled. Directional logic starts with a detection on one

channel. This channel will go into the pending state, display Pnd on the LC D , a nd N O T output a c a l l. W hen both

of the paired channels have dete ction, the last channel to have detection will output a call until the detection for the

last c ha n ne l e nd s , e ve n if t h e d e te c t ion ends fo r t he fi rs t c hannel. None of t he t i mi n g f un c t io ns of the f ir s t channe l

with a detection will ti me (Delay, Extens ion, Max Presence, a nd Detector Disconnect) a nd the first channel w ill

always operate in the Presence Mode regardless of the programming of the channel.

This feature is intended to be used in parking lot applicatio ns where vehicles can e nter or exit from the sa me lane,

freewa y ra mp s for wro ng w a y de tec t ion, a nd le ft t urn lane s whe re ot her mo ve men ts in t he inte rs ec ti o n te nd t o cl ip

the detection zone of the left turn lane. The expected installation is two loops, one after the other in the same lane,

spaced anywhere from slightly overlapping to 6 feet apar t. NOTE: Contact a Field Engineer at Reno A & E

regarding proper loop configurations and spacing for specific applications.

When Directional Detect ion is turned on, a vehicle entering the first loop will cause that channel to enter t he

pending state. As the vehicle enters the second loop w hile still occupying the first loop, the second channel will

enter the Call state while the first c hanne l remains in t he pending s tate. A call is never outp ut on the first c hannel

with a detection. Under normal conditions both outputs can never be on at the same time. However, if one of the

loops fail, both outputs will come on a nd stay on until the failure is corrected.

2.15 OPTION 11, AUDIBLE DETECT SIGNA L

Each channel’s, Audible Detect Signal setting ca n be toggled ON or OFF by mo mentarily pressing either t he

(UP) or (DOWN) butto n. Only one channel can be turned ON at a time. Turning this option ON for one

channe l automatically t u r ns it O F F fo r t he o t he r channe l. W hen this o p t io n is ena b le d (ON), a n audible signal w i l l

be activated whenever the detection zone for the selected channel is occupied. The audible signal indicates actual

occupancy of the loop detection zone. Timing a nd disconnect functio ns have no e ffect on t he audible s ignal. T his

feature allows a technician to watch the det ection zone on the street and confirm correct detector operation without

having to look at the detector display as well. NOTE: This option is automatical ly disabled 15 minutes after

activation or on loss of power.

2.16 OPTION 12: DETECTOR DISCONNECT

Each channel’s Detector Disconnect se tting can be toggled ON o r OFF and the Extension t imer toggled between

ON and OFF by momenta r il y pr es sing ei t h er t he (UP) or (DOWN) button. The Detector Disconnect feature

requires that the Phase Green Input for the channel be connected to the proper controller phase. When the Phase

Green I nput is n ot a cti ve (low), the cha nne l s hal l oper ate nor ma lly. W hen t he P has e Gre en I np ut is active (high),

the extension timer will start to count down at the end of each detection. If this timer reaches zero before the next

detection, this channel will no longer output a call until the Phase Green Input is not active. Since t he extension

timer is used as a disconnect timer while in this mode, two different disconnect types are available:

Optio n 12.1 OF F : Extension timi ng stil l o ccurs and the e xt ension timer is also the discon nect timer duri ng phase

green. This will cause the call output to remain in the Ca ll state until disconnect occurs. Th is may allow the

user to use gap times appropriate for the advance loops without considering the effects on the stop bar loops.

Option 12.1 ON: Extension timing is disabled and the extension timer is used a s the disconnect timer. This will

cause the call output to follow the occupation of the loop detection zone until disconnect occurs.

This feature is intended to be used in applications where a loop at the stop ba r is not needed after any waiting

queue in the associated traffic lane is movi ng during t he green p hase. The e xpected installatio n is a sto p bar loop

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 5 of 25

Page 12

Sensitivity Boost Setting

14.0

14.1

14.2

14.3

14.4

Increase in Sensitivity Level(s)

0 1 2 3 4

Detection Zone

Phase Green

Output w/ 12.1 Off

Output w/ 12.1 On

This example assumes an extension time of 2 seconds. The dott ed lines show where disconnect would occur.

Seconds 0 5 10 15 20 25 30 35 40 45 50 55

(typically a 20΄ to 30΄ long detection zone) and an advance detection loop (typically a 6΄ long detection zone) for a

single traffic lane. This feature provides a means for keeping the stop bar loop from placing calls to the traffic

controller after the stop bar loop has served its intended purpose during the beginning period of the associated

Phase Green is the state of the light (actual Phase Green Input is i nv er ted).

green phase. The channel connected to the stop bar loop would have the Detector Disconnect feature turned ON

and have a programmed extension time that functions as the disconnect time. The channel connected to the

advance detection loop would be programmed as normal.

When the Detector Disconnect feature is turned ON and the signal is not green, the channel outputs calls to the

traffic contr oller as us ual. When the signal t urns green, vehicles begin to move and eve ntually the stop bar

detection zone is cleared. At the time that the stop bar detection zone is cleared the disconnect timer begins to

count down. If another vehic le enters the stop bar detection zone before the disconnect timer reaches zero, the

channel outputs the new call to the traffic controller and the disconnect t imer is reset to its initial value. Once the

stop bar detection zone remains clear for a time eq ual to the programmed disconnect time, the detector channel is

disabled and will not generate any further calls to the traffic controller until after the green has terminated. When

the stop bar detection loop is disabled, the green phase can only be extended by vehicles detected by the advance

detection loop. NOTE: The dis connect timer will always time an initial gap each ti me that the p hase tur ns gree n.

If Option 12.1 is OFF, the channel will generate an output for the specified extension time at the start of each

green phase.

2.17 OPTION 13: TRUE PRESENCE

TRUE PRESENCE can be set from 13.0 to 13.5 by press ing the (UP) or (DOWN) pushbutton. When Option

13 is OFF (13.0), the detector operates in the normal PRESENCE mode. When this option is set to 13.1 thro ugh

13.5, TRUE PRESENCE is ON. W hen Option 13 is ON, TRUE PRESENCE will hold the Call as long as the

vehicle is present and power is not removed or the detector reset. TRUE PRESENCE time applies only for normal

size automobiles and trucks and for normal size loops (approximately 12 ft

PRESENCE operation is required, use a setting of 13.1. Contact Re no A & E Technical Suppor t for advice on

applications using loops larger than 120 ft

2

and/or TRUE PRESENCE settings 13.2 to 13.5.

2

- 120 ft2). NOTE: If TRUE

2.18 OPTION 14: SENSITIVITY BOOST

SENSITIVITY BOOST can be set from 14.0 to 14.4 by pressing the (UP) or (DOWN ) pus hbut ton. When

Option 14 is set to 14.0, SENSITIVITY BOOST is turned O FF. When this option is set to 14.1 through 14.4,

SENSITIVITY BOOST is ON. SENSITIVITY BOOST increases the sensitivity of the detector once it has

detected an object. When setting this option, the digit to the right of the dec imal point indicates the number o f

sensitivity levels that the sensitivity will increase after a detection has occurred.

NOTE: The maximum sensitivity level that can be achieved with or without b oost is sensitivity level 9. If a

detector channel is set to sensitivity level 9, the maximum boos t setting attainable is 14.0, i.e. no boost. If a

detector channel is set to sens itiv ity le vel 8, the m aximum boos t s etting at tainable is 14.1, i.e. one (1) level of boost.

If a detector channel is set to sensitivity level 7, the maximum boost setting attainable is 14.2, i.e . two (2) levels of

boost. If a detector channel is set to sensitivity level 6, the maximum boost setting attainable is 14.3, i.e. thr ee (3)

levels of boost. If a detector channel is set to sensitivity level 5, 4, 3, 2, or 1, the maximum boost setting attainable

is 14.4, i.e. four (4) levels of boost.

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 6 of 25

Page 13

Section 3 Specifications

3.1 PHYSICAL

WEIGHT: 34 oz. (963.9 gm).

S

IZE: 6.45 inches (16.38 cm) high x 2.50 inches (6.35 cm) wide x 6.35 inches (16.13 c m) deep (excluding

connectors). Connectors add .675 inch (1.71 cm) to depth measurement.

O

PERATING TEMPERATURE: -40° F to +180° F (-40° C to +82° C).

C

IRCUIT BOARD: Printed circuit boards are 0.062 inch thick FR4 material with 2 oz. copper on both sides and

plated through holes. Circuit board and components are conformal coated with polyur ethane.

C

ONNECTOR: Two (2) MS3102A-18-1P. See Section 3.6 for pin assignments.

3.2 ELECTRICAL

POWER: 89 to 135 VAC, 50/60 Hz, 6 Watts maximum (120 volt AC models). 9.6 to 14.4 VDC, 250 mA

maximum, 3.8 Watts maximum (12 volt DC models).

LOOP INDUCTANCE RANGE: 20 to 2500 microhenries w ith a Q factor o f 5 or grea ter.

L

OOP INPUTS: Transformer isolated. The minimum capacitance added is 0.068 microfarad.

L

IGHTNING PROTECTION: Meets and/or exceeds all applicable NEMA TS 1-1989 specifications for transient

voltage protection.

R

ESET: M eets and/o r e xceeds NEM A TS 1-1989 detector specifications. The detec tor can be reset by removing

and reapplying power or by changing the setting of Option 4 (Noise Filter Disab le). Each detector channel can be

independently reset by pressing the CHAN button until the desired cha nnel is selected, then pressing and ho lding

the CHA N b ut t o n fo r t hr e e se c o nd s . A ls o, c ha n gi n g either the sensitivit y or loop fr e q uency o f a channe l will res e t

that channel.

P

HASE GREEN INPUTS: Also known as Call Delay Overrides. Meets and/or exceeds all NEMA TS 1-1989

requirements. Application of a high state voltage (89 to 135 VAC) to pin J of the MS connector of channel 1 or 2

causes the delay timer for the channel to ab ort the delay t i ming function a nd also pro vides control for Phase Gree n

Loop Co mpensat ion, Max P resence T iming (E nd-of-Green), Extension Timing, and Detector Dis connect, if the

features are programmed.

R

ELAY RATING: The relay contacts are rated for 6 Amps maximum, 150 VDC maximum, and 180 Watts maximum

switched power.

S

OLID STATE OUTPUT RATING: Optically isolated. 30 VD C maximum collector (drain) to e mitter (source). 100

mA maximum saturation curre nt. 2 VDC maximum transistor sa turation voltage. The o utput is protected with a

33-volt Zener diode connected between the collector (drain) a nd emitter (source).

3.3 OPERATIONAL

DISPLAY: The LCD backlighting illuminates whenever any pushbutton is pressed. The backlighting will

extinguish 15 minutes after the last pushbutton press.

D

ETECT INDICATOR: Each channel has a super bright, high intensity, red light e mitting diode (LE D) to indicate a

Call Output, Delay Timing, Extension Timing, Pending State, or Failed Loop co nditio n.

R

ESPONSE TIME: Meets or exceeds NEMA TS 1-1989 response time specifications. (See Section 3.4 for actual

response times.)

S

ELF-TUNING: The detector automatically tunes and is operational within two seconds after application of power

or after being reset. Full sensitivity and hold time require 30 seconds of operation.

E

NVIRONMENTAL & TRACKING: The detector is fully self-compe nsating for environme ntal changes a nd loop drift

over t he full te mperature range and the entire loop inductance r ange.

G

ROUNDED LOOP OPERATION: The loop is olation transformer allows operation with poor qualit y loops (which may

include one short to ground at a single point).

L

OOP FEEDER LENGTH: Up to 5000 feet (1500 m) maximum with proper feeder cable and appropriate loops.

L

OOP (FAIL) MONITOR: If the tota l ind uct anc e of t he cha nne l’s loop inp ut ne twor k goes out of the range specified

for the detector, or rapidly changes by more than ±25 %, the channel will immediate ly e nte r t he Fail-Safe mode and

display LOOP FAIL o n the LCD. The type of loop failure will also be disp layed as L lo (for -25% change or

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 7 of 25

Page 14

Respons e Time

(Option 4 O FF)

Respons e Time

(Option 4 ON)

OFF

-------

-------

-------

1

0.64%

133 ±27 ms

20 ±4 ms

2

0.32%

133 ±27 ms

20 ±4 ms

3

0.16%

133 ±27 ms

20 ±4 ms

4

0.08%

133 ±27 ms

20 ±4 ms

5

0.04%

133 ±27 ms

20 ±4 ms

6

0.02%

133 ±27 ms

27 ±5 ms

7

0.01%

133 ±27 ms

42 ±8 ms

8

0.005%

133 ±27 ms

72 ±14 ms

9

0.0025%

133 ±27 ms

133 ±27 ms

CALL

-------

-------

-------

add these times together.

Function

Channel 1

Channel 2

Frequency 3 7

Sensitivity 6 6

Delay Time 0 0

Extens ion Time 0 0

Max Presence Time

OFF

OFF

Presence / Pulse Mode

Presence

Presence

EOG

OFF

OFF

Option 1 - Loop Inductance Display

OFF

OFF

Option 2 - Loop Inductance -∆L/L Display

OFF

OFF

Option 3 - Call Extension Control

OFF

OFF

Option 4 - Noise Filt er Disable

OFF

OFF

Option 5 - Phase Green Loop Compensation

OFF

OFF

Option 9 - Third Car Passage

OFF

OFF

Option 10 - Dire c tional Logic

OFF

OFF

Option 11 - Audible Detect Signal

OFF

OFF

Option 12.0 - Detector Disconnect

OFF

OFF

Option 12.1 - Detector Disconnect Type

OFF

OFF

Option 13 - True Presence

13.0

13.0

Option 14 - Sensitivity B oost

14.0

14.0

shorted loop conditions) or L hi (for +25% change or open loop cond itio ns). T his w ill c ontinue as long as the loop

fault exists. However, if the detector is reset, or power is momentarily lost, the detector will retune if the

loop inductance is withi n the acceptable range. If any type of loop failure occurs in one (or more) loop(s) in

a group of two or more loops wired in parallel, the detector will not respond with a Fail-Safe output

following any type of reset. It is essential that multiple loops wired to a common detector channel always be

wired in series to ensure Fail-Safe operation under all circumstances. At the time of a loop failure, the

channel’s LED will begin to flash at a rate of three flashes per second. The LED will continue this display pattern

until the channel is manually reset or power is removed. If the loop self-he als, the LOO P FAIL mess age on the

LCD will extinguish and the channel will re sume operation in a normal manner; exce pt the LED will continue t he

three flashes per second display pattern, thus providing an alert that a prior Loop Fail condition has occurred. Each

loop failure for the channel is counted and accumulated into the Loop Fail Memory. The total number of loop

failures written into the Loop Fail Memory (since the last power interruption or manual reset) is viewed by

stepping through the channel’s functions in Program Mode until the LOO P FAIL message is displayed.

3.4 TABLE: SENSITIVITY, -∆L/L, AND RESPONSE TIME

Sensitivity -ΔL/L

NOTE: Entries in this table are based on the assumption that both channels are set to the same sensitivity. To approximate response

time for a detector with the channels set to different sensitivities, look up the response time for each channel and divide it by two, then

Noise Filter Enabled

Noise Filter Disabled

3.5 TABLE: DEFAULT SETTINGS

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 8 of 25

Page 15

Pin

Function

Pin

Function

Power, Neutral, 120 VAC (AC Models)

12 VDC Common (DC Models)

B

Channel 1 Output, Relay Common

B Channel 2 Output, Rela y Com mo n

Power, Line, 120 VAC (AC Models)

+12 VDC (DC Models)

D

Channel 1 Loop Input

D Channel 2 Loop Input

E

Channel 1 Loop Input

E Channel 2 Loop Input

F

Channel 1 Output, Relay Normally Open

F Channel 2 Output, Relay Normally Open

G

Channel 1 Output, Relay Normally Closed

G Channel 2 Output, Relay Normally Closed

H

Chassis Ground

H Chassis Ground

I

No Connection

I No Connection

J

Channel 1 Phase Green Input (Delay Override)

J Channel 2 Phase Green Input (Delay Override)

NOTE: Relay contact states are shown with power applied, loop(s) connected, and no vehicle(s) present.

Pin

Function

Pin

Function

Power, Neutral, 120 VAC (AC Models)

12 VDC Common (DC Models)

B

Channel 1 Output, Emitter (Source)

B Channel 2 Output, Emitter (Source)

Power, Line, 120 VAC (AC Models)

+12 VDC (DC Models)

D

Channel 1 Loop Input

D Channel 2 Loop Input

E

Channel 1 Loop Input

E Channel 2 Loop Input

F

Channel 1 Output, Collector (Drain)

F Channel 2 Output, Collector (Drain)

G

No Connection

G No Connection

H

Chassis Ground

H Chassis Ground

I

No Connection

I No Connection

J

Channel 1 Phase Green Input (Delay Override)

J Channel 2 Phase Green Input (Delay Override)

3.6 TABLE: PIN ASSIGNMENTS

RELAY OUTPUTS

C

HANNEL 1 CONNECTOR CHANNEL 2 CONNECTOR

A

C

A No Connection

C No Connection

SOLID STATE OUTPUTS

C

HANNEL 1 CONNECTOR CHANNEL 2 CONNECTOR

A

C

A No Connection

C No Connectio n

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 9 of 25

Page 16

FUNC

CHAN

1

2

CHANNEL

MODEL S

VEHICLE DETECTOR

CH 1

CH 2

-∆L/L

FREQ

LOOP FAIL

OPTIO

MAX

OFEOSCANNI

EXTENSION

SENSITIVITY

DELA

PULS

SECONDS

ON

Seven Segment Display

Vehicle Count

Parameter Description

Function Select Pushbutton

Channel Select Pushbutton

Press and Hold for Three

UP Pushbutton

Bargraph

Numbered Loop Symbols

LED Indicators

DOWN Pushbutton

MODEL S-1300

Section 4 User Interface

• Vehicle Signal Strength

• Frequency Setting

• Parameter Values

• Timer Countdown

• Frequency Reading

• Inductance Value

• -∆L/L Value

• Pending Call State

• Type of Loop Failure

• L hi = Open Loop or L

High

• L lo = Shorted Loop or L

Low

•

• Name of Parameter

• Timer in Operation

• Channel Displayed

• Flashing = Program Mode

• Call

• Delay Time in Progress

• Extension Time in Progress

• Pending Call State

• Loop Fault has Occurred

• Change Displayed Channel

Press and Release

• Exit Program Mode

Press and Hold for One Second

• RESET Channel

Seconds

• Press Momentarily to Enter

Program Mode and to Step

Through Parameters

• Increments Values

• Toggles ON and OFF

• Decrements Values

• Toggles ON and OFF

NOTE: There are no internal switches or jumpers to set.

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 10 of 25

Page 17

FREQ KHZ

1

©

SENSITIVITY

1

©

©

PULSE

1

Section 5 Installation and Set-Up

The dete ctor has no DIP switches or jumpers to configure. C onnect the detector to an appropriately wired harness

and apply power. If the detector is not new from the factory, it may be advantageous to reset the detect or back to

the factory defaults to a void having to check every setting for each channel. To reset the detector to factory

defaul t, pres s and ho ld all fo ur pus hbutto n switc hes simu ltaneo usly fo r five s econds . When a ll four b uttons are

depressed, the display will start count ing d own fro m five (5). W hen the countdown reaches zero (0), releasing the

pushbuttons will reload the factory defaults and reset both channels.

All operating parameters can be adjusted from the front panel. The detector continues to operate normally while it

is in the P rogram Mode. The value currently displayed is always the actual value bei ng used. Examp le: If you are

changing the delay time, the time displayed at the instant that a vehicle entere d the detection zone for that channel

would be the value used for the delay timer.

Pressing the FUNC button enters t he Progra m Mode. The FUNC button has a n auto repeat function. This a llows

quick navigation to the desired parameter. T he FUNC button only moves forward through all of the parameters.

There is no way to move backwards through the parameters.

While viewing any parameter, pressing t he CHAN button will display the same para meter for the next channel.

The currently selected channel is indicated at the bottom of the LCD. Pressing and holding the CHAN button for

one seco nd w ill exit the Program Mode and return to the Normal Mode.

Pressi ng and ho lding e ither the (UP) or (D OWN) b utton wi ll cause the val ue to cha nge rap idly unt il the

button is released.

5.1 PROGRAM MODE DISPLAY SCREENS

PARAMETER ...................Frequency.

S

ETTINGS ........................E ight (8) S elections - 1 to 8.

S

ETTING DISPLAYED ......Bargraph indicates settings from 1 (left) to 8 (rig ht).

7

SEGMENT DISPLAY ......Actual Frequency of the loop circuit. Typically 20.0 to 99.9

D

EFAULT SETTING..........Channel 1 = 3, Channe l 2 = 7.

E

XAMPLE ........................Frequency setting 4 is selected for channel 1. The loop

N

OTES .............................Changing the frequenc y will reset the channe l. An unstable

P

ARAMETER ...................Sensitivity.

S

ETTINGS ........................11 Selections - 1 to 9, OFF, or CALL.

S

ETTING DISPLAYED ......7-segment display will sho w the currently selected setti ng.

7

SEGMENT DISPLAY ......Currently selected Sensiti vity.

D

EFAULT SETTING..........6 fo r bot h channels.

E

XAMPLE ........................Sensitivity 5 is selected for c ha nnel 1.

N

OTES .............................Changing the s ensiti vity wil l reset the channel. If the chan nel is

P

ARAMETER ...................Presence / Pulse Mode.

S

ETTINGS ........................Presence or Pulse.

S

ETTING DISPLAYED ......The word PRESENCE or PULSE will be displayed.

7

SEGMENT DISPLAY ......Blank.

D

EFAULT SETTING..........Presence for both channels.

E

XAMPLE ........................Pulse Mode is selected for channel 1.

N

OTES .............................If the channel is in the call state when this parameter is

kilohertz.

frequency is 34.9 kHz.

frequency display varying more than ±0.2 kilohertz may

indicate loop crosstalk or other interference.

in the call state when viewing this pa rameter, the bargraph will

show the strength of vehicle calls so that the correct sensitivity

can be verified from this screen.

changed, the change will not take effect until the detection zone

is empty or the channel is reset.

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 11 of 25

Page 18

©

DELAY

SECONDS

1

EXTENSION

SECONDS

1

©

MAX PRESENCE

SECONDS

1

©

EOG

1

ON © OPTION

1

ON © OPTION

OFF

1

©

ARAMETER ...................Delay.

P

S

ETTINGS ........................256 Selections - 0 to 255 Seconds in one-se cond steps.

S

ETTING DISPLAYED ......7-segment display will sho w the currently selected setti ng.

7

SEGMENT DISPLAY ......Currently selected Delay time in seconds.

D

EFAULT SETTING..........0 seconds for both channels.

E

XAMPLE ........................Delay of 10 seconds selected for channel 1.

N

OTES .............................If the channel’s detection zone is occupied when this parameter

P

ARAMETER ...................Extension.

S

ETTINGS ........................256 Selections - 0 to 255 Seco nds in one-se c ond steps.

S

ETTING DISPLAYED ......7-segment display will sho w the currently selected setti ng.

7

SEGMENT DISPLAY ......Currently selected Extension time in seconds.

D

EFAULT SETTING..........0 seconds for both channels.

E

XAMPLE ........................Extension of 25 seconds selected for channel 1.

N

OTES .............................This pa ramet er wil l hold t he Dis connec t time r val ue if Op tion

P

ARAMETER ...................Max Presence.

S

ETTINGS ........................1000 Selections - 1 second to 999 seco nds or O FF.

S

ETTING DISPLAYED ......7-segment display will show currently se lec te d s e tting.

7

SEGMENT DISPLAY ......Currently selected Max Presence time in seconds.

D

EFAULT SETTING..........OFF for both channels.

E

XAMPLE ........................M ax Prese nce is turned OFF f or chan nel 1.

N

OTES .............................If the channel’s detection zone is occupied when this parameter

P

ARAMETER ...................EOG (End Of Green).

S

ETTINGS ........................ON or OFF.

S

ETTING DISPLAYED ......The word ON or OFF will be displayed.

7

SEGMENT DISPLAY ......Blank.

D

EFAULT SETTING..........OFF for both channels.

E

XAMPLE ........................EOG is turned ON for channel 1.

N

OTES .............................This pa rameter is o n l y displayed if the Max Presence setting for

P

ARAMETER ...................Option 1 (Loop / Lead-In Induc tance Display).

S

ETTINGS ........................ON or OFF.

S

ETTING DISPLAYED ......The word ON or OFF will be displayed.

7

SEGMENT DISPLAY ......The number of this option.

D

EFAULT SETTING..........OFF for both channels.

E

XAMPLE ........................Option 1 is turned ON for all channels

N

OTES .............................This option is a detector wide setting. Changing it for one

PARAMETER ...................Option 2 (Percentage o f Inductance cha nge, -∆L/L).

S

ETTINGS ........................ON or OFF.

S

ETTING DISPLAYED ......The word ON or OFF will be displayed.

7

SEGMENT DISPLAY ......The number of this option.

D

EFAULT SETTING..........OFF for both channels.

E

XAMPLE ........................Option 2 is turned OFF for all cha nnels.

N

OTES .............................This option is a detector wide setting. Changing it for one

is changed, the change will not take effect until the detection

zone is empty or the channel is re set.

12.0 is ON and extension will not be added to a vehicle call if

Option 12.0 and 12.1 are ON.

is changed, the change will not take effect until the detection

zone is empty or the channel is re set.

the cha nnel ha s bee n prog ramme d with a value betw een 1 a nd

999. Operation of this feature requires that the Phase Green

Inputs be correctly connected to the controller phase green

circuitry.

channel changes it for both channels. This option will

automatically turn off 15 minutes after being activated o r on

loss of power.

channel changes it for both channels. This option will

automatically turn off 15 minutes after being activated o r on

loss of power.

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 12 of 25

Page 19

OPTION

1

ON © OPTION

OFF

1

©

OPTION

1

ON

©

OPTION

OFF

1

©

OPTION

OFF

1

©

OPTION

1

ON

©

PARAMETER ...................Option 3 (Call Extension Control).

S

ETTINGS ........................ON or OFF.

S

ETTING DISPLAYED ......The word ON or OFF will be displayed.

7

SEGMENT DISPLAY ......The number of this option.

D

EFAULT SETTING..........OFF for both channels.

E

XAMPLE ........................Option 3 is turned ON for channel 1.

N

OTES .............................Operation of this option requires tha t the Phas e G r een Input s b e

P

ARAMETER ...................Option 4 ( Noise F ilter D isable).

S

ETTINGS ........................ON or OFF.

S

ETTING DISPLAYED ......The word ON or OFF will be displayed.

7

SEGMENT DISPLAY ......The number of this option.

D

EFAULT SETTING..........OFF for both channels.

E

XAMPLE ........................Option 4 is turned OFF for all cha nnels.

N

OTES .............................This option is a detector wide setting. Changing it for one

P

ARAMETER ...................Option 5 (Phase Green Loop Compensation).

S

ETTINGS ........................ON or OFF.

S

ETTING DISPLAYED ......The word ON or OFF will be displayed.

7

SEGMENT DISPLAY ......The number of this option.

D

EFAULT SETTING..........OFF for bot h channe ls.

E

XAMPLE ........................Option 5 is turned ON for channel 1.

N

OTES .............................Operation of this option requires that the Phase Gree n Inputs be

P

ARAMETER ...................Option 9 (Third Car Passage).

S

ETTINGS ........................ON or OFF.

S

ETTING DISPLAYED ......The word ON or OFF will be displayed.

7

SEGMENT DISPLAY ......The number of this option.

D

EFAULT SETTING..........OFF for both channels.

E

XAMPLE ........................Option 9 is turned OFF for cha nnels 1 and 2.

N

OTES .............................This is a paired channel option. Channel 1 is paired with

P

ARAMETER ...................Option 1 0 (Directional Logic ) .

S

ETTINGS ........................ON or OFF.

S

ETTING DISPLAYED ......The word ON or OFF will be displayed.

7

SEGMENT DISPLAY ......The number of this option.

D

EFAULT SETTING..........OFF for both channels.

E

XAMPLE ........................Option 10 is turned OFF for cha nnels 1 and 2.

N

OTES .............................This is a paired channel option. Channel 1 is paired with

P

ARAMETER ...................Option 11 (Audible Detect).

S

ETTINGS ........................ON or OFF.

SETTING DISPLAYED ......The word ON or OFF will be displayed.

7

SEGMENT DISPLAY ......The number of this option.

D

EFAULT SETTING..........OFF for both channels.

E

XAMPLE ........................Option 11 is turned ON for c hannel 1.

N

OTES .............................This op tion is mutua lly excl usive w ith the same op tion on t he

correctly connected to the controller phase green circuitry.

channe l change s it for both cha nnels. Chang ing the s etting o f

this option will reset both detector channels. It is

recommended that this option be set to OFF for normal

operation.

correctly connected to the controller phase green circuitry.

channe l 2. Cha nging t he setti ng for o ne chan nel also change s

the setting for the paired channel. Turning ON Option 9

automatically turns OFF Optio n 10.

channe l 2. Cha nging t he setti ng for o ne chan nel also change s

the setting for the paired channel. Turning ON Option 10

automatically turns OFF Opti on 9.

other channel. Turning it ON for one c hannel turns it OFF for

the other channel. T his option will a utomatically turn OFF 15

minutes after being activated or on loss of power.

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 13 of 25

Page 20

OPTION

1

ON © OPTION

OFF

1

©

LOOP FAIL

1

©

OPTION

1

ON © OPTION

1

ON

©

PARAMETER ...................Option 12.0 (Detector Disconnect).

S

ETTINGS ........................ON or OFF.

S

ETTING DISPLAYED ......The word ON or OFF will be displayed.

7

SEGMENT DISPLAY ......The number of this option.

D

EFAULT SETTING..........OFF for both channels.

E

XAMPLE ........................Option 12.0 is turned ON for channel 1.

N

OTES .............................When this option is turned ON, the value entered in Extension

P

ARAMETER ...................Option 12.1 (Detector Disconnect Type).

S

ETTINGS ........................ON or OFF.

S

ETTING DISPLAYED ......The word ON or OFF will be displayed.

7

SEGMENT DISPLAY ......The number of this option.

D

EFAULT SETTING..........OFF for both channels.

E

XAMPLE ........................Option 12.1 is turned O FF for channe l 1.

N

OTES .............................When this option is turned ON, the value entered in Extension

P

ARAMETER ...................Option 13 (True Presence).

S

ETTINGS ........................S ix (6) Selections - 13.0 to 13.5.

S

ETTING DISPLAYED ......The word ON or OFF will be displayed.

7

SEGMENT DISPLAY ......The number of this option.

D

EFAULT SETTING..........13.0 for both channels.

E

XAMPLE ........................Option 13 is set to 13.1 (True Prese nce) for c hannel 1.

N

OTES .............................When this option is turned OFF, the detector operates in

P

ARAMETER ...................Option 14 (Sensitivity Boost).

S

ETTINGS ........................Five (5) Selections - 14.0 to 14.3.

S

ETTING DISPLAYED ......The word ON or OFF will be displayed.

7

SEGMENT DISPLAY ......The number of this option.

D

EFAULT SETTING..........14.0 for both channels.

E

XAMPLE ........................Option 14 is set to 14.2 for channel 1.

N

OTES .............................The digit to the right of the de cimal point represents the number

P

ARAMETER ...................Loop Fail.

S

ETTINGS ........................Pressing the (UP) or (DOWN) button will clear the Loop

S

ETTING DISPLAYED ......View only.

7

SEGMENT DISPLAY ......Loop Failures since the last time it was cle ared manually or due

D

EFAULT SETTING..........0 fo r bot h c hanne ls.

E

XAMPLE ........................There are eight (8) Loop Failures in the accumulator for

N

OTES .............................Count will be reset to zero after loss of power, by pressing the

time is used as a Disconnect t ime. Operation of this option

requires that the Phase Green Inputs be correctly connected to

the controlle r phase green circuitry.

time is used as a Disconnect time and no extension of the call is

made. When Opt ion 12.1 is turned OFF, Extension time is

active. Extension time and Disconnect time function

concurrently.

Normal Presence mode. When this optio n is turned ON, True

Presence is ON and the detector will hold a Call as long as a

vehicle is present and power is not removed or the detector

reset. If TRUE PRESENCE operation is required, use a setting

of 13.1.

of sensitivity levels that the sensitivity will be boosted once

vehicle detection has occurred.

Fail memo r y.

to power failure.

channel 1.

(UP) or (DOWN) butt on, or by resett ing the c hannel.

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 14 of 25

Page 21

© 1 © 1 ©

PRESENCE

PRESENCE

1

©

PULSE

1

©

PRESENCE

DELAY

SECONDS

1

©

ARAMETER .............................Firmwar e Vers ion and R evision.

P

S

ETTINGS ..................................View Only.

S

ETTING DISPLAYED ................View Only.

7

SEGMENT DISPLAY ................Model letter and firmwa re version on

D

EFAULT SETTING....................Not Applicable.

E

XAMPLE ..................................Model S firmware version 34,

5.2 NORMAL MODE DISPLAY SCREENS

STATE .............................Idle.

B

ARGRAPH DISPLAY .......OFF.

7

SEGMENT DISPLAY ......Three Dashes.

T

EXT ...............................PULSE or PRESENCE indicating detection mode of the

C

HANNEL LED ...............OFF.

C

HANNEL OUTPUT..........OFF.

E

XAMPLE ........................Channel 1 is idle and in the presence mode of detection.

N

OTES .............................This is the nor mal stat e fo r th e dis pla y w hen t he loop detectio n

S

TATE .............................Presence Call.

B

ARGRAPH DISPLAY .......N umbe r of se nsit ivit y le vels t hat t he ind ucta nce c hange caus ed

7

SEGMENT DISPLAY ......Call.

T

EXT ...............................PRESENCE, indicating detection mode of the channel.

C

HANNEL LED ...............Solid ON.

C

HANNEL OUTPUT..........ON.

E

XAMPLE ........................Channel 1 detect ion zone is occupied by a vehicle that exceeds

S

TATE .............................Pulse Cal l.

B

ARGRAPH DISPLAY .......OFF.

7

SEGMENT DISPLAY ......-

T

EXT ...............................PULSE, indicating detection mode of the channel.

C

HANNEL LED ...............ON for 125 milliseconds.

C

HANNEL OUTPUT..........ON for 125 milliseconds.

E

XAMPLE ........................Channel 1 detection zone is occupied and channel 1 is

N

OTES .............................This display is only shown for 125 milliseconds (the duration of

S

TATE .............................Ti ming Delay.

B

ARGRAPH DISPLAY .......N umbe r of se nsit ivit y le vels t hat t he ind ucta nce c hange caus ed

7

SEGMENT DISPLAY ......Countdown of remaining Delay time (in seconds).

T

EXT ...............................SEC O N DS, DELAY, and PULSE or PRESENCE.

C

HANNEL LED ...............Four Hz flash rate w ith 50% duty cycle (125 ms ON , 125 ms

C

HANNEL OUTPUT..........OFF.

EXAMPLE ........................Channel 1 detection zone is occupied by a vehicle that exceeds

channel.

zone is unoccup ied and t he channe l does not have a ny timin g

options set.

by the vehicle exceeds the detection threshold (first dot =

current sensitivity level, second dot = next lower sensitivity

level, etc.) .

the detection threshold by four (4) s ensitiv ity levels and channel

1 is outputtin g a call.

outputting a call of 125 milliseconds duration.

the pulse output).

by the vehicle exceeds the detection threshold (first dot =

current sensitivity level, second dot = next lower sensitivity

level, etc.) .

OFF).

the detection threshold by two (2) sensitivity levels, there are

three (3) seconds of Delay remaining, and channel 1 is not

outputting a call.

Π

- for 125 milliseconds.

one screen and firmware revision on

the other screen.

revision .00.

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 15 of 25

Page 22

PRESENCE

EXTENSION

SECONDS

1

©

MAX PRESENCE

SECONDS

1

©

MAX PRESENCE

EOG

SECONDS

1

©

PRESENCE

1

©

STATE .............................Timing Exte ns i o n.

B

ARGRAPH DISPLAY .......OFF.

7

SEGMENT DISPLAY ......Countdown of remaining Extension time (in seconds).

T

EXT ...............................SEC O N DS, EXTENSION, and PULSE or PRESEN CE.

C

HANNEL LED ...............16.6 Hz flash rate with 50% duty cycle (30 ms ON, 30 ms

C

HANNEL OUTPUT..........ON.

E

XAMPLE ........................Channel 1 detection zone is vacant, there 25 seconds of

N

OTES .............................When Option 12.0 is ON and 12.1 is O FF, the E xte nsi on t ime r

TATE .............................Timing Max Presence.

S

B

ARGRAPH DISPLAY .......N umbe r of se nsit ivit y le vels t hat t he ind ucta nce c hange caus ed

7

SEGMENT DISPLAY ......Countdown of remaining seconds of Max Presence.

T

EXT ...............................SEC O N DS and MAX PRESEN CE.

C

HANNEL LED ...............Solid ON.

C

HANNEL OUTPUT..........ON.

E

XAMPLE ........................Cha nne l 1 d ete ct ion z one is oc cup ied by a vehicle that exceeds

S

TATE .............................Max Presence Timed Out and Waiting for End Of Green.

B

ARGRAPH DISPLAY .......N umbe r of se nsit ivit y le vels t hat t he ind ucta nce c hange caus ed

7

SEGMENT DISPLAY ......000 - Showing that the Max Presence timer has timed out.

T

EXT ...............................SECONDS, MAX PRESENCE, and EOG (EOG will be

C

HANNEL LED ...............Solid ON.

C

HANNEL OUTPUT..........ON.

E

XAMPLE ........................Channel 1 detection zone is occupied by a vehicle that exceeds

S

TATE .............................Pending.

B

ARGRAPH DISPLAY .......N umbe r of se nsit ivit y le vels t hat t he ind ucta nce c hange caus ed

7

SEGMENT DISPLAY ......Pnd.

T

EXT ...............................PULSE or PRESENCE indicating detection mode of the

C

HANNEL LED ...............3.3 Hz flash rate with 83% dut y cycle (250 ms ON, 25 ms

C

HANNEL OUTPUT..........OFF.

E

XAMPLE ........................Channel 1 detection zone is occupied by a vehicle that exceeds

N

OTES .............................The Pending sta te is used whe n the channel w ould normal ly

OFF).

Extension ti me remaining, and channel 1 is outputting a call.

becomes the Disconnect timer.

by the vehicle exceeds the detection threshold (first dot =

current sensitivity level, second dot = next lower sensitivity

level, etc.) .

the detection threshold by five (5 ) sensitivity levels, there are

30 seconds of Max Presence remaining, and channel 1 is

outputting a call.

by the vehicle exceeds the detection threshold (first dot =

current sensitivity level, second dot = next lower sensitivity

level, etc.) .

flashing).

the detection threshold by five (5) sensitivity levels, Max

Presence has timed out and is waiting fo r the End Of Green,

and channel 1 is outputting a call.

by the vehicle exceeds the detection threshold (first dot =

current sensitivity level, second dot = next lower sensitivity

level, etc.) .

channel.

OFF).

the detection threshold by seven (7) sensitivity levels and

channel 1 is not outputting a ca ll. Either Option 9 (Third Car

Passage), Option 10 (Directional Logic), or Option 12 (Detector

Disconnect) has been selected.

output a call but is not, due to the operational functions of

Options 9 (Third Car Passage), Option 10 (Directio nal Log ic),

or Option 12 (Detector Disconnect).

889-1908-00 Model S-1300 Operations Manual Rev Apr 2020 Page 16 of 25

Page 23

L =

1

©

-∆L/L =

1

©

LOOP FAIL

1

©

+25% change Or

LOOP FAIL

1

©

-25% change Or

conditions.

-∆L/L =

LOOP FAIL

OPTION

MAX PRESENCE

OFF

EOG

SCANNING

EXTENSION

SENSITIVITY

DELAY

PULSE

SECONDS

3 2 1

4

ON

©

STATE .............................Loop Inductance Disp lay (Optio n 1 ON).

B

ARGRAPH DISPLAY .......O FF if no vehicle is detected. Number of sensitivity levels that

7

SEGMENT DISPLAY ......Loop / Lead-In ci rc uit in duc ta nc e i n mic ro he nr ies . I f t he va l ue

T

EXT ...............................L=.

C

HANNEL LED ...............The detect LED operates normally indicating call, no call,

C

HANNEL OUTPUT..........The channel o utput operates normall y.

E

XAMPLE ........................Channel 1 Loop / Lead-I n ci rc uit i nd uc ta nc e is 98 mic ro he n rie s

N

OTES .............................If Option 2 (-∆L/L D ispla y) is ON , th is dis play is onl y visi ble

S

TATE .............................Loop Inductance -∆L/L Display (% Change) (Opt io n 2 ON).

B

ARGRAPH DISPLAY .......OFF.

7

SEGMENT DISPLAY ......Percentage of change in inductance of the Loop / Lead-In

T

EXT ...............................-∆L/L.

C

HANNEL LED ...............The detect LED operates normally indicating call, no call,

C

HANNEL OUTPUT..........The channel o utput operates normall y.

E

XAMPLE ........................Percentage change of inductance of the call on channel 1 is

N

OTES .............................This display is only visible while the channel is detecting a

S

TATE .............................LCD Tes t .

B

ARGRAPH DISPLAY .......A ll segme nts on.

7

SEGMENT DISPLAY ......All segments on.

T

EXT ...............................All segments on.

C

HANNEL LED ...............The detect LED operates normally indicating call, no call,

C

HANNEL OUTPUT..........The channel o utput operates normall y.

E

XAMPLE ........................All segments on.

N

OTES .............................This display is visible whenever two or three pushbutton

the inductance change caused by the vehicle exceeds the

detection threshold (first do t = current se nsitivity level, seco nd

dot = next lower sensitivity level, etc.) if a vehicle is detected.

exceeds 999, the display will alternate between the thousand s

place (1 or 2) and the lower three digits of the inductance value.

delay, extension, and /or pend ing as expected .

and channel 1 is not detecting a vehicle.

when the channel is not detect i ng a vehicle.

circuit.

delay, extension, and /or pend ing as expected .

0.087%.

vehicle and not timing any functions.

delay, extension, and /or pend ing as expected .

switches are pressed at the same time.

5.3 LOOP FAIL INDICATIONS

If the to tal induc tanc e of a c han nel’s loop inp ut net work goes out o f the

range specified for the detector, or rapidly c hanges by more than ±25%,

the channel will enter the Fail-Safe mode and LOOP FAIL will be

displayed on the LCD. The type of loop failure wi ll a ls o be d isp la ye d a s

L lo (for -25% change or shorted loop cond itions) or L hi (for +25%

change or open loop conditions). This will cont inue as long as the loop

fault exists. Fail-Safe mode generates a continuous call in Presence