Page 1

Line Array User’s Manual

1

Page 2

Line Array User’s Manual

Monday through Friday between 8:00 AM and 5:00 PM Pacific Time.

TECHNICAL SUPPORT

If you have a question about line

arrays or run into a problem

using one of our line arrays,

call our technical support staff.

Phone: 949 588 9997

Ask for:

Jim Mobley (Extension 104)

Jonas Domkus (Extension 135)

E-mail

Jim@renkus-heinz.com

Jonas@renkus-heinz.com

2

Page 3

Line Array User’s Manual

PLEASE take a little time to learn how to get great results with y our

Renkus-Heinz Line Array System. It’s a small investment that will

generate a large pa yoff: more satisfied clients, more efficient

operations and better recognition for your skill as a sound

reinforcement prof essional.

INTRODUCTION

Renkus-Heinz Engineering has developed unique appr oaches to the line array

The Isophasic Plane Wave Generator lens sha pes high frequency response so that vertical arrays produce a

continuous, coherent wavefront whose curvature can be shaped to the audience area by curving the array.

The Midrange Diffraction Baffle used in the PN102/LA and PNX102/LA modules moves the woofers’ acoustic

centers closer together in the horizontal plane to eliminate “coverage collapse” in the crossover region.

The CDT1.5 CoEntrant Driver used in the STLA/9 and STXLA/9 integrates 6.5 inch carbon fiber cone and 2.5

inch voice coil titanium compression drivers into a high output wideband point source.

Line Arrays are not hard to use when you understand how they w ork…

The R&D behind our Line Arra y Systems is grounded in years of practical experience with the problems of

delivering refer ence r eproduction for large audiences at prof essional SPLs. Our engineered solutions include a

simple yet highly accurate software design tool – AimW are. The flying hardware is ke y ed to the design software

and will easily enable you to fly your array at the height and angle determined using AimWare, and with the

proper curvature. Self-powered line array modules include all the system optimization and protection functions

needed to ensure peak performance. Externally-powered modules use RH-Engineered controllers to pro vde

the same high performance with centralized power amplifier racks.

… but curved vertical arrays r equir e diff erent design techniques…

For the past 20 years, sound reinforcement professionals ha ve worked with horizontal arrays that use

megaphone-variant horns to deliver “[more or less] equal power to equal angles.” Vertical arra ys (so-called “line

arrays”) are designed to deliver “[more or less] equal power to equal areas.” This is the key to consistent SPL

and frequency response from the front to the rear of the audience area.

... and unfamiliar operational practices.

Over the years, system designers and operators have developed a number of signal processing techniques to

disguise and partly overcome the limitations of “constant directivity” horns: for more information on these

techniques and their limitations, see our White Papers on the True Array Principle and Refer ence Point Array

design. “Frequency shading,” “amplitude shading,” “system tuning,” all of these are tools of the advanced sound

system operator .

WHILE THESE TECHNIQUES ARE APPLICABLE T O LINE ARRAY S, THEY OFFER LIMITED IMPRO VEMENT TO

THE LINE ARRAYS PERFORMANCE. Instead of enhancing the ar ray’s performance the y could severely degrade

it. This is because line array performance depends on all array modules receiving the same signal at the same lev el,

in order to produce a continuous, coherent wavefr ont. Coverage control is achiev ed by mainly by tilting and

curving the array relative to it’s hang height. Subtle amplitude shading of the bottom most loudspeakers can

improve fr ont to back coverage consistency, but it needs to be used with care.

For more information on line array design practices, refer to pages 10 to 12 of this manual.

3

Page 4

Line Array User’s Manual

TABLE OF CONTENTS

TABLE OF CONTENTS

TECHNICAL SUPPORT ......................................................................................................................................2

INTRODUCTION ............................................................................................................................3

TABLE OF CONTENTS .................................................................................................................. 4

LINE ARRA Y SYSTEM COMPONENTS ......................................................................................... 6

PN102/LA SYSTEM.........................................................................................................................................................6

PNX102/LA SYSTEM .....................................................................................................................................................6

ALL PN/LA SYSTEMS.....................................................................................................................................................6

STLA L

INE ARRA Y SYSTEMS .................................................................................................................................................7

STXLA LINE ARRAY SYSTEMS ..............................................................................................................................................7

ALL STLA SYSTEMS .............................................................................................................................................................7

ALL LA SYSTEMS............................................................................................................................................................8

ARRAY DESIGN USING AIMWARE.............................................................................................10

Basic CONCEPTS.............................................................................................................................................................. 10

LINE SOURCE COUPLING ONLY OCCURS AT LONGER WAVELENGTHS/LO WER FREQUENCIES ..................................................... 10

THE LONGER THE LINE, THE LOWER THE FREQUENCIES IT WILL CONTROL AND THE TIGHTER THE BEAM ................................... 10

HIGH FREQUENCIES ARE ALWA Y S RADIA TED FR O M SEP ARATE SOURCES AND WA VEGUIDES........................................................ 10

VERTICAL ARRAYS TAKE ONE OF THREE POSSIBLE SHAPES: FLAT “|”, SYMMETRICALLY CURVED “)” AND

asymmetrically curved “J”....................................................................................................................................... 12

VARIANTS OF THE “J” PRODUCE THE BEST RESULTS IN THE VAST MAJORITY OF APPLICATIONS .................................................. 12

LINE ARRAYS ARE NOT “POINT AND SHOOT” SYSTEMS.......................................................................................................... 12

AIMWARE PROVIDES A VISUAL INTERFACE TO THE COMPLEX MATH BEHIND VERTICAL ARRAY OPTIMIZA TION............................. 12

SYSTEM SETUP: ELECTRONICS .................................................................................................13

STLA SELF-POWERED SYSTEMS......................................................................................................................................... 13

Source Signal............................................................................................................................................................. 13

STXLA ELECTRONICS ...................................................................................................................................................... 13

STX Amplifier Selection.......................................................................................................................................... 13

PN/LA ELECTRONICS ....................................................................................................................................................... 14

Source Signal............................................................................................................................................................. 14

PNX/LA ELECTRONICS.................................................................................................................................................... 14

PNX Amplifier Selection......................................................................................................................................... 14

RIGGING PROCEDURES .............................................................................................................. 15

SAFETY FIRST ............................................................................................................................................ 15

Flying Loudspeakers Safely ..................................................................................................................................... 15

Ground Stacking Loudspeakers Safel y.................................................................................................................. 16

Training & Education ............................................................................................................................................... 16

4

Page 5

Line Array User’s Manual

Setup Procedures..........................................................................................................................17

Landing The System & Loading Out ...........................................................................................24

TROUBLESHOO TING & SYSTEM CHECK LIST........................................................................................ 27

X12, X14, X24 ANALOG CONTROLLERS...................................................................................................................................27

D26 DIGITA L CONTROLLER ............................................................................................................................................... 27

EXTERNAL AMPLIFIERS ....................................................................................................................................................... 27

SIGNAL PATH – FOR SELF-POWERED SYSTEMS....................................................................................................................... 27

LOUDSPEAKER WIRING ....................................................................................................................................................... 27

VERTICAL ARRAY CONFIGURATION .................................................................................................................................... 28

FINAL PRE-SOUND-CHECK CHECK ................................................................................................................................... 28

INSTALLATION T OOLS AND SYSTEM MAINTENANCE ........................................................................ 28

ECOMMENDED INSTALLATION TOOLS AND EQUIPMENT .............................................................................................................................. 28

R

TESTING AND MAINTENANCE ................................................................................................................................................................... 29

5

Page 6

Line Array User’s Manual

Thank you for selecting a Renkus-Heinz Line Array System. This manual is intended to help you obtain optimum

performance from your system. Your system is one of the four types described below and on the next page.

PN/PNX SYPN/PNX SY

PN/PNX SY

PN/PNX SYPN/PNX SY

PN102/LA SYSTEMS

PN102/LA Self-Powered Line Array Module. 2x 10" LF drivers with Midrange Acoustic Diffraction Baffles and two

1" exit HF drivers on an Isophasic Plane Wa v e Generator. Engineered for use in vertical arra ys; integral two-

point flying hardware. Self-powered with the PN-1 PowerNet amplif ier: R-Control optional.

PNX102/LA SYSTEMS

STEMSSTEMS

STEMS

STEMSSTEMS

PN102/LA & PNX102/LA

PNX102/LA Line Arra y Module. Designed for bi-amp power with external amplifiers using X-Series analog or

D26 digital controllers for Loudspeak er Specif ic Pr ocessing and protection. Uses the same components and

pattern control technologies as the self-power ed PN102/LA module.

The PNX102LA uses 16 Ohm LF and 16 Ohm HF driver configurations. This enables a single amplif ier to drive

a number of array modules.

ALL PN102/LA & PNX102/LA SYSTEMS

RHANG/LA Fly Bar. Coupled with the two-point angle-setting system on Renkus-Heinz Line Array modules,

it provides a safe, flexible and simple means of flying vertical arrays up to12 deep.

RHANG/LA Tie Bars and Quick-Disconnect pins provide a choice of splay angles and metal-to-metal reliability.

102Dolly holds up to 4 PN102/LA or PNX102/LA modules.

6

Page 7

Line Array User’s Manual

STLA/STXLA SYSTLA/STXLA SY

STLA/STXLA SY

STLA/STXLA SYSTLA/STXLA SY

STLA Line Array Systems

STLA/9 Self-Power ed Line Array Module. 136 dB peak output, yet under 200 lbs. 2x 12" LF drivers and two

CDT1.5 CoEntrant Drivers on an Isophasic Plane Wa v e Generator. Engineered for use in vertical arrays; integral

two-point flying hardwar e. Self-powered with the PM-3 Pow erNet Tri-Amplifier: R-Contr ol optional and

CobraNet inputs optional.

Subwoofer: DR18-2 self-powered dual 18” subwoofer recommended.

STEMSSTEMS

STEMS

STEMSSTEMS

STXLA Line Arra y Systems

STXLA/9 Line Arra y Module. Designed for tri-amp power with external amplifiers using the X14 Controller fo r

Loudspeaker Specific Processing. Uses the same components and pattern control technologies as the self-powered

STLA/9 module.

Subwoofer: DRS18-2 externally-power ed dual 18” subwoofer recommended.

All STLA Systems

RHANGSTLA Fly Bar. Coupled with the two-point angle-setting system on Renkus-Heinz Line Ar ray modules, it

provides a safe, flexible and simple means of flying vertical arrays up to12 deep.

RHANGSTLA Tie Bars and Quick-Disconnect pins provide a choice of splay angles and metal-to-metal reliability.

STDolly holds up to 4 STLA/9 or STXLA/9 modules

7

Page 8

Line Array User’s Manual

ALL LA SYSTEMS

RH Engineering has developed an acoustic lens of the “path length refractor” type in order to change the output of

a horn/driver into a planar wav efr ont. A schematic of the HF section of a Renkus-Heinz Line Array Module looks

like this:

Renkus-Heinz line array modules use pattern contr ol techniques that have been borrowed fr om microwave

research. Since microwaves have characteristics similiar to high frequency sound waves, these techniques are useful

for creating continuous HF wavefronts. The Path Length Equalization Technology used in this device has a significant

advantage over other techniques (such as reflectors and obstacle arrays). Reflectors and obstacle arrays operate

over a relativ ely nar row bandwidth: perhaps four octaves. This limitation is due to the transition from the “ray

model” (reflection) to the “wave model” (refraction and diffraction) that occurs as wav elengths become long in

relation to the reflector or the obstacles.

The path length refractor, how e v er, can generate planar wavefr onts o ver a wide operating band. When higher

frequencies pass through the device, it operates on the “ray model,” as illustrated below:

When the “wav e model” takes over due to the longer wa v elengths, the path length refractor lens functions as

closely spaced array of diffraction slots, as illustrated on the next page.

8

Page 9

Line Array User’s Manual

THE STLA’S COENTRANT DRIVER

The patented CoEntrant Driver integrates the output of a cone transducer and a compression driver into a single

high output, wideband point source. Coupling these devices with Complex Conic horns has generated a number

of highly effective horizontal array modules – the ST Series of products.

The new CDT 1.5 CoEntrant driver has been dev eloped f or use in high output line array modules. It integrates a

6.5 inch carbon fiber cone transducer with a 2.5 inch voice coil compression driv er. The CDT1.5 can be crossed

over as low as 350 Hz, allowing a properly designed waveguide to control dispersion over a fr equency range of

almost six octaves.

CDT (COENTRANT DRIVER TECHNOLOGY) & PWGT: (PLANE WAVE GENERA TOR

TECHNOLOGY): AN IDEAL COMBINA TION

Because of its ability to function as a diffraction slot array at lower frequencies and as a path length refractor at

higher frequencies, the Plane Wa v e Generator is able to control vertical dispersion over the entir e operating

bandwidth of the CDT1.5. A vertical array of these devices will produce a coher ent wavefront from 350 Hz to

19 kHz. The sound system design can shape the vertical dispersion of this wavefront b y altering the splay angle

between modules. This is the k e y to ada pting the line ar ray’s output to a particular venue in or der to deliv er

consistent SPL from front to r ear.

For more information on Path Length Equalization Technology and the Plane Wave Generator, please refer to the

Renkus-Heinz White Paper on “New Approaches to Line Array Module Design. ”

Renkus-Heinz AimWare. Windows software simplifies the design and implementation of PN/PNX and ST/STX

line arrays. Please consult the Renkus-Heinz web site (rh.com or renkus-heinz.com) to download the latest

software releases.

Tie Bars and Quick-Release Pins are included with each Renkus-Heinz Line Array module. They provide simple

selection of inter-module splay angles within a metal-to-metal load bearing system that is independent of the

enclosure structure.

Please devote your time and attention to r eading this man ual. A compr ehensiv e understanding of line array theory ,

curved vertical arrays and specif ic features of your Renkus-Heinz Line Array System will help you to operate these

products safely and obtain optimal performance.

9

Page 10

Line Array User’s Manual

Line source coupling only occurs at longer wa v elengths/low er fr equencies

This is because adjacent sources have to be less than 1/2 wavelength a part in order to couple coher ently. Audible

frequencies hav e a wide range of wavelengths, from over 50 feet at 20 Hz to about 1/2 inch at 20 kHz. Obviously

it’s easy to get two sources to couple coher entl y at 20 Hz, because the wavelength is about 50 feet. Since high

output compression drivers hav e v oice coils betw een 2 and 4 inches in diameter, it is almost impossible to

produce line source coupling at 10 kHz, where the wavelength is about 1 inch.

The longer the line, the lower the frequencies it will control and the tighter the beam

A theoretical point source, with perfectly spherical radiation, can be considered as a line with no height. For any

line of finite dimensions, the transition from line source radiation (flat or plane wave with –3 dB energy loss per

doubling of distance) to point source radiation (spherical wa v e with –6 dB per distance doubling) begins at the

frequency whose wav elength is twice the height of the line, and is complete one octave lower at the fr equency

whose wavelength is f our times the line’s height. F or example, a 12 deep array of STLA/9 modules will be 15.5

feet tall and will radiate as a line source above 35 Hz.

High frequencies are alwa ys radiated from separate sources and wa veguides

Applying the line source calculations summarized abov e, it becomes clear that 2.5 voice coil compression drivers

cannot couple as a line source above 2650 Hz (6.5 inch midrange cones radiate as separate sources above 1025

Hz). Yet the compression driver must operate up to 18 or 19 kHz. Clearly, some sort of wav eguide technique

that allows adjacent array modules to pr oduce a coher ent and continuous wavefront is r equir ed.

Christian Heil was the first to demonstrate that such a waveguide was possible. Since then a number of other

approaches ha v e been used successfully. Interestingly enough, all of these have been used for decades to control

microwa v e radiation, which happens to have many of the same characteristics as high frequency sound. RenkusHeinz has employed the acoustic lens technique in its Isophasic Wave Generator. One advantage of an acoustic

lens is that the technique is equally successful with a wave model (i.e. at lower octaves) and with a ra y model

(higher octaves). Therefor e the lens technique is effective at controlling a broader range of frequencies than

reflection-based designs which are only operative on rays (very high frequencies). Another advantage of the

acoustic lens is that the wavefr ont curvature is independent of the path length fr om the driver to the wav eguide

exit.

Vertical arra ys tak e one of thr ee possible shapes: flat (line, straight or “|”arrays, symmetrically curved or “)”

arrays and asymmetricall y curved or “J” arrays.

The flat shape is a pure line source, at least at low frequencies. Curving the line array broadens the dispersion.

Curving the bottom of the line array only widens dispersion in the lower section (coincidentall y this is the section

that is closest to the audience). It also tilts the main beam of the arra y do wnwar d.

Variants of the “J” produce the best results in the vast majority of applications

By “best” we mean the “most consistent amplitude and frequency response from the fr ont to the r ear of the

audience. ”

As a point of reference, horizontal arrays are pie sections of a spherical source: their energy is reduced by 6 dB

with each doubling of distance. In the typical large venue with a distance ratio of 4:1 fr om the closest to the

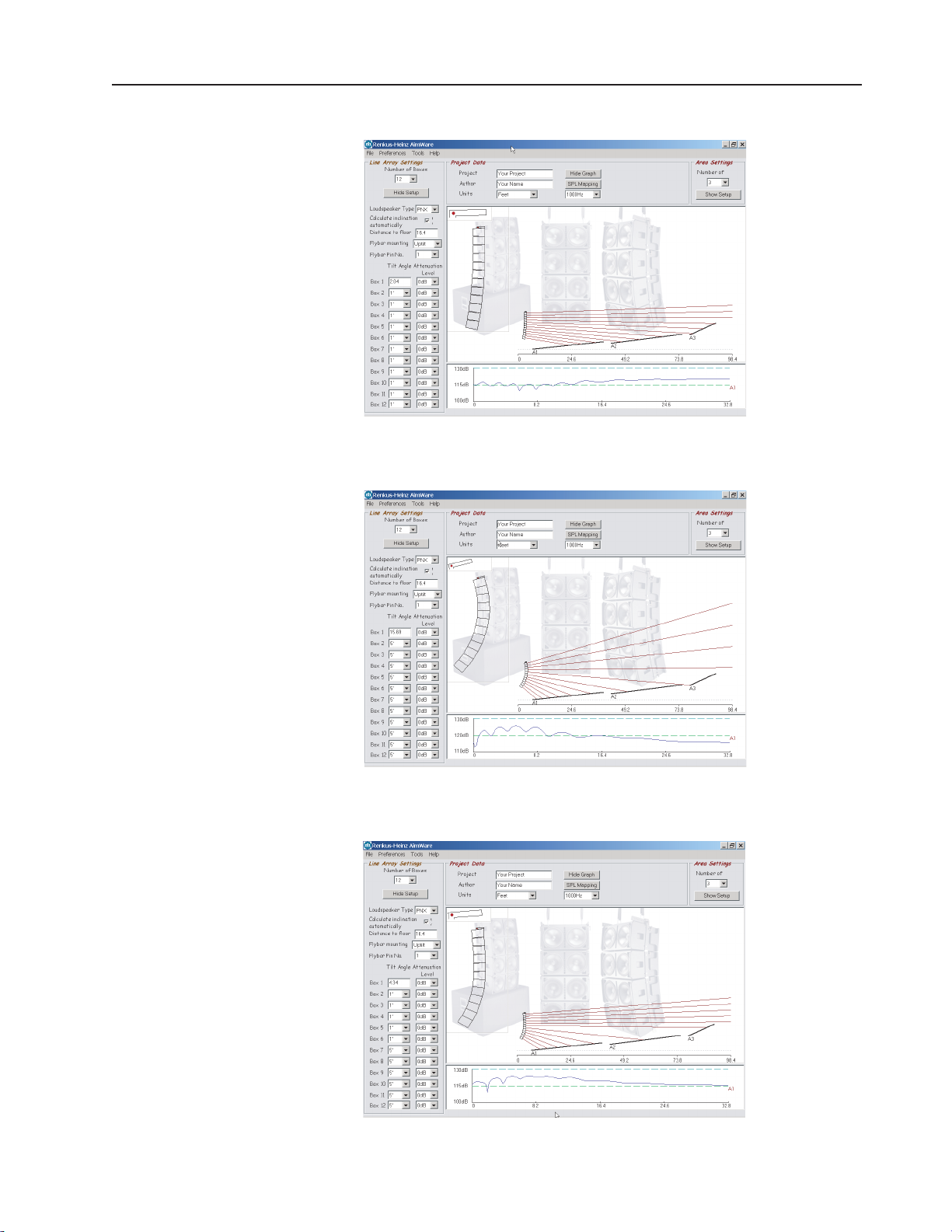

farthest seats, this means that the front rows ar e 12 dB louder than the back. Look closely at the Aimware

screens shown on the following pages. They illustrate how the thr ee vertical array shapes behave in this type of

venue.

10

Page 11

Straight (flat) Line Arra y

Line Array User’s Manual

Curved Line Ar ray

“J” Line Arra y

11

Page 12

Line Array User’s Manual

AimWar e pr ovides a visual interface to the complex math behind vertical arra y optimization

If you happen to own a “line array” system and hav e a week or two in an empty venue to prepare for your next

event, feel free to set up multiple measurement systems at, fro example, a dozen points in the audience area. Then

experiment with different hang points, aiming angles, number of modules and splay angles. The possibilities are

almost endless and a large number of data points are requir ed bef or e reliable correlations between various design

factors and the actual results begin to appear.

Alternatively, you can download AimWare, the Renkus-Heinz Windows based software program for the design

and optimization of vertical arrays. AimWare lets y ou def ine audience ar eas that closel y model the r eal world

of performance venues. It then allows you experiment with different arra y conf igurations (hang points, trim

height, tilt angle, number of modules and splay angles). Best of all, AimWare shows you accurate predictions of

real world results in seconds, not hours.

When you are done y ou can save the design as a file for later r ecall or modif ication. You can also import the file

into EASE 4.1 or EASE JR 4.1 for further evaluation in EASE.

Line arrays are not “point and shoot” systems

A little experimentation in AimWar e will conf irm that it is not good design practice to simpl y aim a flat “line

source” vertical arra y at the center of the audience ar ea. The typical result w ould be a fe w very loud rows in the

middle of the seating area with insufficient lev el at the front and rear. Nor is it possible to get g ood r esults b y

aiming the top module in the array at the back r o w of the audience and the bottom row at the front row. The

height, tilt angle and curvature of the arra y all interact to pr oduce the desir ed eff ect (consistent SPL fr ont to r ear).

The optimum angles are often non-intuitive (there is no simple “formula” that says “hang X boxes at 0° vertical

splay, then X more at medium splay and X at the bottom with maximum spla y.”

Designing a Vertical Array with AimWare

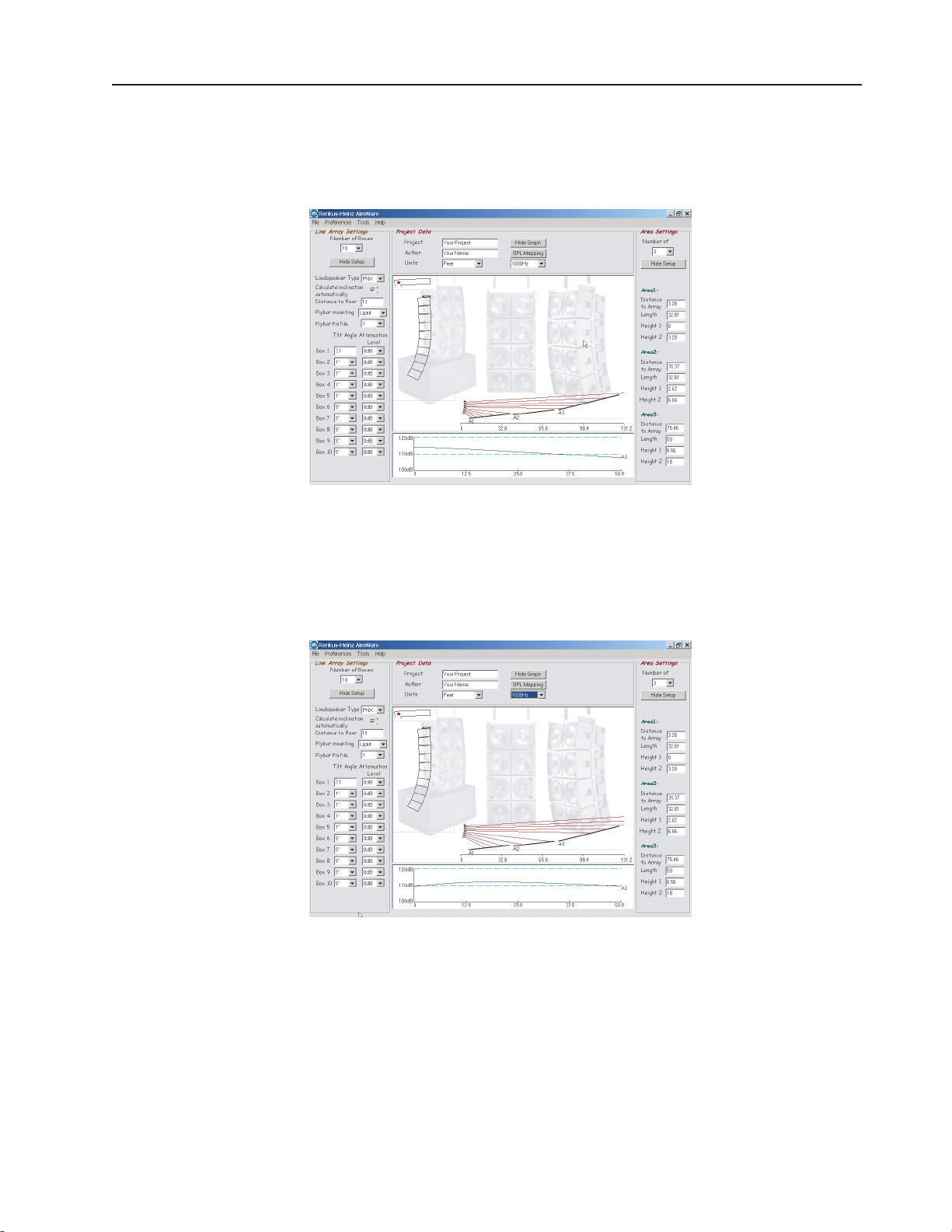

Define the Venue

Define the depth and location of up to three audience areas with independent start and end points.

12

Page 13

Locate the Array

Line Array User’s Manual

In most venues your choice of location will be extremely limited.

Optimize the Array

Your goal is to make the frequency response curve as flat as possible while delivering the desir ed SPL. Use the

boxes at the left of the screen to ad d or r emov e modules and to set the splay angles. AimWare shows y ou

instantly whether you are getting closer to an optimum design or farther away. For most venues, the entire design

process will take less than one hour.

Save Y our Configuration

The final step is to save the design as a f ile for later r ecall or modif ication. You can also import the file into EASE

4.1 or EASE JR 4.1 for further evaluation in EASE.

13

Page 14

Line Array User’s Manual

SY STEM SETUP: ELECTRONICS

STLA Self-P owered Systems

STLA line array modules are self-po w er ed with the PM-3 PowerNet Tri-Amplifier. The Class D amplifier section

and the Loudspeaker Specific Pr ocessing electronics require appropriate AC power. Audio inputs can be either

high-CMRR analog audio inputs with XLR looping connectors or CobraNet digital audio inputs. If a R-Control

remote control and supervision network is installed, its connections can be made via a separate twisted

pair cable and Phoenix connector or in systems having CobraNet, with the CobraNet connectors.

Source Signal

Source signal connections to aself-power ed STLA ar ray are quite straightforwar d. Connecting analog signal simply

requires one cable from the top module to the snake. Subsequent modules can then be connected using the PM3’s looping XLR inputs and outputs. Of course, if you intend to use level shading as part of your array design, you

will need to attenuate the inputs to all modules that receive diff erent signal levels.

STXLA Externally-P owered Systems

STX Amplifier Selection

STXLA array modules are tri-amplified. For optimum performance we r ecommend the X14 Controller

and the following power amplifier ratings:

LF 1,000 to 2,000 watts, RMS @ 4 ohms

MF 400 to 800 watts, RMS @ 4 ohms

HF 160 to 320 watts, RMS @ 4 ohms

All amplifiers must hav e the same voltage gain.

INPUT

LOW - OUT - HIGH

SUB - OUT - MID

SENSE CONNECTIONS, NOT

X14A

SHOWN FOR CLARITY, MUST BE

CONNECTED AS SHOWN IN

X14A MANUAL. .

MF OUTPUT

HF OUTPUT

OUT TO OPTIONAL

SUBWOOFER AMP.

LF OUTPUT

MINIMUM LOAD IMPEDANCES:

1 x STXLA/9 = 8 OHMS/CHANNEL

2 x STXLA/9 = 4 OHMS/CHANNEL

3 x STXLA/9 = 2.7 OHMS/CHANNEL

4 x STXLA/9 = 2 OHMS/CHANNEL

Stereo

Amplifier

Stereo

Amplifier

IMPORTANT NOTE:

AMPLIFIER GAINS MUST

BE SET THE SAME.

INPUT

CH 1

CH 2

LOOP

OUT

INPUT

CH 1

CH 2

LOOP

OUT

OUT

10

10

0100

0100

CH 1 CH 2

HIGH FREQUENCIES 4+, 4-

MID FREQUENCIES 3+, 3-

OUT

10

10

0100

0100

CH 1

CH 2

LOW FREQUENCIES 2+, 2LOW FREQUENCIES 1+, 1-

AMPLIFIER RACK

EIGHT CONDUCTOR

LOOPING CABLE,

SUPPLIED BY

RENKUS-HEINZ

SPEAKON PIN OUT:

1+,1-, LF 1, 8 OHM

2+,2-, LF2, 8 OHM

3+,3, MF, 16 OHM

4+, 4-, HF, 16 OHM

EIGHT CONDUCTOR CABLE

14

Page 15

Line Array User’s Manual

PN/LA Self-P owered Systems

PN/LA modules are self-powered with the PN-1 PowerNet Amplifier. The Class A/B amplifier section and the

Loudspeaker Specific Processing electronics require appropriate AC power. Audio inputs are high-CMRR analog

audio inputs with XLR looping connectors. If the R-Control r emote supervision network is installed, connections

can be made via a separate twisted pair cable and Phoenix connector.

Source Signal

Source signal connections to a PN/LA arra y are quite straightforward, unless you intend to use level shading as

part of your array design. Connecting analog signal simply requires one cable from the top module to the snak e.

Subsequent modules can be connected using the PN-1’s looping XLR inputs and outputs. Of course, if you intend

to use level shading as part of your arra y design, you will need to attenuate the inputs to all modules that receive

different signal levels.

Optional CobraNet Connections

The optional Renkus-Heinz CobraNet Breakout Box provides a very simple wa y to ad d CobraNet connectivity

to the system. Each Breakout Box can supply signal for up to six modules.

PNX/LA Externally-P owered Systems

PNX Amplifier Selection

PNX/LA array modules ar e bi-amplif ied. For optimum performance we recommend the X12 Contr oller and the

following power amplifier ratings:

LF 400 to 800 watts, RMS @ 16 Ohms

HF 80 to 160 watts RMS @ 16 Ohms

FROM MIXER

INPUT

Stereo

Amplifier

LOW - OUT - HIGH

INPUT

CH 1

LOOP

OUT

SENSE CONNECTIONS, NOT

SHOWN FOR CLARITY, MUST BE

CONNECTED AS SHOWN IN X12A

MANUAL. X24A COULD BE USED

FOR STEREO SYSTEM.

CH 2

X12A

IMPORTANT NOTE:

AMPLIFIER GAINS MUST

BE SET THE SAME.

OUT

10

10

0100

0100

CH 1 CH 2

FOUR CONDUCTOR

LOOPING CABLE,

SUPPLIED BY

RENKUS-HEINZ

TO ADDITIONAL

AMPLIFIERS IF NEEDED.

ALL AMPLIFIERS SHOULD

BE IDENTICAL

SPEAKON PIN OUT:

LOW FREQUENCIES, 1+, 1-

HIGH FREQUENCIES, 2+, 2-

15

Page 16

Line Array User’s Manual

Rigging Procedures

The designs of the RHANG/LA and RHANGSTLA rigging systems have been optimized for the mechanical and

acoustical characteristics of Renkus-Heinz line array modules. RHANG flying hardware enables a variety of system

configurations to be flown with a minimum number of motor hoists. Vertical angle adjustment between cabinets has

been limited to specific settings to ensure proper acoustic coupling.

Before flying any Renkus-Heinz line ar ray, please ensure that all necessary components are present and undamaged.

The RHANG system is a professional precision tool and should be handled with extr eme care. Only persons who are

fully conversant with the operation of the RHANG flying hardwar e and provided with suitable safety equipment

should install and operate the system. Misuse of the RHANG hardware system could lead to injury. Please refer to

the Safety section below for advice concerning installation and handling.

Maximum efficiency will be realized when thr ee experienced persons participate in the set-up: typically one motor

hoist operator, and one PN/LA or STLA operator per side of the array . Good synchronization and crosscheck

between the operators are the k e ys to r eliability and safety.

Used and maintained correctly, RHANG flying hardwar e will giv e many years of reliable service in portable systems.

This requires frequent, regular and thorough inspection, maintenance and cleaning of the system. Please refer to the

appendix for further information.

SAFETY FIRST

This manual offers guidance only for Renkus-Heinz loudspeak er systems. References in this manual to other rigging

equipment, such as motor hoists, steels, shackles etc. , are made to clarify the description of rigging procedures. The

user must ensure that operators are pr operl y trained by other agencies in the use of these items.

The following points are designed to r emind the user of saf e practice when flying any loudspeaker system. They

cannot address every possible circumstance in which the system might be deplo y ed; therefore the user must always

apply his or her knowledge, experience and common sense. If in any doubt, seek assistance fr om qualified rigging

personnel.

Flying Loudspeakers Safel y

Always inspect all the rigging components and cabinets for damage bef or e assembl y. Pay special attention to the lifting

points and safety clips. If you suspect that any of the components are damaged or defective, DO NOT USE THE

AFFECTED P ARTS. Contact your supplier for replacements.

Ensure that all local and National regulations regar ding the saf ety and operation of flying equipment are understood

and adhered to. Information on these regulations can usually be obtained from Local Government Offices.

When flying a loudspeaker system alwa ys wear protective headw ear, footwear and e y e pr otection.

Do not allow inexperienced persons to handle the loudspeaker system. Installation personnel should be trained in

loudspeaker flying techniques and should be fully conv ersant with this manual.

Ensure that motor hoists, hoist control systems and ancillary rigging components are cur r entl y certif ied as safe and

that they pass a visual inspection prior to use.

16

Page 17

Line Array User’s Manual

Ensure that public and personnel are not allowed to pass beneath the system during the installation process. The

work area should be isolated from public access.

Never lea v e the system unattended during the installation process.

Do not place any object, no matter how small or light, on top of the system during the installation pr ocedur e. The

object may fall when the system is flown and is lik ely to cause injury.

Secondary safety steels must be installed once the system has been flown to the operating height. Secondary steels

must be fitted irrespective of requirements of the local saf ety standards a pplicable to the ter ritory.

Do not fly the system over areas to which the audience has access.

Ensure that the system is secure and pre v ented from pivoting about the motor hoist. A void any form of dynamic

loading to the assembly .

NEVER attach any item to the RHANG hardware other than the RHANG accessories.

When flying outdoor systems ensure that the system is not exposed to wind or snow loads and is protected from

rainfall.

The RHANG flying hardware requires regular inspection. We recommend that the system be inspected visually at

every opportunity . For more information on visual inspection procedures and common problems with rigging

components, download the Rigging Inspection Poster from ATM Flyware (http://www.atmflywar e.com/flyhome.html).

When de-rigging the system ensure that the same care is given to the procedure as for the installation. Pack RHANG

components carefully to pre vent damage during transit.

Ground Stacking Loudspeakers Safel y

Statistically , many more injuries occur due to unstable ground stack ed PA systems than to improperly flown systems.

There are sev eral r easons for this fact, however the message is clear.

Always survey the supporting structure upon which a gr ound stack is to be built. A lways look beneath PA wings to

inspect the deck support and if necessary ask for the stage scrims and dressings be removed to allow access.

If the stage surface slopes, as it does in some theatres, ensure that the system is prevented from sliding f orwar d due to

vibration. This may require attaching w ood battens to the stage floor.

For outdoor systems, ensure that that the system is protected from wind forces which might cause the gr ound stack

to become unstable. Wind forces can be huge, especially upon large systems and should never be underestimated.

Observe meteorological forecasts, calculate the “w orst case” effect upon the system prior to erection and ensure that

the system is secured appropriatel y.

Take care when stacking cabinets. Always employ safe lifting procedur es and never attempt to build stacks without

sufficient personnel and equipment.

Never allow an yone, whether operators, artists or members of the public, to climb onto a ground stacked P A system.

Anyone who needs to climb ov er 6 feet high should be f itted with suitable saf ely equipment including a clip-on harness.

Please refer to local Health and Safety legislation in y our territory. Your Renkus-Heinz distributor can help with advice

on access to this information.

Apply the same attention to all safety matters when de-stacking systems.

Be aware that saf ety procedures are as important in the truck and in the warehouse as the y ar e at the venue.

Training & Education

Correct training is fundamental to safe practice when working with loudspeaker flying systems. We recommend that

users contact local industry associations for information on appropriate courses.

17

Page 18

Line Array User’s Manual

SETUP PROCEDURES

- STLA line array modules can be stacked up to four high on the STDolly

Splay angles can be set while the cabinets are on the gr ound. To set minimum splay angle, simply insert the quick-

release pin through the receiving tube and into the tie bar.

18

Page 19

Line Array User’s Manual

Splay angles can be set while the cabinets ar e on the gr ound. To set minimum splay angle, simply insert the quick-release

pin through the receiving tube and into the tie bar.

To set medium or maximum splay angle, two operators (one per side of the enclosur e) should lift the top

enclosure until the proper holes on the tie bar and receiving pin ar e aligned. Then insert the quick-release pin.

Check to make sure that both sidesof the enclosur e are set to the same play angle.

The RHANGSTLA fly bar will support arrays up to 12 deep . It provides a simple way to alter the ar r ay’s tilt

angle without requiring multiple rigging points and motors.

19

Page 20

Line Array User’s Manual

Before attaching the flybar to the top array module, attach the side pieces using the pr ovided quick-release pins.

RHANGSTLA hardware is manufactur ed f or Renkus-Heinz by ATM Flyware.

To attach the RHANGSTLA fly bar , insert it into the receiving tube and then insert the quick-release pin.

20

Page 21

Line Array User’s Manual

The tilt angle of the entire array is set b y mo ving the bridle attachment bar forwar d or backwar d. When moving the

bridle attachment points, check that the attachment knobs are completely locked. Also check that both sides of the

top bar are located to the same hole on the angle-setting bar.

- Attach the rigging to the bridle attachment point.

Start lifting the array

21

Page 22

Line Array User’s Manual

Inspect the shackles

Self-powered modules require a signal connection (analog XLR or digital CobraNet). Connect the top module of each

group that will receiv e the same signal first.

All modules in the group that will receive this signal can be connected using the Looping XLR connectors. Note: if you

are not using level shading, the “group is the entire array.

22

Page 23

Line Array User’s Manual

- Once A C po w er is connected y ou will be able to check the status of the module’s LF, midrange and HF sections

using the Mute buttons and LED indicators on the PM-3 Digital T ri-Amplif ier.

Renkus-Heinz uses the Neutrik PowerCon connector f or self-po wered loudspeaker systems. Each module

requires its own AC cable and connector. Make sure the connector is lock ed into the socket.

- To power the module on, use the Po wer switch next to the connector.

23

Page 24

Line Array User’s Manual

The RHANGSTLA Tie Bar has 3 angle setting positions

To set adjacent modules at 0° splay, align the bottom hole on the Tie Bar with the bottom hole in the lower module’s

receiving tube.

For medium splay (3° in “uptilt” position or 2° in the “do wntilt” position) align the top hole in the Tie Bar with the top hole

in the receiving tube.

24

Page 25

Line Array User’s Manual

For maximum splay (i.e. 5° in “uptilt” position or 4° in “downtilt” position) align the middle hole on the Tie Bar with the

bottom hole on the receiving tube.

LANDING THE SYSTEM AND LOADING OUT

Carefully lower the array onto the dolly.

Align the front edge of the dolly (the one without a supporting ledge) and the front edge of the lowest module.

25

Page 26

Line Array User’s Manual

The module’ s tie bars f it into slots on the sides of the doll y.

Attach the module to the dolly using quick release pins on both sides.

- The STDolly will support up to four modules. Remove the quick release pins from both sides of the fourth

26

Page 27

Line Array User’s Manual

module from the bottom.

Have one operator stabilize the dolly-stack ed modules, then raise the array until the tie bars ar e fr ee of the r eceiving

tubes.

Roll the dolly and the stack of modules out of the way and repeat the process until the entire array has been stacked on

dollys.

27

Page 28

Line Array User’s Manual

Detach the fly bar from the top array module. Make sur e that all parts ar e properly stowed f or transport.

Remove the shackles from the RHANGSLTA fly bar

TROUBLESHOOTING & SYSTEM CHECK LIST

X12, X24 and X14 Controllers

Are the sense lines properly connected to the amplif iers? Are the correct Loudspeaker Specif ic Processing

modules installed?

D26 Digital Controller

Is the proper loudspeaker-specific configuration selected on your D26?

External Amplifiers

Are all power amplifiers used with X-type externally po w ered line array modules and subwoofers properly

configured? In particular, check voltage gain settings and input gain settings.

Signal path – for self-powered systems

Are all line arra y modules properly connected? Are the subwoofers connected with the same polarity as the

main arrays? If the subs and the main arrays are driven by separate sends from the main console, are those

outputs in phase?

Loudspeaker wiring

Are all line array modules receiving the same signal? For externally power ed modules, are all three sections

functioning? Are they in pr oper polarity? Do the subs have the same polarity as the main array? Are all the subs

wired with the same polarity (if you turn one section off does the lev el decrease (proper polarity), increase

(trouble!) or stay the same (also trouble!)?

28

Page 29

V ertical Array Configuration

Are the splay angles the same on both sides of each module? Are the splay angles set as per the design generated

by Aimware? Are the aiming angles the same for both left and right arrays?

Final Pre-Sound-Check Check

Play a CD and send a mono-summed signal first to the left array, then to the right. Both sides should sound the

same when listening from a position along the center line between both arrays. Now play both sides at once, in

mono: all frequency bands should appear to originate fr om a “phantom center” source located on the center line

between the two arrays. If this is not the case, you must lower both arrays and r epeat the previous steps to

locate the source of the problem.

INSTALLA TION TOOLS AND SYSTEM MAINTENANCE

Recommended installation tools and equipment

Line Array User’s Manual

Many of the tools listed below are not actually required if you used AimWare to design your line array .

However, they are useful to verify that the array’s location and aiming conforms to the AimWare design criteria.

Tape measure – should be 30m/100ft in length and be of durable fiber material. Hav e one per array a vailable to

speed up the installation process.

Laser inclinometer – For measuring vertical and horizontal angles in the venue. An ideal pr oduct is the Calpac

‘Laser projecting a dot’ version.

Carpenter’ s le v el – used to ascertain the trueness of the surface fr om which the angle measur ements originate.

Rangefinder measuring device – either a Disto type laser measure or an optical laser rangefinder can be used.

Sports rangefinders, such as the Bushnell “Y ar dage Pro”, provide sufficient accuracy, are easy to use, and w ork

outdoors in bright sunlight.

Electronic calculator with trigonometric functions to calculate the height from ground level to points in the

room. The formula to calculate height of a point from measured angle and distance is:

Height of point = Sin(vertical angle in degrees) x distance to point NB: Take care when using Excel or other

spreadsheets, which typically default to a calculation using radians. To convert degrees to radians use the formula:

Angle (in radians)=3.142 x Angle (in degrees)/180. The factor 3.142 is, of course, an approximination of p (pi).

Computer – Laptop or Desktop PC running Windows 95/98/2000 or XP with the current version of RenkusHeinz AimWar e installed. It is not possible to configure a Renkus-Heinz Line Arra y properly without using

AimWar e. Designs can, of course, be prepared prior to arrival at the venue, but it is often necessary to modify

or update the design to accommodate special circumstances. A PC is absolutely essential to mak e such changes.

29

Page 30

Line Array User’s Manual

Digital remote inclinometer – with a remote sensor in the bumper and a meter unit at ground level to ensure

precise aiming of the cluster. A typical unit for this purpose is the Schaevitz Anglestar.

Audio Analysis Software – strongly recommended but perhaps not absolutely essential. SDA EASERA, or SIA

SmaartLive, SmaartPro or Spectraf oo enable ra pid and detailed analysis of the acoustical perf ormance. EASERA

and SmaartLive offer the additional benefit of enabling you to adjust FOH EQ on the D26 Digital Contr oller while

observing the results in a dual-FFT window on your laptop. Consider taking a training course in using one of

these tools if you are not already competent with them – it will pay dividends in increased performance and in

your general knowledge of the principles underlying sound reinf orcement.

Testing and Maintenance

Transducers:

Your Renkus-Heinz Line Ar ray system is a precision piece of equipment that needs periodic maintenance in order

to give long and reliable service. W e r ecommend regular testing of all cone, compression and CoEntrant drivers,

preferably using a suitable test rig and process testing softwar e or at least a sine wave generator and car eful

listening test coupled with a visual inspection.

Hardware:

There are sev eral critical points in the cabinets. Of primary concern are:

a) The machine screws attaching the enclosure to the flying hardware

b) The screws attaching the field-replaceable horn flare to the front of the enclosure (STLA & STXLA only)

These fasteners should be regularly checked and tightened as necessary.

Cleaning:

The exterior of the cabinet and the rigging system can be cleaned with a damp cloth soaked in mild soap y water.

On no account use solvent-based cleansers , which ma y damage the f inish of the cabinet. After cleaning, the

rigging system must be treated with a suitable lubricant (such as Scottoil FS365, a water-based lubricant with a

mixture of machine oil, surfactant and anti-rust treatment) to prevent rusting.

19201 Cook Street, Foothill Ranch, CA 92610-3501

Tel: 949-588-9997 Fax: 949-588-9514 E-mail: Sales@renkus-heinz.com Web: www.renkus-heinz.com

30

RH546 16/04

Loading...

Loading...